Page 1

Power and Energy Meters

Code No. LIT-1900845

Issued September 2, 2014

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters

EM-1000 Series Meter Description

The EM-1000 Series monitor is an affordable multifunction power

meter designed to be used in electrical substations, panel boards

and as a power meter for OEM equipment. The unit provides

multifunction measurement of all electrical parameters. It is easy to

use and install and is perfect both for new metering applications and

as a simple replacement of existing analog meters.

The EM-1000 Series meter is designed with advanced measurement

capabilities, allowing it to achieve high performance accuracy. The

EM-1000 Series meter is specified as a 0.5% class energy meter,

meeting ANSI C12.20 (0.5%) and IEC 62053-22 (0.5%) accuracy

classes.

The EM-1000 Series meter supplies multifunction measurement

including voltage, current, power, frequency, energy, etc. For serial

communication, the EM-1000 Series meter has a combination

RS485/Pulse Com port.

The EM-1000 Series meter has an LED with 3 .56”, bright red lines

of display for easy readability.It features an anti-dither algorithm to

improve reading stability, benefitting operators. The unit utilizes high

speed DSP technology with high resolution A/D conversion to

provide stable and reliable measurements.

EM-1000 Series Meter Features

• 0.5% Class Accuracy

• Measurements Including Voltage, Current, Power, Frequency,

Energy, Etc.

• Standard RS485 with Modbus

• Large Bright Red LED Display

• % of Load Bar for Analog Meter Perception

• Fits Both ANSI and DIN Cut-outs

• Great For Retrofit and New Applications

• Uses Minimal Panel Space and Depth

• Easy-to-Use Faceplate Programming

• Phasor Diagram Showing Wiring Status

• Display Auto-Scroll Feature

• Color Coordinated Voltage and Current Inputs

®

Protocol*

Applications

• Commercial Metering

• Industrial Metering

• Power Generation

• Campus Metering

• Sub-metering

• Indication Meter Replacement

Available Models

The EM-1000 Series meter can be ordered in any of the following

models:

• B – Volts and Amps Meter – Default model

• C – Volts, Amps, kW, kVAR, PF, kVA, Freq

• D – Volts, Amps, kW, kVAR, PF, kVA, Freq, kWh, kVAh, kVARh

Advanced Communication Capability

Back Mounted Communication Port with KYZ Pulse

• RS485 – This port allows RS485 communication using Modbus

Protocol. Baud rates are from 9,600 to 57,600.

• KYZ Pulse – In addition to the RS485, this port includes a KYZ pulse

mapped to positive energy. This is a fixed energy pulse.

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

Rugged and Safe Voltage and Current Inputs

The EM-1000 Series meter is ruggedly designed for harsh electrical

applications in both high voltage and low voltage power systems. This

is especially important in Power Generation, Utility Substation and

Critical User applications. The structural and electrical design of this

meter was developed based on the recommendations and approval of

many of our utility customers.

High Isolation Universal Voltage Inputs

Voltage inputs allow measurement of up to 416 Volts Line to Neutral

and 721 Volts Line to Line. This insures proper meter safety when

wiring directly to high voltage systems. One unit will perform to

specification on 69 Volt, 120 Volt, 230 Volt, 277 Volt and 347 Volt power

systems.

Short Circuit Safe Current Inputs

Current inputs use a unique dual input method:

• Method One – CT Lead Pass Through. The CT Lead passes directly

through the meter without any physical termination on the meter. This

insures that the meter cannot be a point of failure on the CT circuit.

This is preferable to utility users when sharing relay class CTs. No

Burden is added to the secondary CT circuit.

• Method Two – Current “Gills.” This unit additionally provides ultra rugged termination pass-through bars, allowing the CT leads to be

terminated on the meter. The EM-1000 Series meter’s stud-based

design insures that your CTs will not open in a fault condition.

ANSI and DIN Installation

The unit mounts directly in an ANSI C39.1 (4" round form) or an IEC 92

mm DIN square form. This is perfect for new installations and for

existing panels. In new installations, simply use DIN or ANSI punches.

For existing panels, pull out old analog meters and replace them with

the EM-1000 Series meter. The meter uses standard voltage and

current inputs so that CT and PT wiring does not need to be replaced.

• Perfect for switchgear panel direct retrofit

• Uses minimal panel space

• Mounts in only 4.25" panel depth

®

* Modbus® is a registered trademark of Schneider Electric, licensed to the

Modbus Organization, Inc.

