Page 1

FEC26 Extended Temperature Field Equipment Controller

Installation Instructions

MS-FEC2611-0ET

Refer to the QuickLIT website for the most up-to-date version of this document.

Applications

The FEC26 extended temperature controller is part of

the Metasys® system Field Equipment Controller

(FEC) family. The FEC26 controller runs

pre-engineered and user-programmed applications

and provides the inputs and output s required to monitor

and control a wide variety of Heating, Ventilating, and

Air Conditioning (HVAC) equipment.

FEC controllers operate on an RS-485 BACnet®

Master-Slave/Token-Passing (MS/TP) Bus as BACnet

Application Specific Controllers (B-ASCs) and integrate

into the Web-based Metasys system.

IMPORTANT: In Metasys system smoke control

applications, use only the MS-FEU2610-0U and

MS-FEU2620-0U models that are UL Listed, UUKL

864 Listed, Smoke Control Equipment. For Metasys

system smoke control applications, you must refer to

the Metasys System UL 864 UUKL Ninth Edition

Smoke Control System Technical Bulletin

(LIT-12011252) for detailed requirements and

procedures for installing and operating UUKL 864

Listed Metasys system devices. Failure to meet the

requirements or follow the procedures in the

Metasys System UL 864 UUKL Ninth Edition Smoke

Control System Technical Bulletin (LIT-12011252)

can void the UUKL 864 listing for Smoke Control

Equipment.

North American Emissions Compliance

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Part No. 24-10143-292, Rev. A

Release 6.0

Issued January 30, 2013

Supersedes January 26, 2012

United States

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area

may cause harmful interference, in which cas e th e

users will be required to correct the interference at

their own expense.

Installation

Observe these guidelines when installing an FEC

extended temperature controller:

• Transport the FEC in the original container to

minimize vibration and shock damage.

• Verify that all parts shipped with the FEC.

• Do not drop the FEC or subject it to physical shock.

Parts Included

• one FEC26 controller with removable terminal

blocks

• one installation instructions sheet

Materials and Special Tools Needed

• three fasteners appropriate for the mounting

surface (M4 screws or #8 screws)

• one 20 cm (8 in.) or longer piece of 35 mm DIN rail

and appropriate hardware for DIN rail mount (only)

• small straight blade screwdriver for securing wires

in the terminal blocks

FEC26 Extended Temperature Field Equipment Controller Installation Instructions 1

Mounting

Observe these guidelines when mountin g an FEC:

• Ensure the mounting surface can support the FEC,

DIN rail, and any user-supplied enclosure.

Page 2

• Mount the FEC on 35 mm DIN rail whenever

Figure 1: Controller Mounting Positions

Figure 2: Back of FEC26 Controller Showing

Extended Mounting Clips, DIN Rail Channel, and

possible.

• Mount the FEC in the proper mounting position

(Figure 1).

• Mount the FEC on a hard, even surface whenever

possible in wall-mount applications.

• Use shims or washers to mount the FEC securely

and evenly on the mounting surface.

• Mount the FEC in an area free of corrosive vapors

and observe the Ambient Conditions in the

Technical Specifications

• Provide for sufficient space around the FEC for

cable and wire connections, easy cover removal,

and good ventilation through the controller (50 mm

[2 in.] minimum on the top, bottom, and front of the

controllers).

• Do not mount the FEC on surfaces prone to

vibration, such as duct work, or in areas where

electromagnetic emissions from other devices or

wiring can interfere with controller communication.

On panel or enclosure mount applications, observe

these additional guidelines:

• Do not install the FEC in an airtight enclosure.

• Mount the FEC so that the enclosure walls do not

obstruct cover removal or ventilation through the

controller.

• Mount the FEC so that the power transformer and

other devices do not radiate excessive heat to the

controller.

section.

DIN Rail Mount Applications

DIN rail mounting is the preferred mounting method.

To mount an FEC on 35 mm DIN rail:

1. Securely mount a 20 cm (8 in.) or longer section of

35 mm DIN rail horizontal and centered in the

desired space so that the controller mounts in the

horizontal position shown in Figure 1.

2. Pull the two bottom mounting clips outward to the

extended position (Figure 2).

3. Hang the controller on the DIN rail by the hooks at

the top of the (DIN rail) channel on the back of the

controller (Figure 2), and position the controller

snugly against the DIN rail.

4. Push the bottom mounting clips inward to secure

the controller on the DIN rail.

To remove the FEC from the DIN rail, pull the bottom

mounting clips out to the extended position and

carefully lift the controller off the DIN rail.

FEC26 Extended Temperature Field Equipment Controller Installation Instructions2

Page 3

Wall Mount Applications

To mount an FEC directly on a wall (or other flat vertical

surface):

1. Pull the two bottom mounting clips outward and

ensure they are locked in the extended positions

as shown in Figure 2.

3. Drill holes in the wall at the locations marked in

Step 2, and insert appropriate wall anchors in all

three holes (if necessary).

4. Hold the FEC in place, and insert the screws

through the mounting clips and into the holes.

Carefully tighten all of the screws.

2. Mark the three mounting hole locations on the wall

using the dimensions in Figure 2 and one of the

mount positions shown in Figure 1 (or ho ld th e

controller up to the wall/surface in a proper mount

position and mark the hole locations throug h th e

mounting clips.)

IMPORTANT: Do not overtighten the mounting

screws. Overtightening the screws may damage the

mounting clips.

FEC26 Extended Temperature Field Equipment Controller Installation Instructions 3

Page 4

Figure 3: FEC2621 Controller Physical Features and Wiring Terminals

BINARY

UNIVERSAL BINARY

CONFIGURABLE

ANALO

G

ADDRESS

24V

~

OUT1OCOM1OUT3OCOM

3

OCOM2OUT2OUT4OCOM4OUT6OCOM6OUT7

OCOM7

OCOM5OUT5

OUT

8

OCOM8OUT9OCOM9COMHO

T

+15V

IN1

ICOM1

IN2

ICOM2

+15V

ICOM6

IN7

ICOM7

ICOM8

IN8

ICOM5

IN6

IN3

ICOM3

IN4

ICOM4

+15v

IN5

COM

SHD

SENSOR

POWER

COM

SA BUS

FC BUS

FEC2611

C

o

n

f

i

g

u

rab

le Output

s can b

e

d

efine

d as:

V

o

l

t

a

g

e

An

a

l

o

g

Out

p

u

t (

0

-

1

0

VDC

)

B

i

n

a

r

y

Output (24 V

AC Triac)

Analo

g

Out

puts

can b

e

defin

e

d

as: Voltage

A

n

alog Output

(

0

-

10

VDC)

Current

A

n

alog Output (

4-20

m

A

)

2

4

VAC, C

l

a

s

s 2

S

u

ppl

y

Po

werTe

r

m

ina

l

Bloc

k

Di

s

p

l

ayN

a

v

i

gatio

n

Buttons

(Not

ava

i

lable on

all

F

E

C

mo

d

e

ls.)

