Page 1

Code No. LIT-12011946

Issued July 29, 2014

EM-4000 Series Meters

Installation and Operation Manual

Page 2

This page intentionally left blank.

Page 3

EM-4000 Series Meters Installation and Operation Manual

Published by:

Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

All rights reserved. No part of this publication may be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying, recording, or information storage or retrieval systems or any future forms of duplication, for

any purpose other than the purchaser's use, without the expressed written permission

of Johnson Controls, Inc.

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls,

Inc. All other marks herein are the marks of their respective owners.

© 2014 Johnson Controls, Inc.

Modbus® is a registered trademark of Schneider Electric, licensed to the Modbus

Organization, Inc.

EM-4000 Series Meters Installation and Operation Manual i

Page 4

This page intentionally left blank.

EM-4000 Series Meters Installation and Operation Manual ii

Page 5

Use of Product for Protection

Our products are not to be used for primary over-current protection. Any protection

feature in our products is to be used for alarm or secondary protection only.

Statement of Calibration

Our instruments are inspected and tested in accordance with specifications published

by Johnson Controls, Inc. The accuracy and a calibration of our instruments are traceable to the National Institute of Standards and Technology through equipment that is

calibrated at planned intervals by comparison to certified standards. For optimal

performance, Johnson Controls, Inc. recommends that any meter be verified for

accuracy on a yearly interval using NIST traceable accuracy standards.

Disclaimer

The information presented in this publication has been carefully checked for

reliability; however, no responsibility is assumed for inaccuracies. The information

contained in this document is subject to change without notice.

This symbol indicates that the operator must refer to an explanation in

the operating instructions. Please see Chapter 4 for important safety

information regarding installation and hookup of the EM-4000 meter.

Dans ce manuel, ce symbole indique que l’opérateur doit se référer à un important

AVERTISSEMENT ou une MISE EN GARDE dans les instructions opérationnelles. Veuillez consulter le chapitre 4 pour des informations importantes relatives à l’installation

et branchement du compteur.

The following safety symbols may be used on the meter itself:

Les symboles de sécurité suivante peuvent être utilisés sur le compteur même:

This symbol alerts you to the presence of high voltage, which can

cause dangerous electrical shock.

Ce symbole vous indique la présence d’une haute tension qui peut

provoquer une décharge électrique dangereuse.

This symbol indicates the field wiring terminal that must be connected

to earth ground before operating the meter, which protects against

electrical shock in case of a fault condition.

Ce symbole indique que la borne de pose des canalisations in-situ qui doit être

EM-4000 Series Meters Installation and Operation Manual iii

Page 6

branchée dans la mise à terre avant de faire fonctionner le compteur qui est protégé

contre une décharge électrique ou un état défectueux.

This symbol indicates that the user must refer to this manual for

specific WARNING or CAUTION information to avoid personal injury or

damage to the product.

Ce symbole indique que l'utilisateur doit se référer à ce manuel pour AVERTISSEMENT

ou MISE EN GARDE l'information pour éviter toute blessure ou tout endommagement

du produit.

EM-4000 Series Meters Installation and Operation Manual iv

Page 7

Table of Contents

Use of Product for Protection iii

Statement of Calibration iii

Disclaimer iii

1: Three-Phase Power Measurement 1-1

1.1: Three-Phase System Configurations 1-1

1.1.1: Wye Connection 1-1

1.1.2: Delta Connection 1-4

1.1.3: Blondel’s Theorem and Three Phase Measurement 1-6

Table of Contents

1.2: Power, Energy and Demand 1-8

1.3: Reactive Energy and Power Factor 1-12

1.4: Harmonic Distortion 1-14

1.5: Power Quality 1-17

2: Meter Overview and Specifications 2-1

2.1: EM-4000 Meter Overview 2-1

2.1.1: Voltage and Current Inputs 2-2

2.1.2: Ordering Information 2-3

2.1.4: Measured Values 2-5

2.1.5: Utility Peak Demand 2-6

2.2: Specifications 2-7

2.3: Compliance 2-12

2.4: Accuracy 2-13

3: Mechanical Installation 3-1

EM-4000 Series Meters Installation and Operation Manual TOC - 1

Page 8

Table of Contents

3.1: Introduction 3-1

3.2: ANSI Installation Steps 3-3

3.3: DIN Installation Steps 3-4

4: Electrical Installation 4-1

4.1: Considerations When Installing Meters 4-1

4.2: CT Leads Terminated to Meter 4-4

4.3: CT Leads Pass Through (No Meter Termination) 4-6

4.4: Quick Connect Crimp-on Terminations 4-7

4.5: Voltage and Power Supply Connections 4-8

4.6: Ground Connections 4-8

4.7: Voltage Fuses 4-9

4.8: Electrical Connection Diagrams 4-10

5: Communication Installation 5-1

5.1: EM-4000 Series Meter Communication 5-1

5.1.1: IrDA Port (Com 1) 5-1

5.1.2: RS485 / KYZ Output (Com 2) 5-1

6: Using the EM-4000 Meter 6-1

6.1: Introduction 6-1

6.1.1: Understanding Meter Face Elements 6-1

6.1.2: Understanding Meter Face Buttons 6-2

6.2: Using the Front Panel 6-3

6.2.1: Understanding Startup and Default Displays 6-3

6.2.2: Using the Main Menu 6-4

EM-4000 Series Meters Installation and Operation Manual TOC - 2

Page 9

Table of Contents

6.2.3: Using Reset Mode 6-5

6.2.4: Entering a Password 6-6

6.2.5: Using Configuration Mode 6-7

6.2.5.1: Configuring the Scroll Feature 6-9

6.2.5.2: Configuring CT Setting 6-10

6.2.5.3: Configuring PT Setting 6-11

6.2.5.4: Configuring Connection Setting 6-13

6.2.5.5: Configuring Communication Port Setting 6-13

6.2.6: Using Operating Mode 6-15

6.3: Understanding the % of Load Bar 6-16

6.4: Performing Watt-Hour Accuracy Testing (Verification) 6-17

7: Data Logging 7-1

7.1: Overview 7-1

7.2: Available Logs 7-1

A: EM-4000 Meter Navigation Maps A-1

A.1: Introduction A-1

A.2: Navigation Maps (Sheets 1 to 4) A-1

B: Modbus® Map and Retrieving Logs B-1

B.1: Introduction B-1

B.2: Modbus® Register Map Sections B-1

B.3: Data Formats B-1

B.4: Floating Point Values B-2

B.5: Important Note Concerning the EM-4000 Meter's

Modbus® Map B-3

EM-4000 Series Meters Installation and Operation Manual TOC - 3

Page 10

Table of Contents

B.5.1: Hex Representation B-3

B.6: Modbus® Register Map (MM-1 to MM-37) B-3

C: Using the USB to IrDA Adapter (CAB6490) C-1

C.1: Introduction C-1

C.2: Installation Procedures C-1

EM-4000 Series Meters Installation and Operation Manual TOC - 4

Page 11

1: Three-Phase Power Measurement

1: Three-Phase Power Measurement

This introduction to three-phase power and power measurement is intended to

provide only a brief overview of the subject. The professional meter engineer or meter

technician should refer to more advanced documents such as the EEI Handbook for

Electricity Metering and the application standards for more in-depth and technical

coverage of the subject.

1.1: Three-Phase System Configurations

Three-phase power is most commonly used in situations where large amounts of

power will be used because it is a more effective way to transmit the power and

because it provides a smoother delivery of power to the end load. There are two

commonly used connections for three-phase power, a wye connection or a delta

connection. Each connection has several different manifestations in actual use.

When attempting to determine the type of connection in use, it is a good practice to

follow the circuit back to the transformer that is serving the circuit. It is often not

possible to conclusively determine the correct circuit connection simply by counting

the wires in the service or checking voltages. Checking the transformer connection

will provide conclusive evidence of the circuit connection and the relationships

between the phase voltages and ground.

1.1.1: Wye Connection

The wye connection is so called because when you look at the phase relationships and

the winding relationships between the phases it looks like a Y. Figure 1.1 depicts the

winding relationships for a wye-connected service. In a wye service the neutral (or

center point of the wye) is typically grounded. This leads to common voltages of 208/

120 and 480/277 (where the first number represents the phase-to-phase voltage and

the second number represents the phase-to-ground voltage).

EM-4000 Series Meters Installation and Operation Manual 1-1

Page 12

1: Three-Phase Power Measurement

V

A

Phase 3

Phase 2

V

B

Figure 1.1: Three-phase Wye Winding

The three voltages are separated by 120o electrically. Under balanced load conditions

the currents are also separated by 120

conditions can cause the currents to depart from the ideal 120

V

C

N

Phase 1

o

. However, unbalanced loads and other

V

A

o

separation. Threephase voltages and currents are usually represented with a phasor diagram. A phasor

diagram for the typical connected voltages and currents is shown in Figure 1.2.

V

C

I

C

N

I

A

I

V

B

Figure 1.2: Phasor Diagram Showing Three-phase Voltages and Currents

B

EM-4000 Series Meters Installation and Operation Manual 1-2

Page 13

1: Three-Phase Power Measurement

The phasor diagram shows the 120o angular separation between the phase voltages.

The phase-to-phase voltage in a balanced three-phase wye system is 1.732 times the

phase-to-neutral voltage. The center point of the wye is tied together and is typically

grounded. Table 1.1 shows the common voltages used in the United States for wyeconnected systems.

Phase to Ground Voltage Phase to Phase Voltage

120 volts 208 volts

277 volts 480 volts

2,400 volts 4,160 volts

7,200 volts 12,470 volts

7,620 volts 13,200 volts

Table 1: Common Phase Voltages on Wye Services

Usually a wye-connected service will have four wires: three wires for the phases and

one for the neutral. The three-phase wires connect to the three phases (as shown in

Figure 1.1). The neutral wire is typically tied to the ground or center point of the wye.

In many industrial applications the facility will be fed with a four-wire wye service but

only three wires will be run to individual loads. The load is then often referred to as a

delta-connected load but the service to the facility is still a wye service; it contains

four wires if you trace the circuit back to its source (usually a transformer). In this

type of connection the phase to ground voltage will be the phase-to-ground voltage

indicated in Table 1, even though a neutral or ground wire is not physically present at

the load. The transformer is the best place to determine the circuit connection type

because this is a location where the voltage reference to ground can be conclusively

identified.

EM-4000 Series Meters Installation and Operation Manual 1-3

Page 14

1.1.2: Delta Connection

V

A

V

B

Delta-connected services may be fed with either three wires or four wires. In a threephase delta service the load windings are connected from phase-to-phase rather than

from phase-to-ground. Figure 1.3 shows the physical load connections for a delta

service.

V

1: Three-Phase Power Measurement

C

Phase 2

Phase 1

Figure 1.3: Three-phase Delta Winding Relationship

In this example of a delta service, three wires will transmit the power to the load. In a

true delta service, the phase-to-ground voltage will usually not be balanced because

the ground is not at the center of the delta.

Figure 1.4 shows the phasor relationships between voltage and current on a threephase delta circuit.

In many delta services, one corner of the delta is grounded. This means the phase to

ground voltage will be zero for one phase and will be full phase-to-phase voltage for

Phase 3

the other two phases. This is done for protective purposes.

EM-4000 Series Meters Installation and Operation Manual 1-4

Page 15

1: Three-Phase Power Measurement

V

A

V

BC

Figure 1.4: Phasor Diagram, Three-Phase Voltages and Currents, Delta-Connected

Another common delta connection is the four-wire, grounded delta used for lighting

loads. In this connection the center point of one winding is grounded. On a 120/240

volt, four-wire, grounded delta service the phase-to-ground voltage would be 120

volts on two phases and 208 volts on the third phase. Figure 1.5 shows the phasor

diagram for the voltages in a three-phase, four-wire delta system.

V

I

C

I

B

V

AB

C

V

CA

I

A

V

CA

V

BC

Figure 1.5: Phasor Diagram Showing Three-phase Four-Wire Delta-Connected System

N

V

AB

V

B

EM-4000 Series Meters Installation and Operation Manual 1-5

Page 16

1: Three-Phase Power Measurement

1.1.3: Blondel’s Theorem and Three Phase Measurement

In 1893 an engineer and mathematician named Andre E. Blondel set forth the first

scientific basis for polyphase metering. His theorem states:

If energy is supplied to any system of conductors through N wires, the total power in

the system is given by the algebraic sum of the readings of N wattmeters so arranged

that each of the N wires contains one current coil, the corresponding potential coil

being connected between that wire and some common point. If this common point is

on one of the N wires, the measurement may be made by the use of N-1 Wattmeters.

The theorem may be stated more simply, in modern language:

In a system of N conductors, N-1 meter elements will measure the power or energy

taken provided that all the potential coils have a common tie to the conductor in

which there is no current coil.

Three-phase power measurement is accomplished by measuring the three individual

phases and adding them together to obtain the total three phase value. In older analog meters, this measurement was accomplished using up to three separate elements.

Each element combined the single-phase voltage and current to produce a torque on

the meter disk. All three elements were arranged around the disk so that the disk was

subjected to the combined torque of the three elements. As a result the disk would

turn at a higher speed and register power supplied by each of the three wires.

According to Blondel's Theorem, it was possible to reduce the number of elements

under certain conditions. For example, a three-phase, three-wire delta system could

be correctly measured with two elements (two potential coils and two current coils) if

the potential coils were connected between the three phases with one phase in common.

In a three-phase, four-wire wye system it is necessary to use three elements. Three

voltage coils are connected between the three phases and the common neutral conductor. A current coil is required in each of the three phases.

In modern digital meters, Blondel's Theorem is still applied to obtain proper metering.

The difference in modern meters is that the digital meter measures each phase voltage and current and calculates the single-phase power for each phase. The meter

then sums the three phase powers to a single three-phase reading.

EM-4000 Series Meters Installation and Operation Manual 1-6

Page 17

1: Three-Phase Power Measurement

Phase B

Phase C

Phase A

A

B

C

N

Node "n"

Some digital meters measure the individual phase power values one phase at a time.

