Page 1

FMS-1655M

Room Pressure Monitor

Installation Instructions

LB-FMS1655M-S01

LB-FMS1655M-T01

LIT-12013119

January 2019

Application

These installation instructions guide the installer through the installation of the FMS-1655M Room Pressure Monitor.

Please read these instructions thoroughly before beginning installation.

North American Emissions Compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when this equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area may cause harmful interference, in which case users will be required to correct the interference at their own expense.

Canada

This Class (A) digital apparatus meets all the requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Installation

NOTICE

Risk of Property Damage.

Ensure that the power source conforms to the requirements of the equipment. Failure to use a correct power source may result in

permanent damage to the equipment.

NOTICE

Risque de dégâts matériels.

S’assurer que la source d’alimentation électrique est conforme aux spécications de l’équipement. L’utilisation d’une source

d’alimentation électrique inappropriée risque d’endommager irrémédiablement l’équipement.

IMPORTANT: The FMS-1655M Room Pressure Monitor must be wired to 24 VAC only. Wiring the unit to 110 VAC will cause

serious damange and void the warranty.

Use of the software that is in (or constitutes) this product or access to the cloud or hosted services applicable to this product, if any,

is subject to applicable terms set forth at www.johnsoncontrols.com/techterms. Your use of this product constitutes an agreement to

such terms. If you do not agree to be bound by such terms, you may return the unused product to your place of purchase.

1

Page 2

FMS-1655M

FMS-1655M Room Pressure Monitor settings

This form should be completed during the initial conguration for each room pressure monitor. Be sure to congure

the unit for either Positive, Negative, or both using the Isolation Mode Conguration setup procedure.

Room Name / Number

Unit Model Number and Serial Number (ESN)

Analog Output

Operating Mode (Direct or PID)

Analog Output Range (zero based or offset)

Analog Output Upper Limit (0-100%)

Analog Output Lower Limit (0-100%)

Analog Output Action (Direct or Reverse)

PID Constants

Proportional Constant (0.5-100%)

Integral Constant (0.0-100%)

Derivative Constant (0.0-100%)

Alarm Limits

Positive Isolation High Alarm Setpoint

Positive Isolation High Warning Setpoint

Positive Isolation Low Warning Setpoint

Positive Isolation Low Alarm Setpoint

Negative Isolation High Alarm Setpoint

Negative Isolation High Warning Setpoint

Negative Isolation Low Warning Setpoint

Negative Isolation Low Alarm Setpoint

Audible Alert

Operating Mode (audible or slient)

Delay Time Base (seconds or minutes)

Delay Setting (0-60)

Alarm Quiet Period Starting Hour (0-23)

Alarm Quiet Period Ending Hour (0-23)

Engineering Units

Inches of Water or Pascals

2

LIT-12013119

Page 3

FMS-1655M

Table of contents

General ......................................................................................................................................................................................... 4

Specications ......................................................................................................................................................................... 4

Part Number Guide ................................................................................................................................................................ 5

Overview ................................................................................................................................................................................ 8

Mounting/Wiring .......................................................................................................................................................................... 9

Installation .............................................................................................................................................................................. 9

Remote sensor mounting procedure ...................................................................................................................................... 9

Display mounting procedure (surface mount) ...................................................................................................................... 10

Flush thin mount mounting procedure .................................................................................................................................. 11

Installation detail view .......................................................................................................................................................... 12

Basic programming ................................................................................................................................................................... 14

Main display screen.............................................................................................................................................................. 14

Conguring Room Pressure Monitor .................................................................................................................................... 14

Setting up alarm limits .......................................................................................................................................................... 14

Selecting displayed units ...................................................................................................................................................... 15

Conguring display options .................................................................................................................................................. 15

Adding password security .................................................................................................................................................... 16

Cleaning the display.................................................................................................................................................................. 17

Alarm setpoints ......................................................................................................................................................................... 18

Setup menu tree ........................................................................................................................................................................ 19

3

LIT-12013119

Page 4

FMS-1655M

General

Specications

Electrical

Pressure Range ……………………………………………………………………………………………………………………… ±0.2500 “WC

Accuracy of Measurement ….....………………………………………………………………………………………………………… ±0.5% FS

*NIST Traceable / Individual certication available as option

Power Supply .....…… Class 2, 24VAC ±10%, 30VA universal 120/240 to 24 VAC, 60/50 Hz, step-down isolation transformer provided

Recommended Cable Type ....………………………………………………………………………………………...…………… Belden 1325A

Communications

BACnet® MS/TP Network……....……………………………………………………...………………Two-wire twisted pair, RS-485 signaling

Recommend Cable Type……...........…………………………………………………………………………………......…………Belden 3107A

Touchscreen User Interface

LCD Size ……………………………………………………………………………………………………………...……………… 3.2” diagonal

LCD Type ………………………………………...…………………………………………………………………......…………… Transmissive

Resolution …………………………………....………………………………………………………………………..………… 240 x 320 portrait

Viewing Area ….……………………………………………………………………………………………………...…… 50.60 mm x 66.80 mm

Color Depth …………………………………………………………………………………………………………..……… 18-bit or 262K colors

Backlight Color …....………………………………………………………………………………………………...………………………… White

Luminous Intensity …………………………………………………………………………………………….…..……………… min 2500 cd/m2

FMS-1655M Monitor Surface Mount Enclosure …..………....……………………….………………………….………… 3”W x 5”H x 1.13”D