B

i

n

a

r

y

I

n

p

u

t

s

ca

n

be d

efined as

:

D

r

y

C

o

n

t

a

c

t

M

a

intaine

d

P

u

l

s

e

C

o

u

n

ter

Mo

d

e

(

5

0

H

z

a

t

50%

d

uty cyc

le)Se

nsor Po

rt(

S

A

Bu

s)RJ-

1

2

6

-

P

inMod

u

l

ar

J

ackFC

Bus

T

e

r

m

ina

l

B

l

o

c

k

S

A

B

u

sTe

r

m

ina

l

Blo

c

k

U

n

i

v

e

r

s

a

l

I

n

p

u

t

s

t

c

a

n

b

e

d

e

f

i

n

e

d

a

s

:

V

o

l

t

a

g

e

A

n

a

l

o

g

I

n

p

u

t

(

0

-

1

0

V

D

C

)

C

u

r

r

e

n

t

A

n

a

l

o

g

I

n

p

u

t

(

4

-

2

0

m

A

)

R

e

s

i

s

t

i

v

e

A

n

a

l

o

g

I

n

p

u

t

s

(

0

-

6

0

0

k

o

h

m

)

:

0

-

2

k

P

o

t

e

n

t

i

o

m

e

t

e

r

R

T

D

:

1

k

N

i

c

k

e

l

,

1

k

P

l

a

t

i

n

u

m

,

o

r

A

9

9

B

S

I

N

T

C

:

1

0

k

T

y

p

e

L

1

0

k

J

C

I

T

y

p

e

I

I

,

o

r

2

.

2

5

2

k

T

y

p

e

I

I

D

r

y

C

o

n

t

a

c

t

B

i

n

a

r

y

I

n

p

u

L

E

D

S

t

a

t

u

s

I

n

d

i

c

a

t

o

r

s

D

e

v

i

c

e

A

d

d

r

e

s

s

D

I

P

S

w

i

t

c

h

B

l

o

c

k

B

i

n

a

r

y

O

u

t

p

u

t

s

2

4

V

A

C

T

r

i

a

c

s

LCD

D

isp

lay A

r

e

a(N

ot

a

vailable on a

l

l

F

E

C model

s.)

F

C

B

u

s

P

o

r

t

R

J

-

1

2

6

-

P

i

n

M

o

d

u

l

a

r

J

a

c

k

(Live 24 VAC

on Exposed Jumper Pins.)

Cover LiftTab

Cover Lift

Tab

POWER

FAULT

SA BUS

FC BUS

FC BUS

EOL

Mounting Clip

(One of T hr ee)

SOURCE 24VAC

FIG:fec26_phys_feats

Binary Output Source Powe r

Selection Jumpers

FEC26 Extended Temperature Field Equipment Controller Installation Instructions4

Page 5

Wiring

!

Figure 4: FC Bus Terminal Block Wiring

Figure 5: SA Bus Terminal Block Wiring

CAUTION: Risk of Electric Shock.

Disconnect the power supply before

making electrical connections to avoid

electric shock.

IMPORTANT: Do not connect supply power to the

controller before finishing wiring and checking all

wiring connections. Short circuits or improperly

connected wires can result in damage to the

controller and void any warranty.

IMPORTANT: Do not exceed the controller

electrical ratings. Exceeding controller electrical

ratings can result in permanent damage to the

controller and void any warranty.

IMPORTANT: Use copper conductors only. Make

all wiring in accordance with local, national, and

regional regulations.

IMPORTANT: Electrostatic discharge can damage

FEC components. Use proper electrostatic

discharge precautions during installation, setup, and

servicing to avoid damaging the FEC controller.

SA Bus Terminal Block

The SA Bus terminal block is a brown, removable,

4-terminal plug that fits into a board-mounted jack.

Wire the removable SA Bus terminal block plugs on the

FEC and other SA Bus devices in a daisy-chain

configuration using 4-wire twisted, shielded cable as

shown in Figure 5. See Table 3 for more information.

For detailed information on configuring and wiring an

MS/TP Bus, Field Controller (FC) Bus, and Sensor

Actuator (SA) Bus, refer to the MS/TP Communications

Bus Technical Bulletin (LIT-12011034).

FEC Terminal Blocks and Bus Ports

See Figure 3 for terminal block and bus port locations

on the FEC26 extended temperature controller.

Observe the following guidelines when wiring an FEC

controller.

Input and Output Terminal Blocks

All of the fixed input terminal blocks are mounted on

the bottom of the FEC. The output terminal blocks are

mounted on the top of the controller. See Table 1 for

more information.

FC Bus Terminal Block

The FC Bus terminal block is a blue, removable,

4-terminal plug that fits into a board-mounted jack.

Wire the removable FC Bus terminal block plugs on the

FEC, and other field controllers in a daisy-chain

configuration using 3-wire twisted, shielded cable as

shown in Figure 4. See Table 3 for more information.

Note: The Shield terminal (SHLD) on the FC Bus

terminal block is isolated and can be used to connect

the cable shields on the bus (Figure 4).

FC Bus Port

The FC Bus port on the front of the FEC is an RJ-12,

6-position modular jack that provides a connection for

the Bluetooth® Wireless Commissioning Converter,

ZigBee™ wireless dongle, or ZFR1811 Wireless Field

Bus Router.

The FC Bus port is connected internally to the FC Bus

terminal block. See Table 3 for more information. The

FC Bus Port pin assignment is shown in (Figure 6).

