Page 1

Installation / Operation Manual

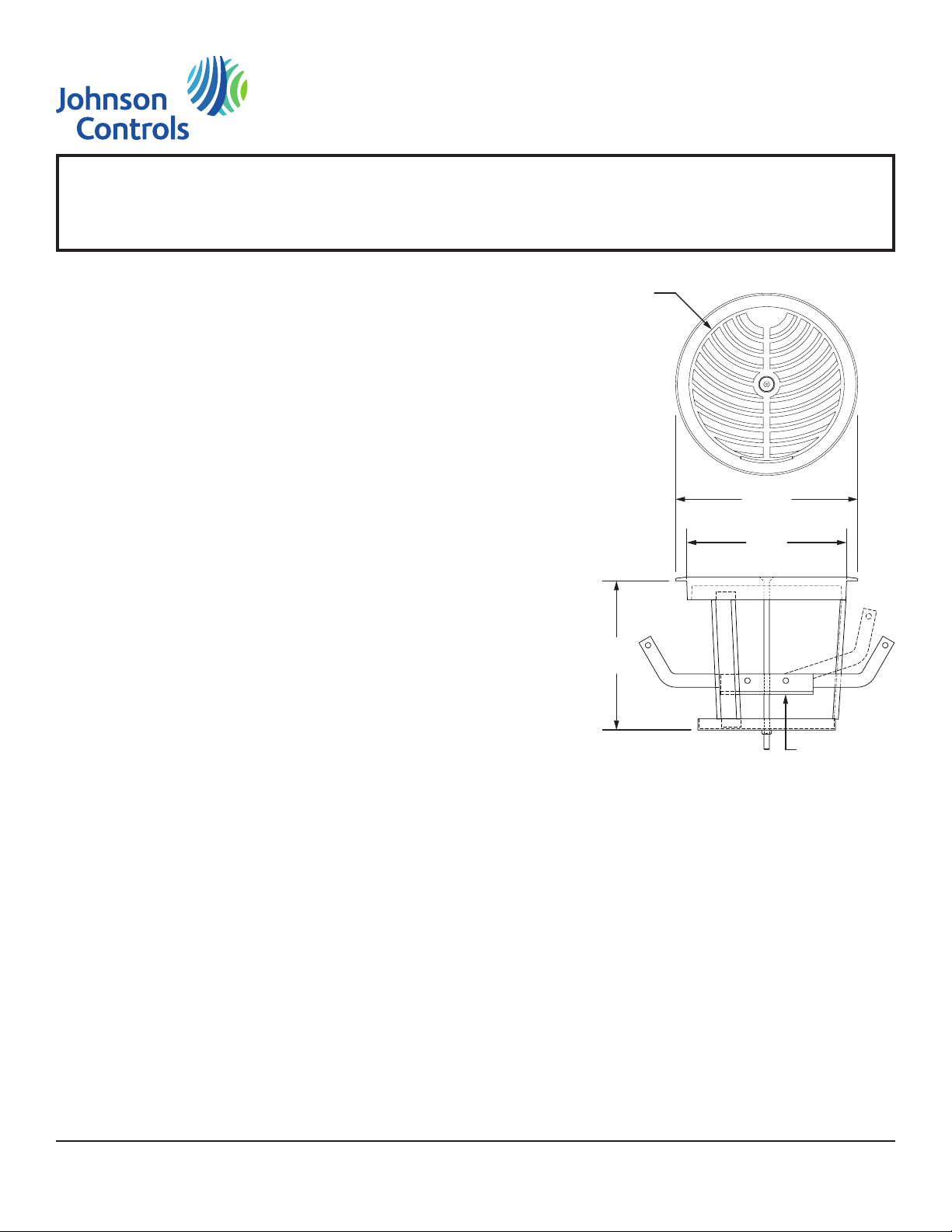

6.75”

171mm

6ӯ

152mm

5.8”

