Page 1

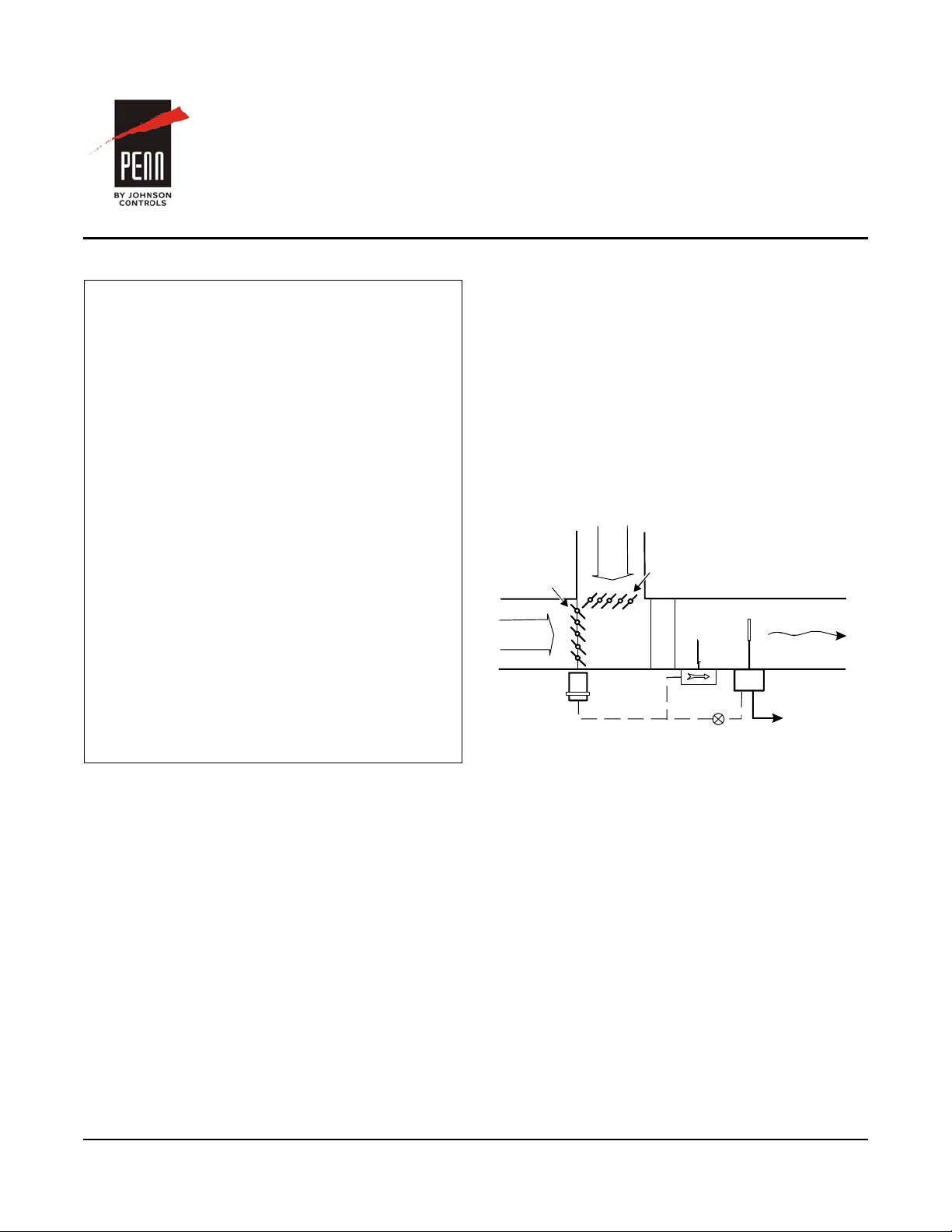

Figure 1: T ypical Application Inst allation fo r the

F240AA Pneumatic Airflow Switch

Normally

Open

Damper

Normally

Closed

Damper

Fan

Airflow

Switch

Control

Supply Air

20 psig

0.007 in.

(0.18 mm)

Pneumatic

Damper

Actuator

Return Air

Outside

Air

F240AA Pneumatic Airflow Switch

Installation Instructions

Part No. 24-7664-3124, Rev. A

Refer to the QuickLIT website for the most up-to-date version of this document.

