Page 1

E-Link Gateway

Installation Instructions

Part No. 24-10404-9, Rev. D

Issued November 2, 2011

Supersedes April 29, 2011

Applications

The E-Link Gateway provides Johnson Controls® and

YORK® mechanical equipment, such as chillers and

rooftop units, with Building Automation System (BAS)

networking connectivity. It is designed with three active

serial ports: Port 1 and Port 4 are used for BAS

networking, Port 2 is reserved for connecting to the

equipment, and Port 3 provides access for auxiliary

monitoring and control.

To simplify the installation and setup, the E-Link

Gateway comes pre-configured with a series of chiller

and rooftop equipment profiles that you can choose by

selecting the correct DIP switch settings.

Several E-Link Gateway models are available for

connection to various types of input voltage and

equipment. For chillers using the OptiView™ or

Latitude Micro Panel, the E-Link Gateway consist s of a

single circuit board attached to four studs inside the

Micro Panel, using the accessory mounting kit. The

panel supplies 12 VDC input power, eliminating the

need for an external power supply.

For chillers using the IPU-II based Micro Panel, the

E-Link Gateway is installed inside the Micro Panel and

requires an additional transformer to supply power to

the E-Link Gateway. The transformer is included in the

E-Link IPU-II Installation Kit. (This kit is not available in

Europe. Use E-Link Gateway YK-ELNKE00-0.)

For other types of chillers, the E-Link Gateway is

packaged in its own enclosure. In addition to the E-Link

Gateway circuit board, a transformer is included inside

the enclosure that converts a 120- or 240-volt input to

24 VAC power.

North American Emissions Compliance

United States

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

the user will be required to correct the interference

at his/her own expense.

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Installation

The E-Link Gateway is supplied as a circuit board that

can be installed directly into the equipment’s enclosure,

or can be supplied pre-mounted in an enclosure ready

for line voltage. Accessory mounting kits are used to

mount the E-link Gateway directly into OptiView

Latitude, and IPU-II based Micro Panels.

IMPORTANT: Do not install the E-Link Gateway

directly into an equipment’s enclosure without the

use of an approved installation kit.

E-Link Gateway Installation Instructions 1

Page 2

IMPORTANT: The E-Link Gateway is intended to

provide an input to equipment under normal

operating conditions. Use this E-Link Gateway only

as an operating control. Where failure or malfunction

of the E-Link Gateway could lead to personal injury

or property damage to the controlled equipment or

other property, additional precautions must be

designed into the control system. Incorporate and

maintain other devices, such as supervisory or

alarm systems or safety or limit controls, intended to

warn of or protect against failure or malfunction of

the E-Link Gateway.

Table 1: YORK Chiller Models (Current

Production)

Board

Number

031-02550 BACnet®,

031-01095 YORK Talk 2,

031-02478 YORK Talk 2,

031-01065 YORK Talk 2,

031-01730 YORK Talk 3 YN, OM RETROFITS,

031-02430 YORK Talk 3 YK, YT, YS, YR, YST,

331-02496 BACnet® YPAL

YORK-003 Modbus R T U YEWS-D1, YEAS,

1

Language

(Native)

Modbus®,

YORK Talk 2,

4,800 bits per

second (bps)

4,800 bps

4,800 bps

1,200 bps

Chiller Model

YCWL, YCUL, YCAL,

YLAA, YCRL, YLPA

YCAS, YCWS, YCRS

YCAV, YCIV, YVAA

YIA, YPC, YG, YB

CR

YD, YMC

YGAS

2

2

Table 2: E-Link Gateway Product Code Numbers

Description Product Code

Numbers

E-Link with Serial Outputs (BACnet

MS/TP, Modbus Remote Terminal Unit

[RTU], and N2)

E-Link with LONWORKS® as an Output YK-ELNK101-0

E-Link with Serial Outputs in

Enclosure

E-Link with L

Enclosure

E-Link OptiView/Latitude Panel

Installation Kit

E-Link IPU-II Panel Installation Kit

(not available in Europe)

ONWORKS Output in

YK-ELNK100-0

YK-ELNKE00-0

YK-ELNKE01-0

YK-ELNKOLK-0

YK-ELNKSTK-0

1. Installing technician must verify board number in unit

prior to installation.

2. Software edition of YEWS-D1 (RHSYEWSD1) V1.08 or

later), YEAS (RHMASB V1.06 or later), YGAS

(RHMYGAS V1.03 or later) are supported.

E-Link Gateway Installation Instructions2

Page 3

Mounting

!

