Page 1

MODEL DSV

AIR CONDITIONING UNITS

INSTALLATION INSTRUCTIONS Supersedes:145.29-IOM2 (812) Form 145.29-IOM2 (814)

MODEL DSV60B-300B

VERTICAL R-410A

AIR CONDITIONING UNITS

STYLE B

Issue Date:

August 25, 2014

Page 2

IMPORTANT!

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDLINES

This equipment is a relatively complicated apparatus.

During installation, operation, maintenance or service,

individuals may be exposed to certain components or

conditions including, but not limited to: refrigerants

materials under pressure, rotating components, and

both high and low voltage. Each of these items has the

potential, if misused or handled improperly, to cause

bodily injury or death. It is the obligation and responsibilty of operating/service personnel to identify and

recognize these inherent hazards, protect themselves,

and proceed safely in completing their tasks. Failure to

comply with any of these requirements could result in

serious damage to the equipment and the property in

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to areas of potential hazard.

DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

All wiring must be in accordance with published specifications and must be performed ONLY

by qualified service personnel. Johnson Controls will not be responsible for damages/problems

resulting from improper connections to the controls or application of improper control signals.

Failure to follow this will void the manufacturers warranty and cause serious damage to property or injury to persons.

, oils,

FORM 145.29-IOM2 (814)

which it is situated, as well as sever personal injury or

death to themselves and people at the site.

This document is intended for use by owner-authorized

operating/service personnel. It is expected that this

individual possesses independent training that will enable them to perform their assigned tasks properly and

safely. It is essential that, prior to performing any task

on this equipment, this individual shall have read and

understood this document and any referenced materials.

This individual shall also be familiar with and comply with

all applicable governmental standards and regulations

pertaining to the task in question.

CAUTION identifies a hazard which

could lead to damage to the machine,

damage to other equipment and/or

environmental pollution. Usually and

instruction will be given, together with a

brief explanation.

NOTE is used to highlight additional information which may be helpful to you.

2 JOHNSON CONTROLS

Page 3

CHANGEABILITY OF THIS DOCUMENT

In complying with Johnson Controls policy for continuous product improvement, the information contained in

this document is subject to change without notice.

While Johnson Controls makes no commitment to update or provide current information automatically to the

manual owner, that information, if applicable, can be

obtained by contacting the nearest Johnson Controls

service office.

TABLE OF CONTENTS

Safety Symbols………………………………………………………… 2

Changeability of This Document…………………….……………….. 3

Nomenclature……………………………………….………………….. 4

Typical Installation Diagram…………………………..………………. 5

General Information……………………………………………………. 6

Pre-Installation Inspection of Equipment……………………………. 6

Installation -

Unit Mounting / Unit Weights…………..……………………………..7

Evaporator / Condenser Assembly…………….…………………… 7

Condensate Trap…..…………………………………………………. 8

Ductwork………………………………………………………………. 9

Optional Accessories -

Variable Frequency Drive (VFD)………..……………………………9

Hot Gas Bypass (HGBP)……….…………….………………………10

Air Side Economizer…………….…………….………………………10

Discharge Plenum…………….……………..……..…………………11

Low Ambient Damper…………….…………..………………………12

Blower Discharge Conversion……..………………………………....13

Electrical Wiring / Electrical Data………………………………….. 13

Fan Performance Data……………………………………………….. 15

Motor and Pulley Data / Blower Speed Adjustment…………… 19

Start-Up and Operation………………………………………………. 21

Refrigerant Charges………………………………………………. 21

Pressure Switch Settings…………………………………………. 21

Microprocessor Controller……………………………………....…… 22

Operation……………………………….………………………….. 22

Microprocessor Flash Codes…………………………………….. 24

Maintenance/Service………………………………………………… 25

Appendix A: Unit Dimensional Drawings…………………………… 26

Appendix B: Typical Service Clearances……………………………36

Appendix C: Typical Wiring Schematics…………………………… 37

R-410A Service Procedures - Quick Reference Guide…………… 47

FORM 145.29-IOM2 (814)

It is the responsibility of operating/service personnel as

to the applicability of these documents to the

equipment in question. If there is any question in the

mind of operating/service personnel as to the

applicability of these documents, then, prior to working

on the equipment, they should verify with the owner

whether the equipment has been modified and if

current literature is available.

JOHNSON CONTROLS 3

Page 4

NOMENCLATURE

Product Category

DS =

Miscellaneous Options

A = None

D = Condensate Overflow Switch

Product Indentifier

V = Vertical, Free Standing Heating Options

0 = None

Nominal Capacity

060 = 5 TON Refrigerant Circuit Options

096 = 8 TON Design Series A = None

120 = 10 TON

B= Current B = Hot Gas Bypass

144 = 12 TON

180 = 15 TON

240 = 20 TON

VOLTAGE Condenser Drive Options

300 = 25TON

2 = 208/230-60-3

1 = Std Motor & Drive

4 = 460-60-3

2 = High Static Drive

5 = 575-60-3

Control Options

M = Std Microprocessor Controls Outdoor Air-side Options

A = Std Air-Side coil

C = Corrosion Protective Coating

ID Motor

1 = Std

2 = High Static Indoor Air-side Options

3 = Std cw VFD*

A = Std Air-Side coil

4 = High Static cw VFD* C = Corrosion Protective Coating

D = Stainless Steel Drain Pan

F = Coated Coil w/ S-S Drain Pan

Supply Air Discharge Configuration

V= Top Ve rtical

H=Front Horizontal

* VFD OPTION AVAILABLE ONLY ON 10 TONS AND UP

Integral Air-Cooled

Packaged A/C, R-410A

1AAMV2HDS120

B

1,2312134,5,6891071116

0

A

14

15A17

1

FORM 145.29-IOM2 (814)

4 JOHNSON CONTROLS

Page 5

DSV - TYPICAL INSTALLATION DIAGRAM

FORM 145.29-IOM2 (814)

JOHNSON CONTROLS 5

Page 6

FORM 145.29-IOM2 (814)

GENERAL INFORMATION

All models 8 ~ 25 tons are shipped as separate

condensing unit and evaporator section modules. The

5 ton models are shipped as factory-charged unitized

packages. All models are designed for freestanding

mounting on the floor, or on a field fabricated

structural steel stand. All models can be ordered in

either top or front fan discharge.

The 5 ton model utilizes a single compressor. All 8

through 25 ton models are dual compressor units with

two independent refrigerant circuits. The 8 ~ 25 ton

models require field connection and charging of the

refrigerant circuits. The 8 ~ 25 ton models are shipped

with a nitrogen holding charge only. Refer to ‘Start-Up

and Operation’ section for charge information.

All units come standard with a microprocessor control

board with safety controls and troubleshooting LED

(refer to ‘Microprocessor’ section).

Units will operate reliably at outdoor ambient down to

50F. In applications requiring operation below this

temperature, a low ambient damper accessory is

available. The damper installs on the condenser air

discharge, and allows operation to 0 F ambient.

ONLY QUALIFIED PERSONNEL SHOULD

PERFORM INSTALLATION AND SERVICE

OF THIS EQUIPMENT.

PRE-INSTALLATION INSPECTION OF EQUIPMENT

All units are factory tested to ensure safe operation

and quality assembly. Units are packaged and sealed

on shipping skids and shipped in first class condition.

Torn and broken packaging, scratched or dented

panels should be reported to carrier immediately.

Internal inspection of all units should be performed

prior to installation. Remove all access doors and

check for visual defects that can occur during

transport. Any problems found internally should be

reported to carrier and manufacturer immediately.

Refrigerant circuit should be checked to ensure no

leaks have occurred during shipment. Install gauge

set to high and low pressure ports to confirm pressure

has been maintained and no leaks have occurred

during shipment. Repair any damage prior to

installation to ensure safe operation.

