Johnson Controls Facility Explorer FX20, Facility Explorer FX60 Installation Instructions Manual

Page 1

Installation Instructions

Issue Date April 9, 2014

FX20/FX60 Supervisory Controllers

Installation Instructions

Application

The FX20 and FX60 are Web-based supervisory class

controllers in the Facility Explorer product family. The

FX20/FX60 manages networks of field controllers

using open communication protocols, such as N2,

L

ONWORKS®, and BACnet® protocols.

Figure 1: FX60 Supervisory Controller

North American Emissions Compliance

United States

This equipment has been tested and found to comply

with the limits for a Class A digital device pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference when this equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in

a residential area is likely to cause harmful

interference, in which case the user will be required to

correct the interference at his/her own expense.

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Installation

Parts Included

Unpack the FX20/FX60 and accessories

(power module, option cards), if ordered. Inspect the

contents of the packages for damaged or missing

components. If damaged, notify the appropriate carrier

and return any damaged components for repair or

replacement.

Included in this package are the following items:

FX Supervisory Series controller

Hardware bag contai ning a grounding wire with

quick disconnect 0.187 in. (4.75 mm) female

connector.

Power modul e (if ordered). The power module

may be one of the following:

LP-FXPM24-0

(24 VAC, DIN rail mountable)

LP-FXPM263-0

(90-263 VAC, DIN rail mountable)

LP-FXPMUS-0

(90-240 VAC, with U.S. wall adapter)

LP-FXPMEU-0

(90-240 VAC, with European wall adapter)

LP-FXPMUK-0

(90-240 VAC, with U.K. wall adapter)

Communication cards (if ordered)

LP-FXLONFTT-1

LP-FXRS232-0

LP-FXRS485-0

LP-FXMDM-0

LP-FXWTC-0

Expansion Input/Output (NDIO) Modules

(if ordered)

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

LP-FXNDIO16-0

LP-FXNDIO34-0

LP-FXRIO16-0

© 2014 Johnson Controls, Inc.

Part No. 24-10174-77, Rev. D www.johnsoncontrols.com

1

Page 2

Materials and Special Tools Needed

You may require the following materials and tools for

installation:

DIN Rail: type NS35/7.5 (35 x 7.5 mm) and DI N

rail end clips. Length of DIN rail depends on the

number of optional DIN rail mounted options.

If using a 24 VAC power module: UL Listed,

Class 2, 24 VAC transformer, rated at minimum of

8.5 VA to 20 VA, dedicated to powering the

FX20/FX60 and its accessories (cannot power

additional equipment).

Suitable screws and screwdriver for mounting DIN

rail or, if DIN rail is not used, for mounting bases of

FX20/FX60 and any optional accessories.

#2 Phillips screwdriver: used to install and remove

optional communication modules.

small flat-bla de screwdriver: used for mounting

and removing the FX20/FX60 from the DIN rail

and for making wiring connections to the RS-485,

ONWORKS, and Input/Output (I/O) connectors.

L

Safety Precautions

The following information relates to the installation and

startup of the FX20/FX60.

!

WARNING: Risk of Electric Shock.

Disconnect power supply before making electrical

connections. Contact with components carrying

hazardous voltage can cause electric shock and

may result in severe personal injury or death.

AVERTISSEMENT: Risque de décharge

électrique. Débrancher l'alimentation avant de

réaliser tout branchement électrique. Tout contact

avec des composants conducteurs de tensions

dangereuses risque d'entraîner une décharge

électrique et de provoquer des blessures graves,

voire mortelles.

IMPORTANT: Use copper conductors only. Make

all wiring connections in accordance with local,

national, and regional regulations. Do not exceed the

FX20/FX60 electrical ratings.

IMPORTANT: Do not install or use the FX20/FX60

in or near environments where corrosive substances

or vapor could be present. Exposure of the

FX20/FX60 to corrosive environments may damage

the device’s internal components, and will void the

warranty.

IMPORTANT: Use this FX20/FX60 only as an

operating control. Where failure or malfunction of the

FX20/FX60 could lead to personal injury or property

damage to the controlled equipment or other

property, additional precautions must be designed in

the control system. Incorporate and maintain other

devices, such as supervisory or alarm systems or

safety or limit controls, intended to warn of or protect

against failure or malfunction of the FX20/FX60.

2 FX20/60 Supervisory Controllers Installation Instructions

Page 3

Static Discharge Precautions

Static charges produce voltages high enough to

damage electronic components. The microprocessors

and associated circuitry within a FX20/FX60 are

sensitive to static discharge.

IMPORTANT: Work in a static-free area. Discharge

any static electricity you may have accumulated.

Discharge static electricity by touching a known,

securely grounded object. Do not handle the Printed

Circuit Board (PCB) without proper protection

against static discharge. Use a wrist strap when

handling PCBs. Secure the wrist strap clamp to

earth ground.

Accessories

The FX20/FX60 has a 20-pin, right-angle, Euro-DIN

connector that accepts accessory modules. The

connector provides power and signal lines to any

connected modules. The connector is located on the

end of the FX20/FX60 opposite the option cards.

IMPORTANT: Turn off power to the FX20/FX60

before inserting or unplugging accessory modules.

Wait for the LED activity to stop (all LEDs off).

!

CAUTION: Risk of Property Damage.

Do not apply power to the system before checking

all wiring connections. Short circuited or improperly

connected wires may result in permanent damage to

the equipment.

MISE EN GARDE: Risque dégâts matériels.

Ne pas mettre le système sous tension avant d'avoir

vérifié tous les raccords de câblage. Des fils formant

un court-circuit ou connectés de façon incorrecte

risquent d'endommager irrémédiablement

l'équipement.

Each accessory module has a DIN-mount base, and

typically provides two 20-pin connectors that allow you

to chain multiple accessories (see DIN Rail Mounting

Instructions). Table 1 lists the currently available

modules.

FX Supervisory Controller Installation Instructions 3

Page 4

Table 1: Accessory Module Details

Model Description Notes

LP-FXPM24-0

LP-FXPM263-0

LP-FXNDIO16-0

LP-FXNDIO34-0

LP-FXRIO16-0

Power module for FX20/FX60

24 VAC/DC, DIN rail mountable

Power module for FX20/FX60

90-263 VAC, DIN rail mountable

16 channel input/output module for

FX20/FX60, DIN rail mountable

34 channel input/output module for

FX20/FX60, DIN rail mountable. In

addition, the NDIO34 provides power to

the attached FX20/FX60, using an

externally supplied 24 VAC transformer or

24 VDC power supply.

16 channel remote input/output Provides the following I/O points:

Install only one power module per FX20/FX60, regardless

of type.

Install only one power module per FX20/FX60, regardless

of type.

Provides the following I/O points:

8 Universal Inputs (UIs)

4 Digital Outpu ts (DOs), Single Poll Single Throw

(SPST) relay type

4 Analog Outputs (AOs) (0-10 VDC)

Up to four (maximum) NDIO16 accessory modules are

supported.