EM-1000 Series Meter

www.johnsoncontrols.com

1

Page 2

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

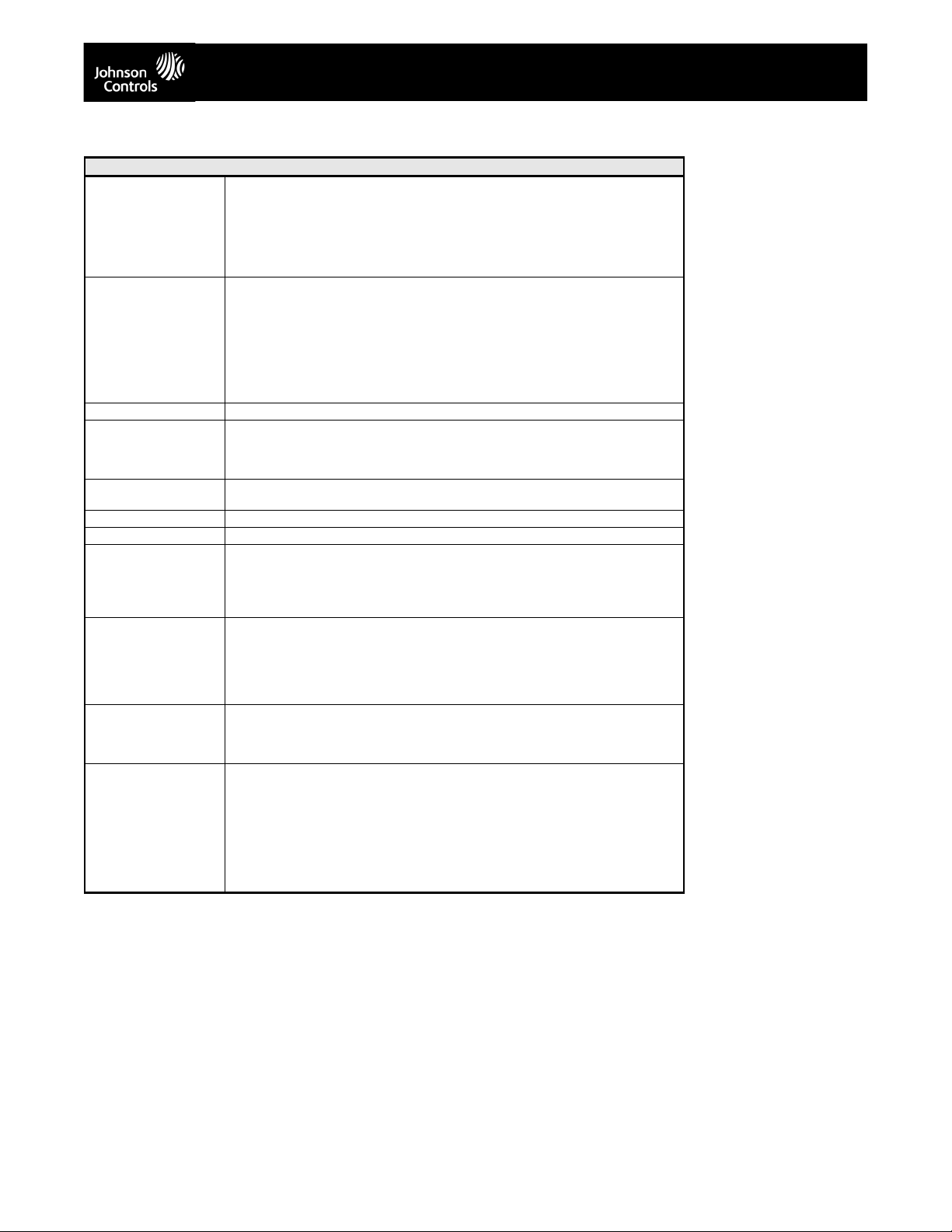

Technical Specifications

EM-1000 Series Meter

Voltage Inputs 20-416 Volts Line to Neutral, 20-721 Volts Line to Line

Current Inputs Class 10: (0 to 10)A, 5 Amp Nominal, 10 Amp Maximum

Isolation All Inputs and Outputs are Galvanically Isolated to 2500 Volts AC

Environmental Rating Storage: (-20 to +70)° C

Sensing Method RMS

Update Rate All Parameters up to Every 60 Cycles

Power Supply (90 to 265) Volts AC

Communication Format RS485 Port (Through Backplate)

KYZ Pulse Typ e F or m A

Dimensions and Shipping Weight: 2 lbs/0.907 kg

Compliance IEC62053-22 (0.5% Accuracy)

Universal Voltage Input

Input Withstand Capability – Meets IEEE C37.90.1 (Surge Withstand Capability)

Programmable Voltage Range to Any PT Ratio

Supports: 3 Element WYE, 2.5 Element WYE, 2 Element Delta, 4 Wire Delta Systems

Burden: 0.014VA/Phase at 120 Volts

Input Wire Gauge Max (AWG 12 / 2.5mm2)

Fault Current Withstand (For 23° C, 3 Phase Balanced WYE or Delta load): 100 Amps for 10

Seconds, 300 Amps for 3 Seconds, 500 Amps for 1 Second

Programmable Current to any CT Ratio

Burden 0.005VA Per Phase Max at 11 Amps

Pickup Current 0.1% of Nominal

Pass Through Wire Gauge Dimension: 0.177" / 4.5mm

Continuous Current Withstand: 20 Amps for Screw Terminated or Pass Through Current

Connections

Operating: (-20 to +70)° C

Humidity: to 95% RH Non-Condensing

Faceplate Rating: NEMA12 (Water Resistant)

Sampling at 400+ Samples per Cycle on All Channels Measured Readings Simultaneously

Com Port Baud Rate: (9,600 to 57,600)

Com Port Address: 0-247

8 Bit, No Parity

RTU, ASCII

Modbus

On Resistance: 23-35 Ohm

Peak Voltage: 350 VDC

Continuous Load Current: 120mA

Peak Load Current: 350mA (10ms)

Off State Leakage Current @ 350VDC: 1mA

Basic Unit: (H4.85 x W4.85 x L4.25) in/(H12.32 x W12.32 x D10.54) cm

Mounts in Either 92mm Square DIN or ANSI C39.1 4" Round Cut-outs

Shipping Container Dimensions: 6" Cube

ANSI C12.20 (0.5% Accuracy)

ANSI (IEEE) C37.90.1 Surge Withstand

ANSI C62.41 (Burst)

