Page 1

USER’S INFORMATION,

ISO 9001

Certified Quality

Management System

MAINTENANCE AND

SERVICE MANUAL

DOWNFLOW/UPFLOW

ELECTRIC FURNACE

MODELS: EB

TABLE OF CONTENTS

CONTACT INFORMATION FOR USA . . . . . . . . . . . . . . . . . . . . . . .1

CONTACT INFORMATION FOR CANADA . . . . . . . . . . . . . . . . . . .1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

TO OPERATE FURNACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

TO SHUT FURNACE OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

LIMIT CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

BLOWER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FURNACE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CIRCUIT BREAKERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

AIR FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

RETURN AIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

WHILE YOU’RE AWAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

AT THE BEGINNING OF EACH HEATING SEASON . . . . . . . . . . . .3

YOUR AUTHORIZED SERVICE TECHNICIAN . . . . . . . . . . . . . . . .3

OPTIONAL AIR CONDITIONING ACCESSORIES . . . . . . . . . . . . . .3

HIGH PERFORMANCE BLOWER ACCESSORY PACKAGE . . . . .3

REPAIR PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

CONTACT INFORMATION FOR USA

• Contact us by mail:

DISTRIBUTED BY:

StyleCrest

801 W. 37th Street

Building #7

Wichita, Ks 67219

MANUFACTURED BY:

Johnson Control, Inc.

5005 York Drive

Norman, OK 73069

The manufacturer recommends that the user read all sections of this manual and keep the manual for future reference.

FOR YOUR SAFETY - Do not store or use gasoline or other fla m-

mable vapors and liquids in the vicinity of this or any other appliance.

For personal safety be sure to turn the electrical power OFF at

the household service box and at the furnace before attempting any service or maintenance operations. Homeowner

should never perform any maintenance which requires opening the furnace electrical panel.

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

CONTACT INFORMATION FOR CANADA

• Go to website at www.york.com click on “contact”, then click on

“contact form” and follow the instructions.

• Contact us by mail:

Johnson Controls, Inc.

Consumer Relations

5005 York Drive

Norman, OK 73069

This furnace and its components, including the air conditioning coils

and blowers listed on the A/C accessory sticker were listed in combination as a system by Underwriters Laboratories.

Use of other components not tested in combination with this furnace

may make the equipment in violation of State Codes, may create a

hazard, and may ruin the equipment.

In addition, the National Manufactured Housing Construction and

Safety Standards Act and its Regulations require the use of components listed or certified by a nationally recognized testing laboratory

in all manufactured homes built and sold subject to that act.

SECTION I: INTRODUCTION

To avoid the possibility of electrical shock do not open electrical box

panels.