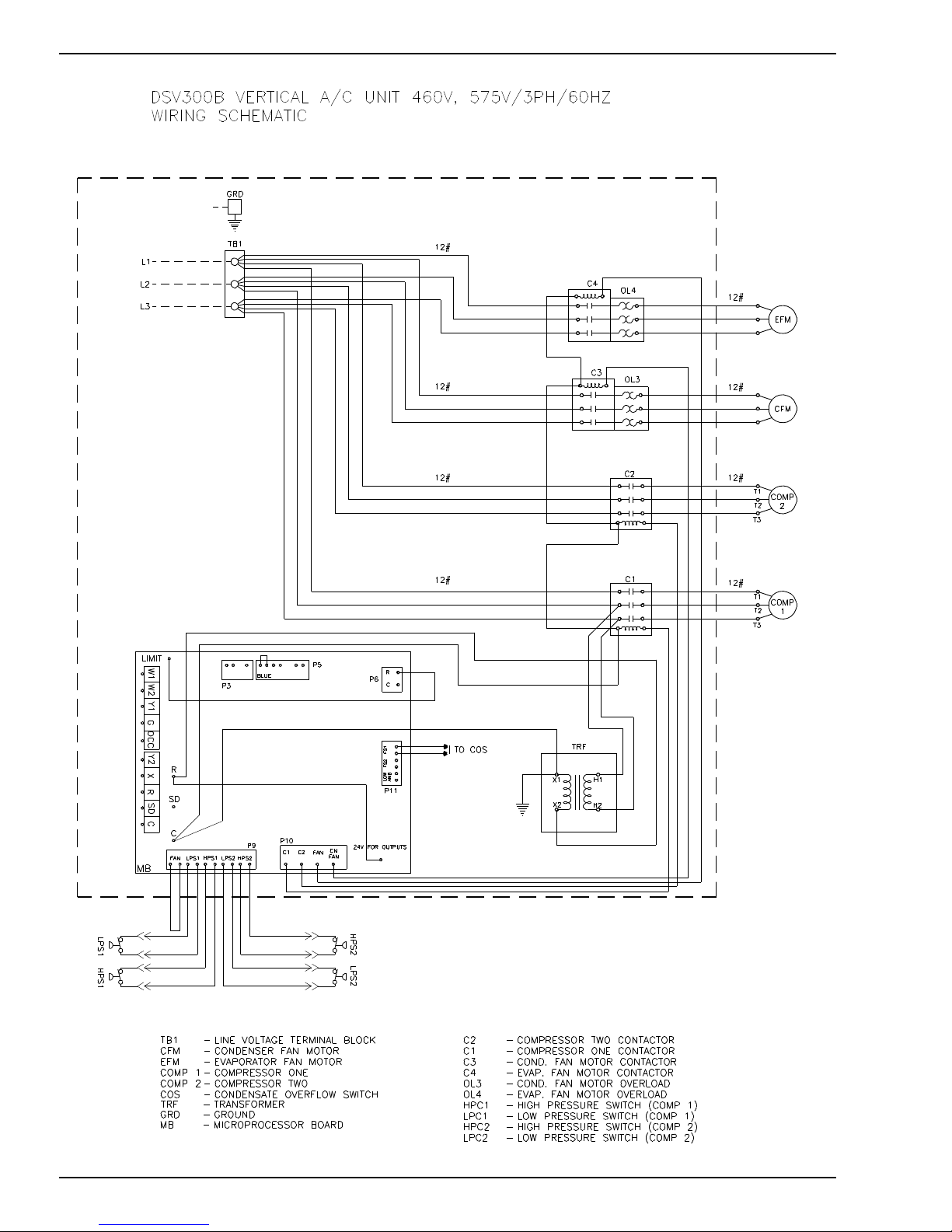

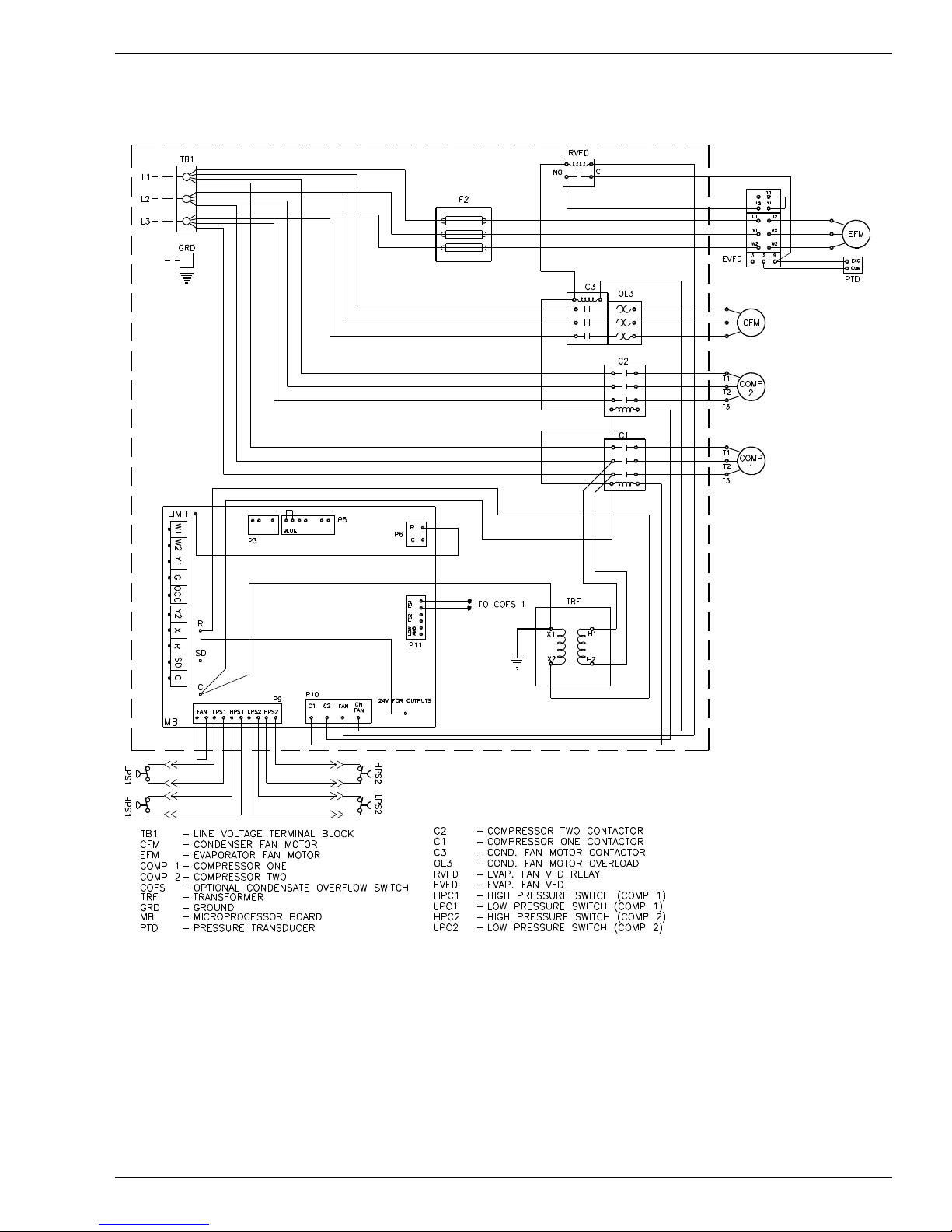

See Appendix section for unit dimensional drawings.

Record any unit damage on the Bill of

Lading and report to carrier and factory

immediately. Shipping and handling

damages are not warranty items.

RIGGING

PRIOR TO MOUNTING UNIT, CHECK

INDIVIDUAL UNIT WEIGHTS (PAGE 10)

AND VERIFY LIFTING CAPACITY OF

LIFTING EQUIPMENT EXCEEDS WEIGHT

OF UNITS BY SAFE MARGINS. FAILURE

TO DO SO MAY RESULT IN UNIT

DAMAGE, PERSONAL INJURY OR EVEN

DEATH.

To ensure safe installation of the unit ensure the base

of the unit is continuously supported.

DETERMINE THE ACTUAL CENTER OF

GRAVITY OF THE UNIT BY PERFORMING A TEST LIFT. LIFTING AN UNBALANCED UNIT CAN CAUSE PERSONAL

INJURY OR EVEN DEATH.

INSTALLATION SITE

LOCK ALL ELECTRICAL POWER SUPPLY SWITCHES IN THE OFF POSITION

BEFORE INSTALLING THE UNIT. FAILURE TO DISCONNECT POWER SUPPLY

MAY RESULT IN ELECTRICAL SHOCK

OR EVEN DEATH.

Location - To ensure unit operates at maximum

efficiencies, choose a dry indoor area where the

temperature is controlled between 50F and 115F.

Consideration of surrounding areas should be taken

when choosing a location to install the unit. Common

vibration and sound levels associated with commercial

equipment may be objectionable to people or

equipment.

Failure to allow adequate space between

units, condenser intake and discharge

may result in poor unit performance and

possible unit failure.

Install thermostats, air supplies and returns so that

each unit will operate only on individual unit control.

To assure fast drainage of condensate run-off, unit

6 JOHNSON CONTROLS

Page 7

FORM 145.29-IOM2 (814)

DSV Operating Weight (Lbs)

Unit

Operating Weight

(Condenser Only)

Shipping Weight

(Condenser Only)

DSV060B

920 (620)

980 (675)

DSV096B

1240 (810)

1290 (865)

DSV120B

1325 (860)

1385 (915)

DSV144B

1560 (980)

1645 (1035)

DSV180B

1655 (1030)

1740 (1090)

DSV240B

1875 (1210)

1960 (1270)

DSV300B

2480 (1400)

2600 (1450)

Corner Bracket

can be slightly pitched in the same direction as drain

pan outlet.

UNIT MOUNTING

The 5 ton model is shipped as a fully assembled

integral package. The 8 ~ 25 ton models are shipped

in two pieces - a separate condensing unit and

evaporator module - which are intended for assembly

into a freestanding vertical package on site. The unit

is not designed for remote condenser / evaporator

installation and must be installed as a packaged

system. Installation or modification of the unit that is

not described in this manual is not factory

recommended nor is it factory supported. User is

responsible for any damage that as a result may

occur.

Flanges for all duct connections, corner securing

brackets, and refrigerant tubing couplings are shipped

in the condensing section of the unit for field

installation. Duct flanges for evaporator return are

incorporated into the filter rack.

Floor mounted units should be secured on a solid,

level pad or sturdy stand. The base of the unit should

be approximately 6 inches higher than the lower edge

of the wall opening. This height will allow the

condenser air ducts to be pitched away from the unit,

offering protection from rain water entering the base

pan (refer to typical installation diagram on Page 4).

The use of an isolating rubber sheet is recommended

to reduce vibration and noise transmission. Ensure

that the entire base is continuously supported. Unit

may be pitched slightly to ensure efficient drainage of

condensate.

Ensure that entire base is continuously

supported. DO NOT support unit at

corner points only!

EVAPORATOR / CONDENSER ASSEMBLY

ASSEMBLY OF SPLIT UNITS (8 - 25 TON MODELS)

- Place the condensing section in the required

location.

- Carefully position the evaporator section atop the

condensing section. Align all sides, the evaporator

motor wire routing hole, and the refrigerant line

routing holes.

- Install the securing brackets at all four corners, on

the evaporator/condenser separation joint.

Securing Corner Bracket

- Units are provided with couplings to mate

refrigerant piping between condenser and

evaporator section. Unit with Hot Gas Bypass

option will be provided with additional copper

couplings for the HGBP piping. Remove shipping

bracket securing spun copper ends in the

condenser, this can be discarded and is not

required.

- Cut off spun copper ends on each refrigerant pipe

in evaporator and condenser. Cut pipe to

appropriate length to fit on couplings. Ensure

circuit 1 from condenser connects to circuit 1

piping in evaporator, follow same procedure for

circuit 2. Do not cross circuits.

- Follow common A/C service practices by brazing

copper couplings to refrigerant pipe using a flow

of nitrogen gas (max. 1 psi) through the refrigerant

piping to minimize contamination to internal

piping. Otherwise damage to unit refrigeration

components may occur. Use the service gauge

ports for this procedure to introduce nitrogen flow.

Once complete pressure test with nitrogen (500

psig).

- Evacuate each circuit to at least 350 microns. If

gauge pressure rises above 500 microns in one

minute, evacuation is incomplete or the system

has a leak.

- Charge circuit(s) to the value indicated on the unit

nameplate or see section ‘Start-Up and

Operation’.

JOHNSON CONTROLS 7

Page 8

FORM 145.29-IOM2 (814)

Evaporator

connections,

couplings included

with unit

Condenser piping

for coupling to

evaporator

Condenser

Securing

Bracket

- Install bushing/clamp into evaporator wiring

routing hole, and pull wires through into electrical

control panel from evaporator. Connect motor

leads to load terminals on contactor/overload

relay.

Typical Piping Connections View (8/10 TON Model without

HGBP Shown)

Do not cross circuits when brazing

refrigerant piping between sections.

SEPARATION OF UNITS - (DSV060B MODEL)

If separation of units is required to pass through

doorways, elevators. Unit is not designed and not

certified to be installed as a remote condenser and

evaporator.

- Reclaim the entire refrigerant charge from each

compressor circuit.

- Disconnect the evaporator motor high voltage

wires. Pull all wiring into the evaporator

compartment. Remove bushing/clamp from

routing hole for evaporator motor wiring.

- Cut and remove sections of all liquid and suction

refrigerant lines. Make two cuts in each line,

approximately 6 inches above and below the

evaporator floor/condenser roof.

Use a TUBING CUTTER ONLY - do not

use a hacksaw to cut refrigerant tubing

otherwise serious damage can occur

to refrigeration system!

- Remove corner securing brackets from the

outside corners of the cabinet, at the joint line

between the evaporator and condenser sections.

- Remove the evaporator section.

- Refer to ‘Assembly of Split Units’ for assembly

instructions.

CONDENSATE TRAP

Unit requires a field installed external condensate trap

otherwise without a trap condensate can be thrown

into the air stream, cause water overflow resulting in

unit and property damage. This system must be

trapped according to a negative pressure (drawthrough) system. Use dimensions given below.

Adhere to local Codes for piping external trap and

condensate.

Example: Trapping a system up to 2” External static

pressure

A= (1” for each 1” of maximum negative static

pressure)) + 1”

B= Half of A

C= A + B + Pipe Diameter

Dimensions for trapping a negative pressure system

Example: Trapping a system up to 2” External static

pressure

A= (2”) + 1” B= A/2 C= A + B + 3/4” = 5-1/4”

8 JOHNSON CONTROLS

Page 9

FORM 145.29-IOM2 (814)

DUCTWORK

When installing ductwork, adhere to local Codes.

Minimize duct runs and avoid abrupt changes in

direction where possible. Allow ample access space

for servicing of the coils and changing of filters.

Perform regular maintenance on ducts to increase unit

life, maintain efficient operation, and reduce

accumulation of explosive dust. Refer to blower

performance charts, and engineer duct runs and

accessory pressure drop so as not to exceed

maximum external static values. Ensure continuous

running condenser intake ambient air temperature do

not exceed 115oF. The condenser exhaust should

discharge into an open area to prevent short cycling of

hot exhaust condenser air with the condenser intake.

Louver sizing guidelines

One of the key issues in obtaining optimum

performance from indoor air-conditioners is the proper

selection of the condenser intake and discharge

louvers. Unlike outdoor air cooled units, which intake

and discharge their cooling virtually unrestricted,

indoor units must overcome the resistance of grilles or

louvers at the outside wall - plus the restriction of any

interconnecting ductwork.

Our indoor air cooled air-conditioners are designed to

accommodate the external static pressure loss

associated with properly sized louvers of the "storm

proof” type. This type of louver typically has a free

area approximately 40-45% of the actual louver size.

To determine the free area required for any given unit,

adhere to the following guidelines:

- Size condenser air intakes for 350-600

feet/minute nominal velocity (Maximum

recommended 700 feet/minute)

- Size condenser air discharge for 1,200-1,500 feet

/minute nominal velocity (Maximum recommended

1,700 feet/minute)

The use of louvers with higher velocities than above

may be employed, at the discretion of the

engineer/installer, provided that the total air pressure

drop does not exceed the capability of the condenser

fan and motor. The use of low restriction louvers with

shallow blade angles can allow higher face velocities

without excessive static pressure loss.

Exceeding the static pressure capability of the

condenser fan will result in insufficient condenser air

volume. This will cause a loss in system capacity, and

may cause compressor shut-down during high

ambient periods. (Installation of an oversize

condenser motor/drive, where applicable, may be

considered in such cases.)

(As a general rule, these velocities will require an

intake louver sized approximately 1.25 to 1.5 times

the dimensions of the duct connection on the unit, and

a discharge louver sized approximately 1.5 to 2 times

the duct connection dimensions.)

Use only louver sections that provide different

deflection angles for air discharge and air intake,

to ensure the unit does not short circuit. Protect

the unit from weather conditions (rain, snow) entering

through the condenser air intake. All outdoor air

ducts should pitch away from the unit, toward the

outside wall. Connect all ducts to unit with canvas

section duct connectors or choose another suitable

noise and vibration absorbing device.

