Page 1

Model DPT 230

Wet/Wet Differential Pressure Transducer

(Available with 3-Valve Manifold Assembly)

Ranges: 0 to ±0.5 psid up to 0 to 100 psid. Liquids or Gases Both Sides

Applications

● Process Control

● Energy Management

Systems

● Flow measurement of

various gases or liquids

● Liquid level measure-

ment of pressurized

vessels

● Pressure Drop Across

Filters

Features

■ NEMA 4/IP65 rating

■ 3-Valve Manifold

Assembly

■ High Accuracy

■ Low Cost

etra Systems Model 230 is a high output,

low differential pressure transducer

designed for wet to wet differential

S

pressure measurements of liquids or gases. A

fast-response capacitance sensor and signal

conditioned electronic circuitry provide a highly

accurate, linear analog output proportional to

pressure. Both unidirectional and bidirectional

pressure ranges are available for applications

with line pressure up to 250 psig.

A unique isolation system transmits the motion

of the differential pressure sensing diaphragm

from the high line pressure environment (e.g.

corrosive liquids) to the dry (air) enclosure where

it moves one of a pair of capacitance plates

proportionally to the diaphragm movement. All

parts exposed to the pressure media are stainless steel and elastomer seals. The 230 has a

NEMA 4/IP65 rated package to withstand

environmental effects. This system responds to

pressure changes approximately 20 times faster

Pressure Ranges

UNIDIRECTIONAL BIDIRECTIONAL

Pressure Pressure Pressure

Range High Side* Low Side*

PSID PSI PSI

0 to 1 20 2.5

0 to 2 40 5

0 to 5 100 12.5

0 to 10 100 25

0 to 25 250 62.5

0 to 50 250 125

0 to 100 250 250

NOTE: Setra quality standards including ISO 9001 are based on

ANSI-Z540-1. The calibration of this product is NIST traceable.

U.S. Patent nos. 4054833

Proof Proof

than conventional fluid-filled transducers. The

electronic circuit linearizes output vs. pressure and

compensates for thermal effects of the sensor.

The Model 230 can be

supplied with a 3-valve

manifold assembly (ordered

as Pressure Fitting Code V)

to protect against excessive

differential overpressure,

which may occur during

installation, start-up or

shut-down. The 230 bleed ports allow for total

elimination of air in the line and pressure

cavities. The manifold’s rugged, yet compact,

construction requires minimum space for

installation. If the Model 230 is ordered with the

3-valve manifold, the system is shipped completely assembled and ready for wall or pipe

mounting. If 3-Valve Manifold Assembly is ordered

separately without 230 transducer, order as

DPT 3-VALVE.

Proof Proof

Pressure Pressure Pressure

Range High Side* Low Side*

PSID PSI PSI

0 to ±0.5 20 1.25

0 to ±1 40 2.5

0 to ±2.5 100 6.25

0 to ±5 100 12.5

0 to ±10 200 25

0 to ±25 250 62.5

0 to ±50 250 125

*The zero will shift slightly when high differential overpressure is applied. The shift may be

as much as ±10% FS with overpressure applied to the low pressure port. Other parameters

(sensitivity, linearity, etc) will not shift. If the overpressure is normally only in one direction,

the user may apply this overpressure to preset the sensor. Subsequent overload of less

magnitude will not cause additional shift. The unit is pr e-zero ed at the factory after application of maximum overload pressure to the high pressure port.

■ Fast Response

■ Gas and Liquid

Compatible

■ Low Differential Ranges

■ Low Line Pressure Effect

■ No Liquid Fill

Diaphragms

ISO

900 1

✓

Certified

Page 2

Performance Data

Accuracy RSS* (at constant temp) ±0.25% FS

Non-Linearity, BFSL ±0.20% FS

Hysteresis 0.10% FS

Non-Repeatability 0.05% FS

Thermal Effects

Compensated Range °F(°C) 30 to 150 (-1 to 65)

Zero shift %FS/°F(%FS/°C) 2.0 (1.8)

Span Shift %FS/°F(%FS/°C) 2.0 (1.8)

Line Pressure Effect Zero shift ±0.004%

FS/psig line pressure.

Resolution Infinite, limited only by

output noise level (0.02%FS)

Static Acceleration Effect 2%FS/g (most sensitive axis)

Natural Frequency 500 Hz (gaseous media)

Warm-up Shift ±0.1% FS total

Response Time 30 to 50 milliseconds

Long T erm Stability 0.5%/1 YR

Maximum Working Pressure 250 psig

*RSS of Non-Linearity, Non-Repeatability and Hysteresis.

Specifications subject to change without notice.

Model 230 Specifications

Environmental Data

Temperature

Operating* °F (°C) 0 to +175 (-18 to +80)

Storage °F (°C) -65 to +250 (-54 to +121)

Vibration 5g from 5Hz to 500Hz

Acceleration 10g

Shock 50g

*Operating temperature limits of the electronics only.