Johnson Controls Unitary Products 570930-BUM-C-0112

Page 2

570930-BUM-C-0112

NOTICE

NOTICE

U

L

R

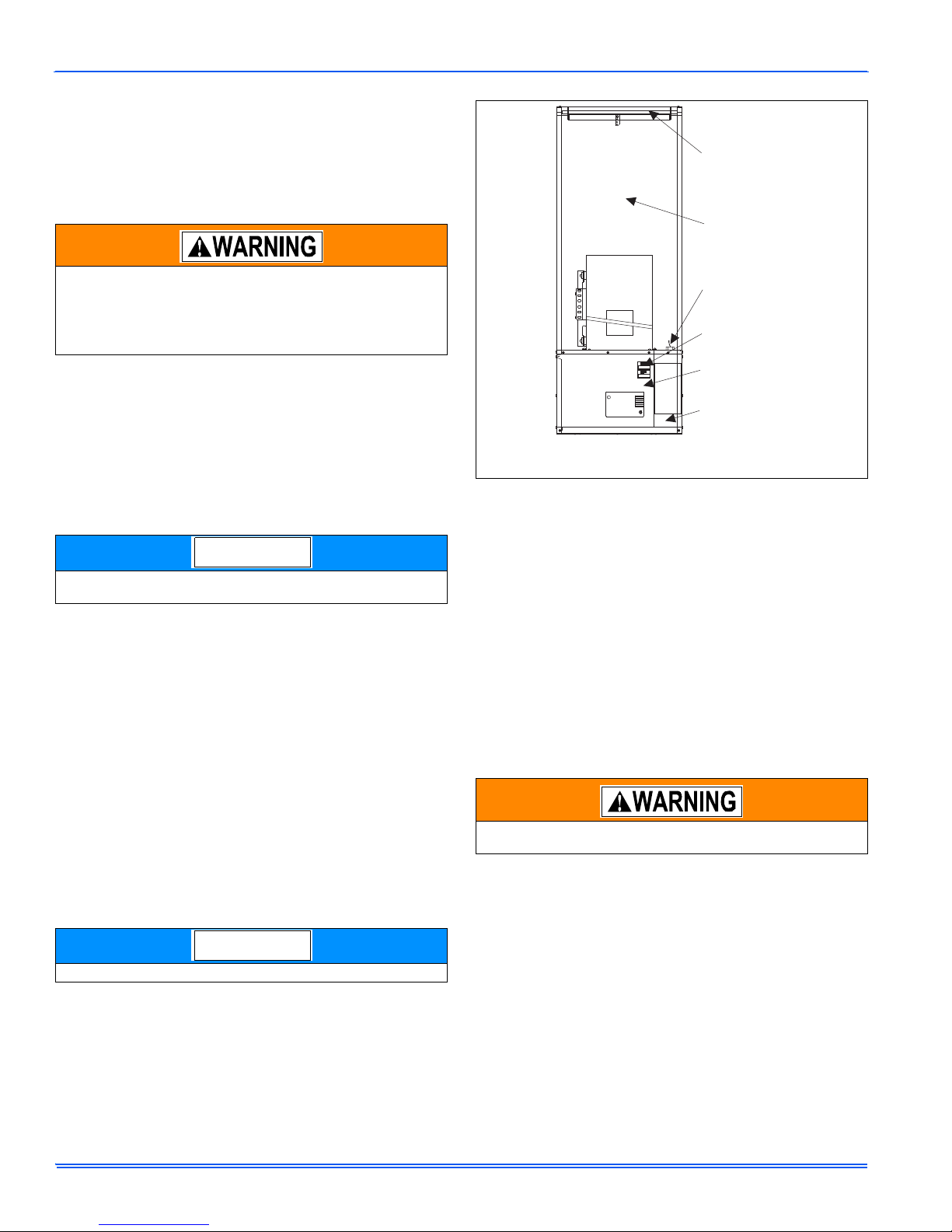

FILTER (IN

DOWNFLOW

ONLY) *

CAVITY

FOR

COIL

THERMOSTAT

WIRES

CIRCUIT

BREAKERS

ELECTRIC

PANEL

FIELD WIRING

PROTECTIVE

SHIELD

Filter in the front panel when louvered doors

are used. Filter located in base for upflow units.

*

SECTION II: TO OPERATE FURNACE

1. Be sure electrical power to furnace is turned on at the house-hold

service box.

2. Set wall thermostat to the desired temperature.

3. If furnace is equipped with Air Conditioning, the System Switch,

located at the wall thermostat, must be turned to HEAT in order for

the furnace to operate in the heating model.

If you have an air conditioner which does not use the furnace blower

for air distribution and operates completely independent of the furnace, the thermostat system must have an interlock to prevent the

furnace and air conditioner from operating at the same time. Such

operation could cause equipment damage, energy waste and overheating of the home.

The interlock system usually contains a heat-cool switch which must be

turned to either HEAT or COOL to activate either heating or cooling

operation.

If an interlock system has not been provided, the electrical supply to the

furnace must be turned OFF at the household service box, when the air

conditioner is being used. When operating the furnace, the electrical

supply to the air conditioner must be turned OFF.

TO SHUT FURNACE OFF

1. Turn thermostat to its lowest setting.

FIGURE 1: Component Locations

SECTION IV: FURNACE OPERATION

CIRCUIT BREAKERS

Furnace will still operate if room temperature falls below thermostat

setting.

2. For complete shut-down, turn off electrical power at the household

service box.

SECTION III: SEQUENCE OF

OPERATION

When room thermostat calls for heat, 24-volt power is supplied to the

heating element switches. As soon as the first heating element switch

closes, the blower starts and power is supplied to the first heating element. Each additional element is staged on in successive intervals.

When the room thermostat is satisfied and no more heat is required, the

elements sequence off in the reverse order and the blower will then turn

off.

LIMIT CONTROLS

Each element has an automatic limit switch which is wired into the circuit and shuts off power to that element if the heat at that point exceeds

the allowable maximum heat.

BLOWER REMOVAL

Your electric furnace is equipped with a unique safety feature - circu it

breakers. These circuit breakers are located behind the door of the furnace, near the bottom of the furnace. See Figure 1. If a component

should fail inside the furnace, the circuit breakers will prevent damage

that can be caused by an electrical short. If the breakers ever trip, they

can be reset by first turning off the power to the furnace at the home's

circuit breaker panel. See Warning below. Then remove the furnace

door and reset the circuit breaker in the furnace. Re-install the furnace

door and turn the power back on at the home's breaker panel. If for

some reason these circuit breakers should trip again, a service technician should be contacted as a problem exists inside the furnace. A list

of authorized service centers is provided with every furnace and will

assist you in obtaining service for your furnace.

Y ou must first de-energize the furnace at the main household power

supply and lock it.

LUBRICATION

The blower motor bearings are factory sealed. Additional lubrication is

not required.

BLOWER ASSEMBLY

Only authorized service technicians should remove the blower.