The Manufacturer will not accept any

liability resulting from incorrect installation of this equipment. Follow installation instructions carefully.

VARIABLE FREQUENCY DRIVE (VFD)

Optional VFD controller for the evaporator fan is

available on the 10 to 25 ton models. Mounted in the

in the evaporator module section, the VFD allows the

operator to set the duct static. The VFD will control the

frequency (speed) of the evaporator fan motor in order

to meet the desired supply duct static set point. For

reliable unit operation unit must have a factory

installed Hot Gas Bypass circuit on refrigeration circuit

# 1.

The unit does not carry a failsafe

circuit to bypass the VFD and run

the evaporator fan in the event of a

VFD malfunction.

VFD is factory mounted and wired. The installer must

field provide and install two sensor tubing lines

complete with static pressure probes. Installer is

required to field wire fan power wiring between

evaporator and condenser as a result of the unit being

shipped factory split. The power wiring can be found

inside the VFD enclosure, no extra power wiring is

required – sufficient length is provided. The VFD

option does not include a evaporator fan bypass

circuit in case of microdrive failure. Microdrive will

need to be replaced to re-activate unit. In case of

VFD failure the evaporator fan will stop running

however unit compressors will continue to run until a

low pressure safety trip is activated.

JOHNSON CONTROLS 9

Page 10

FORM 145.29-IOM2 (814)

Jumper set

to 4-20mA

4-20mA Output from

Transducer (–COM)

Transducer

Power (+EXC)

Refer to separate ‘VFD Installation and Operation

Manual’ for detailed installation and operation

instructions.

Do not run evaporator fan motor

below 30Hz otherwise coil freeze-up

and nuisance lock-outs may occur.

Building excessive ductwork

pressure can cause damage to unit

or personnel

VFD Input/Output

Note: Jumper is required between contacts 10 & 11

HOT GAS BYPASS (HGBP)

Optional HGBP on the lead compressor circuit (circuit

#1) meters flow of compressor discharge hot gas to

the system low side in order to balance the system

capacity to the space load requirement. HGBP is

factory installed using an adjustable hot gas regulator.

The bypassed hot gas from the compressor is

discharged to the evaporator inlet (i.e.: between the

TX valve and distributor) via a Tee connection.

Adjusting HGBP set point

The desired coil suction pressure or coil temperature

when the HGBP valve opens is selectable by

adjusting the screw on the HGBP valve. To set the

load run the unit and cool down the evaporator coil by

either shutting the fans or by blocking the airflow until

the suction pressure drops at least 5psi below the

desired evaporator coil setpoint. The next step is to

allow the pressure to be raised by the bypassed gas,

the screw spring adjustment can be set until the

HGBP valve closes at the desired set point.

The pressure of the evaporator coil is set to maintain

an evaporator coil temperature above the point where

frost and coil freeze up could form.

AIR SIDE ECONOMIZER

Optional air side economizer mixing box is designed

to attach the return air side of the evaporator. Mixing

comes with low-leakage opposed blade dampers.

Economizer is used to provide ventilation and free

cooling for the JCI DSV series of vertical air handlers.

Economizer setup is done through the LCD keypad

display locating on the economizer control module

mounted on the mixing box. Access to the mixing box

is required.

The factory supplied economizer includes:

economizer module, mixing box, actuator, enthalpy

sensor, temperature sensor, dampers, and wiring

harness. Refer to Appendix C for economizer

electrical wiring schematics.

SEQUENCE OF OPERATION

High enthalpy sequence

Enthalpy sensor should be located in the outdoor air

duct. When the outside air enthalpy exceeds the

enthalpy set-point, the economizer module Y1-In and

Y1-Out terminals are closed and economizer will be

forced into the minimum damper position setting. The

DSV unit’s microprocessor board will control

mechanical cooling requirements.

Low enthalpy sequence

When the outside air enthalpy is below the enthalpy

set-point, economizer module Y1-In and Y1-Out

terminals are opened and free cooling is activated.

The JCI unit’s microprocessor board turns off

compressor operation.

Damper Modulation

The temperature sensor should be located in the

supply discharge air duct. Locating the sensor in the

discharge air provides effective 'low-limit' sensing and

control. The outside-air damper remains at minimum

position if the discharge air temperature is below 500 F

or 100 C. If the discharge air temperature is between

500 to 560 F (100 to 13.30 C) the outside air damper

will modulate between minimum position and fully

open. Above 560 F (13.30 C) the outside air damper

will remain in the fully open position.

10 JOHNSON CONTROLS

Page 11

FORM 145.29-IOM2 (814)

Plenum Dimensions (Inches)

MODEL

W

D

H

Side Grille

Front Grille

DSV060B

52

29

24

16x12 (2x)

32x12

DSV096B

71.5

32

24

20x18 (2x)

48x18

DSV120B

71.5

32

24

20x18 (2x)

48x18

Plenum Dimensions (Inches)

MODEL

W

D

H

Side Grille

Front Grille

DSV144B

82.5

34

28

24x20 (2x)

28x20 (2x)

DSV180B

82.5

34

28

24x20 (2x)

28x20 (2x)

DSV240B

90.5

34

28

24x20 (2x)

32x20 (2x)

A B C D E

DSV060B VASE-060B-1 49.00 27.75 24.00 40.00 14.00

DSV096B/120B VASE-120B-1 66.50 36.25 26.50 58.00 19.50

DSV144B/180B VASE-180B-1 78.00 35.75 28.50 70.00 19.50

DSV240B VASE-240B-1 86.00 41.25 34.00 78.00 25.00

DSV300B VASE-300B-1 104.00 45.00 34.00 90.00 25.00

MODEL

PART NO.

MIXING BOX

DAMPER

1

FINISHED PRODUCTS

SPOT WELD WELD

INSULATE

PAINTING

NONONONO

6.75

3.625

EDB

TOP VIEW

FRONT VIEW

4

(vertical) discharge evaporator blower configuration.

Discharge plenum for 5 – 10 Ton model comes with

single front grille and single side grilles. The 12 – 20

Ton models come with double front grilles and single

side grilles.

Discharge plenum is constructed of heavy gauge

sheet metal with supply grilles mounted on three side

(front, left and right sides). Discharge plenum is

secured to the unit using 4X corner brackets included

with plenum.

Refer to separate ‘Air Side Economizer Installation

and Operation Manual’ for more detailed installation

and operation instructions.

DISCHARGE PLENUM

Optional discharge plenum is available for field

mounting to the top of evaporator for the 5-20 ton

models. Discharge plenum is only compatible with top

JOHNSON CONTROLS 11

Page 12

FORM 145.29-IOM2 (814)

MODEL PART NO. A B C

DSV060B VADK-060B-1 47.375" 5.0" 11.875"

DSV096B/120B VADK-120B-1 66.375" 5.0" 14.125"

DSV144B/180B VADK-180B-1 77.5" 5.0" 14.125"

DSV240B VADK-240B-1 85.5" 5.0" 12.875"

DSV300B VADK-300B-1 103.5" 5.0" 12.875"

LOW AMBIENT DAMPER INSTALLATION

If unit operation is required at outdoor ambient below

50 F, the optional Low Ambient Damper kit should be

installed to maintain acceptable condensing pressure.

The damper is installed directly onto the intake duct

connection as illustrated. The damper position is

determined by refrigerant pressure. A direct-coupled

electric damper actuator motor drives the damper

open or closed, depending on the output signal from a

proportional pressure control module. A pressure

transducer senses the high-side refrigerant pressure,

through a service access port, located on the liquid

refrigerant line leaving the condenser. The pressure

controller, complete with terminal connection blocks

for wiring, is attached to a field-installed mounting

bracket. Appropriate mounting hardware for the

pressure control module and the damper actuator

motor are provided with the kit. A routing hole is

provided in the condenser corner panel, near the

actuator mounting location, to allow installation of the

plenum-rated cable between the motor and the control

module.

12 JOHNSON CONTROLS

On dual compressor units, the pressure

transducer MUST be connected to the #1

circuit liquid line fitting. Connection to

the second stage refrigerant circuit will

result in system malfunction.

For detailed installation instructions, refer to the

supplementary ‘Low Ambient Damper Kit’

installation instructions.

Page 13

FORM 145.29-IOM2 (814)

EVAPORATOR BLOWER DISCHARGE

CONVERSION

All models can be factory ordered with either front or

top fan discharge.

Procedure for converting the fan discharge is similar

on all models. Original drive belts will need to be

replaced, see ‘Drive Belt’ section for alternate belt

information.

- Remove the panel attachment screws on the

alternate location access panel. Remove the

panel and set aside.

- Remove blower drive belt on all models with

base mounted motors.

- Remove the panel attachments screws on the

blower mounting panel. Do not remove fasteners

securing blowers to panel! The blowers are to

remain attached to the mounting panel at all

times.

- Carefully remove the blower panel assembly

from the evaporator cabinet. Do not allow blower

housings to contact the evaporator coil during the

removal. On some models, the housing(s) will

have to be "rotated" to exit through the panel

opening.

- Interchange the blower panel assembly with the

position of the alternate access panel. Exercise

care in locating the panel. Do not allow blower

housings to contact the evaporator coil. Install

the attachment screws and tighten securely.

- Install the blank access panel into the remaining

evaporator opening. Fasten securely.

- Install new drive belts.

- Adjust drive belts to appropriate tension. Test run

blower and observe operation for unusual

sounds or vibration.

ELECTRICAL WIRING

Follow local electrical codes when making electrical

connections. Units are completely factory wired for

normal supply voltages (ie.208-230, 460,

575V/3Ph/60Hz) Confirm unit specifications by

checking unit data plate. All electrical components are

accessible through an independent electrical panel

located on the "front" face of the condensing section.

The electrical control boxes are located behind outer

access panels. The condenser section electrical cover

is installed with wiring diagrams on the inside, which

must be opened to be read.

Ensure evaporator motor rotation is

correct upon unit start-up. Switch any

two wires at contactor if blower rotation

is not correct.

DISCONNECT AND LOCK OUT POWER

WHEN SERVICING UNIT. UNIT MAY

START AUTOMATICALLY IF POWER IS

NOT DISCONNECTED. FAILURE TO DO

SO MAY RESULT IN PERSONAL INJURY OR DEATH DUE TO ELECTRICAL

SHOCK.

If canvas flexible joints are used on ductwork, install a

ground wire to the ductwork as well.

IMPORTANT: All wiring must comply

with applicable local and national codes

(NEC). Type and location of disconnect

switches must comply with all

applicable codes.

For low voltage thermostat wiring, 18 gauge wire may

be used for up to 50 feet lengths. Low voltage runs up

to 125 feet require 16 gauge wire.

