Page 1

Very Low Differential Pressure Transducer

HIGH OVERPRESSURE

CAPABILITY

Up to10 PSI

Model DPT 264

Unidirectional Ranges: 0 - 0.1 to 0 - 100 in. W.C.

Bidirectional Ranges: 0 - ±0.5 to 0 - ±50 in. W.C.

Air or Non-Conducting Gas

3-year

Unconditional

Warranty

Applications

● Heating, Ventilating and

Air Conditioning (HVAC)

● Energy Management

Systems

● Variable Air Volume and

Fan Control (VAV)

● Environmental Pollution

Control

● Lab and Fume Hood Control

●Oven Pressurization and

Furnace Draft Controls

Features

■ Installation Time

Minimized with Snap Track

Mounting and Easy- ToAccess Pressure Ports and

Electrical Connections

■ 0 to 5 VDC or 2-wire 4 to

20 mA Analog Outputs Are

Compatible with Energy

Management Systems

etra Systems 264 pressure transducers sense differential or gauge (static)

S

pres sure and convert this pressure

difference to a proportional electrical output for either unidirectional or bidirectional

pressure ranges. The 264 Series is offered

with a high level analog 0 to 5 VDC or 4 to

20 mA output.

Used in Building Energy Management

Systems, these transducers are capable of

measuring pressures and flows with the

accuracy necessary for proper building

pressurization and air flow control.

The 264 Series transducers are available for

air pressure ranges as low as 0.1 in. W.C. full

scale to 100 in. W.C. full scale. Static standard

accuracy is ±1.0% full scale in normal ambient

temperature environments, but higher

accuracies are available. The units are

temperature compensated to 0.033% FS/oF

thermal error over the temperature range of

0oF to +150oF.

The Model 264 utilizes an improved all

stainless steel micro-tig welded sensor. The

tensioned stainless steel diaphragm and

insulated stainless steel electrode, positioned

close to the diaphragm, form a variable

capacitor. Positive pressure moves the

diaphragm toward the electrode, increasing the capacitance. A decrease in pressure moves the diaphragm away from the

electrode, decreasing the capacitance. The

change in capacitance is detected and

converted to a linear DC electrical signal by

Setra’s unique electronic circuit.

The tensioned sensor allows up to 10 PSI

overpressure (range dependent) with no

damage to the unit. In addition, the parts that

make up the sensor have thermally matched

coefficients, which promote improved

temperature performance and excellent long

term stability.

■ Reverse Wiring Protection

■ Internal Regulation Permits

Use with Unregulated DC

Power Supplies

■ Fire Retardent Case

(UL 94 V-0 Approved)

■ Meets CE Conformance

Standards

NOTE: Setra quality standards are based on ANSI-Z540-1.

The calibration of this product is NIST traceable.

U.S. Patent nos. 6019002; 6014800

IS O -90 01 Cer tifi ed

Page 2

Performance Data

Standard Optional

Accuracy* RSS(at constant temp) ±1.0% FS ±0.5% FS ±0.25% FS

Non-Linearity, BFSL

±0.96% FS ±0.38% FS

±0.22% FS

Hysteresis 0.10% FS 0.10% FS 0.10% FS

Non-Repeatability 0.05% FS 0.05% FS 0.05%FS

Thermal Effects**

Compensated Range °F(°C) 0 to +150 (-18 to +65)

Zero/Span Shift %FS/°F(°C) 0.033 (0.06)

Maximum Line Pressure 10 psi

Overpressure (Range Dependant) Up to 10 psi

(Range Dependent)

Long Term Stability 0.5% FS/1 YR

Zero Offset

Position Effect Range (%FS/G)

(Unit is factory calibrated at 0g To 0.5 in. WC 0.60

effect in the vertical position.) To 1.0 in. WC 0.50

To 2.5 in. WC 0.22

To 5 in. WC 0.14

* RSS of Non-Linearity, Hysteresis, and Non-Repeatability.

**Units calibrated at nominal 70˚F. Maximum thermal error computed from

this datum.

