Page 1

F240EA Pneumatic Liquid Flow Switch

Installation Instructions

Part No. 24-7664-3132, Rev. A

Issued October 15, 2015

Refer to the QuickLIT website for the most up-to-date version of this document.

Applications

IMPORTANT: Do not use F240EA Pneumatic

Liquid Flow Switches with fluids that are

incompatible with the wetted materials (forged

normal brass, free machining bronze, and Viton®)

and which are classed as a hazardous material. Use

in this condition may cause malfunction or improper

operation.

IMPORTANT: Do not use F240EA Pneumatic

Liquid Flow Switch where the fluid in the pipes drops

below the fluid’s freezing point, causing an internal

freeze-up.

IMPORTANT: Use thi s F240EA Pneumatic Liquid

Flow Switch only as an operating control. Where

failure or malfunction of the flow switch could lead to

personal injury or property damage to the controlled

equipment or other property , additional precautions

must be designed into the control system. Incorporate

and maintain other devices, such as supervisory or

alarm systems or safety or limit controls, intended to

warn of or protect against failure or malfunction of the

flow switch.

IMPORTANT: Utiliser ce F240EA Pneumatic Liquid

Flow Switch uniquement en tant que dispositif de

régulation. Lorsqu'une défaillance ou un

dysfonctionnement du flow switch risque de

provoquer des blessures ou d'endommager

l'équipement contrôlé ou un autre équipement, la

conception du système de contrôle doit intégrer des

dispositifs de protection supplémentaires. Veiller

dans ce cas à intégrer de façon permanente

d'autres dispositifs, tels que des systèmes de

supervision ou d'alarme, ou des dispositifs de

sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de

défaillance ou de dysfonctionnement du flow switch.

The F240EA switch uses a variety of paddle sizes to

respond to liquid flow rates in applications with pipe

sizes greater than 1-inch trade size. The paddle has

three segments. You can remove (or trim) the paddle

segments for pipe sizes under 3 inches. A 6 in. paddle

that can be trimmed for 4 in. and 5 in. pipe is available.

The F240EA Pneumatic Liquid Flow Switch acts as an

automatic operating control in air conditioning, heating

and cooling water systems and in processing work.

Typical applications include:

• Flow detection switch to start the refrigeration

compressor on a liquid chiller system when flow

has been established.

• Signal or alarm switch to indicate when the pump

on a condenser cooling water system shuts down.

• Proving the flow of water before an electric

immersion heater is turned on.

