Johnson Controls DCPM12NWM41Q1, DCPM09NWM42Q1, DCPM09NWM41Q1, DCPM12NWM42Q1, DCPM18NWM42Q1 Installation Manual

...Page 1

PREMIUM DUCTLESS SINGLE-SPLIT

INSTALLATION MANUAL

AIR CONDITIONERS AND HEAT PUMPS

MODELS: 22 SEER

3/4 to 3 TONS – 1 PHASE

LIST OF SECTIONS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SHIPPING AND PACKAGING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

REQUIRED INSTALLATION TOOLS (NOT SUPPLIED) . . . . . . . . . . . . . . . . . .3

SELECTING THE INSTALLATION LOCATION . . . . . . . . . . . . . . . . . . . . . . . . .3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

REFRIGERANT LINE SET REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . .6

UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

TORQUE REQUIREMENTS FOR CAPS AND FASTNERS . . . . . . . . . . . . . . . .9

INDOOR UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INDOOR UNIT WIRING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

PIPE FORMING AND DRAIN PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

LIST OF FIGURES

Indoor Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Prevailing Wind Barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Clearances for Outdoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Condensate Drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Typical System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Indoor Unit Mounting Brackets with Weights & Dimensions . . . . . . . . . . . . . . . . .8

Outdoor Unit Weights & Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Mounting Bracket Spots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Masonry Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

PVC Wall Sleeve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Indoor Unit Wall Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Indoor Electrical Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Drain Piping Outlets Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Proper and Improper Drain Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Left or Right Side Exits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Right or Right Rear Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Left or Left Rear Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Drain Hose Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Drain Hose Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Pipe Cutting Approved Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Deburring Line Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Flaring Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Proper and Improper Flaring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connections at Indoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Flare Nuts Tighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Indoor Unit Attachment to Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Proper and Improper Drain Hose Installation Application . . . . . . . . . . . . . . . . . .13

Indoor Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Outdoor Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Outdoor Unit Slab or Frame Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Outdoor Unit Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Outdoor Unit Wiring Terminal Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Indoor/Outdoor Piping Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

FLARING WORK AND PIPING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . 12

INDOOR UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OUTDOOR UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OUTDOOR UNIT WIRING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PURGING PROCEDURE, LEAK TEST AND TEST RUN . . . . . . . . . . . . . . . . 16

TEST OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

INSTALLATION AND MAINTENANCE OF

HEALTHY FILTER (ACCESSORY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

TYPICAL UNIT WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

INDOOR AND OUTDOOR UNITS ERROR CODES . . . . . . . . . . . . . . . . . . . . . 31

Outdoor Line Set Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Line Set Connection Insulation and Taping . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Utility Bundle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Exterior Wall Utility Cover (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

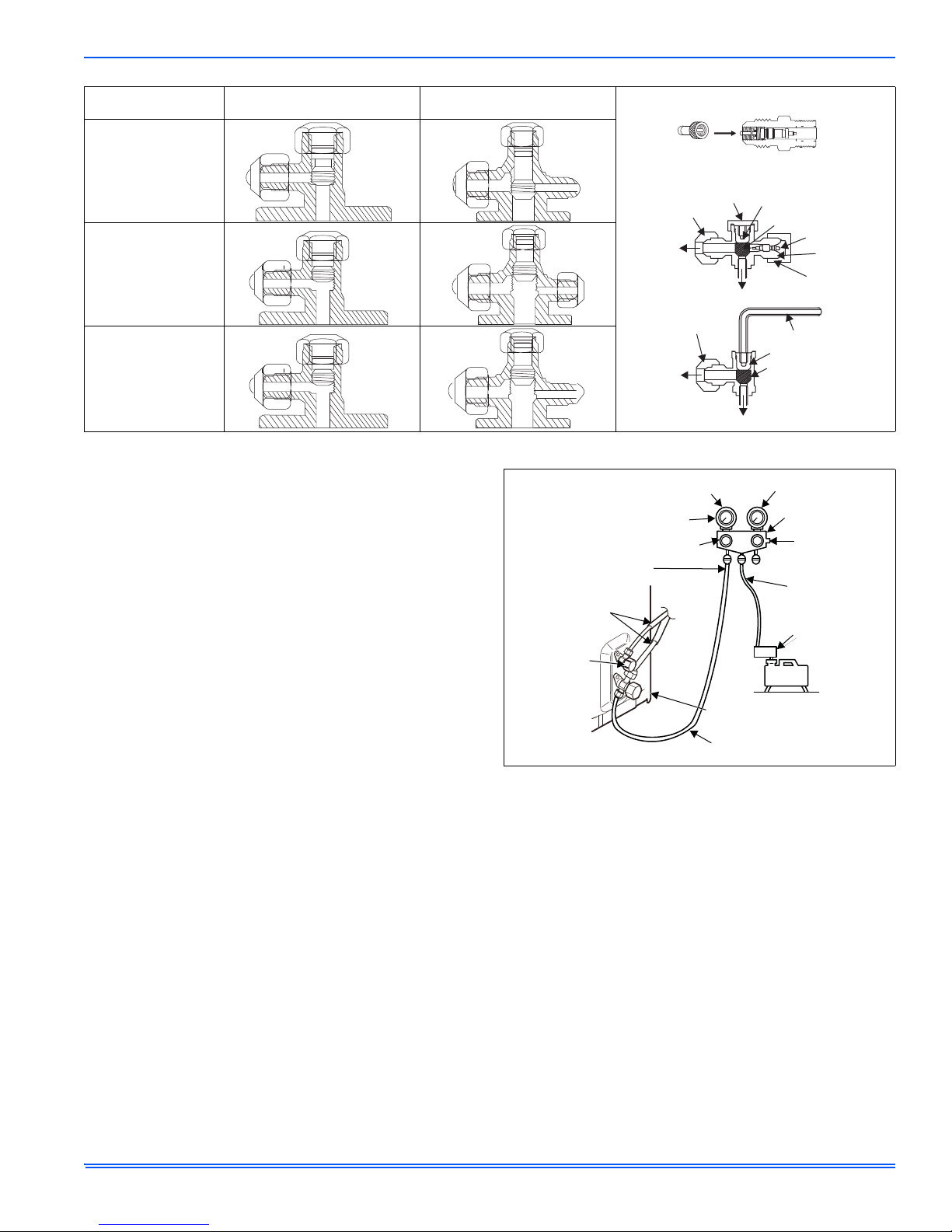

Service Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Gauge Set Connections for Test Leaks, Evacuation Charging . . . . . . . . . . . . . 17

Leak Test Line Set Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Emergency Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

09K & 12K 115V Outdoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

09K & 12K Outdoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

18K & 24K 115V Indoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

18K & 24K Indoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

18K Outdoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

18K Indoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

24K Outdoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

24K Indoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

36K Outdoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

36K Indoor Air Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

09K & 12K 115V Outdoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

09K & 12K Outdoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

18K & 24K 115V Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

18K & 24K Indoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

18K Outdoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

18K Indoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

24K Outdoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

24K Indoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

30K Outdoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

30K Indoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

36K Outdoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

36K Indoor Heat Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Indoor Unit Front Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LIST OF TABLES

Indoor Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Outdoor Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

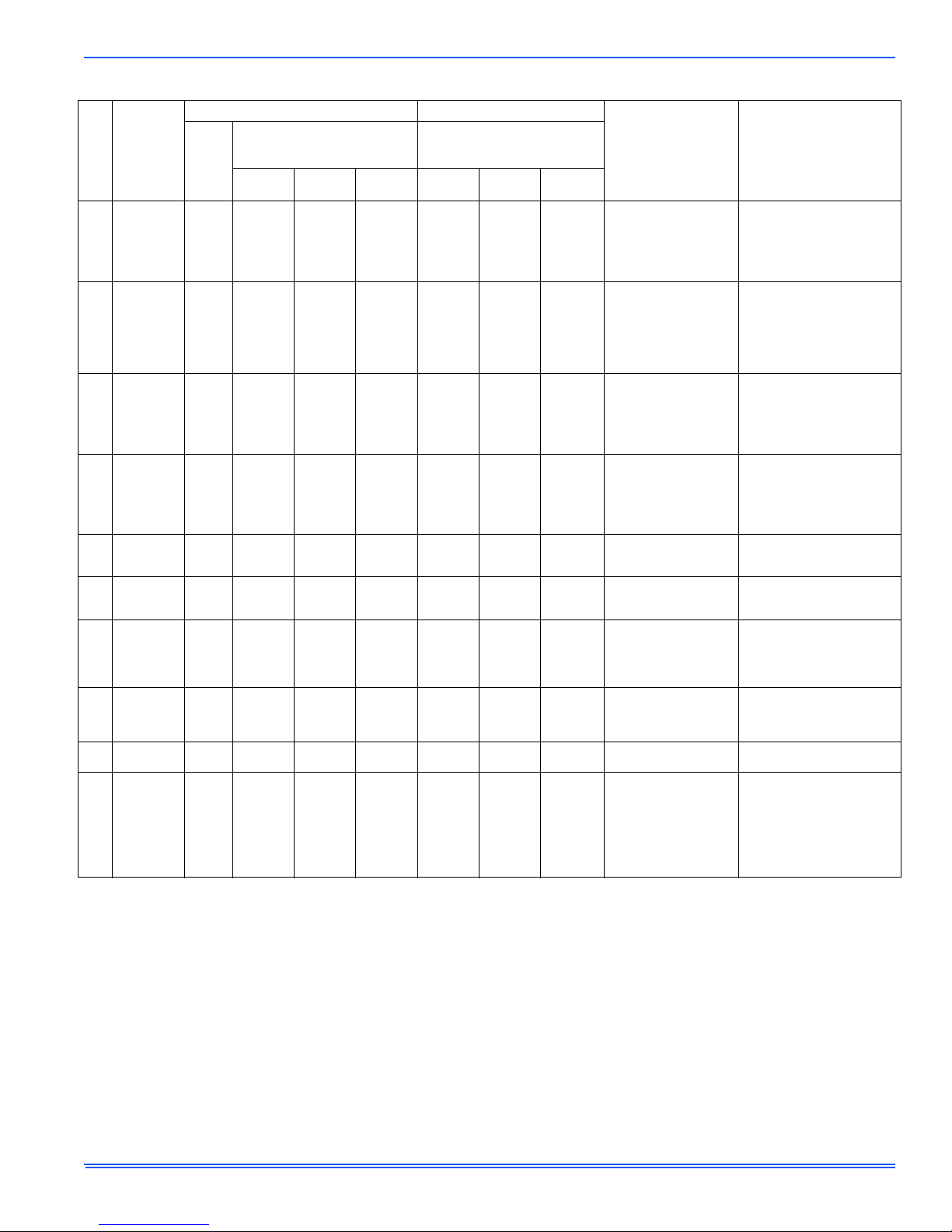

Air Conditioner Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Heat Pump Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Insulation Thickness & Material Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Refrigerant Line Set Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Indoor Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Outdoor Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Caps and Fasteners Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wire Color Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Flare Nut Torque Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Error Codes - 09K 12K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Error Codes - 18K 24K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Error Codes - 30K 36K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

Johnson Controls Unitary Products 898841-UIM-B-0113

Page 2

898841-UIM-B-0113

SECTION I: GENERAL

These instructions are intended as a general guide and do not supersede local codes in any way. Consult authorities having jurisdiction

before installation.