Issued October 15, 2015

Applications

IMPORTANT: Use this F240AA Pneumatic Airflow

Switch only as an operating control. Where failure or

malfunction of the F240AA switch could lead to

personal injury or property damage to the controlled

equipment or other property , additional precautions

must be designed into the control system. Incorporate

and maintain other devices, such as supervisory or

alarm systems or safety or limit controls, intended to

warn of or protect against failure or malfunction of the

F240AA switch.

IMPORTANT: Utiliser ce F240AA Type Pneumatic

Airflow Switch uniquement en tant que dispositif de

régulation. Lorsqu'une défaillance ou un

dysfonctionnement du F240AA switch l risque de

provoquer des blessures ou d'endommager

l'équipement contrôlé ou un autre équipement, la

conception du système de contrôle doit intégrer des

dispositifs de protection supplémentaires. Veiller

dans ce cas à intégrer de façon permanente

d'autres dispositifs, tels que des systèmes de

supervision ou d'alarme, ou des dispositifs de

sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de

défaillance ou de dysfonctionnement du

F240AA switch.

The F240AA Pneumatic Airflow Switch detects airflow

or the absence of airflow by responding only to the

velocity of air movement within a duct.

Typical applications include:

• make-up air systems

• air cooling or heating processes

• exhaust systems

The switch features a T ype 3R (NEMA)/IP43 en closure

with an integral mounting plate and a moun ting gasket.

It is calibrated for a maximum pneumatic input

pressure of 20 psig (138 kPa).

For a typical application installation for the

F240AA Pneumatic Airflow Switch, see Figure 1.

FIG:F240AA_smpl_app

Temperature

Restrictor

Absence of airflow during the normal operation of air

handling systems may cause overheating, coil icing, or

other conditions that may be detrimental to the

equipment.