To remove blower from furnace, turn off power at household service

box, turn furnace circuit breakers OFF. Disconnect wiring to blower, and

remove five (5) screws holding blower in furnace and slide blower out

from front of the furnace. See Figure 1.

Re-install blower in reverse order when assembling back into furnace.

2 Johnson Controls Unitary Products

Every electric furnace comes equipped with a blower capable of operating a heat pump or air conditioner. With the addition of the proper heat

pump, you can enjoy comfort and savings all year long. An air conditioner will also work with your furnace and will provide cool summer

days, at a very low operating cost.

Page 3

570930-BUM-C-0112

NOTICE

NOTICE

AIR FILTER

The filter supplied with the furnace is a throw-away type. Filters need to

be cleaned frequently. Shake out all loose dirt, and use vacuum cleaner

to clean additionally. This method of cleaning will prolong life of filters.

DO change filters often since clean filters not only provide added comfort, better and cleaner environment, but increase the efficiency of the

furnace as well.

FILTER LOCATION: The furnace's front panel must be removed to gain

access to the filter of the downflow furnace. (See Figure 1.) However,

the filter for the upflow furnace* is located behind the return air grill,

adjacent to the furnace closet or any other location in the return air.

RETURN AIR

Return air must be provided back to the circulating blower in order to

provide air distribution. DO NOT OBSTRUCT ANY RETURN AIR

GRILLE. To do so will cause the furnace heating elements to cycle off

and on repeatedly.

WHILE YOU’RE AWAY

The power supply to your furnace is equipped with either a fused or

breaker type disconnect. In case of an overload, this will interrupt the

operation of your furnace until it is reset or fuse replaced. For this reason it is never practical to assume that the furnace will operate unattended for long periods of time, especially if there is a possibility of

damage to your property because of freezing. So, if you plan to be

away, arrange for someone to check your home every day or so.

AT THE BEGINNING OF EACH HEATING SEASON

Be sure electrical supply to furnace is turned off at the household

service box and furnace circuit breakers before cleaning.

1. Replace filters as discussed previously. Clean dust and lint from in

and around the furnace. Clean dust and lint from blower and blower

compartment.

2. If furnace fails to operate properly:

a. Be sure electrical power is being supplied to furnace. Check

main household power supply.

b. If, after following this procedure, the furnace still fails to oper-

ate, shut off furnace and contact your service technician.

YOUR AUTHORIZED SERVICE TECHNICIAN

Your furnace's best friend is your service technician. If the unit gives

any indication of improper operation, call your authorized service technician. If the service technician is allowed to perform the normal routine

care of your furnace, many times he can detect potential difficulties and

make corrections before trouble develops. Preventive maintenance of

this type will allow you to operate this unit with a minimum of concern

and pay for itself in added years of comfort.

OPTIONAL AIR CONDITIONING ACCESSORIES

This furnace is equipped with a blower and control system to add-on air

conditioning and heat pumps to specified sizes. Insulation and coil shelf

kit (3500-8941 for downflow or 3500-8961/A for upflow) must be

installed when adding on such remote air conditioning systems.

If the controls are located at the top of the unit, the furnace is an

upflow furnace and the airflow is forced up through the furnace and

into the airways.

Failure to install this insulation and coil shelf kit could result in damage to equipment and/or personal injury. Liability and warranty from

the manufacturer could also be void.

HIGH PERFORMANCE BLOWER ACCESSORY

PACKAGE

All EB furnaces are equipped with a blower and control system to addon air conditioning and heat pumps to specified sizes. If the requirement is to achieve more air flow or cooling than specified, then the

blower inside the furnace has to be replaced with an accessory blower

package 3500-7901*. This accessory blower package would deliver air

conditioning up to 5-tons, and heat pump up to 4-tons. Accessory package (3500-7901*) includes blower, insulation, coil shelf, trap, clamps,

etc. Please refer to the installation instructions packed with the accessory package for more information.

All areas around the line sets, drain hoses and other openings in the

furnace should be sealed airtight. Use some moldable compound or

caulking to seal the area. Failure to do so may result in loss of performance and premature compressor failure.