Installation

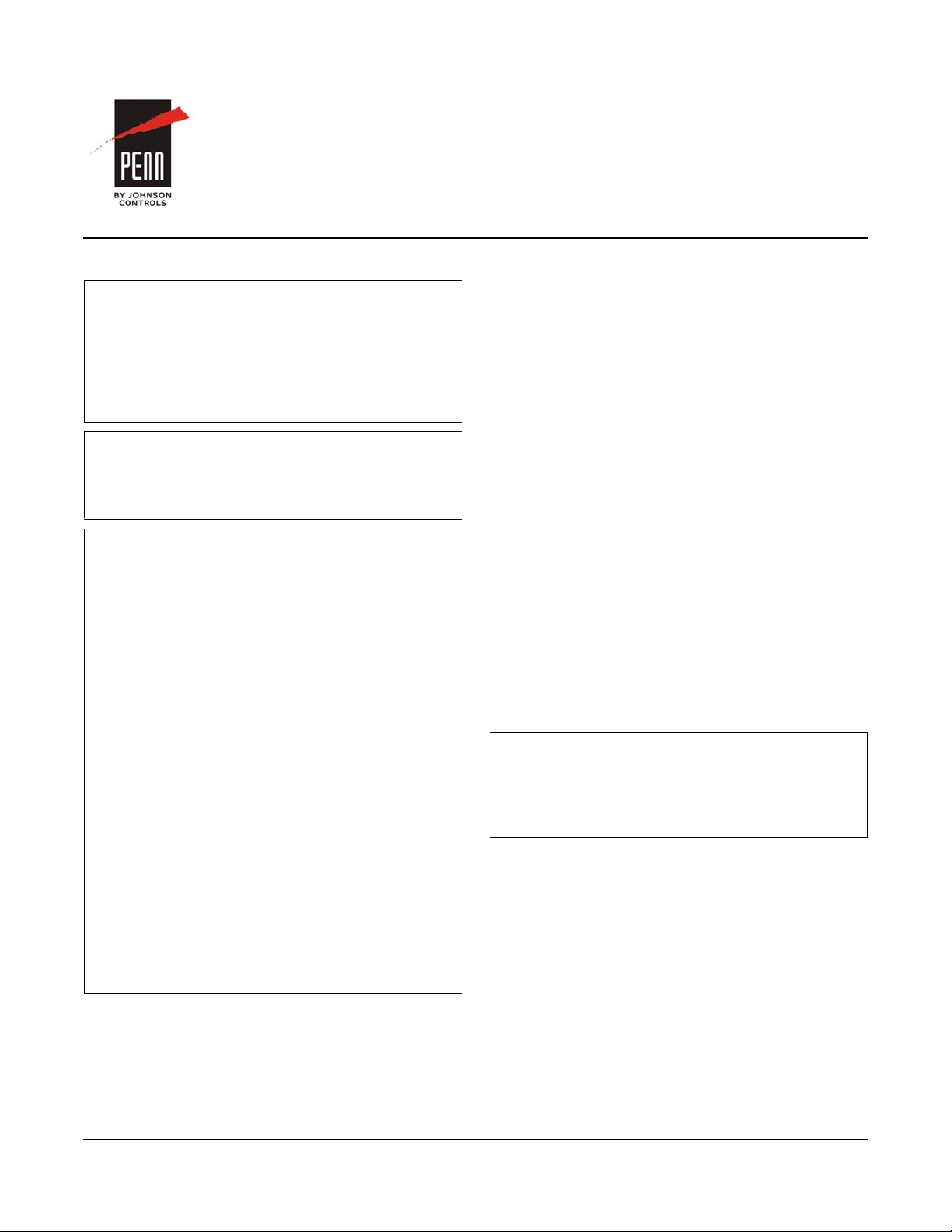

The F240EA Pneumatic Liquid Flow Switch is

packaged with 1 in., 2 in., and 3 in. stainless steel flow

paddles along with a paddle screw and lock washer.

See Table 2 for replacement parts.

IMPORTANT: The flow paddle must not touch the

pipe or any restrictions in the pipe. If the flow paddle

touches the pipe (or restrictions in the pipe), the

switch may not be able to properly detect changes in

fluid flow.

Adjust the flow paddles to the size of the pipe used.

Install the large flow paddle, if needed. Trim the flow

paddle at the arc corresponding to the pipe size. See

Figure 1, Figure 2, Figure 3, and Table 1.

The F240EA Pneumatic Liquid Flow Switch detects the

increase or decrease of liquid flow in a pipe. The

F240EA switch responds to liquid flow in a pipe that

carries water, ethylene glycol, or other nonhazardous

fluids.

