Page 1

Product Bulletin FX40

Issue Date September 20, 2005

FX40 Supervisory Controller

The FX40 brings a new generation of Web-based

technology into the Facility Explorer product family.

The FX40 manages a network of field controllers

using standard communication protocols. It also

supports a full set of building automation features

and functions specifically designed for commercial

facilities, including event scheduling, alarm

management, histories, and totalization.

The FX40 can support up to 100 field controllers

using any combination of N2, L

BACnet® Internet Protocol (IP) protocols. The FX40

also provides onboard, hardwired input and output

points for direct monitoring of equipment status or

analog sensors and control of auxiliary devices or

alarms.

The FX40 provides a user interface and

configuration tool that users can access with a Web

browser. Multiple users can concurrently connect to

the FX40. Security and presentation preferences are

managed through user profiles, logon IDs, and

passwords. Remote access is easily achieved from

an Internet, intranet, or a dial-up connection.

ONWORKS®, and

Figure 1: FX40

Features and Benefits

Web-Based User Interface Requires no proprietary or desktop software

to access the FX40. A Web browser is all that

is needed.

Adoption of Industry

Standard Communication

Protocols

Onboard Configuration

Tool

Onboard Inputs and

Outputs

© 2005 Johnson Controls, Inc.

Code No. LIT-12011046

1

Allows for the integration of a wide variety of

field controllers. This includes Facility Explorer

field controllers and controllers provided by

others without intermediate gateways or

translators.

Allows configuration and system diagnosis

from any Web browser.

Allows direct control of auxiliary devices,

which could reduce the number of field

devices.

Page 2

Overview

The FX40 provides integrated control supervision

and network management services for one or more

local networks of field controllers used to monitor

and control Heating, Ventilating, and Air

Conditioning (HVAC), lighting, and other electrical

systems. The FX40 provides system-wide

coordination of field controller activities to improve

occupant comfort, reduce energy usage, and

optimize operating efficiencies. The FX40 organizes

system information into user displays, reports, and

graphics that users can access from a Web browser.

Onboard Inputs and Outputs (I/Os)

The FX40 features 10 onboard inputs and outputs

for direct control over auxiliary devices, such as

temperature and humidity sensors, pressure

transducers, alarm indicators, and energy meters.

The FX40 I/O complement includes:

• four form C Single-Pole, Double-Throw (SPDT)

relay outputs rated for 24 VAC/DC @ 2 Ampere

resistive each with Light-Emitting Diode (LED)

indication

• six universal inputs for 10k ohm type III

thermistors, 4-20 mA and 0-10 VDC active

inputs, or dry contact binary inputs

Supported Field Controllers

The FX40 can interface with many different types of

field controllers and monitoring devices. Three

field-level network communication protocols are

currently supported: N2, L

BACnet IP Ethernet.

N2 Communication

The FX40 includes one RS-485 communication port

and an N2 protocol driver that allows integration of a

wide variety of N2 field controllers. Supported

N2 field controllers include:

• Facility Explorer Field Controllers fitted with an

N2 Open Communication Card (for example,

FX05, FX15, FX16, or MD20)

• Metasys® Application Specific Controller (ASC)

devices (Air Handling Unit [AHU], Unitary [UNT],

Variable Air Volume [VAV])

• Metasys System 91 Devices (DX-9100)

• Metasys Variable Air Volume Modular Assembly

(VMA1400)

• third-party devices supporting N2 Open protocol

(VND)

LONWORKS Communication

The FX40 includes one LONWORKS FTT-10A port

and a LonTalk® device protocol driver that allows

integration of L

ONMARK® devices, including:

ONWORKS, and

2 FX40 Supervisory Controller Product Bulletin

• Facility Explorer field controllers fitted with a

ONWORKS Communication Card (for example,

L

FX05, FX15, or FX16)

• third-party L

certified)

ONMARK devices (compliant or

Page 3

BACnet IP Ethernet

The FX40 includes one 10/100 Mb Ethernet

communication port and a BACnet IP driver that

allows integration of BACnet devices. The FX40 can

integrate field controllers that support standard

BACnet objects and services.

To determine if a third-party BACnet device is

supported, compare its Protocol Implementation

Conformance Statement (PICS) with the FX40 PICS.