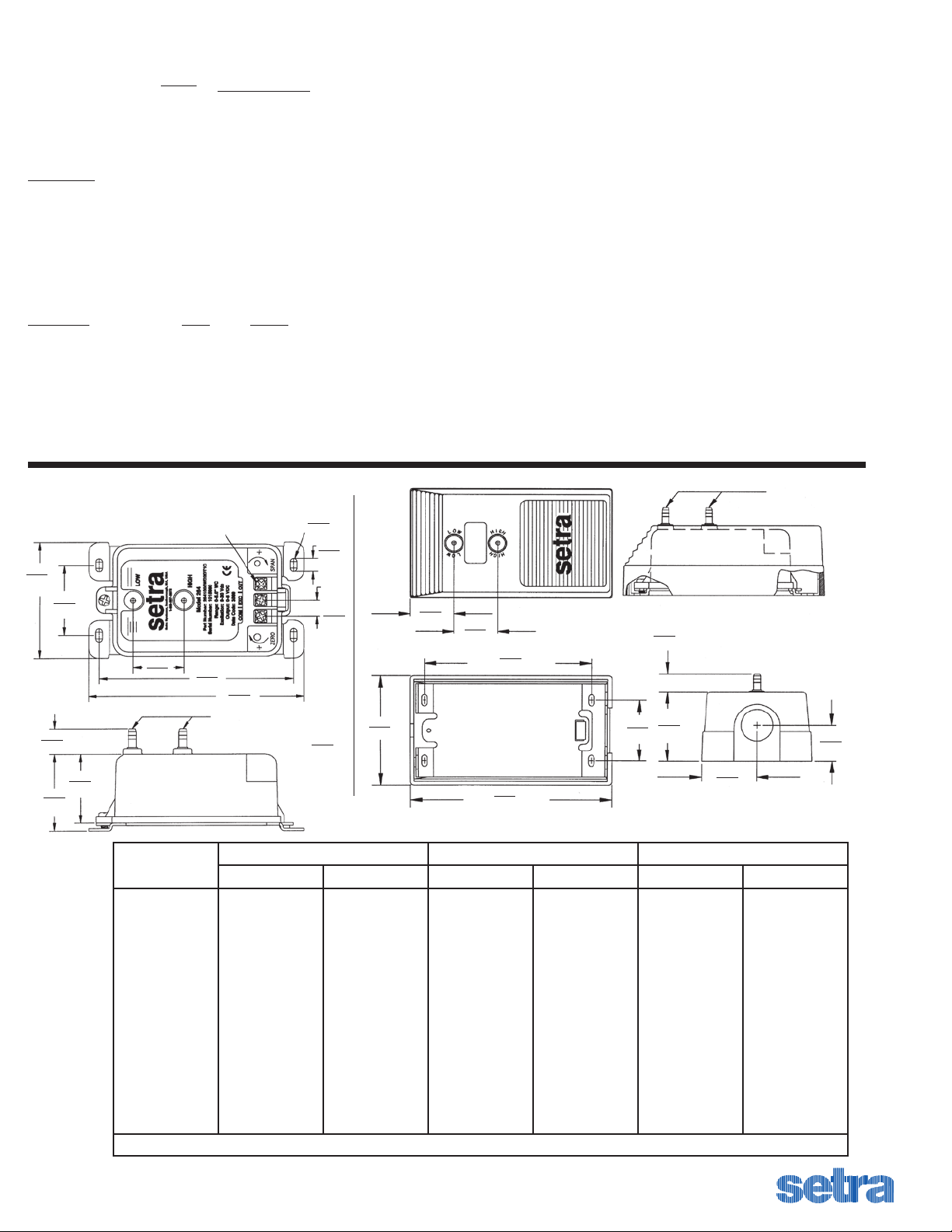

Outline Drawings

Code T1 Electrical Termination Dimensions

#6 SCREW WIRE CLAMP 3 PLACES

2.750

69.85

1.662

42.21

0.594

15.08

1.811

45.99

1.624

41.25

1.187

30.15

4.562

115.87

5.062

128.57

PRESSURE PORTS

Model 264 Specifications

Environmental Data

Temperature

Operating* °F (°C) 0 to +175 (-18 to +79)

Storage °F (°C) -65 to +250 (-54 to +121)

*Operating temperature limits of the electronics only. Pressure media

temperatures may be considerably higher.

Physical Description

Case Fire-Retardant Glass Filled

Polyester (UL 94 V-0 Approved)

Mounting Four screw holes on removable

zinc plated steel base (designed

for 2.75” snap track)

Electrical Connection Screw Terminal Strip

Pressure Fittings 3/16” O.D. barbed brass

pressure fitting for 1/4” push-on

tubing

Zero and Span Adjustments Accessible on top of case

Weight (approx.) 10 ounces

Pressure Media

Typically air or similar non-conducting gases.

Specifications subject to change without notice.

Optional 1/2” Conduit Electrical Enclosure Dimensions

0.078

1.98

0.312

7.92

0.385

9.78

3.00

IN

MM

76.20

ORDERING INFORMATION

1.19

30.15

1.19

30.15

4.56

115.87

5.51

139.83

Electrical Data (Voltage)

Circuit 3-Wire (Com, Exc, Out)

Excitation 9 to 30 VDC

Output* 0 to 5 VDC**

Bidirectional output at zero

pressure: 2.5 VDC

Output Impedance 100 ohms

*Calibrated into a 50K ohm load, operable into a 5000 ohm load or greater.