EN61000-6-2 - Immunity for Industrial Environments: 2005

EN61000-6-4 - Emission Standards for Industrial Environments: 2007

EN61326-1 - EMC Requirements: 2006

UL File #E363785

UL Spec: 61010-1

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

2

Page 3

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

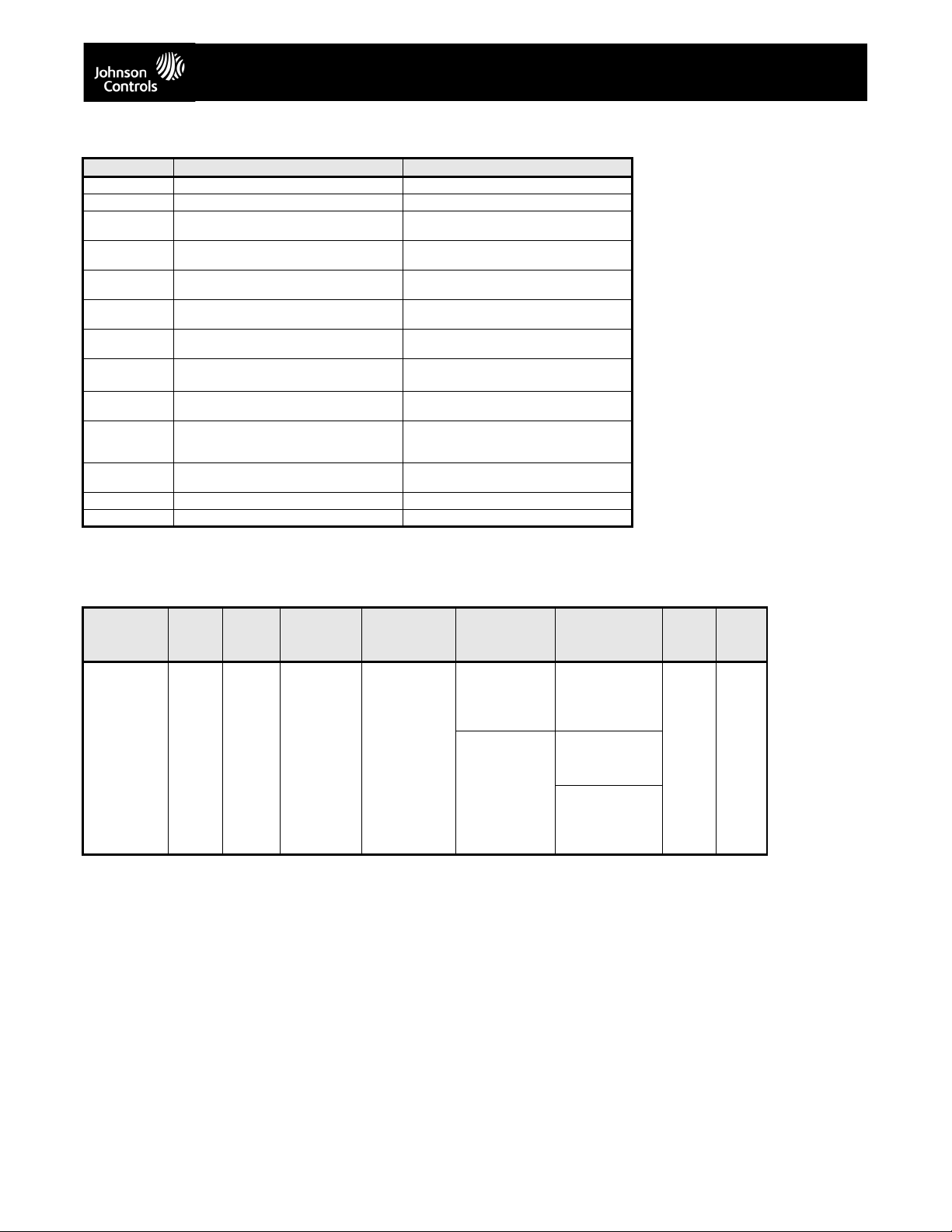

EM-1000 Series Meter Accuracy - For 23o C, 3 Phase Balanced Wye or Delta Load

Parameter Accuracy Accuracy Input Range

Voltage L-N [V] 0.2% of reading

Voltage L-L [V] 0.4% of reading (120 to 600)V

Current Phase

[A]

Current Neutral

(calculated) [A]

Active Power

Tot al [ W]

Active Energy

Tot al [ Wh ]

Reactive Power

Total [VAR]

Reactive Energy

Total [VARh

Apparent Power

Tot al [ VA]

Apparent

Energy Total

[VAh]

Power Factor 1.0% of reading

Frequency +/- 0.01Hz (45 to 65)Hz

Load Bar +/- 1 segment

0.2% of reading

2.0% of Full Scale

0.5% of reading

0.5% of reading

1.0% of reading

1.0% of reading

]

1.0% of reading

1.0% of reading

2

1

1

1,2

1,2

1,2

1,2

1,2

1,2

1,2

1

(69 to 480)V

(0.15 to 5)A

(0.15 to 5)A @ (45 to 65)Hz

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0 to 0.8)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0 to 0.8)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.005 to 6)A

1

For 2.5 element programmed units,

degrade accuracy by an additional 0.5%

of reading.

2

For unbalanced voltage inputs where at

least one crosses the 150V auto-scale

threshold (for example, 120V/120V/208V

system), degrade accuracy by additional

0.4%.

The EM-1000 Series meter’s accuracy

meets the IEC62053-22 Accuracy

Standards for 0.5% Class meters.

EM-1000 Series Meter Ordering Chart

Product-

S e r i e s

EM-1

EM-1000

Series Meter

Network

Protocol

4

Modbus

485

Freq. -Power

Supply

60

60 Hz

System

-0

90-265

VAC

Current Class -Mounting V-SwitchTM

Pack

0

5 Amp

Secondary

-A

ANSI Mounting BDefault V-Switch

Volts/

Amps

-D

DIN Mounting

C

above with

Power and Freq

D

above

with DNP 3.0 and

Energy Counters

0 0

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

3

Page 4

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

EM-2000 Series Meter Description

The EM-2000 Series monitor is a revenue grade power meter with

native BACnet/IP protocol. This meter is designed to integrate

seamlessly into existing and new building management systems

using the popular BACnet

data on voltage, current, power and energy usage throughout a

facility.

The EM-2000 Series meter’s metrology is industry recognized as

superior, providing revenue testable 0.2% Energy accuracy with

compliance to modern ANSI and IEC standards (ANSI C12.20

(0.2%) and IEC 62053-22 (0.2%) accuracy classes). The unit utilizes

advanced DSP technology, high sampling rates and 24-bit analog to

digital conversion to measure and analyze power accurately and

reliably.

The EM-2000 Series meter was designed to be the perfect device for

“Green” initiatives, LEED certified projects, smart buildings and all

kinds of smart energy projects. It has embedded RJ45 10/100BaseT

Ethernet communication that supplies an embedded Web server,

that lets you view energy usage through any standard browser. By

letting you track energy use and power quality from wherever you

are, the meter gives you the information you need to accurately

identify cost-saving measures and respond to power quality

problems when they arise.

EM-2000 Series Meter Features

• Multifunction Measurements of AC Voltage, Current, Frequency,

Power and Energy

• Industry Recognized Superior 0.2% Energy Class Accuracy

• BACnet/IP 100BaseT Ethernet Protocol

• Highly Reliable Industrial Rated Design

• Utility Block and Rolling Average Demand

• Adjustable Demand Profiles

• Max and Min Available on Most Other Parameters

• Voltage Provides Instantaneous Max and Min for Surge and Sag

Limits

Applications

• LEED Projects

• Smart Buildings

• Commercial Energy Management

• HVAC Efficiency Monitoring

• Building Management Systems

EM-2000 Series Meter’s BACnet/IP Through the

Web

The EM-2000 Series meter’s BACnet/IP comes standard with a Web

interface. Use the BACnet/IP

BACnet/IP

with any standard Web browser. You do not need to be on-site - you

can check on your buildings from anywhere in the world! There is

also a Modbus

Modbus

configuration and track energy usage through the Internet

TCP Socket that can be used to simultaneously poll

TCP through the same device.

Traceable Watt-Hour Test Pulse for Accuracy

Verification

The EM-2000 Series meter is a traceable revenue meter. It contains

a utility grade test pulse allowing power providers to verify and

confirm that the meter is performing to its rated accuracy. This is an

essential feature required of all billing grade meters.

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

®

protocol. The unit allows users to gather

Interface to remotely set up the

EM-2000 Series Meter

Rugged and Safe Voltage and Current Inputs

The EM-2000 Series meter is ruggedly designed for harsh electrical

applications in both high voltage and low voltage power systems. This

is especially important in Power Generation, Utility Substation and

Critical User applications. The structural and electrical design of this

meter was developed based on the recommendations and approval of

many of our utility customers.

High Isolation Universal Voltage Inputs

Voltage inputs allow measurement of up to 416 Volts Line to Neutral

and 721 Volts Line to Line. This insures proper meter safety when

wiring directly to high voltage systems. One unit will perform to

specification on 69 Volt, 120 Volt, 230 Volt, 277 Volt and 347 Volt power

systems.

Short Circuit Safe Current Inputs

Current inputs use a unique dual input method:

• Method One – CT Lead Pass Through. The CT Lead passes directly

through the meter without any physical termination on the meter. This

insures that the meter cannot be a point of failure on the CT circuit.

This is preferable to utility users when sharing relay class CTs. No

Burden is added to the secondary CT circuit.

• Method Two – Current “Gills.” This unit additionally provides ultra rugged termination pass-through bars, allowing the CT leads to be

terminated on the meter. The EM-2000 Series meter’s stud-based

design insures that your CTs will not open in a fault condition.

IrDA Port

The EM-2000 Series meter has an IrDA port on its faceplate, for remote

interrogation by an IrDA-equipped laptop PC.