This means the meter samples the voltage and current on one phase and calculates a

power value. Then it samples the second phase and calculates the power for the second phase. Finally, it samples the third phase and calculates that phase power. After

sampling all three phases, the meter adds the three readings to create the equivalent

three-phase power value. Using mathematical averaging techniques, this method can

derive a quite accurate measurement of three-phase power.

More advanced meters actually sample all three phases of voltage and current

simultaneously and calculate the individual phase and three-phase power values. The

advantage of simultaneous sampling is the reduction of error introduced due to the

difference in time when the samples were taken.

Figure 1.6: Three-Phase Wye Load Illustrating Kirchhoff’s Law and Blondel’s Theorem

Blondel's Theorem is a derivation that results from Kirchhoff's Law. Kirchhoff's Law

states that the sum of the currents into a node is zero. Another way of stating the

same thing is that the current into a node (connection point) must equal the current

out of the node. The law can be applied to measuring three-phase loads. Figure 1.6

shows a typical connection of a three-phase load applied to a three-phase, four-wire

service. Kirchhoff's Law holds that the sum of currents A, B, C and N must equal zero

or that the sum of currents into Node "n" must equal zero.

If we measure the currents in wires A, B and C, we then know the current in wire N by

Kirchhoff's Law and it is not necessary to measure it. This fact leads us to the

conclusion of Blondel's Theorem- that we only need to measure the power in three of

EM-4000 Series Meters Installation and Operation Manual 1-7

Page 18

the four wires if they are connected by a common node. In the circuit of Figure 1.6 we

must measure the power flow in three wires. This will require three voltage coils and

three current coils (a three-element meter). Similar figures and conclusions could be

reached for other circuit configurations involving Delta-connected loads.

1.2: Power, Energy and Demand

It is quite common to exchange power, energy and demand without differentiating

between the three. Because this practice can lead to confusion, the differences

between these three measurements will be discussed.

Power is an instantaneous reading. The power reading provided by a meter is the

present flow of watts. Power is measured immediately just like current. In many

digital meters, the power value is actually measured and calculated over a one second

interval because it takes some amount of time to calculate the RMS values of voltage

1: Three-Phase Power Measurement

and current. But this time interval is kept small to preserve the instantaneous nature

of power.

Energy is always based on some time increment; it is the integration of power over a

defined time increment. Energy is an important value because almost all electric bills

are based, in part, on the amount of energy used.

Typically, electrical energy is measured in units of kilowatt-hours (kWh). A kilowatthour represents a constant load of one thousand watts (one kilowatt) for one hour.

Stated another way, if the power delivered (instantaneous watts) is measured as

1,000 watts and the load was served for a one hour time interval then the load would

have absorbed one kilowatt-hour of energy. A different load may have a constant

power requirement of 4,000 watts. If the load were served for one hour it would

absorb four kWh. If the load were served for 15 minutes it would absorb ¼ of that

total or one kWh.

Figure 1.7 shows a graph of power and the resulting energy that would be transmitted

as a result of the illustrated power values. For this illustration, it is assumed that the

power level is held constant for each minute when a measurement is taken. Each bar

in the graph will represent the power load for the one-minute increment of time. In

real life the power value moves almost constantly.

The data from Figure 1.7 is reproduced in Table 2 to illustrate the calculation of

energy. Since the time increment of the measurement is one minute and since we

EM-4000 Series Meters Installation and Operation Manual 1-8

Page 19

1: Three-Phase Power Measurement

0

10

20

30

40

50

60

70

80

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Time (minutes)

sttawolik

specified that the load is constant over that minute, we can convert the power reading

to an equivalent consumed energy reading by multiplying the power reading times 1/

60 (converting the time base from minutes to hours).

Figure 1.7: Power Use over Time

EM-4000 Series Meters Installation and Operation Manual 1-9

Page 20

1: Three-Phase Power Measurement

Time

Interval

(minute)

Power

(kW)

Energy

(kWh)

Accumulated

1 30 0.50 0.50

2 50 0.83 1.33

3 40 0.67 2.00

4 55 0.92 2.92

5 60 1.00 3.92

6 60 1.00 4.92

7 70 1.17 6.09

8 70 1.17 7.26

9 60 1.00 8.26

10 70 1.17 9.43

11 80 1.33 10.76

12 50 0.83 12.42

13 50 0.83 12.42

Energy

(kWh)

14 70 1.17 13.59

15 80 1.33 14.92

Table 1.2: Power and Energy Relationship over Time

As in Table 1.2, the accumulated energy for the power load profile of Figure 1.7 is

14.92 kWh.

Demand is also a time-based value. The demand is the average rate of energy use

over time. The actual label for demand is kilowatt-hours/hour but this is normally

reduced to kilowatts. This makes it easy to confuse demand with power, but demand

is not an instantaneous value. To calculate demand it is necessary to accumulate the

energy readings (as illustrated in Figure 1.7) and adjust the energy reading to an

hourly value that constitutes the demand.

In the example, the accumulated energy is 14.92 kWh. But this measurement was

made over a 15-minute interval. To convert the reading to a demand value, it must be

normalized to a 60-minute interval. If the pattern were repeated for an additional

three 15-minute intervals the total energy would be four times the measured value or

EM-4000 Series Meters Installation and Operation Manual 1-10

Page 21

1: Three-Phase Power Measurement

0

20

40

60

80

100

12345678

Intervals (15 mins.)

sruoh-ttawolik

59.68 kWh. The same process is applied to calculate the 15-minute demand value.

The demand value associated with the example load is 59.68 kWh/hr or 59.68 kWd.

Note that the peak instantaneous value of power is 80 kW, significantly more than the

demand value.

Figure 1.8 shows another example of energy and demand. In this case, each bar represents the energy consumed in a 15-minute interval. The energy use in each interval

typically falls between 50 and 70 kWh. However, during two intervals the energy rises

sharply and peaks at 100 kWh in interval number 7. This peak of usage will result in

setting a high demand reading. For each interval shown the demand value would be

four times the indicated energy reading. So interval 1 would have an associated

demand of 240 kWh/hr. Interval 7 will have a demand value of 400 kWh/hr. In the

data shown, this is the peak demand value and would be the number that would set

the demand charge on the utility bill.

As can be seen from this example, it is important to recognize the relationships

between power, energy and demand in order to control loads effectively or to monitor

use correctly.

EM-4000 Series Meters Installation and Operation Manual 1-11

Figure 1.8: Energy Use and Demand

Page 22

1.3: Reactive Energy and Power Factor

V

I

I

R

I

X

0

The real power and energy measurements discussed in the previous section relate to

the quantities that are most used in electrical systems. But it is often not sufficient to

only measure real power and energy. Reactive power is a critical component of the

total power picture because almost all real-life applications have an impact on reactive power. Reactive power and power factor concepts relate to both load and generation applications. However, this discussion will be limited to analysis of reactive power

and power factor as they relate to loads. To simplify the discussion, generation will

not be considered.

Real power (and energy) is the component of power that is the combination of the

voltage and the value of corresponding current that is directly in phase with the voltage. However, in actual practice the total current is almost never in phase with the

voltage. Since the current is not in phase with the voltage, it is necessary to consider

1: Three-Phase Power Measurement

both the inphase component and the component that is at quadrature (angularly

rotated 90

o

or perpendicular) to the voltage. Figure 1.9 shows a single-phase voltage

and current and breaks the current into its in-phase and quadrature components.

Figure 1.9: Voltage and Complex Current

The voltage (V) and the total current (I) can be combined to calculate the apparent

power or VA. The voltage and the in-phase current (I

real power or watts. The voltage and the quadrature current (I

) are combined to produce the

R

) are combined to cal-

X

culate the reactive power.

The quadrature current may be lagging the voltage (as shown in Figure 1.9) or it may

lead the voltage. When the quadrature current lags the voltage the load is requiring

both real power (watts) and reactive power (VARs). When the quadrature current

EM-4000 Series Meters Installation and Operation Manual 1-12

Page 23

1: Three-Phase Power Measurement

Displacement PF cos=

leads the voltage the load is requiring real power (watts) but is delivering reactive

power (VARs) back into the system; that is VARs are flowing in the opposite direction

of the real power flow.

Reactive power (VARs) is required in all power systems. Any equipment that uses

magnetization to operate requires VARs. Usually the magnitude of VARs is relatively

low compared to the real power quantities. Utilities have an interest in maintaining

VAR requirements at the customer to a low value in order to maximize the return on

plant invested to deliver energy. When lines are carrying VARs, they cannot carry as

many watts. So keeping the VAR content low allows a line to carry its full capacity of

watts. In order to encourage customers to keep VAR requirements low, some utilities

impose a penalty if the VAR content of the load rises above a specified value.

A common method of measuring reactive power requirements is power factor. Power

factor can be defined in two different ways. The more common method of calculating

power factor is the ratio of the real power to the apparent power. This relationship is

expressed in the following formula:

Total PF = real power / apparent power = watts/VA

This formula calculates a power factor quantity known as Total Power Factor. It is

called Total PF because it is based on the ratios of the power delivered. The delivered

power quantities will include the impacts of any existing harmonic content. If the voltage or current includes high levels of harmonic distortion the power values will be

affected. By calculating power factor from the power values, the power factor will

include the impact of harmonic distortion. In many cases this is the preferred method

of calculation because the entire impact of the actual voltage and current are

included.

A second type of power factor is Displacement Power Factor. Displacement PF is based

on the angular relationship between the voltage and current. Displacement power factor does not consider the magnitudes of voltage, current or power. It is solely based

on the phase angle differences. As a result, it does not include the impact of harmonic

distortion. Displacement power factor is calculated using the following equation:

EM-4000 Series Meters Installation and Operation Manual 1-13

Page 24

where is the angle between the voltage and the current (see Fig. 1.9).

Time

Amps

– 1000

– 500

0

500

1000

In applications where the voltage and current are not distorted, the Total Power Factor

will equal the Displacement Power Factor. But if harmonic distortion is present, the

two power factors will not be equal.

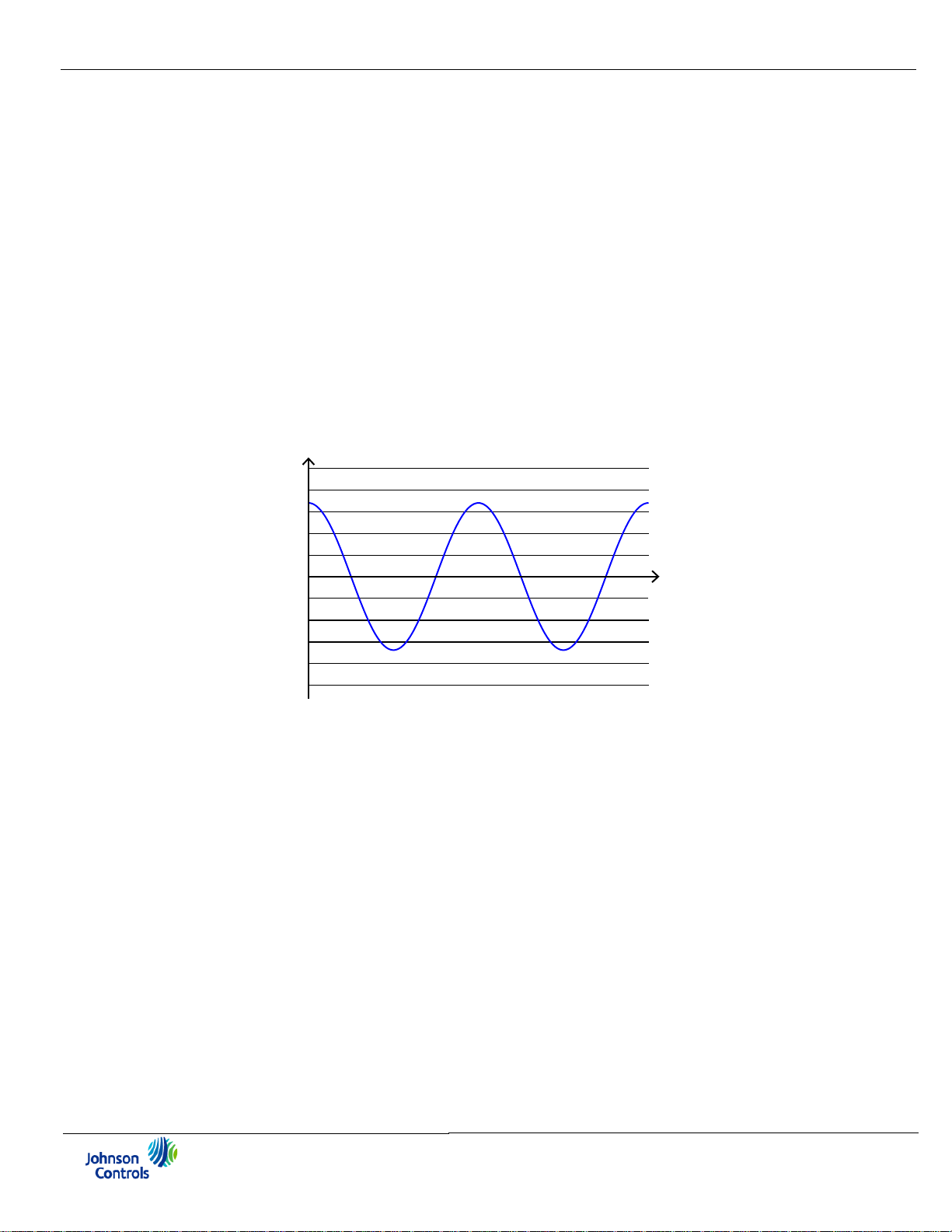

1.4: Harmonic Distortion

Harmonic distortion is primarily the result of high concentrations of non-linear loads.

Devices such as computer power supplies, variable speed drives and fluorescent light

ballasts make current demands that do not match the sinusoidal waveform of AC

electricity. As a result, the current waveform feeding these loads is periodic but not

sinusoidal. Figure 1.10 shows a normal, sinusoidal current waveform. This example

has no distortion.