These units must be installed as a matched system as specified in

the UPG Ductless Technical Guide.

SECTION II: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words DANGER,

WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury

• The unit should be installed by an authorized dealer or contractor according to local codes and in compliance with this manual.

• Follow the instructions detailed in the installation manual.

• Confirm proper insulating, taping and bundling of refrigeration lines, main power lines and drain line (see procedure starting on Page 14).

• Perform electrical work according to the installation manual and local codes. Be sure to use a dedicated circuit (do not connect other electr ical

appliances to the same circuit).

• Ground the unit correctly - do not connect the ground wire to a gas pipe, lightning rod, telephone ground or water pipe. Defective grounding

could cause equipment malfunction and/or electric shock.

• Do not damage the wires.

• Shut off the main power when setting up the indoor P.C. board or wiring.

• Use the specified wires to securely connect the indoor and outdoor units. Attach the wires firmly and avoid applying to much pressure to the terminal block - Stranded wire is highly recommended to connect the outdoor unit to the indoor unit. The stranded wire ensures proper system

communication and operation.

• Do not install the unit in a place where flammable gas may leak.

• Do not use intermediate connection of the power cord or a power extension cord.

• The refrigerant temperature tends to get very high. Make sure you keep the electrical wires away from the copper tube.

• Use the parts provided or specified parts for the installation work.

• Securely attach the electrical cover to the indoor unit and the service panel to the outdoor unit.

• When installing or relocating the unit, make sure that no substance other than the specified refrigerant (R410A) enters the refrigerant circuit.

• Do not discharge the refrigerant into the atmosphere. Check that the refrigerant gas does not leak after installation has been completed. If refrigerant leaks during installation, ventilate the room.

• Use appropriate tools and piping materials for installation - the pressure of R410A is 1.6 times higher than R22. Not using the appropriate tools

and materials, or improper installation could cause the pipes to burst causing an injury.

• When pumping down the refrigerant, stop the compressor before disconnecting the refrigerant pipes.

• When installing the unit, securely connect the refrigerant pipes before starting the compressor.

• Fasten a flare nut with a torque wrench as specified in this manual.

• Perform the drainage/piping work securely according to the installation manual - If there is defect in the drainage/piping work, water could drip

from the unit, and damage household items.

• Do not install the outdoor unit where small animals may live. Keep the area around the unit clean

• The included remote control could be shipped in various locations in the unit packaging. Locate remote control before discarding packaging (i.e.

bag assembly, styrofoam, etc.). Unit cannot be properly operated without the included remote control.

.

WARNING indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury

CAUTION indicates a potentially hazardous situation, which, if not

avoided may result in minor or moderate injury

alert against unsafe practices and hazards involving only property damage.

Improper or incomplete installation, adjustment, alteration, service or

maintenance could cause personal injury, loss of life, or damage to

property. Installation and service must be performed by a licensed

professional dealer or contractor.

The Clean Air Act of 1990 bans the intentional venting of refrigerant

(CFCs, HCFCs and HFCs) as of July 1, 1992. Approved methods of

recovery, recycling or reclaiming must be followed. Fines and/or

incarceration may be levied for noncompliance.

.

. It is also used to

SECTION III: SHIPPING AND PACKAGING

LIST

Check the unit components for shipping damage. If you see any damage, contact the carrier immediately.

2 Johnson Controls Unitary Products

ASSEMBLED INDOOR UNIT

The assembled indoor unit will include the following items:

Page 3

898841-UIM-B-0113

A

D

C

B

TABLE 1:

Wall mounting bracket

attached to indoor unit)

Indoor Parts

Remote Control 1

Batteries (AAA) 2

screws

Foam tube insulation

(for condensate line

09, 12 & 18 kBtu (5)

24K kBtu (10)

1

ASSEMBLED OUTDOOR UNIT

The assembled outdoor unit will include the following items which are

located with the unit:

TABLE 2:

Auxiliary drain hole plugs

Outdoor Parts

(heat pump only)

Drain plug

(heat pump only)

1 - 3

1

Flare nut 1/4" for small

line on all size units

except 30K which

uses 5/8".

Cable routing guide

with mounting

hardware (18 - 24 kBtu

systems only)

Installation Manual 1

User’s Information

Manual

2. Select a location where the condensate can be easily drained out.

3. Install in a location where there is enough space to access the unit

for routine maintenance (air filter can be removed for cleaning or

replacement).

4. Install where airflow is not blocked.

5. Install in a location for optimized cold or warm air distribution.

6. Install in a location that's not exposed to direct sunlight.

7. Install in a location that's at least 3 ft away from a TV and radio to

avoid possible interferences with the operation of the air conditioner/heat pump.

8. Install in a location that's at least 3 feet away from fluorescent and

incandescent lights to avoid interference with the remote control.

1

1

1

SECTION IV: REQUIRED INSTALLATION

TOOLS (NOT SUPPLIED)

1. Gauge manifold

2. Electronic balance for refrigerant charging

3. Phillips head screwdriver

4. Knife or wire stripper

5. Carpenters level

6. Hammer

7. Drill

8. Tube cutter

9. Tube flaring tool

10. Torque wrench

11. Adjustable wrench

12. Reamer (for de-burring)

13. Vacuum pump (For R410A)

14. Gas leakage detector

SECTION V: SELECTING THE

INSTALLATION LOCATION

INDOOR UNIT (SEE FIGURE 2 FOR INSTALLATION

DIMENSIONS)

1. Install the unit securely in a place that can bear the weight and

vibration of the unit.

Reference Location

A Clearance between unit and ceiling 6 inches

B Clearance between unit and floor 6 feet

C / D Clearance to the right and left of the unit 6 inches

FIGURE 1: Indoor Clearances

Required

Clearance

REMOTE CONTROL

1. Keep the remote control where it is convenient to operate and easily visible.

2. Keep the remote control away from children.

3. When using the I FEEL feature, select a location for the remote

control that's about 4 ft. above the floor.

Johnson Controls Unitary Products 3

Page 4

898841-UIM-B-0113

NOTICE

PREVAILING WINTER WINDS

WIND BARRIER

INLET AIR

12” (305MM) MINIMUM DISTANCE

DISCHARGE AIR

INSTALL UNIT AWAY

FROM WINDOW

E

F

G

H

I

NOTICE

NOTICE

In rooms where inverter type fluorescent lamps are used, the signal

from the wireless remote controller may not be received.

OUTDOOR UNIT (SEE FIGURE 3 FOR

INSTALLATION DIMENSIONS)

1. Some localities are adopting sound ordinances based on the unit's

sound level registered from the adjacent property, not from the

property where the unit is installed. Install the unit as far as possible

from the property line.

2. When possible, do not install the unit directly outside a window.

Glass has a very high level of sound transmission. For proper

placement of unit in relation to a window see Figure 3.

3. Install unit level or, if on a slope, maintain slope tolerance of 2

degrees (or 2 inches per 5 feet) away from building structure.

4. Install the unit high enough above the ground or roof to allow adequate drainage of defrost water and prevent ice or snow build-up

(required for heat pumps).

5. In heavy snow areas, do not locate the unit where drifting will occur.

The unit base should be elevated above the depth of average

snows.

6. When installed in areas where low ambient temperatures exist,

locate unit so winter prevailing winds do not blow directly onto outdoor unit.

7. If unit coil cannot be installed away from prevailing winter winds, a

wind barrier should be constructed. Size barrier at least the same

height and width as outdoor unit. Install barrier 12 inches minimum

from the sides of the unit in the direction of prevailing winds as illustrated in Figure 2.

Reference Location

E Clearance above unit 2 feet

F Clearance between air inlet and structure 12 inches

G

H 7 feet

I 12 inches

FIGURE 3: Clearances for Outdoor Unit

Clearance between unit and structure

Required

Clearance

12 inches

FIGURE 2: Prevailing Wind Barrier

8. Locate unit away from overhanging roof lines which would allow

water or ice to drop on, or in front of, coil or into unit.

9. Install in a location that has good airflow.

10. Install in a location that has a rigid wall or support to minimize the

sound operation and/or vibration.

11. Slab or roof mounting - install the unit a minimum of 4 inches above

the roof or ground surface to avoid ice build-up around the unit.

Locate the unit above a load bearing wall or area of the roof that

can adequately support the unit. Consult local codes for rooftop

applications.

12. Install in a location that's far away from combustible materials and

vapors.

13. Install in a location that's at least 10 ft away from a TV and radio

antennas to avoid possible interferences with the operation of the

air conditioner/heat pump.

14. Install the unit horizontally.

It is advisable to make a piping loop near outdoor unit so as to

reduce vibration.

For increased efficiency, install the outdoor unit in a location where

continuous direct sunlight or excessive water can be avoided as

much as possible.

When operating the air conditioner in low outside temperature, be

sure to follow the instructions described below.

• Never install the outdoor unit in a place where its air inlet/outlet

side may be exposed directly to wind.

• T o prevent exposure to wind, inst all the out door unit with it s air inlet

side facing the wall and a baffle board on the air outlet side.

Avoid the following places for installation where air conditioner trouble

is liable to occur.

• Where flammable gas could leak.