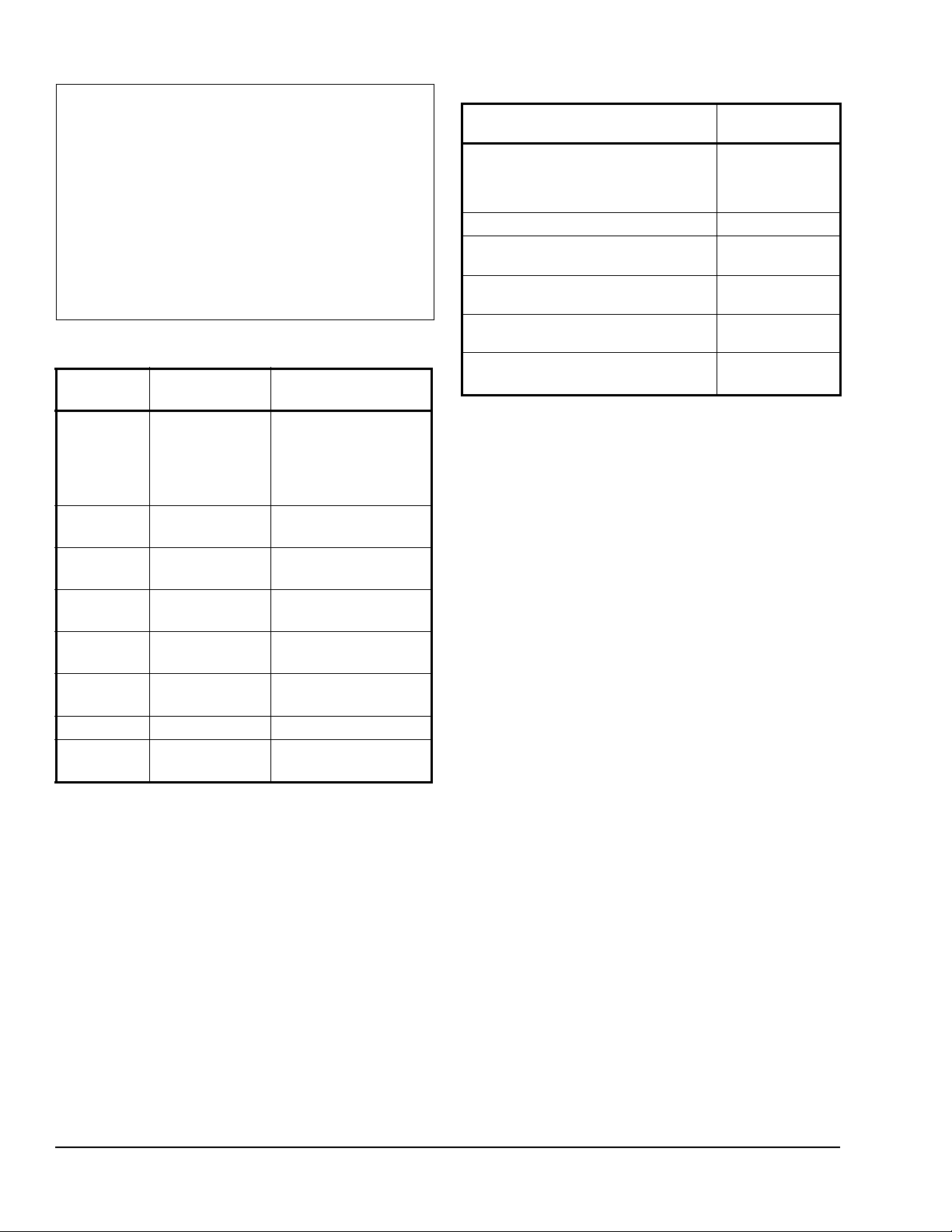

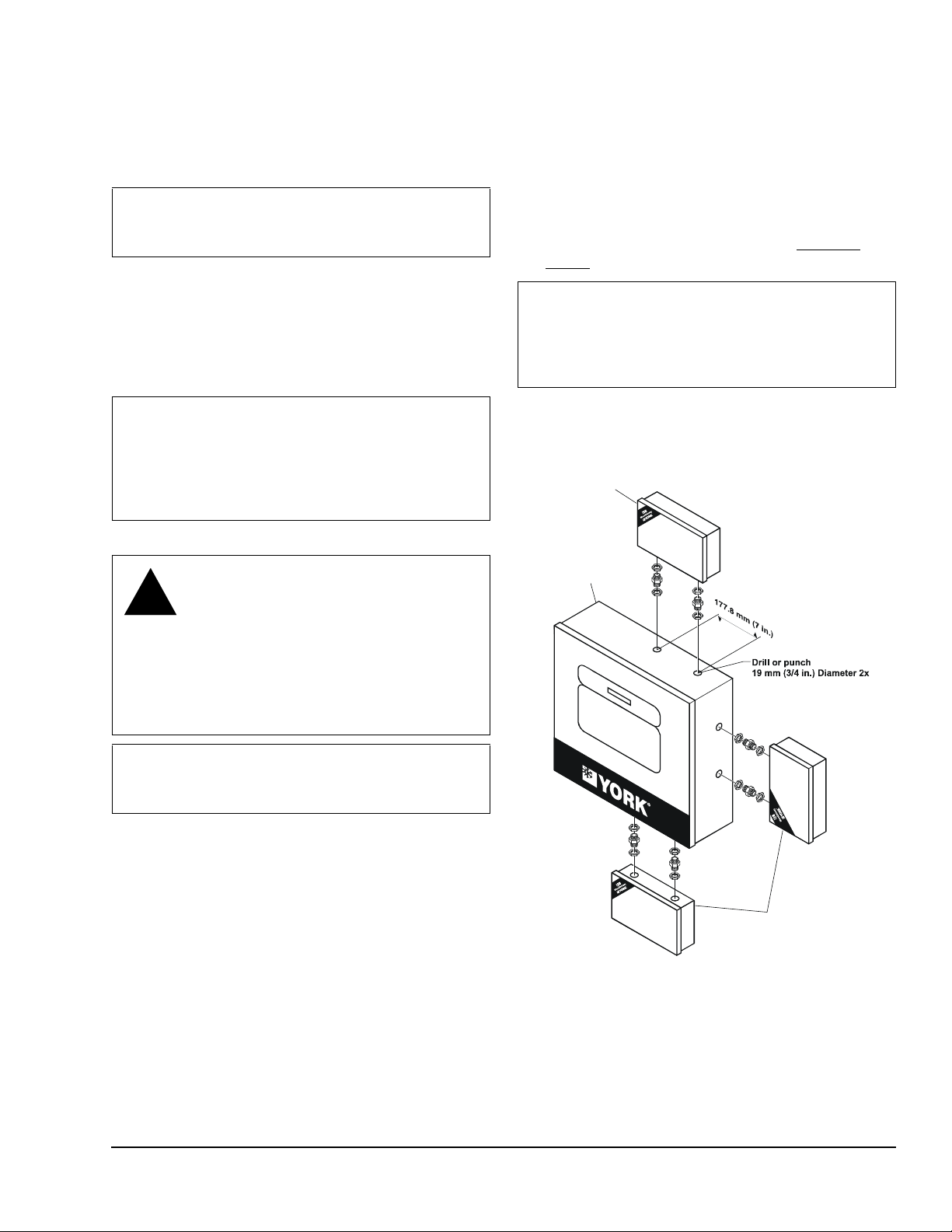

FIG:Opti_Pnl

Figure 1: OptiView Micro Panel Connected to

E-Link Gateway

FIG:Opti_Pnl1

Figure 2: OptiView Micro Panel for YMC2

Connected to E-Link Gateway

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections.

More than one disconnect or isolation

may be required to completely deenergize equipment. Contact with

components carrying hazardous voltage

can cause electric shock and may result

in severe personal injury or death.

OptiView Panel Installation

1. Attach the E-Link Gateway board to the studs

provided inside the chiller enclosure (Figure 1 or

Figure 2), using the four screws and washers

provided in the OptiView/Latitude installation kit.

2. Connect the communications cable (included with

the kit) from Port 2B on the E-Link Gateway to J2

on the OptiView Micro Panel. Ensure that wires are

connected according to Table 3.

3. Check for stray wire strands, which could cause

short circuits, and ensure all components are

secure.

4. Connect the BAS network to Port 1 (if the protocols

are transported by RS-485) or Port 4 (if the BAS

network is L

ONWORKS).

Note: For RS-485 2-wire operation, connect a 100

ohm 1 W resistor between COM and the E-Link

Gateway’s TB5 COM (see Figure 24).

5. Ensure jumper JP27 is set for RS-232 (see

Figure 20).

6. Connect the power harness (included with the kit)

from J2 on the E-Link Gateway to J21 on the

Optiview Micro Panel (see Figure 20).

The E-Link Gateway is now ready to be configured

using Quick Start; see the Commissioning a Standard

Application section in this document.

Table 3: OptiView Wiring - E-Link Port 2B

E-Link Port 2B OptiView Port Wire Color

RX GTX Black

TX GRX Red

REF N/A Shield/Drain

Table 4: BAS Wiring - E-Link Port 1

E-Link Port 1 BAS Wire Color

++White

--Blue

REF REF Black

E-Link Gateway Installation Instructions 3

Page 4

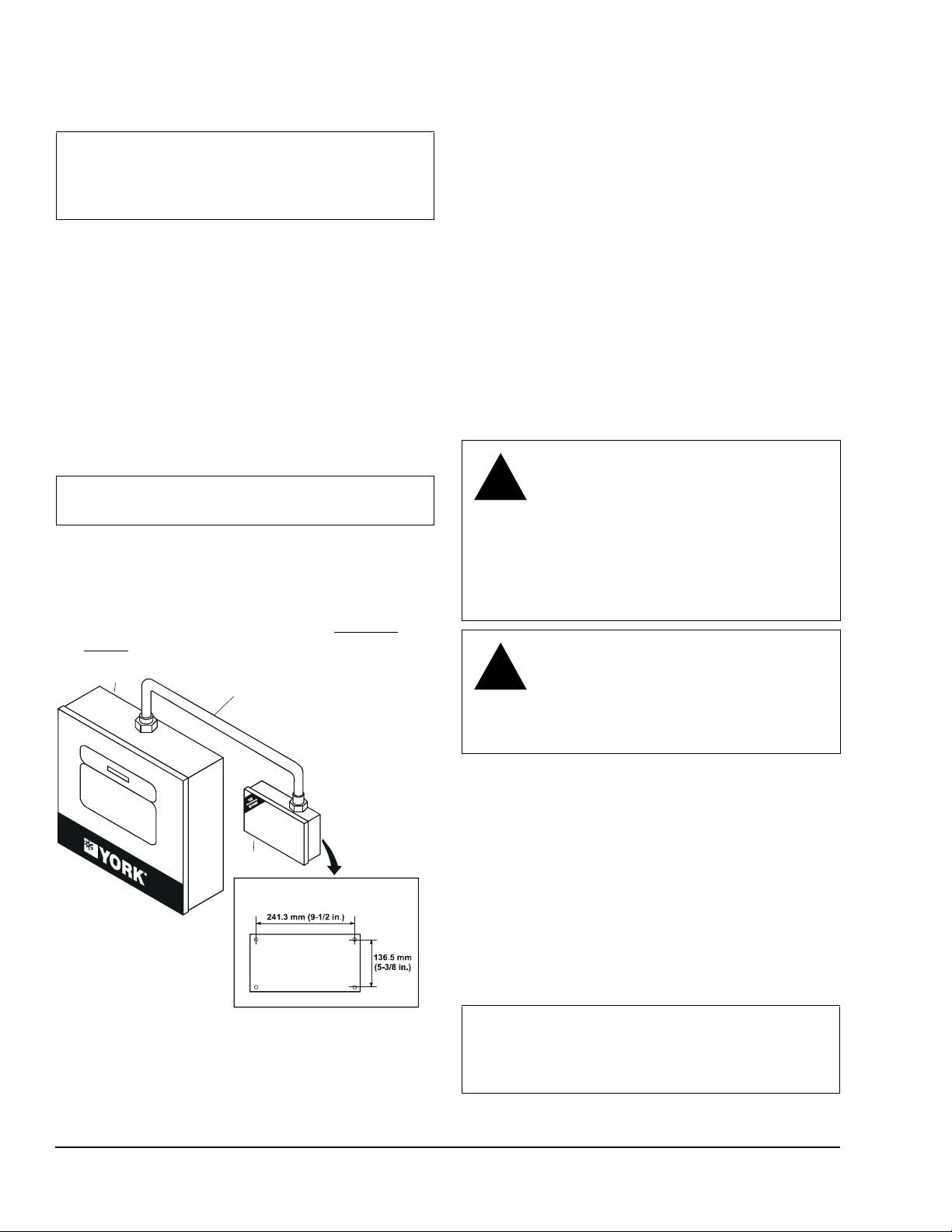

IPU-II Panel Installation

Micro Boar

d

24 VAC

Transforme

r

Expansion

Nut

Expansion

Nut

Screw

Sheet

Metal

Screw

Resisto

r

Secondar

y

Powe

r

Wiring

Harness

Tie

Wrap

T

B5

TB 2

E-LIN

K

Transforme

r

Secondar

y

Ground

Communication

Wiring Harness

Com

Ground

T B 1

T B 5

The Resistor is used for BAS

RS485 2 Wire Connection.