JOHNSON CONTROLS 13

Page 14

FORM 145.29-IOM2 (814)

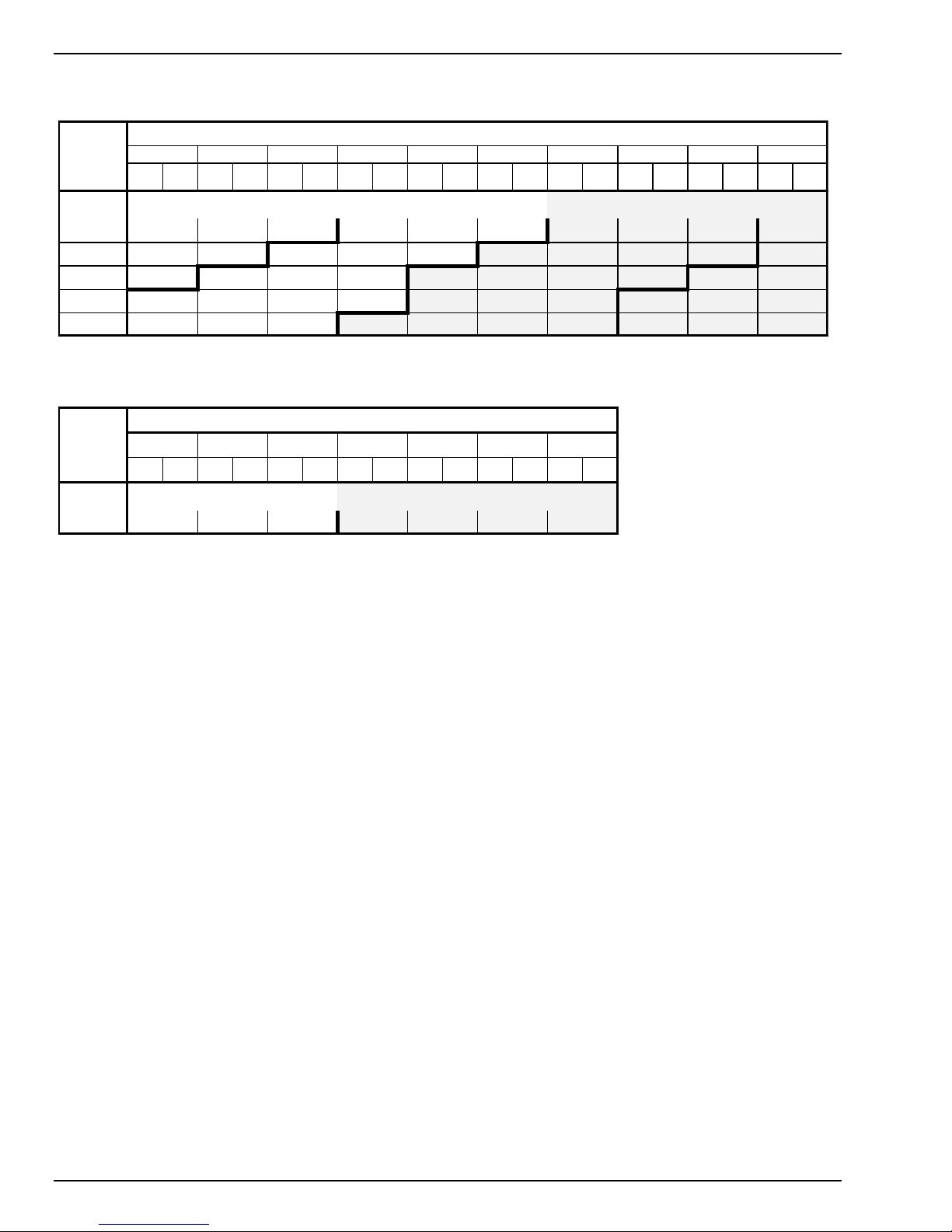

ELECTRICAL DATA - STANDARD EVAPORATOR MOTOR

MODEL #

VOLTAGE

COMPRESSOR

EVAP.

FAN

COND. FAN

MCA

MAX FUSE

/ CCT.

BKR. AMP

QTY RLA

LRA

HP

FLA

HP

FLA

DSV060B2

208-230/3/60

1 @ 16.0

110.0

1.00

3.1

1.50

4.5

27.60

40

DSV060B4

460/3/60

1 @ 7.8

52.0

1.00

1.5

1.50

2.2

13.45

20

DSV060B5

575/3/60

1 @ 5.7

38.9

1.00

1.2

1.50

1.8

10.13

15

DSV096B2

208-230/3/60

2 @ 15.3

83.0

1.00

3.1

2.00

5.8

43.33

50

DSV096B4

460/3/60

2 @ 6.2

41.0

1.00

1.5

2.00

2.9

18.35

20

DSV096B5

575/3/60

2 @ 4.8

33.0

1.00

1.2

2.00

2.3

14.30

15

DSV120B2

208-230/3/60

2 @ 16.0

110.0

1.50

4.5

3.00

8.5

49.00

60

DSV120B4

460/3/60

2 @ 7.8

52.0

1.50

2.2

3.00

4.2

23.95

30

DSV120B5

575/3/60

2 @ 5.7

38.9

1.50

1.8

3.00

3.4

18.03

20

DSV144B2

208-230/3/60

2 @ 19.0

123.0

2.00

5.8

3.00

8.5

57.05

70

DSV144B4

460/3/60

2 @ 9.7

62.0

2.00

2.9

3.00

4.2

28.93

35

DSV144B5

575/3/60

2 @ 7.4

50.0

2.00

2.3

3.00

3.4

22.35

25

DSV180B2

208-230/3/60

2 @ 23.2

164.0

3.00

8.5

5.00

14.0

74.70

90

DSV180B4

460/3/60

2 @ 11.2

75.0

3.00

4.2

5.00

6.6

36.00

45

DSV180B5

575/3/60

2 @ 7.9

54.0

3.00

3.4

5.00

5.3

26.48

30

DSV240B2

208-230/3/60

2 @ 30.1

225.0

5.00

14.0

7.50

19.4

101.13

125

DSV240B4

460/3/60

2 @ 16.7

114.0

5.00

6.6

7.50

9.7

53.88

70

DSV240B5

575/3/60

2 @ 12.2

80.0

5.00

5.3

7.50

7.8

40.55

50

DSV300B2

208-230/3/60

2 @ 34.0

240.0

7.50

20.4

10.00

25.0

121.90

150

DSV300B4

460/3/60

2 @ 16.0

140.0

7.50

9.7

10.00

12.5

58.20

70

DSV300B5

575/3/60

2 @ 12.9

107.6

7.50

7.8

10.00

10.0

46.83

50

ELECTRICAL DATA - OVERSIZED EVAPORATOR MOTOR

MODEL #

VOLTAGE

COMPRESSOR

EVAP.

FAN

COND. FAN

MCA

MAX FUSE

/ CCT.

BKR. AMP

QTY RLA

LRA

HP

FLA

HP

FLA

DSV060B2

208-230/3/60

1 @ 16.0

110.0

1.50

4.5

1.50

4.5

29.00

45

DSV060B4

460/3/60

1 @ 7.8

52.0

1.50

2.2

1.50

2.2

14.15

20

DSV060B5

575/3/60

1 @ 5.7

38.9

1.50

1.8

1.50

1.8

10.73

15

DSV096B2

208-230/3/60

2 @ 15.3

83.0

1.50

4.5

2.00

5.8

44.73

60

DSV096B4

460/3/60

2 @ 6.2

41.0

1.50

2.2

2.00

2.9

19.05

25

DSV096B5

575/3/60

2 @ 4.8

33.0

1.50

1.8

2.00

2.3

14.90

15

DSV120B2

208-230/3/60

2 @ 16.0

110.0

2.00

5.8

3.00

8.5

50.30

60

DSV120B4

460/3/60

2 @ 7.8

52.0

2.00

2.9

3.00

4.2

24.65

30

DSV120B5

575/3/60

2 @ 5.7

38.9

2.00

2.3

3.00

3.4

18.53

20

DSV144B2

208-230/3/60

2 @ 19.0

123.0

3.00

8.5

3.00

8.5

59.75

70

DSV144B4

460/3/60

2 @ 9.7

62.0

3.00

4.2

3.00

4.2

30.23

35

DSV144B5

575/3/60

2 @ 7.4

50.0

3.00

3.4

3.00

3.4

23.45

30

DSV180B2

208-230/3/60

2 @ 23.2

164.0

5.00

14.0

5.00

14.0

80.20

100

DSV180B4

460/3/60

2 @ 11.2

75.0

5.00

6.6

5.00

6.6

38.40

45

DSV180B5

575/3/60

2 @ 7.9

54.0

5.00

5.3

5.00

5.3

28.38

35

DSV240B2

208-230/3/60

2 @ 30.1

225.0

7.50

20.4

7.50

20.4

108.53

125

DSV240B4

460/3/60

2 @ 16.7

114.0

7.50

9.7

7.50

9.7

56.98

70

DSV240B5

575/3/60

2 @ 12.2

80.0

7.50

7.8

7.50

7.8

43.05

50

14 JOHNSON CONTROLS

Page 15

FAN PERFORMANCE

SUPPLY AI R BLOWER PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1600 408 0.13 555 0.29 652 0.38 739 0.45 819 0.54 893 0.63 963 0.71 1029 0.81

1800 459 0.20 600 0.39 689 0.48 770 0.58 846 0.66 917 0.76 984 0.86 1047 0.96

2000 510 0.25 647 0.51 729 0.61 806 0.71 877 0.81 944 0.92 1008 1.00 1069 1.14

2200 561 0.35 695 0.65 772 0.76 843 0.88 911 0.99 975 1.10 1036 1.23 1094 1.34

2400 612 0.45 745 0.83 816 0.95 883 1.07 947 1.19 1008 1.31 1066 1.44 ~ ~

1. Blower performance includes evaporator coil and 2" filters

2. At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Decrease airflow downward as necessary.

CONDENSER FAN PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3100 513 0.50 615 0.65 706 0.80 790 0.98 867 1.15 938 1.33 1006 1.50

Hi-Static Drive

Standard Factory Drive 1.5 HP

SUPPLY

CFM

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0.0

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C. ¹

Optional Hi-Static Drive +1 .5 HP

OUTDOOR

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Standard Factory Drive + 1 HP

Field Supplied Low Static

Drive

SUPPLY AI R BLOWER PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2600 496 0.28 605 0.40 701 0 .50 788 0.62 868 0.74 947 0.89 1016 1.04 1045 1.19 1075 1.35 1105 1.50

2900 514 0.36 618 0.48 710 0 .60 794 0.72 872 0.86 944 0.98 1017 1.12 1075 1.28 1128 1.42 ~ ~

3200 538 0.44 636 0.58 725 0 .70 806 0.84 881 0.98 952 1.12 1018 1.26 1081 1.42 ~ ~ ~ ~

3500 571 0.56 664 0.70 748 0 .84 826 0.98 898 1.14 967 1.28 1031 1.44 ~ ~ ~ ~ ~ ~

3800 613 0.70 700 0.86 779 1 .00 853 1.16 923 1.32 989 1.48 ~ ~ ~ ~ ~ ~ ~ ~

1. Blower performance includes evaporator coil and 2" filters

2. At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Decrease airflow downward as necessary.

CONDENSER FAN PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

4400 478 0.60 560 0.78 634 0 .96 702 1.14 765 1.34 824 1.54 880 1.74

Standard Factory Drive + 2 HP

Optional Hi-Static Drive + 2 HP

OUTDOOR

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Optional Hi-Static Drive + 1.5 HP

Standard Factory Drive + 1 HP

Low Static

Drive

SUPPLY

CFM

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C. ¹

DSV060B

FORM 145.29-IOM2 (814)

DSV096B

JOHNSON CONTROLS 15

Page 16

DSV120B

SUPPLY AI R BLOWER PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3200 573 0.48 668 0.62 754 0.76 833 0.88 906 1.02 975 1.18 1040 1.32 1102 1.48 1160 1.66 1225 1.86

3600 621 0.66 708 0.80 788 0.96 863 1.10 933 1.26 999 1.42 1061 1.58 1121 1.74 1178 1.90 ~ ~

4000 667 0.86 748 1.02 823 1.18 893 1.34 960 1.52 1023 1.68 1083 1.86 1141 2.04 ~ ~ ~ ~

4400 723 1.12 797 1.28 868 1.46 934 1.64 997 1.84 1057 2.02 ~ ~ ~ ~ ~ ~ ~ ~

4800 775 1.40 845 1.60 911 1.80 973 2.00 ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

1. Blower performance includes evaporator coil and 2" filters

2. At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Decrease airflow downward as necessary.

CONDENSER FAN PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

5500 614 1.22 680 1.44 741 1.66 799 1.90 854 2.14 906 2.38 956 2.62

Standard Factory Drive + 1.5 HP

Low Static

Drive

Optional Hi-Static Drive + 2 HP

Opt. Hi-Static Drive +3HP

Standard Factory Drive + 3 HP

OUTDOOR

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

SUPPLY

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C. ¹

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

SUPPLY AI R BLOWER PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

4000 436 0.48 521 0.64 597 0.80 667 0.98 730 1.16 790 1.34 845 1.54 896 1.75 946 2.01 992 2.29

4400 456 0.58 536 0.76 609 0.94 676 1.12 738 1.32 796 1.52 851 1.72 902 1.82 950 2.17 996 2.52

4800 475 0.70 555 0.88 621 1.08 686 1.28 746 1.48 803 1.70 857 1.92 908 2.14 956 2.36 1000 2 .70

5200 494 0.84 567 1.04 634 1.24 697 1.46 755 1.68 811 1.90 863 2.12 913 2.36 961 2.60 1007 2 .84

5600 517 1.00 587 1.22 651 1.44 711 1.66 768 1.90 822 2.14 873 2.38 922 2.62 969 2.86 ~ ~

1. Blower performance includes evaporator coil and 2" filters

2. At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Decrease airflow downward as necessary.

CONDENSER FAN PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

6000 535 1.02 609 1.28 679 1.56 744 1.84 805 2.14 862 2.44 921 2.82

SUPPLY

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C. ¹

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

OUTDOOR

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Standard Factory Drive + 3 HP