FEC26 Extended Temperature Field Equipment Controller Installation Instructions 5

Page 6

Sensor Port

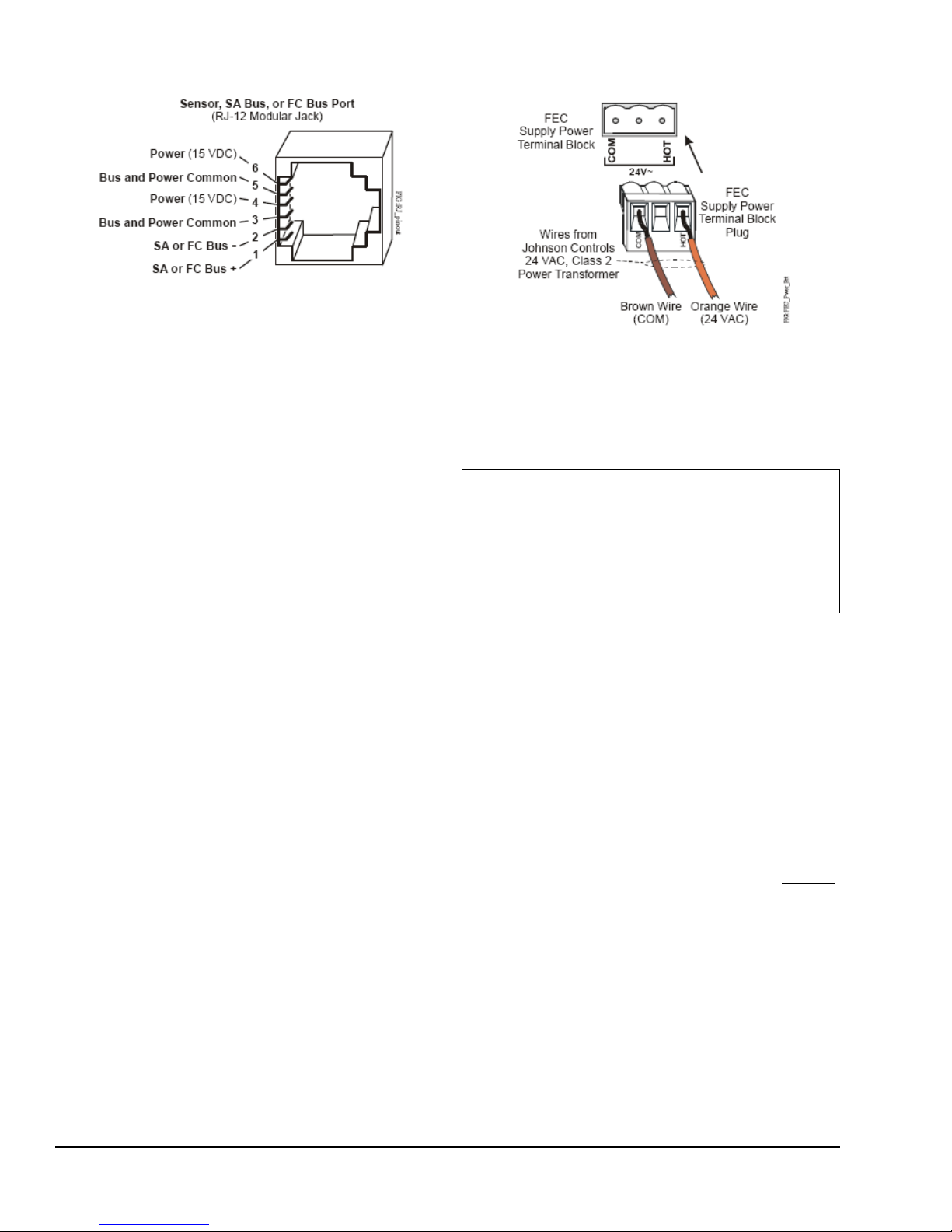

Figure 6: Pin Number Assignments for

Sensor, SA Bus, and FC Bus Ports on

FEC, IOM, and VMA16

Figure 7: 24 VAC Supply Power

Terminal Block Wiring

The Sensor (SA Bus) port on the bottom of the FEC

(Figure 3) is an RJ-12, 6-position modular jack that

provides a connection for the Wireless Commissioning

Converter, the VAV Balancing Tool, specified network

sensors, or other SA Bus devices with RJ-12 plugs.

A DIS1710 Local Controller Display also can be

connected to the SA Bus port (but only on FEC models

without an integral display and push buttons).

The Sensor port is connected internally to the SA Bus

terminal block. See Table 3 for more information. The

Sensor Port pin assignment is shown in Figure 6.

Supply Power Terminal Block

The 24 VAC supply power terminal block is a gray,

removable, 3-terminal plug that fits into a boardmounted jack on the top right of the FEC.

Wire the 24 VAC supply power wires from the

transformer to the HOT and COM terminals on the

terminal plug as shown in Figure 7. The middle

terminal on the supply power terminal block is not

used. See Table 3 for more information.

The supply power wire colors may be different on

transformers from other manufact ur er s. Re fe r to th e

transformer manufacturer’s instructions and the project

installation drawings for wiring details.

IMPORTANT: Connect 24 V AC supply power to the

FEC and all other network devices so that

transformer phasing is uniform ac ro ss th e ne two rk

devices. Powering network devices with uniform

24 VAC supply power phasing reduces noise,

interference, and ground loop problems. The FEC

does not require an earth ground connection.

Wireless Network Applications

The FEC can also be installed in a wireless application.

To configure a controller for use with the ZFR1800

Series Wireless Field Bus system:

1. Wire the input/output terminals and SA Bus.

Note: In wireless network applications, do not

connect any wires to the FC Bus terminal block.

2. Connect the ZFR181 1 Wireless Field Bus Router to

the FC Bus port (RJ-12 modular jack) on the front

of the FEC.

3. Ensure that the FEC device address DIP switches

are set to the correct device address. See Setting

the Device Address.

FEC26 Extended Temperature Field Equipment Controller Installation Instructions6

4. Position DIP switch 128 to ON to enable wireless

operation on the FEC.

For more information on installing an FEC in a wireless

configuration, refer to the ZFR1811 Wireless Field Bus

Router Installation Instructions (Part No. 24-10325-1).

Page 7

FEC Terminal Functions, Ratings,

Requirements, and Wiring Guidelines

Input and Output Wiring Guidelines

Table 1 provides information and guidelines about the

functions, ratings, and requirements for the FEC input

and output terminals, and references guidelines for

determining proper wire sizes and cable lengths.