Johnson Controls Unitary Products 3

Page 4

570930-BUM-C-0112

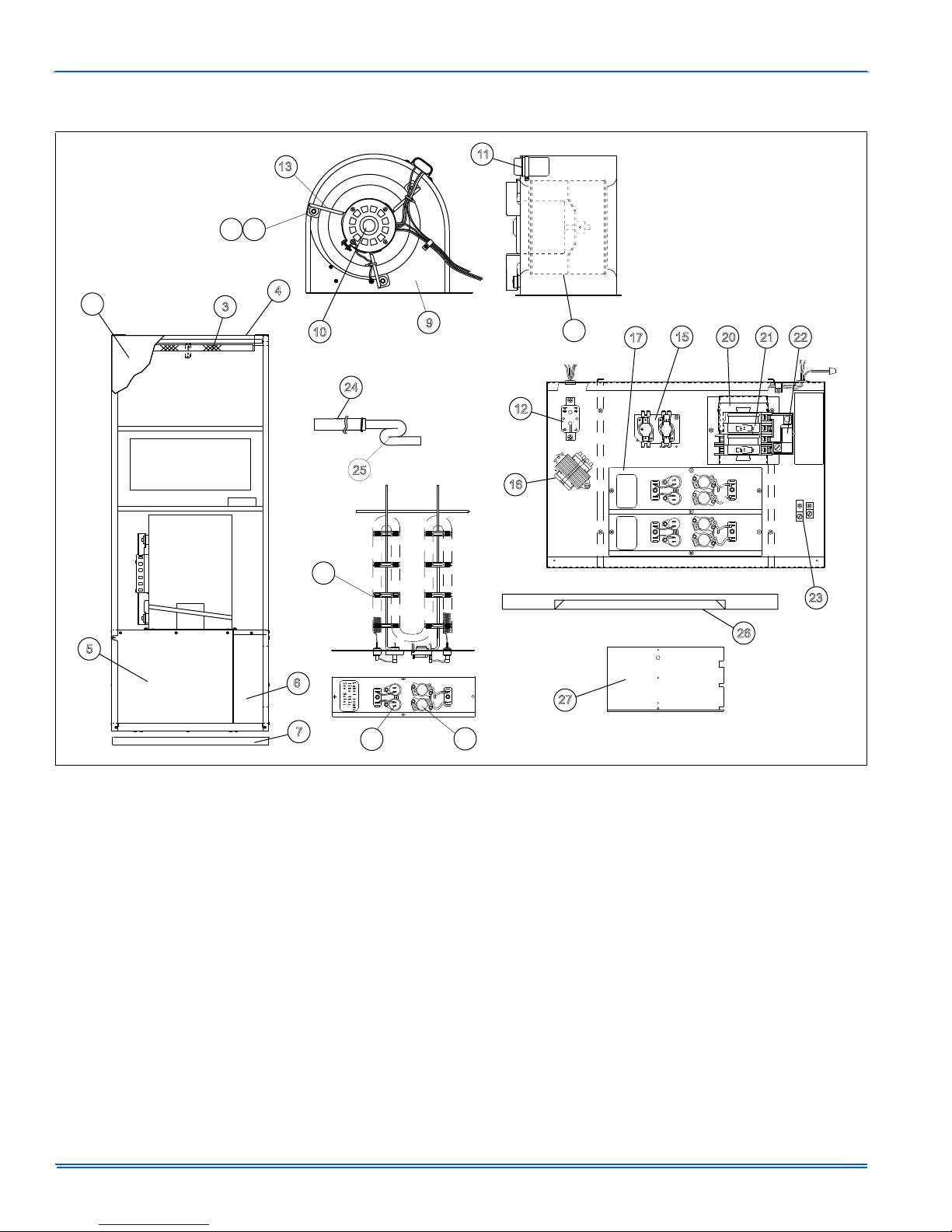

1

24

25

3

4

5

6

26

9

10

11

7

17

16

15

20

21

22

23

12

27

13

14

19

17

18

29 28

1

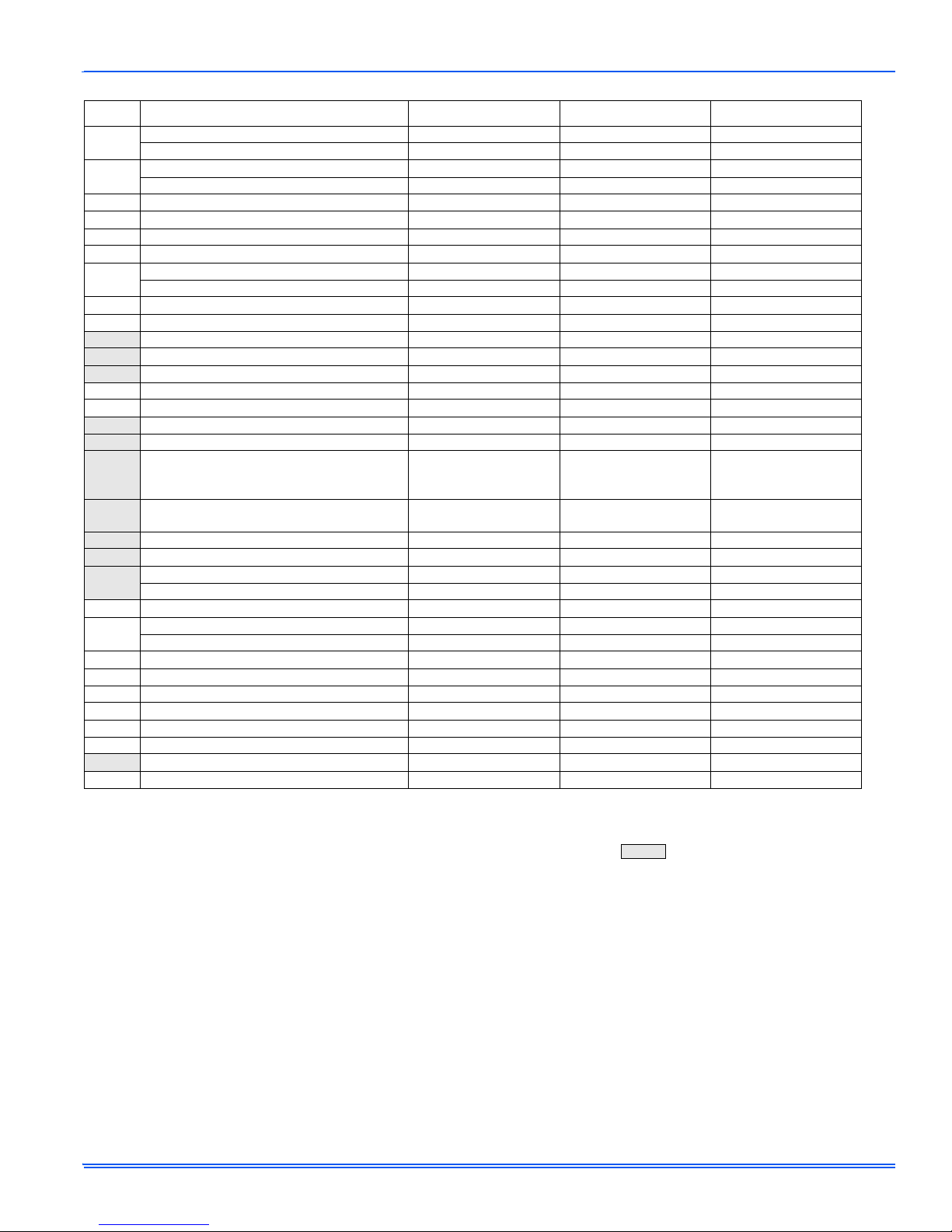

SECTION V: REPAIR PARTS LIST

4 Johnson Controls Unitary Products

Page 5

570930-BUM-C-0112

ITEM DESCRIPTION EB10D EB12D EB15D <

Front Panel (Insulated) 3501-9111 3501-9111 3501-9111

1

Filter

(20 x 20 x 1) (Front Return Panel) S1-1214-2521 S1-1214-2521 S1-1214-2521

2* (Opt)

Front Panel (Louvered, 4-Ton) (Insul) 3501-9211 3501-9211 3501-9211

Front Panel (Front Return, 5-Ton) 3500-1591 3500-1591 3500-1591

3 Filter (16 x 20 x 1) S1-1214-2511 S1-1214-2511 S1-1214-2511

4 Support Angle (Door) S1-3500-1861 S1-3500-1861 S1-3500-1861

5 Cover, Electric Box S1-3500-2351/A S1-3500-2361/A S1-3500-2361/A

6 Cover (Service Entrance) S1-3500-1271 S1-3500-1271 S1-3500-1271