• Where there is an excessive amount of machine oil in the air.

• Where sulfide gas is generated such as a hot spring.

• Where there is high-frequency equipment.

CONDENSATE DRAINAGE REQUIREMENT (HEAT

PUMP ONLY)

Condensate formed during the heating and defrost processes must be

drained from heat pump units. Drain holes are provided in the base of

the units to ensure proper drainage. Heat pumps must be raised when

installed on a concrete pad or the ground to allow drainage to occur. If

the heat pump unit is installed on a wall mounting bracket, insert the

provided drain connector into one of the 1 inch drain holes and attached

a field-provided insulated drain hose to the connector. Use the provided

rubber plugs to cover any unused drain holes. See Figure 4.

4 Johnson Controls Unitary Products

Page 5

FIGURE 4: Condensate Drainage

DRAIN-WATER HOLE

BOTTOM FRAME

DRAIN PLUG

DRAIN CONNECTOR

HOSE (available commerially, inner dia. 0.63”)

NOTICE

SECTION VI: SPECIFICATIONS

POWER SUPPLY AND INDOOR/OUTDOOR WIRE

CONNECTION

• The system should be powered from a dedicated circuit.

• Wiring work should be based on applicable technical standards.

• Wiring connections should be made following the provided

diagrams.

• Make sure all electrical connections are securely tightened.

898841-UIM-B-0113

Solid conductor AWG14 or stranded conductor AWG14 are the MINIMUM allowable wire sizes. There are some applications that will require

larger gauge conductors depending on the voltage and amperage ratings on the data plate and the distance that the conductors will be

routed. It is the installing contractor's responsibility to properly size the

electrical conductors for the equipment and for the application.

All of the indoor units and outdoor units should have the electrical conductors sized using the National Electrical Code (NEC) and the local

authority having jurisdiction whichever is more stringent. If the equipment is installed outside of the United States, all local codes within the

country of origin must be followed.

The Ductless indoor units

volt double insulated copper conductors. The conductors for the indoor

unit can be either solid or stranded copper. When possible the indoor

unit should have stranded wire for the communication to ensure proper

communication between the indoor and outdoor unit(s).

The Ductless outdoor units

volt double insulated copper conductors with the exception of the following models: DHPM30CSM42Q1, DHPM36CSM42Q1, and

DCPM36CSM42Q1, which require 10 gauge wire. The conductors for

the outdoor unit should be solid or stranded copper conductors.

The listed wire sizes are only minimum requirements, as previously

stated, the conductors for both indoor and outdoor units must be

sized using the NEC and local authority having jurisdiction.

must have a minimum of 14 gauge, 600

must have a minimum of 12 gauge, 600

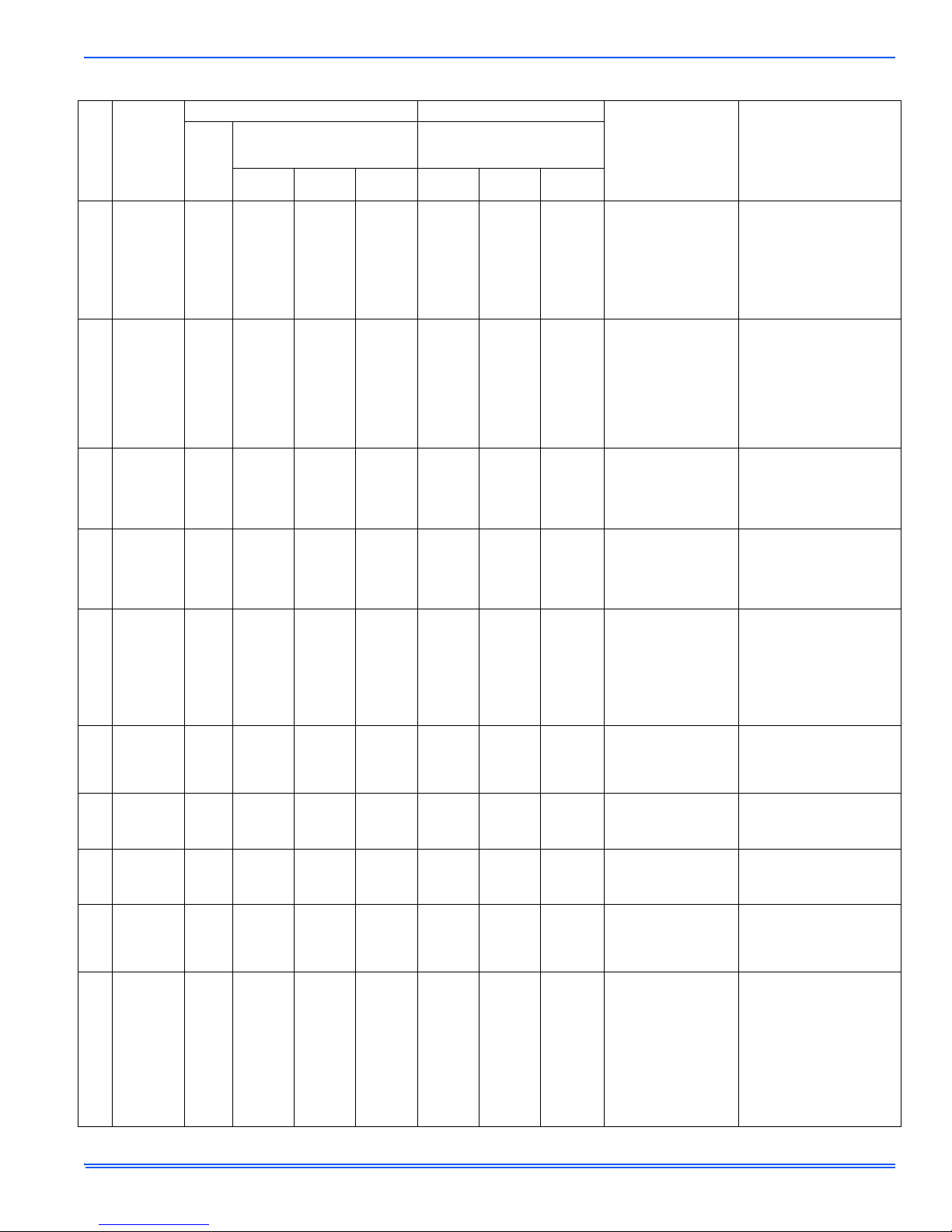

TABLE 3:

Air Conditioners DCPM09NWM42Q1 DCPM09NWM41Q1 DCPM12NWM42Q1 DCPM12NWM41Q1

Power Supply (V, Phase, Hz) 208/230V/1 115V/1 208/230V/1 115V/1

Min. Circuit Ampacity 10 16 10 16

Fan Motor (F.L.A) 0.2 0.38 0.2 0.38

Air Conditioners DCPM18NWM42Q1 DCPM24NWM42Q1 DCPM36NWM42Q1

Power Supply (V, Phase, Hz) 208/230V/1/60HZ 208/230V/1/60HZ 208/230V/1/60HZ

Min. Circuit Ampacity 16 16 17

Fan Motor (F.L.A) 0.28 0.24 0.4

Air Conditioners DCPM09CSM42Q1 DCPM09CSM41Q1 DCPM12CSM42Q1 DCPM12CSM41Q1

Power Supply (V, Phase, Hz) 208/230V/1 115V/1 208/230V/1 115V/1

Max. Fuse Size (time delay) (A) 15 25 15 25

Min. Circuit Ampacity 10 16 10 16

Fan Motor (F.L.A) 0.14 0.17 0.14 0.17

Compressor

Air Conditioners DCPM18CSM42Q1 DCPM24CSM42Q1 DCPM36CSM42Q1

Power Supply (V, Phase, Hz) 208/230V/1/60HZ 208/230V/1/60HZ 208/230V/1/60HZ

Max. Fuse Size (time delay) (A) 20 20 25

Min. Circuit Ampacity 16 16 17

Fan Motor (F.L.A) 0.32 1.1 0.45

Compressor

Air Conditioner Electrical Specifications

INDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

R.L.A 6.21 12.23 5.34 12.43

L.R.A 13.8 33 13.8 33

OUTDOOR UNIT

R.L.A 9.35 10.45 12.66

L.R.A///

Johnson Controls Unitary Products 5

Page 6

898841-UIM-B-0113

NOTICE

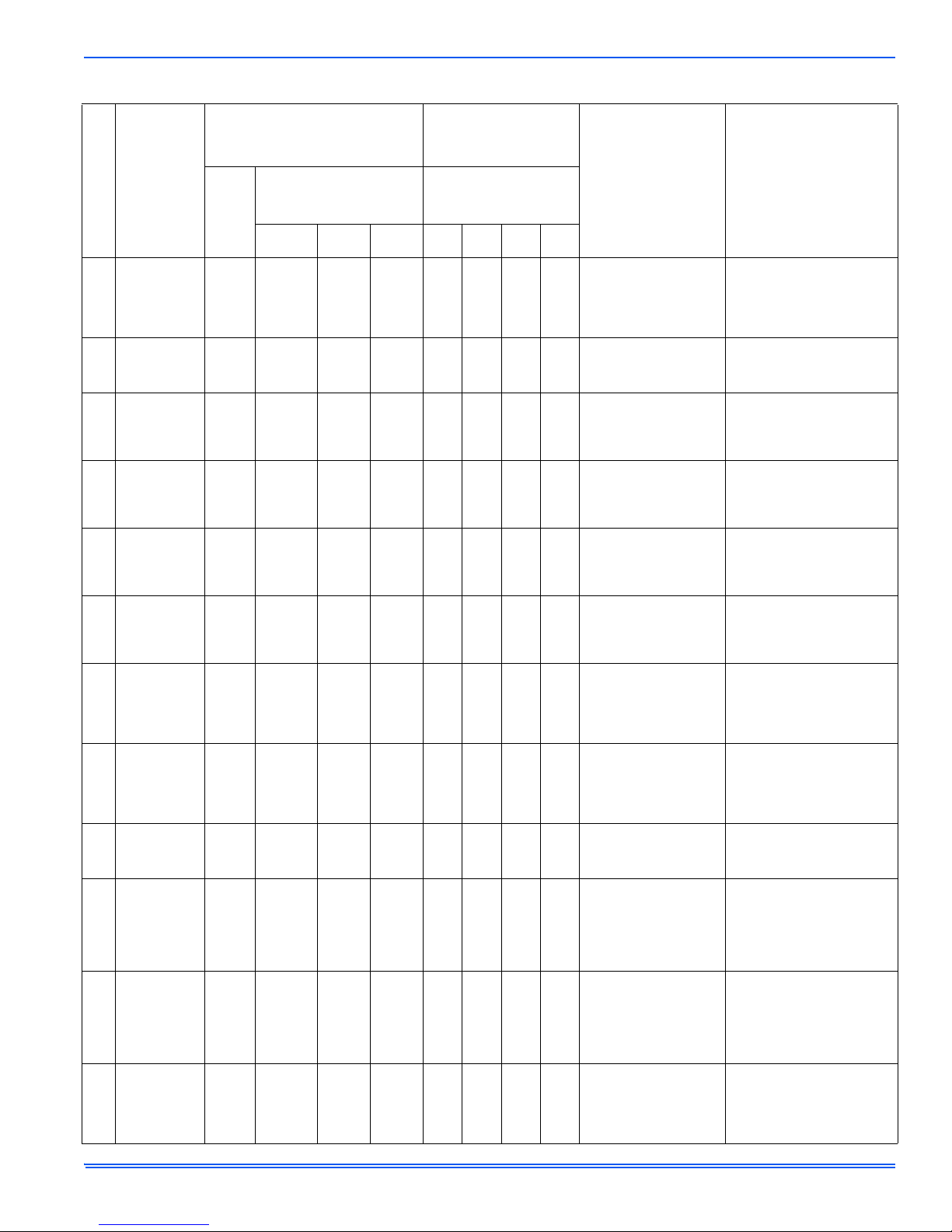

TABLE 4:

Heat Pumps DHPM09NWM42Q1 DHPM09NWM41Q1 DHPM12NWM42Q1 DHPM12NWM41Q1

Power Supply (V, Phase, Hz) 208/230V/1 115V/1 208/230V/1 115V/1

Min. Circuit Ampacity 10 16 10 16

Fan Motor (F.L.A) 0.2 0.38 0.2 0.38

Heat Pumps DHPM18NWM42Q1 DHPM24NWM42Q1 DHPM30NWM42Q1 DHPM36NWM42Q1

Power Supply (V, Phase, Hz) 208/230V/1/60HZ 208/230V/1/60HZ 208/230V/1/60HZ 208/230V/1/60HZ

Min. Circuit Ampacity 16A 16A 15 23

Fan Motor (F.L.A) 0.28A 0.24A 0.4 0.47

Heat Pumps DHPM09CSM42Q1 DHPM09CSM41Q1 DHPM12CSM42Q1 DHPM12CSM41Q1

Power Supply (V, Phase, Hz) 208/230V/1 115V/1 208/230V/1 115V/1

Max. Fuse Size (time delay) (A)15251525

Min. Circuit Ampacity 10 16 10 16

Fan Motor (F.L.A) 0.14 0.17 0.14 0.17

Compressor

Heat Pumps DHPM18CSM42Q1 DHPM24CSM42Q1 DHPM30CSM42Q1 DHPM36CSM42Q1

Power Supply (V, Phase, Hz) 208/230V/1/60HZ 208/230V/1/60HZ 208/230V/1/60HZ 208/230V/1/60HZ

Max. Fuse Size (time delay) (A) 20A 20A 25 35

Min. Circuit Ampacity 16A 16A 15 23

Fan Motor (F.L.A) 0.32A 1.1A 0.45 0.73

Compressor

Heat Pump Electrical Specifications

INDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

R.L.A 6.21 12.23 5.34 12.43

L.R.A 13.8 33 13.8 33

OUTDOOR UNIT

R.L.A 9.35A 10.45A 11.42 16.95

L.R.A / / / /

Connecting Wires and the Ground Wire

• Use double insulated copper wire with 600V insulation.

• Use copper conductors only.

• Follow all local electrical codes.

Power Supply Cable and Ground Wire

• Use copper conductors only.

• Follow all local electrical codes.

The the indoor unit is powered from the outdoor unit, depending on

local code, a disconnect switch needs to be installed to a power supply circuit.

SECTION VII: REFRIGERANT LINE SET

• To prevent condensation, insulate the two refrigerant pipes.

• Refrigerant pipe bending radius must be 4 in. (100 mm) or more.

Be sure to use the insulation of specified thickness (refer to Table 5).

Excessive insulation may cause incorrect installation of the indoor

unit, and too little insulation may cause condensate to form.

• The unit has flared connections on both indoor and outdoor sides

• Remove the valve cover from the outdoor unit then connect the

pipe

• Refrigerant pipes are used to connect the indoor and outdoor units

• Be careful not to crush or over bend the pipe in pipe bending

• Refrigerant adjustment

• If pipe length exceeds 25 ft. (7.5 m), additional refrigerant (R410A)

charge is required (The outdoor unit is charged with refrigerant for

pipe length up to 25 ft. [7.5 m]).

REQUIREMENTS

TABLE 5:

Insulation Thickness & Material Information

Pipe

Liquid Line .375 (9.52) 0.0315 (0.8) 0.315 (8)

Gas Line .625 (15.9) 0.0394 (1.0) 0.315 (8)

Outside Diameter

Inch (mm)

Minimum Wall

Thickness

Insulation

Thickness

Insulation

Material

Heat Resistant Foam Plastic

0.045 Specific Gravity

6 Johnson Controls Unitary Products

Page 7

898841-UIM-B-0113

E

G

H

TAPE

L

REFRIGERANT LINE SET, CONDENSATE LINE

AND INDOOR / OUTDOOR CABLE

RETURN AIR

B

C

D

K

SUPPLY AIR

A

D

DISPLAY

INDICATORS

COOL

DRY

FAN

HEAT

RUN

TEMPERATURE SETTING

INDOOR AMBIENT TEMPERATURE

OR ERROR CODE

NOTE:

Temperature can be

displayed in either fahrenheit or celsius.

F

IMPORTANT:

The refrigerant metering device for this

system is located in the outdoor unit.

This makes it necessary to insulate the

refrigerant lines individually to prevent

sweating.

UTILITY

BUNDLE

WIRELESS REMOTE

CONTROL

OUTDOOR UNIT

(AIR CONDITIONER

OR HEAT PUMP)

AIR IN

AIR OUT

OUTDOOR UNIT

TERMINAL BLOCK

TO INDOOR

UNIT

TO POWER

SUPPLY

ACCESS COVER FOR

SERVICE VALVES

(-18, -24 AND -30 ONLY)

2-WAY SHUT-OFF VAVLE

2-WAY SUCTION / VAPOR LINE SERVICE

VALVE (FLARE CONNECTION)

H

J

A. Remote control

B. Front Panel

C. Filters

D. Guide louver with display

E. Line set (wrapped in foam insulation)

F. UV-rated tape (field-provided)

G. Wiring (field-provided)

H. Condensate drain line (field-provided)

(wrapped in foam insulation). Recommend

installation of a vent when making long

horizontal runs on condensate line.

I. 2-way suction / vapor line service valve

and 2-way shut-off valve.

J. Access cover for power and control wiring

connections.

K. Indoor unit wiring connections (under access plate).

L. Communication cable (30 kBtu system only)

INDOOR UNIT

I

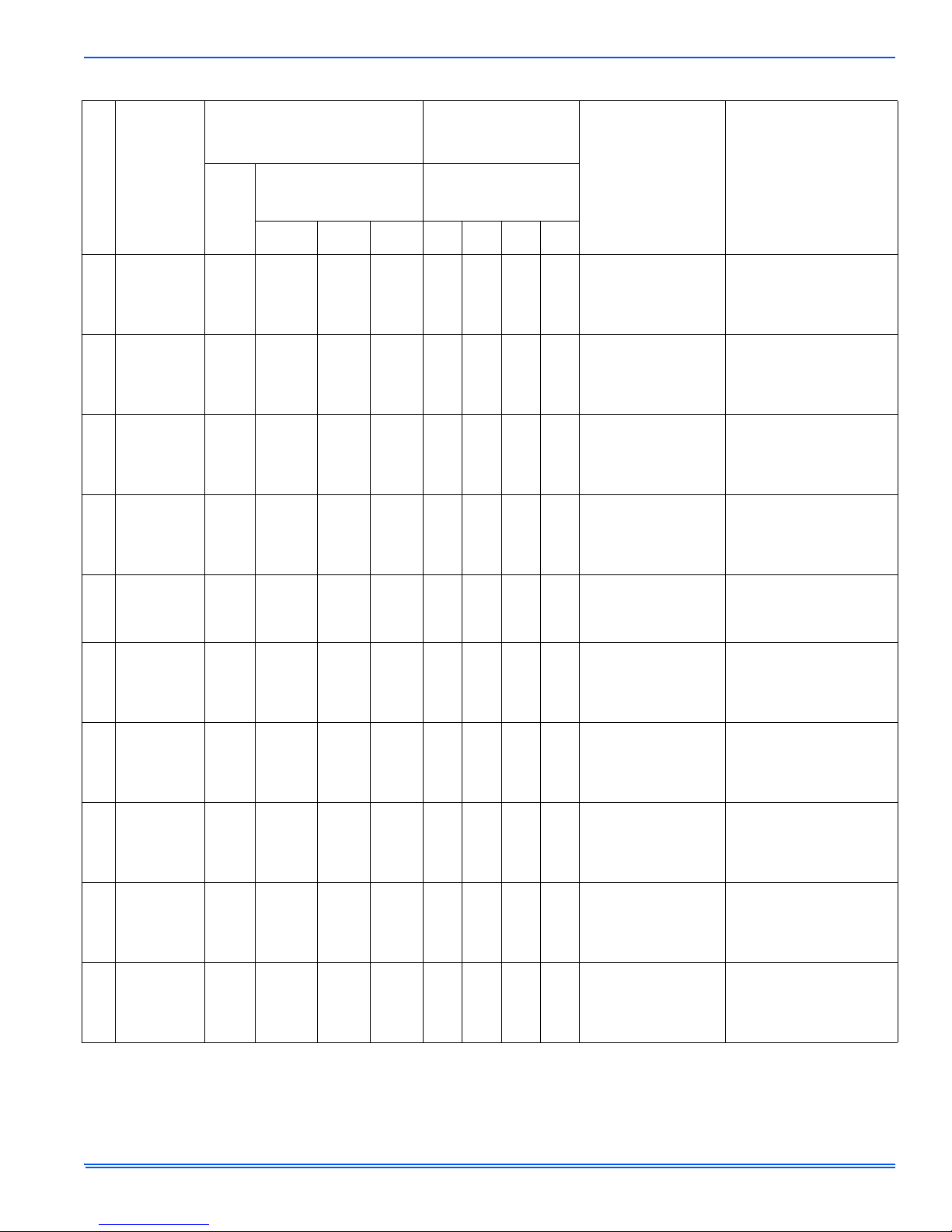

TABLE 6:

Refrigerant Line Set Requirements

AC & HP Indoor Units D(C,H)PM09NWM D(C,H)PM12NWM D(C,H)PM18NWM D(C,H)PM24NWM DHPM30NWM D(C,H)PM36NWM

AC & HP Outdoor Units D(C,H)PM09CSM D(C,H)PM12CSM D(C,H)PM18CSM D(C,H)PM24CSM DHPM30CSM D(C,H)PM36CSM

Connection Pipe length ft. 24.6 24.6 24.6 24.6 24.6 24.6

Connection Pipe Gas

Additional Charge

oz/ft. 0.2 0.2 0.2 0.2 0.5 0.5

Outer Diameter Liquid Pipe Inch 1/4 1/4 1/4 1/4 1/4 1/4

Outer Diameter Gas Pipe Inch 3/8 3/8 1/2 1/2 5/8 5/8

Max Distance Height ft. 32.8 32.8 32.8 32.8 32.8 32.8

Max Distance Length ft. 49.2 49.2 82 82 98.4 98.4

Refrigerant Metering Device Type Electronic Expansion Valve

FIGURE 5: Typical System Components

Johnson Controls Unitary Products 7

Page 8

898841-UIM-B-0113

09K 12K

18K

24K

A

C

B

256

27.3 (693)

5.3

(135)

2.1 (53)

7.8 (198)

11.8 (300)

2.2 (56)

2.2 (56)

1.8 (46)

.6 (15)

.6 (15)

3.3 (84)

22.2 (564)

33.3 (846)

6.3

(160)

4.9

(124)

40.1 (1018)

7.4

(188)

2.6 (66)

3.5 (89)

1.4 (36)

22.6 (574)

2.5 (64)

1.8 (46)

2.6 (66)

27 (686)

2.6 (66)

1 (25)

4

(102)

4

(102)

1 (25)

2.6 (66)

21.3 (541)

2.2 (56)

2.2 (56)

2 (51)

4 (101)

5 (127)

2 (51)

30K & 36K

10.9 (277)

B

A

C

SECTION VIII: UNIT DIMENSIONS

FIGURE 6: Indoor Unit Mounting Brackets with Weights & Dimensions

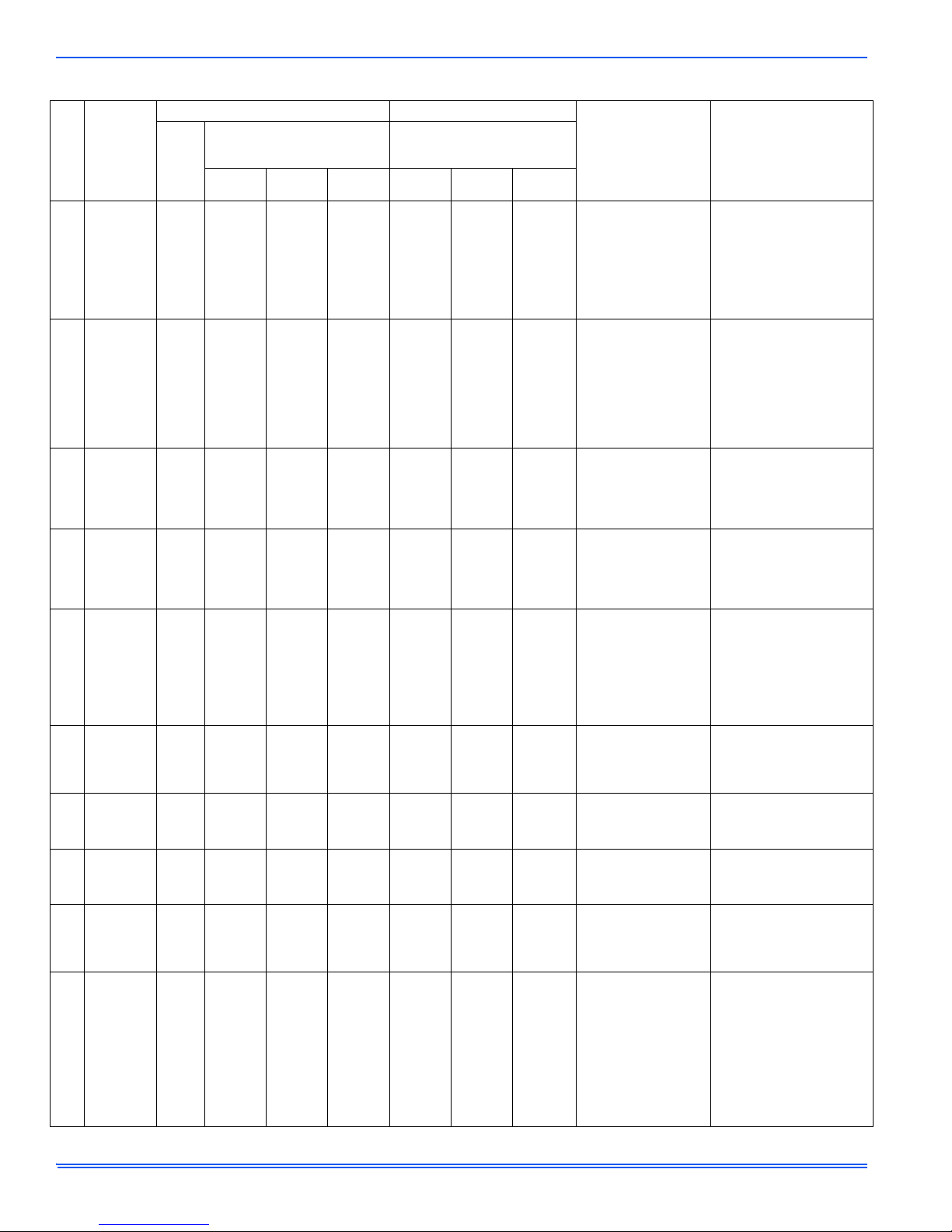

TABLE 7:

Indoor Unit Dimensions

Model Size A B C

09K & 12K 33 (838) 7 (178) 10.9 (277) 31 lbs (14 kg) 37 lbs (17 kg)

18K 37 (940) 8 (203) 12 (305) 31 lbs (14 kg) 46 lbs (21 kg)

24K 39.8 (1011) 8.5 (216) 12.4 (315) 46 lbs (21 kg) 56 lbs (25 kg)

30K & 36KK 53 (1346) 10 (254) 12.9 (328) NA 60 lbs (27 kg)

FIGURE 7: Outdoor Unit Weights & Dimensions

TABLE 8:

Outdoor Unit Dimensions

Model SizeABC

09K 33 (838) 12.6 (320) 21 (533) 91 lbs (41 kg) 110 lbs (50 kg)

12K 33 (838) 12.6 (320) 21 (533) 97 lbs (44 kg) 119 lbs (54 kg)

18K 35 (889) 13.4 (340) 27.5 (699) 121 lbs (55 kg) 148 lbs (67 kg)

24K 38 (965) 16.9 (429) 31.1 (790) 132 lbs (60 kg) 161 lbs (73 kg)

30K & 36K 38 (965) 16.9 (429) 31.1 (790) NA 163 lbs (74 kg)

8 Johnson Controls Unitary Products

Unit Gross Weight

Air Conditioner Heat Pump

Air Conditioner Heat Pump

Unit Gross Weight

Page 9

SECTION IX: TORQUE REQUIREMENTS

NOTICE

Mark on the middle of it

5.9inch

Left

Space

to the

wall

above

Right

Space

to the

wall

above

5.9inch

WALL

WALL

LEVELING DEVICE

(REAR PIPING HOLE)

(REAR PIPING HOLE)

DRILL PILOT HOLES

USE ANCHORS

INSTALLANCHORS

INSIDE

OUTSIDE

CAULKING

2.2”

WALL PIPE

NOTICE

FOR CAPS AND FASTNERS

When servicing or repairing HVAC components, ensure the fasteners

are appropriately tightened. The table below provides torque values for

fasteners.

TABLE 9:

Caps and Fasteners Torque Requirements

Recommended Torque

Parts

English

(ft. - lb.)

Service valve cap 8 ft. - lb. 11

Sheet metal screws 16 ft. - lb. 2

Machine screws #10 27 ft. - lb. 3

Compressor bolts 7 ft. - lb. 10

Gauge port seal cap 8 ft. - lb. 11

Only use Allen wrenches of sufficient hardness (50Rc - Rockwell

Harness Scale minimum). Fully insert the wrench into the valve stem

recess.

Service valve stems are factory-torqued (from 9 ft-lbs for small

valves, to 25 ft-lbs for large valves) to prevent refrigerant loss during

shipping and handling. Using an Allen wrench rated at less than

50Rc risks rounding or breaking off the wrench, or stripping the valve

stem recess.

SECTION X: INDOOR UNIT INSTALLATION

INSTALLING THE WALL MOUNTING BRACKET

Determine that the wall will support the weight of the indoor unit. Refer

to system specifications for indoor unit weight. Install the wall mounting

bracket and make sure it's positioned horizontally and vertically. The

indoor unit must be installed level on the wall to allow proper condensate drainage.

1. Determine the best exit location for utility bundle (line set, condensate line and wiring).

2. Use the wall mounting bracket as a template to determine the exit

point for utility bundle. Use a carpenter's level or tape measure to

verify the wall mounting bracket is horizontally level and mark the

boring points on the wall. See Figure 11.