FMS-1655M Monitor Thin Mount Enclosure .............................................................................................................. 5”W x 8”H x 0.75”D

External Remote Sensor Housing ………………………….…………….……………………………………..………… 2.3”W x 4”H x 2.7”D

Stainless Steel Cover Plate for Flow Tube ……………………………….……………………………………..……… 2.7”W x 4.5”H x 0.2”D

Stainless Steel Cover Plate for Remote Sensor ………………………….……………………………………..……… 2.7”W x 4.5”H x 0.2”D

Surface Mount FMS-1655M Monitor with Power Supply ………………..……………………………….……...….....…… approx. wt. 3.7 lb.

Flush Thin Mount FMS-1655M Monitor with Power Supply ………………....…………………………………......……… approx. wt. 5.4 lb.

FMS-1655M Monitor Mounting Options ………………………………......……………………………………………...……… Surface, Flush

Flow Tube Cover Plate Mounting …………………………..........………………………………………………...………….… Surface, Flush

Remote Pressure Sensor Mounting ……………..............……………………………………………………………......…….………… Flush

Environmental

Operating Temperature …………………………...……………………………………....…………………………… 32° to 125° F Operating

Operating Humidity ………....……………………………………………………………......……………… 10% - 95% RH, Non-condensing

4

LIT-12013119

Page 5

FMS-1655M

Part Number Guide

BRAND

LB = Johnson Controls

UNIT

FMS = Flow Monitor Station (FMS)

SERIES

1655M = BACnet Monitor

STYLE

S = Surface mount

T = Thin flush mount

REMOTE SENSOR

01 = Standard remote sensor

- -

5

LIT-12013119

Page 6

FMS-1655M

System Precautions

Warning

Failure to follow the wiring diagrams could result in damage to your equipment and could void your warranty. Under no

circumstances should a single transformer be split between actuator and controller. Doing so will damage the actuator, the

transformer, the controller or all units. A single 120/24V 30Va transformer is required for the controller and a separate 120/24V

20Va transformer is required for the actuator. This equipment contains electrostatic sensitive components. To prevent possible

damage, take precautions to prevent electrostatic discharge when handling or servicing this equipment by wearing an

approved ESD grounding wrist strap connected to an earth ground source.

CORRECT

120/24VAC, 30Va

Transformer

Supplied by Johnson

Controls

Controller

Actuator

FAST ACTING

ELECTRONIC ACTUATOR

CORRECT

120/24VAC, 20Va Third Party

Transformer

6

LIT-12013119

Page 7

FMS-1655M

System Precautions

Red / 24 VAC / 30VA

connected to the FMS

Only Class 2 wiring in this

compartment.

Ground

}

Transformer

50/60 Hz

Blue

White

}

1 Amp Slow Blow

Fuse

}

Stepdown Isolation Transformer

Black

(provided with FMS-1655)

240 VAC

50/60 Hz

120 VAC

50/60 Hz

Note:

This product should be installed with the manufacturer provided isolated power supply and connected to an electrical circuit

protected by a minimum 20A circuit breaker. This circuit breaker should be mounted in an approved electrical enclosure located

separately, but in close proximity to this product.

7

LIT-12013119

Page 8

FMS-1655M

Overview

The Johnson Controls FMS-1655M Room

Pressure Monitor is an ultra-sensitive

instrument used to monitor differential

pressure in hospital rooms, isolation

rooms, surgical suites, laboratories,

and clean rooms. This unit is capable of

measuring and displaying differential air

pressures as low as 0.0001” WC (0.0249

Pa).

Key features of the FMS-1655M Monitor

include:

• Full-color touchscreen display with

programmable display options and

adjustable backlight

• Safety Halo™ edge lighting

• Intuitive user interface that simplies

setup and conguration of unit

• Graphical display that indicates room

status

• Audible and visual alarms

• Multi-level password protection

• Zero calibration feature allows in-eld

recalibration of zero pressure reading

• 2 factory-calibrated analog outputs,

one for PID control and one for remote

monitoring room DP

• BACnet® BMS network comms port

The FMS-1655M Monitor is equipped

with a 3.2” full-color touchscreen display

in portrait orientation (240 pixels by 320

pixels). The password-protected menu

tree is intuitive and simplies the setup

and conguration of the unit. The menus

incorporate touch-based interfaces such

as sliders, radio buttons, and dialog popups to facilitate the ease-of-use of the

FMS-1655M Monitor.

The display has a bright background

color that changes to indicate the three

different room statuses. The background

colors indicate “Normal” when pressure

is within dened limits, “Warning”

when pressure is nearing an out-oflimits condition, and “Alarm” when

pressure is outside dened acceptable

limits. The pressure ranges for these

conditions are easily set by the user for

the specic installation. The background

color changes provide an at-a-glance

conditions of the monitored room.