Sub-base (Optional) S1-3500-1071/B S1-3500-1071/B S1-3500-1071/B

7

Sub-base (M10) (Optional) 3500-5221 3500-5221 3500-5221

8

9 Blower Housing S1-37323744001 S1-37323744001 S1-37323744001

10 Blower Motor S1-02427651000 S1-02427651000 S1-02427651000

11 Capacitor (7.5MFD/370V) S1-02420045700 S1-02420045700 S1-02420045700

12 Relay, Fan S1-3110-3301 S1-3110-3301 S1-3110-3301

13 Motor Mount Assembly Kit (1PC) S1-37319831002 S1-37319831002 S1-37319831002

14 Blower Wheel S1-02632627700 S1-02632627700 S1-02632627700

15 Sequencer S1-3110-3571 S1-3110-3571 S1-3115-3571

16 Transformer (240/24V-40A) S1-3300-3861 S1-3300-3861 S1-3300-3861

Heater Element Assembly w/Limit and Jumper

17

Wire

(9.6Kw)

S1-02541236000

(11.2Kw)

S1-02541238000

(4.8Kw) & (9.6Kw)

S1-02541237000

S1-02541236000

Limit Switch S1-02541249000 (Open

18

200, Close 60)

S1-02541249000 (Open

200, Close 60)

S1-02541249000 (Open

200, Close 60)