F240EA Pneumatic Liquid Flow Switch Installation Instructions

1

Page 2

Figure 1: Installing the Flow Paddles

FIG:in stl_fl w_pddl

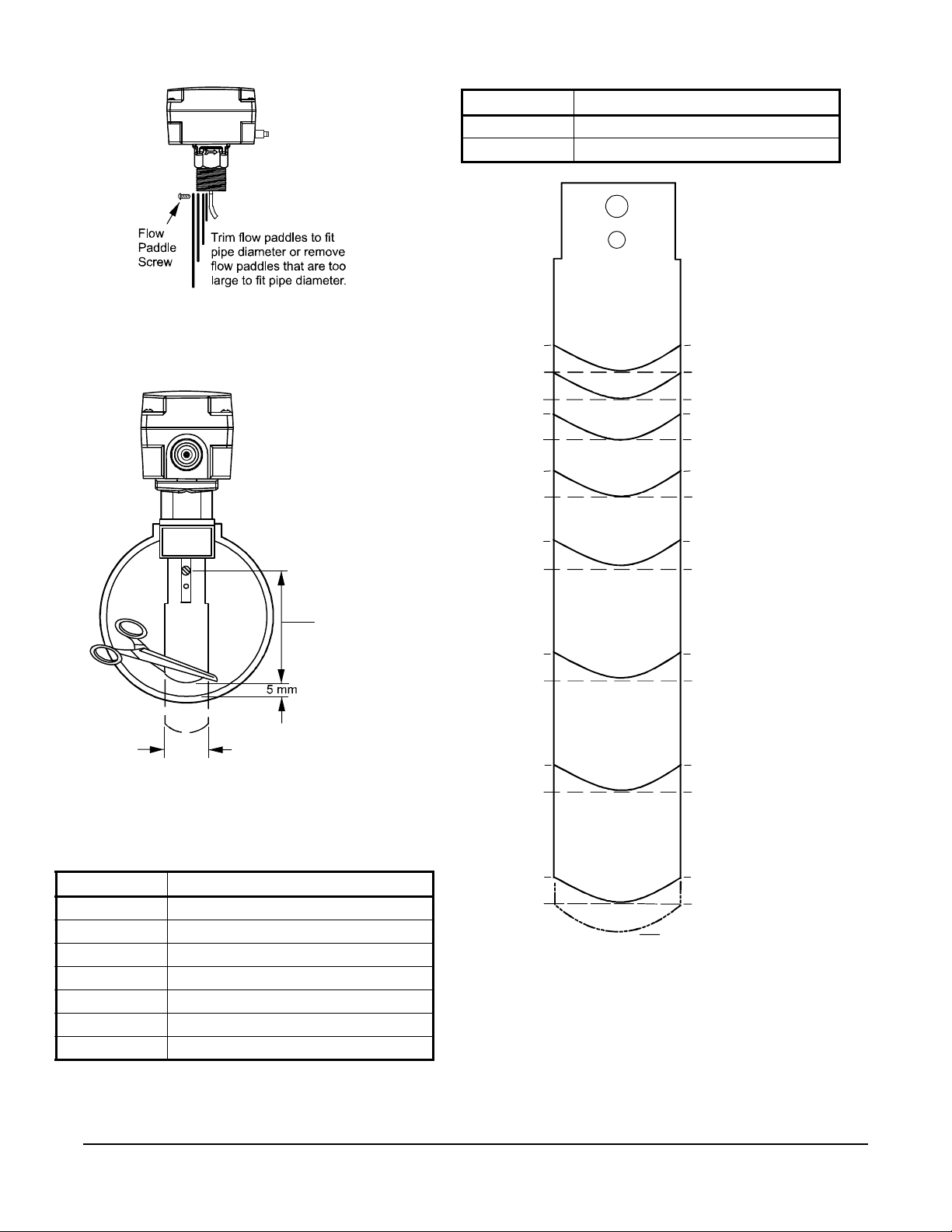

Figure 2: Trimming the Flow Paddles

2 in. [

3 in. [

4 in. [

5 in. [

6 in.

37 mm]

43 mm]

54 mm]

67 mm]

83 mm]

103 mm]

134 mm]

b

1 in. padd le

Figure 3: Trimming Diagram for the Large Flow

Paddle

2 in. pipe

1 in. pipe

Original Length

FIG:pdd l_tmpl t

Note: Allow a minimum clearance of 3/16 in. (5 mm)

between the end of the flow paddle and the pipe wall.

Table 1: Trimming the Flow Paddles (Part 2 of 2)

Paddle Size Use or Trim This Paddle to Fit

5 in. 6 in.

6 in. 6 in.

1-1/2 in. pipe

FIG:trm_f lw_pddl_ F240EA

1 in. [

1-1/4 in. [

1-1/2 in. [

2-1/2 in. [

b = 25 mm fo r th e

b = 29 mm fo r th e paddle 2, 3, or 6 in .

29 mm]

[162 mm]

Table 1: Trimming the Flow Paddles (Part 1 of 2)

Paddle Size Use or Trim This Paddle to Fit

1 in. 1 in.

1-1/4 in. 2 in.

1-1/2 in. 2 in.

2 in. 2 in.

2-1/2 in. 3 in.

3 in. 3 in.

4 in. 6 in.

2-1/2 in. pipe

3 in. pipe

4 in. pipe

5 in. pipe

6 in. pipe

F240EA Pneumatic Liquid Flow Switch Installation Instructions

2

Page 3

Dimensions

Figure 4: Dimensions for F240EA Standard Flow Switch, in. [mm]

FIG:dmnsns_F240EA

[54]

[66]

1-3/8

[35]

2-3/4

[70]

1/2 [13]

Typical

Thread

Engagement

30mm Hex

3-1/2

[89]

4-1/2

[114]

5-11/16

[144]

1-1/8

[28]

4

[102]

2

[51]

4-9/16

[116]

Barbed connector for

1/4 [6] O.D. x

3/16 [4] I.D.