1: Three-Phase Power Measurement

Figure 1.10: Nondistorted Current Waveform

Figure 1.11 shows a current waveform with a slight amount of harmonic distortion.

The waveform is still periodic and is fluctuating at the normal 60 Hz frequency.

However, the waveform is not a smooth sinusoidal form as seen in Figure 1.10.

EM-4000 Series Meters Installation and Operation Manual 1-14

Page 25

1: Three-Phase Power Measurement

–1000

–500

0

500

1000

t

)spma( tnerruC

a

2a

–1500

1500

Time

Amps

3rd harmonic

5th harmonic

7th harmonic

Total

fundamental

– 500

0

500

1000

Figure 1.11: Distorted Current Waveform

The distortion observed in Figure 1.11 can be modeled as the sum of several sinusoidal waveforms of frequencies that are multiples of the fundamental 60 Hz frequency.

This modeling is performed by mathematically disassembling the distorted waveform

into a collection of higher frequency waveforms.

These higher frequency waveforms are referred to as harmonics. Figure 1.12 shows

the content of the harmonic frequencies that make up the distortion portion of the

waveform in Figure 1.11.

Figure 1.12: Waveforms of the Harmonics

EM-4000 Series Meters Installation and Operation Manual 1-15

Page 26

1: Three-Phase Power Measurement

The waveforms shown in Figure 1.12 are not smoothed but do provide an indication of

the impact of combining multiple harmonic frequencies together.

When harmonics are present it is important to remember that these quantities are

operating at higher frequencies. Therefore, they do not always respond in the same

manner as 60 Hz values.

Inductive and capacitive impedance are present in all power systems. We are accustomed to thinking about these impedances as they perform at 60 Hz. However, these

impedances are subject to frequency variation.

X

= jL and

L

= 1/jC

X

C

At 60 Hz, = 377; but at 300 Hz (5th harmonic) = 1,885. As frequency changes

impedance changes and system impedance characteristics that are normal at 60 Hz

may behave entirely differently in the presence of higher order harmonic waveforms.

Traditionally, the most common harmonics have been the low order, odd frequencies,

such as the 3rd, 5th, 7th, and 9th. However newer, non-linear loads are introducing

significant quantities of higher order harmonics.

Since much voltage monitoring and almost all current monitoring is performed using

instrument transformers, the higher order harmonics are often not visible. Instrument

transformers are designed to pass 60 Hz quantities with high accuracy. These devices,

when designed for accuracy at low frequency, do not pass high frequencies with high

accuracy; at frequencies above about 1200 Hz they pass almost no information. So

when instrument transformers are used, they effectively filter out higher frequency

harmonic distortion making it impossible to see.

However, when monitors can be connected directly to the measured circuit (such as

direct connection to a 480 volt bus) the user may often see higher order harmonic

distortion. An important rule in any harmonics study is to evaluate the type of equipment and connections before drawing a conclusion. Not being able to see harmonic

distortion is not the same as not having harmonic distortion.

It is common in advanced meters to perform a function commonly referred to as

waveform capture. Waveform capture is the ability of a meter to capture a present

picture of the voltage or current waveform for viewing and harmonic analysis.

EM-4000 Series Meters Installation and Operation Manual 1-16

Page 27

Typically a waveform capture will be one or two cycles in duration and can be viewed

as the actual waveform, as a spectral view of the harmonic content, or a tabular view

showing the magnitude and phase shift of each harmonic value. Data collected with

waveform capture is typically not saved to memory. Waveform capture is a real-time

data collection event.

Waveform capture should not be confused with waveform recording that is used to

record multiple cycles of all voltage and current waveforms in response to a transient

condition.

1.5: Power Quality

Power quality can mean several different things. The terms "power quality" and

"power quality problem" have been applied to all types of conditions. A simple definition of "power quality problem" is any voltage, current or frequency deviation that

1: Three-Phase Power Measurement

results in mis-operation or failure of customer equipment or systems. The causes of

power quality problems vary widely and may originate in the customer equipment, in

an adjacent customer facility or with the utility.

In his book Power Quality Primer, Barry Kennedy provided information on different

types of power quality problems. Some of that information is summarized in Table

1.3.

EM-4000 Series Meters Installation and Operation Manual 1-17

Page 28

1: Three-Phase Power Measurement

Cause Disturbance Type Source

Impulse transient Transient voltage disturbance,

sub-cycle duration

Oscillatory

transient with decay

Transient voltage, sub-cycle

duration

Sag/swell RMS voltage, multiple cycle

duration

Interruptions RMS voltage, multiple

seconds or longer duration

Under voltage/over voltage RMS voltage, steady state,

multiple seconds or longer

duration

Voltage flicker RMS voltage, steady state,

repetitive condition

Harmonic distortion Steady state current or volt-

age, long-term duration

Lightning

Electrostatic discharge

Load switching

Capacitor switching

Line/cable switching

Capacitor switching

Load switching

Remote system faults

System protection

Circuit breakers

Fuses

Maintenance

Motor starting

Load variations

Load dropping

Intermittent loads

Motor starting

Arc furnaces

Non-linear loads

System resonance

Table 1.3: Typical Power Quality Problems and Sources

It is often assumed that power quality problems originate with the utility. While it is

true that many power quality problems can originate with the utility system, many

problems originate with customer equipment. Customer-caused problems may manifest themselves inside the customer location or they may be transported by the utility

system to another adjacent customer. Often, equipment that is sensitive to power

quality problems may in fact also be the cause of the problem.

If a power quality problem is suspected, it is generally wise to consult a power quality

professional for assistance in defining the cause and possible solutions to the

problem.

EM-4000 Series Meters Installation and Operation Manual 1-18

Page 29

2: Meter Overview and Specifications

2: Meter Overview and Specifications

2.1: EM-4000 Meter Overview

The EM-4000 meter is a multifunction, data

logging, power and energy meter with waveform recording capability, designed to be

used in electrical substations, panel boards,

as a power meter for OEM equipment, and as

a primary revenue meter, due to its high performance measurement capability. The unit

provides multifunction measurement of all

electrical parameters and makes the data

available in multiple formats via display and

communication systems. The unit also has

data logging and load profiling to provide

historical data analysis.

The EM-4000 meter offers 2 MegaBytes of Flash memory. (Because the memory is

flash-based rather than NVRAM (non-volatile random-access memory), some sectors

are reserved for overhead, erase procedures, and spare sectors for long-term wear

reduction.) The unit provides you with up to four logs: three historical logs and a

sequence of events log.

The purposes of these features include historical load profiling, voltage analysis, and

recording power factor distribution. The EM-4000 meter’s real-time clock allows all

events to be time stamped.

The EM-4000 meter is designed with advanced measurement capabilities, allowing it

to achieve high performance accuracy. It is specified as a 0.2% class energy meter for

billing applications as well as a highly accurate panel indication meter. It supplies

0.001 Hz Frequency measurement which meets generating stations’ requirements.

The EM-4000 meter provides additional capabilities, including standard RS485,

Figure 2.1: EM-4000 meter

Modbus® protocol support, and an IrDA port for remote interrogation.

Features of the EM-4000 meter include:

• 0.2% Class revenue certifiable energy and demand metering

• Meets ANSI C12.20 (0.2%) and IEC 62053-22 (0.2%) classes

EM-4000 Series Meters Installation and Operation Manual

2-1

Page 30

2: Meter Overview and Specifications

• Multifunction measurement including voltage, current, power, frequency, energy,

etc.

• Optional secondary Voltage display (see the EM Series Communicator Software

User Manual for instructions on setting up this feature)

• Percentage of Load bar for analog meter reading

• 0.001% Frequency measurement for Generating stations

• Interval energy logging

• Line frequency time synchronization

• Easy to use faceplate programming

• IrDA port for laptop PC remote read

• RS485 communication

• Transformer/Line Loss compensation (see the EM Series Communicator Software

User Manual for instructions on using this feature)

• CT/PT compensation (see the EM Series Communicator Software

instructions on using this feature)

2.1.1: Voltage and Current Inputs

Universal Voltage Inputs

Voltage inputs allow measurement up to Nominal 576VAC (Phase to Reference) and

721VAC (Phase to Phase). This insures proper meter safety when wiring directly to

high Voltage systems. The unit will perform to specification on 69 Volt, 120 Volt, 230

Volt, 277 Volt, and 347 Volt power systems.

NOTE: Higher Voltages require the use of potential transformers (PTs).

User Manual for

Current Inputs

The unit supports a 5 Amp secondary for current measurements.

The current inputs are only to be connected to external current transformers.

EM-4000 Series Meters Installation and Operation Manual

2-2

Page 31

2: Meter Overview and Specifications

The EM-4000 Series meter’s current inputs use a unique dual input method:

Method 1: CT Pass Through:

The CT wire passes directly through the meter without any physical termination on

the meter. This insures that the meter cannot be a point of failure on the CT circuit.

This is preferable for utility users when sharing relay class CTs. No Burden is added to

the secondary CT circuit.

Method 2: Current “Gills”:

This unit additionally provides ultra-rugged termination pass through bars that allow

CT leads to be terminated on the meter. This, too, eliminates any possible point of

failure at the meter. This is a preferred technique for insuring that relay class CT

integrity is not compromised (the CT will not open in a fault condition).

2.1.2: Ordering Information

EM-4000 Series Meter Ordering chart

Product-

Series

EM-4

EM-4000

Series

Meter

Example:

EM-4460-05-AI00

which translates to an EM-4000 Series meter with Modbus® communication, 60Hz

system, 90-265VAC/100-370VDC Power Supply, 5A Secondary Class, and ANSI

Network

Protocol Freq.

4

Modbus

50

50 H z

System

60

60 Hz

System

-Power

Supply

-0

90-265

VAC/

100-370

VDC

DI

Current

Class

5

5 Amp

S e c o n d a r y

Mounting 0 0

AI

ANSI

Mounting

DIN

Mounting

-

mounting. The last two options do not pertain to the EM-4000 Series meter, so the

ordering code contains 0s for them.

EM-4000 Series Meters Installation and Operation Manual

2-3

Page 32

2: Meter Overview and Specifications

CodeNumber Description

UNICOM2500 RS485toRS232Converter

UNICOM2500ͲF RS485toRS232orFiberConverter

E145350 2wireto4wireRS485cable,6'longforusewithUnicom2500/2500F

EIͲ1SPͲ100Ͳ00 100/5AsplitcoreCTwith.84"x2.0"window

EIͲ1SPͲ200Ͳ00 200/5AsplitcoreCTwith.84"x2.0"window

EIͲWC4Ͳ400ͲRA05

400/5AsplitcoreCTwith1.3"x1.7"window

EIͲ615Ͳ401 400/5AsplitcoreCTwith1.3"x1.6"window

EIͲ3SPͲ600Ͳ00 600/5AsplitcoreCTwith2.19"x3.25"window

EIͲ3SPͲ800Ͳ00 800/5AsplitcoreCTwith2.19"x3.25"window

EIͲ5SPͲ1200Ͳ00 1200/5AsplitcoreCTwith2.88"x4.25"window

EIͲ7SPͲ1600Ͳ00

1600/5AsplitcoreCTwith2.88"x6.25"window

EIͲ91SPͲ2000Ͳ00 2000/5AsplitcoreCTwith4.00"x7.50"window

EIͲ91SPͲ3000Ͳ00 3000/5AsplitcoreCTwith4.00"x7.50"window

EIͲ91SPͲ4000Ͳ00 4000/5AsplitcoreCTwith4.00"x7.50"window

EIͲ2SFTͲ500

50/5AsolidcoreCTwith1.13'IDwithterminalsandfeet

EIͲ2SFTͲ101 100/5AsolidcoreCTwith1.13'IDwithterminalsandfeet

EIͲ2SFTͲ201 200/5AsolidcoreCTwith1.13'IDwithterminalsandfeet

EIͲ5SFTͲ401 400/5AsolidcoreCTwith1.56'IDwithterminalsandfeet

EIͲ2DARLͲ500

50/5AsolidcoreCTwith1.00'ID

EIͲ2DARLͲ101 100/5AsolidcoreCTwith1.00'ID

EIͲ2DARLͲ201 200/5AsolidcoreCTwith1.00'ID

EIͲ5ARLͲ401 400/5AsolidcoreCTwith1.56'IDwithterminalsandfeet

EIͲ7RLͲ601 600/5AsolidcoreCTwith2.50'ID

EIͲ7RLͲ801 800/5AsolidcoreCTwith2.50'ID

EIͲ76RLͲ122

1200/5AsolidcoreCTwith3.00'ID

EIͲ8RLͲ162 1600/5AsolidcoreCTwith3.00'ID

EIͲ2VTͲ460Ͳ480FF 3PhDeltaͲDelta480/120VPotentialTransformer,fusedP&S

EIͲ3VT472Ͳ480Ͳ208FF 3PhWyeͲWye277/480:208/120VPT,fusedP&S

EIͲ75481P 480/120,75VAcontrolpowertransforme

r

EIͲCP protectivefuse/fuseblockki

t

EIͲMSB10Ͳ400 surgeprotecto

r

EIͲSBͲ6TC EMSeriesMetersixpoleCTshortingblockwithprotectivecove

r

EIͲFPͲ8110SAͲ25 EMSeriesMeterfibercom10/100CoppertoFibermediaconverte

r

CAB6490 EMSeriesMeterUSBtoIrDAadapter

ANT18769 remotewirelessantennaki

t

The following chart lists components that can be ordered along with the EM-4000

meter.

EM-4000 Series Meters Installation and Operation Manual

2-4

Page 33

2: Meter Overview and Specifications

2.1.4: Measured Values

The EM-4000 Series meter provides the following measured values all in real time

instantaneous. As the table below shows, some values are also available in average,

maximum and minimum.

