Page 1

Installation Instructions F61

Issue Date July 30, 2002

F61 Series Standard Flow Switches

Installation

IMPORTANT: All F61 Series Flow Switches are

intended to control equipment under normal

operating conditions. Where failure or malfunction of

an F61 Flow Switch could lead to an abnormal

operating condition that could cause personal injury

or damage to the equipment or other property, other

devices (limit or safety controls) or systems (alarm or

supervisory) intended to warn of, or protect against,

failure or malfunction of the F61 Flow Switch must

be incorporated into and maintained as part of the

control system.

Some models of the F61 Series Standard Flow

Switches require installation or adjustment of paddles

prior to mounting. See Installing the Flow Paddles.

Parts Included

Standard models of the F61 flow switch include an

installed three-piece flow paddle. Some models also

include a large flow paddle for large pipe sizes.

Table 1: Replacement Parts

Kit Number Description

KIT21A-600

KIT21A-601

PLT52A-600R

CVR62A-600R Replacement Cover Assembly for LB,

Stainless Steel Three-piece Paddle

(3 in., 2 in., and 1 in. Segments)

Stainless Steel 6 in. Paddle

Stainless Steel Three-piece Paddle

(3 in., 2 in., and 1 in. Segments) and

6 in. Paddle

MB, MD, and MG types

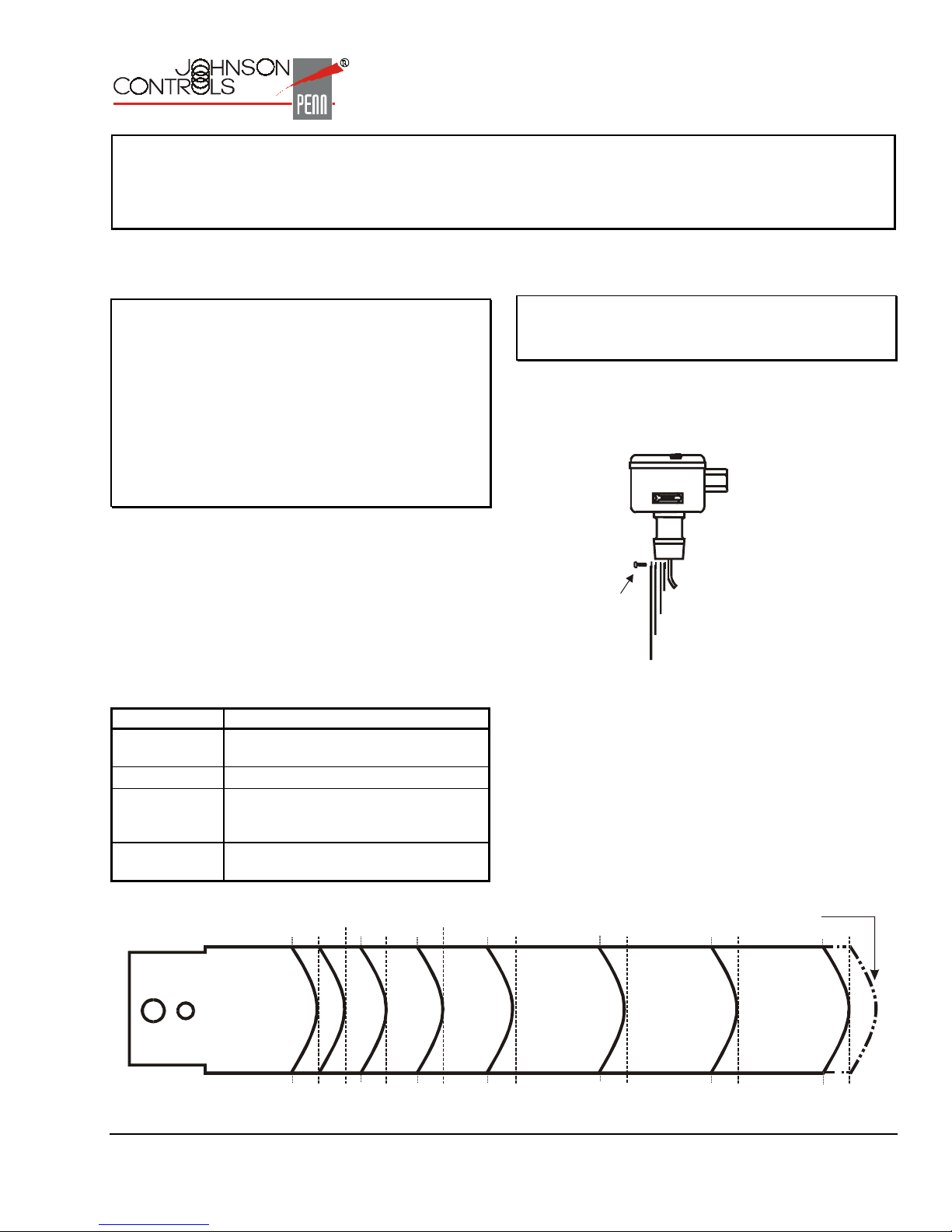

Installing the Flow Paddles

IMPORTANT: To allow the switch to detect changes

in the fluid flow, the flow paddle must not touch the

pipe or any restrictions in the pipe.

Adjust flow paddles to the size of the pipe used. If

needed, trim the large flow paddle at the arc

corresponding to pipe size (see Figure 1 and Figure 2)

and install.

Flow

Paddle

Screw

Trim flow paddles to fit

pipe diameter or remove

flow paddles that are

too large to fit pipe diameter.

Figure 1: Installing the Paddles

1 in.

Figure 2: Trimming Diagram for Large Flow Paddle

© 2002 Johnson Controls, Inc.

Part No. 24-8407-4, Rev. C www.johnsoncontrols.com

1-1/2 in.

2 in.

2-1/2 in.

4 in.3 in.

5 in.

Original

Length

6 in.