Provides the following I/O points:

16 Universal Inputs (UIs)

10 Digital Outputs (DOs), SPST relay type

8 Analog Outputs (AOs) (0-10 VDC)

One NDIO34 plus up to 2 additional NDIO16 modules are

supported. Do not power the NDIO34 if using a separate

wall plug power module.

8 Universal Inputs (UIs)

4 Form A Relay Outputs

4 1-10 VDC Analo g Outputs

Up to 4 FXRIO10 modules supported on FX20

Up to 16 FXRIO16 modules supported on FX60

4 FX20/60 Supervisory Controllers Installation Instructions

Page 5

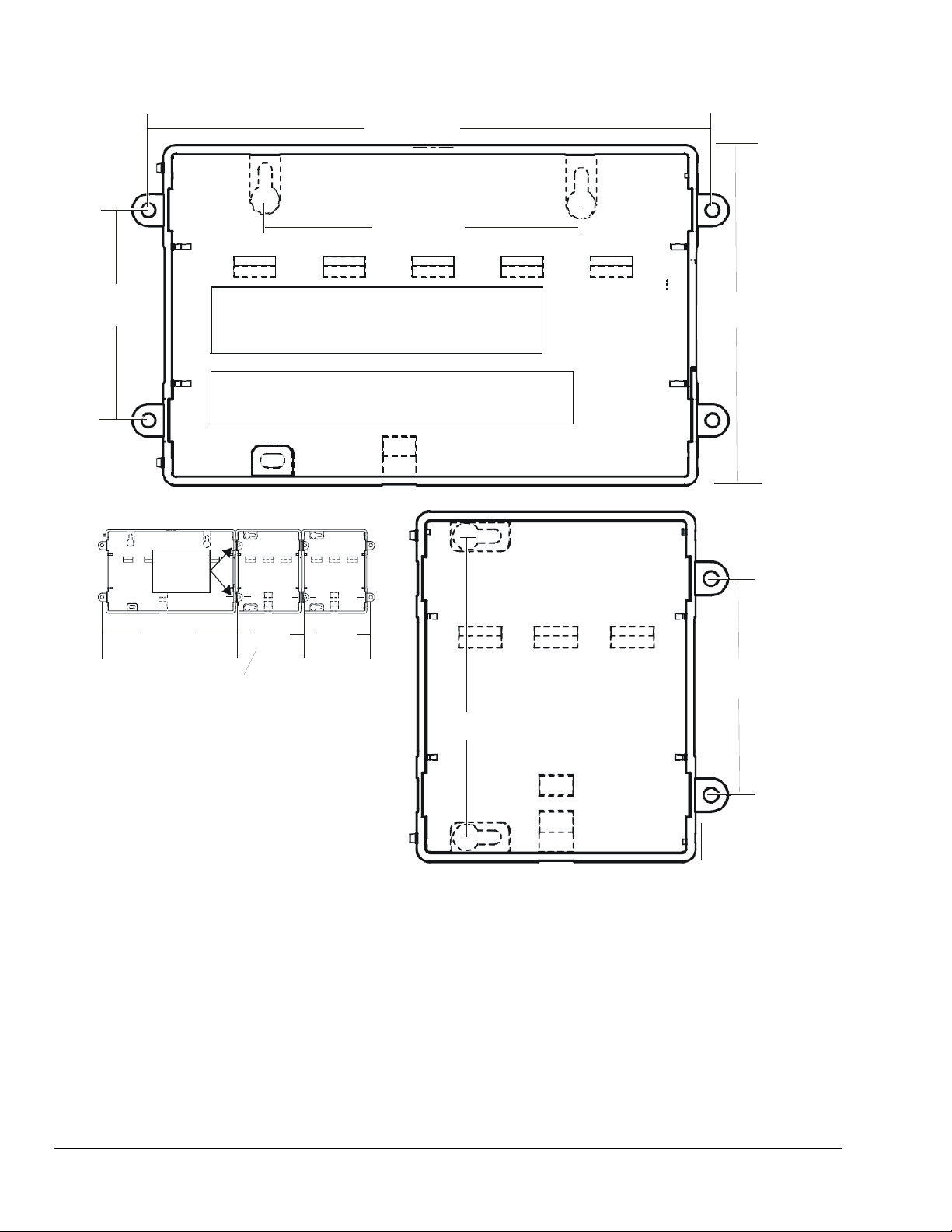

Mounting

Mount the FX20/FX60 in a location that allows

clearance for wiring, servicing, and module removal.

For mounting details, see Figure 2 through Figure 5.

Follow these recommendations and precautions

when mounting and installing the unit.

Use this controller for indoor use only. Do not

expose the unit to ambient conditions outside

the range of 0 to 50ºC (32 to 122ºF) and relative

humidity outside the range of non-condensing

5 to 95% (Pollution Degree 1).

For a controller mounted inside an enclosure,

ensure that the enclosure is designed to keep

the unit within its required operating range

(considering a 20-watt dissipation by the

controller). This is especially important if the

controller is mounted inside an enclosure with

other heat producing equipment.

Do not mount the unit:

in an area where excessive moisture,

corrosive fumes, or explosive vapors are

present

where vibration or shock is likely to occur

in a location subject to electrical noise. This

includes the proximity of large electrical

contactors, electrical machinery, welding

equipment, and spark igniters.

Physical Mounting

The following information applies to the physical

mounting of the FX20/FX60.

You do not need to rem ove the cover before

mounting.

Mount the FX20/FX60 in a ny orientation.

Mount the unit on a 35-mm wide DIN rail

(recommended). The FX20/FX60 unit base and

its accessories have molded DIN rail slots and

locking clips. Mounting these components on a

DIN rail ensures accurate alignment of

connectors between all modules.

If DIN rail mounting is impractical, use screws in

mounting tabs on the FX20/FX60 and in any

end-connected accessory (power module, NDIO

module). See Figure 2 for tab dimensions.