Table 1:

Measured Values Instantaneous Avg Max Min

Voltage L-N X X X

Voltage L-L X X X

Current per Phase X X X X

Current Neutral X X X X

WATT(A,B,C,Tot.) X X X X

VAR (A,B,C,Tot.) X X X X

VA (A,B,C,Tot.) X X X X

PF (A,B,C,Tot.) X X X X

+Watt-Hour (A,B,C,Tot.) X

-Watt-Hour (A,B,C,Tot.) X

Watt-Hour Net X

+VAR-Hour (A,B,C,Tot.) X

-VAR-Hour (A,B,C,Tot.) X

VAR-Hour Net (A,B,C,Tot.) X

VA-Hour (A,B,C,Tot.) X

Frequency X X X

Voltage Angles X

Current Angles X

% of Load Bar X

Waveform Scope X

EM-4000 Series Meters Installation and Operation Manual

2-5

Page 34

2.1.5: Utility Peak Demand

The EM-4000 Series meter provides user-configured Block (Fixed) window or Rolling

window Demand modes. This feature lets the user set up a customized Demand profile. Block window Demand mode records the average demand for time intervals the

user defines (usually 5, 15 or 30 minutes). Rolling window Demand mode functions

like multiple, overlapping Block windows. The user defines the subintervals at which

an average of Demand is calculated. An example of Rolling window Demand mode

would be a 15-minute Demand block using 5-minute subintervals, thus providing a

new Demand reading every 5 minutes, based on the last 15 minutes.

Utility Demand features can be used to calculate Watt, VAR, VA and PF readings.

Voltage provides an instantaneous Max and Min reading which displays the highest

surge and lowest sag seen by the meter. All other parameters offer Max and Min

capability over the user-selectable averaging period.

2: Meter Overview and Specifications

EM-4000 Series Meters Installation and Operation Manual

2-6

Page 35

2.2: Specifications

Power Supply

Range: Universal, (90 to 265)

Power Consumption: (5 to 10)VA, (3.5 to 7)W -

Voltage Inputs

(For Accuracy specifications, see Section 2.4.)

2: Meter Overview and Specifications

VAC @50/60Hz or (100 to 370)VDC

depending on the meter’s hardware

configuration

Absolute Maximum Range: Universal, Auto-ranging:

Phase to Reference (Va, Vb, Vc to

Vref): (20 to 576)VAC

Phase to Phase (Va to Vb, Vb to Vc,

Vc to Va): (0 to 721)VAC

Supported hookups: 3 Element Wye, 2.5 Element Wye,

2 Element Delta, 4 Wire Delta

Input Impedance: 1M Ohm/Phase

Burden: 0.36VA/Phase Max at 600 Volts;

0.014VA at 120 Volts

Pickup Voltage: 20VAC

Connection: 7 Pin 0.400” Pluggable Terminal

Block

AWG#12 -26/ (0.129 -3.31) mm

EM-4000 Series Meters Installation and Operation Manual

2-7

2

Page 36

2: Meter Overview and Specifications

Fault Withstand: Meets IEEE C37.90.1

Reading: Programmable Full Scale to any PT

ratio

Current Inputs

(For Accuracy specifications, see Section 2.4.)

Class 10: 5A Nominal, 10A Maximum

Burden: 0.005VA Per Phase Max at 11 Amps

Pickup Current: 0.1% of Nominal (0.2% of Nominal

if using Current Only mode, that is,

there is no connection to the

Voltage inputs)

Connections: O Lug or U Lug electrical connec-

tion (Figure 4.1)

Pass through wire, 0.177” / 4.5mm

maximum diameter (Figure 4.2)

Quick connect, 0.25” male tab

(Figure 4.3)

Fault Withstand (at 23

Reading: Programmable Full Scale to any CT

o

C): 100A/10sec., 300A/3sec.,

500A/1sec.

ratio

Continuous Current Withstand: 20 Amps for screw terminated or

pass through connections

EM-4000 Series Meters Installation and Operation Manual

2-8

Page 37

2: Meter Overview and Specifications

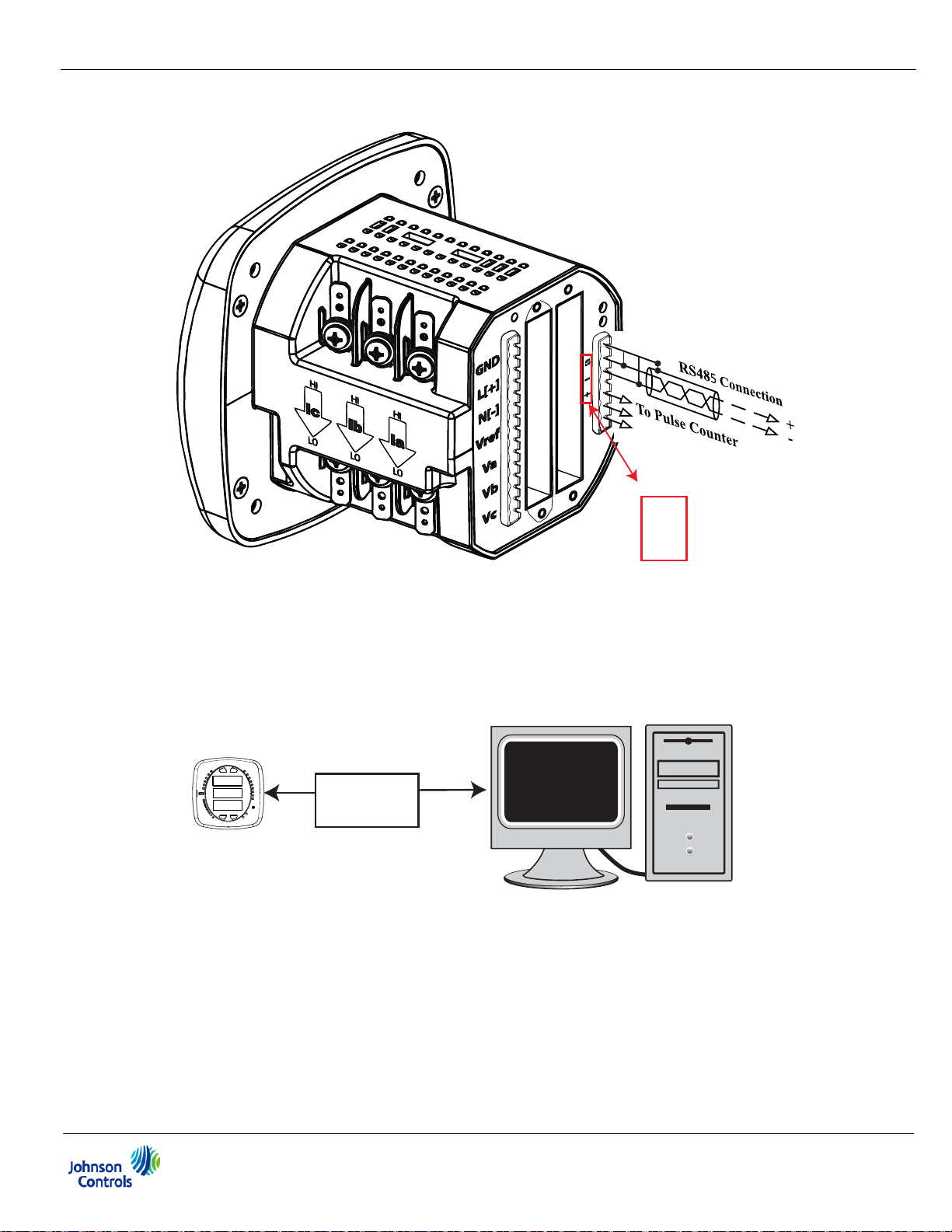

KYZ/RS485 Port Specifications

RS485 Transceiver; meets or exceeds EIA/TIA-485 Standard

Type: Two-wire, half duplex

Min. input Impedance: 96kΩ

Max. output current: ±60mA

Wh Pulse

KYZ output contacts, and infrared LED light pulses through face plate (see Section 6.4

for Kh values):

Pulse Width: 90ms

Full Scale Frequency: ~3Hz

Contact type: Solid state – SPDT (NO – C – NC)

Relay type: Solid state

Peak switching voltage: DC ±350V

Continuous load current: 120mA

Peak load current: 350mA for 10ms

On resistance, max.: 35Ω

Leakage current: 1µA@350V

Isolation: AC 3750V

Reset state: (NC - C) Closed; (NO - C) Open

EM-4000 Series Meters Installation and Operation Manual

2-9

Page 38

2: Meter Overview and Specifications

(De-energized state)

N

O

C

N

C

90ms 90ms

][

3600

][

WattP

pulse

Watthour

Kh

sT

»

¼

º

«

¬

ª

LED

ON

LED

ON

LED

OFF

LED

OFF

LED

OFF

IR LED Light Pulses

Through face plate

N

O

C

N

C

N

O

C

N

C

N

O

C

N

C

N

O

C

N

C

N

O

C

N

C

KYZ output

Contact States

Through Backplate

P

[Watt] - Not a scaled value

K

h See Section 6-4 for values

Infrared LED:

Peak Spectral wavelength: 940nm

Reset state: Off

Internal schematic:

Output timing:

EM-4000 Series Meters Installation and Operation Manual

2-10

Page 39

Isolation

Environmental Rating

2: Meter Overview and Specifications

All Inputs and Outputs are galvanically isolated to 2500 VAC

Storage: (-20 to +70)

Operating: (-20 to +70)

o

C

o

C

Humidity: to 95% RH Non-condensing

Faceplate Rating: NEMA12 (Water Resistant), mount-

ing gasket included

Measurement Methods

Voltage, current: True RMS

Power: Sampling at over 400 samples per

cycle on all channels

Update Rate

Watts, VAR and VA: Every 6 cycles (e.g., 100ms @ 60

Hz)

All other parameters: Every 60 cycles (e.g., 1 s @ 60 Hz)

1 second for Current Only measurement, if reference Voltage is not

available

Communication

Standard:

1. RS485 port through backplate

2. IrDA port through faceplate

3. Energy pulse output through backplate and Infrared LED through faceplate

EM-4000 Series Meters Installation and Operation Manual

2-11

Page 40

2: Meter Overview and Specifications

Protocols: Modbus® RTU, Modbus® ASCII,

DNP 3.0

Com Port Baud Rate: RS485 Only: 1200, 2400, 4800;

All Com Ports: 9600 to 57600 bps

Com Port Address: 001-247

Data Format: 8 Bit, No Parity (RS485: also Even

or Odd Parity)

Mechanical Parameters

Dimensions: see Chapter 3.

Weight: 2 pounds/ 0.9kg (ships in a 6”

/15.24cm cube container)

2.3: Compliance

• UL/cUL Listed

• CE (EN61326-1, FCC Part 15, Subpart B, Class A)

• IEC 62053-22 (0.2% Class)

• ANSI C12.20 (0.2% Accuracy)

• ANSI (IEEE) C37.90.1 Surge Withstand

• ANSI C62.41 (Burst)

• EN61000-6-2 Immunity for Industrial Environments: 2005

• EN61000-6-4 Emission Standards for Industrial Environments: 2007

• EN61326 EMC Requirements: 2006

EM-4000 Series Meters Installation and Operation Manual

2-12

Page 41

2.4: Accuracy

(For full Range specifications see Section 2.2.)

2: Meter Overview and Specifications

EM-4000 Clock Accuracy: Max. +/-2 seconds per day at 25

For 23

o

C, 3 Phase balanced Wye or Delta load, at 50 or 60 Hz (as per order), 5A

(Class 10) nominal unit, accuracy as follows:

Table 2:

Parameter Accuracy Accuracy Input Range1

Voltage L-N [V] 0.1% of reading (69 to 480)V

Voltage L-L [V]

Current Phase [A]

Current Neutral (calculated) [A]

Active Power Total [W]

Active Energy Total [Wh]

0.2% of reading

0.1% of reading

2% of Full Scale

0.2% of reading

0.2% of reading

2

1, 3

1

1, 2

1, 2

(120 to 600)V

(0.15 to 5) A

(0.15 to 5) A @ (45 to 65)

Hz

(0.15 to 5) A @ (69 to

480) V @ +/- (0.5 to 1)

lag/lead PF

(0.15 to 5) A @ (69 to

480) V @ +/- (0.5 to 1)

lag/lead PF

o

C

Reactive Power Total

[VAR]

0.2% of reading

1, 2

(0.15 to 5) A @ (69 to

480) V @ +/- (0 to 0.8)

lag/lead PF

Reactive Energy Total

[VARh]

0.2% of reading

1, 2

(0.15 to 5) A @ (69 to

480) V @ +/- (0 to 0.8)

lag/lead PF

Apparent Power Total [VA]

0.2% of reading

1, 2

(0.15 to 5) A @ (69 to

480) V @ +/- (0.5 to 1)

lag/lead PF

Apparent Energy Total

[VAh]

0.2% of reading

1, 2

(0.15 to 5) A @ (69 to

480) V @ +/- (0.5 to 1)

lag/lead PF

Power Factor

0.2% of reading

1, 2

(0.15 to 5) A @ (69 to

480) V @ +/- (0.5 to 1)

lag/lead PF

Frequency [Hz] +/- 0.001 Hz (45 to 65) Hz

Load Bar

+/- 1 segment

1

(0.005 to 6) A

EM-4000 Series Meters Installation and Operation Manual

2-13

Page 42

2: Meter Overview and Specifications

1

• For 2.5 element programmed units, degrade accuracy by an additional 0.5% of

reading.

• For 1A (Class 2) Nominal, degrade accuracy to 0.5% of reading for watts and

energy; all other values 2 times rated accuracy.

• For 1A (Class 2) Nominal, the input current range for accuracy specification is

20% of the values listed in the table.

2

For unbalanced Voltage inputs where at least one crosses the 150V auto-scale

threshold (for example, 120V/120V/208V system), degrade the accuracy to 0.4%

of reading.

3

With reference Voltage applied (VA, VB, or VC). Otherwise, degrade accuracy to

0.2%. See hookup diagrams 8, 9, and 10 in Chapter 4.