19 Fusible Link S1-02435663000 S1-02435663000 S1-02435663000

20 Bracket (Circuit Breaker) 3500-128 3500-128 3500-128

Circuit Breaker (1 Req’d) S1-3500-377P/A --- ---

21

Circuit Breaker (2 Req’d) --- S1-3500-377P/A S1-3500-377P/A

22 Buss Bar (See Note 2) S1-3500-378P S1-3500-378P S1-3500-378P

Ground Lug (Large) 1216-231 1216-231 1216-231

23

Ground Lug (Small) --- --- S1-02521798000

24 Drain Tube (See Note 1) S1-02922184001 S1-02922184001 S1-02922184001

25 Condensate Trap (See Note 1) S1-3240-3051 S1-3240-3051 S1-3240-3051

26 Coil Shelf (See Note 1) 3500-174 3500-174 3500-174

27 Coil Shelf Panel (See Note 1) 3500-171 3500-171 3500-171

28 Ferrule (3 Req’d) S1-02320541000 S1-02320541000 S1-02320541000

29 Grommet (3 Req’d) S1-02814740000 S1-02814740000 S1-02814740000

30 Fuse S1-02532746026 S1-02532746026 S1-02532746026

31* Wiring diagram 570551 570539 570540

NOTE: *Not Shown

New replacement parts shown in bold face type at the first printing of parts list dated 4/10.

Major components and suggested stocking items are shown with shaded item number.

“<“ Across from row indicates a change in that row.

--- Not applicable to specified model.

All parts with three digit suffix numbers are “Special Order” parts. These parts are subject to factory

availability and require extra time for delivery.

1 Not Standard with furnace, contained in accessory kit no. 3500-8941/B.

2 Standard on EB12*.

Johnson Controls Unitary Products 5

Page 6

570930-BUM-C-0112

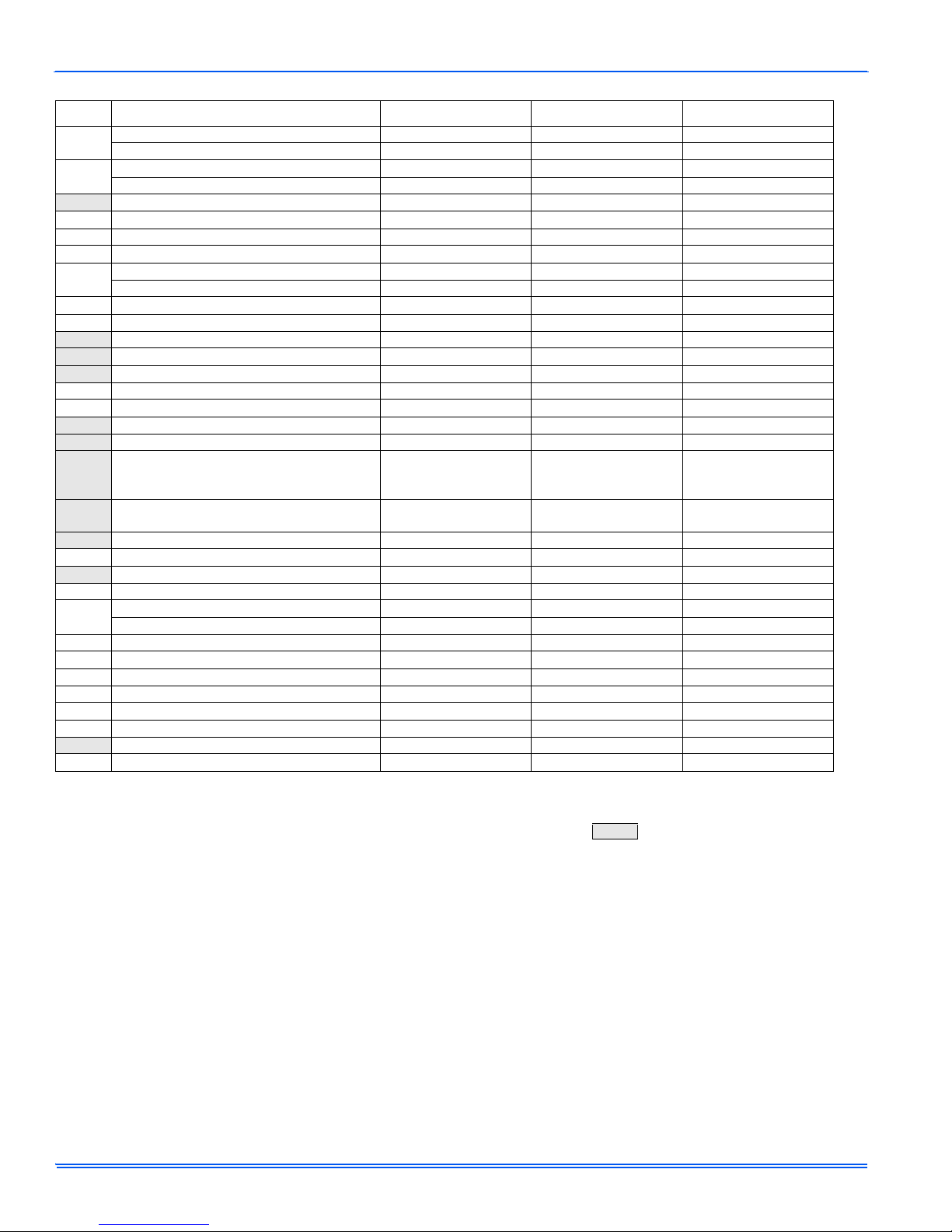

ITEM DESCRIPTION EB17D EB20D EB23D <

Front Panel (Louvered, 4-Ton) (Insul) 3501-9211 3501-9211 3501-9211

1

Filter

(20 x 20 x 1) (Front Return Panel) S1-1214-2521 S1-1214-2521 S1-1214-2521

2* (Opt)