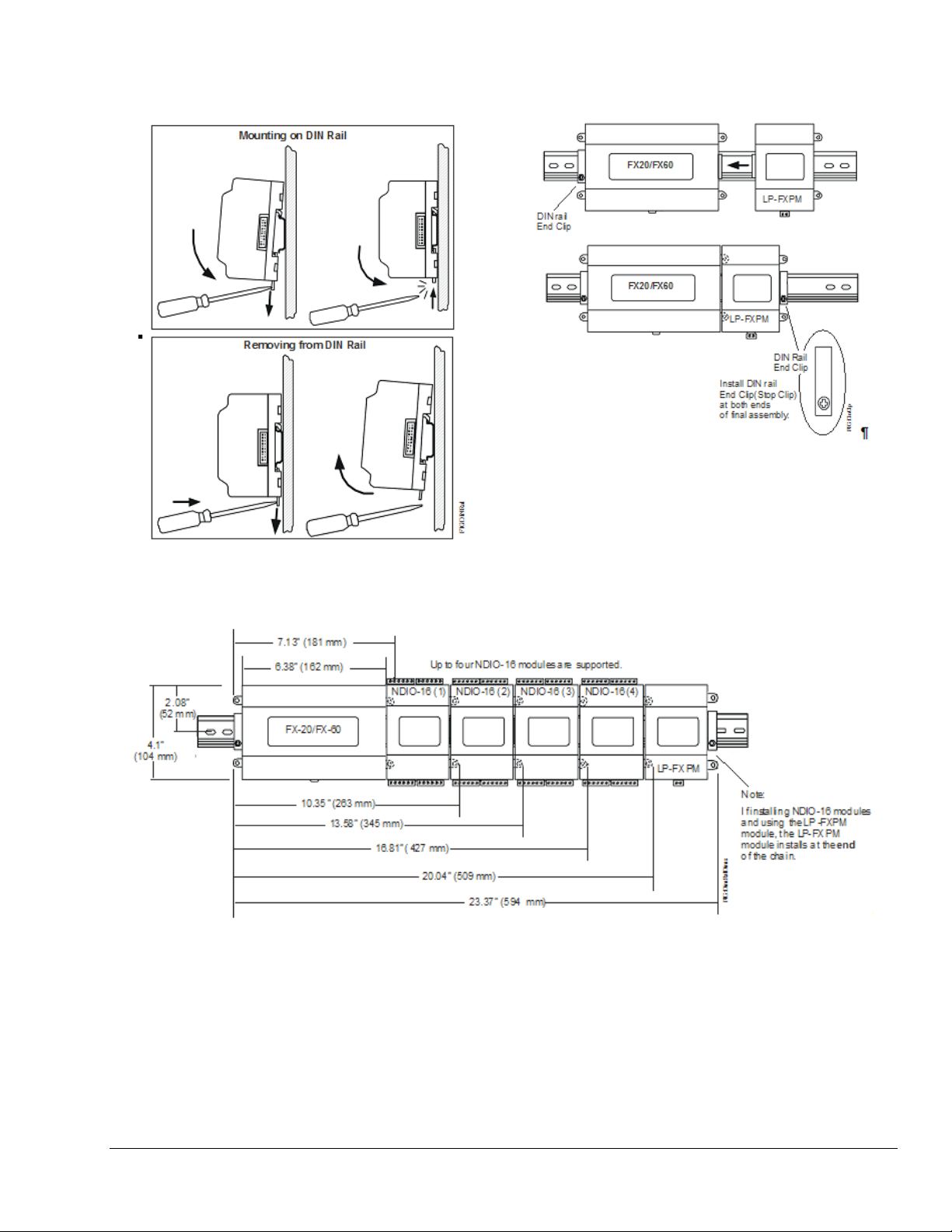

DIN Rail Mounting Instructions

To mount on DIN rail:

1. Securely install the DIN rail using at least 2

screws near both ends of the rail.

2. Position the FX20/FX60 on the rail, then tilt it to

hook the DIN rail tabs over one edge of the DIN

rail (see Figure 3).

3. Use a screwdriver to pry down the plastic

locking clip, and push the FX20/FX60 down and

in, which forces the locking clip to snap over the

edge of the DIN rail.

4. Mount the accessory modules (NDIO modules

and power module) onto the DIN rail in the

same manner (see Figure 5). See Table 1 for

quantities allowed.

5. Slide the accessory along the DIN rail to

connect its 20-position plug into the

FX20/FX60.

6. Repeat these instructions for all accessories,

until all are mounted on the DIN rail and firmly

connected to each other. For an example, see

Figure 4.

To keep the final assembly together, secure at both

ends with DIN rail end-clips. This also prevents the

assembly from sliding on the DIN rail. See Figure 4.

FX Supervisory Controller Installation Instructions 5

Page 6

6.719 in. (170.66 mm)

0.170 in. Diame ter

( 4.3 2 mm)

FX-20/60

3.75 in. (95. 25 mm)

E l ectroni c and pri nted versions of this document may n ot show

2.5 0 i n.

(63.50 mm)

Note:

the d i m ensions to s cale. Verify all measur em ents bef or e drilling.

DIN mounting is recommended over ta b mounting.

4.0 0 i n.

(101.6 mm)

FX-20/60

Acc essory

module

side tabs

6. 719 in .

(170.66 mm)

Distan ce between center of tabs

fr o m on e u nit to anot he r un it .

TIP: If mounting accessory modules, future removal

or replacement of the FX-20/60 is simplified i f you

do not install screws in the accessory module side

tabs of the c ontroller (see above).

NDIO-16

3.2 5 i n.

(82.55 mm)

ND I O -1 6 or

LP-FXPM

3.2 5 i n.

(82.55 mm)

Figure 2: Tab Mounting Dimensions, in. (mm)

2.5 0 i n.

(63.50 mm)

NDIO-16

2.5 0 i n.

(63.50 mm)

6 FX20/60 Supervisory Controllers Installation Instructions

Page 7

Figure 4: Using End Clips to Secure Modules

Figure 3: DIN Rail Mounting

Figure 5: Mounting Accessories

7 FX Supervisory Controller Installation Instructions

Page 8

Removing and Replacing the Cover

The FX20/FX60 cover is removable. You must remove

the FX20/FX60 cover to connect the battery on a new

unit, to replace the battery on an existing unit or to

install any optional communication cards. The cover

snaps onto the base with four plastic tabs (two on

each end). To remove the cover, press in the four tabs

on both ends of the unit and lift off the cover.

Note: If accessory modules are plugged into the

FX20/FX60, you may need to slide them away from

the unit to get to the cover tabs.

To replace the cover, position it so the cutout area for

the communication ports is correct, then push inward

to snap in place.

Serial port LEDs on bott om

Option Slot 2

Bat te r y Br a cket

(on t o p of optio n

cards, if any)

board; r emove cover to see.

COM1

COM2

Board Layout

See Figure 6 for the location of Light-Emitting Diodes

(LEDs), option slots, and other features of the

FX20/FX60. See Figure 9 for a side view of

communication ports and other features.

Status

Beat

Mode Jumper (for

serial shell access)

20-pin

connector

(I/O and

power

modules)

LAN2

LAN1

Battery

Connector

Option Slot

Connectors

Option Slot 1

RS-485 (3-positi on)

COM2 (bot tom board)

Secondary Ethernet (RJ-45)

LAN2 (t op board)

RS-232 (D-9)

COM1

Primary Ether ne t (RJ -45)

LAN1 (top board)

Figure 6: FX20/FX60 Board Layout Details

FIG :BrdL yt

Earth ground

spade l ug

Barrel pow e r

connector for

wall mounted

power module.

8 FX20/60 Supervisory Controllers Installation Instructions

Page 9

Expansion Options

The FX20/FX60 provides for field-installable expansion

with two options:

Option Cards: these are installed on connectors

inside the FX20/FX60 base unit. See Option

Cards.

Accessory Modules: these are chained onto the

FX20/FX60’s 20-pin connector. See Accessories.

Option Cards

The FX20/FX60 has 2 options slots for custom option

cards designed for use with the

FX20/FX60. Each slot has a 20-pin connector on the

FX20/FX60 base unit.

Table 2: Option Card Details

!