1

Page 2

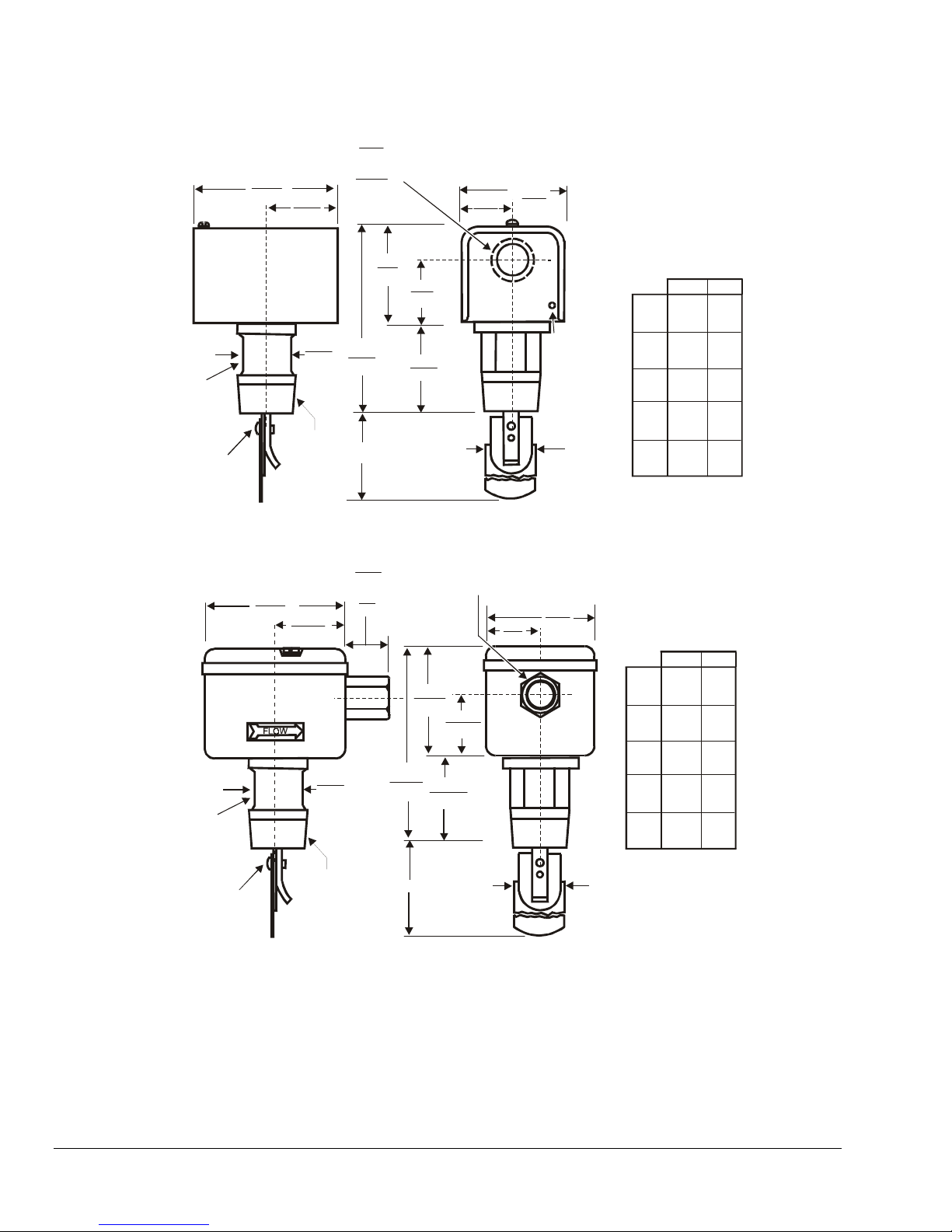

Dimensions

4

(102)

2

(51)

7/8

Diameter Hole for 1/2 in. Trade Size Conduit

(22)

1-1/16

Diameter Knockout Ring for 3/4 in. Trade Size Conduit

(27)

1-3/8

(35)

2-3/4

(71)

Use these

wrench flats

to tighten

the flow switch

at installation.

Paddle

Screw

Figure 3: NEMA 1 Enclosure (F61KB Types) Dimensions, in./mm

Use these

wrench flats

to tighten

the flow switch

at installation.

Paddle

Screw

3-11/16

(94)

1-1/4

4-3/4

(33)

(121)

1 in.

11-1 / 2 NP T

1-13/16

(47)

1-1/4

(33)

1 in. 11-1/2 NPT

2-11/16

(68)

1-3/4

(44)

1-1/8

(29)

A

1-1/8

On MB and MG Types

(29)

5/8

On LB Types

(15)

2-7/8

(73)

4-3/4

(121)

A

B

1/2-14 NPSM Thread

1-3/8

(35)

1-9/16

(40)

1-1/16

(27)

B

Grounding

Screw

Hole

2-3/4

(71)

Dimension by

Liquid Line Size

1-7/16

1

(37)1 (25)

(25)

2-1/2

2

(64)

(51)

3-1/2

3

(89)

(76)

4

6-5/8

(101)

(168)

5

6-5/8

(152)

(168)

Dimension by

Liquid Line Size

1-7/16

1

(37)1 (25)

(25)

1-1/8

2-1/2

2

(64)

3-1/2

(89)

6-5/8

(168)

6-5/8

(168)

(29)

1-1/8

(29)

1-1/8

(29)

1-1/8

(29)

(51)

3

(76)

4

(101)

5

(152)

BA

1-1/8

(29)

1-1/8

(29)

1-1/8

(29)

1-1/8

(29)

BA

Figure 4: NEMA 3 or NEMA 3R Enclosure (F61LB, F61MB, F61MG Types) Dimensions, in./mm