147mm

COLLAPSABLE

RETENTION BAR

5”

127mm

FlexSys Underoor Air Terminal (Constant Volume)

V160 829

Model:

Élan - 06R - 180

TOOLS REQUIRED:

1. Power Screwdriver (low torque setting)

• Phillips #3 Bit - oor panel screws

• Allen-Head Bit (5/32" / 4mm) - retention bar center screw

2. Panel Lifter (suction cups) - remove oor panels

3. Jigsaw - cut opening in oor panel (if panels are not pre-cut)

4. Carpet Knife - cut opening in carpet tile / oor covering

MATERIALS REQUIRED:

1. Élan-06R-180 Underoor Air Terminal

PREPARATION:

1. Verify that the Élan-06R-180 is the correct model, unit count

and location(s) per scheduled placement.

2. Remove the oor covering / oor panel at the desired

location(s) (if installed).

3. Verify that all adjacent oor panels are properly installed.

INSTALLATION:

The Élan-06R-180 is designed for drop-in installation in a oor

panel. If the oor panel was installed with a 6"Ø [+1/8"/-0"]

(152mm [+3.175/-.00]) round hole pre-cut, skip to Step 2. If the

unit is being added to an existing installation, begin with Step 1.

IMPORTANT: When adjusting the center screw to loosen

or tighten the retention bar, a power screw driver on a LOW

TORQUE SETTING is recommended. Overtightening can

warp the sliding damper plate, resulting in the inability to

adjust air ow.

Take care to avoid slippage of the driver bit;

ALL DIMENSIONS NOMINAL +/- 0.1" (2.5mm)

this may result in scratch damage to the diffuser grille.

1. Remove the oor panel and cut a 6"Ø [+1/8"/-0"]

(152mm [+3.175/-.00]) round opening for the Élan terminal.

Cut opening in carpet tile using same dimensions / position.

Replace oor panel / carpet tile when nished.

NOTE: Floor panels with pre-cut openings may be

4. To secure the Élan terminal in place, tighten the

retention bar to the underside of the oor panel

by turning the center screw clockwise.

5. For protection of the grille’s nish during

construction, a Grille Cover is recommended.

supplied by ooring manufacturer.

2. Verify that there is enough clearance between the retention

bar and diffuser grille to allow the collapsable arms to fold in

and clear the edge of the opening. If there is not enough

clearance, turn the center screw counter-clockwise to lower

the retention bar.

3. Insert the Élan terminal into the opening in the oor panel.

The collapsable arms of the retention bar should fold back

out to their default position once the opening is cleared.

REFER TO PAGE 2 FOR ADDITIONAL INFORMATION:

OPERATION / MAINTENANCE / PARTS

©2016 Johnson Controls | The performance specications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specications, consult the local

Johnson Controls ofce. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products.

1

© 2016 AirFixture, LLC

Page 2

Installation / Operation Manual

FlexSys Underoor Air Terminal (Constant Volume)

V160 829

Model:

OPERATION:

• Increase Air Flow:

Slide control lever in a counter-clockwise direction to open

the damper plate, increasing air ow.

• Reduce Air Flow:

Slide control lever in a clockwise direction to close the

damper plate, reducing air ow.

MAINTENANCE:

To remove debris that has collected in the catch pan:

1. Turn center screw counter-clockwise to loosen retention bar.

Set retention bar as low as possible, to allow easier access

to the catch pan.

2. Lift unit as far up as possible. Keep unit level; tilting it too far

may cause debris to dump out under the oor.

3. While holding unit, vacuum debris out of the catch pan.

4. Lower unit back down into oor. Using center screw, tighten

retention bar to secure unit back in place.

PAR TS:

• Grille Cover: P/N 620.0120.05

Élan - 06R - 180

©2016 Johnson Controls | The performance specications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specications, consult the local

Johnson Controls ofce. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products.

2

© 2016 AirFixture, LLC

Loading...

Loading...