In addition to the wiring guidelines in Table 1, observe

these guidelines when wiring FEC inputs and outputs:

•Run all low-voltage wiring and cables separate

from high-voltage wiring.

• All input and output cables, regardless of wire size

or number of wires, should consist of stranded,

insulated, and twisted copper wires.

• Shielded cable is not required for input or output

cables.

• Shielded cable is recommended for input and

output cables that are exposed to high

electromagnetic or radio frequency noise.

• Inputs/outputs with cables less than 30 m (100 ft)

typically do not require an offset in the software

setup. Cable runs over 30 m (100 ft) may require

an offset in the input/output software setup.

Table 1: I/O Terminal Blocks, Functions, Ratings, Requirements, and Cables (Part 1 of 3)

T e rminal Block

Label

UNIVERSAL

(Inputs)

BINARY

(Inputs)

Terminal

Function, Ratings, and Requirements Determine Wire Size and

Labels

+15 V 15 VDC Power Source for active (3-wire) input devices

INn Analog Input - Voltage Mode (0-10 VDC)

ICOMn Universal Input Common for all Universal IN terminals

INn Binary Input - Dry Contact Maintained Mode

ICOMn Binary Input Common for all Binary Input (IN) terminals

connected to the Universal INn terminals.

Provides 100 mA total current.

10 VDC maximum input voltage

Internal 75k ohm Pulldown

Analog Input - Current Mode (4-20 mA)

Internal 100 ohm load Impedance

Note: A current loop fail-safe jumper can be positioned

to maintain a closed 4-20 mA current loop even when

power to the controller is interrupted or off. See Binary

Output Source Power Selection Jumpers.

Analog Input - Resistive Mode (0-600k ohm)

Internal 12 V, 15k ohm pull up

Qualified Sensors: 0-2k potentiometer,

RTD (1k Nickel [Johnson Controls® sensor],

1k Platinum, and A99B Silicon Temperature Sensor)

Negative Temperature Coefficient (NTC) Sensor

(10k Type L, 10k JCI Type II, 2.252k Type II)

Binary Input - Dry Contact Maintained Mode

1 second minimum pulse width

Internal 12 V, 15k ohm pull up

Note: All Universal ICOMn terminals share a common,

which is isolated from all other commons.

0.01 second minimum pulse width

Internal 18 V, 3k ohm pull up

Binary Input - Pulse Counter/Accumulator Mode

0.01 second minimum pulse width

(50 Hz at 50% duty cycle)

Internal 18 V, 3k ohm pull up

Note: All Binary ICOMn terminals share a common,

which is isolated from all other commons, except the

Configurable Output (CO) common (OCOMn) when the

CO is defined as an Analog Output.

Maximum Cable Length

Same as (Universal) INn.

Note: Use 3-wire cable for

devices that source power

from the +15 V terminal.

See Guideline A in Table 2.

See Guideline B in Table 2.

See Guideline A in Table 2.

See Guideline A in Table 2.

Same as (Universal) INn.

See Guideline A in Table 2.

1

FEC26 Extended Temperature Field Equipment Controller Installation Instructions 7

Page 8

Table 1: I/O Terminal Blocks, Functions, Ratings, Requirements, and Cables (Part 2 of 3)

T e rminal Block

Label

ANALOG

(Outputs)

BINARY

(Outputs)

Power Selection

Jumper positioned

to External (EXT).

BINARY

(Outputs)

Power Selection

Jumper positioned

to Internal (INT).

Terminal

Function, Ratings, and Requirements Determine Wire Size and

Labels

OUTn Analog Output - Voltage Mode (0-10 VDC)

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1,000 ohms or more.

Note: The AO operates in Voltage Mode when

connected to devices with impedances greater than

1,000 ohms. Devices that drop below 1,000 ohms may

not operate as intended for Voltage Mode applications.

Analog Output - Current Mode (4-20 mA)

Requires an external load between 0-300 ohms.

Note: The AO operates in Current Mode when

connected to devices with impedances less than

300 ohms. Devices that exceed 300 ohms may not

operate as intended for Current Mode applications.

OCOMn Analog Output Signal Common for all Analog OUT

terminals.

Note: All Analog OCOMn terminals share a common,

which is isolated from all other commons.

OUTn Binary Output - 24 VAC Triac (External Power)

Connects OUTn to OCOMn when activated.

External Power Source:

30 VAC maximum output voltage

0.5 A maximum output current

1.3 A at 25% duty cycle

Maximum 6 cycles/hour with M9220-BGx-3

40 mA minimum load current

OCOMn Binary Output Common (for OUTn terminal)

Note: Each Binary Output common terminal (OCOMn) is

isolated from all other commons, including other Binary

Output commons.

OUTn Binary Output - 24 VAC Triac (Internal Power)

Sources internal 24 VAC power (24~ HOT)

OCOMn Binary Output - 24 VAC Triac (Internal Power)

Connects OCOMn to 24~ COM when activated.

Internal Power Source:

30 VAC maximum voltage to load

0.5 A maximum output current

1.3 A at 25% duty cycle

Maximum 6 cycles/hour with M9220-BGx-3

40 mA minimum load current

Maximum Cable Length

See Guideline A in Table 2.

See Guideline B in Table 2.

Same as (Analog) OUTn.

See Guideline C in Table 2.

See Guideline C in Table 2.

1

FEC26 Extended Temperature Field Equipment Controller Installation Instructions8

Page 9

Table 1: I/O Terminal Blocks, Functions, Ratings, Requirements, and Cables (Part 3 of 3)

T e rminal Block

Label

CONFIGURABLE

(Outputs)

1. See Table 2 to determine wire size and cable lengths for cables other than the recommended cables.

Terminal

Function, Ratings, and Requirements Determine Wire Size and

Labels

OUTn Analog Output - Voltage Mode (0-10 VDC)

10 VDC maximum output voltage

10 mA maximum output current

Requires an external load of 1000 ohm or more

Binary Output 24 VAC Triac

Connects OUT to OCOM when activated.

External Power Source:

30 VAC maximum voltage to load

0.5 A maximum output current

1.3 A at 25% duty cycle

Maximum 6 cycles/hour with M9220-BGx-3

40 mA minimum load current

OCOMn Analog Output Signal Common: All Con f i g urable

Outputs defined as Analog Outputs share a common,

which is isolated from all other commons except the

Binary Input common.