Alarm conditions may be dened by

the user, in terms of desired differential

pressure settings for the room being

monitored. When an alarm condition

occurs, it may be annunciated in three

user-denable ways:

1. On the display

2. With an audible alarm

3. Safety Halo™ edge lighting

4. Over the BMS network

The alarm will automatically reset when

the unit has sensed that the room

differential pressure has returned to

proper limits. The user may easily mute

the audible alarm by touching the Alarm

Audible button at the bottom of the

touchscreen display.

The FMS-1655M Monitor provides a

single digital input that may be used

for monitoring a door switch. The

conguration of the door switch input

is congured for normally-closed

operation, and is active-high triggered.

A SPDT magnetic door switch type is

recommended for use with function.

The user may set up multiple multi-level

passwords to prevent unauthorized

or casual access to the FMS-1655M

Monitor conguration settings. Up to

ten passwords of up to eight digits

may be programmed, with each having

one of four associated access levels.

Administrators and facility management

personnel may have unrestricted access,

while general staff may be assigned

restricted access passwords which limit

the functionality of the user menus.

Room pressure selection of Positive,

Negative, or Neutral Isolation may

be protected using limited access

passwords, thereby eliminating the

need for keylock switches and keys. In

some locales, it is prohibitive to allow

an isolation room controller to switch

between positive and negative modes

of isolation. To accommodate this

situation, the FMS-1655M Monitor may

be congured at the factory for either

Positive- and Neutral-isolation modes only

or Negative- and Neutral-isolation modes

only.

The FMS-1655M Monitor isolation monitor

is powered by a supplied universal

120/240 VAC to 24 VAC isolation power

supply that is fused at the secondary with

a 1-amp slow blow fuse. This powers both

the touchscreen display along with the

connected differential pressure sensor

module.

A 10 ft. length of 4-conductor cable is

provided with the FMS-1655M Monitor to

interface the two modules. If the distance

between the display and remote sensor

modules exceeds 10 ft, then this cable

may be substituted with the required

length of 4 conductor, dual twisted pair,

shield cable (Belden part no. 1325A).

The FMS-1655M Monitor includes a

remotely mounted sensor for measuring

the differential pressure of the monitored

room or space. This remote sensor

must be installed in the wall between

the monitored isolation room and the

adjoining corridor or anteroom. The front

port (P1) must be oriented towards the

isolation room and the rear port (P2)

towards the corridor or anteroom. Please

see the illustration on pages 8-9 for more

details.

The FMS-1655M Monitor incorporates

a PID output signal that may be used to

control a damper actuator. The factorycalibrated analog signal is available as a

voltage between 0-10VDC or 2-10VDC

at the remote sensor connector. Refer to

page 12 and 13 for more information.

8

LIT-12013119

Page 9

FMS-1655M

Mounting/Wiring

Installation

Remote sensor mounting procedure

1. Cut an opening in the wall of the

isolation room to receive the supplied

single-gang “old work” low voltage

mounting bracket (Figure 1) for the

remote sensor module. Nominal

dimensions for the cutout are 3.65” H x

2.15” W. Drill a 7/16” hole through the

opposite wall for the ow tube.

2. Install the single-gang low voltage

mounting bracket in the cutout. Route

a length of supplied ow tube through

the mounting bracket and through the

7/16” hole in the opposite wall.

Separate the backplate from the

touchscreen display enclosure by

turning the set screw at the bottom of

the display enclosure fully clockwise

to release the backplate. Pull the

backplate bottom out slightly to

clear the bottom edge of the display

enclosure and slide the backplate down

away from the tabs at the top of the

enclosure. Disconnect either end of the

gray harness between the backplate

and display module by pushing down

on the locking tab, and then sliding the

connector out. Disconnect the interface

cable from the display module by

removing the terminal block from the

4 pin connector CN3 on the display

module PC board.

5. The FMS-1655M Monitor has a

factory-calibrated analog output and is

available as voltage at the Vo terminal.

The designated output (Vo) can be

used to control a damper actuator to

maintain a user set pressure setpoint

when the FMS-1655M Monitor is used

in a controller application.

6. Attach the pluggable connector to the

mating header on the remote sensor

module. Attach the end of the ow tube

to the barbed tting at back of sensor,

and then secure the remote sensor

module to the mounting bracket with

two supplied 6-32 x ¾” screws.

7. Install the louvered cover plate onto

the installed sensor module using

two supplied machine screws. On the

opposite side of the wall (corridor side),

attach the end of the ow tube to the

barbed tting of the ow tube mounting

plate.

8. Press the mounting plate into place,

allowing the excess tube length to

go into the wall space. Secure the

mounting plate with the supplied

screws and wall anchors.

9. Install a louvered cover plate

onto the mounting plate using two

supplied machine screws.

3. Conrm that the 4-conductor

interface cable between the remote

sensor module and the touchscreen

display module has its red and black

conductors securely attached to the

+V and GND terminals, respectively.

Route the end of the interface cable

with the 3 and 4 pin connector down

the wall to the anticipated location of

the touchscreen display module.