Front Panel (Insulated) 3501-9111 3501-9111 3501-9111

Front Panel (Front Return 5-Ton) 3500-1591 3500-1591 3500-1591

3 Filter (16 x 20 x 1) S1-1214-2511 S1-1214-2511 S1-1214-2511

4 Support Angle (Door) S1-3500-1861 S1-3500-1861 S1-3500-1861

5 Cover, Electric Box S1-3500-2361/A S1-3500-2361/A S1-3500-2361/A

6 Cover (Service Entrance) S1-3500-1271 S1-3500-1271 S1-3500-1271

Sub-base (Optional) S1-3500-1071/B S1-3500-1071/B S1-3500-1071/B

7

Sub-base (M10) (Optional) 3500-5221 3500-5221 3500-5221

8

9 Blower Housing S1-37323744001 S1-37323744001 S1-37323744001

10 Blower Motor S1-02427651000 S1-02427651000 S1-02427651000

11 Capacitor (7.5MFD/370V) S1-02420045700 S1-02420045700 S1-02420045700

12 Relay, Fan S1-3110-3301 S1-3110-3301 S1-3110-3301

13 Motor Mount Assembly Kit (1PC) S1-37319831002 S1-37319831002 S1-37319831002

14 Blower Wheel S1-02632627700 S1-02632627700 S1-02632627700

15 Sequencer S1-3115-3571 S1-3120A3571 S1-3120A3571

16 Transformer (240/24V-40A) S1-3300-3861 S1-3300-3861 S1-3300-3861

Heater Element Assembly w/Limit and Jumper

17

Wire

(5.6Kw) & (10.4Kw)

S1-02541239000

S1-02541240000

Limit Switch S1-02541249000 (Open

18

200, Close 60)

2 Ea. (9.6Kw)

S1-02541236000

S1-02541249000 (Open

200, Close 60)

(10.4Kw) & (11.2Kw)

S1-02541240000

S1-02541238000

S1-02541249000 (Open

200, Close 60)

19 Fusible Link S1-02435663000 S1-02435663000 S1-02435663000

20 Bracket (Cir cuit Breaker) 3500-128 3500-128 3500-128

21 Circuit Breaker (2 Req’d) (See Note 2) S1-3500-377P/A S1-3500-377P/A S1-3500-377P/A

22 Buss Bar S1-3500-378P S1-3500-378P S1-3500-378P

Ground Lug (Large) 1216-231 1216-231 1216-231

23

Ground Lug (Small) S1-02521798000 S1-02521798000 S1-02521798000

24 Drain Tube (See Note 1) S1-02922184001 S1-02922184001 S1-02922184001

25 Condensate Trap (See Note 1) S1-3240-3051 S1-3240-3051 S1-3240-3051

26 Coil Shelf (See Note 1) 3500-174 3500-174 3500-174

27 Coil Shelf Panel (See Note 1) 3500-171 3500-171 3500-171

28 Ferrule (3 Req’d) S1-02320541000 S1-02320541000 S1-02320541000

29 Grommet (3 Req’d) S1-02814740000 S1-02814740000 S1-02814740000

30 Fuse S1-02532746026 S1-02532746026 S1-02532746026

31* Wiring diagram 570571 570572 570573

NOTE: *Not Shown

New replacement parts shown in bold face type at the first printing of parts list dated 4/10.

Major components and suggested stocking items are shown with shaded item number.

“<“ Across from row indicates a change in that row .

--- Not applicable to specified model.

All parts with three digit suffix numbers are “Special Order” parts. These parts are subject to fact ory

availability and require extra time for delivery.

1 Not Stand ard with furnace, contained in accessory kit no. 3500-8941/B

6 Johnson Controls Unitary Products

Page 7

NOTES

570930-BUM-C-0112

Johnson Controls Unitary Products 7

Page 8

Limited Warranty

Manufactured Housing Furnace

UPG warrants this product to be free from defects in factory workmanship and material under normal use and service and will replace parts that prove to have

such defects according to the ter m s ou tli ned below.

Furnace Model Parts Coverage Labor and Trip Coverage*

EB 2 years 1 years

The warranty period for any replacement part provided here under shall not extend beyond the warranty period stated above.