tubing

1-11 1/2 NPT

3/4

[18]

2-1/8

2-9/16

Accessories

Table 2: Replacement Paddle Parts

Product Code

Number

KIT21A-600 Stainless steel 3-piece paddle (3 in., 2 in., and 1 in. segments)

KIT21A-601 Stainless steel 6 in. paddle

KIT21A-602 Stainless steel 3-piece paddle (3 in., 2 in., and 1 in. segments) and Stainless steel 6 in. paddle

Description

F240EA Pneumatic Liquid Flow Switch Installation Instructions

3

Page 4

Mounting

Figure 5: Use Only the Wrench Flats Provided

Figure 6: Flow Direction for Vertical Mounting

Figure 7: Required Piping Distance

FLOW FLOW

FLOW

Dimension must be at le ast

A

Tee or Welded

Half-Coupling

FIG:ppng_dst

IMPORTANT: To avoid damaging the switch, do

not tighten the switch to the tee by grasping the

switch enclosure. Use only the wrench flats

provided.

Location Considerations

FIG:wrnch_flts

FIG: Flw_di r_F240EA

IMPORTANT: Do not use in a vertical pipeline with

a downward flow (Figure 6).

Mount the F240EA Pneumatic Liquid Flow Switch

using the following guidelines:

• Install the switch so that the enclosure and interior

are accessible.

• Mount the switch so that the flow of the fluid is in

the direction of the arrow on the enclosure.

• Use a pipe union on each side of the flow switch to

allow for easy removal or replacement.

• Do not allow the pipe to extend too far into the flow

switch casing.

• Use pipe thread sealer or Teflon® tape on the male

threads only.

For standard 1 in. x 1 in. pipe installation, mount the

F240EA Pneumatic Liquid Flow Switch in a standard 1

in. x 1 in. x 1 in. tee. For larger sizes of pipe, use a

reducing tee to keep the flow switch close to the pipe

and provide adequate paddle length in the flow stream.

Example: Use a 2 in. x 2 in. x 1 in. tee for a 2 in.

pipe. If a standard 2 in. x 2 in. x 2 in. tee is used,

install a face or hex bushing in the top openin g to

reduce the top opening to 1 in.

Mount the F240EA Pneumatic Liquid Flow Switch in a

horizontal pipeline or a vertical pipeline with upward

fluid flow. When mounted in a vertical pipe with an

upward flow, the switch trips at a slightly higher flow

than shown in Table 3 and Table 4, due to the effect of

gravity on the switch mechanism.

Mount the F240EA Pneumatic Liquid Flow Switch in a

section of pipe where there is a straight run of at least

5 pipe diameters from the nearest elbow, valve, or

other pipe restriction (Figure 7).

nc_F240EA

five pipe diameters from the near est

elbow, valve, or other pipe r estriction.

When mounting the flow switch on horizontal pipe,

mount the flow switch within 60 degrees of vertical. See

Figure 8.

F240EA Pneumatic Liquid Flow Switch Installation Instructions

Note: Do not subject the flow switches to water

hammer. Use a suitable water hammer arrester if a

fast-closing valve is located downstream of the switch.

See Figure 9.

4

Page 5

!

Figure 8: Angle Allowed

120° up

60°

from

vertical

60°

from

FIG:mtg_ang l_F240EA

Figure 9: Water Hammer Arrester Location

FLOW

Hammer

Arrester

!

Figure 10: Flow Rate Adjustment

(Screw)

Flow Rat e

Higher

Less water flow

required to

activate switchthe

required to

water

-

Water

vertical

FLOW

CAUTION: Risk of Property Damage.

Do not attempt to change sealed

settings. Attempted adjustment may

damage the control or cause loss of

calibration or other property damage.

MISE EN GARDE : Risque de dégâts

matériels.

Ne pas essayer de modifier la position

des éléments de réglage bloqués. Toute

tentative de réglage risque

d'endommager le dispositif de contrôle

ou de provoquer la perte des valeurs

d'étalonnage ou d'autres dégâts

matériels.

Lower

Flow Rate

More flow

activate the switch

Adjustment Bushing

+

FIG:wat_ham_a rr_F240EA

FIG:ad jst_fl w_rte _F240EA

Setup and Adjustments

CAUTION: Risk of Property Damage.

Do not set the switch lower than the

factory setting. The switch is factory set

at approximately the minimum flow rate.