Connect one end of the

Resistor to the COM o

f

TB5 (24 VAC) and the othe

r

to Port 1 COM.

Use this resistor only if the

BAS wiring utilizes a 2 Wire

communication trunk

Communication Wiring Harness:

Connect to Micro Board

TB1 as Follows:

Wire Color / Terminal

Red / +

Black / -

+

-

REFSHLD

TB 1 RS485

F

I

G

:

I

P

U

p

n

l

i

n

s

t

Terminal block location

for YCAL-D, YCAL-E, and YLAA.

Terminal block location

for YCAL-C, YCWL, and

Primary Powe

r

Wiring Harness

TB2

TB5

Y

CUL-C.

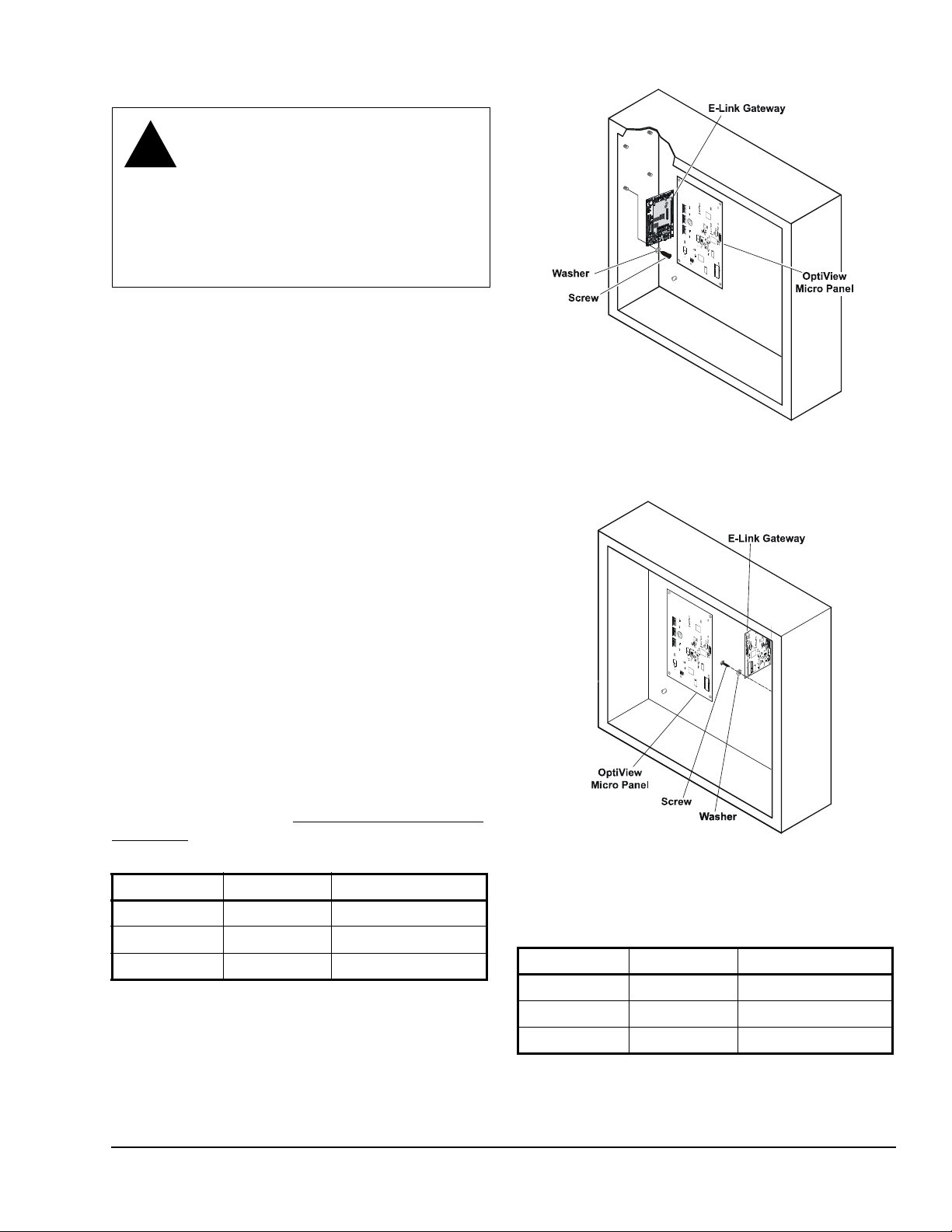

Figure 3: IPU-II Panel Installation (Installation Kit Not Available in Europe)

(Installation Kit Not Available in Europe)

1. Attach the E-Link Gateway board to the panel in

the upper right side of the enclosure using the four

expansion screws and nuts provided in the IPU-II

Panel Installation Kit (see Figure 3).

2. Attach the 24 VAC transformer to the panel to the

left of the E-Link board using two screws (see

Figure 3).

3. Connect the communications cable (included with

the kit) between the E-Link board and IPU-II Micro

board.

4. Connect the transformer to the terminal block.

5. Connect the transformer to E-Link. Secure the

wiring with tie-wraps.

6. Connect the resistor if the RS-485 2-wire operation

is required.

7. Connect the communications cable shielded

ground to the ground screw.

The E-Link Gateway is now ready to be configured

using Quick Start; see the Commissioning a Standard

Application section in this document.

E-Link Gateway Installation Instructions4

Page 5

Other Chiller Panel Installation

!

E-LINK

Enclosure

YORK Chiller

Micro Panel

Alternative

Mounting

Locations

FIG:MntEquip

Figure 4: Mounting on the Equipment

For all other applications, the E-Link Gateway includes

an optional enclosure. The optional enclosure does not

include communication cables due to the variety of

types and lengths that may be required.

3. Locate and remove the two plastic caps in the

bottom of the E-Link Gateway enclosure.

4. Mark an appropriate place on the enclosure for a

matching set of knock out holes. Mark and drill, or

punch, two holes in the Micro Panel.

IMPORTANT: Never install the E-Link Gateway

outside the confines of a building unless within

another enclosure rated IP 65/NEMA 4x or higher.

The E-Link Gateway can be mounted as a stand-alone

enclosure either on the outside surface of the chiller

Micro Panel (close coupled), or on a smooth surface

within close proximity of the chiller panel enclosure.

For mounting on a Micro Panel, the line voltage power

is supplied by a power source in the Micro Panel.

IMPORTANT: Make sure that the cover is securely

fastened to the enclosure and the internal ground

wire is attached before placing the Gateway in

operation. These steps help to minimize Radio

Frequency Interference (RFI) from being generated

and picked up.

Mounting on a Micro Panel

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections.

More than one disconnect or isolation

may be required to completely

de-energize equipment. Contact with

components carrying hazardous voltage

can cause electric shock and may result

in severe personal injury or death.

5. Using two bulkhead pipe couplers, attach the

E-Link Gateway enclosure to the Micro Panel.

6. Complete wiring as described in the Applying

Power section in this document.

IMPORTANT: Be careful not to damage the E-link

Gateway or Micro Panel’s circuit boards during the

installation. Protect all circuit boards from metal

chips, which may cause short circuits if left on the

boards at startup.

Note: Use of bulkhead pipe couplers provides

sufficient clearance to allow removal of the E-Link

Gateway cover.

IMPORTANT: When attaching the E-Link Gateway

to a Micro Panel, ensure the E-Link Gateway does

not impede access to other components.

To mount the E-Link Gateway on a Micro Panel:

1. Disconnect power to the chiller Micro Panel.

2. Make sure the E-link Gateway enclosure fits

properly and that no obstructions, such as internal

boards, switches, or external conduit, prevent

mounting or servicing of the panel. See Figure 4 for

examples of good mounting locations.