2 F61 Series Standard Flow Switches Installation Instructions

Page 3

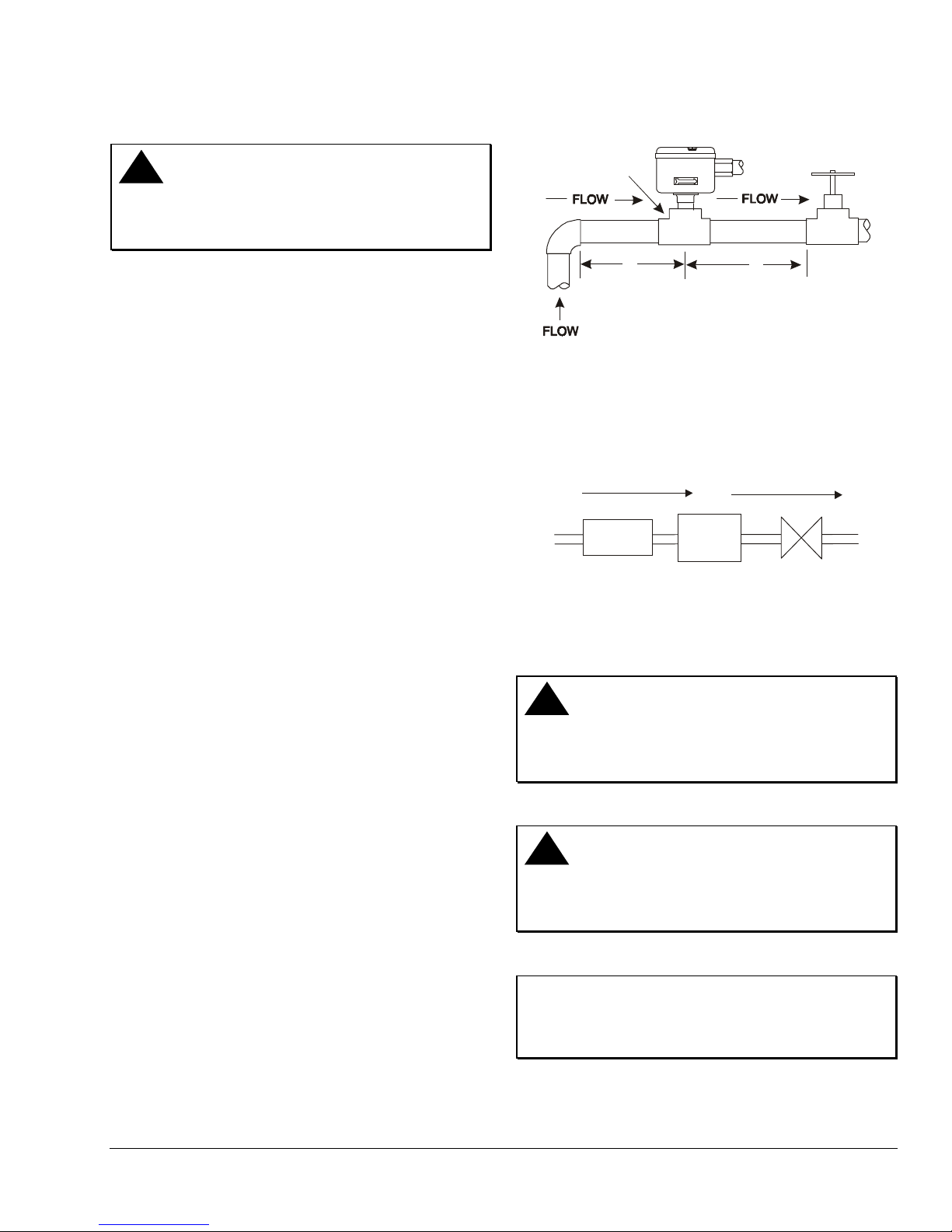

Mounting

!

CAUTION: Risk of Equipment Damage.

To avoid damaging the switch, do not tighten the

switch to the tee by grasping the switch enclosure.

Use only the wrench flats provided.

Tee or Welded

Half-coupling

Mount the F61 Series Flow Switch, using the following

guidelines:

• Install the switch so that the cover and interior are

accessible.

• Mount the switch so that the flow of fluid is in the

direction of the arrow on the switch casing.

• Use a pipe union on each side of the flow switch to

allow easy removal or replacement.

• Mount the switch so that the pipe does not extend

too far into the flow switch casing.

• Use pipe thread sealer on male threads only.

• Do not remove the cover gasket or the wire

grommet from the conduit opening.

For 1 in. pipe installation, mount the F61 flow switch in

a standard 1 in. x 1 in. x 1 in. tee. For larger sizes of

pipe, use a reducing tee to keep the flow switch close

to the pipe and provide adequate paddle length in the

flow stream.

Example: Use a 2 in. x 2 in. x 1 in. tee for a

2 in. pipe. If a standard 2 in. x 2 in. x 2 in. tee is

used, install a face or hex bushing in the top

opening to reduce it to 1 in.

Mount the flow switch so the terminals or wire leads

are easily accessible for wiring. Screw the flow switch

in position so the flat of the paddle is at a right angle to

the flow. The arrow on the side of the case must point

in the direction of the flow.

A

Dimension must be at least

five pipe diameters from the nearest

elbow, valve, or other pipe restriction.

A

A

Figure 5: Required Piping Distance

Do not subject the flow switches to water hammer.

Use a suitable water hammer arrester if a fast-closing

valve is located downstream of the flow switch. See

Figure 6.