CAUTION: Risk of Property Damage.

Do not apply power to the system before checking

all wiring connections. Short circuited or improperly

connected wires may result in permanent damage to

the equipment.

MISE EN GARDE: Risque dégâts matériels.

Ne pas mettre le système sous tension avant d'avoir

vérifié tous les raccords de câblage. Des fils formant

un court-circuit ou connectés de façon incorrecte

risquent d'endommager irrémédiablement

l'équipement.

IMPORTANT: Be careful to plug an option card into

the connector properly with its pins properly aligned.

Option cards typically provide additional

communication capabilities, such as those listed in

Table 2. For a list of supported COM port and slot

assignments for the option cards, see Table 3.

Model Description Number of Option Cards Allowed per Controller

LP-FXLONFTT-1

LP-FXRS485-0

LP-FXMDM-0

LP-FXRS232-0

LP-FXWTC-0

LP-FXSED-0

LP-FXGPRS-0

LP-FXGPRSW-0

* If a modem card is installed, and the mode jumper is put in Serial Shell position (see Figure 6), then the FX20/FX60 base

RS-232 port becomes active immediately following a reboot. This allows an RS-232 conn ection to the se rial shell for

debugging purposes. To re-enable the modem, you must put the mode jumper back in the Normal position and reboot.

ONWORKS FTT-10A adapter with a

L

2-position removable screw terminal

plug

Dual, optically isolated, RS-485 adapter

with two 3-position removable screw

terminal connector plugs

56 Kbps auto-dial/auto-answer modem

with one RJ-11 connector for phone line

Single port RS-232 adapter, with a

DB-9M connector

Wireless TEC Card (WTC) with direct

mount antenna

Sedona Framework™ option card One

GPRS Modem card One

GPRS Modem option card with

Wyless™ SIM card

One or two

One or two

One*

One or two

One

One

FX Supervisory Controller Installation Instructions 9

Page 10

Table 3: COM Port and Option Slot Assignments for FX20/FX60 Option Cards

Option Slot 1 Option Slot 2 Onboard RS232 Onboard RS485

None None COM1 COM2

RS-232 = COM3 None COM1 COM2

RS-232 = COM3 RS-232 = COM4 COM1 COM2

RS-232 = COM3 RS-485 = COM4, COM5 COM1 COM2

RS-232 = COM3 LON = LON1 COM1 COM2

RS-232 = COM3 Sedona = COM4 COM1 COM2

RS-232 = COM3 GPRS = COM4,COM5 COM1 COM2

RS-485 = COM3, COM4 None COM1 COM2

RS-485 = COM3, COM4 RS-232 = COM5 COM1 COM2

RS-485 = COM3, COM4 RS-485 = COM5, COM6 COM1 COM2

RS-485 = COM3, COM4 LON = LON1 COM1 COM2

RS-485 = COM3, COM4 Sedona = COM5 COM1 COM2

RS-485 = COM3, COM4 GPRS = COM5, COM6 COM1 COM2

LON = LON1 None COM1 COM2

LON = LON1 RS-232 = COM3 COM1 COM2

LON = LON1 RS-485 = COM3, COM4 COM1 COM2

LON = LON1 LON = LON2 COM1 COM2

LON = LON1 Sedona = COM3 COM1 COM2

LON = LON1 GPRS = COM3, COM4 COM1 COM2

Wireless TEC = COM1 None Disabled COM2

Wireless TEC = COM1 RS-232 = COM3 Disabled COM2

Wireless TEC = COM1 RS-485 = COM3, COM4 Disabled COM2

Wireless TEC = COM1 LON = LON1 Disabled COM2

Wireless TEC = COM1 Sedona = COM3 Disabled COM2

Wireless TEC = COM1 GPRS = COM3, COM4 Disabled COM2

Sedona = COM3 None COM1 COM2

Sedona = COM3 RS-232 = COM4 COM1 COM2

Sedona = COM3 RS-485 = COM4, COM5 COM1 COM2

Sedona = COM3 LON = LON1 COM1 COM2

Sedona = COM3 GPRS = COM4,COM5 COM1 COM2

Modem = COM1 None Disabled COM2

Modem = COM1 RS-232 = COM3 Disabled COM2

Modem = COM1 RS-485 = COM3, COM4 Disable d COM2

Modem = COM1 LON = LON1 Disable d COM2

Modem = COM1 Sedona = COM3 Disabled COM2

Modem = COM1 GPRS = COM3, COM4 Disabled COM2

GPRS = COM3, COM4 None COM1 COM2

GPRS = COM3, COM4 RS-232 = COM5 COM1 COM2

GPRS = COM3, COM4 RS-485 = COM5, COM6 COM1 COM2

GPRS = COM3, COM4 LON = LON1 COM1 COM2

GPRS = COM3, COM4 SEDONA = COM5 COM1 COM2

10 FX20/60 Supervisory Controllers Installation Instructions

Page 11

Mounting Option Cards

For complete details, refer to the specific mounting

and wiring guide that shipped with the option card.

Follow these basic steps:

1. Remove power from the FX20/FX60.

2. Remove the cover.

3. Remove the battery and bracket assembly by

taking out the four screws holding it in place. Set

the screws aside for later. Unplug the battery from

the connector on the FX20/FX60.

4. Remove the blanking end plate for the slot into

which you are installing the option card. Retain the

blanking plate in case you need to remove the

option card at a later time.

5. Carefully insert the pins of the option card into the

socket of the appropriate option card slot. The

mounting holes on the option card should line up

with the standoffs on the base unit. If they do not,

the connector is not properly aligned. Press until

the option card is completely seated.

6. Place the custom end plate that came with the

option card over the connector(s) of the option

card.

7. Insert the battery connector plug into the battery

connector on the FX20/FX60.

8. Set the battery and bracket assembly back over

the option card slots, with the mounting holes

aligned with the standoffs.

9. Place the four screws through the battery bracket,

end plates, and into the standoffs on the

FX20/FX60 base unit. Hand-tighten these screws.

10. Replace the cover.

Wiring

See Figure 6 to locate connectors and other

components on the FX20/FX60.

Make connections to the FX20/FX60 in the following

order.

1. Install any option cards (LON, RS-232, RS-485,

modem, WTC) in Option Slots 1 and 2. See

Mounting Option Cards for the general procedure.

For complete details, refer to the specific mounting

and wiring guide that shipped with the option card.

2. Connect supplied earth grounding wires (with

spade connector) from the earth ground lug on the

FX20/FX60 and any accessory modules (if used)

to a nearby earth grounding point. See Grounding

for details.

3. Prepare power wiring (leave the unit powered off).

See Power Wiring for details.

4. Connect communications cables. See

Communications Wiring for ports available on the

FX20/FX60 base unit. For ports on any installed

option card (LON, RS-232, RS-485, modem, and

WTC), refer to the specific mounting and wiring

guide for additional details.

5. If NDIO modules are installed, connect the I/O

wiring. Refer to the appropriate mounting and

wiring guide for complete details.

6. Connect the backup battery to the FX20/FX60

battery connector, and apply power to the unit.