4. Using a suitable length of 2 conductor

20 AWG cable, connect the output of

the universal isolated power supply

module to the power input at the

remote sensor module. The output

of this power supply module is nonpolarized, so the two red wire may be

wired to power input terminals in either

orientation. Refer to page 12-13 for

power wiring details.

Fig 1. Single-gang, low-voltage mounting

bracket.

9

LIT-12013119

Page 10

FMS-1655M

Display mounting procedure (surface mount)

1. Cut an opening in the wall adjacent

to the door of the isolation room for

installing the supplied single-gang “old

work” low voltage mounting bracket

(Figure 1) for the touchscreen display

module. Nominal dimensions for the

cutout are 3.65” H x 2.15” W.

2. Install the single-gang low voltage

mounting bracket in the cutout.

3. Pull the loose end of the interface

cable from the remote sensor module

through the cutout in the drywall, and

then through the hole in the center of

the display enclosure backplate (Figure

2).

4. Attach the backplate to the mounting

bracket with two 6-32 x ¾” screws,

carefully aligning it using the two

mounting slots on the backplate before

tightening.

Fig 2. Route interface cable through center

hold at display enclosure backplate.

5. Connect the loose end of the interface

cable (4 pin) to the corresponding

header at the top of the display module

circuit board (see Figure 3). Conrm all

4 conductors of the interface cable are

securely attached at the terminal plugs.

Re-connect gray harness between

backplate and display module.

6. Reconnect the gray harness to the

backplate circuit board and attach the

display enclosure to the backplate

by inserting the tabs at the top of

the display into the corresponding

slots at the top of the backplate.

Secure the display enclosure to

the backplate by turning the slotted

setscrew at the bottom of the enclosure

counterclockwise until it is ush with

the enclosure bottom.

7. Finally, apply power to the monitoring

system by applying line power to the

power supply module. If the unit was

shipped with the 24VDC wall adapter

power supply, power up the system by

plugging it into an available electrical

receptacle, preferably located at a

location above the ceiling tile directly

above the surface mounted display

Fig 3a. Basic FMS Assembly with close up of

wall sensor connections.

Fig 3. Interface connected to 4-pin header at

top of display module.

10

LIT-12013119

Page 11

FMS-1655M

Thin ush mount mounting

procedure

The FMS-1655M thin ush mount

model offers an attractive stainless steel

faceplate with an ultra-thin enclosure

(less than ¾” thick) that may be installed

in any application where wall depth is

either unknown or extremely limited.

New construction applications can take

advantage of the included wall box

that may be installed during the rough-

in phase. For retrot applications not

requiring electrical conduit termination,

the unit may be installed using the

retrot mounting plate that simpliesthe

installation process.

1. The FMS-1655M thin ush mount

modeloffers an attractive stainless

steel faceplate with an ultra-thin

enclosure (less than ¾” thick) that

may be installed in any application

where wall depth is either unknown or

extremely limited. New construction

applications can take advantage of the

included wall box that may be installed

during the rough-in phase. For retrot

applications not requiring electrical

conduit termination, the unit may be

installed using the retrot mounting

plate that simplies the installation

process.

2. If this is a new construction project and

the wall box has been installed, you

may skip the next two steps. If this is a

retrot application and existing drywall

is in place, then proceed with the next

step to prepare the opening for the

FMS-1655M thin ush mount model.

3. Using the retrot mounting plate (see

Figure 3b) as a template, trace the

inner outline ontothe drywall at the

desired mounting location with a pencil

or marker. Also mark the location of the

two mounting holes on the drywall. Cut

along the traced outline with a drywall

knife or saw, taking care not to make

the opening too large. Drill out the two

holes to clear access to the mounting

clip nuts. Remove the cut section of

drywall and discard. Be sure to brush

off any drywall dust or remnants from

the inside surface of the opening to

ensure proper adhesion of the retrot

mounting plate.

4. Remove the paper backing from the

two adhesive strips on the retrot

mounting plate and insert it into the

cut opening of the drywall. The retrot

plate should be oriented such that the

corner notch is located at the lower left

corner of the opening in the drywall,

with the tabs bent towards you. Using

the four tabs on the retrot mounting

plate as alignment guides, press the

mounting plate onto the inside surface

of the drywall opening rmly to ensure

maximum adhesion.

Fig 3b. Retrot Mounting Plate

5. The electrical connections must

terminated before installing the

stainless steel faceplate of the FMS1655M. Run the 4-conductor, dual

twisted pair, interface cable from the

FMS1655M remote sensor to the

FMS1655M display. Refer to the wiring

diagram shown at end of this manual

for details.

6. Terminate the interface cable

originating from the remote sensor

at the 4-position terminal block CN3

on the back side of the FMS-1655M

display, ensuring proper electrical

connections. Power connections

should be terminated at +V and GND

of the CN3 terminal block and sensor

comms at + & - terminals at CN3.

Insure proper polarity of the comms

wiring is maintained between sensor

and display.

7. For monitoring the FMS1655M over

a BACnet MS/TP network, terminate

the BACnet network cable at CN7 of

the FMS1655M display. Refer to wiring

diagrams at end of this manual for

details.

8. With the electrical connectionsproperly

terminated, the stainless steel

faceplate may be installed using

the two at head machine screws.