Binary Output Signal Common: All Configurable

Outputs defined as Binary Outputs are isolated from all

other commons, including other Configurable Output

commons.

Maximum Cable Length

See Guideline A in Table 2.

See Guideline C in Table 2.

Same as (Configurable)

OUTn.

1

Table 2 defines cable length guidelines for the various

wire sizes that may be used for input and output wiring.

Table 2: Cable Length Guidelines for Recommended Wire Sizes

Guideline Wire Size/Gauge and Type Maximum Cable Length

and Type

A

1.5 mm

0.8 mm

0.6 mm

2

(18 AWG) stranded copper

(20 AWG) stranded copper

(22 AWG) stranded copper

N/A (24 AWG) stranded copper 107 m (350 ft) twisted wire

B

1.5 mm

0.8 mm

0.6 mm

N/A

2

(18 AWG) stranded copper

(20 AWG) stranded copper

(22 AWG) stranded copper

(24 AWG) stranded copper

C See Figure 8 to select wire size/gauge.

Use stranded copper wire.

457 m (1,500 ft) twisted wire 100 mV maximum voltage drop

297 m (975 ft) twisted wire

183 m (600 ft) twisted wire

229 m (750 ft) twisted wire 100 mV maximum voltage drop

137 m (450 ft) twisted wire

91 m (300 ft) twisted wire

61 m (200 ft) twisted wire

See Figure 8 to determine

cable length. Use twisted

wire cable.

Assumptions

Depending on the cable length and

the connected input or output device,

you may have to define an offset in

the setup software for the input or

output point.

Depending on the cable length and

the connected input or output device,

you may have to define an offset in

the setup software for the input or

output point.

N/A

FEC26 Extended Temperature Field Equipment Controller Installation Instructions 9

Page 10

Maximum Cable Length versus Load Current

Figure 8: Maximum Wire Length by Current and Wire Size

Use Figure 8 to estimate the maximum ca ble length

relative to the wire size and the load current (in mA)

when wiring inputs and outputs.

FC and SA Bus and Supply Power Wiring

Guidelines

Table 3 provides information about the functions,

ratings, and requirements for the FEC communication

•Run all low-voltage wiring and cables separate

from high-voltage wiring.

• All FC and SA Bus cables, regardless of wire size,

should be twisted, insulated, stranded copper wire.

bus and supply power terminals; and provide s

guidelines for wire sizes, cable types, and cable

lengths when wiring the FEC communication buses

and supply power.

In addition to the guidelines in Table 3, observe these

guidelines when wiring the SA/FC Buses and supply

power:

• Shielded cable is strongly recommended for all FC

and SA Bus cables.

• Refer to the MS/TP Communications Bus

Technical Bulletin (LIT-12011034) for detailed

information regarding wire size and cable length

requirements for the FC and SA buses.

T able 3: Communication Bus and Supply Power Terminal Blocks, Funct ions, Rat ings, Re quirements, and

Cables (Part 1 of 2)

Terminal

Block/Port

Terminal

Labels

Function, Electrical Ratings/Requirements

Recommended Cable Type

1

Label

FC BUS

2

+

COM Signal Reference (Common) for bus communications

SHLD Isolated terminal (optional shield drain connection)

FC Bus Communications 0.6 mm (22 AWG) stranded, 3-wire

twisted, shielded cable

recommended

FEC26 Extended Temperature Field Equipment Controller Installation Instructions10

Page 11

T able 3: Communication Bus and Supply Power Terminal Blocks, Functions, Ratings, Requirements, and

Figure 9: Device Address Switches Set to 21

Cables (Part 2 of 2)

Terminal

Block/Port

Terminal

Labels

Function, Electrical Ratings/Requirements

Recommended Cable Type

1

Label

FC Bus

(Port)

SA BUS

SENSOR

24~ HOT 24 VAC Power Supply - Hot

2

2

+

COM SA Bus Signal Reference and 15 VDC Common

SA PWR 15 VDC Supply Power for Devices on the SA Bus

2

SENSOR RJ-12 6-Position Modular Connector provides:

COM 24 VAC Power Supply Common (Isolated from all other

RJ-12 6-Position Modular Connector provides:

FC Bus Communications

FC Bus Signal Reference and 15 VDC Common

15 VDC, 240 mA, Power for Wireless Commissioning

Converter or ZFR1811 Wireless Router.

SA Bus Communications 0.6 mm (22 AWG) stranded, 4-wire

(Maximum total current draw for SA Bus is 240 mA.)

SA Bus Communications

SA Bus Signal Reference and 15 VDC Common

15 VDC Power for devices on the SA Bus and

Wireless Commissioning Converter.

Supplies 20-30 VAC (Nominal 24 VAC)

Common terminals on controller)

Wireless Commissioning

Converter retractable cable or

24 AWG 3-pair CAT 3 Cable

<30.5 m (100 ft)

(2 twisted-pairs), shielded cable

recommended

Note: The + and - wires are one

twisted pair and the COM and

SA PWR are the second twisted

pair of wires.

24 AWG 3-pair CAT 3 Cable

<30.5 m (100 ft)

0.8 mm to 1.5 mm

(20 to 16 AWG) 2-wire

2

1. See Table 2 to determine wire size and cable lengths for cables other than the recommended cables.

2. The SA Bus and FC Bus wiring recommendations in this table are for MS/TP bus communications at 38.4k baud. For more

information, refer to the MS/TP Communications Bus Technical Bulletin (LIT-12011034).

Setup and Adjustments

Setting the Device Address

Metasys field controllers are master devices on

BACnet MS/TP (SA or FC) buses. Before operating

field controllers on a bus, you must set a valid and

unique device address for each controller on the bus.

Y ou set a field controller's device address by setting the

positions of the switches on the Device Address DIP

switch block at the top of the controller (Figure 3).

Device addresses 4 through 127 are the valid

addresses for these controllers.