ANSI and DIN Installation

The unit mounts directly in an ANSI C39.1 (4" round form) or an IEC 92

mm DIN square form. This is perfect for new installations and for

existing panels. In new installations, simply use DIN or ANSI punches.

For existing panels, pull out old analog meters and replace them with

the EM-2000 Series meter. The meter uses standard voltage and

current inputs so that CT and PT wiring does not need to be replaced.

• Perfect for switchgear panel direct retrofit

• Uses minimal panel space

• Mounts in only 4.25" panel depth

www.johnsoncontrols.com

4

Page 5

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

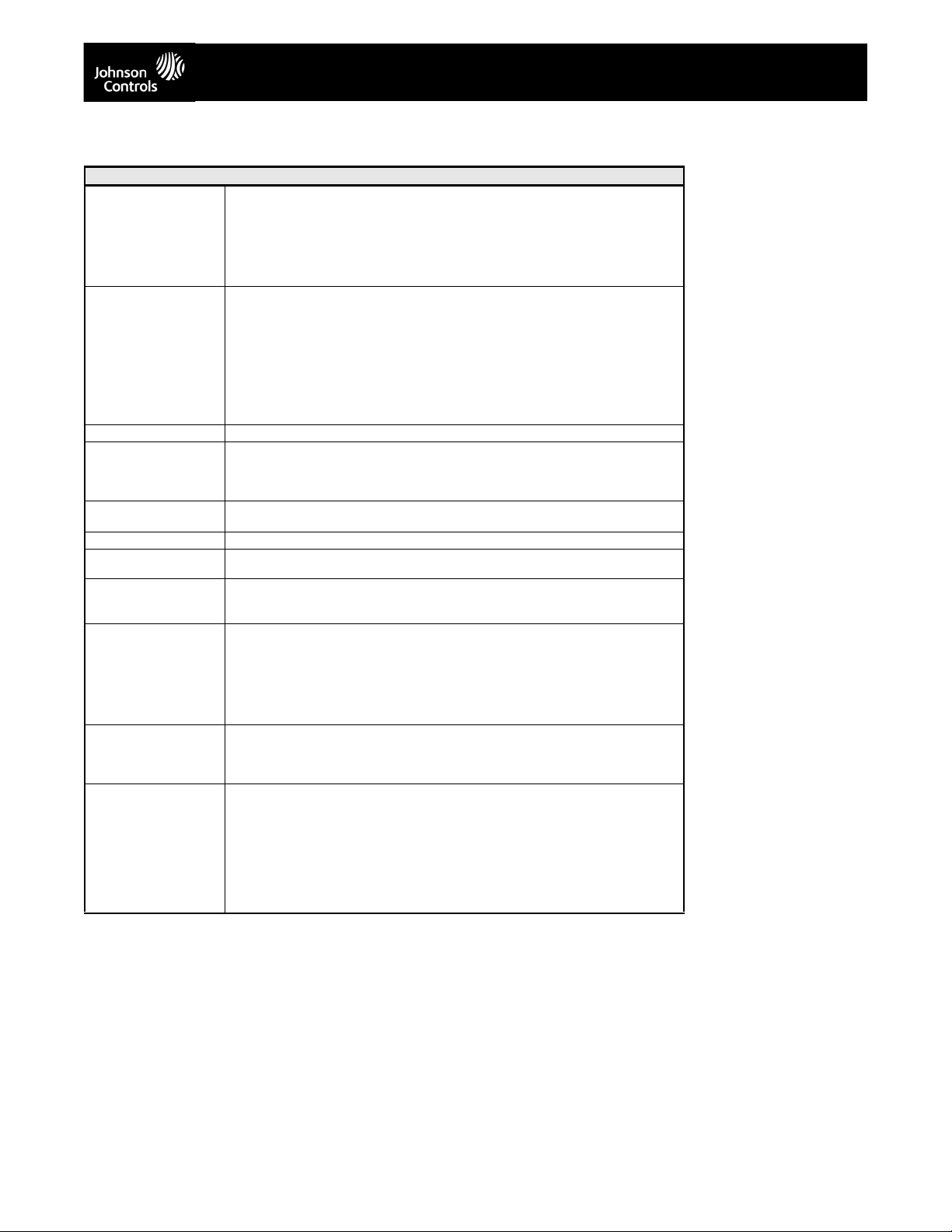

Technical Specifications

EM-2000 Series Meter

Voltage Inputs 20-416 Volts Line to Neutral, 20-721 Volts Line to Line

Current Inputs Class 10: (0 to 10)A, 5 Amp Nominal, 10 Amp Maximum; Class 2: (0 to 2)A, 1 Amp Nominal,

Isolation All Inputs and Outputs are Galvanically Isolated to 2500 Volts AC

Environmental Rating Storage: (-20 to +70)° C

Sensing Method RMS

Update Rate Watt, VAR, and VA- Every 6 Cycles; All Other Parameters - Every 60 Cycles

Power Supply (90 to 265) Volts AC / (100 to 370) Volts DC

Communication Format BACnet/IP

KYZ Pulse Typ e F or m A

Dimensions and Shipping Weight: 2 lbs/0.907 kg

Compliance IEC62053-22 (0.2% Accuracy)

Universal Voltage Input

Input Withstand Capability – Meets IEEE C37.90.1 (Surge Withstand Capability)

Programmable Voltage Range to Any PT Ratio

Supports: 3 Element WYE, 2.5 Element WYE, 2 Element Delta, 4 Wire Delta Systems

Burden: 0.36VA/Phase Max at 600 Volts; 0.014VA/Phase at 120 Volts

Input Wire Gauge Max (AWG 12 / 2.5mm2)

Secondary

Fault Current Withstand (For 23° C, 3 Phase Balanced WYE or Delta load): 100 Amps for 10

Seconds, 300 Amps for 3 Seconds, 500 Amps for 1 Second

Programmable Current to any CT Ratio

Burden 0.005VA Per Phase Max at 11 Amps

Pickup Current 0.1% of Nominal

Pass Through Wire Gauge Dimension: 0.177" / 4.5mm

Continuous Current Withstand: 20 Amps for Screw Terminated or Pass Through Current

Connections

Operating: (-20 to +70)° C

Humidity: to 95% RH Non-Condensing

Faceplate Rating: NEMA12 (Water Resistant)

Sampling at 400+ Samples per Cycle on All Channels Measured Readings Simultaneously

(18- to 60) Volts DC optional power supply

IrDA (Through Faceplate)

Modbus TCP

On Resistance: 23-35 Ohm

Peak Voltage: 350 VDC

Continuous Load Current: 120mA

Peak Load Current: 350mA (10ms)

Off State Leakage Current @ 350VDC: 1mA

Opto-Isolation: 3750V (6 0Hz, 1min)