EM-4000 Series Meters Installation and Operation Manual

2-14

Page 43

3: Mechanical Installation

0.06 [

0.15]

0.77 [1.95]

5.02 [12

.75]

Gasket

3.25 [8.26]

4.85 [12.32]

4.85 [12

.32]

0.95 [2.41]

3.1: Introduction

The EM-4000 meter can be installed using a standard ANSI C39.1 (4” round) or an

IEC 92mm DIN (square) form. In new installations, simply use existing DIN or ANSI

punches. For existing panels, pull out old analog meters and replace them with the

EM-4000 meter. See Chapter 4 for wiring diagrams.

NOTE: The drawings shown below and on the next page give you the meter dimensions in inches and centimeters [cm shown in brackets]. Tolerance is +/- 0.1” [.25

cm].

3: Mechanical Installation

Figure 3.1: Meter Front and Side Dimensions

EM-4000 Series Meters Installation and Operation Manual

3-1

Page 44

3: Mechanical Installation

3.56 [9.04]

3.56 [9.04]

CM

CM

3Q

8v

v

Figure 3.2: Meter Back Dimensions

Figure 3.3: ANSI and DIN Cutout Dimensions

Recommended Tools for EM-4000 meter Installation:

• #2 Phillips screwdriver

• Small adjustable wrench

• Wire cutters

The EM-4000 meter is designed to withstand harsh environmental conditions; however it is recommended you install it in a dry location, free from dirt and corrosive

substances (see Environmental specifications in Chapter 2).

EM-4000 Series Meters Installation and Operation Manual

3-2

Page 45

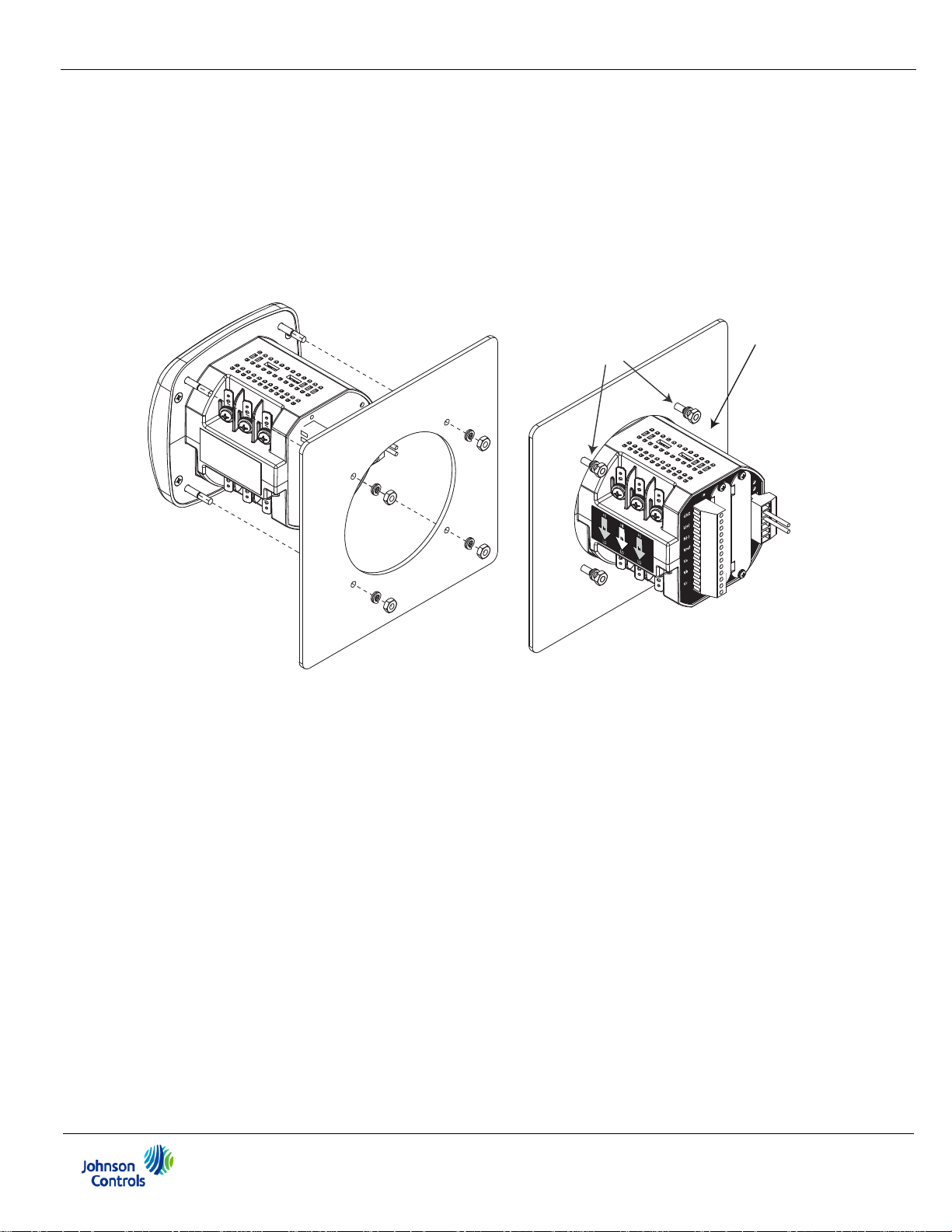

3.2: ANSI Installation Steps

ANSI Installation

ANSI Studs

4.0” Round form

1. Slide meter with Mounting Gasket into panel.

2. Secure from back of panel with flat washer, lock washer and nut on each threaded

rod. Use a small wrench to tighten. Do not overtighten. The maximum installation

torque is 0.4 Newton-Meter.

3: Mechanical Installation

Figure 3.4: ANSI Installation

EM-4000 Series Meters Installation and Operation Manual

3-3

Page 46

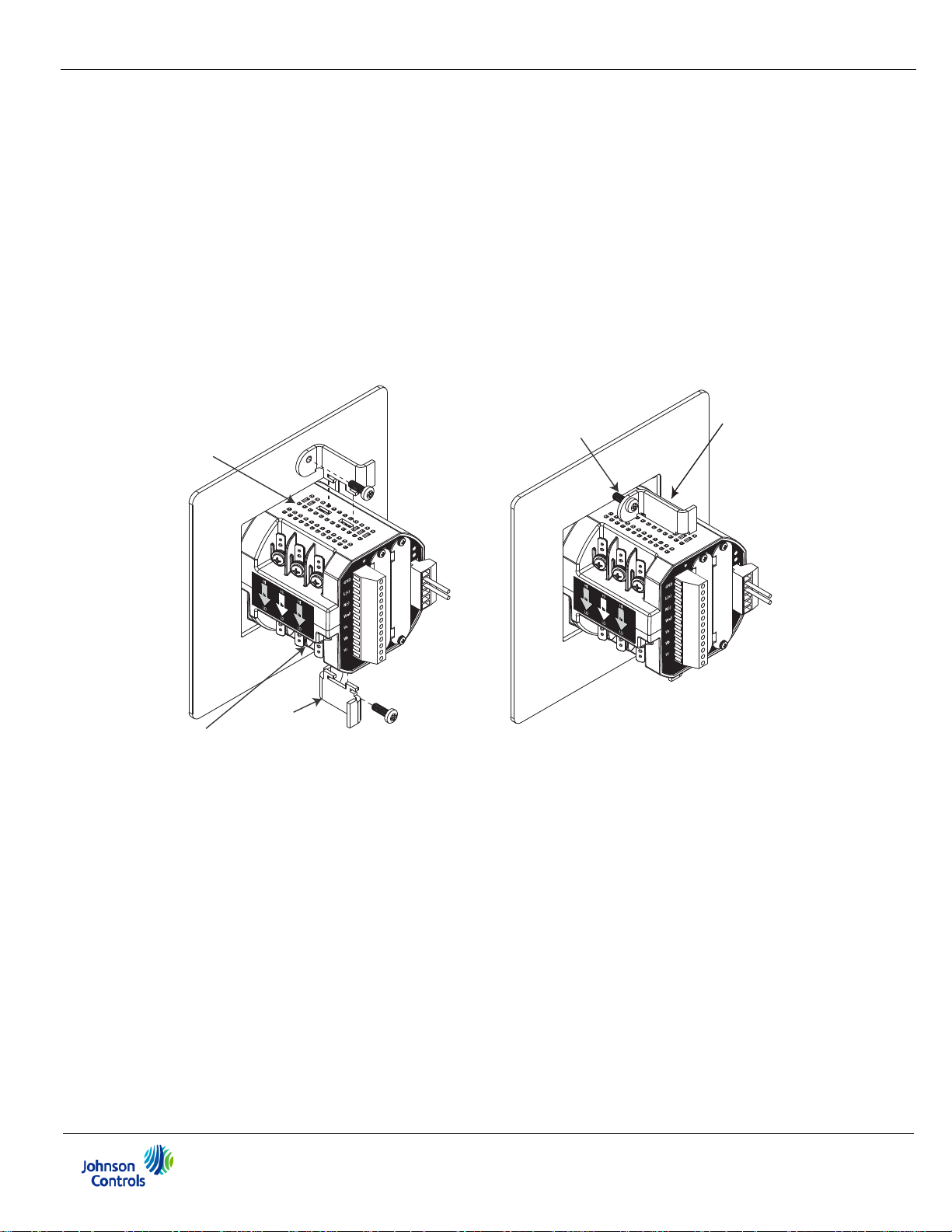

3.3: DIN Installation Steps

DIN mounting

bracket

Top mounting

bracket groove

Bottom

mounting

bracket groove

DIN Mounting brackets

Remove (unscrew) ANSI studs

for DIN installation

DIN Installation

92mm Square

form

1. Slide meter with NEMA 12 Mounting Gasket into panel (remove ANSI Studs, if in

place).

2. From back of panel, slide 2 DIN Mounting Brackets into grooves in top and bottom

of meter housing. Snap into place.

3. Secure meter to panel by using a #2 Phillips screwdriver to tighten the screw on

each of the two mounting brackets. Do not overtighten: the maximum installation

torque is 0.4 Newton-Meter.

3: Mechanical Installation

Figure 3.5: DIN Installation

EM-4000 Series Meters Installation and Operation Manual

3-4

Page 47

4: Electrical Installation

4: Electrical Installation

4.1: Considerations When Installing Meters

Installation of the EM-4000 meter must be performed only by qualified personnel who follow standard safety precautions during all procedures. Those personnel should have appropriate training and

experience with high Voltage devices. Appropriate safety gloves,

safety glasses and protective clothing are recommended.

During normal operation of the EM-4000 meter, dangerous Voltages flow through

many parts of the meter, including: Terminals and any connected CTs (Current Transformers) and PTs (Potential Transformers), all I/O Modules (Inputs and Outputs) and

their circuits.

All Primary and Secondary circuits can, at times, produce lethal Voltages and

currents. Avoid contact with any current-carrying surfaces.

Do not use the meter or any I/O Output device for primary protection or in

an energy-limiting capacity. The meter can only be used as secondary

protection.

Do not use the meter for applications where failure of the meter may cause harm or

death.

Do not use the meter for any application where there may be a risk of fire.

All meter terminals should be inaccessible after installation.

Do not apply more than the maximum Voltage the meter or any attached device can

withstand. Refer to meter and/or device labels and to the specifications for all devices

before applying voltages. Do not HIPOT/Dielectric test any Outputs, Inputs or Communications terminals.

Caution: Risk of Property Damage.

Do not apply power to the system before checking all wiring connections. Short circuited or improperly connected wires may result in

permanent damage to the equipment.

EM-4000 Series Meters Installation and Operation Manual

4-1

Page 48

4: Electrical Installation

Johnson Controls recommends the use of Fuses for Voltage leads and power supply

and shorting blocks to prevent hazardous Voltage conditions or damage to CTs, if the

meter needs to be removed from service. CT grounding is optional, but recommended.

NOTE: The current inputs are only to be connected to external current transformers

provided by the installer. The CTs shall be Approved or Certified and rated for the

current of the meter used.

Caution: Risk of Property Damage.

Ensure that the power source conforms to the requirements of the

equipment. Failure to use a correct power source may result in permanent damage to the equipment.

L'installation des compteurs de EM-4000 Series doit être effectuée

seulement par un personnel qualifié qui suit les normes relatives aux

précautions de sécurité pendant toute la procédure. Le personnel

doit avoir la formation appropriée et l'expérience avec les appareils

de haute tension. Des gants de sécurité, des verres et des vête-

ments de protection appropriés sont recommandés.

AVERTISSEMENT! Pendant le fonctionnement normal du compteur EM-4000 Series

des tensions dangereuses suivant de nombreuses pièces, notamment, les bornes et

tous les transformateurs de courant branchés, les transformateurs de tension, toutes

les sorties, les entrées et leurs circuits. Tous les circuits secondaires et primaires

peuvent parfois produire des tensions de létal et des courants. Évitez le contact avec les surfaces sous tensions. Avant de faire un travail dans le compteur, assurez-vous d'éteindre l'alimentation et de mettre tous les circuits

branchés hors tension.

Ne pas utiliser les compteurs ou sorties d'appareil pour une protection primaire ou capacité de limite d'énergie. Le compteur peut seulement être

utilisé comme une protection secondaire.

Ne pas utiliser le compteur pour application dans laquelle une panne de compteur

peut causer la mort ou des blessures graves.

Ne pas utiliser le compteur ou pour toute application dans laquelle un risque

d'incendie est susceptible.

EM-4000 Series Meters Installation and Operation Manual

4-2

Page 49

4: Electrical Installation

Toutes les bornes de compteur doivent être inaccessibles après l'installation.

Ne pas appliquer plus que la tension maximale que le compteur ou appareil relatif

peut résister. Référez-vous au compteur ou aux étiquettes de l'appareil et les spécifications de tous les appareils avant d'appliquer les tensions. Ne pas faire de test

HIPOT/diélectrique, une sortie, une entrée ou un terminal de réseau.

Les entrées actuelles doivent seulement être branchées aux transformateurs externes

actuels.

Johnson Controls recommande d'utiliser les fusibles pour les fils de tension et alimentations électriques, ainsi que des coupe-circuits pour prévenir les tensions dangereuses ou endommagements de transformateur de courant si l'unité EM-4000 Series

doit être enlevée du service. Un côté du transformateur de courant doit être mis à

terre.