E-Link Gateway Installation Instructions 5

Page 6

Wall Mounting

YORK Chiller

Micro Panel

Template for Mounting

on a Wall

Conduit

E-Link

Enclosure

FIG:WllMnt

Figure 5: Wall Mounting

!

!

To mount the E-Link Gateway on a wall:

IMPORTANT: When wall mounting, make sure

there is no interference with other components in the

near vicinity. Use appropriate conduit to connect the

power and communications wiring.

1. Check for proper clearances for the necessary

electrical and communications cable runs.

2. Ensure that power and communications wiring is in

compliance with all local, national, and regional

codes, and customer requirements.

3. Select a suitable location and mark the anchor

points. Ensure that the enclosure is level. See

Figure 5 for an example.

4. Drill the appropriate holes in accord an ce w ith th e

type of wall anchor used.

5. Install the enclosure on the wall.

IMPORTANT: Be careful not to damage the circuit

boards during installation.

6. Check that the mounting is secure and the wiring

connections are correct and tight. Check that no

loose wire strands or other metal objects that could

cause a short circuit are on the circuit board.

7. Complete wiring as described in the Applying

Power section.

Applying Power

When using an enclosure type of E-Link Gateway,

power can be supplied from either a separate power

supply or the main terminal strip in the chiller panel.

Locate the power source within 0.9 m (3 ft) of the

E-Link Gateway, and protect it with a suitable fuse or

circuit breaker. Ensure th e power is supplied from a

dedicated source and not controlled by a programmed

switch.

If the enclosure is mounted on a wall, the wiring from

the power source to the E-Link Gateway must always

run in a suitable conduit. To obtain the best

Electromagnetic Interference (EMI) and

Electromagnetic Compatibility (EMC) performance,

ensure that the conduit is bonded to the metal of both

enclosures. Scraping the paint around the knockouts

usually helps provide a better electrical connection

between the joining parts.

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections.

More than one disconnect or isolation

may be required to completely

de-energize equipment. Contact with

components carrying hazardous voltage

can cause electric shock and may result

in severe personal injury or death.

CAUTION: Risk of Property Damage.

Do not apply power to the system before

checking all wiring connections. Short

circuited or improperly connected wires

may result in permanent damage to the

equipment.

E-Link Gateway Installation Instructions6

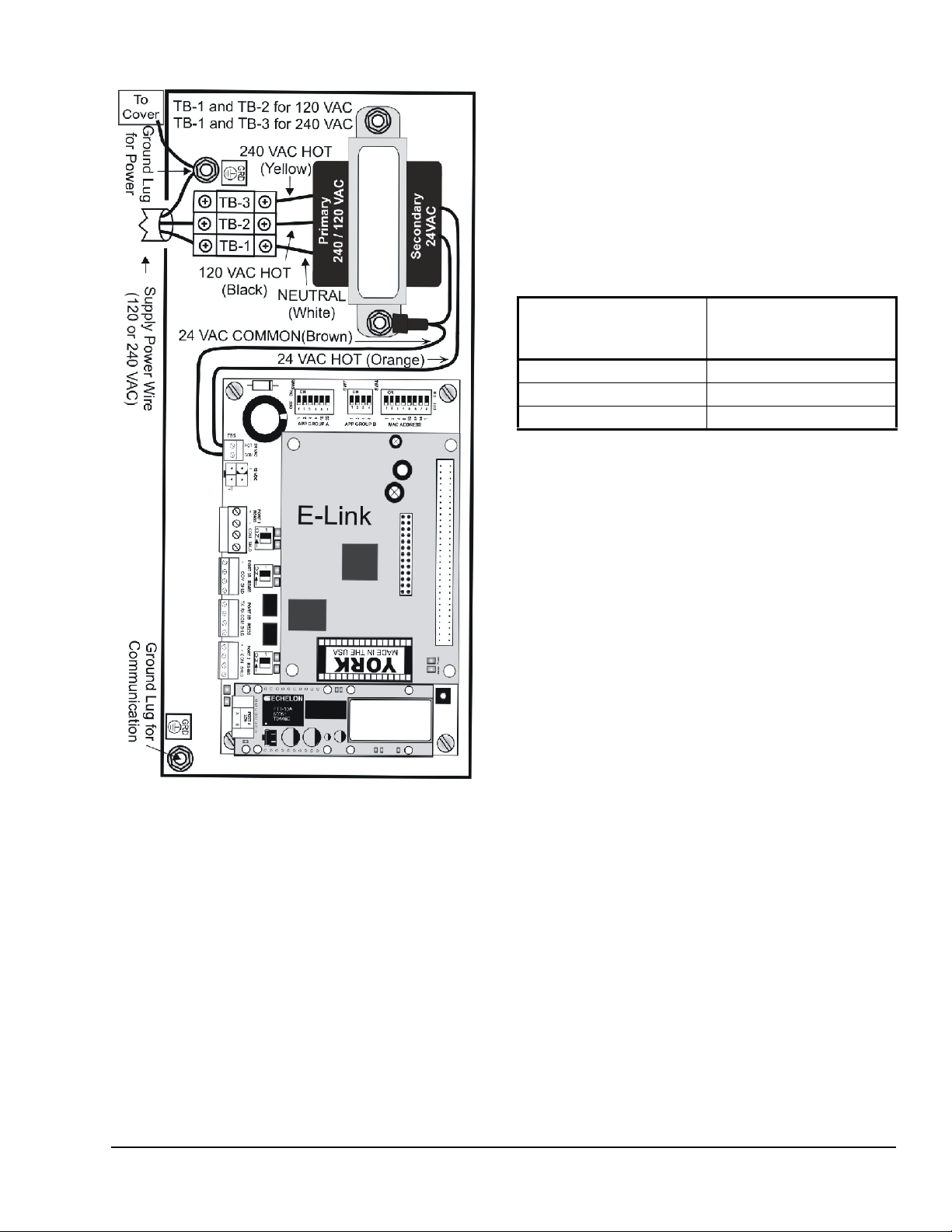

1. Connect a 1.29-1.02 mm (16-18 AWG) wire from a

reliable ground reference to the E-Link Gateway’s

incoming power ground lug. Do not remove the

existing wire that connects the ground lug to the

enclosure cover.

2. On 120 VAC applications, connect the Hot wire to

TB2 and the Neutral wire to TB1. Connect the

ground wire to a ground lug.

On 240 VAC applications, connect the Hot wire to

TB3 and the Neutral wire to TB1. Connect the

ground wire to a ground lug.

IMPORTANT: Use copper conductors only.

Make all wiring connections in accordance with

local, national, and regional regulations. Do not

exceed the E-Link Gateway’s electrical ratings.

Page 7

1. Apply power and verify that the red power

FIG:PwrConn

Figure 6: Power Connection Shown as 120 VAC

Light-Emitting Diode (LED) on the IPU-II board is

on. Make sure the T-switch is set to OFF, and then

set the required Media Access Control (MAC)

address. Set the MAC address in accordance with

the system integrator to ensure that a unique

address is used. If any non-standard setup is

required, refer to the E-Link Commissioning and

Troubleshooting Guide (LIT-12011238) for more

details.

Table 5: Allowable MAC Addresses

Protocol Max Allowable Switch

Settable MAC

Addresses

BACnet MS/TP 1 – 127

N2 1 – 127

Modbus RTU 1 – 127

2. Based on the equipment to be integrated (see

Table 8) and the required BAS output protocol (see

Table 9), select the appropriate settings on

GROUP A and GROUP B switches. For equipment

points lists, refer to the Johnson Controls Portal

(Products and Services>Delivery>Products/

Service Field Support>Equipment

Integration>YORK Equipment Data Maps).

Commissioning a Standard Application

Once the E-Link Gateway has been mechanically and

electrically installed (that is, it has been located in its

enclosure, wired, and terminated appropriately), it may

be Quick Commissioned.

3. Press, hold a few seconds, then release the push

button shown in Figure 11. The status LED flashes

quickly. After the E-Link Gateway re-initializes, the

commissioning is complete.

4. When commissioning a

LONWORKS BAS output

protocol, disconnect the BAS network and cycle

the power on the E-Link Gateway to activate the

Quick St art and the

LONWORKS FTT10 ProtoCessor.

The ProtoCessor does not recognize the push

button as a trigger to reset and load the correct

conversion file. Wait a minimum of 10 minutes

before reconnecting the BAS network.