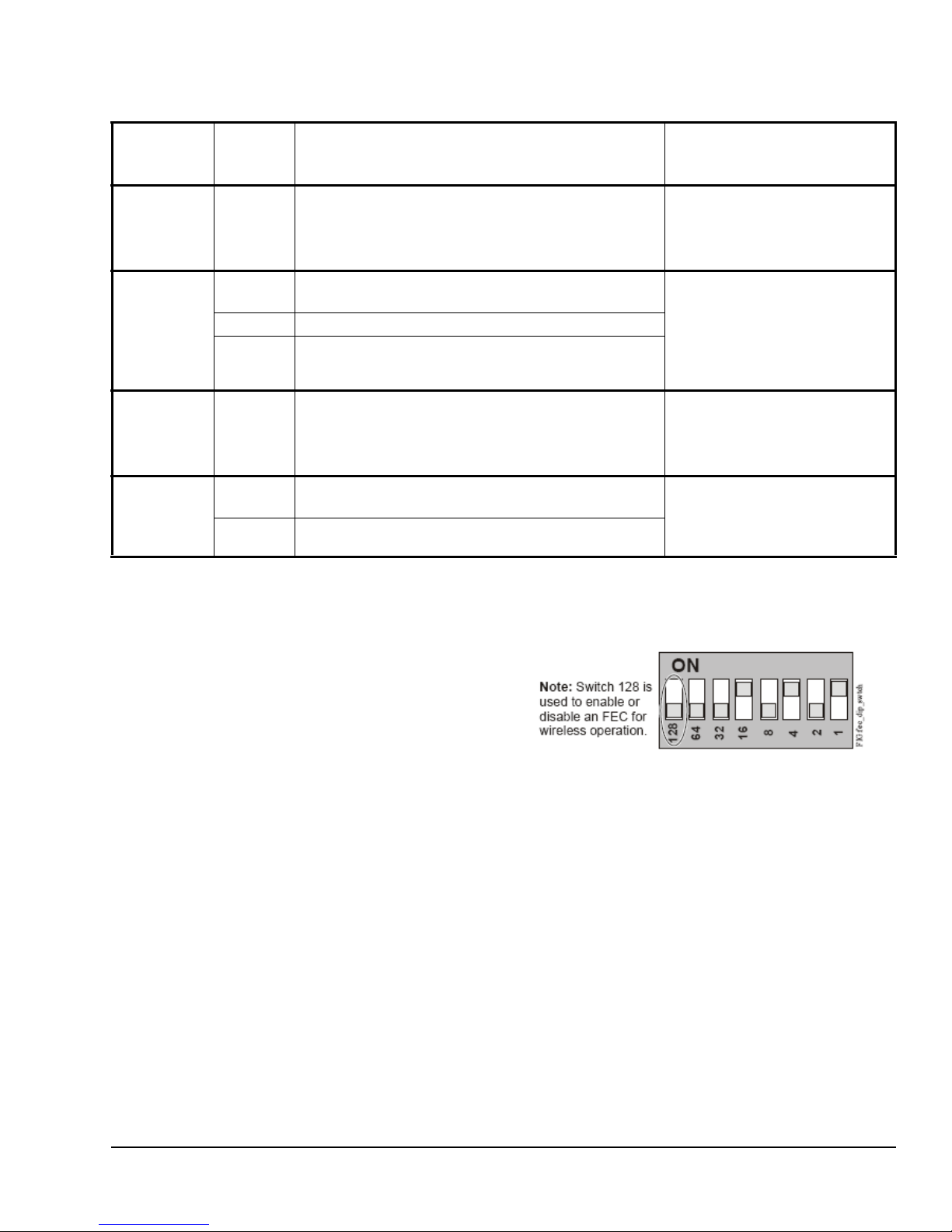

The DIP switch block (Figure 9) has eight switches

numbered 128, 64, 32, 16, 8, 4, 2, and 1. Switches 64

through 1 are device address switches. Switch 128 is a

mode switch that enables a field controller to operate

on a ZFR1800 Series Wireless Field Bus. Switch 128

must be set to off for all hard-wired SA and FC Bus

applications. Set switch 128 to ON for wireless FC Bus

applications only.

Note: Metasys field controllers ship with switch 128

ON and the remaining address switches off rendering

the controllers wired slave devices, which do not

operate on MS/TP buses, but do not interfere with bus

operation. Set a valid and unique device address on

the field controller before applying power to the

controller on the bus.

To set the device addresses on Metasys field

controllers:

1. Set all of the switches on the field controller’s

device address DIP switch block (128 through 1) to

off.

FEC26 Extended Temperature Field Equipment Controller Installation Instructions 11

Page 12

2. Set one or more of the seven address switches (64

through 1) to ON, so that the sum of the switch

numbers set to ON equals the intended device

address. See Table 4 for valid field controller

addresses.

Set the highest number switch that is less than or

equal to the intended device address to ON. Then

continue setting lower numbered switches until the

total equals the intended address. For example, if

the intended device address is 21, set switch 16 to

ON first, then set switch 4 ON, followed by switch 1

(16+4+1= 21). See Figure 9.

3. Set switch 128 to ON only for controllers on a

ZFR1800 Series Wireless Field Bus application.

For all hard-wired SA and FC Bus applications,

ensure that switch 128 is set to off.

Note: Do not connect a field controller with switch

128 set to ON to an active (hard-wired) SA or FC

Bus. When a controller with switch 128 set to ON

and a device address from 4 to 127 is connected to

a wired field bus, the entire field bus is rendered

inoperable until the controller is disconnected or

switch 128 is set to off.

Refer to the ZFR1800 Series Wireless Field Bus

System T echnical Bulletin (LIT-1201 1295) for more

information on device addresses in wireless

applications.

4. Set a unique and sequential device address for

each of the field controllers connected on the SA or

FC Bus starting with device address 4.

To ensure the best bus performance, set

sequential device addresses with no gaps in the

device address range (4, 5, 6, 7, 8, 9, and so on).

The field controllers do not need to be physically

connected on the bus in their numerical device

address order.

5. Write each field controller's device address on the

white label below the DIP switch block on the

controller's cover.

Refer to the MS/TP Communications Bus Technical

Bulletin (LIT-12011034) for more information on field

controller device addresses and how to set them on

MS/TP buses.

Table 4 shows and describes the valid FC Bus and

SA Bus devices addresses for Johnson Controls®

MS/TP communications bus applications.

Table 4: SA/FC Bus Device Address Descriptions

Device

Address Description

Address

0

(Switch

128 Off)

1 to 3

(Switch

128 Off)

4 to 127

(Switch

128 Off)

0 to 3

(Switch

128 ON)

4 to 127

(Switch

128 ON)

Reserved for FC Bus Supervisory Controller

(not valid for field controllers).