Optional Hi-Static Drive + 3 HP

Field Supplied Low Static Drive

Standard Factory Drive + 2 HP

Optional Hi-Static Drive + 3 HP

FORM 145.29-IOM2 (814)

DSV144B

16 JOHNSON CONTROLS

Page 17

DSV180B

SUPPLY AI R BLOWER PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

4800 529 0.84 601 1.02 667 1.22 729 1.42 786 1.64 841 1.84 893 2.06 942 2.28 987 2.54 1037 2 .78

5400 580 1.14 646 1.36 707 1.58 764 1.80 819 2.02 870 2.26 920 2.50 967 2.74 1012 2.98 1056 3.2 4

6000 610 1.42 671 1.66 729 1.90 783 2.14 835 2.40 885 2.64 933 2.90 979 3.16 1023 3.44 1066 3.7 0

6600 702 2.04 757 2.30 809 2.56 858 2.84 906 3.10 952 3.38 996 3.66 1039 3.96 1080 4.24 1121 4.54

7200 760 2.62 810 2.90 858 3.18 905 3.48 950 3.78 993 4.08 1035 4.38 1076 4.68 1116 5.00 ~ ~

1. Blower performance includes evaporator coil and 2" filters

2. At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Decrease airflow downward as necessary.

CONDENSER FAN PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

7200 642 1.78 706 2.08 766 2.40 823 2.74 877 3.08 929 3.42 979 3.78

Standard Factory Drive + 5 HP

Optional Hi-Static Drive + 5 HP

Standard Factory Drive + 3 HP

Optional Hi-Static Drive + 5 HP

Field Supplied Low Static Drive

OUTDOOR

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

SUPPLY

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C. ¹

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

SUPPLY AI R BLOWER PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

6400 592 1.38 659 1.63 721 1.96 779 2.26 835 2.58 888 2.88 942 3.02 1001 3.38 1058 3.76 1101 4.18

7200 645 1.88 706 2.18 770 2.50 818 2.84 870 3.18 920 3.52 965 3.88 1014 4.24 1065 4.61 1113 4.98

8000 698 2.46 769 2.80 808 3.14 858 3.50 907 3.88 954 4.26 1000 4.64 1044 5.02 1087 5.42 1128 5.82

8800 756 3.20 808 3.56 858 3.96 905 4.34 951 4.72 995 5.14 1038 5.54 1080 5.96 1121 6.38 1160 6.82

9600 811 4.04 859 4.44 905 4.84 950 5.26 993 5.68 1035 6.12 1076 6.56 1116 7.00 1154 7.45 ~ ~

1. Blower performance includes evaporator coil and 2" filters

2. At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Decrease airflow downward as necessary.

CONDENSER FAN PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

10800 775 3.87 827 4.29 877 4.71 925 5.16 971 5.61 1016 6.06 1052 7.0 0

Field Supplied Low Static Drive

Standard Factory Drive + 5 HP

Optional Hi-Static Drive + 7.5 HP

Standard Factory Drive + 7.5 HP

OUTDOOR

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

SUPPLY

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C. ¹

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

FORM 145.29-IOM2 (814)

DSV240B

JOHNSON CONTROLS 17

Page 18

DSV300B

SUPPLY AI R BLOWER PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

8200 581 1.80 647 2 .16 707 2.49 765 2.85 819 3.24 870 3.60 920 3.99 967 4.38 1012 4.80 1056 5.19

8800 639 2.31 699 2 .70 755 3.06 809 3.45 860 3.84 910 4.26 957 4.65 1002 5.07 1045 5.49 1087 5.94

9200 676 2.70 733 3 .09 787 3.48 839 3.87 888 4.29 935 4.71 981 5.13 1025 5.58 1068 6.00 1109 6.45

9600 716 3.15 771 3 .54 822 3.96 872 4.38 920 4.80 965 5.25 1010 5.7 0 1052 6.15 1093 6.60 1113 7.05

10000 755 3.63 807 4.05 856 4.47 904 4.92 950 5.37 994 5.82 1037 6.27 1079 6.75 1119 7.20 ~ ~

1. Blower performance includes evaporator coil and 2" filters

2. At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Decrease airflow downward as necessary.

CONDENSER FAN PERFORMANCE

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

12800 735 4.41 790 4.98 843 5.55 894 6.15 944 6.78 992 7.41 1031 8.01

SUPPLY

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C. ¹

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Optional Hi-Static Drive + 10HP

Field Supplied Low Static Drive

OUTDOOR

CFM

AVAILABLE EXTERNAL STATIC PRESSURE - Inches W.C.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Standard Factory Drive + 7.5HP

Optional Hi-Static Drive +7.5HP

Standard Factory Drive + 10HP

FORM 145.29-IOM2 (814)

18 JOHNSON CONTROLS

Page 19

MOTOR AND PULLEY DATA

Frame Pitch Dia. Browning Pitch Dia. Browning

Size (in) Part No. (in) Part No.

DSV060B 568-852 1 145 1.9-2.9 1VP34X7/8 6.2 AK64H A28 A36

DSV096B 593-890 1 145 1.9-2.9 1VP34X7/8 5.9 AK61H A42 A51

DSV120B 614-921 1.5 145 1.9-2.9 1VP34X7/8 5.7 AK59H AX42 AX51

DSV144B 555-768 2 145 2.4-3.4 1VP40X7/8 8.2 AK84H AX46 AX55

DSV180B 640-854 3 184 2.8-3.8 1VP44X1 1/8 8.2 AK84H AX45 AX52

DSV240B 769-965 5 184 4.7-5.9 1VP60X1 1/8 10.4 BK110H B56 B65

DSV300B 716-882 7.5 213 5.2-6.4 1VP65X1 3/8 12.7 BK130H BX65 BX75

Frame Pitch Dia. Browning Pitch Dia. Browning

Size (in) Part No. (in) Part No.

DSV060B 803-1112 1.5 145 2.4-3.4 1VP40X7/8 5.7 AK59H A28 A36

DSV096B 745-1117 1.5 145 1.9-2.9 1VP34X7/8 4.7 AK49H AX40 AX49

DSV120B 843-1167 2 145 2.4-3.4 1VP40X7/8 5.2 AK56H AX42 AX51

DSV144B 724-925 3 184 3.4-4.4 1VP50X1 1/8 8.7 AK89H AX46 AX55

DSV180B 837-1027 5 184 4.4-5.4 1VP56X1 1/8 9.2 BK95H BX48 BX55

DSV240B 949-1145 7.5 213 5.4-6.6 1VP71X1 3/8 10.4 BK110H BX57 BX66

DSV300B 850-1047 7.5 213 5.2-6.4 1VP65X1 3/8 10.4 BK110H BX61 BX72

Frame Pitch Dia. Browning Pitch Dia. Browning

Size (in) Part No. (in) Part No.

DSV060B 568-852 1.5 145 1.9-2.9 1VP34X7/8 6.9 AK71H AX70

DSV096B 486-729 2 145 1.9-2.9 1VP34X7/8 7.2 AK74H AX68

DSV120B 640-854 3 184 2.8-3.8 1VP44X1 1/8 8.2 AK84H AX70

DSV144B 571-761 3 184 2.8-3.8 1VP44X1 1/8 9.2 AK94H AX79

DSV180B 686-866 5 184 3.4-4.4 1VP50X1 1/8 9.7 BK100H BX80

DSV240B 769-965 7.5 213 4.8-5.2 1VP60X1 3/8 10.4 BK110H BX89

DSV300B 741-894 10 215 5.8-7.0 1VP71X1 3/8 13.7 BK140H BX103

Frame Pitch Dia. Browning Pitch Dia. Browning

Size (in) Part No. (in) Part No.

DSV060B 568-852 1.5 145 1.9-2.9 1VP34X7/8 5.2 AK54H A68

DSV096B 486-729 2 145 1.9-2.9 1VP34X7/8 5.4 AK56H AX65

DSV120B 640-854 3 184 2.8-3.8 1VP44X1 1/8 6.9 AK71H AX68

DSV144B 571-761 3 184 2.8-3.8 1VP44X1 1/8 7.7 AK79H AX76

DSV180B 686-866 5 184 3.4-4.4 1VP50X1 1/8 8.3 BK85H BX77

DSV240B 769-965 7.5 213 4.8-5.2 1VP60X1 3/8 9.7 BK100H BX87

DSV300B 854-1020 10 215 6.2-7.4 1VP75X1 3/8 12.7 BK130H BX103

Belts

Belts

EVAPORATOR-STANDARD BLOWER MOTOR AND DRIVE DATA

Drive

Range

(RPM)

Motor

HP

Adjustable

EVAPORATOR-OVERSIZED BLOWER MOTOR AND DRIVE DATA

Model

Drive

Range

(RPM)

Motor

Adjustable

Fixed

Motor Pulley

Model

Blower Pulley

HP

Motor Pulley

Fixed

Blower Pulley

Horizontal

Discharge

Vertical

Discharge

Horizontal

Discharge

Model

Drive

Range

(RPM)

Motor

Adjustable

Fixed

Belts

Motor Pulley

Blower Pulley

HP

Standard

CONDENSER-STANDARD BLOWER MOTOR AND DRIVE DATA

Vertical

Discharge

CONDENSER-OVERSIZED DRIVE DATA

Model

Drive

Range

(RPM)

Motor

Adjustable

Fixed

Belts

Motor Pulley

Blower Pulley

HP

Standard

FORM 145.29-IOM2 (814)

JOHNSON CONTROLS 19

Page 20

FORM 145.29-IOM2 (814)

BLOWER SPEED ADJUSTMENT

The blower speed can be adjusted to increase or decrease the unit CFM for non-VFD units. The RPM of the

supply air and condenser air blowers will depend on the required CFM, and the static resistances of both the

supply/discharge and the return/intake duct systems.

An air balance should be done after installation to verify air flow and static. Adjustments to drive may be required.

Only operate unit in the regions defined by the fan tables. Units can be ordered with oversized motors and/or

drive kits for high static requirements.

Units with oversized motors or oversized drive kits are designed to operate in the shaded

region of the fan table otherwise motor amp draw will exceed overload setting resulting in

overload trips and possible damage to unit. Refer to fan tables for recommended operating

range of standard and oversized motors and drive kits.

The RPM for the blowers can be determined from the blower performance tables. Adjustment of blower speed is

accomplished as follows:

1) Loosen belt tension by moving motor towards the blower shaft via the adjustable mounting.

2) Loosen the setscrew in the adjustable motor pulley flange. Remove external key on pulleys 4 in. diameter and

larger.

3) Blower speed will increase when moveable flange is adjusted towards the fixed flange (closed). Blower speed

will decrease when the moveable flange is adjusted away from the fixed flange (opened). Pulleys are

adjustable only in half-turn increments. Do not open pulley more than five full turns for "4L" and "A" belts, or

six full turns for "B" belts.

4) Once the pulley has been opened/closed the appropriate number of turns, replace the external key and

tighten the adjustment setscrew. Proper torque is 110-130 in.-lbs.

5) Install drive belt and adjust motor mount to tension belt (see page 20: MAINTENANCE/SERVICE for further

information).

20 JOHNSON CONTROLS

Page 21

FORM 145.29-IOM2 (814)

Pressure Switch Settings - All Models

High

Low

Cut Out (PSIG)

625

25

Cut In (PSIG)

500

38

Refrigerant Charge (LBS)

UNIT

Circuit 1

Circuit 2

DSV060B

13.25 (13 lbs 4 oz)

-

DSV096B

11.35 (11 lbs 6 oz)

11.60 (11 lbs 10 oz)

DSV120B

13.90 (13 lbs 14 oz)

14.20 (14 lbs 3 oz)

DSV144B

16.60 (16 lbs 10 oz)

15.60 (15 lbs 10 oz)

DSV180B

19.00 (19 lbs 0 oz)

17.80 (17 lbs 13 oz)

DSV240B

25.00 (25 lbs 0 oz)

24.10 (24 lbs 2 oz)

DSV300B

32.00 (32 lbs 0 oz)

32.80 (32 lbs 13 oz)

START-UP AND OPERATION

Start unit and check rotation of fans and compressors.

Scroll compressors will only compress in one

rotational direction. Three phase compressors will

rotate in either direction depending upon phasing of

the power. Since there is a 50-50 chance of

connecting power in such a way as to cause rotation

in the reverse direction, it is important to ensure

proper rotation direction is achieved when the system

is installed and operated.

Prior to start-up it is important to

ensure proper compressor and fan

rotation direction is achieved when

the system is installed and

operated.

Monitor the microprocessor board for any fault codes.