5. Check the E-Link Gateway’s LEDs. First, check the

ST ATUS LED; if the E-Link Gateway has no errors,

it flashes continuously (1/2 second on, 1/2 second

off). If the LED is not flashing continuously, see

Table 6 for possible reasons.

E-Link Gateway Installation Instructions 7

Page 8

6. Place the equipment in remote oper at ing mod e to

accept commands from the E-Link Gateway. Refer

to the equipment installation literature for the

proper configuration settings.

Table 6: LED Status indication

Flash Rate Status LED Indication

LED Off No database configuration is loaded, or no

1 Flash Terminal mode has been invoked (Switch

2 Flashes An equipment to E-Link communications

3 Flashes A Quick Start has a configuration error.

LED On No errors with custom/field modified

Flashing

Continuously

input power is present.

T is on).

error has occurred.

application.

No errors with factory standard

application.

For all chillers that use the YORK T alk protocols, check

that the Port 2 communication LEDs, Red (TX) and

Green (RX), are flashing. This scenario indicates that

the chiller panel is being polled and is responding. See

Figure for the location of Port 2 communication LEDs.

What You Should Know before Using Quick Starts

The E-Link is designed to use a set of predefined data

maps to associate equipment data with a set of fixed

BAS network variables. You are not able to make any

field changes to these data maps; attempting to do so

results in the automatic reversal of any edits that you

may have made. For any field patches, refer to your

local FSC (Field Support Center) for guidance.

The data maps used by the E-L i nk Gate way ar e based

on a collection of version controlled equipment point

lists, which are supplied by the equipment business for

the purpose of integrating equipment into BAS

networks. Unless noted otherwise, the equipment’s

data is available in these supported BAS protocols:

BACnet MS/TP, N2,

LONWORKS, and Modbus RTU.

The first release of the E-Link was positioned to

provide the equivalent functionality as offered by the

YORK MicroGateway. That release requires you to

reference point lists which are version J or earlier. All

subsequent E-link releases use point lists version K or

later.

Table 7: E-Link Releases

Firmware/Database Revision Point Lists

SSM4567 JCF0003BL.BIN J and earlier only

SSM4567 JCF0008BL.BIN J and earlier, or K

Quick Starts 1 through 16 all use the J version point

lists, whereas Quick Starts 17 through 33 use the K

version. The primary difference between the two

categories is that Quick Starts 1 through 16 have

limited network visible points. In this case, the available

points are those which were originally available at the

time when the MicroGateway was first released.

Quick Starts 17 and higher offer a much richer

equipment point compliment that is more reflective of

what the equipment currently makes available today.

These Quick Starts also create profiles that use more

descriptive BACnet point names, use engineering

units, and follow the BACnet Testing Laboratories™

(BTL) guidelines for compliance as a B-ASC contro ller.

In most cases, using a Quick Start that corresponds to

the equipment being integrated is sufficient to configure

the E-Link Gateway for operating on the BAS network;

however, in some circumstances, you will be required

to provide further customizing by connecting a laptop

computer onto Port 3 and then accessing the User

Reports (refer to the E-Link Gateway Commissioning

and Troubleshooting Technical Bulletin [LIT-12011238]

for more information).

E-Link Gateway Installation Instructions8

Page 9

Table 8: Equipment Quick Start Selections

APP Group Switch A Equipment Profile Quick Starts

Switch Settings 32168421Functionality

1

1

2 0 0 0 0 1 0 YK with VSD Imperial (YORK Talk-III) J version points

1

3

4 0 0 0 1 0 0 YT with VSD Imperial (YORK Talk-III) J version points

1

5

1

6

7 0 0 0 1 1 1 YK with VSD Metric (YORK Talk-III) J version points

1

8

9 0 0 1 0 0 1 YT with VSD Metric (YORK Talk-III) J version points

1

10

11 0 0 1 0 1 1 YORK Talk II, 1200, 1 Section (YORK Talk-II) J version points

12 0 0 1 1 0 0 YORK Talk II, 4800, 1 Section (YORK Talk-II) J version points

2

13

14 0 0 1 1 1 0 YD Imperial (YORK Talk-III) J version points

15 0 0 1 1 1 1 YD Metric (YORK Talk-III) J version points

16 0 1 0 0 0 0 ECO2 / YPAL / S100 (BACnet MS/TP via an IPU-I)

17 0 1 0 0 0 1 YK with SSS Imperial (YORK Talk-III) K version points

18 0 1 0 0 1 0 YK with VSD Imperial (YORK Talk-III) K version points

19 0 1 0 0 1 1 YT with SSS Imperial (YORK Talk-III) K version points

20 0 1 0 1 0 0 YT with VSD Imperial (YORK Talk-III) K version points

21 0 1 0 1 0 1 YS / YR with SSS Imperial (YORK Talk-III) K version points

22 0 1 0 1 1 0 YK with SSS Metric (YORK Talk-III) K version points

23 0 1 0 1 1 1 YK with VSD Metric (YORK Talk-III) K version points

24 0 1 1 0 0 0 YT with SSS Metric (YORK Talk-III) K version points

25 0 1 1 0 0 1 YT with VSD Metric (YORK Talk-III) K version points

26 0 1 1 0 1 0 YS / YR with SSS Metric (YORK Talk-III) K version points

27 0 1 1 0 1 1 YST Imperial (YORK Talk-III) K version points

28 0 1 1 1 0 0 YIA Imperial (YORK Talk-III) K version points

29 0 1 1 1 0 1 YST Metric (YORK Talk-III) K version points

30 0 1 1 1 1 0 YIA Metric (YORK Talk-III) K version points

31 0 1 1 1 1 1 YEWS-D1/YEAS/YGAS (Modbus native)

32 1 0 0 0 0 0 YD Imperial (YORK Talk-III) K version points

33 1 0 0 0 0 1 YD Metric (YORK Talk-III) K version points

34 1 0 0 0 1 0 YMC2 Imperial (YORK Talk-III) K version points

35 1 0 0 0 1 1 YMC2 Metric (YORK Talk-III) K version points

63 1 1 1 1 1 1 Reserved for Field adjustments

0 0 0 0 0 1 YK with SSS Imperial (YORK Talk-III) J version points

0 0 0 0 1 1 YT with SSS Imperial (YORK Talk-III) J version points

0 0 0 1 0 1 YS / YR with SSS Imperial (YORK Talk-III) J version points

0 0 0 1 1 0 YK with SSS Metric (YORK Talk-III) J version points

0 0 1 0 0 0 YT with SSS Metric (YORK Talk-III) J version points

0 0 1 0 1 0 YS / YR with SSS Metric (YORK Talk-III) J version points

0 0 1 1 0 1 YORK Talk II, 4800, 2 Sections (YORK Talk-II) J version points

1. A Quick Start that references a Solid State Starter (SSS) is also applicable to a mechanical starter.

2. Two sections are required for equipment equipped with three or more compressors, or two systems.

E-Link Gateway Installation Instructions 9

Page 10

Table 9: BAS Output Protocol Quick Start Selections

APP Group

Output Protocol Quick Starts

Switch B

Switch Settings 8421Port 1 Port 3 Port 4

1

0

2, 5

1

2, 5

2

2, 5

3

2, 5

4

2, 5

5

2, 5

6

2, 5

7

2, 5

8

3, 5, 6

9

4, 5, 6

10

11

4, 5

12

2, 5

13

14

15 7

3, 5

2, 5

0000MS/TP, AUTO, N, 8, 1 Modbus, 19,200, N, 8, 1 Terminal

0001MS/TP, AUTO, N, 8, 1 Modbus, 19,200, N, 8, 1 Terminal

0010MS/TP, AUTO, N, 8, 1 Modbus, 19,200, N, 8, 2 Terminal

0011MS/TP, AUTO, N, 8, 1 N2, 9,600, N, 8, 1 Terminal

0100N2, 9,600, N, 8, 1 MS/TP, 38,400, N, 8, 1 Terminal

0101Modbus, 19,200, N, 8, 1 MS/TP, 38,400, N, 8, 1 Terminal

0110Modbus, 19,200, N, 8, 2 MS/TP, 38,400, N, 8, 1 Terminal

0111Modbus, 9,600, E, 8, 1 MS/TP, 38,400, N, 8, 1 Terminal

1000Modbus, 9,600, N, 8, 1 MS/TP, 38,400, N, 8, 1 Terminal

1001N2, 9,600, N, 8, 1 Modbus, 19,200, N, 8, 1 L

1010N2, 9,600, N, 8, 1 Modbus, 19,200, N, 8, 1 L

ONWORKS – Pass through

ONWORKS – Conversion

1011Modbus, 19,200, N, 8, 2 N2, 9,600, N, 8, 1 LONWORKS – Pass through

1100Modbus, 19,200, N, 8, 2 N2, 9,600, N, 8, 1 LONWORKS – Conversion

1101Modbus, 9,600, E, 8, 1 Modbus, 19,200, N, 8, 2 Terminal

1110MS/TP, 38,400, N, 8, 1 N2, 9,600, N, 8, 1 Terminal

1111Reserved Reserved Terminal

1. When making edits to User Report 4 (Port Configuration), Group Application Switch B must be set to zero. This setting

ensures that the edits are stored. Otherwise, the edits are overwritten to the default values assigned to the particular Group

Switch B setting the next time E-Link is reset, or power is cycled. Edits made in any other User Reports do not require

alterations to either bank of Group Application switches. For standard set-up, not requiring modifications via User Report 4,

use application switch B, settings 1 to 14.