Pressure media temperatures may be considerably higher or lower.

Physical Description

Case Stainless Steel/Aluminum

Electrical Connection Barrier strip terminal block with conduit

enclosure & 0.875 DIA conduit opening.

Pressure Fittings 1/4”-18” NPT internal

Weight (approx.) 14.4oz

Sensor Cavity Volume 0.27 in3 Positive Port,

0.08 in3 Negative Port

(With 1/4”NPT external fittings installed - does not include

cavity volume of 1/4”NPT external fittings.)

Electrical Data (Voltage)

Circuit 3-Wire (Exc., Out, Com)

Excitation 9 to 30 VDC for 0-5 VDC output

13 to 30 VDC for 0-10 VDC output

Electrical Data (Voltage) Cont’d.

*

Output

Output Impedance 100 ohms

*Calibrated into a 50K ohm load, operable into a 5000 ohm load or greater.

**Zero output factory set at 50mV (±25mV) for 0-5 VDC and 50mV

(±50mV) for 0-10 VDC.

**Span output factory set at 5 VDC (±25mV) or 10 VDC (±50mV).

0-5 VDC

0-10 VDC

**

**

Electrical Data (Current)

Circuit 2-Wire

Output

*

4 to 20mA

**

External Load 0 to 1000 ohms

Minimum loop supply voltage (VDC) = 9 + 0.02 x

(Resistance of receiver plus line).

Maximum loop supply voltage (VDC) = 30 + 0.004 x

(Resistance of receiver plus line).

*Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

**Zero output factory set at 4mA (±.08mA)

**Span output factory set at 20mA (±.08mA)

Pressure Media

Gases or liquids compatible with 17-4 PH Stainless Steel, 300

Series Stainless Steel, Viton and Silicone O-Rings.

Note: Hydrogen not recommended for use with 17-4 PH stainless steel.