F240AA Pneumatic Airflow Switch Installation Instructions

1

Page 2

Installation

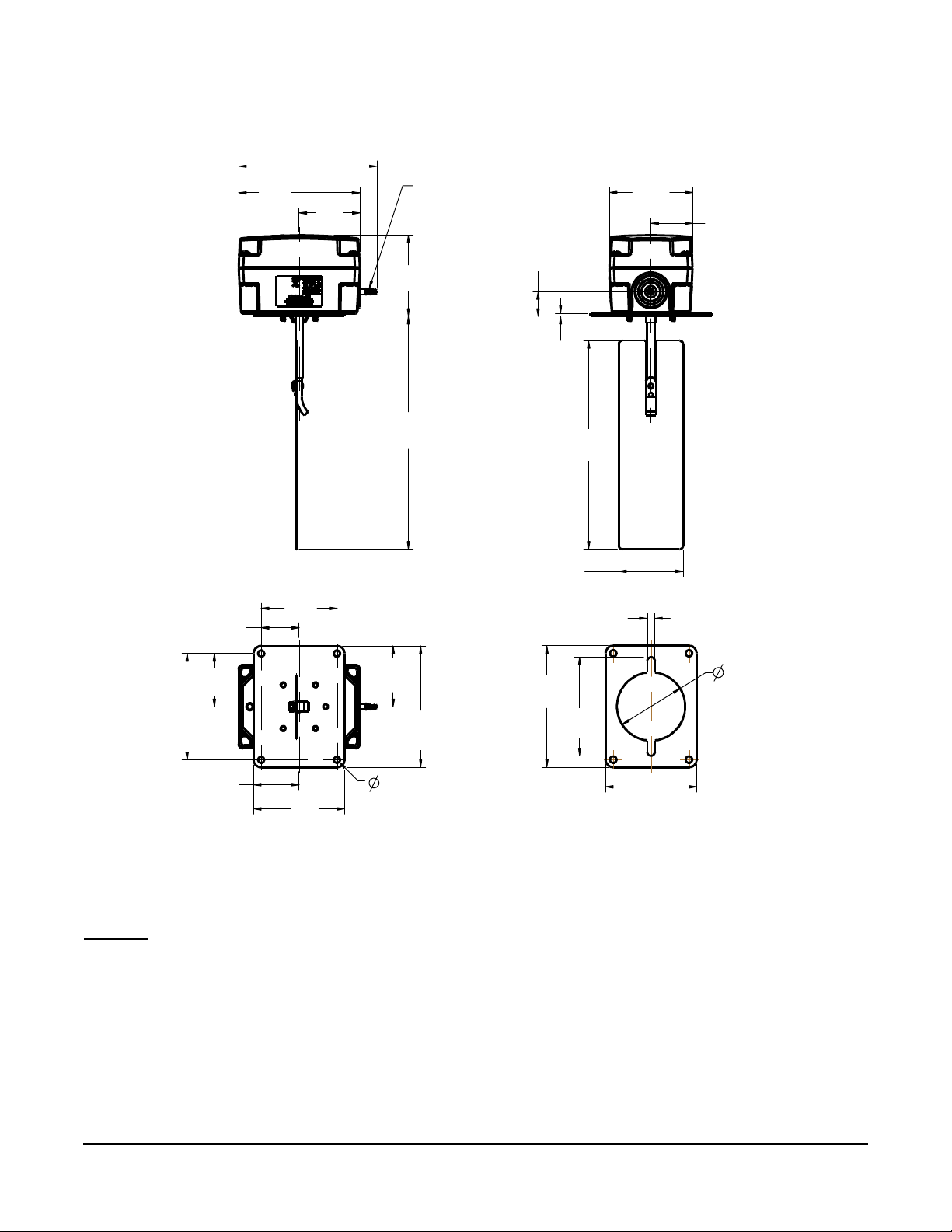

Figure 2: F240AA Airflow Switch with Type 3R (NEMA)/IP43 Enclosure Dimensions, in. [mm]

- -

1/4 [6] O.D. x

3/16 [4] I.D.

tubing

2

[51]

4

[102]

[116]

1-3/8

[35]

2-3/4

[70]

7-11/16

[197]

6-7/8

[175]

2-1/8 [54] Standard

3-1/8 [79] O pt ional

1/4 [6]

4

[102]

4

[102]

3-1/4

[83]

2

[51]

1-1/4

[32]

1-3/4

[45]

2-1/2

[64]

3-1/2

[89]

1-1/2

[38]

3

[76]

3

[76]

2-11/16

[68]

13/16

[21]

1/16

[2]

FIG:F240AA_dmnsns

3/16 [5] di am eter

mounting holes for

No. 10 screws, 4 places

[57]

Dimensions

4-9/16

Barbed connector for

2-1/4

Installation Procedure

Select the proper location and orientation. See

Mounting

1. Use the mounting plate gasket as a template and

2. Drill or punch screw holes.

.

mark hole positions.

3. Cut the center hole large enough for the paddle to

pass through.

4. Trim the paddle, if necessary (see Figure 3). The

standard paddle fits into ducts of 3 x 8 in.

(76 x 203 mm) minimum. Th e paddle ma y be

trimmed for installing in ducts as small as 3 x 6 in.

(76x152mm).