See Powerup and Initial Checkout.

Grounding

An earth ground spade lug (0.187 in. [4.75 mm]) is

provided on the base of the FX20/FX60 for connection

to earth ground. For maximum protection from

electrostatic discharge or other forms of

electromagnetic interference, connect the supplied

earth grounding wire to this lug and a nearby earth

ground (see Figure 7). Keep this wire as short as

possible.

Power is provided for the FX20/FX60 plug-in

accessory modules through the 20-pin accessory

connectors; however, connect the earth ground spade

lug of each accessory module to ground in the same

manner.

FX Supervisory Controller Installation Instructions 11

Page 12

Power Wiring

The FX20/FX60 must be powered by an approved 15

VDC power source. This can come from one of the

following:

an external wall mount AC adapter

(LP-FXPMUS/EU/UK-0)

a DIN rail mount 24 VAC/DC powered module

(LP-FXPM24-0)

a DIN rail mount line voltage

(90-263 VAC) module (LP-FXPM263-0)

an NDIO34 module (LP-FXNDIO34-0)

The FX20/FX60 does not include an on/off switch. To

apply power, you can do one of the following:

plug in the power connector to the FX20/FX60, if

the wall mount power module is used

plug in its 2-position power connector, if the

24 VAC DIN rail power supply is used

energize the AC circuit (90-263 VAC) wired to that

module, if the line voltage DIN rail power supply is

used

!

CAUTION: Risk of Property Damage.

Do not apply power to the system before checking

all wiring connections. Short circuited or improperly

connected wires may result in permanent damage to

the equipment.

Wall Mount Power Module

Three models of wall power modules are available:

United States (U.S.), European Union (EU), and

United Kingdom (U.K.). All are self-contained, isolated

switching power supplies designed to plug into a

standard building power receptacle for appropriate

voltage. To supply power to the FX20/FX60, you

simply plug the barrel connector plug from the power

module into the barrel power connector on the

FX20/FX60 base unit (see Figure 9).

IMPORTANT: Do not plug the barrel connector plug

from the power module into the FX20/FX60 until all

other mounting and wiring is completed.

Wiring LP-FXPM24-0 Power Module

The LP-FXPM24-0 module lets you power the

FX20/FX60 (and, if installed, the NDIO16 modules)

from a dedicated, Class 2, 24 VAC transformer, or

from a 24 VDC power supply. If installing NDIO16

modules, install the power module as the last (end)

module in the chain. See Figure 5.

IMPORTANT: If powering from a 24 VAC

transformer, do not power any other equipment with

it. Otherwise, conducted noise problems may result.

Also, do not ground either side of the transformer’s

secondary.

MISE EN GARDE: Risque dégâts matériels.

Ne pas mettre le système sous tension avant d'avoir

vérifié tous les raccords de câblage. Des fils formant

un court-circuit ou connectés de façon incorrecte

risquent d'endommager irrémédiablement

l'équipement.

If desired, you can use the wall mount power adapter

in your office to initially commission the FX20/FX60,

and then install the DIN rail mount power supply at the

project site.

12 FX20/60 Supervisory Controllers Installation Instructions

Page 13

LP-FXPM

(cover removed)

FX-20/FX-60

Dedicated 24 VA C transformer

Neither side of secondary tied

to earth ground.

Line volta ge

(Mains)

24 VAC

Figure 7: LP-FXPM Power Module Wiring Connections

Located at the bottom of the power module is a

2-position power connector and an earth ground spade

lug (see Figure 7). Connect the supplied earth ground

wire to a nearby earth ground point. Unplug the power

connector plug from the module and make

connections to it as shown in Figure 7.

!

CAUTION: Risk of Property Damage.

Do not apply power to the system before checking

all wiring connections. Short circuited or improperly

connected wires may result in permanent damage to

the equipment.

MISE EN GARDE: Risque dégâts matériels.

Ne pas mettre le système sous tension avant d'avoir

vérifié tous les raccords de câblage. Des fils formant

un court-circuit ou connectés de façon incorrecte

risquent d'endommager irrémédiablement

l'équipement.

Power consumption depends on installed accessories

and option cards, and may vary from:

Earth Ground

24 VDC Pow er S upp ly

(polarity not critical)

Neither side tied to

earth ground.

OR

24 VDC

FIG:BrdLyt

LP-FXPM263-0 Line Voltage Power Module

Using the LP-FXPM263-0 module lets you power the

FX20/FX60 (and, if installed, the NDIO16 modules)

from AC line power, with a universal input range from

90-263 VAC. If installing NDIO16 modules, install the

power module as the last (end) module in the chain

(see Figure 5).

!

WARNING: Risk of Electric Shock.

Disconnect power supply before making electrical

connections. Contact with components carrying

hazardous voltage can cause electric shock and

may result in personal injury or death.

AVERTISSEMENT: Risque de décharge

électrique. Débrancher l'alimentation avant de

réaliser tout branchement électrique. Tout contact

avec des composants conducteurs de tensions

dangereuses risque d'entraîner une décharge

électrique et de provoquer des blessures graves,

voire mortelles.

FX20/FX60 with power module alone: approximately

8.5 VA (AC) or 8.5 W (DC)

FX20/FX60 with power module and 4 NDIO modules,

plus option cards: up to 20 VA (AC) or 20 W (DC)

13 FX Supervisory Controller Installation Instructions

Note: The 6-pin connector of the LP-FXPM263-0 is

not used with a FX20/FX60.

Page 14

.

Remove cover

FX-20/FX-60 or

last NDIO-16.

120 or 240 VAC

50-60 Hz

Single Phase

Line

Neutral

L N

Figure 8: LP-FXPM263-0 Line Voltage Power Module Wiring Connections

To wire the DIN rail mount line voltage power module,

see Figure 8 and follow these instructions:

1. Remove power from the AC circuit being wired to

the power module.

2. Remove the power module cover by pressing in

the 4 tabs on both ends of the unit, and lifting the

cover off. If the power module is plugged into the

FX20/FX60 or an NDIO16, you may need to slide

it away to access the cover tabs.

3. Connect the supplied earth grounding wire to a

nearby grounding point (see Figure 8).

4. Make AC circuit connections line (mains) and

neutral to the terminals labeled INPUT PWR.

6-pin

connector

not used.

AC Input

Earth Ground

FIG:LnePwrModWr ng

!

CAUTION: Risk of Property Damage.

Do not apply power to the system before checking

all wiring connections. Short circuited or improperly

connected wires may result in permanent damage to

the equipment.

MISE EN GARDE: Risque dégâts matériels.

Ne pas mettre le système sous tension avant d'avoir

vérifié tous les raccords de câblage. Des fils formant

un court-circuit ou connectés de façon incorrecte

risquent d'endommager irrémédiablement

l'équipement.

5. Replace the cover on the power module.

6. Make sure that all modules in the assembly are

firmly connected together and secured.

14 FX Supervisory Controller Installation Instructions

Page 15

Communications Wiring

Connect communications wiring to the ports on the

bottom of the FX20/FX60.