This includes the supported BACnet Interoperability

Building Blocks (BIBB) and details the level of

BACnet conformance.

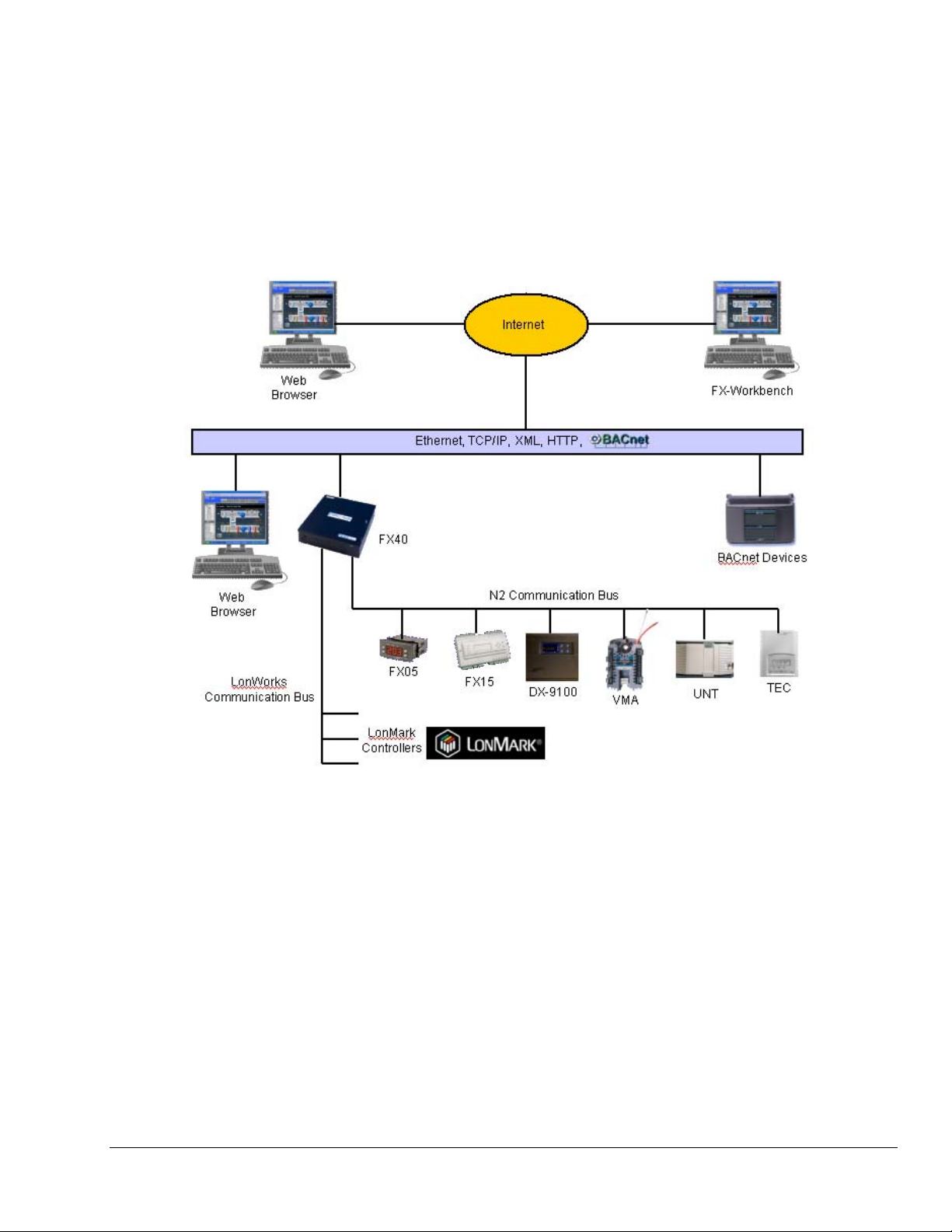

of an FX40 configuration.

Figure 2 displays an example

Figure 2: Example of an FX40 Configuration

FX40 Supervisory Controller Product Bulletin 3

Page 4

FX Workbench

Users can configure the FX40 controller with the FX

Workbench tool. FX Workbench can operate as a

software application on a computer, or the FX40 can

serve up the application for users to access via a

Web browser.