F240AA Pneumatic Airflow Switch Installation Instructions

2

Page 3

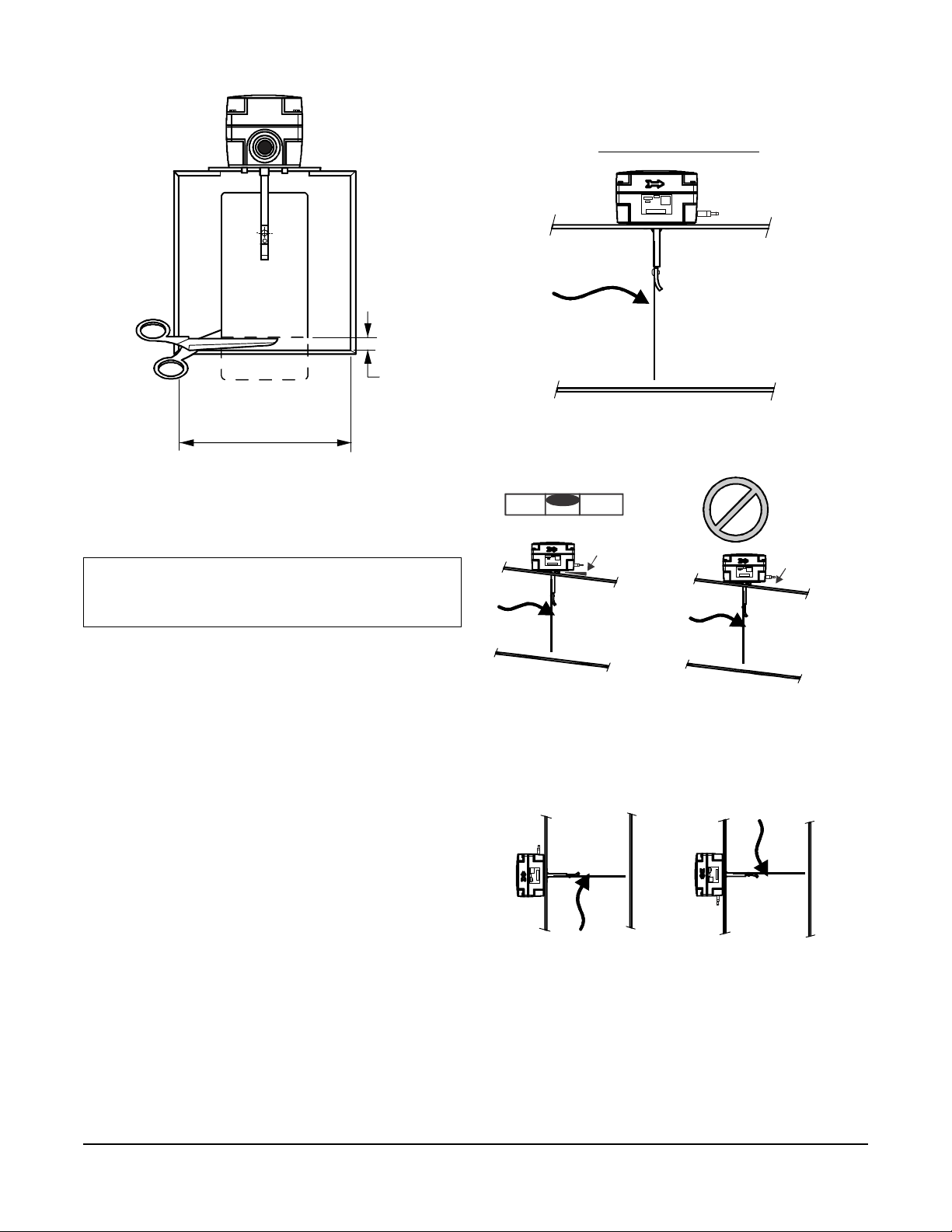

Figure 3: Trimming the Paddle,

Dimensions, in. [mm]

3-15/16

[100]

3/16

[5]

FIG:F240AA_mnt_trm

Figure 4: Mounting the F240AA Switch in a

Horizontal Duct

FIG:hrzntl_mntg_ F240AA

Figure 5: Mounting the F240AA Switch in an

Angled Duct

shim

FIG:mntng_angl_dct_F240AA

Figure 6: Mounting the F240AA Switch in a

Vertical Duct

FIG:vrtc l_mntg_F2 40AA

Mounting

IMPORTANT: Mount the switch so that the housing

is level horizontally (or plumb vertically). Use a shim,

if necessary.

• When mounting the switch in a vertical duct where

the airflow is downward (Figure 6), you must

readj ust the minimum flow required to actuate the

switch (see Setup and Adjustments

on page 4).

no shim

• Install the switch so that the cover and interior are

accessible for adjustment.

• Ensure that the arrow on the side of the switch

body points in the direction of flow.

• Mount the F240AA switch on the top, side, or

bottom of a duct.

• Mount the switch in a horizontal duct whenever

possible. In a horizontal duct, the switch housing

must be level, and the paddle should be at

approximately a right angle to the airflow

(Figure 4).

• When mounting the switch in a horizontal duct that

is not horizontally true, check with a le vel and place

a shim under the switch mounting plate. Do not

mount the switch without a shim (Figure 5).

• When mounting the switch in a vertical duct where

the airflow is upward (Figure 6), see T able 2 for the

minimum flow required to actuate the switch. The

maximum air velocity should not exceed

2,000 FPM (10.16 m/s).

Note: When the switch is mounted in a vertical duct,

the values shown in Figure 10 do not apply.

!

F240AA Pneumatic Airflow Switch Installation Instructions

3

Page 4

Location Considerations

Figure 7: Required Duct Distance

FLOW

FLOW

A

FIG:reqd_dc t_dstn

Figure 8: Flow Rate Adjustment

(Screw)

Flow Rate

Higher

Less airflow

required to

activate switchthe

More flow

required to

air

-

!