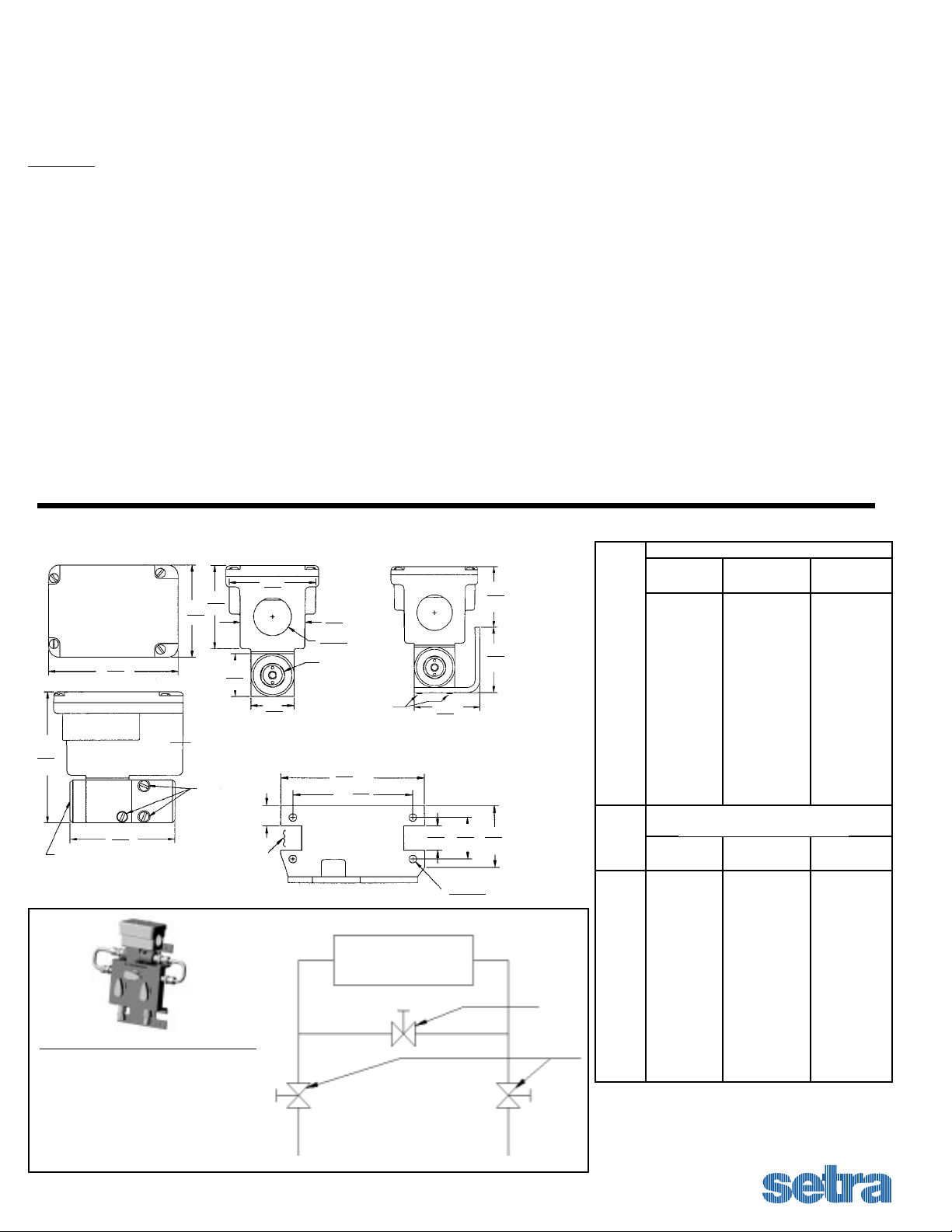

Outline Drawings

3.01

77

3.05

77

2.44

62

1/4-18 NPT

HIGH PRESSURE

PORT

2.15

55

BLEED

SCREWS

1.94

49

1.00

25

NOTCHED

MOUNTING

FOR

CLAMP

2.00

51

1.00

Ordering Information

Input Product Codes

Range 0 to 5 VDC 0 to 10 VDC 4 to 20 mA

1.50

Dia. 0.156

Dia. 4.0

38

1.63

41

33

1.50

38

Dia.875

Conduit

Opening

Dia.22

1/4-18NPT

LOW PRESSURE

PORT

25

TRANSDUCER

MOUNTING

HOLES(screws provided: mounts t o

bottom of 230 Transmitter)

3.00

76

2.50

64

1.63

41

0.52130.88221.30

PSID Output Output Output

0 to 1 DPT2300-001D DPT2302-001D DPT2301-001D

0 to 2 DPT2300-002D DPT2302-002D DPT2301-002D

0 to 5 DPT2300-005D DPT2302-005D DPT2301-005D

0 to 10 DPT2300-010D DPT2302-010D DPT2301-010D

0 to 25 DPT2300-025D DPT2302-025D DPT2301-025D

0 to 50 DPT2300-050D DPT2302-050D DPT2301-050D

0 to 100 DPT2300-100D DPT2302-100D DPT2301-100D

-0.5 to 0.5 DPT2300-0R5B DPT2302-0R5B DPT2301-0R5B

-1 to 1 DPT2300-001B DPT2302-001B DPT2301-001B

-2.5 to 2.5 DPT2300-2R5B DPT2302-2R5B DPT2301-2R5B

-5 to 5 DPT2300-005B DPT2302-005B DPT2301-005B

-10 to 10 DPT2300-010B DPT2302-010B DPT2301-010B

-25 to 25 DPT2300-025B DPT2302-025B DPT2301-025B

-50 to 50 DPT2300-050B DPT2302-050B DPT2301-050B

Product Codes

Input

Range 0 to 5 VDC 0 to 10 VDC 4 to 20 mA

PSID Output Output Output

0 to 1 DPT2300-001D-V DPT2302-001D-V DPT2301-001D-V

0 to 2 DPT2300-002D-V DPT2302-002D-V DPT2301-002D-V

0 to 5 DPT2300-005D-V DPT2302-005D-V DPT2301-005D-V

0 to 10 DPT2300-010D-V DPT2302-010D-V DPT2301-010D-V

0 to 25 DPT2300-025D-V DPT2302-025D-V DPT2301-025D-V

0 to 50 DPT2300-050D-V DPT2302-050D-V DPT2301-050D-V

0 to 100 DPT2300-100D-V DPT2302-100D-V DPT2301-100D-V

with 3-Valve Manifold Option

3-Valve Manifold Assembly Description

(Order by adding “-V” to standard part number. See example below.)

Manifold Block Brass

Valves (3) V1 for connection to +port

V2 for connection to -port

V3 for equalizing pressure

Valve type 90 Degree On/Off

Process Connections 1/4” -18 NPT Internal Thread

V3

V1 V2

-0.5 to 0.5 DPT2300-0R5B-V DPT2302-0R5B-V DPT2301-0R5B-V

-1 to 1 DPT2300-001B-V DPT2302-001B-V DPT2301-001B-V

-2.5 to 2.5 DPT2300-2R5B-V DPT2302-2R5B-V DPT2301-2R5B-V

-5 to 5 DPT2300-005B-V DPT2302-005B-V DPT2301-005B-V

-10 to 10 DPT2300-010B-V DPT2302-010B-V DPT2301-010B-V

-25 to 25 DPT2300-025B-V DPT2302-025B-V DPT2301-025B-V

-50 to 50 DPT2300-050B-V DPT2302-050B-V DPT2301-050B-V

For calibration certificate, add DPT-CAL-REPORT

after part number.

For separate 3-Valve Manifold order as DPT 3-VALVE

Example: Part No. 2300-005D-V for a 230 Transducer, 0 to 5 PSID.

Unidirectional Range, 0 to 5 VDC Output. Assembled with the

3-Valve Manifold.

SSPC230JCI Rev.C-2pg. 02/22/02

Loading...

Loading...