2. The Terminal setting on Port 4 is restricted for factory use only.

To comply with the LONMARK® specification, all data transmitted on the LONWORKS network must be expressed in SI units

(metric units). The L

ONWORKS ProtoCessor performs no unit conversions; it assumes that the data supplied is already

correctly expressed.

3. Use Quick Start 9 and 11 if the equipment is supplying the data in SI units (the E-Link is not required to perform any

conversions, so it operates in pass-through mode).

4. Use Quick Start 10 and 12 if the equipment is supplying the data in Imperial units and the E-Link is required to convert these

units into SI.

5. Setting Switch T = ON, on the MAC address, forces TERMINAL mode of Port 3, at 57,600 baud, N, 8, 1. This setting is only

required to debug the E-Link Gateway’s operation, or access the User Reports.

6. Select Quick Starts 9 and 10 when connecting the E-Link Gateway to an ECO2 unit.

7. Quick Starts 15 on APP Group B, and 63 on APP Group A, are reserved for field adjustments.

E-Link Gateway Installation Instructions10

Page 11

Wiring

!

!

!

GRD

Figure 7: Grounding Label

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections.

More than one disconnect or isolation

may be required to completely

de-energize equipment. Contact with

components carrying hazardous voltage

can cause electric shock and may result

in severe personal injury or death.

CAUTION: Risk of Property Damage.

Do not apply power to the system before

checking all wiring connections. Short

circuited or improperly connected wires

may result in permanent damage to the

equipment.

IMPORTANT: Make all wiring connections in

accordance with local, national, and regional

regulations.

Install the wiring so it does not cause a hazard, and is

protected against electrical and mechanical damage.

Power

The E-Link Gateway circuit board is powered from

either a 12 VDC, or a 24 VAC, Class 2 power source.

When used with an OptiView chiller, the Micro Panel

supplies low-voltage power via a power harness

supplied by the OptiView/Latitude installation kit. If the

E-Link Gateway circuit board is installed in its own

enclosure, a transformer is included in the enclosure.

Line voltage may be supplied using an external power

source, or drawn from the input voltage terminal strip

inside the equipment. Be sure the capacity of the

power conductors supplying the equipm ent is rat ed for

the additional power (VA) required by the E-Link

Gateway. Use a wire that is one size larger than

required for the amperage draw (maximum 400 mA) to

connect the line voltage feed to the E-Link Gateway.

For the line voltage power source, use a dedicat ed line

(with a separate fuse) that is isolated (using a control

transformer) from other equipment in the plant room

that may generate Electromagnetic Interference (EMI).

Grounding

For the enclosure style, a ground wire must be

connected directly to the enclosure supply power

ground lug at the point of entry. A small label (Figure 7)

identifies this grounding point. This ground wire should

be connected through a continuous ground circuit to

the incoming ground at the source transfo r me r.

d

n

r

G

:

G

I

F

Note: Besides pr ovidin g safety protection , th e gr ound

connection plays an extremely important part in the

operation of the communication circuitry.

WARNING: Risk of Electric Shock.

Ground the E-Link Gateway enclosure

according to local, national, and regional

regulations. Failure to ground the E-Link

Gateway may result in electric shock and

severe personal injury or death.

Protection of Communication Ports

When using RS-485 technology, it is possible that

electrical disturbances, such as voltage spikes, can

damage a circuit board. The E-Link Gateway includes

tranzorbs on each RS-485 port to protect against

damaging electrical spikes and stray voltage.

The equipment panel should also be equipped with

protection against electrical disturbances. Whereas

OptiView Micro Panels are equipped with onboard

tranzorbs, other equipment panels may require the

addition of an external board. Refer to the equipment

documentation for details. Port 1 of the E-Link Gateway

is also electrically isolated, providing a means of

mitigating common mode voltage induced problems.

High Noise Environments

Electrical equipment that employs high speed

switching circuits (Variable Speed Drives [VSD], Solid

State Starters [SSS], and computing equipment)

generates Electromagnetic Interference (EMI) noise

and Radio Frequency Interference (RFI), which can

generate transient voltage between ground points in

the communication wiring. The RS-485 circuitry is

designed to withstand some low transient volt age, but if

this difference exceeds certain limits, it can

permanently damage the RS-485 circuitry.

IMPORTANT: Ensure that the Micro Panel and the

E-Link Gateway are powered from a source with a

true earth ground.

E-Link Gateway Installation Instructions 11

Page 12

IMPORTANT: Do not run communication cables in

Figure 8: RS-485 EOL Switches

Figure 9: MAC Dip Switch

close proximity to, or parallel with, high-voltage

power cables (maintain at least 457.2 mm [18 in.] of

separation, or use a grounded met al conduit).

Electrical Noise Mitigation to Equipment

The likelihood of transient voltage is greatly reduced if

the E-Link Gateway is close-coupled to the Micro

Panel. Close-coupling requires that the E-Link

Gateway and Micro Panel share the same line voltage

power source and are physically close to one another.

Typically, the E-link Gateway is mounted on the Micro

Panel enclosure. This scenario ensures a short

communication cable, which is usually protected

entirely within the two enclosures.

Electrical Noise Mitigation for E-Link to BAS

When the E-Link is used in an electrically hostile

environment (for example, with VSD-enabled

equipment), a double-shielded cable should be used to

help mitigate the adverse effects electrical noise can

have on the system. The double-shielded cable should

connect the E-Link’s BAS port (Port 1 or Port 4) to the

next controller(s) in the daisy-chained network.

The outer shield of the double-shielded cable should

be grounded directly at the low noise end (the end

most distant from the VSD), and ideally, indirectly

through an appropriate capacitor at the high noise end

(the end closest to the VSD). If a capacitor is not

available, the outer shield may be left unconnected, or

tied directly to ground. The best results on the site

determine the specific termination strategy employed.

The inner shield of the double-shielded cable should be

grounded directly at the low noise end (the end most

distant from the VSD), and left open at the high noise

end (the end closest to the VSD).

Setup and Adjustments

There are a number of settings that you may make on

an E-Link Gateway or to the connected equipment.

Network Termination

Terminate all End-of-Line (EOL) devices at either end

of the RS-485 bus (that connect to only one set of

RS-485 network wires). EOL termination provides

biasing of the network, and assists in returning the

signal to a normal state in the event of voltage

transients. If the E-link Gateway happens to be the

end-of-line device, terminate the network by setting the

EOL switch located above each of the

E-Link Gateway’s RS-485 ports to the ON position.

IMPORTANT: Ensure that the EOL switches are

not set to the ON position for controllers that do not

terminate the RS-485 network.

Media Access Control (MAC) Address

The E-Link Gateway’s network hardware address is set

on a single 8-way DIP switch. Switch 8, the T switch, is

reserved to invoke Terminal mode on Port 3, leaving

the remaining 7 switches for setting the address. Refer

to the E-Link Gateway Commissioning and

Troubleshooting Technical Bulletin

(LIT-12011238) for more details.

Types of Communication Ports

The E-Link Gateway uses three communication

protocols to connect to other devices: RS-485 and FFT

are used for multi-drop networking, whereas RS-232 is

primarily used for point-to-point connectivity.

RS-485

The RS-485 standard uses three conductors to

connect network nodes: two signal wires and a

reference. The E-Link Gateway uses either a third wire

for the reference or the building’s infrastructure. The

wiring method depends on the port being used: an

electrically isolated Port 1 typically uses a third wire,

whereas Ports 2 and 3 normally use chassis or bu ilding

ground for the reference.

E-Link Gateway Installation Instructions12

The network address is binary weighted, allowing you

to set up to 127 unique addresses.