For retrot applications where the

mounting plate has been afxed to

the inside surface of the drywall, the

two mounting screws thread into the

clip nuts of the mounting plate. For

those applications where the wall box

has been installed, the two mounting

screws fasten the faceplate directly.

Fig 3c. Basic FMS1655M thin mount assembly

11

LIT-12013119

Page 12

FMS-1655M

+ (RS485)

- (RS485)

GNDIN+VsIoVo

- Vin

+Vin

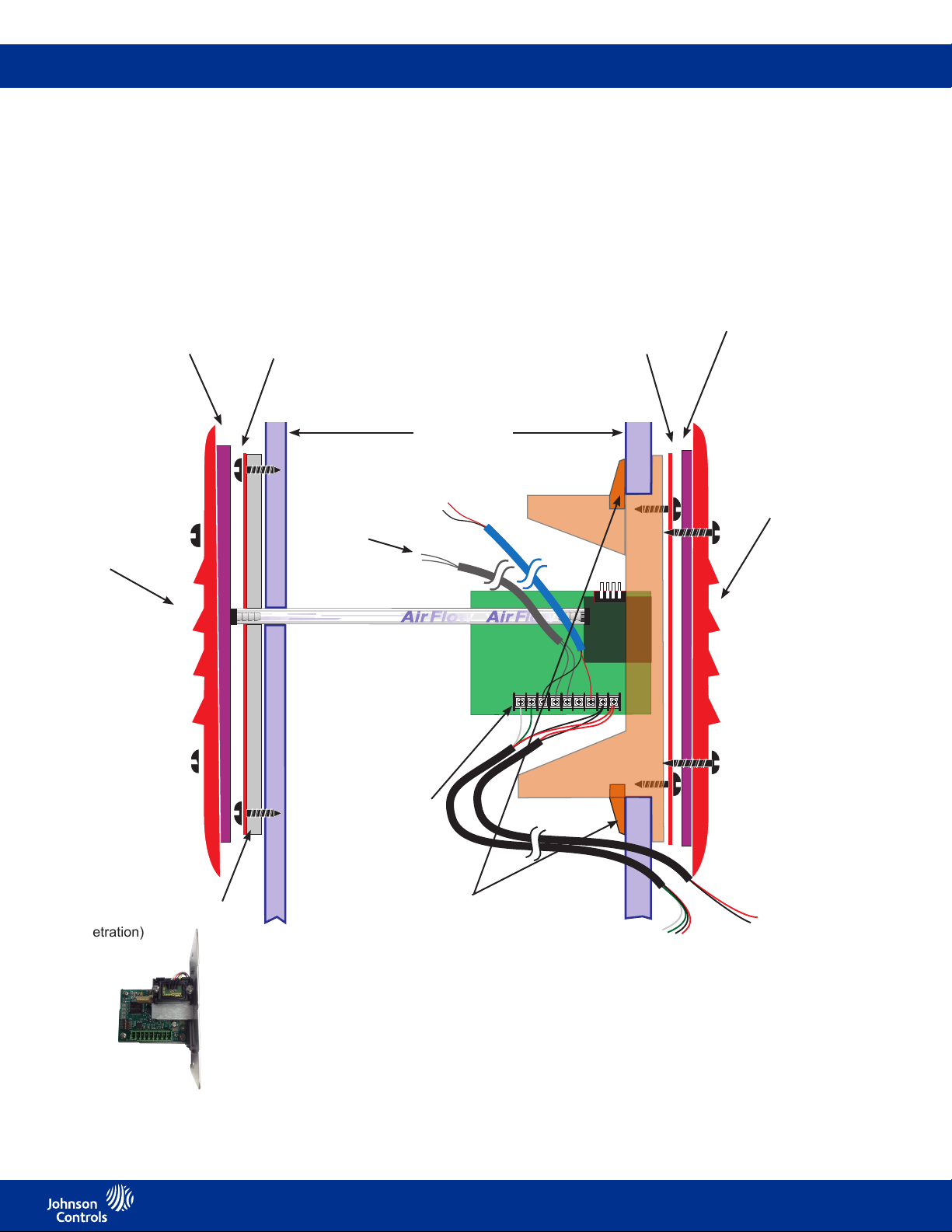

Installation detail view

Gasket

Louvered

Cover Plate

Remote Sensor Installation Detail

Stainless Steel

Flow Tube

Mounting Plate

To optional

door switch

(with standard 24 VAC power supply)

(Side View)

Wall Section

(cutaway view)

Optional Analog

Output Damper

Control

Stainless Steel

Mounting Plate

Gasket

Louvered

Cover Plate

Corridor

Thin Silicone Caulking

(apply around tube and

between stainless steel

plate and wall to seal unit

penetration)

Flow Tube

When Flow Tube

mounting plate is located

directly opposite the

sensor, ow tubing

must be cut as short as

possible to prevent kinks.

Note: To maintain sensor

accuracy, Flow tube should

not exceed 36 inches.

Terminal

For connection of

transmitter to

FMS-1655M

Monitor

Orange wall bracket

to be installed

rst by using the

rotating clamps

for secure wall

attachment.