NOTE: Les entrées actuelles doivent seulement être branchées dans le transformateur externe actuel par l'installateur. Le transformateur de courant doit être approuvé

ou certifié et déterminé pour le compteur actuel utilisé.

IMPORTANT!

IF THE EQUIPMENT IS USED IN A MANNER NOT SPECIFIED

BY THE MANUFACTURER, THE PROTECT I ON PROVIDED BY

THE EQUIPMENT MAY BE IMPAIRED.

• THERE IS NO REQUIRED PREVENTIVE MAINTENANCE OR INSPEC TION NECESSARY FOR SAFETY. HOWEVER, ANY REPAIR OR MAIN TENANCE SHOULD BE PERFORMED BY THE FACTORY.

DISCONNECT DEVICE: The following part is considered the equipment disconnect device. A SWITCH OR CIRCUIT-BREAKER SHALL BE

INCLUDED IN THE END-USE EQUIPMENT OR BUILDING INSTALLATION. THE SWITCH SHALL BE IN CLOSE PROXIMITY TO THE EQUIPMENT AND WITHIN EASY REACH OF THE OPERATOR. THE SWITCH

SHALL BE MARKED AS THE DISCONNECTING DEVICE FOR THE

EQUIPMENT.

EM-4000 Series Meters Installation and Operation Manual

4-3

Page 50

4: Electrical Installation

IMPORTANT! SI L'ÉQUIPEMENT EST UTILISÉ D'UNE FAÇON

NON SPÉCIFIÉE PAR LE FABRICANT, LA PROTECTION FOURNIE PAR L'ÉQUIPEMENT PEUT ÊTRE ENDOMMAGÉE.

NOTE: Il N'Y A AUCUNE MAINTENANCE REQUISE POUR LA PRÉVENTION OU INSPEC-

TION NÉCESSAIRE POUR LA SÉCURITÉ. CEPENDANT, TOUTE RÉPARATION OU MAINTENANCE DEVRAIT ÊTRE RÉALISÉE PAR LE FABRICANT.

DÉBRANCHEMENT DE L'APPAREIL : la partie suivante est considérée l'appareil de débranchement de l'équipement.

UN INTERRUPTEUR OU UN DISJONCTEUR DEVRAIT ÊTRE INCLUS

DANS L'UTILISATION FINALE DE L'ÉQUIPEMENT OU L'INSTALLATION.

L'INTERRUPTEUR DOIT ÊTRE DANS UNE PROXIMITÉ PROCHE DE

L'ÉQUIPEMENT ET A LA PORTÉE DE L'OPÉRATEUR. L'INTERRUPTEUR DOIT AVOIR LA

MENTION DÉBRANCHEMENT DE L'APPAREIL POUR L'ÉQUIPEMENT.

4.2: CT Leads Terminated to Meter

The EM-4000 meter is designed to have current inputs wired in one of three ways.

Figure 4.1 shows the most typical connection where CT Leads are terminated to the

meter at the current gills. This connection uses nickel-plated brass studs (current

gills) with screws at each end. This connection allows the CT wires to be terminated

using either an “O” or a “U” lug. Tighten the screws with a #2 Phillips screwdriver. The

maximum installation torque is 0.7376 foot-pounds (1 Newton-Meter).

EM-4000 Series Meters Installation and Operation Manual

4-4

Page 51

4: Electrical Installation

Current Gills

(nickel-plated

brass studs)

Other current connections are shown in figures 4.2 and 4.3. Voltage and RS485/KYZ

connections are shown in Figure 4.4.

Figure 4.1: CT Leads Terminated to Meter, #8 Screw for Lug Connection

Wiring Diagrams are shown in Section 4.8 of this chapter.

Communications connections are detailed in Chapter 5.

EM-4000 Series Meters Installation and Operation Manual

4-5

Page 52

4: Electrical Installation

$5XJSFQBTTJOH

UISPVHINFUFS

$VSSFOUHJMMT

SFNPWFE

4.3: CT Leads Pass Through (No Meter Termination)

The second method allows the CT wires to pass through the CT inputs without terminating at the meter. In this case, remove the current gills and place the CT wire

directly through the CT opening. The opening accommodates up to 0.177” / 4.5mm

maximum diameter CT wire.

Figure 4.2: Pass Through Wire Electrical Connection

EM-4000 Series Meters Installation and Operation Manual

4-6

Page 53

4.4: Quick Connect Crimp-on Terminations

Quick connect

crimp-on

terminations

For quick termination or for portable applications, 0.25” quick connect crimp-on

connectors can also be used

4: Electrical Installation

Figure 4.3: Quick Connect Electrical Connection

EM-4000 Series Meters Installation and Operation Manual

4-7

Page 54

4: Electrical Installation

QPXFS

TVQQMZ

JOQVUT

7PMUBHF

JOQVUT

34PVUQVU

%0/05QVU

7PMUBHFPO

UIFTF

UFSNJOBMT

,:;

*

4.5: Voltage and Power Supply Connections

Voltage inputs are connected to the back of the unit via optional wire connectors. The

connectors accommodate AWG# 12 -26/ (0.129 - 3.31)mm

2

.

*The power supply voltage range is Universal, (90 to 265) VAC @50/60Hz or

(100 to 370)VDC.

4.6: Ground Connections

The meter’s Ground terminals should be connected directly to the installation’s

protective earth ground. Use AWG# 12/2.5 mm

WARNING: Risk of Electric Shock.

Ground the meter according to local, national, and regional regulations.

Failure to ground the meter may result in electric shock and severe

personal injury or death.

AVERTISSEMENT: Risque de décharge électrique.

Effectuer la mise à terre selon les règlements locaux, nationaux et régionaux. La non mise

à la terre du compteur peut provoquer une décharge électrique, des blessures graves ou

provoquer la mort.

Figure 4.4: Meter Connections

2

wire for this connection.

EM-4000 Series Meters Installation and Operation Manual

4-8

Page 55

4.7: Voltage Fuses

Johnson Controls recommends the use of fuses on each of the sense voltages and on

the control power.

• Use a 0.1 Amp fuse on each voltage input.

• Use a 3 Amp Slow Blow fuse on the power supply.

4: Electrical Installation

EM-4000 Series Meters Installation and Operation Manual

4-9

Page 56

4.8: Electrical Connection Diagrams

The following pages contain electrical connection diagrams for the EM-4000 meter.

Choose the diagram that best suits your application. Be sure to maintain the CT

polarity when wiring.

The diagrams are presented in the following order:

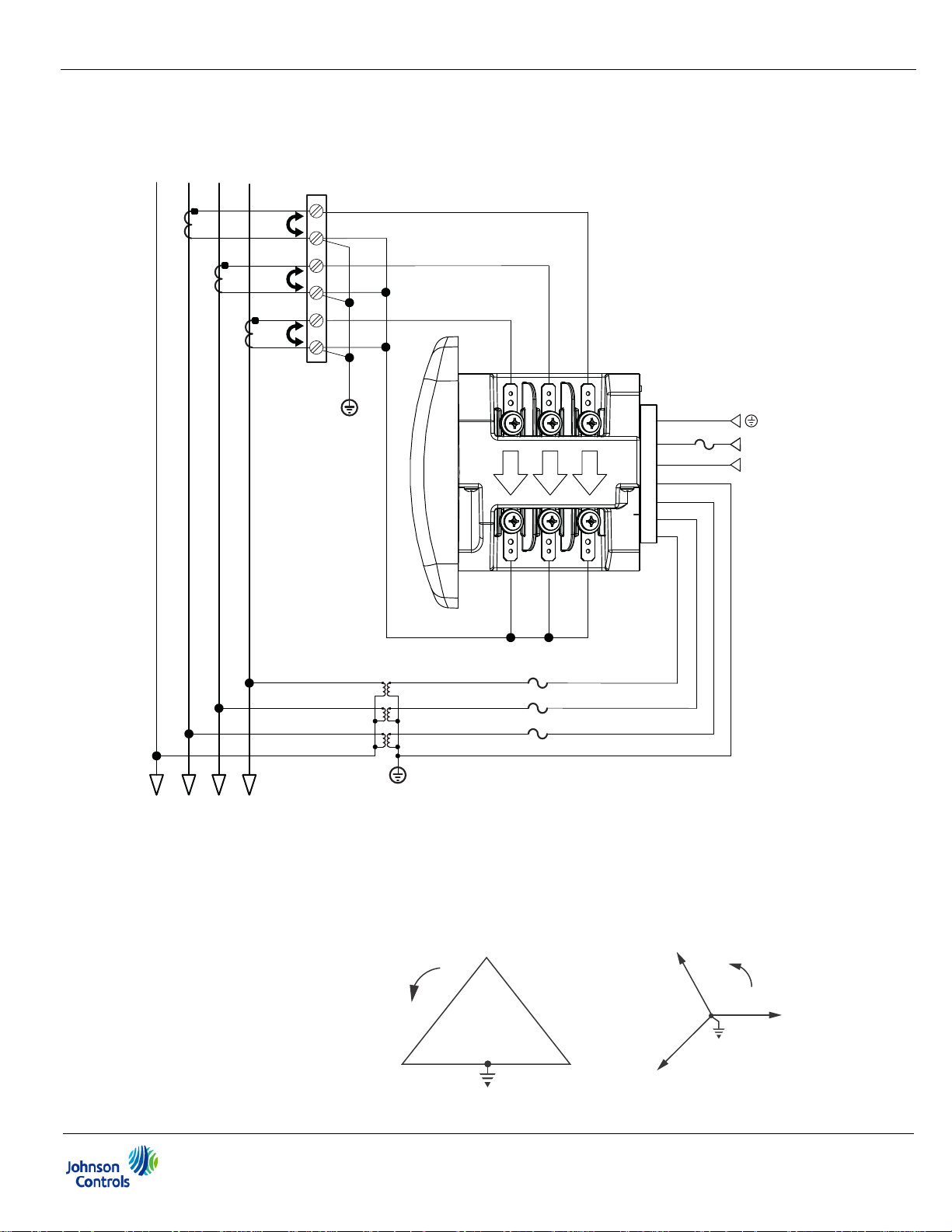

1. Three Phase, Four-Wire System Wye/Delta with Direct Voltage, 3 Element

a. Example of Dual-Phase Hookup

b. Example of Single Phase Hookup

2. Three Phase, Four-Wire System Wye with Direct Voltage, 2.5 Element

4: Electrical Installation

3. Three-Phase, Four-Wire Wye/Delta with PTs, 3 Element

4. Three-Phase, Four-Wire Wye with PTs, 2.5 Element

5. Three-Phase, Three-Wire Delta with Direct Voltage

6. Three-Phase, Three-Wire Delta with 2 PTs, 2 CTs

7. Three-Phase, Three-Wire Delta with 2 PTs, 3 CTs

8. Current Only Measurement (Three Phase)

9. Current Only Measurement (Dual Phase)

10.Current Only Measurement (Single Phase)

WARNING: Risk of Electric Shock.

Disconnect the power supply before making electrical connections.

Contact with components carrying hazardous voltage can cause electric shock

and may result in severe personal injury or death.

AVERTISSEMENT: Risque de décharge électrique.

Débranchez l’alimentation électrique avant de faire un branchement électrique. Le contact

avec des composants ayant des tensons importantes peut provoquer une décharge

électrique, des blessures personnelles graves ou la mort.