Flow

Flow

Switch

Water

Hammer

Arrester

Val ve

Figure 6: Water Hammer Arrester Location

Schematic

Wiring

!

WARNING: Risk of Electrical Shock.

Disconnect power supply before making electrical

connections. Failure to follow this precaution may

result in electrical shock or death.

Location Considerations

Mount the F61 flow switch in a horizontal pipeline or a

vertical pipeline with upward fluid flow. Do not use in a

vertical pipeline with downward flow. When mounted in

a vertical pipe with upward flow, the switch trips at a

slightly higher flow than shown in Table 3 through

Table 6, due to the effect of gravity on the switch

mechanism.

Mount the F61 flow switch in a section of pipe where

there is a straight run of at least five pipe diameters on

each side of the flow switch from the nearest elbow,

valve, or other pipe restriction. See Figure 5.

!

CAUTION: Risk of Equipment Damage.

Using terminal screws other than those provided will

void the warranty and may damage the switch. Use

only the terminal screws furnished.

IMPORTANT: To prevent moisture from entering

and condensate from forming inside the NEMA 3R

enclosure, do not remove the cover gasket or the

wire grommet from the conduit opening.

F61 Series Standard Flow Switches Installation Instructions 3

Page 4

IMPORTANT: Install all wiring in accordance with

the National Electrical Code and local regulations.

Make all wiring connections using copper conductors

only. Do not exceed the control’s electrical rating.

The F61KB and F61LB models have three color-coded

terminals. Red is common. See Table 2 and Figure 1

for switch action.

The F61MB and F61MG models have four color-coded

wire leads. Red is common, green is ground. See

Table 2.

!

CAUTION: Risk of Equipment Damage.

Sealed settings (screws marked with black paint) are

not intended to be changed. Adjustment attempts

may damage the control or cause loss of calibration,

voiding the warranty.

To adjust the setting of the flow switch:

1. Disconnect power supply before making electrical

connections.

Table 2: Switch Action

Flow Action Switch Closure

Increase

Decrease

Increase in Flow

Above Setpoint

Red

Ye ll ow

Blue

Red to Yellow

Red to Blue

Decrease in Flow

Above Setpoint

Figure 7: Switch Action

Setup and Adjustments

!

WARNING: Risk of Electrical Shock.

Disconnect power supply before making electrical

connections. Failure to follow this precaution may

result in electrical shock or death.

2. Remove the F61 flow switch cover.

3. Turn the adjusting screw clockwise to raise the

flow rate. Turn the adjusting screw

counterclockwise to lower the flow rate. See

Figure 8.

4. Replace the cover after completing adjustments.

Tighten the cover screws to 12 in⋅lbs of torque.

Note: Do not lower the flow rate unless it has been

raised from the factory setting.

Lower Flow Rates

Less liquid flow

required to switch

from R-Y to R-B.

Adjusting Screw

Higher Flow Rates

More liquid flow

required to switch

Red

Blue

from R-Y to R-B.

Yellow

Figure 8: Flow Rate Adjustment

!

CAUTION: Risk of Improper Operation.

The switch is factory set at approximately the

minimum flow rate (see Table 3 through Table 6).

Do not set lower than the factory setting because

that may result in the switch failing to return to a no

flow position.

4 F61 Series Standard Flow Switches Installation Instructions

Page 5

To verify that the flow rate is set above the factory

minimum (see Figure 9):

1. depress the main lever numerous times. If the

lever fails to click upon return at any time, the flow

rate is set below the factory-set minimum.

2. raise the flow rate to approximately the factory

minimum by turning the adjusting screw clockwise

until the lever clicks upon return every time.