+ (RS485)

- (RS485)

GNDIN+VsIoVo

- Vin

+Vin

To FMS-1655M

Monitor

Isolation Room

To Johnson

Controls isolation

transformer

12

LIT-12013119

Page 13

FMS-1655M

Installation detail view

Stainless Steel

Flow Tube

Mounting Plate

Isolation Room

Gasket

Flow Tube

When Flow Tube

mounting plate is located

directly opposite the

sensor, ow tubing

must be cut as short as

possible to prevent kinks.

Note: To maintain sensor

accuracy, Flow tube

should not exceed 36

inches.

Terminal

For connection of

transmitter to

FMS-1655M Monitor.

To FMS-1655M Monitor

monitor

Optional Analog

Output Damper

Control

To optional

door switch

+ (RS485)

- (RS485)

GNDIN+VsIoVo

Louvered Cover

Plate

- Vin

+Vin

Thin Silicone Caulking

(apply around tube and

between stainless steel

plate and wall to seal

unit penetration)

Corridor

To Johnson Controls

isolation transformer

Wall Section

(cutaway view)

Remote Sensor Installation Detail

(Bottom View)

13

Rotating clamps secure

assembly to wall board

Gasket

Stainless Steel

Mounting Plate

LIT-12013119

Page 14

FMS-1655M

Basic programming

FMS-1655M Monitor basic

programming

After the FMS-1655M Monitor unit has

been properly installed, apply power

to the unit. Upon power up, the Safety

Halo™ status indication bezel will cycle

through seven colors (red, green, blue,

yellow, magenta, cyan, and white),

followed by three action icons (normal,

caution, alarm), and nally, the Johnson

Controls splash screen indicating serial

numbers, rmware version numbers, and

BACnet MAC address. This splash screen

remains displayed for approximately 10

seconds and disappears to reveal the

main display screen. This splash screen

can be redisplayed using the About this

FMS option in the Diagnostics Menu.

Main display screen

All FMS-1655M Monitor units come

shipped from the factory in the neutral

isolation mode. The neutral isolation

mode will be represented on a blue

background (Figure 4). Information

displayed on the main screen includes the

following:

• Name of monitored room (up to 25

characters)

• Current isolation mode (positive,

negative, or neutral)

• Current differential pressure reading in

selected engineering units (default is

“WC)

• Time and date

• Door Status (If door switch is used)

While in neutral isolation mode, the

background color of the main display

screen is blue. However, while in either

positive or negative isolation modes, the

background color actively represents the

current status of the monitor. A green

background indicates that the current

differential pressure is within allowable

limits of the desired setpoint.

Fig 4. Main display shows isolation mode, room

status and differential pressure.

A yellow background indicates one of two

conditions: 1) door to monitored space

is open (if door switch is enabled), or 2)

current differential pressure has drifted

outside of the allowable limits of the

desired setpoint and are in the caution

range.

A red background indicates that the

current differential pressure has reached

a critical condition and is outside of the

allowable limits of the desired setpoint.

The FMS-1655M Monitor incorporates

a full-color touchscreen and includes

an extensive easy-to-use menu system

that allows the user to quickly setup

the monitor for immediate use. Also

integrated into the FMS-1655M Monitor

display are several hotspots that provide

quick access to various settings. Refer

to page 17 for details on using these

hotspots as display settings shortcuts.

Touching the screen anywhere other than

one of the reserved hotspots invokes

the menu system, unless one or more

security passwords have been entered.

FMS-1655M Monitor may be congured

to start displaying the real-time differential

pressure of the isolation room being

monitored.

Setting up alarm limits

To determine the various setpoints at

which the unit status changes from

normal to warning, and from warning to

alarm, the alarm limits must be congured

accordingly.

Alarm limits are only in effect while the

unit is in either positive or negative

isolation mode, as the alarms are

disabled while neutral isolation mode

is active.

In order to specify the alarm limits for

positive or negative isolation mode,

set the isolation mode accordingly by

selecting the Room Setup option from

the Unit Setup menu, and then select

the Isolation Mode option from the

Set Isolation Mode menu. Select the

desired isolation mode from the resulting

conguration popup window and press

“OK.”

Conguring Room Pressure

Monitor

Conguring the FMS-1655M Monitor

settings is extremely easy using the

intuitive user menus integrated in the

touchscreen display. Within minutes, the

14

LIT-12013119

Page 15

FMS-1655M

0.100

main display, setting the system time and

date, adjusting the display brightness, and

setting the Safety HaloTM function. The

Display Options menu item allows the

main display to be congured as required

by the specic application. If desired, the

user may individually enable or disable

the display of the isolation mode, room

status, and the time/date at the bottom of

the screen.

Fig 5. Enter high alarm setpoint for positive

isolation mode using keyboard popup.

To begin specifying the alarm and warning

setpoints, select the Alarm Limits option

from the System Setup menu. The user

is prompted to sequentially enter the high

alarm and warning limits, followed by

the low warning and alarm limits, in that

order. For example, if positive isolation

mode was selected above, then the

conguration popup shown in Figure 5 will

be displayed, prompting the user to enter

the positive isolation high alarm setpoint

using the keypad.