Basic Unit: (H4.85 x W4.85 x L4.25) in/(H12.32 x W12.32 x D10.54) cm

Mounts in Either 92mm Square DIN or ANSI C39.1 4" Round Cut-outs

Shipping Container Dimensions: 6" Cube

ANSI C12.20 (0.2% Accuracy)

ANSI (IEEE) C37.90.1 Surge Withstand

ANSI C62.41 (Burst)

EN61000-6-2 - Immunity for Industrial Environments: 2005

EN61000-6-4 - Emission Standards for Industrial Environments: 2007

EN61326-1 - EMC Requirements: 2006

UL File #E363785

UL Spec: 61010-1

Ethernet (Through Backplate)

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

5

Page 6

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

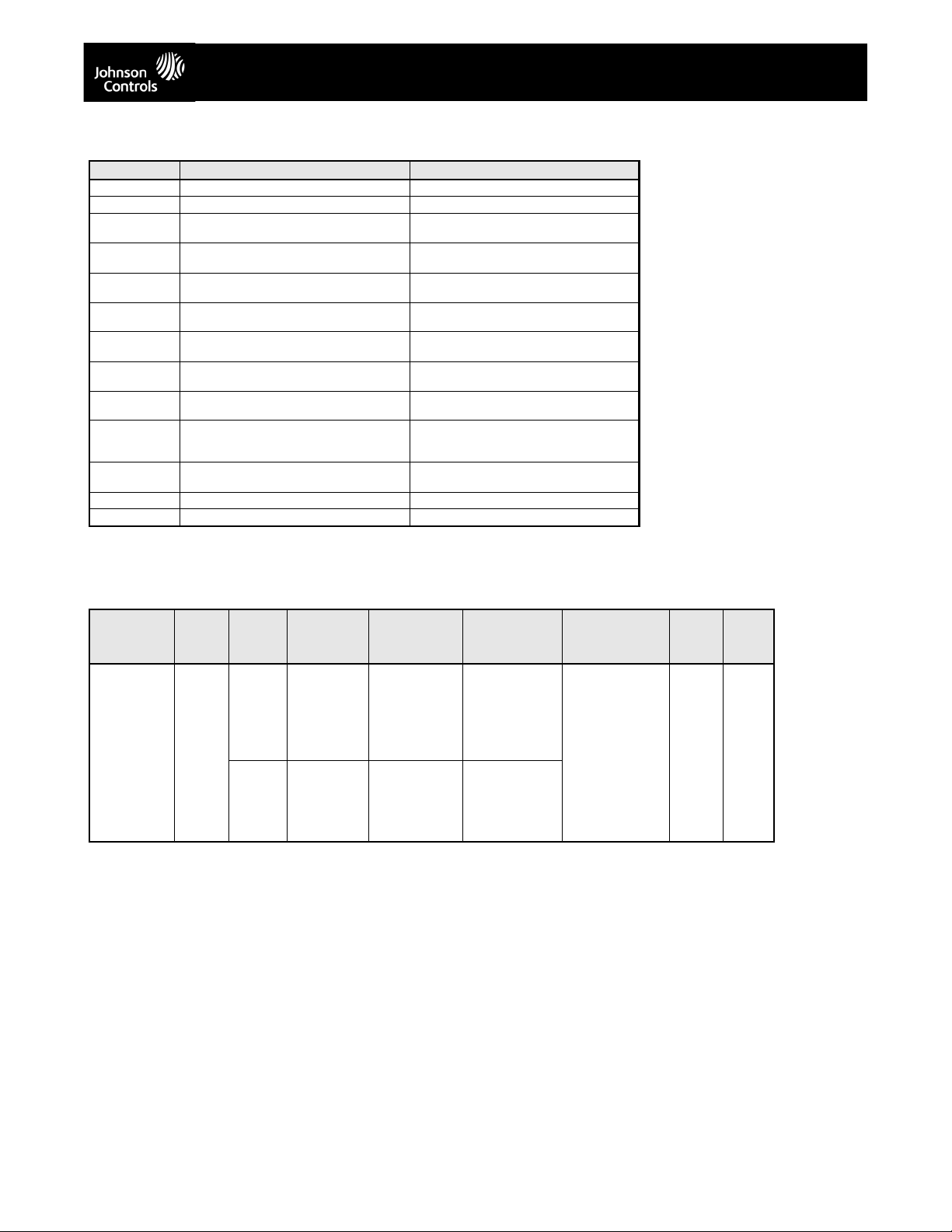

EM-2000 Serial Meter Accuracy - For 23o C, 3 Phase Balanced Wye or Delta Load

Parameter Accuracy Accuracy Input Range

Voltage L-N [V] 0.1% of reading

Voltage L-L [V] 0.1% of reading (120 to 600)V

Current Phase

[A]

Current Neutral

(calculated) [A]

Active Power

Total [W ]

Active Energy

Total [W h]

Reactive Power

Total [VAR]

Reactive Energy

Total [VARh]

Apparent Power

Total [VA ]

Apparent

Energy Total

[VAh]

Power Factor 0.2% of reading

Frequency +/- 0.01Hz (45 to 65)Hz

Load Bar +/- 1 segment

0.1% of reading

2.0% of Full Scale

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

2

1

1

1,2

1,2

1,2

1,2

1,2

1,2

1,2

1

(69 to 480)V

(0.15 to 5)A

(0.15 to 5)A @ (45 to 65)Hz

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0 to 0.8)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0 to 0.8)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.005 to 6)A

1

For 2.5 element programmed units,

degrade accuracy by an additional 0.5%

of reading.

- For 1A (Class 2) Nominal, degrade

accuracy by an additional 0.5% of

reading.

- For 1A (Class 2) Nominal, the input

current range for Accuracy specification

is 20% of the values listed in the table.

2

For unbalanced voltage inputs where at

least one crosses the 150V auto-scale

threshold (for example, 120V/120V/208V

system), degrade accuracy by additional

0.4%.

EM-2000 Series Meter Ordering Chart

Product-

S e r i e s

EM-2

EM-2000

Series Meter

Network

Protocol

7

BACnet/

IP

Freq. -Power

Supply

50

5 0 H z

System

90-265

VAC/100-

VDC

60

60 Hz

System

18-60

VDC

-0

370

-1

Current Class -Mounting V-Switch

Pack

5

5 Amp

Secondary

1

1 Amp

-A

ANSI Mounting 0Default V-Switch

Volts/

Amps

-D

DIN Mounting

Secondary

0 0

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

6

Page 7

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

EM-3000 Series Meter Description

The EM-3000 Series meter is a high performance product designed

to measure revenue grade electrical energy usage and communicate

back that information using modern communication media. The unit

supports RJ45 Ethernet or IEEE 802.11 WiFi Ethernet connections.

This allows it to be placed anywhere within a facility and have it

communicate back to central software quickly and automatically. The

unit also has a front IrDA port that can be read and configured with

an IrDA-equipped device, such as a laptop PC.

The unit is designed with advanced measurement capabilities,

allowing it to achieve high performance accuracy. The EM-3000

Series meter is specified as a 0.2% class energy meter for billing

applications.