This will ensure proper unit operation. Verification of

proper compressor direction is made by observing

that suction pressure drops and discharge pressure

rises when the compressor is energized. Reverse

compressor rotation also results in an elevated sound

level as well as substantially reduced current draw.

There is no negative impact on durability caused by

operating three phase Scroll compressors in the

reversed direction for a short period of time (under

one hour). However, after several minutes of

operation the compressors internal protector will trip.

If opposite rotation is needed, disconnect and reverse

any two leads of the three phase supply. Reconnect

power.

Observe unit operation and check for

unusual noise or vibration.

The Air Conditioning section of this

equipment is charged with R-410A; a high

pressure refrigerant. Only qualified

technicians, using appropriately pressure rated test instruments, should

perform troubleshooting or service on

this equipment.

JOHNSON CONTROLS 21

Page 22

FORM 145.29-IOM2 (814)

MICROPROCESSOR CONTROLLER

The microprocessor control system is specifically

designed for single and dual stage air cooled systems.

The control system interfaces with a conventional type

thermostat.

Unit shall be complete with self-contained low-

voltage control circuit

Unit shall incorporate a lockout circuit which

provides reset capability at the space thermostat

or base unit, should any of the following standard

safety devices trip and shut off compressor.

- Loss-of-charge/Low-pressure switch

- High-pressure switch

- Condensate Overflow protection switch

Unit shall operate with conventional thermostat

designs and have a low voltage terminal strip for

easy hook-up.

Unit control board shall have on-board diagnostics

and fault code display.

Standard controls shall include anti-short cycle

and low voltage protection

Control board shall monitor each compressor and

refrigerant safety switch independently.

Control board shall have random start feature

Control board shall retain last 5 fault codes in non

volatile memory which will not be lost in the event

of a power loss.

OPERATION

For cooling the room t-stat energizes the low-voltage

circuit between “R” & “Y1”.

The call is passed to the unit microprocessor control,

which then determines whether the requested

operation is available and, if so, which components to

energize.

CONTINUOUS BLOWER

By setting the room t-stat fan switch set to “ON”, the

supply air blower will operate continuously. With the

room t-stat fan switch set to “AUTO”, the blower is

energized whenever a cooling operation is requested.

The blower is energized after any specified delay

associated with the operation.

When energized, the indoor blower has a minimum

run time of 30 seconds. Additionally, the indoor blower

has a delay of 10 seconds between operations.

When the room t-stat calls for cooling, the low-voltage

control circuit from “R” to “Y1”and “G” is completed.

The compressor and fan motor are energized. After

completing the specified fan on delay for cooling, the

microprocessor control will energize the blower motor.

Once the room t-stat has been satisfied, it will de-

energize “Y1”. If the compressor has satisfied its

minimum run time, the compressor and fan deenergize. Otherwise, the unit operates the cooling

system until the minimum run time for the compressor

has been completed. After the compressor deenergizes, the blower is stopped following the elapse

of the fan-off delay for cooling.

To be available, a compressor must not be locked-out

due to a high-pressure switch; low- pressure switch;

condensate overflow switch; and the anti-short cycle

delay (ASCD) must have elapsed.

SAFETY SWITCHES

Each refrigerant system is monitored to ensure it does

not operate outside of its intended operating

parameters. Safety switches are handled as described

below. All system errors override minimum run times

for compressors.

High-Pressure Limit Switch

If a high-pressure limit switch opens, the

microprocessor control de-energizes the compressor,

initiates the ASCD, and stops the fan. If a call for

cooling or heating is still present at the conclusion of

the ASCD, the microprocessor control will re-energize

the compressor and unit fan.

Should a high-pressure switch open three times within

two hours of operation, the microprocessor control will

permanently lock-out the compressor. The system

must be manually reset by de-energizing the 24 volt

power to unit, or turning the room t-stat to the “OFF”

position then back to cooling position. The

microprocessor control will flash a fault code

indicating a high-pressure lock-out.

Low-Pressure Limit Switch

The low-pressure limit switch is not monitored during

the initial 30 seconds of compressor operation. After

the initial 30 seconds have passed, the

microprocessor control will monitor the low-pressure

switch for another 30 seconds. If the low-pressure

switch fails to close after the 30 second monitoring

phase, the microprocessor control will de-energize the

compressor, initiate the ASCD, and stop the fan.

Once the low-pressure switch has been proven

(closed during the 30-second monitoring period as

described above), the microprocessor control board

will continue to monitor the low-pressure limit switch

22 JOHNSON CONTROLS

Page 23

FORM 145.29-IOM2 (814)

for any openings. If the low-pressure switch opens for

greater than 5 seconds, the microprocessor control

board will de-energize the compressor, initiate the

ASCD, and stop the fan.

If the call for cooling is still present at the conclusion

of the ASCD, the microprocessor control will reenergize the compressor.

Should a low-pressure switch fault three (3) times

within one (1) hour of operation, the microprocessor

control board will lock-out the compressor and flash a

fault code indicating a low-pressure lock-out.

Condensate Overflow Switch

A Condensate Overflow fault occurs when the

Condensate Overflow switch opens for more than two

line cycles. The compressor is shutdown regardless

of Minimum Run Time, ASCD is initiated, and alarm is

tripped. The fan continues operating in its current

state. Compressor will re-energize once the

Condensate Overflow switch closes, and ASCD has

been satisfied and a call for cooling is still present.

The microprocessor control board logs the first

incident per compressor request. If the compressor

request is removed, the fault occurrence counter is

reset to zero. Should the Condensate Overflow

switch open three within two hours of run time, the

microprocessor control board will lock-out the

compressor, turn off the fan and flash a fault code

indicating a Condensate Overflow lock-out.

SAFETY CONTROLS

The microprocessor control monitors the following

inputs:

1. A High-Pressure Switch on each compressor

circuit to protect against excessive discharge

pressures.

2. A Low-Pressure Switch on each compressor

circuit to protect against loss of refrigerant charge.

3. A Condensate Overflow Switch to protect against

condensate overflow.

Compressor Protection

In addition to the external pressure switches, the

compressor also has inherent (internal) protection. If

there is an abnormal temperature rise in a

compressor, the internal protection will immediately

shut down the compressor. The microprocessor

control incorporates features to minimize compressor

wear and damage. An anti-short cycle delay (ASCD)

is utilized to prevent short cycling of the compressor.

Additionally, a minimum run time is imposed any time

a compressor is energized. The ASCD is initiated on

unit start-up and on any compressor reset or lockout.

Microprocessor Control Unit Flash Codes

Various flash codes are utilized by the microprocessor

control to aid in troubleshooting. Flash codes are

distinguished by the short on and off cycle used

(approximately 200ms on and 200ms off). To show

normal operation, the control boards flash a 1 second

on, 1 second off “heart beat” during normal operation.

This is to verify that the microprocessor is functioning

correctly. Do not confuse this with an error flash code.

To avoid confusion the 1-flash, fault code is not used.

JOHNSON CONTROLS 23

Page 24

Current alarms or active restrictions are flashed on the

FLASH CODES

Description

On Steady

This is Control Failure

2 Flashes

Control waiting ASCD (Anti-Short Cycle Delay) *

3 Flashes

High Pressure Compressor 1 Lockout

4 Flashes

High Pressure Compressor 2 Lockout

5 Flashes

Low Pressure Compressor 1 Lockout

6 Flashes

Low Pressure Compressor 2 Lockout

7 Flashes

Condensate Overflow Switch Lockout

11 Flashes

Compressor(s) locked out due to Economizer running (Free Cooling) *

13 Flashes

Compressor Held Off due to Low Voltage

14 Flashes

EEPROM Storage Failure

OFF

No Power or Control Failure

Note: Flash rates marked with * are NOT alarms.

microprocessor control LED.

1. LAST ERROR – When this button is pressed and

released, it flashes the last five (5) flash codes on

the board’s LED. The most recent alarm is shown

first and the oldest alarm is shown last.

2. TEST RESET – When this button is pressed and

released, any anti-short cycle delays (ASCD) are

bypassed for one cycle. When pressed twice, any

active lockouts are reset.

3. COMM SETUP – If the board is to be networked

with other units, this button is used to set the

network address. Press the button once and it

scans the bus, then assigns itself the first

available address, (starts at 2). It then flashes that

address one time. Pressing the button twice

causes the control to flash the address.

FORM 145.29-IOM2 (814)

24 JOHNSON CONTROLS

Page 25

FORM 145.29-IOM2 (814)

Filters

Qty/Size

DSV060B

4/25x14x2

DSV096B

4/24x18x2

2/20x18x2

DSV120B

4/24x18x2

2/20x18x2

DSV144B

8/20x18x2

DSV180B

8/20x18x2

DSV240B

4/24x20x2

4/20x20x2

DSV300B

6/25x18x2

6/20x18x2

LD13547

BELT TENSION ADJUSTMENT

DEFLECTION FORCE VERSUS DRIVE BELT CROSS-SECTION

MAINTENANCE / SERVICE

DISCONNECT AND LOCK OUT

POWER WHEN SERVICING UNIT.

FAILURE TO DO SO MAY RESULT IN

PERSONAL IN-JURY OR DEATH

DUE TO ELECTRICAL SHOCK.

Exercise care when working around

the sharp metal edges of door panels

or door frames, etc. These edges can

cause injury.

EVAPORATOR AND CONDENSER COILS

Inspect the evaporator coil at filter change intervals.

Inspect the condenser coil at least semi-annually. A

dirty condenser coil will result in elevated condensing

pressures and poor unit performance. Dirty or clogged

evaporator coils causes low suction pressure and lost

capacity. If the coils appear dirty, they should be

cleaned using a mild detergent or a commercial coil

cleaning agent.

REFRIGERANT CIRCUIT(S)-

With the unit operating, check and record the

compressor discharge and suction pressures. The

compressor running current should also be recorded.

A maintenance log of these readings can indicate if

the unit is operating within its normal limits. Abnormal

readings should be investigated, and the Cause

corrected.

BLOWERS -

Inspect both the evaporator and condenser blowers at

each regular service interval. Clean blower wheels as

needed. Bearings are permanently sealed ball type,

and do not require lubrication. Check bearings for any

signs of wear (movement between inner and outer

races). Ensure bearing locking collars are secure to

the shaft, and that collar locking screw is properly set.

Check that the blower wheel is tight on the shaft, and

that the hub set screws are properly torqued.

DRIVE BELTS -

Examine belts periodically for wear. Glazed areas on

the drive surfaces indicate overheating due to belt

slippage. Ideal tension is the lowest tension at which

the belt will not slip under peak load conditions. Overtensioning shortens belt and bearing life (see section

‘Blower Speed Adjustment’).

The tension on the belt should be adjusted for a

deflection of 1/64 of an inch per inch of belt span, with

the appropriate force applied at the midpoint of the

span. Tension “New” belts at the maximum value

indicated. Used belts should be maintained at the

minimum value.

FILTERS -

Inspect filters monthly and replace as necessary. Use

UL Class 2 rated filters. Factory supplied filters are

medium efficiency, extended surface pleated type.