3. Prior to making the hole and installing wall sleeve for the utility bundle, check to ensure that neither studs nor plumbing are directly

located behind the hole location.

4. Secure the wall mounting bracket to the wall using the provided

screws. If possible, align the rear panel screw holes with wall stud

locations marked on the wall. Make sure you use as many screws

into studs as possible. All other screws must be secured using plastic wall anchors. See Figure 13.

5. If the wall is made of brick, concrete or other similar material, then

drill pilot holes in the wall. Insert field-provided anchors for mounting screws. See Figure 13.

It is important to use all screws provided to secure the wall mounting

bracket to the wall. Additional holes may be drilled through the metal

wall mounting bracket to better secure wall bracket to wall studs.

Johnson Controls Unitary Products 9

(Newton Meter)

898841-UIM-B-0113

Metric

FIGURE 8: Mounting Bracket Spots

FIGURE 9: Masonry Applications

WALL HOLE DRILLING

Be sure to caulk the gaps around the pipes with caulking material to

prevent water leakage.

1. Determine the wall hole position.

2. Drill a 2-1/2 inch diameter hole in the wall. The hole should be

slightly downward slant 3/16" to 3/8" (5 to 10 mm) lower than the

indoor side.

3. Measure the thickness of the wall from inside to outside edges and

cut field-provided PVC pipe at a slight angle 1/4" (6mm) shorter

than the thickness of the wall.

4. Place a field-provided plastic cover on the outside end of the PVC

pipe and insert the pipe in the wall hole.

5. After completing refrigerant piping, wiring, and drain piping, caulk

pipe hole gap with putty.

FIGURE 10: PVC Wall Sleeve Installation

SECTION XI: INDOOR UNIT WIRING

CONNECTIONS

When the indoor unit is powered from the o utdoor unit, a disconnect switch needs to be installed to power supply circuit

between indoor and outdoor units depending on local codes.

Page 10

898841-UIM-B-0113

WALL

WIRING

FIELD PROVIDED

PVC WALL SLEEVE

GROUND

WIRE

TERMINAL BLOCK

TERMINAL COVER

SCREW

SCREW

CORD CLAMP

CONNECTING CABLE

TERMINAL BLOCK

YELLOW-GREEN

BLUE

BROWN

BLACK

CONNECTING

CABLE

ABOUT 5.9”

2.8”

0.39”

GROUND

LINE

0.39”

1.97”

RIGHT

REAR RIGHT

RIGHT DOWNWARD REAR LEFT

LEFT DOWWARD

LEFT

Mis-wiring could damage unit or cause communication errors

between indoor and outdoor unit.

1. Remove the front panel.

2. Open the front panel upward and pull it toward you.

3. Remove the terminal cover and cord clamp.

4. Insert the connecting cable (according to local codes) into the pipe

hole on the wall.See Figure 11.

5. Pull the connecting cable through the cable slot on the rear case so

that it protrudes about 6 inches (~15 cm) out of the front.

6. Connect the ground wire to the ground terminal of electrical box.

7. Insert the connecting cable fully into the terminal block and secure it

with screws while making sure no part of its core is visible. Make

sure you don't mis-wire the unit. See Figure 12.

8. Firmly tighten the terminal screws to prevent them from getting

loose.

9. Secure the connecting cable with the cord clamp.

10. Attach the terminal cover and front panel on the indoor unit.

TABLE 10:

Color Code Color

Wire Color Reference

Color Code or

Symbol

Color

WH White BN Brown

YE Yellow BU Blue

RD Red BK Black

YEGN Yellow Green

FIGURE 11: Indoor Unit Wall Mounting Bracket

Be sure to refer to the wiring system diagram labeled inside the front

panel.

Check local electrical regulations for any specific wiring instructions

or limitations.

10 Johnson Controls Unitary Products

FIGURE 12: Indoor Electrical Wiring Connections

SECTION XII: PIPE FORMING AND DRAIN

PIPING

FIGURE 13: Drain Piping Outlets Option

PIPE FORMING

Interchange the drain cap and the drain hose.

1. Place the drain hose below the refrigerant piping.

2. Make sure the drain hose is not bent or kinked.

3. Do not pull the hose when applying the tape.

4. When the drain hose passes the room, be sure to wrap field-provided insulation material around it.

5. In the case of bending refrigerant piping, keep the following precautions in mind to avoid abnormal sounds that may be generated if

improper work is conducted.

a. Do not press the refrigerant pipes onto the bottom frame.

b. Do not press the refrigerant pipes on the front grille.

Page 11

FIGURE 14: Proper and Improper Drain Piping

SLIT

RIGHT

PIPING

BOTTOM

PIPING

BIND WITH VINYL TAPE

PIPE (TOP) REAR PIPING

INDOOR UNIT

DRAIN HOSE (BOTTOM)

INDOOR UNIT

DRAIN HOSE

DRAIN CAP

FOR LEFT OUTLET

PIPING, CUT OFF

THE PIPING OUTLET

CUTTING GROOVE

WITH A HACKSAW

REMOVE DRAIN

CAP BY PULLING

AT THE PROJECTION

AT THE END OF THE

CAP WITH PLIERS, ETC.

How to replace the drain plug and drain hose

• How to remove the drain cap

Clamp drain cap with needle-nose pliers, and pull out.

• How to remove the drain hose

The drain hose is secured in place by a screw.

Remove the screw securing the drain hose, then

pull out the drain hose.

• How to attach the drain cap

1. Insert hexagonal wrench (0.16inch).

2. Firmly insert drain cap.

• How to attach the drain hose

secure it in place using the original screw.

Do not apply lubricating oil

(refrigerant machine oil) when

inserting the drain cap. If applied

deterioration and leakage of the

drain plug may occur.

Insert a hexagon wrench

(4 mm)

No gap

Drain Hose

0.16”

Insulation

fixing screw

RIGHT OR RIGHT REAR PIPING

For Right Side Utility Bundle Exit - Cut out the corner of the right/left

plastic cabinet with a hacksaw or similar tool. See Figure 15.

1. Put the refrigerant piping and the drain hose together. Position

them to the left side and then firmly apply piping tape from the end.

2. Insert the drain hose into field-provided PVC sleeve and hook the

upper part of the indoor unit on the wall mounting bracket.

3. Check if the indoor unit is hooked securely on the wall mounting

bracket by trying to move the unit left and right.

4. Thrust the lower part of the indoor unit into the wall mounting

bracket.

898841-UIM-B-0113

LEFT OR LEFT REAR PIPING

For Left Side Utility Bundle Exit - Cut out the corner of the right/left

plastic cabinet with a hacksaw or similar tool.

Make sure you reattach the drain hose and the drain cap in case of left

or left rear piping. Otherwise, it could cause drops of water to drip from

the drain hose.

1. Put the refrigerant piping and the drain hose together then firmly

apply felt tape from the end.

2. Pull out the drain cap at the rear right of the indoor unit.

3. Pull out the drain hose at the rear left of the indoor unit.

4. Put the drain cap into the section to which the drain hose is to be

attached at the rear of the indoor unit.

5. Insert the drain hose fully into the drain pan at the rear right of the

indoor unit.

6. Insert the drain hose into field-provided PVC sleeve and hook the

upper part of the indoor unit on the wall mounting bracket.

FIGURE 15: Left or Right Side Exits

FIGURE 16: Right or Right Rear Piping

Johnson Controls Unitary Products 11

FIGURE 17: Left or Left Rear Piping

REAR OR DOWNWARD PIPING

1. Put the refrigerant piping and the drain hose together then firmly

apply felt tape from the end. Use bandage stopper at the end of felt

tape.

2. Insert the drain hose into field-provided PVC sleeve and hook the

upper part of the indoor unit on the wall mounting bracket.

Page 12

898841-UIM-B-0113

SHIELD PIPE

DRAIN HOSE

INSIDE THE ROOM

EXTENSION

DRAIN HOSE

DRAIN HOSE

INSULATION (DRAIN HOSE)

COPPER

PIPE

SLANTED

UNEVEN ROUGH

90°

PIPE

REAMER

POINT DOWN

"A"

BAR

HANDLE

YOKE

CONE

RED ARROW MARK

CLAMP HANDLE

COPPER PIPE

BAR

Outside Dia.

Inch

0.24

0.37

0.47

0.63

0.75

A

Inch

0~0.02

~0.02

~0.02

~0.04

~0.05

0

0

0

0.04

SMOOTH ALL ROUND

INSIDE IS SHINY WITHOUT SCRATCHES

= IMPROPER FLARING =

EVEN LENGTH

ALL ROUND

INCLINED

SURFACE

DAMAGED

CRACKED

UNEVEN

THICKNESS

1. In order to align the drain hose and drain cap, be sure to insert

securely and vertically. Incline insertion will cause water leakage.

2. After removing drain hose, be sure not to forget mounting drain

cap.

3. Be sure to fix the drain hose with tape to the bottom of piping.

4. Prevent drain water from freezing in low temperature environment.

When installing indoor unit’s drain hose outdoors, necessary measure for frost protection should be taken to prevent drain water

freezing.

• Under low temperature environment (when outdoor temperature under 32 °F), after cooling operation is executed, water in

the drain hose could be frozen.

• Once drain water is frozen, the drain hose will be blocked and

water leakage may result from indoor unit.

DRAIN PIPING

• If the extension drain hose has to pass through a room, make

sure it's wrapped with commercially sold insulation.

• The drain hose should point downward for easy drain flow.

• If the drain hose provided with the indoor unit is too short, make

sure you connect it with a field-provided drain hose.

• When connecting the drain hose to the hard vinyl chloride pipe,

make sure it's inserted securely into the pipe.

DRAIN HOSE JUNCTION

• If drain hose extension or embedded drain piping is required, use

appropriate parts that match the hose front end. See Figure 18.

• Insert drain hose into the handle of drain pan, and join drain hose

and connecting hose according to Figure 18.

• Attach the Insulation (Drain hose) to the drain hose. See Figure

19.

SECTION XIII: FLARING WORK AND

PIPING CONNECTIONS

FLARING WORK

Main cause for refrigerant leakage is due to defect in the flaring work.

Carry out correct flaring work using the following procedure.

1. Measure the distance between the indoor and outdoor units.

2. Cut the copper pipe about 6 to 8 inches (15 to 20 cm) longer than

the measured distance with a pipe cutter.

