Page 1

Liquid Level and Flow Controls

F261 Series Fluid Flow Switches

Code No. LIT-1900948

Description

The F261 Series Flow Switches respond to

fluid flow in lines carrying water, ethylene

glycol, or other nonhazardous fluids. These

models also work in applications with

swimming pool water and lubricating oils.

F261 Series Standard Flow Switches use a

variety of paddle sizes to respond to fluid flow

rates in applications with pipe sizes greater

than 1 inch trade size.

Refer to the F261 Series Fluid Flow Switches

Product Bulletin (LIT-12011987) for important

product application information.

Features

• Type 3R (NEMA) or Type 4 (NEMA)

e

nclosure allows use in indoor or outdoor

applications.

• Viton® diaphragms allow use in fluid line

rying chlorinated water, treated water,

car

or other nonhazardous fluids.

• low-flow operation on low-flow

ctuates switch with less t

a

1.0 GPM (3.8 L/min) flow for water

a

pplications or 9.0 GPM (34.1 L/min) flow

for steam applications.

• maximum fluid pressure of 290 ps

(

20 bar) permits use in a wide range

p

ressure flow conditions.

models

han

ig

of

s

F261 Flow Switch

Repair Information

If the F261 Series Flow Switch fails to operate

within its specifications, replace the unit. For a

replacement F261 Series Flow Switch, contact

the nearest Johnson Controls®

representative.

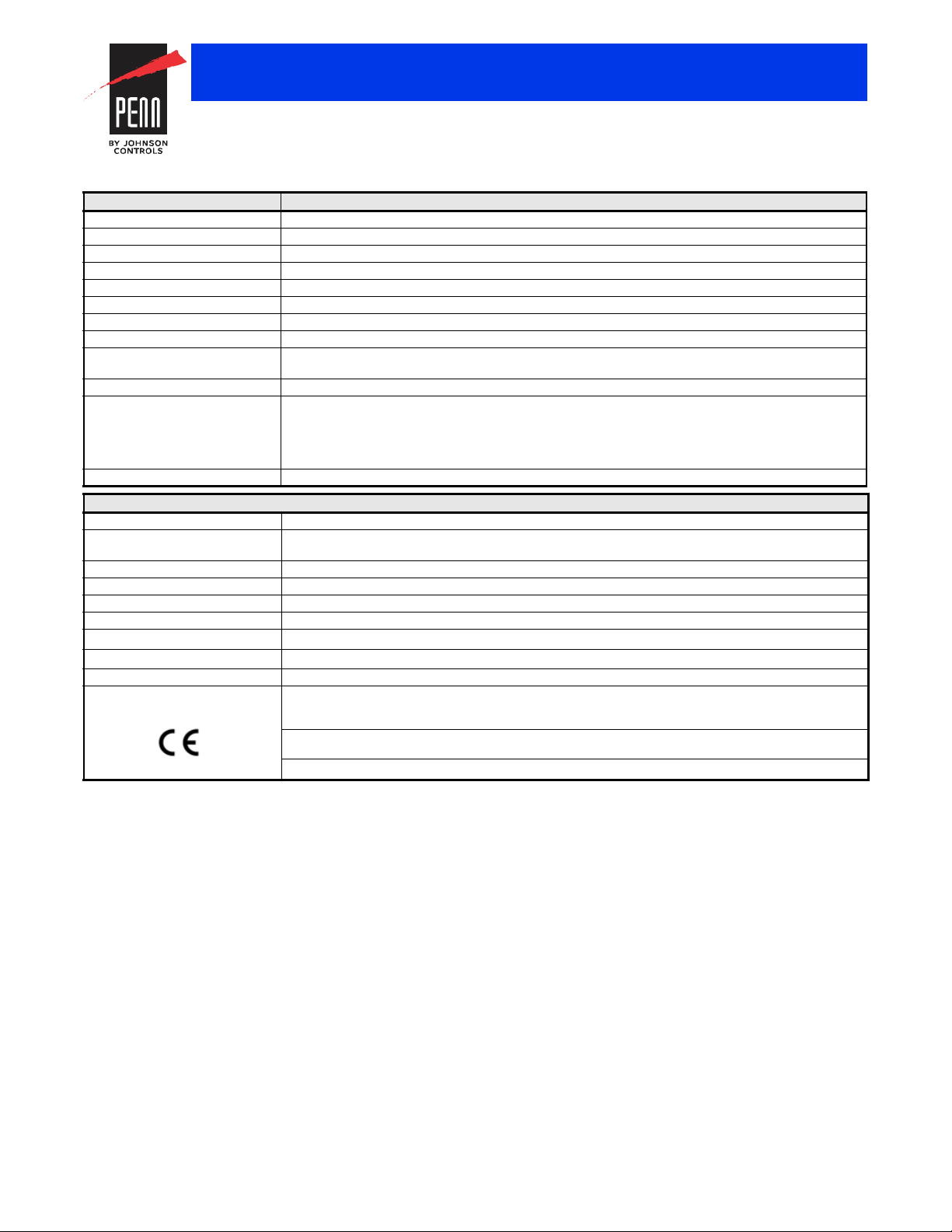

Selection Chart

F261 Series Standard Model Flow Switches

Product Code Number Description

F261KAH-V01C Standard model flow switch with Type 3R (NEMA) enclosure; 1 in., 2 in., 3 in., and 6 in. stainless steel paddles, lock-tooth washer,