In addition, users can configure the FX40 online

while directly or remotely connected with FX

Workbench. The PC version of FX Workbench

allows users to create an FX40 configuration offline

and then download it at a later time. FX Workbench

also:

• provides the automatic discovery of L

and BACnet devices and points

• provides assisted importing of N2 device points

• provides a check box method of enabling and

disabling point extensions, such as scheduling,

histories, and totalization

• automatically links the field device’s occupancy

point to the scheduler

• automatically creates graphics and binds the

graphics to point information

ONWORKS

System User Interface

The FX40 User Interface (UI) provides the user with

system-wide monitoring and controlling capability.

The UI is embedded and provided by the FX40. This

allows users to access the system from anywhere on

the supervisory network via a Web browser.

System administrators can format the UI according

to specific user preferences. The presentation of the

information can be as rich or as limited as needed to

support a variety of user interface hardware

(computer, Personal Digital Assistant [PDA], or cell

phone). For a richer user interface experience, the

FX40 incorporates a full library of HVAC equipment

and control symbols, ductwork and piping symbols,

and animated graphics.

Figure 3: Facility Explorer User Interface

Building Automation Features

Event Scheduling

In Event Scheduling (Figure 4), users determine

certain scheduling activities like building occupancy

and the start and stop times of HVAC equipment

based on regular, repeating, or unique events. The

user interface provides a visual method to configure

the schedule time and date.

Figure 4: Event Scheduling

4 FX40 Supervisory Controller Product Bulletin

Page 5

Histories

The Histories feature (Figure 5) allows the FX40 to

collect, store, and display pertinent system data for

analysis. This includes control performance

indication, energy consumption, and system

troubleshooting. Users can configure the FX40 to

create a history on any data point in the FX40

system database. The Histories feature present s the

stored data either graphically or in a sortable table.

Users can export stored data in a TXT, PDF, or CSV

format.

Figure 6: Alarms

Totalization

The Totalization feature allows the FX40 to

accumulate data on a point over a period of time.

Users can add a totalization extension to any data

point in the FX40 system database to summarize

runtime, to accumulate change of state counts, or to

summarize dynamic analog data.

Figure 5: Histories

Alarming

The Alarm feature (Figure 6) allows the FX40 to

route and manage alarms and events according to

user-defined criteria. Users can configure the FX40

to generate alarms on any data point in the FX40

system database. Each alarm record c ontains

valuable information, including the alarm and

return-to-normal time and date, time duration in

current state, text description, and alarm class.

The alarm class allows the routing of alarms with

similar characteristics to common recipients. Users

can create multiple alarm classes to have a variety

of alarm routing options. Users can configure alarm

recipients to receive alarms via a Web browser or

e-mail. Alarm recipients have a variety of options to

manage alarms, including sorting, acknowledging,

silencing, and tagging.

Software Upgrades

Each FX40 includes a 1-year software maintenance

agreement. This agreement allows you to upgrade

the FX40 software with any new or interim service

release for 1 year from the date of purchase. Once

the software maintenance agreement expires, you

can order additional upgrades. See

details.

Table 1 for

FX40 Supervisory Controller Product Bulletin 5

Page 6

Table 1: FX40 Ordering Information

Part Number Description

LP-FX4020A-0

LP-FX4022A-0

LP-FX40MA-0

LP-FX40UPG-0

LP-FXTSUP-0

LP-FXTSUPP-0

FX40 pre-loaded with FX Workbench, N2 Driver, L

(Supports a maximum of 100 devices). Includes a 1-year software maintenance agreement.

FX40 with factory installed modem. Pre-loaded with FX Workbench, N2 Driver, L

Driver, BACnet IP driver. (Supports a maximum of 100 devices). Includes a 1-year software

maintenance agreement.

One additional year of annual software maintenance for one FX40. Includes ne w releases and

interim service releases for 1 year from the date of purchase. Covers all applications or drivers

licensed for the FX40.

One time, new release software upgrade for one FX40. Includes all applications and drivers

licensed for the FX40.

FX Workbench (PC version)

FX Workbench Pro (PC version)

ONWORKS Driver, BACnet IP driver.