The EM-3000 Series meter uses standard 5 or 1 Amp CTs (either

split or donut). It surface mounts to any wall and is easily

programmed in minutes. The unit is designed specifically to be a low

cost, highly accurate sub-meter with advanced communication and

easy installation.

EM-3000 Series Meter Features

• 0.2% Class Revenue Certifiable Energy and Demand Sub-meter

• Meets ANSI C12.20 (0.2%) and IEC 62053-22 (0.2%) Classes

• Multifunction Measurement Capability

• Bright Red LED Display with three .56" lines

• % of Load Bar for Analog Meter Perception

• Ethernet or Wireless Ethernet via Modbus TCP

• Direct Interface with Most Building Management Systems

• Very Easy To Install - Small Footprint

Applications

• Universities

• Commercial Buildings

• Shopping Malls

• Airports

• Industrial Sub-metering

• Government Facilities

• Military

• Energy Efficiency OEMs

Available Models

The EM-3000 Series meter can be ordered in either of the following

models:

• E – Volts and Amps Meter with Energy Counters– Default model

• F – Volts and Amps Meter with Energy Counters, and Harmonics

and Limits

WiFi or Land Based Ethernet

The EM-3000 Series meter gives you two Ethernet options — either

an RJ45 wired, or a WiFi connection. Both connections are easily

configurable using Telnet. The sub-meter communicates over any

existing wireless or wired Ethernet infrastructure. Just install the unit,

plug in its IP address, and the device automatically connects to your

LAN.

The WiFi option allows the EM-3000 Series meter to be used on

standard WiFi base stations, providing a simple, over-the-counter

wireless architecture. You can extend the network simply by adding

WiFi access points. Wireless Ethernet is reliable and easy to

integrate, making it the superior solution for mass meter deployment.

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

Benefits of WiFi Over Dedicated Radio

• Standard Infrastructure - No Dedicated Hardware

• Low Cost to Deploy and Expand

• Superior Speed over Dedicated Wireless Networks

• Significantly Easier to Configure and Maintain

• Secure Connection - WEP, WPA, or WPA2 Wireless Security

• Standard Modbus

• Can Be Easily Integrated through Internet

IrDA Port

The EM-3000 Series meter has an IrDA port on its faceplate, for remote

interrogation by an IrDA-equipped laptop PC.

Traceable Watt-Hour Test Pulse for Accuracy

Verification

The EM-3000 Series meter is a traceable revenue meter. It contains a

utility grade test pulse allowing power providers to verify and confirm

that the meter is performing to its rated accuracy. This is an essential

feature required of all billing grade meters.

KYZ Pulse

For applications in which a pulse is needed, the unit also provides a

KYZ output which pulses proportional to the amount of energy

consumed. This feature is used for pulse counting applications or for

building management systems where serial or Ethernet protocol is not

available.

Utility Peak Demand Metering

The EM-3000 Series meter provides user-configured Block Window or

Rolling Window Demand. This allows you to set up a particular utility

demand profile. Block Window Demand is demand used over a fixed

user-configured demand period (usually 5, 15 or 30 minutes). Rolling

Window Demand is a fixed window demand that moves for a user

specified sub-interval period. An example is a 15-minute demand using

3 subintervals, providing a new demand reading every 5 minutes based

on the last 15 minutes. Readings for kW, kVAR, kVA and PF are

calculated using utility demand structures. Other parameters offer max

and min capability over the user-selectable averaging period. Voltage

provides a non-rolling instantaneous max and min reading, displaying

the highest surge and lowest sag seen by the meter.

EM-3000 Series Meter

®

TCP Data Stream

www.johnsoncontrols.com

7

Page 8

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

Technical Specifications

EM-3000 Series Meter

Voltage Inputs 20-416 Volts Line to Neutral, 0-721 Volts Line to Line

Current Inputs Class 10: (0 to 10)A, 5 Amp Nominal,10 Amp Maximum; Class 2: (0 to 2)A, 1 Amp Nominal,

Isolation All Inputs and Outputs are Galvanically Isolated to 2500 Volts AC

Environmental Rating Storage: (-20 to +70)° C

Sensing Method RMS

Update Rate Watt, VAR, and VA- Every 6 Cycles; All Other Parameters - Every 60 Cycles

Power Supply (90 to 400) Volts AC / (100 to 370) Volts DC

Communication Format 10/100BaseTEthernet or 802.11b WiFi

Dimensions Basic Unit: (H7.9 x W7.6 x D3.2) in/(H20.07 x W19.30 x D8.13) cm

Compliance IEC62053-22 (0.2% Accuracy)

Universal Voltage Input

Input Withstand Capability – Meets IEEE C37.90.1 (Surge Withstand Capability)

Programmable Voltage Range to Any PT Ratio

Supports: 3 Element WYE, 2.5

Element WYE, 2 Element Delta, 4 Wire Delta Systems

Burden: 0.36VA/Phase Max at 600 Volts; 0.014VA/Phase at 120 Volts

Input Wire Gauge AWG #16-26

Secondary

Fault Current Withstand (For 23° C, 3 Phase Balanced WYE or Delta load): 100 Amps for 10

Seconds

Programmable Current to any CT Ratio

Burden 0.005VA Per Phase Max at 11 Amps

Pickup Current 0.1% of Nominal

Operating: (-20 to +70)° C

Humidity: to 95% RH Non-Condensing

Faceplate Rating: NEMA12 (Water Resistant)

Sampling at 400+ Samples per Cycle on All Channels Measured Readings Simultaneously

Harmonic %THD (% of Total Harmonic Distortion)

Burden 16VA Max

IrDA (Through Faceplate)

TCP

Modbus

9,600 to 57,600 Baud Rate

Com Port Address 0-247

Weight: 4 lbs/1.81 kg

ANSI C12.20 (0.2% Accuracy)

ANSI (IEEE) C37.90.1 Surge Withstand

ANSI C62.41 (Burst)

EN61000-6-2 - Immunity for Industrial Environments: 2005

EN61000-6-4 - Emission Standards for Industrial Environments: 2007

EN61326-1 - EMC Requirements: 2006

UL File #E363785

UL Spec: 61010-1

FCC Part 15, Subpart B

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

8

Page 9

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

EM-3000 Series Meter Accuracy - For 23o C, 3 Phase Balanced Wye or Delta Load

Parameter Accuracy Accuracy Input Range

Voltage L-N [V] 0.1% of reading

Voltage L-L [V] 0.1% of reading (120 to 600)V

Current Phase

[A]

Current Neutral

(calculated) [A]

Active Power

Total [W ]

Active Energy

Total [W h]

Reactive Power

Total [VAR]

Reactive Energy

Total [VARh]

Apparent Power

Total [VA ]

Apparent

Energy Total

[VAh]

Power Factor 0.2% of reading

Frequency +/- 0.01Hz (45 to 65)Hz

Total Harmonic

Distortion

Load Bar +/- 1 segment

0.1% of reading

2.0% of Full Scale

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

1

5.0%

2

1

1

1,2

1,2

1,2

1,2

1,2

1,2

1,2

1

(69 to 480)V

(0.15 to 5)A

(0.15 to 5)A @ (45 to 65)Hz

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0 to 0.8)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0 to 0.8)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.5 to 10)A or (69 to 480)V, measurement

range (1 to 99.99)%

(0.005 to 6)A

1

For 2.5 element programmed units,

degrade accuracy by an additional 0.5%

of reading.

