Page 1

Liquid Level and Flow Controls

F262 Airflow Switch

Description

The F262 Airflow Switch detects airflow or the

absence of airflow by responding only to the

velocity of air movement within a duct. The

single-pole, double-throw (SPDT) control can

be wired to open one circuit and close a

second circuit for either signaling or interlock

purposes.

Airflow failure during the normal operation of

air handling systems may cause overheating,

coil icing, or other conditions that may be

detrimental to the equipment.

Refer to the F262 Airflow Switch Product

Bulletin (LIT-12011988) for important product

application information.

Application

The F262 switch detects airflow or the

absence of airflow by responding only to the

velocity of air movement within a duct. The

SPDT control can be wired to open one circuit

and close a second circuit for either signaling

or interlock purposes.

Failure of airflow during the normal operation

of air handling systems may cause

overheating, coil icing, and other conditions

that may be detrimental to the equipment.

Typical applications include:

• Make-up air systems

• Air cooling or heating processes

• Exhaust systems

The control has a Type 3R (NEMA) enclosure

with an integral mounting plate. A mounting

plate gasket is supplied with each switch.

Features

• Type 3R (NEMA) Polycarbonate enclosure

allows use in indoor applications and

provides dust protection and is approved

for use in a plenum according to NEC

• dependable dust-protected SPDT

snap-acting PENN switch detects the

presence or absence of airflow

• large wiring space makes wiring

convenient and easily accessible

• easily accessible range adjustment screw

allows easy field adjustment

Code No. LIT-1900949

F262 Airflow Control

Repair Information

If the F262 Airflow Switch fails to operate

within its specifications, replace the unit. For a

replacement F262 Airflow Switch, contact the

nearest Johnson Controls® representative.

Selection Charts

F262 Airflow Switch

Product Code Number Description

F262KDH-01C Airflow switch with a 2-1/8 in. wide x 6-7/8 in. long (54 mm x 175 mm) paddle installed and a

Replacement Paddle Kits for F262 Switch

Product Code Number Description

PLT112-1R 2-1/8 in. wide x 6-7/8 in. long (54 mm x 175 mm) paddle

PLT112-2R 3-1/8 in. wide x 6-7/8 in. long (79 mm x 175 mm) paddle

3-1/8 in. wide x 6-7/8 in. long (79 mm x 175 mm) paddle supplied with the control

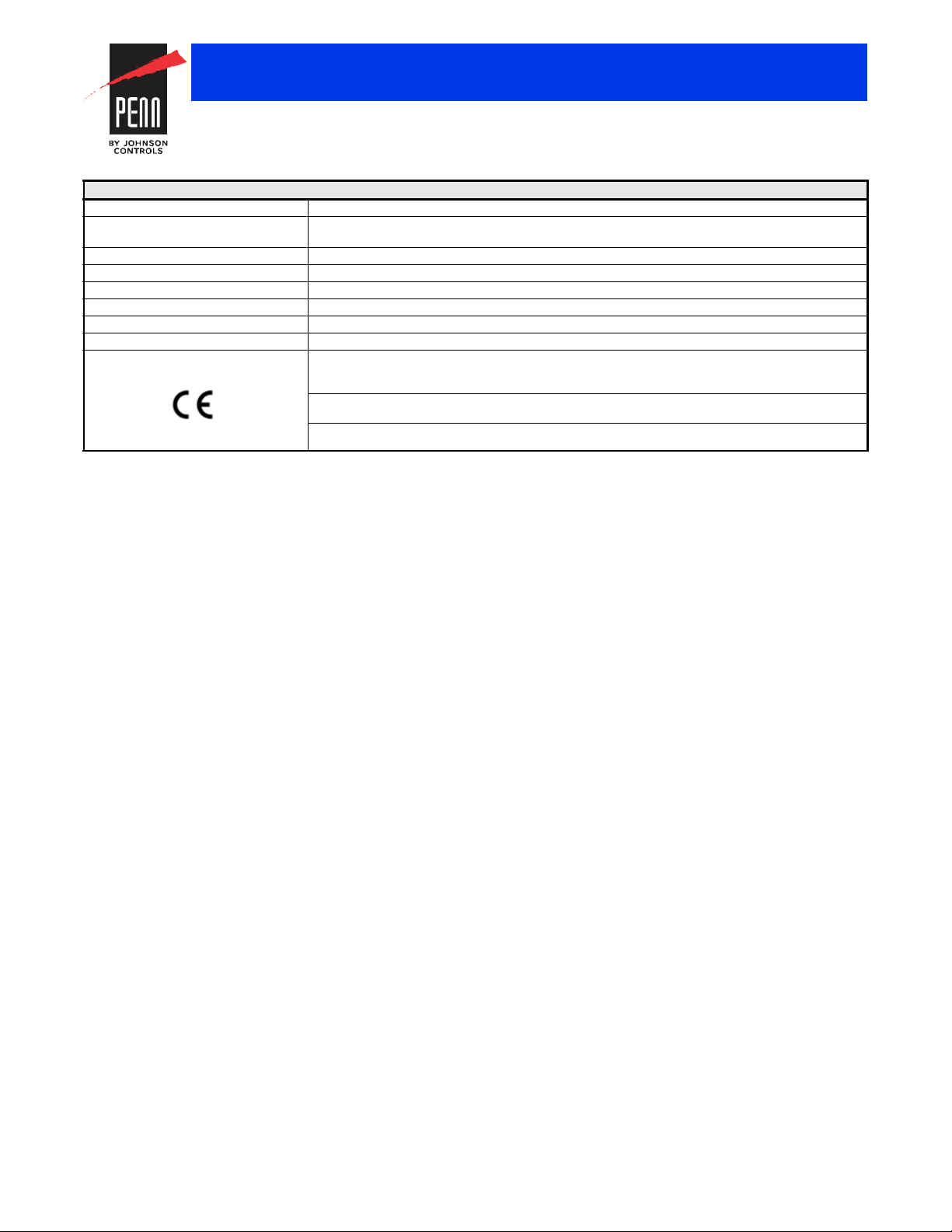

Technical Specifications

F262 Switch Electrical Ratings

Volts 50/60 Hz UL60730 EN60730

24 120 208 240 24 230

Horsepower –111––

Full Load Amperes –161010–8

Locked Rotor Amperes –966060–48

Resistive Amperes 16 16 10 10 16 16

Plot Duty VA 125 720 720 720 125 720

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R–130

Page 2

Liquid Level and Flow Controls

F262 Airflow Switch (Continued)

F262 Series Airflow Switch

Switch SPDT

Enclosure UL: Type 3R

Wiring Connections Three color-coded screw terminals and one ground terminal

Conduit Connection One 7/8 in. (22 mm) hole for 1/2 in. trade size (or PG16) conduit

Paddle Material 0.006 in. (0.15 mm) stainless spring steel

Maximum Air Velocity 2,000 FPM (10.16 m/s)

Maximum Duct Air Temperature 176°F (80°C)

Ambient Conditions 32 to 104°F (0 to 40°C)

Compliance North America: cULus Listed; UL 60730, File E6688;

CE: IP43

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential

requirements and other relevant provisions of the EMC Directive and the Low Voltage Directive.

Australia/New Zealand Mark: RCM Compliant

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R–131

Loading...

Loading...