Battery in bracket

(on top of option

car d s, if any )

Battery

Connector

Option Slot area

(Slot #1 this side)

Ethernet (RJ-45)

LAN 2

Figure 9: FX20/FX60 Bottom Side (Cover Removed)

Ethernet Port

Two female 10/100-Mbit Ethernet connections are

provided on the FX20/FX60. These connections are

capable of running at either 10 Mbps or 100 Mbps; the

controller automatically adjusts to either speed. This

means the FX20/FX60 can exist on the same network

with a mixture of 10BaseT and 100BaseTX hardware

connected to a smart 10/100 hub capable of adjusting

to the devices it supports.

Two RJ-45 connectors labeled LAN1 and LAN2 are

provided for the Ethernet connections (Figure 9). Use

a standard Ethernet patch cable for connecting to a

hub or Ethernet switch. An activity LED for each

Ethernet port is visible, labeled LAN1 and LAN2 on the

cover.

The factory default IP address for LAN1 is

192.168.1.149. By default, LAN2 is disabled.

Note: Typically, you only use LAN1 (primary port). If

you have a specific application for isolating a driver’s

network traffic to a separate local area network (LAN),

you can use LAN2. Do not use LAN2 as the primary

port.

Prior to connecting cables, provide strain relief for

them to prevent damage to the controller.

Primary Ethernet (RJ-45)

RS-232

(DB-9)

COM1

LAN 1

RS-485

(3-position)

COM2

Barrel power

connector for

power module

20-pin

Connector

(I/O and Pow er

Modules)

FIG :FX20_BtmSde

Earth Ground

Spade Lug

Serial Ports

The FX20/FX60 has two serial ports (see Figure 9).

Each port has a Universal Asynchronous Receive

Transmit (UART) capable of operation of up to

115,200 baud. The left port is an RS-232 port that

requires a DB-9 male plug connector. The right port is

a non-isolated RS-485 port that uses two wires with a

shield connection and a screw-terminal connector

plug. In addition, the FX60 controller has a standard

Universal Serial Bus (USB) port (not shown).

Note: A green receive LED and yellow transmit LED

are provided for each serial port. These LEDs are

located on the bottom board opposite of the serial

connectors (see Figure 6). The LEDs are labeled on

the board (COM1, COM2) and are not visible with the

cover on.

RS-232 Port

An RS-232 serial port uses a DB-9 male connector

and always operates as COM1. You can use a

standard DB-9 serial cable with this port. The

FX20/FX60 is a serial Data Terminal Equipment (DTE)

device, so connecting another DTE device (computer)

requires a null modem cable. To connect the

FX20/FX60 to a Data Communication Equipment

(DCE) device (modem), use a straight-through cable.

Table 4 provides the standard serial DB-9 pinouts.

FX Supervisory Controller Installation Instructions 15

Page 16

Table 4: Serial Port Pinouts

Pinout References Signal DB-9

DB-9 Plug (Male)

1

6

5

FIG:DB-9

9

DCD Data carrier detect 1

RXD Receive data 2

TXD Transmit data 3

DTR Data terminal ready 4

GND Ground 5

DSR Data set ready 6

RTS Request to send 7

CTS Clear to send 8

Not used on the FX20/FX60 9

RS-485 Port

Setup and Adjustments

An RS-485 non-isolated port uses a 3-position, screw

terminal connector and always operates as COM2.

Use shielded 18-22 AWG wire for this connector (refer

to the Telecommunications Industry

Default Communication and Login Properties

The new FX20/FX60 are pre-configured with default

properties as defined in Table 5.

Association/Electronic Industries Alliance

[TIA/EIA-485 standard]). As shown in Table 4, the

screw terminals (from left to right) are shield, plus (+),

and minus (–).

USB Port (FX60 only)

A single USB port is on the top of the FX60.

Note: The USB port is for future use. Do not use the

port at this time.

Table 5: FX20/FX60 Default Properties

Name Default Property

Internet Protocol (IP)

Address

Subnet Mask

Default Gateway

Remote User Name

Remote Password

Plug Pin

Base RS-485

Port (COM2)

Pinouts

S + -

192.168.1.149

255.255.255.0

192.168.1.1

jci

explorer

FIG:3pos

Powerup and Initial Checkout

Ensure that power wiring to the transformer is

complete before you proceed (see Power Wiring). See

Figure 6 for locations of the battery connector, status

LEDs, and barrel power connector. See Figure 7 for

location of the power connector on the DIN rail power

modules.

After you have completed all mounting and wiring

steps:

1. Connect the backup battery.

2. Apply power.

Check the status LEDs.

16 FX20/60 Supervisory Controllers Installation Instructions

Page 17

Connecting the Backup Battery

With the cover removed from the FX20/FX60, locate

the red and black wires with a plug on the backup

battery. Insert the plug into the battery connector on

the bottom board as shown in Figure 10.

Battery

Assembly

Battery

Connector

FIG :Bcku pB att

Figure 10: Backup Battery Connector Location

The connector is keyed so you cannot insert it

incorrectly. The red (positive) connection should be the

furthest from the two 30-pin option board connectors.

For more battery details, see About the Battery.

Operation

Apply power to the FX20/FX60 by plugging in the

power plug into either the FX20 (if using the wall

mount power module) or the 24 VAC/DC power

module. If the controller is using the line voltage power

module, energize the 90-263 VAC circuit.

About the Battery

The FX20/FX60 is provided with a custom, 10-cell

NiMH battery pack mounted to the unit under the

cover. This battery allows the FX Supervisory to

continue operation through very short power

interruptions (a few seconds in duration). If a longer

power outage occurs, the battery provides enough run

time for the FX Supervisory to backup data and then

shutdown. Typically, this takes 1 minute to complete.

Shutdown occurs automatically, after data is backed

up to onboard flash memory.

The FX20/FX60 charges the battery during normal

operation, until fully charged. Typically, the charge

operation completes within 18 hours. Following a

power outage, the battery is charged again, as

necessary. The power and battery circuitry is

monitored by a station running on the FX20/FX60 (via

the PowerMonitorService). Station alarms are

generated when primary power is lost, or if the battery

is uncharged or unable to hold a sufficient charge.

The battery should be replaced about every 3 years. If

the unit is in a high temperature environment, replace

it more often.

Note: The NiMH battery looses its charge if not left

in trickle-charge mode. If you leave the battery

disconnected or attached to the unit when powered off,

the battery fully discharges in a matter of weeks. A

new FX20/FX60 ships from the factory with a

completely discharged battery; after installation, allow

at least 18 hours for the battery to fully charge.

Using Status LEDs

The FX20/FX60 includes several LEDs that can help

determine the status of the unit. These LEDs include:

IMPORTANT: Do not connect both the wall power

module and the DIN rail power modules at the same

time, or equipment damage will result, or a power

outage may go unrecognized.

Checking the Status LEDs

When power is applied, the green LED labeled Status

is lit. This indicates that the system is normal and

power is applied. Once the FX20/FX60 boots, the

yellow BEAT (heartbeat) LED begins to blink, with a

typical rate of about one blink per second. Blinking

should begin within 30 seconds after power is applied.