Reserved for peripheral devices (not valid for

field controllers).

Valid for MS/TP Master field controllers on a

hard-wired SA Bus or FC Bus.

Reserved addresses for wired slave devices

(not valid for field controllers).

Note: Metasys controllers ship with 128 ON

and the remaining address switches off,

rendering the controllers wired slave devices,

which do not operate on Metasys field buses.

Valid for MS/TP Master field controllers on

wireless FC Buses only.

Note: Do not connect a Metasys controller

with these device addresses to an active

wired SA or FC Bus. When a controller with

one of these device address is connected to

a wired field bus, the field bus is rendered

inoperable until the controller is disconnected

or switch 128 is set to off.

Removing the FEC Housing Cover

IMPORTANT: Electrostatic discharge can damage

controller components. Use proper electrostatic

discharge precautions during installation, setup, and

servicing to avoid damaging the controller.

IMPORTANT: Disconnect all power sources to the

controller before removing cover and changing the

position of any jumper or the EOL switch on the

controller. Failure to disconnect power before

changing a jumper or EOL switch position can result

in damage to the controller and void any warranties.

The controller cover is held in place by four plastic

latches that extend from the base and snap into slots

on the inside of the housing cover. To remove the

controller cover:

1. Place your fingernails under the two cover lift tabs

on the sides of the housing cover (Figure 3) and

gently pry the top of the cover away from the base

to release the cover from the two upper latches.

2. Pivot the top of the cover further to release it from

the lower two latches.

FEC26 Extended Temperature Field Equipment Controller Installation Instructions12

Replace the cover by placing it squarely over the base,

and then gently and evenly push the cover on to the

latches until they snap into the latched position.

Page 13

Setting the EOL Switch

Figure 10: FEC26 with Cover Removed

Showing Jumper and EOL Switch Positions

Figure 11: EOL Switch Positions

!

Figure 12: Example Binary Outputs and the

Associated Source Power Jumper Positions

Each field controller has an End-of-Line (EOL) switch,

which, when set to ON/up, sets the field controller as a

terminating device on the bus. See Figure 3 or

Figure 10 for the EOL switch location on the field

controller. The default EOL switch position is off/down.

Setting the Input and Output Jumpers

Binary Output Source Power Selection Jumpers

CAUTION: Risk of Electric Shock.

Disconnect supply power to the FEC26

controller before attempting to adjust the

Binary Output Source Power Selection

Jumpers. Failure to disconnect the

supply power may result in electric shock.

IMPORTANT: Do not connect an external power

source to a Binary Output (BO) when the BO power

source jumper is in the internal power (INT) position.

Connecting external power to a BO that sources

internal power can damage the controller and void

any warranties.

The BO source power selection jumpers determine

whether a BO provides internal power (sourced from

the FEC) to the output load (INT position) or requires

an external power source (EXT position) for the output

load. Figure 12 shows an example of an FEC16

controller BOs and the associated power sele ctio n

jumpers to the right of the BOs terminal block.

To set the EOL switch on a field controller:

1. Determine the physical location of the field

controller on the SA or FC Bus.

2. Determine if the field controller must be set as a

terminating device on the bus.

Note: The EOL termination rules for SA Buses

and FC Buses are different. Refer to the

MS/TP Communications Bus Technical Bulletin,

(LIT-12011034) for detailed information regarding

EOL termination rules and EOL switch settings on

SA and FC Buses.

3. If the field controller is a terminating device on the

SA Bus or FC Bus, set the EOL switch to ON. If the

field controller is not a terminating device on the

bus, set the EOL switch to off.

When a field controller is connected to power with its

EOL switch set to ON, the amber EOL Light-Emitting

Diode (LED) on the controller cover is lit.

Universal Input Current Loop Jumpers

The Universal Input (UI) current loop fail-safe jumpers

are on the circuit board under the housing cover near

the UI terminals (Figure 10). When a UI is defined (in

the system software) as a 4-20 mA analog input and

the UI’s current loop jumper is in the (default) Disabled

position (Figure 13), the 4-20 mA current loop circuit

opens whenever power to the FEC is interrupted or off.

FEC26 Extended Temperature Field Equipment Controller Installation Instructions 13

Page 14

Setting the current loop jumper to the Enabled position

Figure 13: Current Loop Jumper Positions

(Figure 13) connects an internal 100 ohm resistor

across the UI terminals, which maintains the 4-20 mA

current loop circuit even when power to the FEC is

interrupted or off.

IMPORTANT: Current Loop jumpers must be in the

(default) Disabled position for all UIs that are not set

up to operate as 4-20 mA analog inputs.

Table 5 identifies the current loop jumpers associated

with each UI on the FEC26 controller.

Table 5: FEC 26 UI Inputs and Jumper Labels

Universal Input

Label

IN1 J20

IN2 J21

IN3 J22

IN4 J23

IN5 J24

IN6 J25

Jumper Label on Circuit

Board

Refer to the DIS1710 Local Controller Display

Technical Bulletin (LIT-12011270) for information on

connecting a DIS1710 display.

T roubleshooting

Observe the LEDs on the front of the controller and see

Table 6 to troubleshoot the controller. To troubleshoot

the integral FEC display, refer to the DIS1710 Local

Controller Display Technical Bulletin

(LIT-12011270).

Commissioning

Commission the FEC with the Metasys Controller Tool

(software), either via the Bluetooth® Wireless

Commissioning Converter, ZigBee™ wireless dongle,

or in passthrough mode when connected to an NAE or

NCE. Refer to Controller Tool Help (LIT-12011147).

Table 6: Status LEDs and Description of LED States

LED Label LED

Color

POWER Green On Steady Off Steady = No Supply Power or the controller’s polyswitch/resettable fuse is

FAULT Red Off Steady Off Steady = No Faults

SA BUS Green Blink - 2 Hz Blink - 2 Hz = Data Transmission (normal communication)

FC BUS Green Blink - 2 Hz Blink - 2 Hz = Data Transmission (normal communication)

EOL Amber Off

Normal

State

(Except on

terminating

devices)

Descriptions of LED States

open. Check Output wiring for short circuits and cycle power to controller.