Replacements should be of the same type, to

maintain optimum airflow performance. Filter sizes are

as follows:

JOHNSON CONTROLS 25

Page 26

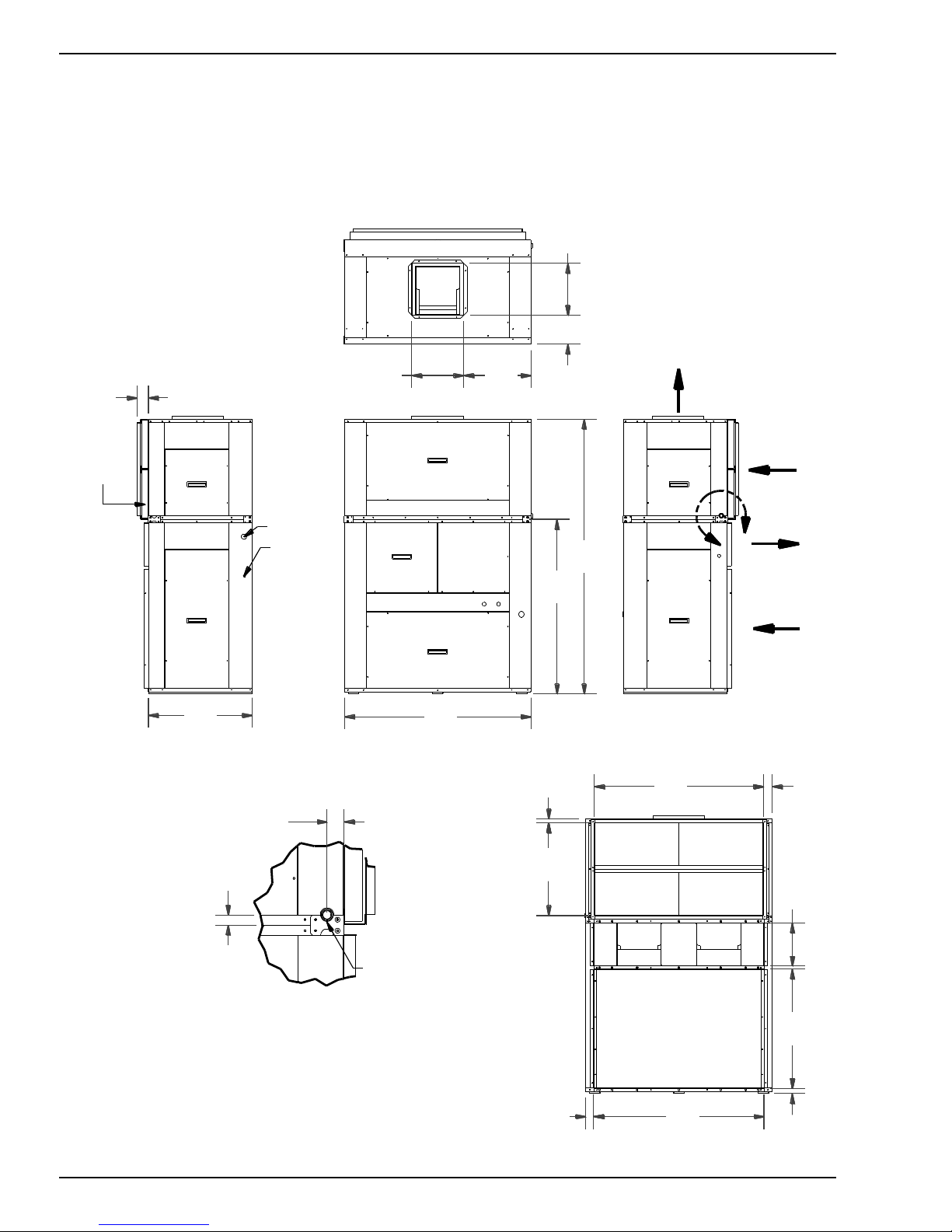

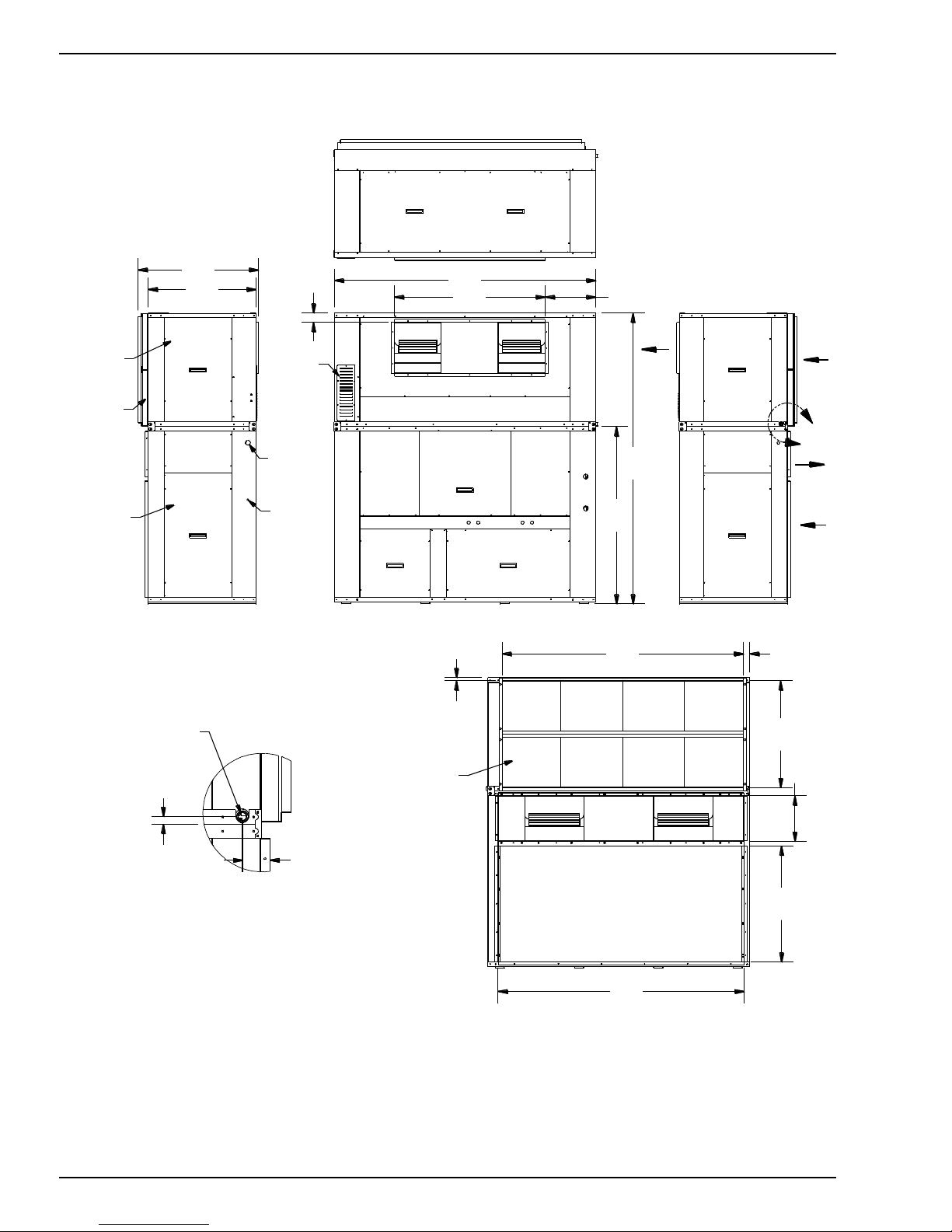

APPENDIX A: DIMENSIONAL DRAWINGS

DETAIL D

SCALE 0.1 : 1

D

FRONT VIEW

3/4" NPT

DRAIN

CONNECTION

BACK VIEW

29.00

52.00

7

6

.5

0

4

8

.6

3

47.50

1

2

.

0

0

3

3

.

1

8

14.50

ELECTR . POWER

CABLE ENTR ANCE

1.75

1.00

RETURN

AIR

CONDENSER

INTAKE

CONDENSER

DISCHARGE

SUPPLY

AIR

BACK RETURN,

VERTICAL DISCHARGE

ELECTR ICAL BOX

ACCESS PANEL

CON DENSER ACCESS PANEL

EVAPORATOR ACCESS PANEL

FILTER ACCESS

(BOTH SIDES)

LOW VOLTAGE

CON NECTION

5 TON VERTICAL A/C UNIT

DIMENSIONAL DATA

NOTE: DIMENSION TOLERANCE IS 1/16"

1

4

.5

0

47.13

2

5

.

8

8

3.12

EVAPORATOR

FAN DR IVE

ACCESS PANEL

CON DENSER

FAN DR IVE

ACCESS PANEL

8

.0

0

1

.0

0

1

.

5

0

2.25

2.44

18.75

DSV060B DIMENSIONAL DATA – TOP DISCHARGE

FORM 145.29-IOM2 (814)

26 JOHNSON CONTROLS

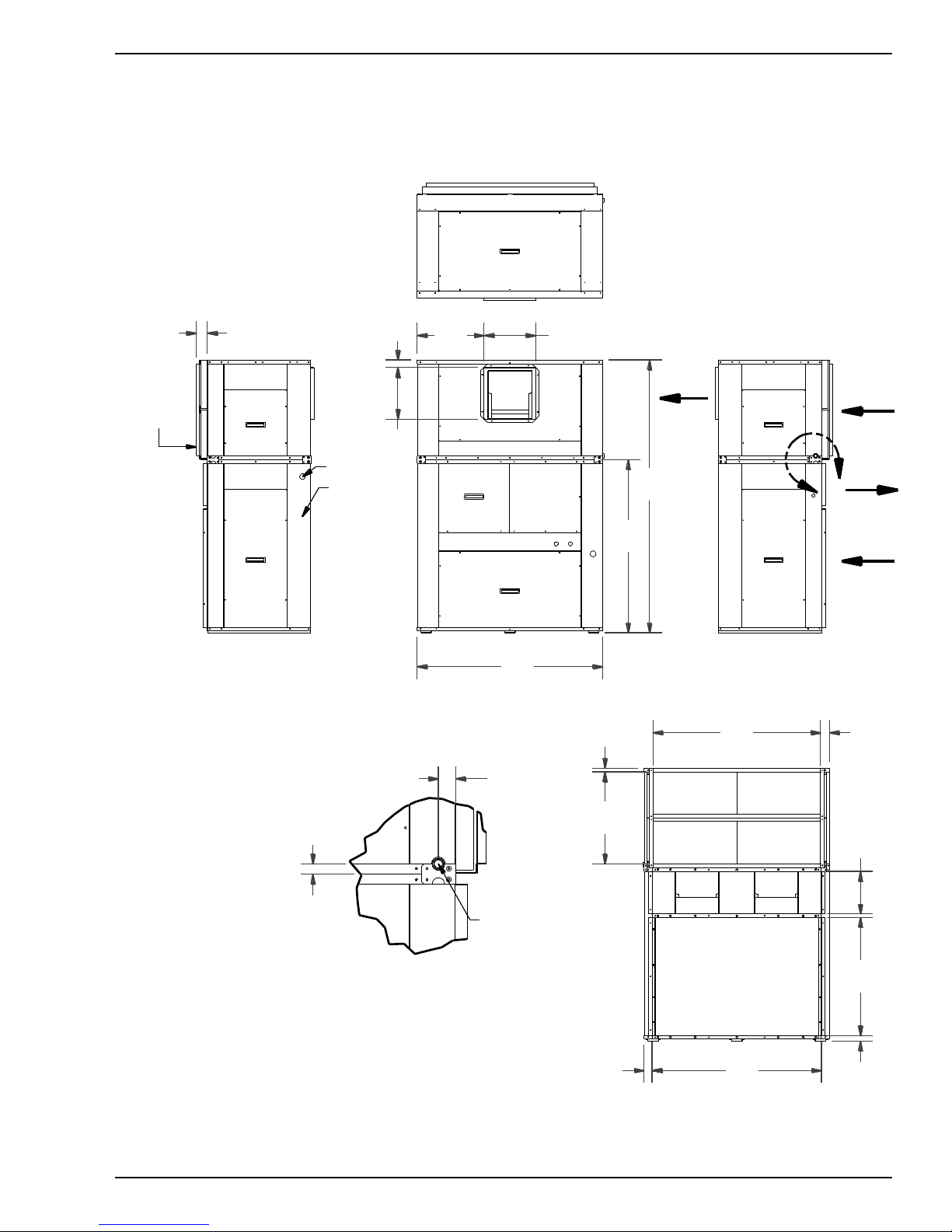

Page 27

DSV060B DIMENSIONAL DATA – FRONT DISCHARGE

DETAIL F

SCALE 0.1 : 1

F

FRONT VIEW

3/4" NPT

DRAIN

CONNECTION

BACK VIEW

RETURN

AIR

CONDENSER

INTAKE

CONDENSER

DISCHARGE

SUPPLY

AIR

BACK RETURN,

FRONT DISCHARGE

ELECTRICAL BOX

ACCESS PANEL

CONDENSER ACCESS PANEL

FILTER ACCESS

(BOTH SIDES)

1

4

.

5

0

14.50

1

.0

0

1.75

52.00

7

6

.

5

0

1

2

.

0

0

3

3

.

1

8

47.50

4

8

.6

3

5 TON VERTICAL A/C UNIT

DIMENSIONAL DATA

CONDENSER

FAN DRIVE

ACCESS PANEL

EVAPORATOR

FAN DRIVE

ACCESS PANEL

47.13

2

5

.

8

8

1

.

5

0

1

.

0

0

2

.