FIGURE 20: Pipe Cutting Approved Method

3. Use a pipe reamer or file to completely remove all burrs from the

cut cross section of the pipe.

a. Put the end of the copper pipe in a downward direction to avoid

having burrs drop in the piping.

FIGURE 21: Deburring Line Set

4. Remove flare nuts attached to indoor and outdoor units then put

them on pipes that have completed burrs removal (not possible to

put them on after flaring work).

5. Use a flaring tool to perform flaring work at the end of the copper

pipe. Use the table below as a guideline when performing flaring

work.

FIGURE 18: Drain Hose Extension

FIGURE 19: Drain Hose Insulation

Insert the drain hose and drain cap into the drain port, making sure

that it comes in contact with the back of the drain port, and then

mount it. If the drain hose is not connected properly, leaking will

occur.

12 Johnson Controls Unitary Products

FIGURE 22: Flaring Tools

6. Check your flaring work and if it's found to be defective, cut off the

defective flare section and redo number 5.

FIGURE 23: Proper and Improper Flaring

7. When flaring is complete, align the center of the pipes and sufficiently tighten the flare nut by hand.

Page 13

FIGURE 24: Connections at Indoor Unit

INDOOR UNIT TUBING

FLARE NUT PIPES

WRENCH

INDOOR UNIT TUBING

OPEN-END WRENCH (FIXED)

FLARE NUT

CONNECTION PIPE

A

MOUNTING PLATE

MARKING

DO NOT RISE THE DRAIN HOSE

DO NOT FORM THE DRAIN HOSE

INTO THE WAVED SHAPE

50 mm

OR MORE

DO NOT PUT THE

DRAIN HOSE END

INTO WATER

DO NOT PUT THE DRAIN

HOSE END IN THE

DRAINAGE CONTAINER

PUSH

PUSH

8. Tighten the flare nut using a wrench.

FIGURE 25: Flare Nuts Tighting

898841-UIM-B-0113

5. Carefully bend the bundle (line set, condensate line and cable) to

run along the outside wall toward the outdoor unit. Downward slope

of wall sleeve will ensure proper condensate drainage.

FIGURE 27: Proper and Improper Drain Hose Installation Application

Pull the indoor unit toward you to confirm that it is firmly hooked

on the mounting bracket.

For detaching the indoor unit from the installation plate, pull the indoor

unit toward you while pushing the bottom up at the specified places.

TABLE 11:

Flare Nut Torque Recommendations

Outside

Diameter

Inches mm

Recommended

English

(ft. - lb.)

Torque

Metric

(Newton Meter)

1/4” 6.35 15 ft - lb. 20

3/8” 9.52 26 ft - lb. 35

1/2” 12.70 41 ft - lb. 55

5/8” 15.88 48 ft - lb. 65

SECTION XIV: INDOOR UNIT

INSTALLATION

1. Shape the refrigerant line set so that it can be guided either out the

back of the indoor unit or through either side of the indoor unit

frame, then through the wall sleeve to the outside unit.

2. Pass the drain hose and refrigerant pipes through the wall hole then

set the indoor unit on the mounting bracket hooks by using the

markings at the top of the indoor unit as a guide.

FIGURE 26: Indoor Unit Attachment to Mounting Bracket

3. Try moving the indoor unit to right and left to confirm that it is firmly

hooked on the installation plate.

4. While pressing the indoor unit onto the wall, hook it at the lower part

on the installation plate.

FIGURE 28: Indoor Unit Removal

6. Use the provided foam insulation to wrap the factory installed condensate line.

7. Connect indoor unit factory installed condensate line to field-provided condensate drain pipe.

8. Use tape approved for waterproofing line connections to secure the

field-provided pipe to the factory-installed condensate line.

9. Put water in the drain pan and make sure that the water is being

drained outside.

Install the drain pipe for proper drainage. Improper drainage can

result in water dripping inside the room.

SECTION XV: OUTDOOR UNIT

INSTALLATION

Refer to page 4 instructions when considering unit positioning and page

4 for condensate drainage requirements (heat pump).

SLAB OR ROOF MOUNTING

• Install the unit a minimum of 4 inches (102 mm) above the roof or

ground surface to avoid ice build-up around the unit.

• Locate the unit above a load bearing wall or area of the roof that

can adequately support the unit.

• Consult local codes for rooftop applications.

Johnson Controls Unitary Products 13

Page 14

898841-UIM-B-0113

BUILDING STRUCTURE

GROUND

LEVEL

Install unit level or maintain slope tolerance of 2 degrees

( or 2 inches per 5 feet [50 mm per 1.5 m] away from building structure.

NOTICE

FOUR FIELD PROVIDED ANCHOR BOLTS

NOTICE

ROUTE WIRES

THROUGH

ROUTING

PLATE

ACCESS PLATE

FIGURE 29: Outdoor Unit Installation

This system contains both refrigerant and oil. Some rubber roofing

material may absorb oil. This will cause the rubber to swell when it

comes into contact with oil. The rubber will then bubble and could

cause leaks. Protect the roof surface to avoid exposure to refrigerant

and oil during service and installation. Failure to follow this notice

could result in damage to roof surface.

SECURING OUTDOOR UNIT TO SLAB OR FRAME

If the outdoor unit is installed on a field-provided slab or frame, use lag

bolts or equivalent to secure the outdoor unit to the slab or frame.

Mis-wiring could damage unit or cause communication errors

between indoor and outdoor unit.

• Refer to unit nameplate for minimum circuit ampacity and maximum overcurrent protection size

• Local codes may require a disconnect between the indoor and outdoor units

• The main system circuit breaker and outdoor unit disconnect

switch should be sized per local codes and unit requirements

• Stranded wire must be used to connect the outdoor unit to the

indoor unit. The stranded wire is necessary to ensure proper system communication and operation.

• Make sure you use an approved circuit breaker or switch

Model Fuse or Circuit Breaker Capacity

9K & 12K 20A

18K & 24k 25A

30K & 36k 30A

1. Remove outdoor unit access panel.

2. Route all wiring to outdoor unit through the wire routing plate.

FIGURE 30: Outdoor Unit Slab or Frame Installation

SECTION XVI: OUTDOOR UNIT WIRING

CONNECTIONS

In the United States, wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada, wiring

must conform with current local codes and the current Canadian

Electrical Code (CEC).

The main system circuit breaker or disconnect should be sized per

unit requirements and should be installed adjacent to outdoor unit.

14 Johnson Controls Unitary Products

FIGURE 31: Outdoor Unit Electrical Connections

3. Connect the control wiring and power supply wiring to the outdoor

unit wiring terminals according to the figures shown in this section.

4. The unit must be grounded according to local codes.

5. Fasten the power supply cord and control wiring with cord clamp.

6. Secure wiring using built-in wire strain relief.

7. Install the outdoor unit access panel back.

Page 15

FIGURE 32: Outdoor Unit Wiring Terminal Designations

OUTDOOR UNIT

TERMINALS

N(1)

23

L1 N

(DATA)

(NEUTRAL)

(GND)

N(1)

2

3

(NEUTRAL)

(GND)

(L1)

N(1)

23

L1 L2

(DATA)

(L2)

(GND)

N(1)

2

3

(GND)

(L1)

N(1) 2 3

N(1)

2

3

L1

L2

(L2)

(GND)

(L1)

(GND)

208-230V SYSTEMS

30 & 36 KBTU (208-230V)

SYSTEM ONLY

115V SYSTEMS

INDOOR UNIT TERMINALS

INDOOR UNIT TERMINALS

INDOOR UNIT TERMINALS

OUTDOOR UNIT

TERMINALS

OUTDOOR UNIT

TERMINALS

OUTDOOR UNIT

TERMINALS

(NEUTRAL)

(NEUTRAL)

(DATA)

NOTICE

MALE FLARE

CONNECTION

APPLY REFRIGERANT

LUBRICANT HERE

A

B

OUTDOOR UNIT

LIQUID SIDE PIPING

(SMALLER DIAMETER)

TORQUE WRENCH

GAS SIDE PIPING

(BIGGER DIAMETER)

REFRIGERANT PIPING CONNECTIONS

A Service port cap protects the service port core from contamination

and serves as the primary leak seal. To access service port:.

1. Remove service port cap with an appropriate sized wrench.

2. Connect gauge set to service port.

3. When testing is complete, replace service port cap and tighten as

follows:

a. With torque wrench - Finger tighten then torque cap per Table 11

requirements.

b. Without torque wrench - Finger tighten then use appropriate

sized wrench to turn an additional 1/6 turn clockwise.

Stem cap protects the valve stem from damage and serves as the primary seal. Replace the stem cap and tighten as follow:

1. With torque wrench - Finger tighten and use torque cap per Table

11.

2. Without torque wrench - Finger tighten then use an appropriate

sized wrench to turn an additional 1/12 turn clockwise.

• Fasten flare nut with a torque wrench as specified in Table 9.

• When fastened too tight, flare nut may break after a long period

and cause refrigerant to leak.

898841-UIM-B-0113

FIGURE 33: Indoor/Outdoor Piping Connections

OUTDOOR UNIT CONNECTION

• Apply a sealing cap or water proof tape to prevent dust or water

from getting into the refrigerant piping before it is connected.

• Apply refrigerant lubricant to the matching surfaces of the flared

line set and union before connecting them together. This will

reduce refrigerant leaks.

• Align the flared refrigerant line with valve connection then tighten

the flare nut lightly at first to obtain a smooth match. Use tightening toque Table 11 as a guideline.

INDOOR UNIT CONNECTION

• Connect both liquid and gas pipes to indoor unit.

• Apply a sealing cap or water-proof tape to prevent dust or water

from getting into the refrigerant piping before it is connected.

• Apply a thin coat of refrigerant oil on the seal surface of the pipe.

• For connection, first align the union tube and flared refrigerant

line with each other then tighten the flare nuts lightly at first to

obtain a smooth match.

• Use tightening toque Table 11 as a guideline for indoor unit side

union joint section and tighten using two wrenches. Excessive

tightening may damage the flare section.