On Steady = Power Connected

On Steady = Device Fault; no application loaded; Main Code download

required, if controller is in Boot mode, or a firmware mismatch exists between

the FEC and the ZFR1811 Wireless Field Bus Router.

Blink - 2 Hz = Download or Startup in progress, not ready for normal operation

Blink Rapidly - 5 Hz = One or more defined SA Bus devices are offline. Check

SA Bus devices for problems, including low batteries on wireless sensor.

Off Steady = No Data Transmission (N/A - auto baud not supported)

On Steady = Communication lost, waiting to join communication ring

Off Steady = No Data Transmission (auto baud in progress)

On Steady = Communication lost, waiting to join communication ring

On Steady = EOL switch in ON position

Off Steady = EOL switch in Off positio n

FEC26 Extended Temperature Field Equipment Controller Installation Instructions14

Page 15

Repair Information

If the FEC26 controller fails to operate within its

Accessories

See Table 7 to order accessories.

specifications, replace the unit. For a replacement

controller, contact the nearest Johnson Controls

representative.

Table 7: FEC26 Extended Temperature Controller Accessories Ordering Information

Product Code Number Description

MS-BTCVT-1 Wireless Commissioning Converter, with Bluetooth® Technology

MS-DIS1710-0 Local Controller Display (for use with MS-FEC2611 model only)

MS-ZFR1811-0 Wireless Field Bus Router for wireless FEC applications

TP-2420 Transformer, 120 VAC Primary to 24 VAC secondary, 20 VA, Wall Plug

Y65T31-0

AS-XFR050

AP-TBK4SA-0 Replacement MS/TP SA Bus Terminal, 4-Position, Brown, Bulk Pack

AP-TBK4FC-0 Re placement MS/TP FC Bus Terminal, 4-Position, Blue, Bulk Pack

AP-TBK3PW-0 Replacement Power Terminal, 3-Position Connector, Gray, Bulk Pack

1. Additional Y60 Series transformers are also available.

1

-0

Transformer , 120/208/240 VAC Primary to 24 VAC Secondary, 40 VA, Foot Mount, 8 in.

Primary Leads and Secondary Screw Terminals, Class 2

Power transformer (Class 2, 24 VAC, 50 VA maximum output), no enclosure

Technical Specifications

FEC26 Extended Temperature Controller

Product Code Numbers MS-FEC2611-0ET Field Equipment Controller

Supply Voltage 24 VAC (nominal, 20 VAC minimum/30 VAC maximum), 50/60 Hz, power supply Class 2

Power Consumption 14 VA maximum for FEC2611

Ambient Conditions Operating: - 40 to 70°C (-40 to 158°F); 10 to 90% RH noncondensing

Controller Addressing DIP switch set; valid field controller device addresses 4–127

Communications Bus BACnet® MS/TP, RS-485:

Processor H8SX/166xR Renesas® 32-bit microcontroller

Memory 1 MB Flash Memory and 512 KB Random Access Memory (RAM)

Input and Output

Capabilities

Analog Input/Analog Output

Resolution and Accuracy

Terminations Input/Output: Fixed Screw Terminal Blocks

Mounting Horizontal on single 35 mm DIN rail mount (preferred), or screw mount on flat surface with

(North America), Safety Extra-Low Voltage (SELV) (Europe)

Note: V A ra ti ng s do not include any power supplied to the peripheral devices connected

to Binary Outputs (BOs) or Configurable Outputs (COs), which can consume up to 12 VA

for each BO or CO; for a possible total consumption of an additional 84 VA (maximum).

Storage: -40 to 80°C (-40 to 176°F); 5 to 95% RH noncondensing

(Device addresses 0–3 and 128–255 are reserved and not valid field controller addresses.)

3-wire FC Bus between the supervisory controller and field controllers

4-wire SA Bus between field controller, network sensors and other sensor/actuator devices,

includes a lead to source 15 VDC supply power (from field controller) to bus devices.

6 - Universal Inputs: Defined as 0-10 VDC, 4-20 mA, 0-600k ohm, or Binary Dry Contact

2 - Binary Inputs: Defined as Dry Contact Maintained or Pulse Counter/Accumulator Mode

3 - Binary Outputs: Defined as 24 VAC Triac (selectable internal or external source power)

4 - Configurable Outputs: Defined as 0-10 VDC or 24 VAC Triac BO

2 - Analog Outputs: Defined as 0-10 VDC or 4-20 mA

Input: 16-bit resolution

Output: 16-bit resolution, ±200 mV accuracy in 0-10 VDC applications

FC Bus, SA Bus, and Supply Power: 4-Wire and 3-Wire Pluggable Screw Terminal Blocks

FC Bus and SA Bus: RJ-12 6-Pin Modular Jacks

three integral mounting clips on controller

FEC26 Extended Temperature Field Equipment Controller Installation Instructions 15

Page 16

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2013 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

FEC26 Extended Temperature Controller

Housing Enclosure material: ABS and polycarbonate UL94 5VB; Self-extinguishing, Plenum Rated

Dimensions

(Height x Width x Depth)

Weight 0.5 kg (1.1 lb)

Compliance United States: UL Listed, File E107041, CCN PAZX, UL 916, Energy Management

The performance specifications are nominal and conform to acceptable industry standard. For application at conditions beyond these

specifications, consult the local Johnson Controls® office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication

or misuse of its products.

Protection Class: IP20 (IEC529)

150 x 190 x 53 mm (5-7/8 x 7-1/2 x 2-1/8 in.) including terminals and mounting clips

Note: Mounting space requires an additional 50 mm (2 in.) space on top, bottom and front

face of controller for easy cover removal, ventilation and wire terminations.

Equipment

FCC Compliant to CFR47, Part 15, Subpart B, Class A

Canada: UL Listed, File E107041, CCN PAZX7, CAN/CSA C22.2 No. 205, Signal

Equipment Industry Canada Compliant, ICES-003

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with

the essential requirements and other relevant provisions of the

EMC Directive 2004/108/EC.

Note: Conducted RF Immunity within EN 61000-6-2 meets performance criteria B.

Australia and New Zealand: C-Tick Mark, Australia/NZ Emissions Compliant

BACnet International: BACnet Testing Laboratories™ (BTL) 135-2004 Listed BACnet

Application Specific Controller (B-ASC)

FEC26 Extended Temperature Field Equipment Controller Installation Instructions16

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...