EM-4000 Series Meters Installation and Operation Manual

4-10

Page 57

4: Electrical Installation

C

B

A

C

BA

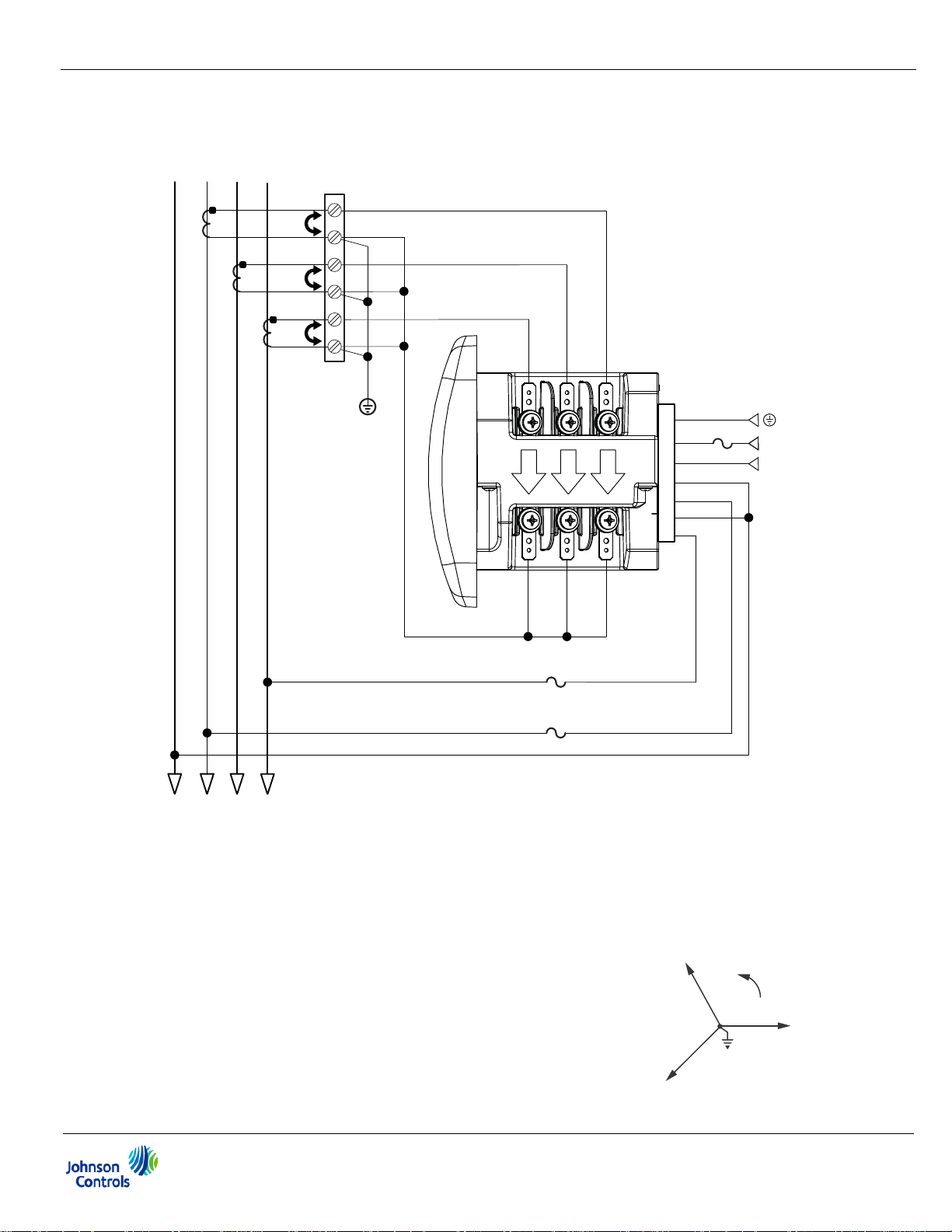

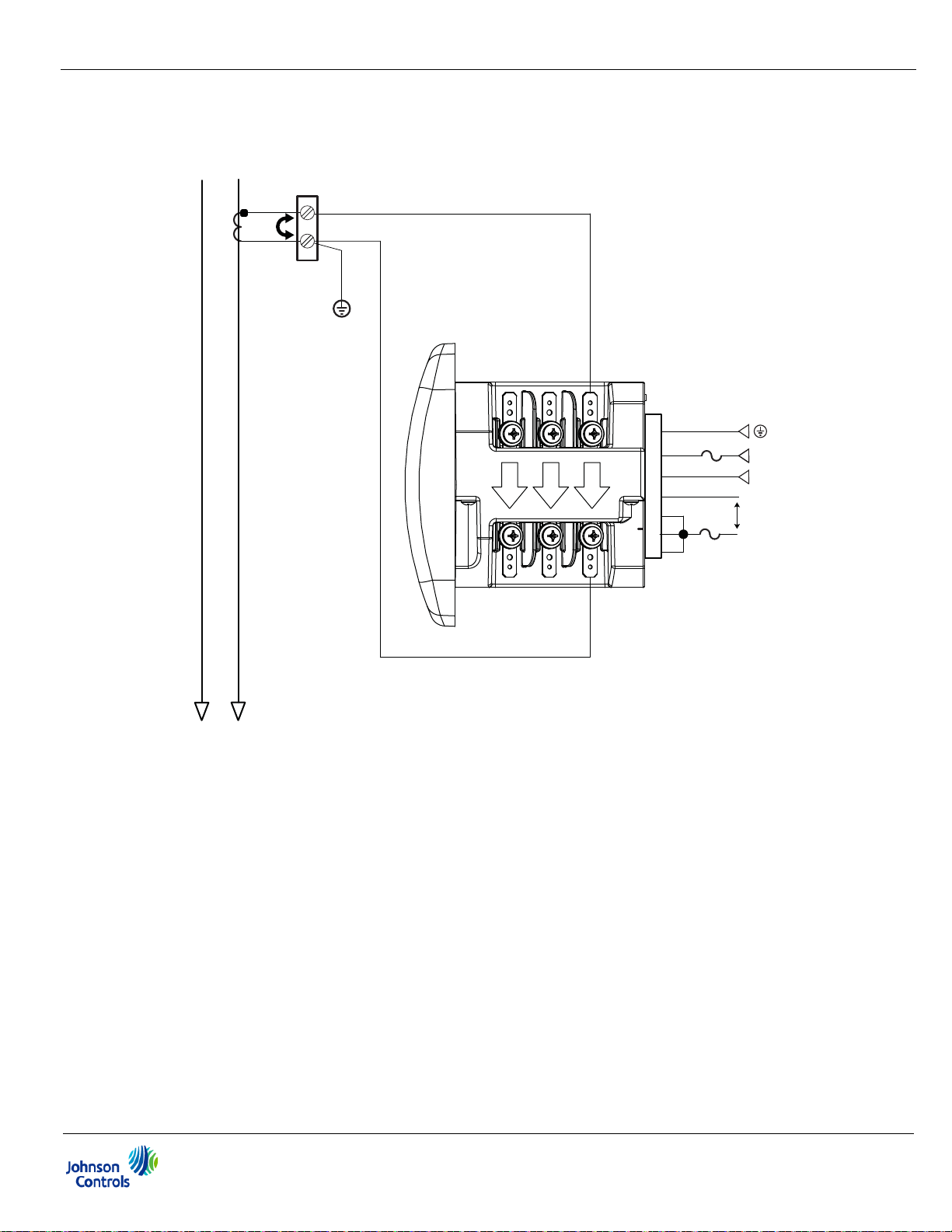

1. Service: WYE/Delta, 4-Wire with No PTs, 3 CTs

LINE

N

A

B

C

CT

Shorting

Block

Earth Ground

lc

LO

Power

Supply

Connection

GND

FUSE

HI

HI

HI

lb

la

LO

LO

L(+)

N(-)

Vref

Va

Vb

Vc

L(+)

3A

N(-)

FUSES

3 x 0.1A

N

A

LOAD

B

C

Select: “ 3 EL WYE ” (3 Element Wye) from the EM-4000 meter’s front panel display

(see Chapter 6).

EM-4000 Series Meters Installation and Operation Manual

4-11

Page 58

1a. Example of Dual Phase Hookup

LINE

C

B

A

N

4: Electrical Installation

N

A

LOAD

CT

Shorting

Block

Earth Ground

HI

HI

HI

lb

lc

LO

FUSES

2 x 0.1A

C

B

la

LO

LO

GND

L(+)

N(-)

Vref

Va

Vb

Vc

x

Power

Supply

Connection

FUSE

3A

L(+)

N(-)

Select: “ 3 EL WYE ” (3 Element Wye) from the EM-4000 meter’s Front Panel Display.

(See Chapter 6.)

EM-4000 Series Meters Installation and Operation Manual

4-12

Page 59

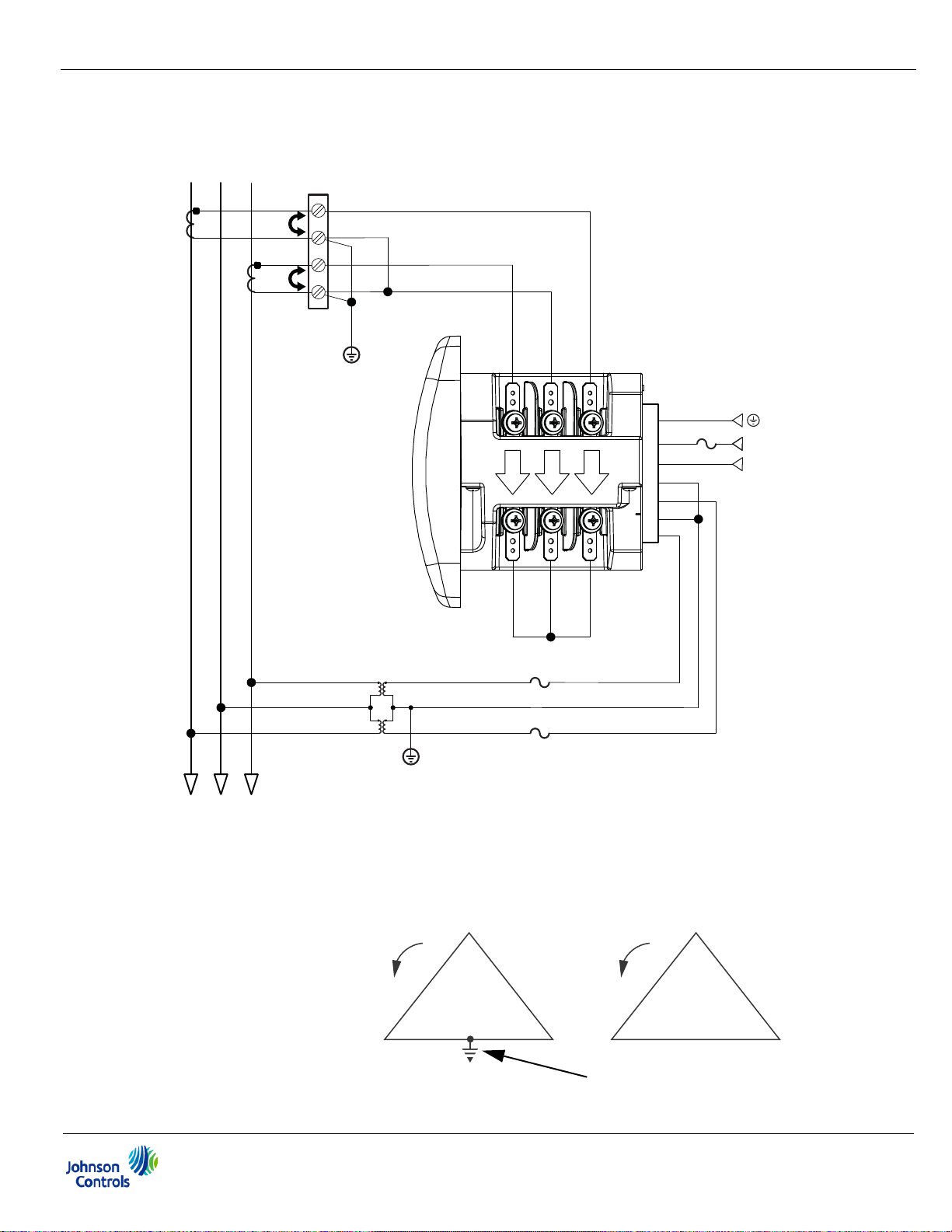

1b. Example of Single Phase Hookup

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

x

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

x

FUSE

0.1A

FUSE

3A

C

C

B

B

A

A

N

N

4: Electrical Installation

Select: “ 3 EL WYE ” (3 Element Wye) from the EM-4000 meter’s Front Panel Display.

(See Chapter 6.)

EM-4000 Series Meters Installation and Operation Manual

4-13

Page 60

4: Electrical Installation

C

B

A

2. Service: 2.5 Element WYE, 4-Wire with No PTs, 3 CTs

LINE

N

A

B

C

CT

Shorting

Block

Earth Ground

lc

LO

Power

Supply

Connection

GND

FUSE

HI

HI

HI

lb

la

LO

LO

L(+)

N(-)

Vref

Va

Vb

Vc

L(+)

3A

N(-)

FUSES

2 x 0.1A

N

A

LOAD

B

C

Select: “2.5 EL WYE” (2.5 Element Wye) from the EM-4000 meter’s front panel

display (see Chapter 6).

EM-4000 Series Meters Installation and Operation Manual

4-14

Page 61

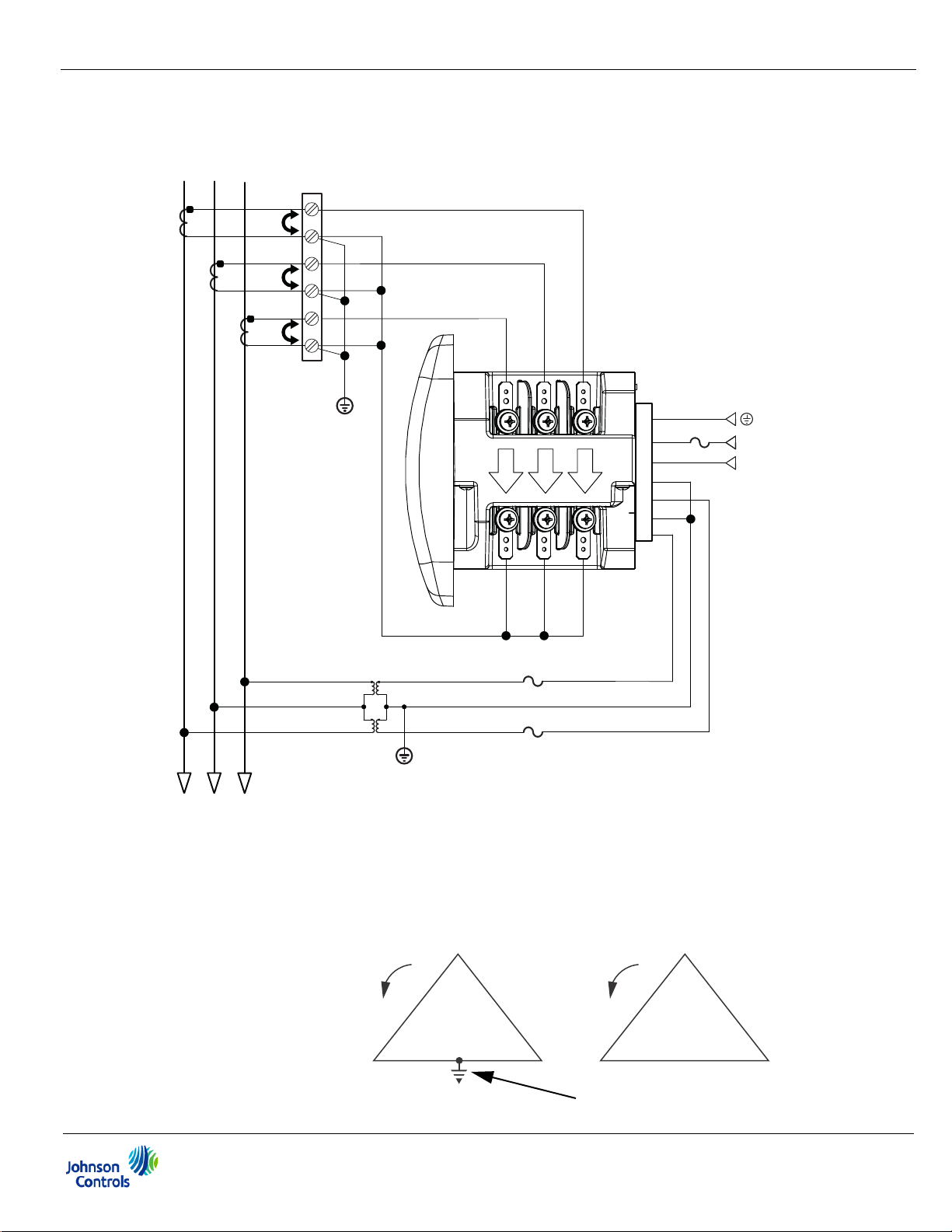

4: Electrical Installation

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

Earth Ground

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

FUSES

3 x 0.1A

FUSE

3A

C

C

B

B

A

A

N

N

C

BA

C

B

A

3. Service: WYE/Delta, 4-Wire with 3 PTs, 3 CTs

Select: “3 EL WYE” (3 Element Wye) from the EM-4000 meter’s front panel display

(see Chapter 6).