F261MAH-V01C Standard model flow switch with Type 4 (NEMA) enclosure; 1 in., 2 in., 3 in., and 6 in. stainless steel paddles, lock-tooth washer,

F261MAL-V01C Standard model flow switch with Type 4 (NEMA) enclosure; 1 in., 2 in., 3 in., and 6 in. stainless steel paddles, lock-tooth washer,

F261 Series Low-Flow Model Flow Switches

Product Code Number Description

F261KEH-V01C Low-flow model flow switch with Type 3R (NEMA) enclosure; 1/2 in. x 1/2 in. External NPTF inlet and outlet

F261KFH-V01C Low-flow model flow switch with Type 3R (NEMA) enclosure; 3/4 in. x 3/4 in. External NPTF inl et and outlet

F261KFH-V02C Low-flow model flow switch with Type 3R (NEMA) enclosure; 3/4 in. x 3/4 in. External NPTF inl et and outlet

F261MEH-V01C Low-flow model flow switch with Type 4 (NEMA) enclosure; 1/2 in. x 1/2 in. External NPTF inlet and outlet

F261MFH-V01C Low-flow model flow switch with Type 4 (NEMA) enclosure; 3/4 in x 3/4 in. External NPTF inlet and outlet

Replacement Paddle Parts

Product Code Number Description

KIT21A-600 Stainless steel three-piece paddle (3 in., 2 in., and 1 in. segments)

KIT21A-601 Stainless steel 6 in. paddle

PLT52A-600R Stainless steel three-piece paddle (3 in., 2 in., and 1 in. segments) and Stainless steel 6 in. paddle

and stainless steel paddle screw supplied uninstalled

and stainless steel paddle screw supplied uninstalled

and stainless steel paddle supplied uninstalled.

Technical Specifications

F261xxH Series Standard Controls Electrical Ratings

Volts, 50/60 Hz UL60730/UL1059 EN60730

24 120 208 240 24 230

Horsepower –111––

Full Load Amperes – 161010 – 8

Locked Rotor Amperes – 966060 – 48

Resistive Amperes 16 16 10 10 16 16

Pilot Duty VA 125 720 720 720 77 720

The performance specifications are nominal and conform to acc

office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

eptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls

R–128

Page 2

Liquid Level and Flow Controls

F261 Series Fluid Flow Switches (Continued)

UL Co

nformity Declaration Information

Information Description

Purpose of Control F261 Fluid Flow Switch

Construction of Control Electronic independently mounted control

Number of Cycles 100,000 cycles

Method of Mounting Control Mounting to sensed media vessel/orientation

Type 1 or Type 2 Action Type 1.C (Microinterruption)

External Pollution Situation Pollution degree 4

Internal Pollution Situation Pollution degree 2

Rated Impulse Voltage 4,000 VAC

Ball Pressure Temperature Enclosure: 266°F (130°C)

Control Adjustment Instruction Field Wiring Rating Wire/Cord Temperature Ratings:

Vessel Pressure F261 Fluid Flow Switch: 290 psi (20 Bar)

Switch Single-Pole, Double-Throw (SPDT)

Enclosure UL: Type 3R or Type 4

Wiring Connections Three color-coded screw terminals and one ground terminal

Conduit Connection One 7/8 in. (22 mm) hole for 1/2 in. trade size (or PG16) conduit

Pipe Connector Standard: 1 in. 11-1/2 NPT Threads

Maximum Fluid Pressure 290 psi (20 bar)

Minimum Fluid Temperature

Maximum Fluid Temperature

Ambient Conditions -40 to 140°F (-40 to 60°C)

Compliance North America: cULus Listed; UL 60730, File E6688;

1. Ensure that the low liquid temperature combined with the low ambient temperature does not lea d to t he freezing the liquid inside the body (or bellows, where

appropriate). Please observe the liquid freezing point.

2. At higher ambient temperatures, the maximum allowed liquid temperature becomes lower. The temperature of the electrical switch inside should not exceed

158°F (70°C).

1

2

Switch Component: 252°F (122°C)

140°F (60°C) only permitted when ambient air and media are less than 113°F (45°C)

167°F (75°C) only permitted when ambient air and media are less than 140°F (60°C)

194°F (90°C) only permitted when ambient air is less than 140°F (60°C) and media is less than 167°F (75°C)

302°F (150°C) permitted when ambient air is less than 140°F (60°C) and media is less than 249°F (121°C)

F261 Series Fluid Flow Switches

CE: IP43 (IP23 with drain hole plug removed) or IP67

-20°F (-29°C)

250°F (121°C)

FCC Compliant to CFR47, Part 15, Subpart B, Class B

Industry Canada (IC) Compliant to Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls, Inc. declares that this product is in compliance with the essential requirement s and

other relevant provisions of the EMC Directive and the Low Voltage Directive.

Australia/New Zealand Mark: RCM Compliant

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls

office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R–129

Loading...

Loading...