APP Group A

APP Group A uses a 6-way DIP switch to select the

desired equipment’s profile. This switch is also binary

weighted, allowing up to 63 unique selections.

Page 13

APP Group B

Figure 10: APP A and APP B DIP Switches

Figure 11: E-Link Gateway Push Button

Figure 12: Micro Panel Rotary Switch

APP Group B uses a 4-way DIP switch to select the

desired output protocol. This switch is also binary

weighted, allowing up to 15 unique selections.

Push Button

The E-Link Gateway uses a push button (Figure 1 1) as

a means of activating any user selections on APP

Group A and APP Group B switches.

Note: Refer to the E-Link Gateway Commissioning

and Troubleshooting Technical Bulletin

(LIT-12011238) for more details.

Setting the Rotary Switch on Chiller Panels

Some Micro Panels

YORK Talk II address (YORK Talk address = Rotary

Switch setting + 1). Since the E-Link Gateway uses a

one-to-one relationship with the chiller panel, this

switch is normally set to 0 (YORK Talk address 1).

However, in a master/subordinate configuration, set

the master Micro Panel rotary switch to 0, and the

subordinate Micro Panel to 1. If the chiller Micro Panel

is not equipped with a rotary switch, the YORK Talk

address may be set using the Micro Panel keypad. In

most cases, you can configure the setting, but some

models are fixed and cannot be changed (refer to the

equipment documentation for specific details).

use a rotary switch to set their

FIG:ChlRot

Network Topology

The E-Link Gateway has three serial communications

ports and an optional

equipment to a BAS system. Port 1 and Port 4 are

designed as the BAS ports, with Port 1 used to sup port

all RS-485 based communication protocols, and Port 4

used for

LONWORKS ProtoCessor module.

LONWORKS connectivity with the addition of a

LONWORKS port to connect

Equipment Configuration

Different pieces of equipment sometimes require a

specific hardware configuration (jumper/switch

settings) to enable communication with the E-Link

Gateway . Refer to the equipment’s inst allation literature

for the proper configuration settings.

Note: See Figure 24 and Figure 25 for additional

information.

E-Link Gateway Installation Instructions 13

Page 14

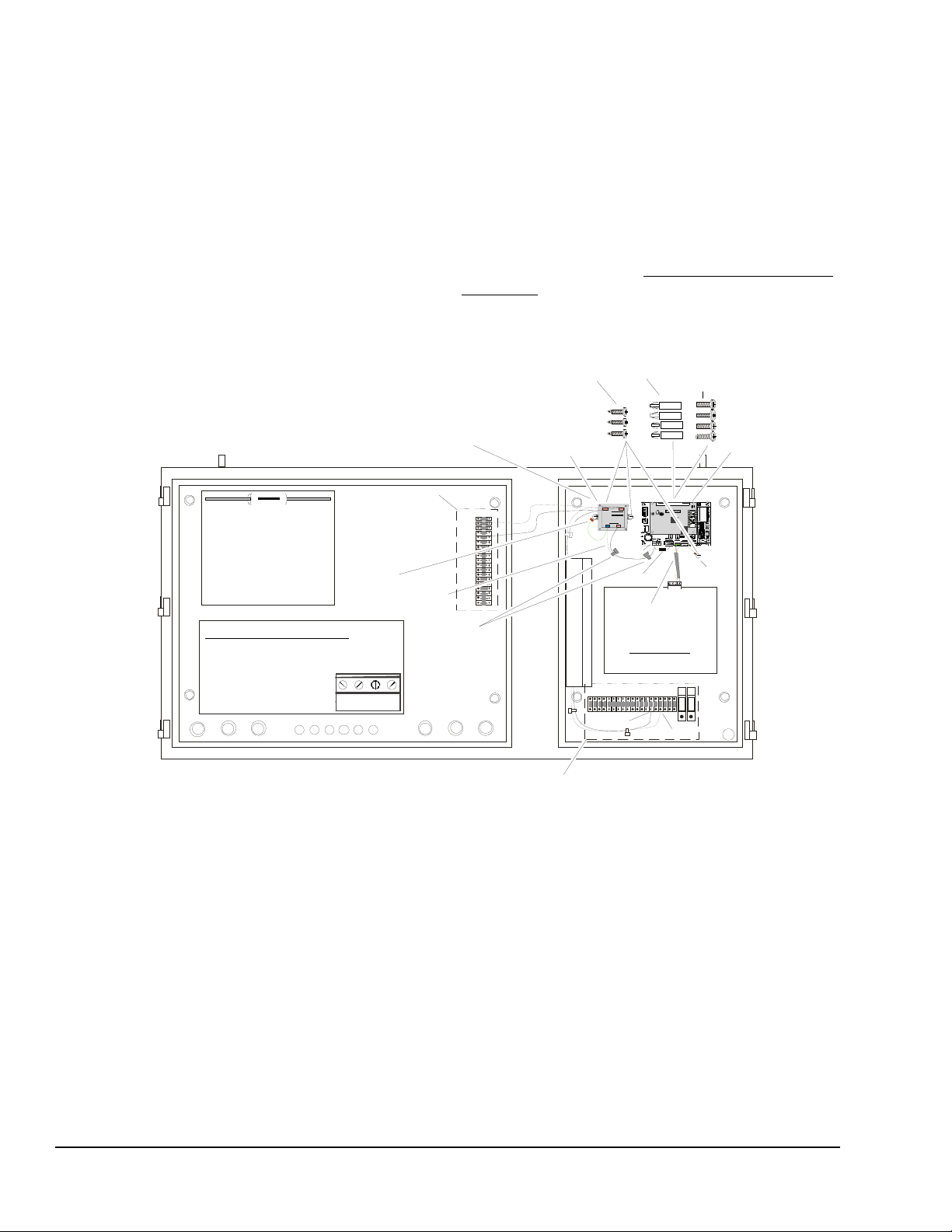

Figure 13: E-Link Gateway Component

Identification

COMMUNICATION CABLE

(OptiView / Latitude)

POWER HARNESS

(OptiView)

4 #8 NYLON WASHERS

POWER HARNESS

(Latitude)

8 x 32

(OptiView)

2 Position

Connector

Connector

4 Position

Connector

4 Position

Connector

Screw

FIG:OptiVwKt

YMC2

COMMUNICATION CABLE

(OptiView)

YMC2

POWER HARNESS

(OptiView)

4 Position

Connector

4 Position

Connector

YMC2 Communication Cable

Figure 14: E-Link OptiView/Latitude

Installation Kit (YK-ELNKOLK-0)

4 Position

(OptiView / Lattitude)

Tap Threa d

M4 x 32 mm

(Latitude)

3/8 in. Screw

E-Link Gateway Installation Instructions14

Page 15

V

V

100 OHM

Nut

Nut

Screw

Power

Primary

Power

Wiring

Harness

Resistor

Secondary

Power

Wiring

Harness

Tie

FIG:IPUII-Kt

Figure 15: E-Link IPU-II Panel Installation Kit

(YK-ELNKSTK-0 Contents)

Unit #2

Last Unit

PORT 3 RS485PORT 3 RS48

5

+ - CM SHLD

Unit #1

POR T 3 RS485

+ - CM SHLD

+ - C M SH LD

+ - C

M S HLD

FIG:BAS_Shld

Figure 16: BAS Trunk Shield Wiring

Primary

120

AC

Secondary

AC

24

24 VAC

Transformer

Wrap

Sheet

Metal

Screw

Expansion

Communication

Wiring Harness

Expansion

E-Link Gateway Installation Instructions 15

Page 16

UI7

TB7

031-01065-xxx

BLUE

WHITE

SHIELD

Jumper

BLUE

WHITE

(Open)

BLUE

WHITE

TB1

NOTE:

If the EPROM used in the board is dated prior

to 11/2000, the ch iller ID is fixed at 0.

If the EPROM used is dated after 11/2000, the chiller

ID is software selectable through the micro panel

SHIELD

BLUE

WHITE

(Open)

031-02050-000

TB1

TB6

NOTE:

The chiller ID is software-selectable through the

micro panel keypad. Set the Chiller ID to 0 to make network

address to 1.

BLUE

WHITE

SHIELD

BLUE

WHITE

(Open)

FIG:ELnk_Yr kTlk

Equipment Connections

Figure 17: E-Link Gateway to YORK Talk II Equipment Connections

(See Table 1 for board cross-reference.)

E-Link Gateway Installation Instructions16

Page 17

E-Link Gateway Installation Instructions 17

Figure 18: E-Link Gateway to YORK Talk II Equipment Connections (Continued)

(See Table 1 for board cross-reference.)