1

3

3.12

ELECTR. POWER

CABLE ENTRANCE

LOW VOLTAGE

CONNECTION

NOTE: DIMENSION TOLERANCE IS 1/16"

2.44

2.25

18.75

FORM 145.29-IOM2 (814)

JOHNSON CONTROLS 27

Page 28

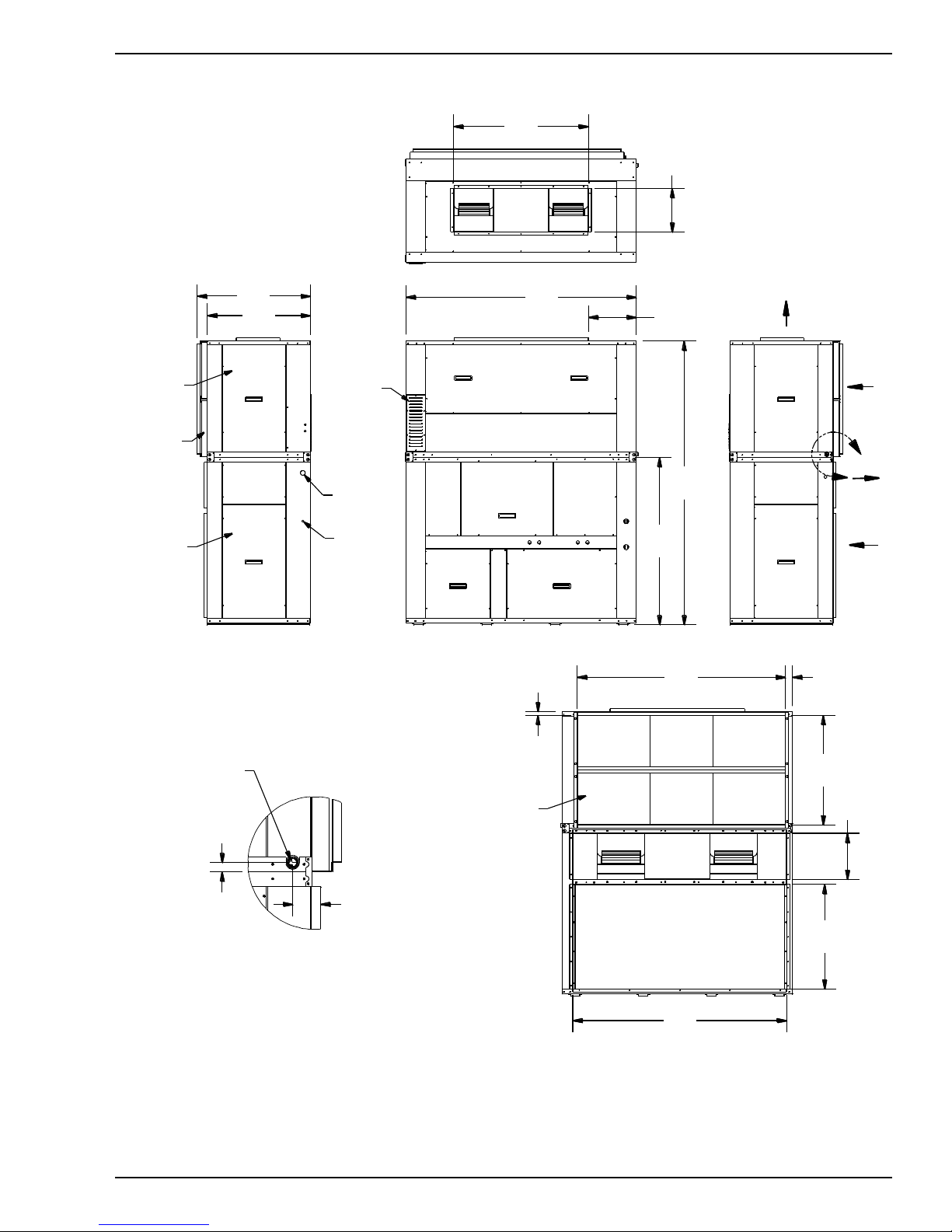

DSV096B & DSV120B DIMENSIONAL DATA – FRONT DISCHARGE

DETAIL A

A

ELECTRICAL BOX

ACCESS PANEL

COMPRESSOR

ACCESS PANEL

CONDENSER

INTAKE

CONDENSER

DISCHARGE

RETURN

AIR

10 TON VERTICAL A/C UNIT

DIMENSIONAL DATA

REAR RETURN,

FRONT DISCHARGE

FRONT VIEW

BACK VIEW

SUPPLY

AIR

NOTE: DIMENSION TOLERANCE IS 1/16"

2.88

0

.

9

3

3/4" NPT DRAIN

CONNECTION

71.50

41.88

1

3

.

6

9

8

8

.

1

3

2

.

7

5

14.81

5

2

.

0

6

32.00

36.06

EVAPORATOR

BLOWER DRIVE

ACCESS DOOR

FILTER ACCESS

(BOTH SIDES)

POWER SUPPLY

CABLE ENTRANCE

LOW VOLTAGE

CONNECTION

VFD LOCATION

(OPTIONAL)

CONDENSER

BLOWER DRIVE

ACCESS DOOR

64.63

3

4

.

1

3

3

2

.

5

0

1

4

.

3

1

1

.

0

0

2.20

66.50

FILTER

FORM 145.29-IOM2 (814)

28 JOHNSON CONTROLS

Page 29

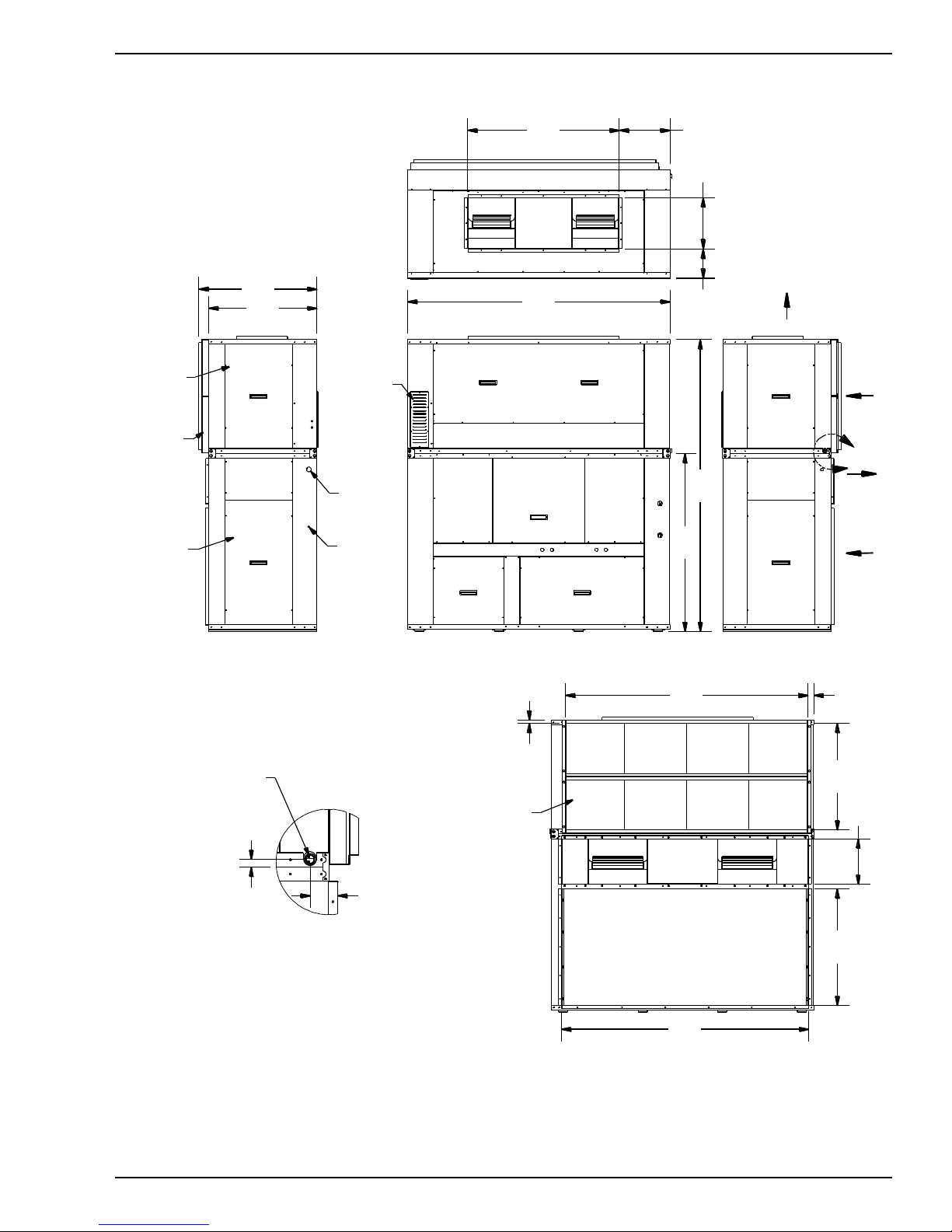

DSV096B & DSV120B DIMENSIONAL DATA - TOP DISCHARGE

DETAIL A

A

10 TON VERTICAL A/C UNIT

DIMENSIONAL DATA

REAR RETURN,

TOP DISCHARGE

CONDENSER

DISCHARGE

RETURN

AIR

CONDENSER

INTAKE

COMPRESSOR

ACCESS PANEL

ELECTRICAL BOX

ACCESS PANEL

FRONT VIEW

BACK VIEW

NOTE: DIMENSION TOLERANCE IS 1/16"

71.50

41.88

1

3

.

6

9

14.81

8

8

.

1

3

5

2

.

0

6

32.00

35.13

SUPPLY

AIR

EVAPORATOR

BLOWER DRIVE

ACCESS DOOR

FILTER ACCESS

(BOTH SIDES)

POWER SUPPLY

CABLE ENTRANCE

LOW VOLTAGE

CONNECTION

CONDENSER

BLOWER DRIVE

ACCESS DOOR

VFD LOCATION

(OPTIONAL)

64.63

3

4

.

1

3

1

.

0

0

2.20

3

2

.

5

0

1

4

.

3

1

66.50

FILTER

2.88

0

.

9

3

3/4" NPT DRAIN

CONNECTION

FORM 145.29-IOM2 (814)

JOHNSON CONTROLS 29

Page 30

DSV144B & DSV180B DIMENSIONAL DATA - FRONT DISCHARGE

DETAIL A

A

FRONT VIEW

BACK VIEW

ELECTRICAL BOX

ACCESS PANEL

COMPRESSOR

ACCESS PANEL

CONDENSER

DISCHARGE

CONDENSER

INTAKE

RETURN

AIR

SUPPLY

AIR

12/15 TON VERTICAL A/C UNIT

DIMENSIONAL DATA

REAR RETURN,

FRONT DISCHARGE

NOTE: DIMENSION TOLERANCE IS 1/16"

82.50

47.63

34.00

38.06

15.97

9

1

.

6

3

5

5

.

8

8

2

.

8

8

EVAPORATOR

BLOWER DRIVE

ACCESS DOOR

FILTER ACCESS

(BOTH SIDES)

POWER SUPPLY

CABLE ENTRANCE

LOW VOLTAGE

CONN ECTION

2.88

0

.

8

0

3/4" NPT DRAIN

CONNECTION

76.13

3

3

.

6

3

1.97

1

.

0

0

1

4

.

3

1

3

6

.

6

9

77.63

VFD LOCATION

(OPTIONAL)

COND ENSER

BLOWER DRIVE

ACCESS DOOR

FILTER

FORM 145.29-IOM2 (814)

30 JOHNSON CONTROLS

Page 31

DSV144B & DSV180B DIMENSIONAL DATA - TOP DISCHARGE

DETAIL A

A

ELECTRICAL BOX

ACCESS PANEL

COMPRESSOR

ACCESS PANEL

CONDENSER

INTAKE

CONDENSER

DISCHARGE

RETURN

AIR

12/15 TON VERTICAL A/C UNIT

DIMENSIONAL DATA

REAR RETURN,

TOP DISCHARGE

FRONT VIEW

BACK VIEW

SUPPLY

AIR

NOTE: DIMENSION TOLERANCE IS 1/16"

82.50

47.63

1

6

.

1

3

9

.

2

5

16.00

9

1

.

6

3

5

5

.

8

8

34.00

37.13

EVAPORATOR

BLOWER DRIVE

ACCESS DOOR

FILTER ACCESS

(BOTH SIDES)

CONDENSER

BLOWER DRIVE

ACCESS DOOR

VFD LOCATION

(OPTIONAL)

POWER SUPPLY

CABLE ENTRANCE

LOW VOLTAGE

CONNECTION

76.13

3

3

.

6

3

3

6

.

6

9

1

4

.

3

1

1.97

1