- For 1A (Class 2) Nominal, degrade

accuracy by an additional 0.5% of

reading.

- For 1A (Class 2) Nominal, the input

current range for Accuracy specification

is 20% of the values listed in the table.

2

For unbalanced voltage inputs where at

least one crosses the 150V auto-scale

threshold (for example, 120V/120V/208V

system), degrade accuracy by additional

0.4%.

EM-3000 Series Meter Ordering Chart

Product-

S e r i e s

EM-3

EM-3000

Series Meter

Network

Protocol

8

WiFi

Freq. -Power

Supply

50

5 0 H z

System

90-400

VAC/100-

VDC

60

60 Hz

System

370

-0

Current Class -Mounting V-Switch

Pack

5

5 Amp

Sec on da ry

-W

Default

E

Default V-Switch

Volts/

Amps, Energy

Counters

1

1 Amp

Secondary

F

above with

Harmonics and

Limits

0 0

Refer to the EM-1000/EM-2000 Series Meters’ Installation and Operation Manual (LIT-12011867) and the EM-3000 Series Meter Installation

and Operation Manual (LIT-12011874) for important product application information.

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

9

Page 10

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

EM-4000 Series Meter

EM-4000 Series Meter Description

The EM-4000 Series monitor is a multifunction data-logging power and

energy meter designed to be used in electrical substations, panel

boards, as a power meter for OEM equipment, and as a primary

revenue meter due to its high performance measurement capability.

The unit provides multifunction measurement of all electrical

parameters. It is easy to use and install and is perfect both for new

metering applications and as a simple replacement of existing analog

meters.

The EM-4000 Series meter is designed with advanced measurement

capabilities, allowing it to achieve high performance accuracy. The EM4000 Series meter is specified as a 0.2% class energy meter, meeting

ANSI C12.20 (0.2%) and IEC 62053-22 (0.2%) accuracy classes.

The EM-4000 Series meter supplies 2 Megabytes of Flash memory for

data-logging and load profiling for historical analysis. For

communication, the EM-4000 Series meter has a front panel IrDA port

and a back panel combination RS485/Pulse Com port.

The EM-4000 Series meter has an LED with 3 .56”, bright red lines of

display for easy readability.It features an anti-dither algorithm to

improve reading stability, benefitting operators. The unit utilizes high

speed DSP technology with high resolution A/D conversion to provide

stable and reliable measurements.

EM-4000 Series Meter Features

• 0.2% Class Revenue Certifiable Energy and Demand Metering

• Multifunction Measurement Including Voltage, Current, Power,

Frequency, Energy, Etc.

• Standard RS485 with Modbus

• 2MegaBytes of Flash Memory for Data-logging

• % of Load Bar for Analog Meter Perception

• Fits Both ANSI and DIN Cut-outs

• 0.001 Hz Frequency Measurement for Generating Stations

• Uses Minimal Panel Space and Depth

• Easy-to-Use Faceplate Programming

• Phasor Diagram Showing Wiring Status

• IrDA Port Enables Laptop PC Reading and Programming

• Color Coordinated Voltage and Current Inputs

®

Protocol

Applications

• Utility Metering

• Substations

• Power Generation

• Industrial Metering

• Commercial Metering

• Campus Metering

• Submetering

• Analog Meter Replacement

• Voltage Recording

Advanced Communication Capability

Back Mounted Communication Port with KYZ Pulse

• RS485 – This port allows RS485 communication using Modbus

Protocol. Baud rates are from 9,600 to 57,600.

• KYZ Pulse – In addition to the RS485, this port includes a KYZ pulse

mapped to positive energy. This is a fixed energy pulse.

®

Rugged and Safe Voltage and Current Inputs

The EM-4000 Series meter is ruggedly designed for harsh electrical

applications in both high voltage and low voltage power systems. This

is especially important in Power Generation, Utility Substation and

Critical User applications. The structural and electrical design of this

meter was developed based on the recommendations and approval of

many of our utility customers.

High Isolation Universal Voltage Inputs

Voltage inputs allow measurement of up to 576 Volts Line to Neutral

and 721 Volts Line to Line. This insures proper meter safety when

wiring directly to high voltage systems. One unit will perform to

specification on 69 Volt, 120 Volt, 230 Volt, 277 Volt and 347 Volt power

systems.

Short Circuit Safe Current Inputs

Current inputs use a unique dual input method:

• Method One – CT Lead Pass Through. The CT Lead passes directly

through the meter without any physical termination on the meter. This

insures that the meter cannot be a point of failure on the CT circuit.

This is preferable to utility users when sharing relay class CTs. No

Burden is added to the secondary CT circuit.

• Method Two – Current “Gills.” This unit additionally provides ultra rugged termination pass-through bars, allowing the CT leads to be

terminated on the meter. The EM-4000 Series meter’s stud-based

design insures that your CTs will not open in a fault condition.

ANSI and DIN Installation

The unit mounts directly in an ANSI C39.1 (4" round form) or an IEC 92

mm DIN square form. This is perfect for new installations and for

existing panels. In new installations, simply use DIN or ANSI punches.

For existing panels, pull out old analog meters and replace them with

the EM-4000 Series meter. The meter uses standard voltage and

current inputs so that CT and PT wiring does not need to be replaced.

• Perfect for switchgear panel direct retrofit

• Uses minimal panel space

• Mounts in only 4.25" panel depth

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

10

Page 11

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

Technical Specifications

EM-4000 Series Meter

Voltage Inputs 20-576 Volts Line to Neutral, 0-721 Volts Line to Line

Current Inputs Class 10: (0 to 10)A, 5 Amp Nominal, 10 Amp Maximum

Isolation All Inputs and Outputs are Galvanically Isolated to 2500 Volts AC

Environmental Rating Storage: (-20 to +70)° C

Sensing Method RMS

Update Rate Watt, VAR, and VA- Every 6 Cycles; All Other Parameters - Every 60 Cycles

Power Supply (90 to 265) Volts AC / (100 to 370) Volts DC

Communication Format RS485 Modbus

KYZ Pulse Type Form A

Dimensions and Shipping Weight: 2 lbs/0.907 kg

Compliance IEC62053-22 (0.2% Accuracy)

Universal Voltage Input

Input Withstand Capability – Meets IEEE C37.90.1 (Surge Withstand Capability)