Page 18

Equipment Cable

York Talk 2

RS485

(4800 baud)

COM 1

COM 2

Jumper

Equipment Cable

York Talk 2

RS485

(4800 baud)

SHIELD

+ - COM SHLDPORT 2A RS48

5

(Open)

E-Link

VGA

PL20 COM 1

Equipment Cable

York Talk 2

RS485

(4800 baud)

Jumpers

SHIELD

PORT 2A RS485

(Open)

E-Link

+RX

NOTE:

Requires ISN EPROMs in locations U4 and U5.

The transfer rate on the chiller must be set to 4800 baud.

Frick RWBII Plus

Jumpers

Jumpers

RWBII Rev. B and Lower

+RX

Jumpers

RWBII Rev. C and Higher

U5U4Port 2

Port 1

SHIELD

PORT 2A RS485

(Open)

E-Link

SHIELD

PORT 2A RS485

(Open)

E-Link

Equipment Cable

York Talk 2

RS485

(4800 baud)

Frick Q2 Board

Frick Q3 Board

PORT 2A RS485

E-Link

+ _ COM SHLD

+ - COM SHLD + - COM SHL

D

+ - COM SHLD

FIG:ELnk_YrkTlk_3

Figure 19: E-Link Gateway to YORK Talk II Equipment Connections (Continued)

(See Table 1 for board cross-reference.)

E-Link Gateway Installation Instructions18

Page 19

Note: Enabling any of

the Latitude’s PRINT

functions will disrupt

BAS/E-Link

communications.

See YORK Equipment

Form 201.21-NMx in the

Installation, Operation &

Maintenance (IOM)

Air-Cooled Screw Liquid

Chillers manual for more

information.

Note: JP1 on the

031-02478-xxx board

must be set to the

RS485 position when

the E-Link BAS

communication is

required.

Equipment Cable

York Talk 3

Rs232

Optiview Microboard

031-01730-XXX

SHIELD

PORT 2B RS232

TX

RX COM SHLD

(Open)

E-Link

E-Link

+12 VDC

SHIELD

(Open)

Equipment Cable

York Talk 2

RS485

(4800 baud)

SHIELD

+ -

COM

SHLD

PORT 2A RS485

(Open)

E-Link

031-02478-xxx

1

2

3

4

5

Latitude

J16

E-Link

Power

E-Link

+12 VDC

PORT 2A RS485

E-Link

+ _ CM SHL

D

PORT 2B RS232

E-Link

TX

RX

COM

SHLD

Equipment Cable

York Talk 3

Rs232

Optiview Microboard

031-02430-XXX

SHIELD

(Open)

PORT 2B RS232

E-Link

E-Link

+12 VDC

SHIELD

(Open)

TX RX COM SHLD

FIG:ELnk_OptiLat

Figure 20: E-Link Gateway to OptiView and Latitude/YCAV/YCIV/YVAA Equipment Connections

(See Table 1 for board cross-reference.)

E-Link Gateway Installation Instructions 19

Page 20

+ _

031-02497-xxx (I/O Board)

331-02496-101

(IPU I Board)

YPAL (ECO2)

1

J4

2

3

4

5

P3+

P3-

GND

+5V

BACnet

MS/TP

(38400 baud)

FIG:YPAL

YPAL (ECO2) Setup for MS/TP Bus:

GRD

+ - COM SHLD

PORT 2A RS485

WHITE

BLUE

Figure 21: E-Link Gateway to YPAL (EC02) Equipment Connections

Equipment Cable

BLUE

(Open)

WHITE

SHIELD

E-Link

PORT 2ARS485

OM SHLD

E-Link

E-Link Gateway Installation Instructions20

Page 21

Communication

Wiring Harness

(Includes a pre-wired E-Link

Port 2 Terminal Block)

RS485

(4800 baud)

SHIELD

P

ORT 2A RS485

(Open)

E-Link

031-02550-xx x (I/O Board)

031-02630-xxx

(IPU II Board)

T

1 RS48

5

+

-

REF

SHLD

IPU-II P1 Setup for York Talk 2:

FIG:STCPrdctIPU2brds

+

-

COM SHLD

Figure 22: E-Link Gateway to IPU-II Equipment Connections

E-Link Gateway Installation Instructions 21

Page 22

E-Link Gateway Installation Instructions22

Figure 23: E-Link Gateway to Wuxi STC YEWS-D1/YEAS/YGAS Equipment Connection

Fig:wuxi_stc

Page 23

E-Link Gateway Installation Instructions 23

Figure 24: E-Link Gateway Communication Port Connections to a BAS System

Page 24

Note: Connect a ground strap between the panel's

Figure 25: E-Link Gateway Communication Port Connections to a BAS System (Continued)

ground path and the E-Link's common path only if this

connection has not been made elsewhere in the

configuration.

E-Link Gateway Installation Instructions 24

Repair Information

If the E-Link Gateway fails to operate within its

specifications, replace the unit. For a replacement

E-Link Gateway, contact the nearest Johnson Controls

representative.

Page 25

Technical Specifications

Power Requirements External to Equipment (Inside Enclosure): 120/240 VAC Primary 50/60 Hz, 24 VAC

Secondary Transformer (+10%/-15%), 400 mA, Nominal 12 VA

Internal to Equipment E-Link Gateway Board Assembly: 24 VAC (±15%), 50/60 Hz,

400 mA, Nominal 12 VA, 12 VDC (+50%/-2%), 400 mA, Nominal 12 VA

Addressing Addressing is selectable by the MAC Address Switch – 8 Position Dip Switch using

Switches 1 through 7.

• BACnet MS/TP Valid Addressing 1 to 127

• Modbus RTU Valid Addressing 1 to 127

• N2 Valid Addressing 1 to 127

Installation Environment Indoor, Dry

Ambient Operating Conditions Temperature: -40 to 85°C; (-40 to 185°F)

Humidity: 0% to 95% Noncondensing

Ambient Storage Conditions Temperature: -40 to 90°C (-40 to 194°F)

Humidity: 0 to 95% RH, Noncondensing

Power External to Equipment (Inside Enclosure): One 3-Position Terminal Block for 120/240

VAC Supply Power

Internal to Equipment E-Link Gateway Board Assembly: Removable Terminal Plug

for 24 VAC Supply Power and Removable Terminal Plug for 12 VDC Supply Power

Communication Wiring

Terminations

Equipment Protocol is selectable by the APP Switch Group A – 6-Position Dip Switch.

Port 2A: RS485 Equipment Port Supporting BACnet MS/TP and YORK Talk II

Protocols with Available EOL Termination Switch

Port 2B: RS232 Equipment Port Supporting YORK Talk 3 Protocol

BAS Protocol is selectable by the APP Switch Group B – 4-Position Dip Switch.

Port 1: RS485 BAS Port Supporting BACnet MS/TP, Modbus RTU, N2 Protocols

With Available EOL Termination Switch

Port 3: RS485 BAS Port supporting BACnet MS/TP, Modbus RTU, N2 Protocols With

Available EOL Termination Switch; When Selected by Switch 8 of the MAC Address

Dip Switch, Terminal Communications

Port 4: RS485 BAS Port Supporting the L

ONWORKS FTT10 Protocol

Wiring Network Cable: 0.51 mm (24 AWG) (3 Cores Plus Shield)

Power Cable: 1.02 mm (18 AWG) Copper Wire Rated for 10 Amperes Per Core

at 250 VAC

Materials External to Equipment:

Metal Enclosure with Removable Lid, E-Link Gateway Board Assembly, Power

Transformer

Internal to Equipment E-Link Board Assembly:

E-Link Gateway Board Assembly

Mounting External to Equipment: Screw Mount Enclosure

Internal to Equipment: E-Link OptiView/Latitude and IPU-II installation kit

Dimensions External to Equipment: 241.3 x 136.5 x 63 mm (9-1/2 x 5-3/8 x 2-1/2 in.)

Internal to Equipment: 102 x 152 x 25.4 mm (4 x 6 x 1 in.)

Shipping Weight Exte rnal to Equipment: 2 kg (4.5 lb)

Internal to Equipment: 227 g (8 oz)

Compliance United States UL Listed 916/FCC Part 15 Conducted and Radiated

Europe CE Mark - Johnson Controls, Inc. declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive 2004 /1 08/EC

and Low Voltage Directive 2006/95/EC.

The performance specifications are nominal and conform to acceptable industry standards. for application of conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

E-Link Gateway Installation Instructions 25

Page 26

E-Link Gateway Installation Instructions26

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2011 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...