ONWORKS

6 FX40 Supervisory Controller Product Bulletin

Page 7

Technical Specifications

Table 2: FX40 Controller (Part 1 of 2)

Product Codes

Power Requirements

Environmental

General

LP-FX4020A-0, LP-FX4022A-0

120 VAC, 50/60 Hz

25 VA maximum

Lead wires for hot/neutral (wire nut), stud for ground connection

Operating Temperature: 0 to 50°C (32 to 122°F)

Storage Temperature: 0 to 70°C (32 to 158°F)

Relative Humidity: 5 to 95%, noncondensing

Motorola® Reduced Instruction Set Computer (RISC) Processor @ 250 MHz

Facility Explorer Control Engine with direct I/O support objects

128 MB RAM, 32 MB flash for database backup

One 10/100 MB Ethernet RJ-45 connector

FCC Class A computing device

Wind River VxWorks® Operating System with Jeode® Java® Virtual Machine

Facility Explorer Software with I/O control objects

Communications

Inputs/Outputs

Battery Backup

One 10/100 Mb Ethernet port–RJ-45 connection

One RJ-45 connector for RS-232 port

One RS-485 port (up to 57,600 baud)

One L

ONWORKS port–FTT-10 with Weidmuller connector

Optional auto-dial/auto-answer 56k modem; RJ-11 connector (uses the RS232 port when installed)

Four form C SPDT relay outputs rated for 24 VAC/DC @ 2 ampere resistive

One LED indicator for each relay

Six Universal Inputs for 10k ohm Type III (10k 4A1-International) Thermistor,

4/20 mA current loop, 0 to 10 volt, or dry contact

12-bit A/D converter

Thermistor Sensor Range: 23.3 to 57.2°C (10 to 135°F). Input accuracy is in

the range of ±1% of span, characteristic curve is customizable

0 – 10 volt or 4/20 mA accuracy is ±2% of span, without user calibration. Uses

an external resistor for current input (four provided). Self-powered or board

powered sensors accepted.

Dry contacts (on UI) 20 Hz max. frequency (25 ms minimum pulse width) 3V

open circuit, 300 µA short-circuit current

20 VDC @ 80 mA to drive 4/20 mA powered sensors.

24 VDC terminal and external resistor can be used if monitoring contacts that

require higher voltages or higher current.

All I/O uses screw terminals on 0.2 in. centers

Provided for all on board functions including I/O.

Monitored and trickle charged.

Battery maintains processor operation through power failures for a

predetermined interval, then writes all data to flash memory, shuts processor

down, and maintains clock for a minimum of 5 years.

FX40 Supervisory Controller Product Bulletin 7

Page 8

Table 2: FX40 Controller (Part 2 of 2)

Chassis – Housed in Metal

Enclosure

Intended for indoor wall mounting only

Cooling: Internal air convection

Dimensions: 11 x 14 x 2.5 in. (27.94 x 35.56 x 6.35 cm)

Weight: Net 4 lbs. (1.814 kg), gross 5 lbs. (2.268 kg)

Agency Listing

United States - UL Listed, File E107041, CCN PAZX, under UL 916,

Energy Management Equipment

FCC compliant to CFR 47, part 15, subpart B, class A

Canada - UL Listed, File E107041, CCN PAZX7, under CSA C22.2 No.

205, Signal Equipment

Industry Canada compliant to ICES-003

Table 3: FX Workbench Requirements

Processor

Operating System

Web Browser

Memory

Hard Disk

Network Support

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, contact a Facility Explorer technical support resource. Johnson Controls, Inc. shall not be liable for damages resulting from

misapplication or misuse of its products.

Federal Communications Commission (FCC) Statement

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of FCC Rules. These limits

are designed to provide reasonable protection against harmful interference when this equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his/her own expense.

Industry Canada (IC) Statement

This Class (A) digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Intel® Pentium® 4, 1 GHz or higher

Microsoft® Windows NT® Version 4.0 with SP 4.0 or later

Microsoft Windows® 2000

Microsoft Windows XP Professional

Microsoft Internet Explorer Version 5.0 or later

Netscape Communicator® Version 4.5 or later

512 MB minimum

1 GB minimum, 5 GB recommended

Ethernet 10/100 Mb with RJ-45 connector

Controls Group

507 E. Michigan Street

P.O. Box 423 .

Milwaukee, WI 53201 Published in U.S.A and Europe

8 FX40 Supervisory Controller Product Bulletin

Loading...

Loading...