EM-4000 Series Meters Installation and Operation Manual

4-15

Page 62

4: Electrical Installation

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

Earth Ground

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

FUSES

2 x 0.1A

FUSE

3A

C

C

B

B

A

A

N

N

C

B

A

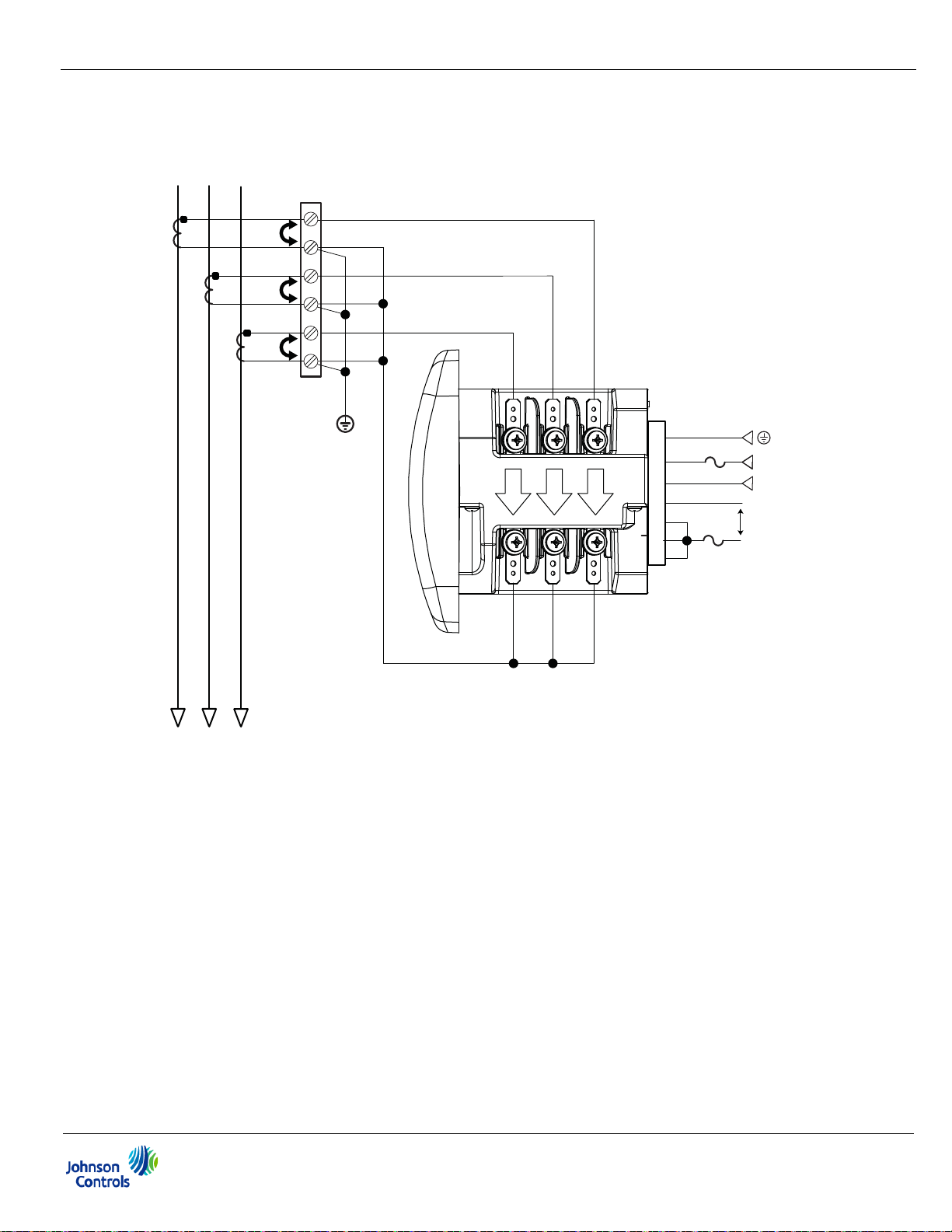

4. Service: 2.5 Element WYE, 4-Wire with 2 PTs, 3 CTs

Select: “2.5 EL WYE” (2.5 Element Wye) from the EM-4000 meter’s front panel

display (see Chapter 6).

EM-4000 Series Meters Installation and Operation Manual

4-16

Page 63

5. Service: Delta, 3-Wire with No PTs, 2 CTs

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

FUSES

3 x 0.1A

FUSE

3A

C

C

B

B

A

A

C

BA

C

BA

Not connected to meter

4: Electrical Installation

Select: “2 CT DEL” (2 CT Delta) from the EM-4000 meter’s front panel display (see

Chapter 6).

EM-4000 Series Meters Installation and Operation Manual

4-17

Page 64

6. Service: Delta, 3-Wire with 2 PTs, 2 CTs

C

BA

C

BA

Not connected to meter

LINE

B

A

C

CT

Shorting

Block

4: Electrical Installation

A

LOAD

B

C

Earth Ground

Earth Ground

lc

HI

LO

FUSES

2 x 0.1A

lb

Power

Supply

Connection

GND

FUSE

HI

HI

la

LO

LO

L(+)

N(-)

Vref

Va

Vb

Vc

L(+)

3A

N(-)

Select: “2 CT DEL” (2 CT Delta) from the EM-4000 meter’s front panel display (see

Chapter 6).

EM-4000 Series Meters Installation and Operation Manual

4-18

Page 65

7. Service: Delta, 3-Wire with 2 PTs, 3 CTs

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

Earth Ground

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

FUSES

2 x 0.1A

FUSE

3A

C

C

B

B

A

A

C

BA

C

BA

Not connected to meter

4: Electrical Installation

Select: “2 CT DEL” (2 CT Delta) from the EM-4000 meter’s front panel display (see

Chapter 6).

NOTE: The third CT for hookup is optional, and is used only for Current

measurement.

EM-4000 Series Meters Installation and Operation Manual

4-19

Page 66

4: Electrical Installation

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

L(+)

Power

Supply

Connection

N(-)

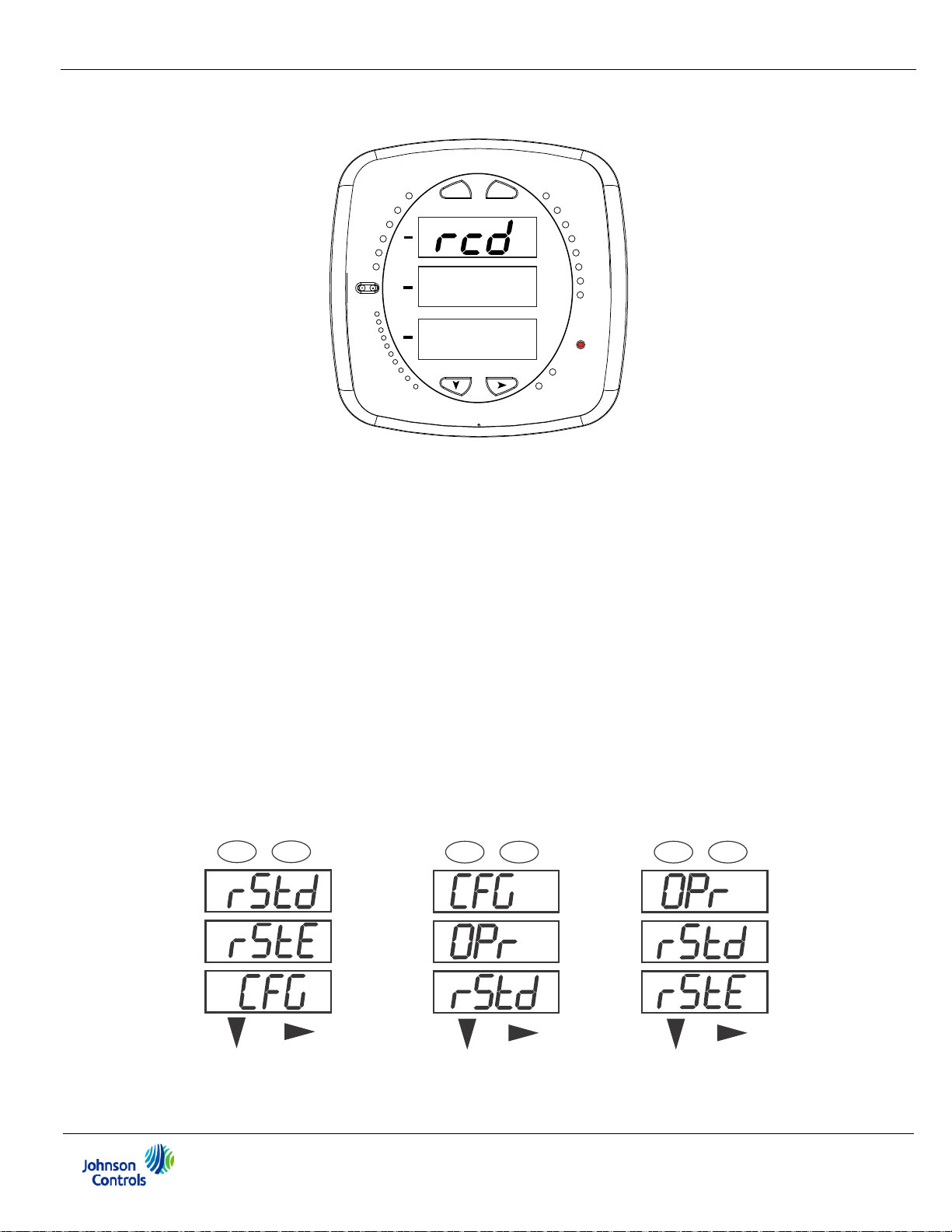

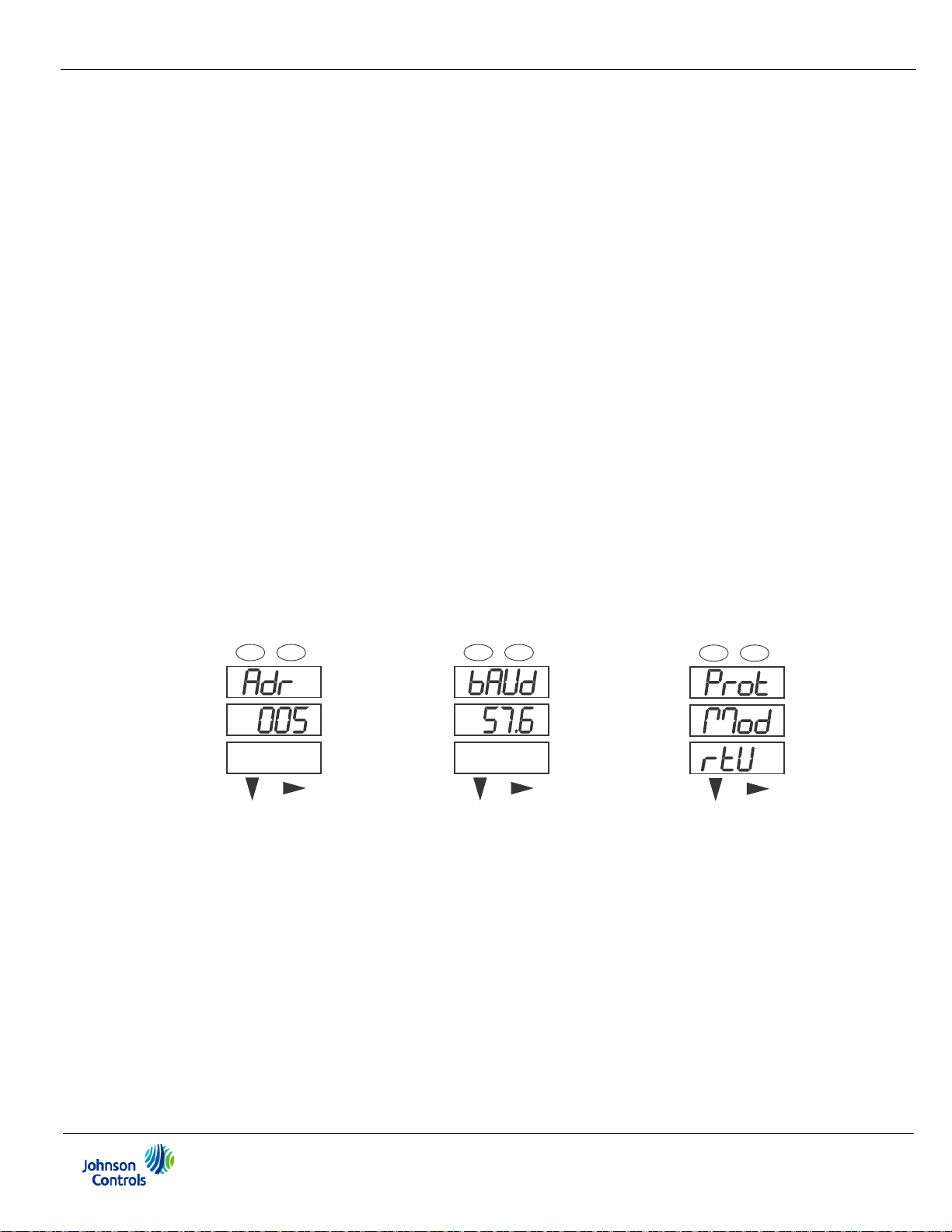

L(+)