!

Setup and Adjustments

IMPORTANT: Mount the switch so that the housing

is level horizontally (or plumb vertically). Use a shim,

if necessary.

Do not use this switch where it is exposed to outdoor

weather. The switch is designed specifically for indoor

use.

Avoid locations close to elbows, dampers, fans, duct

openings, or other areas where excess ive tur bul en ce

occurs.

Mount the switch away from such areas at least five

times the distance of the smallest duct dimension

(Figure 7).

Example: On a 3 in. × 8 in. duct, mount the

F240AA switch at least 15 in. (381 mm) from the

nearest bend.

c

A

CAUTION: Risk of Property Damage.

Do not set the switch lower than the

factory setting. The switch is factory set

at approximately the minimum flow rate.

A lower setting may result in the switch

failing to return to a no-flow position

which may result in damage to the

controlled equipment or other property.

MISE EN GARDE : Risque de dégâts

matériels.

Ne pas régler le commutateur sur une

valeur inférieure au paramètre d'usine.

Le commutateur est réglé en usine sur

une valeur correspondant environ au

débit minimum. Un réglage sur une

valeur inférieure risque d'empêcher le

commutateur de revenir sur une position

« aucun-débit », ce qui risque

d'endommager l'équipement contrôlé ou

de provoquer d'autres dégâts matériels.

CAUTION: Risk of Property Damage.

Do not attempt to change sealed settings

(screws sealed with Threadlock®).

Attempted adjustment may damage th e

switch or cause loss of calibration or

other property damage.

Dimension A must be at least five times the distance

of the smal l est duct dimen sion.

The standard paddle fits into ducts of 3 x 8 in.

(76 x 203 mm) minimum. The paddle may be trimmed

for installing in ducts as small as 3 x 6 in.

(76 x 152 mm).

Lower

Flow Rate

activate the switch

+

Adjustment Bushing

MISE EN GARDE : Risque de dégâts

matériels.

Ne pas essayer de modifier la position

des éléments de réglage bloqués (vis

identifiées par de la peinture noire).

Toute tentative de réglage risque

d'endommager le dispositif de contrôle

ou de provoquer la perte des valeurs

d'étalonnage ou d'autres dégâts

matériels.

To adjust the setting of the flow switch:

1. Remove the enclosure cover.

2. Adjust the switch’s flow rate (Figure 8):

• Turn the adjustment screw counterclockwise

to lower the flow rate required to activate the

switch.

• Turn the adjustment screw clockwise to raise

the flow rate required to activate the switch.

Note: Do not lower the flow rate required to

FIG:ad jst_fl w_rte _F240AA

activate the switch, unless the flow rate required to

activate the switch was raised from the factory-set

flow rate.

F240AA Pneumatic Airflow Switch Installation Instructions

4

Page 5

3. Replace the enclosure cover and tighten the cover

Figure 9: Minimum Adjustment

DepressMainLeverHere

AdjustmentBushing(Screw)

screws with 10 to 12 in·lb of torque.

Verification

To verify that the flow rate is set above the factory

minimum, depress the main lever (see Figure 9)

multiple times.

If the lever fails to operate the switch upon return at any

time, the flow rate is set below the factory-set

minimum.

Turn the adjustment screw clockwise to raise the flow

rate required to activate the switch. See Figure 8.

Operation

The pneumatic airflow switch responds to pressure

exerted on the flow paddle by the velocity of air

movement within a duct. The control port closes on

increasing flow and opens on decreasing flow. See

Table 1 for switch action.

Table 1: Switch Action

Airflow Action Switch Action

Increasing Flow Closes

Decreasing Flow Opens

Table 2 and Figure 10 show airflow velocities in FPM

required to activate the switch for any given duct size

(horizontal or vertical upward flow). The flow rate is

based on a standard air density of 0.075 lb/ft

[1.2 kg/m

3

]. The switch is factory-set at the minimum

3

flow rate shown in Figure 10.