These limits should be specied to

identify the differential pressure range

which is considered normal, as well as

the range which indicates a warning

condition, and the range which is

considered critical and indicates an alarm

condition.

The gure on page 14 shows the

relationship of these four alarm setpoints

and how they relate to the normal

operating differential pressure of the

monitored isolation room.

Conguring alarm buzzer

The FMS-1655M Monitor alarm resources

provide support for both visual and

audible alerts. The audible alert option on

the System Setup menu allows the alarm

buzzer settings to be easily congured.

Selecting this option invokes the

conguration screen shown in Figure 6.

Fig 6. Alarm buzzer may be congured for

audible or silent mode.

The alarm buzzer may be selected for

one of two modes of operation: audible or

silent mode. If audible mode is selected,

a delay may be specied in seconds or

minutes. If silent mode is selected, then

the alarm buzzer will not sound whenever

the unit encounters an alarm condition. If

audible mode is selected, the user may

specify an alarm quiet period. This feature

allows the audible alerts to be suppressed

between the specied hours every day,

thereby eliminating the potential for

nuisance alarms. Hospitals may take

advantage of this feature to minimize

nuisance alarms during non-visiting hours

in patient rooms.

Selecting displayed units

The FMS-1655M Monitor displays

differential pressure readings in one

of two units: inches of water column

(in WC) or Pascals (Pa). Touching the

differential pressure reading in the upper

LCD window of the display will invoke

the Select Engineering Units selection

screen. If the engineering units selection

is changed, the corresponding alarm

setpoints are automatically converted to

the newly selected units.

Conguring display options

The Display Setup menu provides

support for conguring all of the display

settings on the FMS-1655M Monitor.

Options are available for conguring the

The Safety Halo

Setup Menu allows the user to disable or

enable this function as well as setting the

intensity of the Safety HaloTM brightness.

A nightly auto-dim feature can be set to

dim the Safety HaloTM brightness to a

user-set level at specied hours every

day.

The set time and date option on the

Display Setup menu allows the user to

specify the current time and date that may

be displayed at the bottom of the main

display. The FMS-1655M Monitor will

maintain the time and date as long as the

unit is not powered down. The time and

date can be synced to the network master

clock when the FMS-1655M Monitor is

connected to the BACnet network.

TM

option on the Display

15

LIT-12013119

Page 16

FMS-1655M

The set brightness option on the Display

Setup menu allows the intensity of the

display backlighting to be adjusted from

very dim to very bright. The brightness

settings are saved in nonvolatile memory

and remain in effect through a power

cycle.

Adding password security

Access to the FMS-1655M Monitor

menu system can be protected from

unauthorized tampering through the

multi-level security passwords. Up to ten

individual passwords may be entered in

the system, each with a specic access

level. A password entry may be created

by selecting the Passwords Setup option

from the System Setup menu, and then

selecting add password. The user is

prompted to enter a minimum of four and

up to eight numeric digits.

Once a password has been specied, the

user is prompted to specify one of four

access levels: Unrestricted, Standard,

Basic, and Restricted. All password

entries are saved to non-volatile memory,

and remain in effect through a power

failure. In the event that a password has

been forgotten, there is a factory-default

“back door” password that will provide

unrestricted access to the user menu

system. Please consult with the factory for

more information regarding this password.

Note: An unrestricted password must

be created rst before any restricted

passwords can be set.

Resetting Sensor Zero Offset

The FMS-1655M Monitor’s remote sensor

can have its zero offset reset to the

factory calibrated default in the event the

monitored pressure does not approach

zero when the door to the monitored

room is opened. Select the Reset Zero

Offset option on the Diagnostics menu

to begin the procedure. once the reading

stabilizes, click the OK button to proceed.

Exit to the main display and verify that the

reading goes to zero. If not, repeat the

above procedure.

Remote monitoring the FMS-1655M

Monitor

The FMS-1655M Monitor provides native

support for BACnet® MS/TP protocol over

a RS-485 serial port located on the FMS1655M Monitor user interface display at

CN7, a 3 pin pluggable terminal block at

back of display (see page 19). The FMS-

1655M Monitor is able to communicate

11 points of information to the building

management system. See page 18 for list

of BACnet® points. The network settings

are easily congured by selecting the

Network Setup option from the Unit

Setup menu. As an alternate means

of remote monitoring, a 4-20mA signal

representing the room DP is available

for connecting to a third party controller

on the BMS. It is located at the green

terminal block on the remote sensor

and labeled as “Io.”

PID output setup

The FMS-1655M Monitor has an analog

output which can be used to control a

damper actuator for closed loop control of

the room differential pressure. This analog

output is present at the 9 pin connector

on remote sensor and can be congured

for a 0-10Vdc or 2-10Vdc output through

the touchscreen display menu. Go to PID

Output option in Room Setup of Unit

Setup menu. Select PID Output Setup,

set operating mode, and output range.

Touch Finish to save settings and exit

back to PID Output Setup menu. If

necessary the PID loop parameters can

be changed by selecting the PID Loop

Setup option where the Proportional,

Integral, & Derivative values can be tuned

for the optimum control loop response.