A lower setting may result in the switch

failing to return to a no-flow position

which may result in damage to the

controlled equipment or other property.

MISE EN GARDE : Risque de dégâts

matériels.

Ne pas régler le commutateur sur une

valeur inférieure au paramètre d'usine.

Le commutateur est réglé en usine sur

une valeur correspondant environ au

débit minimum. Un réglage sur une

valeur inférieure risque d'empêcher le

commutateur de revenir sur une position

« aucun-débit », ce qui risque

d'endommager l'équipement contrôlé ou

de provoquer d'autres dégâts matériels.

To adjust the setting of the flow switch:

1. Remove the enclosure cover.

2. Adjust the control’s flow rate (Figure 10):

• Turn the adjustment screw clockwise to raise

the flow rate required to activate the switch.

• Turn the adjustment screw counterclockwise

to lower the flow rate required to activate the

switch

Note: Do not lower the flow rate required to

activate the switch, unless the flow rate required to

activate the switch was raised from the factory-set

flow rate.

3. Replace the enclosure cover and tighten the cover

screws with 12 in·lb of torque.

To verify that the flow rate is set above the factory

minimum, depress the main lever (see Figure 11)

multiple times:

• If the lever clicks every time when returning to the

original position, then the control’s flow rate may be

set at or above the factory-set minimum value.

F240EA Pneumatic Liquid Flow Switch Installation Instructions

5

Page 6

• If the lever fails to click every time when returning

Figure 11: Minimum Adjustment

Depress Main LeverHere

AdjustmentBushing(Screw)

to the original position, then the control’s flow rate

is set below the factory-set minimum value.

Turn the adjustment scr ew clockwise to raise the

flow rate required to activate the switch. See

Figure 10.

Table 3 and Table 4 show the range of flow settings

typically obtainable. These values represent inst allation

in a horizontal line with at least 10 pipe diameters of

straight pipe before and after a typical tee. The typical

tee has a 1 in. tapping (without bushing) facing up. The

F240EA switch is threaded into this tapping. Fluid is

water at 40 psi (276 kPa) pressure.