Programmable Voltage Range to Any PT Ratio

Supports: 3 Element WYE, 2.5 Element WYE, 2 Element Delta, 4 Wire Delta Systems

Burden: 0.36VA/Phase Max at 600 Volts; 0.014VA/Phase at 120 Volts

Input Wire Gauge Max (AWG 12 / 2.5mm2)

Fault Current Withstand (For 23° C, 3 Phase Balanced WYE or Delta load): 100 Amps for 10

Seconds, 300 Amps for 3 Seconds, 500 Amps for 1 Second

Programmable Current to any CT Ratio

Burden 0.005VA Per Phase Max at 11 Amps

Pickup Current 0.1% of Nominal

Pass Through Wire Gauge Dimension: 0.177" / 4.5mm

Continuous Current Withstand: 20 Amps for Screw Terminated or Pass Through Current

Connections

Operating: (-20 to +70)° C

Humidity: to 95% RH Non-Condensing

Faceplate Rating: NEMA12 (Water Resistant)

Sampling at 400+ Samples per Cycle on All Channels Measured Readings Simultaneously

®

IrDA (Through Faceplate)

Com Port Baud Rate: (1,200 to 57,600bps)

Com Port Address: 0-247

®

Modbus

On Resistance: 23-35 Ohm

Peak Voltage: 350 VDC

Continuous Load Current: 120mA

Peak Load Current: 350mA (10ms)

Off State Leakage Current @ 350VDC: 1mA

Opto-Isolation: 3750V (6 0Hz, 1min)

Basic Unit: (H4.85 x W4.85 x L4.25) in/(H12.32 x W12.32 x D10.54) cm

Mounts in Either 92mm Square DIN or ANSI C39.1 4" Round Cut-outs

Shipping Container Dimensions: 6" Cube

ANSI C12.20 (0.2% Accuracy)

ANSI (IEEE) C37.90.1 Surge Withstand

ANSI C62.41 (Burst)

EN61000-6-2 - Immunity for Industrial Environments: 2005

EN61000-6-4 - Emission Standards for Industrial Environments: 2007

EN61326-1 - EMC Requirements: 2006

UL File #E363785

UL Spec: 61010-1

(Through Backplate)

RTU, ASCII

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

11

Page 12

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

EM-4000 Serial Meter Accuracy - For 23o C, 3 Phase Balanced Wye or Delta Load

Parameter Accuracy Accuracy Input Range

Vol ta ge L-N [V ] 0.1% of reading

Voltage L-L [V] 0.2% of reading (120 to 600)V

Current Phase

[A]

Current Neutral

(calculated) [A]

Active Power

Tot al [ W]

Active Energy

Tot al [ Wh ]

Reactive Power

Total [VAR]

Reactive Energy

Total [VARh]

Apparent Power

Tot al [ VA]

Apparent

Energy Total

[VAh]

Power Factor 0.2% of reading

Frequency +/- 0.001Hz (45 to 65)Hz

Load Bar +/- 1 segment

0.1% of reading

2.0% of Full Scale

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

0.2% of reading

2

1

1

1,2

1,2

1,2

1,2

1,2

1,2

1,2

1

(69 to 480)V

(0.15 to 5)A

(0.15 to 5)A @ (45 to 65)Hz

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0 to 0.8)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0 to 0.8)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5)A @ (69 to 480)V @ +/- (0.5 to 1)

lag/lead PF

(0.005 to 6)A

EM-4000 Series Meters Ordering Chart

Product-Series Network

Protocol

EM-4

EM-4000 Series

Meter

4

Modbus

Freq. -Power Supply Current Class -Mounting 0 0

50

50 Hz

S y s t e m

60

60 Hz

System

90-265 VAC/

100-370VDC

-0

5

5 Amp

Secondary

-AI

ANSI Mounting

-DI

DIN Mounting

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

12

Page 13

EM-1000/-2000/-3000/-4000 Series Multifunction Power and Energy Meters (Continued)

EM-1000/-2000/-3000/-4000 Series Meters Accessories Ordering Chart

Product Code Number Description

UNICOM 2500 RS485 to RS232 converter

UNICOM 2500-F RS485 to RS232 or fiber converter

E145350 2-wire to 4-wire RS485 cable, 6 ft long, for use with Unicom 2500/2500F

EI-1SP-100-00 100/5A split core CT with 0.84 x 2.0 in. window

EI-1SP-200-00 200/5A split core CT with 0.84 x 2.0 in. window

EI-WC4-400-RA05 400/5A split core CT with 1.3 x 1.7 in. window

EI-615-401 400/5A split core CT with 1.3 x 1.6 in. window

EI-3SP-600-00 600/5A split core CT with 2.19 x 3.25 in. window

EI-5SP-1200-00 1200/5A split core CT with 2.88 x 4.25 in. window

EI-7SP-1600-00 1600/5A split core CT with 2.88 x 6.25 in. window

EI-91SP-2000-00 2000/5A split core CT with 4.00 x 7.50 in. window

EI-91SP-3000-00 3000/5A split core CT with 4.00 x 7.50 in. window

EI-91SP-4000-00 4000/5A split core CT with 4.00 x 7.50 in. window

EI-2SFT-500 50/5A solid core CT with 1.13 ft ID with terminals and feet

EI-2SFT-101 100/5A solid core CT with 1.13 ft ID with terminals and feet

EI-2SFT-201 200/5A solid core CT with 1.13 ft ID with terminals and feet

EI-5SFT-401 400/5A solid core CT with 1.56 ft ID with terminals and feet

EI-2DARL-500 50/5A solid core CT with 1.00 ft ID

EI-2DARL-101 100/5A solid core CT with 1.00 ft ID

EI-2DARL-201 200/5A solid core CT with 1.00 ft ID

EI-5ARL-401 400/5A solid core CT with 1.56 ft ID with terminals and feet

EI-7RL-601 600/5A solid core CT with 2.50 ft ID

EI-7RL-801 800/5A solid core CT with 2.50 ft ID

EI-76RL-122 1200/5A solid core CT with 3.00 ft ID

EI-8RL-162 1600/5A solid core CT with 3.00 ft ID

EM-1000/-2000/-3000/-4000 Series Meters Comparison Chart

Features EM-1000 Series EM-2000 Series EM-3000 Series EM-4000 Series

Accuracy Class† 0.5% 0.2% 0.2% 0.2%

Frequency Accuracy 0.01% 0.01% 0.01% 0.001%

Current Class Class 10 Class 10

Class 2

Comm Standard RS485 Standard Ethernet Standard RS485

Protocol Modbus RTU/ASCII BACnet/IP Modbus RTU/ASCII/

Power Supply 90-265VAC 90-265VAC

100-370 VDC

or

18-60VDC

Data-logging No No No Yes

Class 10

Class 2

Optional Ethernet

Optional WiFi

TCP**

DNP3.0 WiFi

90-265VAC

100-370 VDC

or

18-60VDC

Class 10

Standard RS485

Modbus RTU/ASCII

90-265VAC

100-370 VDC

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

www.johnsoncontrols.com

13

Loading...

Loading...