Typical Flow Rates for Standard F61 Flow Switches

Table 3: F61KB, F61LB, and F61MB Models, 1-3 in. Paddles

GPM (m

Pipe Size (in.) 1 1-1/411-1/2

Flow

Increase

(R to Y

Minimum

Adjustment

Maximum

Adjustment

1. Values for 2 in. paddle trimmed to fit pipe.

2. Values for 3 in. paddle trimmed to fit pipe.

3. Values calculated for factory-installed set of 1, 2, and 3 in. paddles.

Closes)

Flow

Decrease

(R to B

Closes)

Flow

Increase

(R to Y

Closes)

Flow

Decrease

(R to B

Closes)

4.20

(0.95)

2.50

(0.57)

8.80

(2.0)

8.50

(1.93)

5.80

(1.32)

3.70

(0.84)

13.3

(3.02)

12.5

(2.84)

3

/hr) Required to Actuate Switch

1

22-1/223435

7.50

(1.70)

5.00

(1.14)

19.2

(4.36)

18.0

(4.09)

13.7

(3.11)

9.50

(2.16)

29.0

(6.59)

27.0

(6.13)

18.0

(4.09)

12.5

(2.84)

34.5

(7.84)

32.0

(7.27)

Adjusting

Screw

Figure 9: Minimum Adjustment

27.5

(6.24)

19.0

(4.32)

53.0

(12.0)

50.0

(11.4)

65.0

(14.8)

50.0

(11.4)

128

(29.1)

122

(27.7)

3

125

(28.4)

101

(22.9)

245

(55.6)

235

(53.4)

3

6

190

(43.2)

158

(35.9)

375

(85.2)

360

(81.8)

Main

Lever

3

8

375

(85.2)

320

(72.7)

760

(173)

730

(166)

Table 4: F61KB, F61LB, and F61MB Models, 6 in. Paddles*

Pipe Size (in.) 4568

Minimum

Adjustment

Maximum

Adjustment

* Where paddle size is larger than pipe size, values are for 6 in. paddle trimmed to fit pipe.

Flow Increase (R to Y Closes) 37.0 (8.40) 57.0 (12.9) 74.0 (16.8) 205 (46.6)

Flow Decrease (R to B Closes) 27.0 (6.13) 41.0 (9.31) 54.0 (12.3) 170 (38.6)

Flow Increase (R to Y Closes) 81.0 (18.4) 118 (26.8) 144 (32.7) 415 (94.3)

Flow Decrease (R to B Closes) 76.0 (17.3) 111 (25.2) 135 (30.7) 400 (90.8)

GPM (m3/hr) Required to Actuate Switch

F61 Series Standard Flow Switches Installation Instructions 5

Page 6

Table 5: F61MG Models, 1-3 in. Paddles

GPM (m

Pipe Size (in.) 1 1-1/411-1/2

Flow

Increase

(R to Y

Minimum

Adjustment

Maximum

Adjustment

1. Values for 2 in. paddle trimmed to fit pipe.

2. Values for 3 in. paddle trimmed to fit pipe.

3. Values calculated for factory-installed set of 1, 2, and 3 in. paddles.

Closes)

Flow

Decrease

(R to B

Closes)

Flow

Increase

(R to Y

Closes)

Flow

Decrease

(R to B

Closes)

3.80

(0.86)

2.50

(0.57)

8.70

(1.98)

8.50

(1.93)

5.30

(1.20)

3.70

(0.84)

13.1

(2.98)

12.5

(2.84)

3

/hr) Required to Actuate Switch

1

22-1/223435

6.90

(1.57)

5.00

(1.14)

18.8

(4.27)

18.0

(4.09)

12.7

(2.88)

9.50

(2.16)

28.9

(6.56)

27.0

(6.13)

16.7

(3.79)

12.5

(2.84)

33.7

(7.65)

32.0

(7.27)

24.3

(5.52)

19.0

(4.32)

52.1

(11.8)

50.0

(11.4)

61.0

(13.8)

50.0

(11.4)

126

(28.6)

122

(27.7)

Table 6: F61MG Models, 6 in. Paddles*

GPM (m

3

/hr) Required to Actuate Switch

Pipe Size (in.) 4568

Minimum

Adjustment

Maximum

Adjustment

* Where paddle size is larger than pipe size, values are for 6 in. paddle trimmed to fit pipe.

Flow Increase (R to Y Closes) 35.0 (7.95) 53.0 (12.0) 69.0 (15.7) 197 (44.7)

Flow Decrease (R to B Closes) 27.0 (6.13) 41.0 (9.31) 54.0 (12.3) 170 (38.6)

Flow Increase (R to Y Closes) 80.0 (18.2) 116 (26.3) 142 (32.2) 412 (93.6)

Flow Decrease (R to B Closes) 76.0 (17.3) 111 (25.2) 135 (30.7) 400 (90.8)

3

118

(26.8)

101

(22.9)

243

(55.2)

235

(53.4)

3

6

183

(41.6)

158

(35.9)

372

(84.5)

360

(81.8)

3

8

362

(82.2)

320

(72.7)

753

(171)

730

(166)

Checkout

IMPORTANT: Ensure installation, wiring, and control

settings are according to the application

requirements. Refer to the controlled system’s

manufacturer specifications for the proper settings

when adjusting these controls.