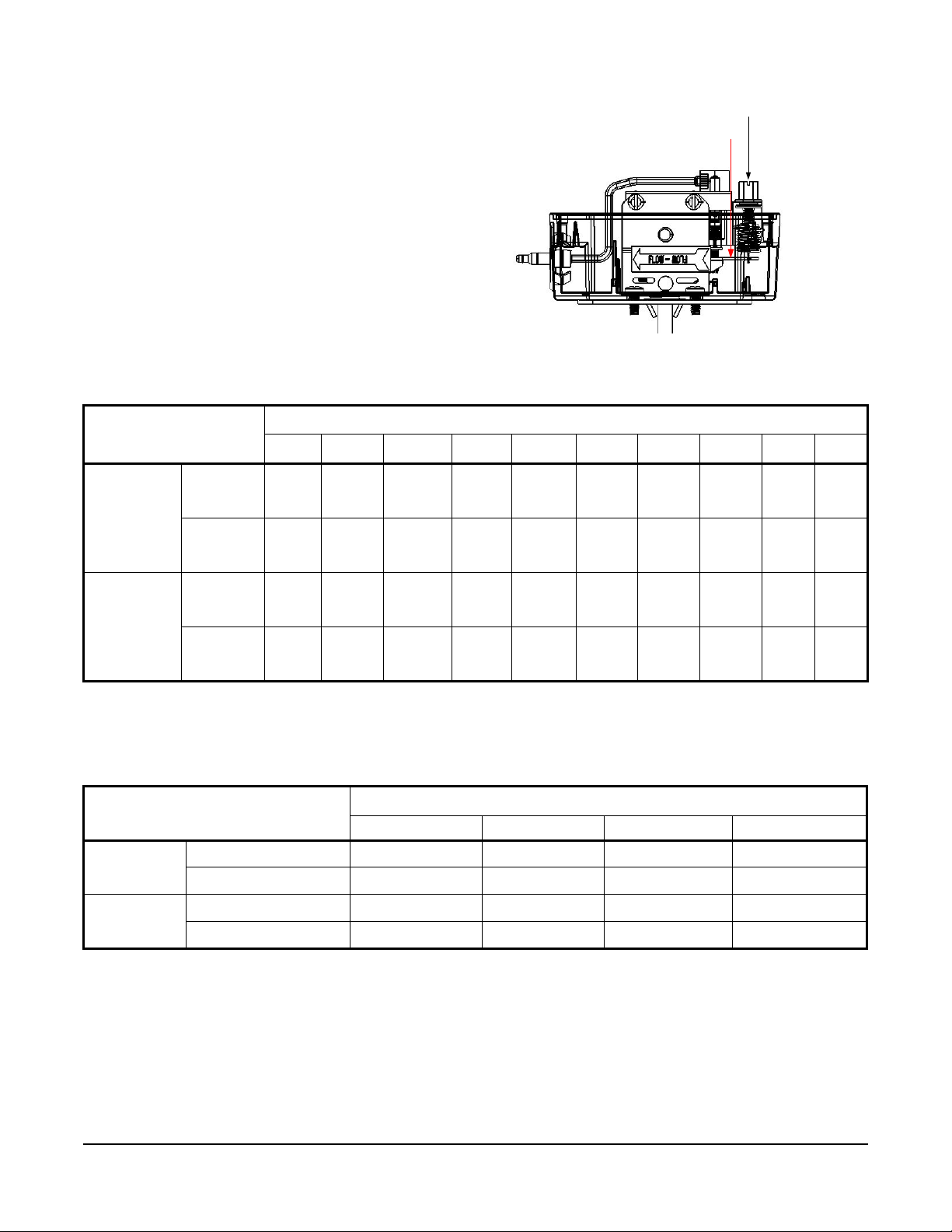

Table 3: Flow Rates for 1 in. to 3 in. Paddles

3

/hr) Required to Activate Switch for Pipe Size (in.)

1

1-1/2

7.50

(1.70)

5.00

(1.14)

19.2

(4.36)

18.0

(4.01)

Minimum

Adjustment

Maximum

Adjustment

Flow

Increase

(Close)

Flow

Decrease

(Open)

Flow

Increase

(Close)

Flow

Decrease

(Open)

1

4.20

(0.95)

2.50

(0.57)

8.80

(2.00)

8.50

(1.93)

GPM (m

1-1/4

5.80

(1.32)

3.70

(0.84)

13.3

(3.02)

12.5

(2.84)

1

2

13.7

(3.11)

9.50

(2.16)

29.0

(6.59)

27.0

(6.13)

2-1/2

18.0

(4.09)

12.5

(2.84)

34.5

(7.84)

32.0

(7.27)

2

3

27.5

(6.24)

19.0

(4.32)

53.0

(12.0)

50.0

(11.4)

3

4

65.0

(14.8)

50.0

(11.4)

128

(29.1)

122

(27.7)

3

5

125

(28.4)

101

(22.9)

245

(55.6)

235

(53.4)

3

6

190

(43.2)

158

(35.9)

375

(85.2)

360

(81.8)

3

8

375

(85.2)

320

(72.7)

760

(173)

730

(166)

1. Values for the 2 in. paddle trimmed to fit the pipe.

2. Values for the 3 in. paddle trimmed to fit the pipe.

3. Values calculated for factory-installed set of 1 in., 2 in., and 3 in. paddles.

Ta ble 4: Flow Rates for 4 in. to 8 in. Pipe Sizes with Larger Paddle

GPM (m

3

/hr) Required to Activate Switch for Pipe Size (in.)

456 8

Minimum

Adjustment

Maximum

Adjustment

Flow Increase (Close)

Flow Decrease (Open)

Flow Increase (Close)

Flow Decrease (Open)

37.0 (8.4)

27.0 (6.1)

81.0 (13.4)

76.0 (17.3)

1

1

1

1

57.0 (12.9)

(41.0 (9.3)

118.0 (26.8)

1 11.0 (25.2)

1. These GPM (m3/hr) values are for the switch with a 6 in. paddle. For 4 in. and 5 in. size pipe, trim the paddle to fit the pipe.

1

1

1

1

74.0 (16.8)

54.0 (12.3)

144.0 (32.7)

135.0 (30.7)

1

1

1

1

205.0 (46.6)

170.0 (38.6)

415.0 (94.2)

400.0 (90.8)

1

1

1

F240EA Pneumatic Liquid Flow Switch Installation Instructions

6

Page 7

Operation

Figure 12: Typical Installation of the F240EA Pneumatic Liquid Flow Switch

BLUE (N.C.)