The warranty period will beg in on the purchase date of the residence w h en the product is installed as original equipment, or the installation date when installed

in a residence previously purchased by the consumer. Return the Warranty Registration Card to UPG promptly after product installation or purchase for your

benefit and protection. The warranty period will begin upon product shipment from UPG in the absence of a recorded Warranty Registration Card.

This warranty applies to the original consumer/purchaser and a ny subsequent purchaser. The warranty does not apply if t he furnace is removed from the original residence, or if the residence has been moved from the original location where the furnace was placed in service.

This warranty applies only to products installed: (1) in the United States of America or Canada; (2) in accordance with UPG recommendations and specifications outlined in the In stallation Manua l provided wi th the produ ct; (3) in ac cordance wi th all natio nal, state/prov incial, and local cod es; and (4 ) in the orig inal

residence.

Exclusions

1. Shipping/freight, or material charges.

2. Damages resulting from transportation, mishandling, improper application, installation or servicing.

3. Damages resulting from accident, abuse, fire, flood, or other acts of nature.

4. Use of the product in a corrosive atmosphere.

5. Alteration, tampering, defacing or removing the product serial number will serve to void the warranty.

6. Damages resulting from inadequacy or interruption of electrical service, improper energy supply, blown fuses, improper wiring external to the unit

or other like damages.

7. Damages resulting from the use of components not approved by UPG.

8. This warranty does not cover consequential damages, incidental damages or incidental expenses including damages to property.

9. Damages caused by failure to perform normal or routine maintenance as set out in the operation and service instructions.

10.Cleaning, replacement of filters, or any other routine maintenance as set out in the User’s Information, Maintenance and Service Manual.

11.Replacement or cleaning of nozzles or orifices.

12.Fuses either internal or external to the product.

13.Excessive fuel or electricity consumption.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SOME STATES DO NOT ALLOW THE DISCLAIMER OF IMPLIED WARRANTY, SO THAT THE ABOVE

DISCLAIMER MAY NOT APPLY TO YOU.

SOME STATES ALLOW ONLY A PARTIAL LIMITATION ON IMPLIED WARRANTIES, OR LIMIT THE DURATION OF IMPLIED WARRANTIES TO THE

DURATION OF THE EXPRESS WARRANTY. IN SUCH STATES, THE DURATION OF IMPLIED WARRANTIES IS HEREBY EXPRESSLY LIMITED TO THE

DURATION OF THE EXPRESS WARRANTY ON THE FACE HEREOF. IN NO EVENT, WHETHER AS A RESULT OF BREACH OF WARRANTY OR CONTRACT TORT (INCLUDING NEGLIGENCE) STRICT LIABILITY OR O THERWISE, SHALL UPG BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LOSS OF USE OF THE EQUIPMENT OR ASSOCIATED EQUIPMENT, LOST REVENUES OR

PROFITS, COST OF SUBSTITUTE EQUIPMENT. THIS WARRANTY DOES NOT COVER CONSEQUENTIAL DAMAGES. THE ABOVE LIMITATIONS

SHALL INURE TO THE BENEFIT OF UPG SUPPLIE RS AND SUBCONTRACTORS. THE ABOVE LI MITATION ON CONSEQUENTIAL DAMAGES SHALL

NOT APPLY TO INJURIES TO PERSONS IN THE CASE OF CONSUMER GOODS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITA TION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENT AL DAMAGES, OR FOR STRICT

LIABILITY IN TORT, SO THAT THE ABOVE EXCLUSIONS AND LIMITATIONS MAY NOT APPLY TO YOU. UPG DOES NOT ASSUME, OR AUTHORIZE

ANY PERSON TO ASSUME FOR UPG ANY LIABILITY FOR THE SALE OF THIS PRODUCT. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS.

YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

TO OBTAIN WARRANTY SERVICE

Consult the Authorized Service Center list packed with the furnace installed in th e manufactured home or contact your installing or servicing dealer.

Or, look in the Yellow Pages of the tel ep hone bo ok under Mo bil e Ho mes-o r Man ufac ture d H ous ing- Re pair and Se rv ice fo r the n ame a n d te le ph on e numb er of

the nearest authorized manufactured housing service center. If local authorized service cannot be obtained, or you are unab le to contact your installing dealer,

contact the authorized distribut or in your area. If there is no di stributor in your area, and yo u cannot obtain proper service under the terms of the warranty,

please write: Unitary Products Group (UPG) Customer Relations Department, PO Box 19014, Wichita, KS 67204-9014.

Subject to change without notice. Published in U.S.A. 570930-BUM-C-0112

Copyright © 2012 by Johnson Controls, Inc. All rights reserved. Supersedes: 570930-BUM-B-1010

Johnson Controls Unitar y Products

P.O. Box 19014

Wichita, KS 67204-9014

Loading...

Loading...