Apply power to the control and controlled equipment.

Cycle the controlled system at least three times at

normal operating conditions.

The circuit between the red and the yellow leads

(terminals) closes when sufficient fluid flows through

the pipe to trip the F61 flow switch.

6 F61 Series Standard Flow Switches Installation Instructions

Page 7

Troubleshooting

Use the information in Table 7 to troubleshoot the flow

switch.

Table 7: Troubleshooting

Symptom/Problem Solution

Water (condensate) is within the enclosure.

Fluid from the tank is leaking into enclosure due to

bellows failure.

Switch does not activate due to debris caught within

the switch mechanism.

Control switch action is reversed.

Repairs and Replacement

Do not make field repairs, except for replacement of

the cover and paddles. For a replacement flow switch,

paddle kit or cover, contact the nearest

Johnson Controls/PENN™ distributor. For more

information, contact Refrigeration Application

Engineering at (800) 275-5676.

Use a model with a NEMA 3R enclosure. If using a model with

a NEMA 3R enclosure, inspect the grommet in the conduit

fitting. Replace grommet if defective.

Replace flow switch.

Clear any debris within the switch mechanism. Test the

operation of switch several times for proper operation.

Ensure connections follow wiring diagrams.

Control does not switch.

Switch fails to return to the no flow position.

Control does not switch on flow increase.

Switch is set lower than the factory setting. Increase the setting.

On vertical pipes, ensure that direction of flow is up. The arrow

on switch must point in direction of flow (up).

Check for cracked/broken paddle. Replace if necessary.

Check connections.

Electrical Ratings

Table 8: Electrical Ratings for F61KB, F61LB, and F61MB Models

Electrical Ratings 120 VAC 208 VAC 240 VAC 277 VAC

Horsepower

Full Load Amperes

Locked Rotor Amperes

Non-inductive Amperes

Pilot Duty

Table 9: Electrical Ratings for F61MG Models

Electrical Ratings 120 VAC

Full Load Amperes

Locked Rotor Amperes

Non-inductive Amperes

Pilot Duty

111-

16.0 8.8 8.0 -

96.0 52.8 48.0 -

16.0 16.0 16.0 16.0

125 VA at 24/277 VAC

1

6

2

125 VA at 24/277 VAC

F61 Series Standard Flow Switches Installation Instructions 7

Page 8

Technical Specifications

Product

Maximum Fluid Pressure

Minimum Fluid

Temperature

Maximum Fluid

Temperature

Switch

Wiring Connections

Pipe Connector

Conduit Connection

F61 Series Standard Flow Switches

150 psig (1034 kPa)

32°F (0°C) (F61KB, F61LB)

-20°F (-29°C) (F61MB, F61MG)

250°F (121°C)

Single Pole Double Throw

Screw Type Terminals (F61KB, F61LB)

Four Color-coded No. 14 AWG Solid Conductor Wire Leads, 7 in. (178 mm) Long (F61MB,

F61MG)

1 in. 11-1/2 NPT Threads

One 7/8 in. (22 mm) Hole for 1/2 in. Conduit with 1-1/8 in. (29 mm) Knockout Ring for

3/4 in. Conduit (F61KB)

Female Hub for 1/2 in. Conduit, 1/2-14 NPSM Threads (F61LB, F61MB, F61MG)

Agency

Listings

UL Listed

CSA

Certified

E5368, CCN NMFT

LR948, Class 3211 06, Class 4813 02, Class 1222 01 (F61KB)

(F61LB - Not CSA Certified)

LR948, Class 3211 06 (F61MB, F61MG)

Shipping Weight

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

Refer to the F61 Series Flow Switches Product/Technical Bulletin (LIT-125225) for necessary information on operating and performance

specifications of this product.

2.8 lb (1.3 kg)

Controls Group

507 E. Michigan Street

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201 www.johnsoncontrols.com

8 F61 Series Standard Flow Switches Installation Instructions

Loading...

Loading...