**Zero output factory set to within ±50mV (±25 mV for optional accuracies).

**Span (Full Scale) output factory set to within ±50mV. (±25 mV for

optional accuracies).

**

Electrical Data (Current)

Circuit 2-Wire

Output* 4 to 20mA

Bidirectional output at zero

pressure: 12mA

External Load 0 to 800 ohms

Minimum supply voltage (VDC) = 9+ 0.02 x

(Resistance of receiver plus line).

Maximum supply voltage (VDC) = 30+ 0.004 x

(Resistance of receiver plus line).

*Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

**Zero output factory set to within ±0.16mA (±0.08 mA for optional

accuracies).

**Span (Full Scale) output factory set to wtihin ±0.16mA (±0.08 mA for

optional accuracies).

0.49

12.55

1.91

1.66

48.51

42.21

1.50

38.10

**

**

PRESSURE PORTS

IN

MM

0.99

25.17

SSP264 Rev.I 04/25/2011

Input Range (Inches

of WC)

0 to 0.1

0 to 0.25

0 to 0.5

0 to 1

0 to 2.5

0 to 5

0 to 10

0 to 25

0 to 50

0 to 100

-0.1 to 0.1

-0.25 to 0.25

-0.5 to 0.5

-1 to 1

-2.5 to 2.5

-5 to 5

Add DPT-CAL-CERT for Calibration Certificate. Note: All units provided with Calibration Certificate

While we provide application assistance on all Setra products, both personally and

through our literature, it is the customer ’s responsibility to determine the suitability

of the product in the application.

Product Codes for Accuracy Product Codes for 0.5% Accuracy Product Codes for 0.25% Accuracy

0 to 5 VDC Output 4 to 20 mA 0 to 5 VDC Output 4 to 20 mA 0 to 5 VDC Output 4 to 20 mA

DPT2640-0R1D-1

DPT2640-R25D-1

DPT2640-0R5D-1

DPT2640-001D-1

DPT2640-2R5D-1

DPT2640-005D-1

DPT2640-010D-1

DPT2640-025D-1

DPT2640-050D-1

DPT2640-100D-1

DPT2640-0R1B-1

DPT2640-R25B-1

DPT2640-0R5B-1

DPT2640-001B-1

DPT2640-2R5B-1

DPT2640-005B-1

DPT2641-0R1D-1

DPT2641-R25D-1

DPT2641-0R5D-1

DPT2641-001D-1

DPT2641-2R5D-1

DPT2641-005D-1

DPT2641-010D-1

DPT2641-025D-1

DPT2641-050D-1

DPT2641-100D-1

DPT2641-0R1B-1

DPT2641-R25B-1

DPT2641-0R5B-1

DPT2641-001B-1

DPT2641-2R5B-1

DPT2641-005B-1

DTP2640-0R1D

DPT2640-R25D

DPT2640-0R5D

DPT2640-001D

DPT2640-2R5D

DPT2640-005D

DPT2640-010D

DPT2640-025D

DPT2640-050D

DPT2640-100D

DPT2640-0R1B

DPT2640-R25B

DPT2640-0R5B

DPT2640-001B

DPT2640-2R5B

DPT2640-005B

DPT2641-0R1D

DPT2641-R25D

DPT2641-0R5D

DPT2641-001D

DPT2641-2R5D

DPT2641-005D

DPT2641-010D

DPT2641-025D

DPT2641-050D

DPT2641-100D

DPT2641-0R1B

DPT2641-R25B

DPT2641-0R5B

DPT2641-001B

DPT2641-2R5B

DPT2641-005B

DPT2640-0R1D-A

DPT2640-R25D-A

DPT2640-0R5D-A

DPT2640-001D-A

DPT2640-2R5D-A

DPT2640-005D-A

DPT2640-010D-A

DPT2640-025D-A

DPT2640-050D-A

DPT2640-100D-A

DPT2640-0R1B-A

DPT2640-R25B-A

DPT2640-0R5B-A

DPT2640-001B-A

DPT2640-2R5B-A

DPT2640-005B-A

DPT2640-0R1D-A

DPT2641-R25D-A

DPT2641-0R5D-A

DPT2641-001D-A

DPT2641-2R5D-A

DPT2641-005D-A

DPT2641-010D-A

DPT2641-025D-A

DPT2641-050D-A

DPT2641-100D-A

DPT2641-0R1B-A

DPT2641-R25B-A

DPT2641-0R5B-A

DPT2641-001B-A

DPT2641-2R5B-A

DPT2641-005B-A

Loading...

Loading...