If, after applying power, the STATUS LED goes out, or

the BEAT LED comes on steady and stays lit for

longer than 2 minutes, contact your technical support

representative for assistance. See also Using Status

LEDs.

Ethernet Ports

Heartbeat

Status

Serial Ports

Refer to Figure 6 for the location of the status LEDs.

Ethernet Ports LEDs

Each Ethernet port has one green LED, visible on the

top cover. A LAN# LED indicates activity on that port

as follows:

Off: No Ethernet link is established.

On: Ethernet link is established, but no activity is

on the LAN.

Blinking: Ethernet link is established with data

activity on the LAN.

FX Supervisory Controller Installation Instructions 17

Page 18

Heartbeat LED

The yellow BEAT LED is located to the right of the

Ethernet status LEDs. Under normal operation, this

LED should blink about once per second. If the BEAT

LED stays on constantly, does not light, or blinks very

fast (more than once per second), contact your

technical support representative for assistance.

IMPORTANT: During boot-up, the heartbeat LED

blinks in a 90% on, 10% off pattern. Do not remove

power during this time, or data loss may result

(NDIO module’s firmware upgrade may be in

progress).

Status LED

The green Status LED is located to the right of the

heartbeat (BEAT) LED. This LED provides a central

processing unit (CPU) machine status check, and

remains lit whenever the FX20/FX60 is powered. If the

Status LED does not light while power is applied,

contact your technical support representative for

assistance.

Serial Port LEDs

LEDs for the 2 serial ports are located on the

FX20/FX60’s bottom board on the opposite side of the

RS-232 and RS-485 ports (see Figure 6). Labels

COM1 and COM2 correspond to the software

configuration of the COM ports. LEDs show, transmit,

and receive activity for the serial ports and optional

modem.

Note: You must remove the cover to see the serial

port LEDs. See Removing and Replacing the Cover.

The yellow Transmit LED indicates that the

FX20/FX60 is sending data out the serial port over

a communications line to a connected device.

The green Receive LED indicates that the

FX20/FX60 is receiving data from a connected

device.

Niagara

AX

Software Installation

As shipped from the factory, FX20/FX60 are pre-

configured with a Niagara build, a license, and four

Johnson Controls® specific Java® Archive (JAR) files.

With these components in place, you only need to

change login credentials and IP settings (per network

requirements) when setting up the FX20/FX60. This

section provides step-by-step instructions for these

tasks.

The most straightforward way to set up an FX20/FX60

(and to upgrade to a newer Niagara build at a later

date) is to use the administrative tools available under

the Tools Menu in the FX Workbench software.

Note: If upgrading JAR files with patches at a later

date, use the Update Remote Site menu item. If

upgrading to a newer Niagara build, use the Upgrade

Remote Software Version menu item. If changing login

credentials, use the Change Remote Login Credentials

menu item.

Preparing for Setup

Providing Power and Connectivity

Perform the initial startup of an FX20/FX60 in your

office before physically mounting it in place at a job

site.

After you complete the commissioning process, mount

and wire the FX20/FX60 at the job site, making

permanent mounting and wiring connections.

For this initial Ethernet connection, you can use one of

the following:

a crossover cable connected directly between your

computer and the FX20/FX60

a standard Local Area Network (LAN) connection

in which your computer and the FX20/FX60 are

physically connected to the same Ethernet hub or

switch

These LEDs are driven by pulse detectors that provide

a fixed on-time sequence when data is detected on the

port. If the receive LED is on constantly, a problem

with the communications channel may be present,

such as a shorted wire or reversed wiring.

18 FX20/60 Supervisory Controllers Installation Instructions

Page 19

IP Address

When shipped, a new FX20/FX60 Series controller is

pre-configured with an IP address of 192.168.1.149

and a default subnet mask of 255.255.255.0.

To change the IP settings, perform the following steps:

1. Use the Microsoft®

Windows® Network

Connections utility on your workstation to

configure your Transmission Control Protocol

(TCP)/IP settings with an IP address of

192.168.1.100 and subnet mask of 255.255.255.0.

2. Make an Ethernet connection to the FX20/FX60

as indicated in Providing Power and Connectivity.

3. Run the FX Workbench application.

4. Under the File Menu, select the Open Remote

Station menu item. When prompted, enter the

Remote Site Address (192.168.1.149), Remote

Username (jci), and Remote Password

(explorer). Click OK. When the Authentication

dialog appears, enter the Username (admin),

leave the Password field empty, and click OK.

5. The station running on the FX20/FX60 opens with

the FX Workbench application, which has a

Navigation Tree on the left and a Display Window

on the right. In the Navigation Tree, open the

Administration folder. Double-click the TCP IP

Configuration option.

6. On the TCP/IP Configuration screen, make sure

the Interfaces field is expanded so that the IP

Address and Subnet Mask fields appear. Modify

the Gateway, IP Address and Subnet Mask fields,

and click Save. When prompted to Reboot Now,

click Yes. Give the FX20/FX60 a couple of

minutes to reboot and restart the station that is

installed.

Note: If the following message appears, just click

OK. The changes are saved anyway.

Initially, you use these default credentials to open a

platform connection (log in) to the FX20/FX60. Like the

factory-assigned IP address, default credentials are

intended to be temporary. Change these credentials to

be something unique, and guard them closely.

To change the Platform Daemon credentials, perform

the following steps:

1. Start the FX Workbench application.

2. Under the File Menu, select the Open Remote

Station menu item. When prompted, enter the

Remote Site Address (for example,

192.168.1.149), Remote Username (jci), and

Remote Password (explorer). Click OK. When the

Authentication dialog appears, enter the

Username (admin), leave the password field

empty, and click OK.

3. Under the Tools menu, select Change Remote

Login Credentials. In the Change Remote Login

Credentials dialog, fill in the Username, Password,

and Confirm Password fields, then click OK. The

next time you log into the FX20/FX60, use these

new credentials.

Restoring a Backed Up Station

If the FX20/FX60 ever gets into an erroneous condition

where you cannot fix a station, you can restore a

previously backed up station by using the Restore

Backed Up Station menu item under the Tools menu.

To restore a backed up station, perform the following

steps:

1. Run the FX Workbench application.

2. Under the File Menu, select the Open Remote

Station menu item. When prompted, enter the

Remote Site Address (for example,

192.168.1.149), Remote Username (jci), and

Remote Password (explorer). Click OK. When the

Authentication dialog appears, enter the

Username (admin), Password (optional), and click

OK.

Platform Daemon Credentials

An FX20/FX60 Series controller is shipped with the

following Platform Daemon (Administrator) credentials:

User Name: jci

Password: explorer

3. Under the Tools menu, select Restore Backed Up

Station. In the Restore Backed Up Station dialog,

enter the Remote Site IP Address, Remote

Username, Remote Password, and select the .dist

(station backup) file. Click OK. The FX20/FX60

reboots automatically.