For most typical applications, PID factory

settings work well.

Editing setpoints

When the FMS-1655M Monitor is used

as a controller, the target differential

pressure setpoints can be set by selecting

the Room Setup option in the Unit Setup

menu. There the Edit Setpoint option can

be selected and the setpoints for Positive,

Negative, and Neutral isolation can be set

as well as a deadband.

Diagnostic menu

The FMS-1655M monitor incorporates

several troubleshooting tools. The

Override PID Output option allows the

analog output to be overridden and

locked while test and balance makes

adjustments to the Supply and Exhaust

dampers. While in the overridden state,

the analog output is “disconnected” from

the PID control loop, if enabled. The

Real-Time View option allows the user to

see in real time the actual values for the

Pressure, Setpoint, PID Output, and Door

Status. A software reset can be invoked

through the Reset Monitor option. It is

recommended to perform this function

after installation to insure that all user

settings are properly stored to nonvolatile

memory.

16

LIT-12013119

Page 17

FMS-1655M

Cleaning the display

• The cloth may be used dry, or lightly dampened with a mild cleaner or ethanol.

• Be sure the cloth is only lightly dampened, not wet. Never apply cleaner directly to touch panel surface; if cleaner is spilled onto

touch panel, soak it up immediately with absorbent cloth.

• Cleaner must be neither acid nor alkali (neutral pH).

• Wipe the surface gently; if there is a directional surface texture, wipe in the same direction as the texture.

• Never use acidic or alkaline cleaners, or organic chemicals such as: paint thinner, acetone, tolulene, xylene, propyl or isopropyl

alchohol, or kerosene.

Tapping the current room

name text brings up an

alphanumeric keyboard to

quickly change the name of

the monitored room.

Tapping the Status line

brings up the Isolation Mode

popup to quickly change the

monitored mode of isolation.

Tap anywhere else on the

screen enters the Main

Setup Menu if no password

is stored. Otherwise, a

password must be entered

before the Main Setup

Menu can be accessed.

Tapping the units brings

up engineering units

selection popup to

quickly change pressure

measurement units.

Tapping Time brings up

the Time Entry popup to

quickly change the current

displayed time.

Tap ALARM AUDIBLE to

toggle mode of audible

alarm. It automatically

reverts back to audible

mode when the alarm

condition is removed.

Hot-Spot Features of FMS-1655M Monitor

Touchscreen Display

17

LIT-12013119

Page 18

FMS-1655M

Alarm setpoints

18

LIT-12013119

Page 19

FMS-1655M

Setup menu tree

19

LIT-12013119

Page 20

FMS-1655M

20

LIT-12013119

Page 21

FMS-1655M

Conguring display module settings

Options Dipswitch (S1) – internal use only

1. Graphics Chip Mode Selection OFF = Programming Mode ON = Run Mode

2. Touch Screen Calibration Mode OFF = Force calibration ON = Auto calibration

3. Reserved

4. Reserved

Options Dipswitch (S2) – mode conguration 1

1. Reserved Set to OFF ON = CMS-1655

2. Reserved Set to OFF ON = Enabled

3. Mode Select OFF = FMS-1655M/ CMS-1655 ON = HMS-1655

4. Operational Mode: OFF = Demo Mode ON = Run Mode

Pushbutton Switch (SW1): Reset Button

Pushbutton Switch (SW2): Reserved

BACnet® objects

The following table itemizes the list of points available for integration in a BMS. This table contains the objects for open BACnet®

integration.

Object

Instance

AI - 1 Analog Input 1 (default: Differential Pressure)

BI - 1 Digital Input 1 (Door Switch) Read-Only

AO - 1 Analog Output (PID 1 OUT) Read-Only

AV - 1 Setpoint (Differential Pressure Setpoint) Read/Write

AV - 2 Low Pressure Alarm Setpoint Read/Write

AV - 3 Low Pressure Warning Setpoint Read/Write

AV -4 High Pressure Warning Setpoint Read/Write

AV -5 High Pressure Alarm Setpoint Read/Write

AV - 6 Pressure Deadband Read/Write

MSO-1

MSO-2 Alarm Status: 1=normal, 2=warning, 3=alarm Read-Only

Isolation Mode: 1=positive, 2=negative,

3=neutral

Functional Description Read or

Write

Analog Inputs

Read-Only

Binary Inputs

Analog Outputs

Analog Values

Multistate Objects

Read/Write

21

LIT-12013119

Page 22

FMS-1655M

FMS-1655M Monitor wiring guide

22

LIT-12013119

Page 23

FMS-1655M

European Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

NA/SA Single Point of Contact:

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

APAC Single Point of Contact:

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142 - CHINA

Building Technologies & Solutions

Headquarters: Milwaukee, Wisconsin, USA

Branch Officies: Principal Cities World-wide

Johnson Controls® is registered trademark of Johnson Controls.

© Copyright 2019 Johnson Controls. All rights reserved. Any unauthorized use or copying is strictly prohibited.

All other marks herein are the marks of their respective owners.

www.johnsoncontrols.com

Loading...

Loading...