Remote Panel

Wire to

Circuit

Wire to

Alarm Circuit

Restrictor

20 psig (138 kPa)

Water Chiller

A

A

Chilled

Water

Supply

Chilled

Water

Dimensi on A must be at least

5 pipe diameters from the near est

elbow, valve, or other pi pe restriction.

Flow Swit ch

Tee or welded

half coup ling

FIG:F240EA_App

The flow switch responds to pressure exerted on the

paddle by the flowing liquid. The pneumatic control port

opens on flow decrease and closes on flow increase.

A range adjustment screw adjusts the rate of the flow

required to activate the switch. For flow rates, see

Table 3 and Table 4.

Supply Air

See Figure 12 for a typical installation of an F240EA

Pneumatic Liquid Flow Switch in an explosion-proof

application (or an application where it is more practical

to run a single pneumatic line instead of electrical

wiring).

P10 Pres s ur e Contr ol

Return

Checkout Procedure

Before you leave the installation, observe at least three

complete operating cycles to be sure that all

components are functioning correctly.

RED (COM)

YELLO W ( N.O.)

Repair Information

Do not make field repairs, except for replacement of

the flow paddle. For a replacement F240EA pn eumatic

fluid flow switch or paddle kit, contact the nearest

Chiller Start

Johnson Controls/PENN® distributor. For more

information, contact Johnson Controls/PENN

application engineering at 1-800-275-5676.

Ordering Information

Table 5: F240EA Pneumatic Liquid Flow Switch

Product Code Number Description

F240EA-01C Pneumatic liquid flow switch with Type 3R (NEMA) enclosure, stainless steel 3-piece paddle

(3 in., 2 in., and 1 in. segments)

Table 6: Replacement Paddle Parts

Product Code Number Description

KIT21A-600 Stainless steel 3-piece paddle (3 in., 2 in., and 1 in. segments)

KIT21A-601 Stainless steel 6 in. paddle

KIT21A-602 Stainless steel 3-piece paddle (3 in., 2 in., and 1 in. segments) and Stainless steel 6 in. paddle

F240EA Pneumatic Liquid Flow Switch Installation Instructions

7

Page 8

Johnson Controls/PENN® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

in the United States of America and/or other countries. All other trademarks used herein are the

property of their respective owners. © Copyright 2015 by Johnson Controls, Inc. All rights reserved.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Troubleshooting

Table 7: Troubleshooting

Symptom Solution

Water (condensate) appears within the

enclosure.

Fluid from the tank leaks into the enclosure

due to a rod seal failure.

Switch does not activate due to debris in

switch mechanism.

Switch action is reversed. Ensure pneumatic connections are made properly.

Switch does not function. Check the pneumatic connections.

Switch fails to return to the no-flow position. The switch may be set lower than the factory setting. Increase the setting.

Switch does not activate on flow increase. Check for a cracked or broken paddle. Replace the paddle, if necessary.

If the control has a Type 3R enclosure, inspect the grommet in the

field-installed cable gland or conduit fitting, and replace the grommet if it is

defective.

Replace the flow switch.

Clear any debris from within the switch mechanism. Test the operation of

the switch several times for proper operation.

On vertical pipes, ensure that the direction of flow is up. The arrow on the

switch enclosure must point in the direction of the flow.

Technical Specifications

F240EA Pneumatic Liquid Flow Switch

Switch Pneumatic

Ambient Operating Conditions 32 to 140°F (0 to 60°C)

1

Maximum Fluid Temperature

Maximum Fluid Pressure 290 psi (2,000 kPa)

Enclosure Type 3R (NEMA)/IP43

Paddle Stainless steel

Pipe Connector 1 in. 11-1/2 NPT Threads

Pneumatic Switch Action Closes on increasing flow, opens on decreasing flow

Tubing Connector Barb fitting for 1/4 in. O.D. plastic tubing

Shipping Weight 1.7 lb (0.8 kg)

250°F (121°C)

1. Ensure that the low liquid temperature combined with the low ambient temperature does not lead to freezing the liquid

inside the body (or bellows, where appropriate). Please observe the liquid freezing point.

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult Johnson Controls/PENN Refrigeration Application Engineering at 1-800-275-5676. Johnson Controls, Inc. shall not be

liable for damages resulting from misapplication or misuse of its products.

F240EA Pneumatic Liquid Flow Switch Installation Instructions

Published in U.S.A. www.johnsoncontrols.com

8

Loading...

Loading...