Note: You can back up a station by using the

Backup Station menu item from the station node’s

popup menu in the Navigation Tree. We

recommend that you back up a station daily to

minimize the chance of information loss.

FX Supervisory Controller Installation Instructions 19

Page 20

Cleaning

If dust or metal filings are present inside the unit, clean

with vacuum or compressed air. Otherwise, no

cleaning inside the unit is required. Optionally, if the

outer enclosure becomes dirty, you can wipe it with a

damp cloth and mild detergent.

Required Battery Maintenance

Battery life expectancy is a function of its discharge

cycles (the number of discharges and their depth) and

the ambient temperature of the battery during normal

operation. In most applications, the battery should see

relatively few discharges. Therefore, ambient

temperature has more to do with determining the life

expectancy of the battery than any other factor. If the

FX20/FX60 is installed in a conditioned space, the

battery should provide dependable service for

approximately 3 years. In an environment where the

operating temperature is higher (50ºC or 122ºF), you

should only expect the battery to last approximately

1 year.

The NiMH battery in the FX20/FX60 is fully discharged

before shipping. Additionally, NiMH batteries lose

charge over time if not kept trickle-charged. Therefore,

even a new unit (or replacement battery) requires up

to 18 hours of powered operation before it becomes

fully charged to provide reliable backup power.

The FX20/FX60 monitors the battery and periodically

loads the battery to test its ability to maintain

battery-backed functions. Investigate any battery

trouble message, and check the battery connections to

the unit. Replace the battery as required.

To order a new battery, see Standard Replacement

Parts.

Replacing the Battery

The replacement battery is a complete assembly,

consisting of a custom NiMH battery pack pre-attached

to a battery bracket (see Figure 10).

IMPORTANT: Use only NiMH battery packs

approved for use with the FX20/FX60.

4. Remove the old battery and bracket assembly by

removing the four screws holding it in place. Set

the screws aside for later.

5. Remove the battery from the connector on the

FX20/FX60.

6. Recycle the battery as defined by your regional

codes. For recycling within the United States, see

the battery label.

7. Plug the battery connector plug of the

replacement battery into the battery connector on

the FX20/FX60.

8. Place the replacement battery/bracket assembly

over the option card slots, with the mounting

holes aligned with the standoffs.

9. Place the four screws through the battery bracket,

option card blanking plates, option cards (if used),

and into the standoffs on the FX20/FX60 base

board. Using a screwdriver, hand-tighten these

screws.

10. Replace the cover.

11. Restore power to the FX20/FX60 and verify

normal operation.

Repair Information

Servicing the FX20/FX60 may call for replacement

parts.

Non-replaceable Parts

Other than the parts listed in the Standard

Replacement Parts section, no serviceable

components are on the base assembly.

Memory

Any addition, modification, or replacement of memory

components requires software configuration changes

and is not field upgradeable. For additional information

on modifying the memory capacity of the FX20/FX60,

consult your local sales representative.

To replace the battery:

1. Back up the FX20/FX60’s configuration to your

computer using FX Workbench.

2. Remove power from the FX20/FX60. Wait for

LED activity to stop. After several seconds, all

LEDs on the FX20/FX60 should be off.

3. Remove the cover. See Removing and Replacing

the Cover.

20 FX20/60 Supervisory Controllers Installation Instructions

Page 21

Fuse

The FX20/FX60 contains a non-user replaceable fuse

soldered on the circuit board. This fuse provides

protection from internal shorts or connection to

incorrect power supplies. If the fuse circuitry is

suspect, contact your technical support representative

for assistance.

Standard Replacement Parts

Standard replacement parts are listed in Table 6.

Table 6: Standard Replacement Parts

Part Number Description

LP-KITFX2BAT-0

NiMH Battery Pack: includes battery

bracket (See Replacing the Battery.)

New Replacement Unit

To replace a faulty FX20/FX60, order a new one. To

ensure proper credit for a FX20/FX60 still under

warranty, contact the Johnson Controls Product Sales

Operations Team for return authorization.

Replacing an FX20/FX60

IMPORTANT: Before handling circuit boards,

discharge any accumulated static by touching the

metal surface of the FX20/FX60.

To replace the FX20/FX60 in the field, follow these

procedures:

1. Use FX Workbench to back up the FX20/FX60

configuration to your computer.

2. Remove power to the FX20/FX60. The unit

powers down automatically.

Note: If NDIO accessory modules are installed, and

any I/O points have voltage, turn the devices off or

disconnect power from them.

a. If DIN rail mounting with DIN end clips were

used, you may be able to remove the DIN rail

end clip that secures the FX20/FX60 end of

the assembly and then slide the FX20/FX60

away from the rest of the assembly. Then,

remove the FX20/FX60 from the DIN rail (see

Figure 3), leaving the mounting and wiring of

the NDIO modules untouched. Go to Step 5.

b. If tab (screw) mounting was used instead of

DIN rail mounting, or if a combination of DIN

rail mounting and tab screws were used,

remove the accessory modules first, then

remove the FX20/FX60. Carefully observe all

wiring terminations, then unplug the I/O

connector plugs and earth ground wires from

the installed NDIO modules. Remove the

installed accessory modules, starting with the

end module. You can secure modules with

screws through the mounting tabs or clipped

to a DIN rail, or fastened by some

combination. Remove any screws fastening

the FX20/FX60 and remove the FX20/FX60.

5. Remove the cover from the old FX20/FX60 (see

Removing and Replacing the Cover). Note the

position of installed option boards, if any. You

must transfer them to the replacement

FX20/FX60.

6. Remove the option boards from the old

FX20/FX60 and install them into the replacement

FX20/FX60, if applicable. See Mounting Option

Cards.

7. Mount the replacement FX20/FX60 as it was

previously, using the same DIN rail location

and/or screws.

8. Reconnect/remount any removed accessory

modules, being careful to replace them in the

same order, using the same DIN rail location

and/or screws. Secure all accessory modules as

done previously.

1. Note the positions of all communications and other

wiring cables going to the FX20/FX60, as well as

all installed accessory modules (if they must be

removed). If necessary, label connectors and

accessory modules to avoid misconnection later

when you are replacing the FX20/FX60.

2. Unplug all Ethernet, serial, LON, modem, and I/O

connectors from the FX20/FX60.

3. Unplug the earth ground wire.

4. If an NDIO accessory module is installed:

9. Reconnect the earth ground wires to the

FX20/FX60 grounding lug and any installed

accessory modules.

FX Supervisory Controller Installation Instructions 21

Page 22

10. Reconnect any Ethernet, serial, modem, and I/O

connectors to the FX20/FX60 and any installed

accessory modules.

11. If using NDIO modules, and if any of your I/O

points have voltage, turn on the devices or

reconnect power to them.

12. Restore power to the FX20/FX60. To verify

operation, see Checking the Status LEDs.

13. Use FX Workbench to recommission the

FX20/FX60 and install the saved station

database.

Johnson Controls® is a registered trademark of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2014 Johnson Controls, Inc.

22 FX20/60 Supervisory Controllers Installation Instructions

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Loading...

Loading...