Table 2: Flow Rate Table, FPM (m/second)

Paddle

Width

2-1/8 in. Increasing Flow (Close) 625 (3.2) 575 (2.9) 950 (4.8) 750 (3.8)

3-1/8 in. Increasing Flow (Close) 500 (2.5) 350 (1.8) 750 (3.8) 500 (2.5)

Switch Actuation

on Flow

(323 cm

Duct Area

Decreasing Flow (Open) 325 (1.7) 220 (1.1) 850 (4.3) 575 (2.9)

Decreasing Flow (Open) 250 (1.3) 100 (0.5) 650 (3.3) 350 (1.8)

Minimum Air Velocity Required to Activate Control

Horizontal Flow Vertical Flow

2

50 in.

2

Larger

) or

Less Than

50 in.

(323 cm

Area

2

2

) Duct

(323 cm

Duct Area

2

50 in.

2

Larger

) or

Less Than

2

50 in.

(323 cm2)

Duct Area

F240AA Pneumatic Airflow Switch Installation Instructions

5

Page 6

Figure 10: Flow Rate Curve for an F240AA Switch Mounted in a Horizontal Duct

0

100

200

300

400

500

600

700

800

900

129 258 387 516 645

774

903 1032 1 161 1290 1419 1548 1677 1806 1935

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

30028026024022020018016014012010080604020

Duct Area, cm

2

Velo ci t y, m/ second

Duct Area, in.

2

Velocity, ft/min.

M

i

n

i

m

m

u

p

e

O

n

i

n

g

P

o

i

n

t

:

2

-

1

/

8

i

n

.

w

i

d

e

p

a

d

d

l

e

M

i

n

i

m

u

m

C

l

o

s

i

n

g

P

o

i

n

t

:

2

-

1

/

8

i

n

.

w

i

d

e

p

a

d

d

l

e

M

i

m

i

m

u

m

C

l

o

s

i

n

g

P

o

i

n

t

:

3

-

1

/

8

i

n

.

w

i

d

e

p

a

d

d

l

e

M

i

m

i

m

u

m

O

p

e

n

i

n

g

P

o

i

n

t

:

3

-

1

/

8

i

n

.

w

i

d

e

p

a

l

d

d

e

Closing Flow

Opening Flow

Checkout Procedure

Before you leave the installation, observe at least three

complete operating cycles to be sure that all

components are functioning correctly.

Repair Information

Do not make field repairs, except for replacement of

the flow paddle. For a replacement control or paddle

kit, contact the nearest Johnson Controls/PENN

distributor. For more information, contact

Johnson Controls/PENN® application engineering at

1-800-275-5676 or 1-414-524-5535.

Ordering Information

Table 3: F240AA Pneumatic Airflow Switch

Product Code Number Description

F240AA-01C Pneumatic airflow switch with Type 3R (NEMA)/IP43 enclosure,

Table 4: Replacement Paddle Kits

Product Code Number Description

PLT112-1R 2-1/8 in. wide x 6-7/8 in. long (54 mm x 175 mm) paddle

PLT112-2R 3-1/8 in. wide x 6-7/8 in. long (79 mm x 175 mm) paddle

2-1/8 in. wide x 6-7/8 in. long (54 mm x 175 mm) paddle installed and a

3-1/8 in. wide x 6-7/8 in. long (79 mm x 175 mm) paddle supplied.

F240AA Pneumatic Airflow Switch Installation Instructions

6

Page 7

Johnson Controls/PENN® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

in the United States of America and/or other countries. All other trademarks used herein are the property

of their respective owners. © Copyright 2015 by Johnson Controls, Inc. All rights reserved.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Technical Specifications

F240AA Pneumatic Airflow Switch

Switch Pneumatic

Ambient Operating Temperature 32 to 140°F (0 to 60°C)

Duct Air Temperature 32 to 104°F (0 to 40°C)

Maximum Air Velocity 2,000 FPM (10.16 m/sec)

Enclosure Type 3R (NEMA)/IP43, polycarbonate

Paddle Material 0.006 in. (0.15 mm) stainless spring steel

Pneumatic Switch Action Closes on increasing flow, opens on decreasing flow

Tubing Connector Barb fitting for 1/4 in. O.D. plastic tubing

Shipping Weight 1.3 lb (0.6 kg)

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult Johnson Controls/PENN Refrigeration Application Engineering at 1-800-275-5676. Johnson Controls, Inc. shall not be

liable for damages resulting from misapplication or misuse of its products.

F240AA Pneumatic Airflow Switch Installation Instructions

Published in U.S.A. www.johnsoncontrols.com

7

Loading...

Loading...