Johnson Controls Unitary Products 15

FIGURE 34: Outdoor Line Set Connections

Page 16

898841-UIM-B-0113

PLASTIC BANDS

INSULATION MATERIAL

CONNECTION

PIPE

VINYL TAPE

(WIDE)

INDOOR

UNIT PIPE

WRAP WITH VINYL TAPE

WRAP WITH VINYL TAPE

PIPE

DRAIN HOSE

VINYL TAPE (WIDE)

INDOOR UNIT

CONNECTING

CABLE

AUXILIARY PIPES

INSTALLATION

PLATE

FIELD PROVIDED PROTECTIVE

CHANNEL (UTILITY BUNDLE INSIDE)

INSULATION AND TAPING

1. Cover piping joints with pipe cover.

2. For outdoor unit, insulate every pipe including all pipe joints.

3. Using piping tape, apply taping starting from entry of outdoor unit.

a. S top the end of piping tape with tape that has an adhesive agent

attached.

b. When pipes have to be arranged through above ceiling, closet or

where temperature and humidity are high, make sure you wind

additional commercially sold insulation to prevent sweating.

4. An optional field-provided exterior wall channel may be used in lieu

of taping the utility bundle to protect the bundle from UV rays,

weather, etc. See Figure 37.

FIGURE 35: Line Set Connection Insulation and Taping

FIGURE 37: Exterior Wall Utility Cover (Optional)

SECTION XVII: PURGING PROCEDURE,

LEAK TEST AND TEST RUN

FIGURE 36: Utility Bundle

SERVICE VALVES

The outdoor unit suction/vapor 2-way service valve is used to purge air,

test for leaks, check operating pressures and add refrigerant to system.

This valve is equipped with a service port which has a factory installed

valve core. Figure below provides information on how to access and

operate the 2-way angle-type service valve and 2-way shut-off valve.

After the piping has been connected to the indoor unit, perform the air

purge.

16 Johnson Controls Unitary Products

Page 17

898841-UIM-B-0113

SUCTION/VAPOR

2-WAY SERVICE VALVE

HOSE WITH

SCHRADER VALVE

PUSH

REQUIRES FIELD PROVIDED 5/16” FEMALE

FLARE TO 1/4” MALE FLAREADAPTER.

VALVE CAP

OPEN POSITION

CLOSED POSITION

SCHRADER CORE

FLARE CAP

TO LINE SET

SERVICE

PORT CAP

SERVICE

PORT

TO OUTDOOR UNIT

FLARE CAP

ALLEN WRENCH (5MM)

OPEN POSITION

CLOSED POISTION

TO OUTDOOR UNIT

TO LINE SET

CLOSED

FULLY

OPEN

FULLY

OPEN

COMPOUND

PRESSURE

GAUGE

PRESSURE GAUGE

-101kPa

(-76cmHg)

HANDLE LOW

MANIFOLD VALVE

HANDLE HIGH

(KEEP FULL

CLOSED)

CHARGE HOSE

CHARGE HOSE

CONNECTING

PIPE

PACKED VALVE

AT LIQUID SIDE

VACUUM PUMP

ADAPTER FOR

COUNTER-FLOW

PREVENTION

PACKED VALVE AT GAS SIDE

SERVICE PORT

SCHRADER CORE

VACUUM

PUMP

Action

Evacuating with a

vacuum pump

Outdoor unit running

Checking pressure

and adding refrigerant

FIGURE 38: Service Valve Operation

LEAK TEST AND EVACUATION

Air and moisture remaining in the refrigerant system will have undesirable effects as indicated below:

1. Pressure in the system rises.

2. Operating current rises.

3. Cooling or heating efficiency drops.

4. Moisture in the refrigerant circuit may freeze and block capillary

tubing (30 kBtu size only).

5. Water may lead to corrosion of parts in the refrigeration system.

The line set between the indoor and outdoor units must be leak tested

and evacuated to remove any non-condensable and moisture from the

system.

AIR PURGING WITH VACCUM PUMP

Be sure to use a vacuum pump with counter-flow prevention function to

make oil inside the pump does not flow back into the system pipes

when the pump stops.

1. Run the vacuum pump.

2. Connect the charge hose from the manifold valve to the service port

of the gas side packed valve.

3. Connect the charge hose to the port of the vacuum pump.

4. Open fully the low pressure side handle of the gauge manifold

valve.

5. Operate the vacuum pump to begin evacuating.

6. The operation time for evacuation varies with the lineset length and

capacity of the pump. Allow the pumpto operate until the system

has been evacuated downto 300 microns. Allow the pump to continue running foran additional 15 minutes.

7. Turn off the pump and leave the connection secured to the suction/

vapor 2-way service port. After five minutes, if the system fails to

hold 500 microns or less, check all connections for tight fit and

repeat the evacuation procedure.

8. Close the low pressure valve handle of gauge manifold.

9. Open fully the valve stem of the packed valves (both gas and liquid

10. Remove the charging hose from the service port.

11. Securely tighten the caps on the packed valves.

sides).

Johnson Controls Unitary Products 17

Shut-off

2-way Valve

Suction/Vapor

2-way Service Valve

FIGURE 39: Gauge Set Connections for Test Leaks, Evacuation

Charging

ADDING REFRIGERANT FOR LONGER LINE SET

1. Open the low side manifold gauge valve and weigh in liquid refrigerant. Use Table 6 to calculate the correct weigh-in charge.

2. Close manifold gauge valves.

LEAK TEST

Use the following procedure to test for system leaks:

1. Connect the manifold gauge set and dry nitrogen gas cylinder to the

suction/vapor service port. See Figure 30.

2. Open valve on nitrogen cylinder.

3. Pressurize the system to no more than 150 PSIG with dry nitrogen.

4. Check for leaks using soapy water.

5. After the system is found to be free of leaks:

• Close valve on nitrogen cylinder

• Relieve the nitrogen pressure by: loosening the charge hose con-

nector at the nitrogen cylinder.

• When the system pressure is reduced to normal, disconnect the

hose from the cylinder.

Page 18

898841-UIM-B-0113

CHECK PLACES FOR

FLARE NUT CONNECTIONS

(INDOOR UNIT)

CHECK PLACES

FOR OUTDOOR UNIT

NOTICE

MANUAL SWITCH

AUTO/STOP

CODE SWITCH

AUTO

TEST

RUN

STOP

NOTICE

FIGURE 40: Leak Test Line Set Connection

SECTION XVIII: TEST OPERATION

1. Check that all tubing and wiring have been properly connected.

2. Check that the gas and liquid side service valves are fully open.

GAS LEAK TEST

Check the flare nut connections for gas leaks with a gas leak detector

and/or soapy water.

RUNNING TEST

1. Turn power on by pressing "ON/OFF" button on the wireless remote

control to start system operation.

2. Press MODE button to select COOL, HEAT or FAN to check the

system operation.

INDOOR UNIT RUNNING TEST

1. Check if operation of each button on the remote control is working

normally and check the corresponding operating indication LED on

the indoor unit to make sure they match.

2. Check the operation of indoor unit louver and make you check its

swinging function.

3. Check the condensate drain and make sure there are no leaks.

OUTDOOR UNIT RUNNING TEST

1. Make sure there are no abnormal noises or vibration during operation.

2. Make sure you check for gas leaks.

SECTION XIX: EMERGENCY OPERATION

If the wireless remote is lost or damaged, the system can be operated

using the manual switch or code switch. The system will run in Auto

Run mode, and will not change the temperature setting nor the fan

speed.

The manual switch can be operated as follows:

• To operate the unit, press the AUTO/STOP button once and the

unit will enter into AUTO RUN mode. The microcomputer will

select the (COOL, HEAT, FAN) mode automatically to maintain

optimum room comfort.

• To stop the unit from operating, press the AUTO/STOP button

once and the unit will shut down.

The code switch can be operated as follows:

• To operate the unit, adjust the code switch to the AUTO position

and the unit will enter into AUTO RUN mode. The microcomputer

will select the (COOL, HEAT, FAN) mode automatically to maintain optimum room comfort.

• To stop the unit from operating, adjust the code switch to the

STOP position and the unit will shut down.

The TEST button is for the technicians' testing, which should not be

used by our user.

18 Johnson Controls Unitary Products

FIGURE 41: Emergency Operation

SECTION XX: MAINTENANCE

OUTDOOR UNIT

1. Ensure power is off before cleaning.

2. It may be necessary to wash the outdoor coil more frequently if it is

exposed to substances which are corrosive or which block airflow

across the coil (e.g., pet urine, cottonwood seeds, fertilizers, fluids

that may contain high levels of corrosive chemicals such as salts).

3. Outdoor Coil (Sea Coast) - Moist air in ocean locations can carry

salt, which is corrosive to most metal. Units that are located near

the ocean require frequent inspections and maintenance. These

inspections will determine the need to wash the unit including the

outdoor coil. Consult your installing contractor for proper intervals/

procedures for your geographic area or service contract.

4. Outdoor unit fan motor is pre-lubricated and sealed. No further

lubrication is needed.

5. Visually inspect all connecting lines, joints and coils for evidence of

oil leaks.

6. Check all wiring for loose connections.

7. Check for correct voltage at unit (unit operating).

INDOOR UNIT

1. Clean or change filters.

2. Check all wiring for loose connections.

3. Check for correct voltage at unit (blower operating).

4. Clean coil, if necessary.

5. Check connecting lines and coils for signs of oil leaks.

6. Check condensate line and clean, if necessary.

The filter must be in place and the front panel must be closed any

time the unit is in operation.

SECTION XXI: INSTALLATION AND

MAINTENANCE OF HEALTHY FILTER

(ACCESSORY)

INSTALLATION OF HEALTHY FILTER (ACCESSORY)

1. Lift up the front panel from its two ends and remove the factory supplied air filter as shown in Fig. A.

2. Attach the healthy filter to the air filter as shown below in Fig. B.

3. Install the air filter properly as shown below in Fig. C and then close

the panel.

Page 19

FIGURE 42: Filter Replacement

AIR FILTER

HEALTHY FILTER

Fig. A

Fig. B

Fig. C

898841-UIM-B-0113

CLEANING AND MAINTENANCE

1. Remove the healthy filter and clean thoroughly. Make sure you

don't use a brush or any hard objects to clean the filter.

2. Make sure you dry the air filter before reinstalling it.

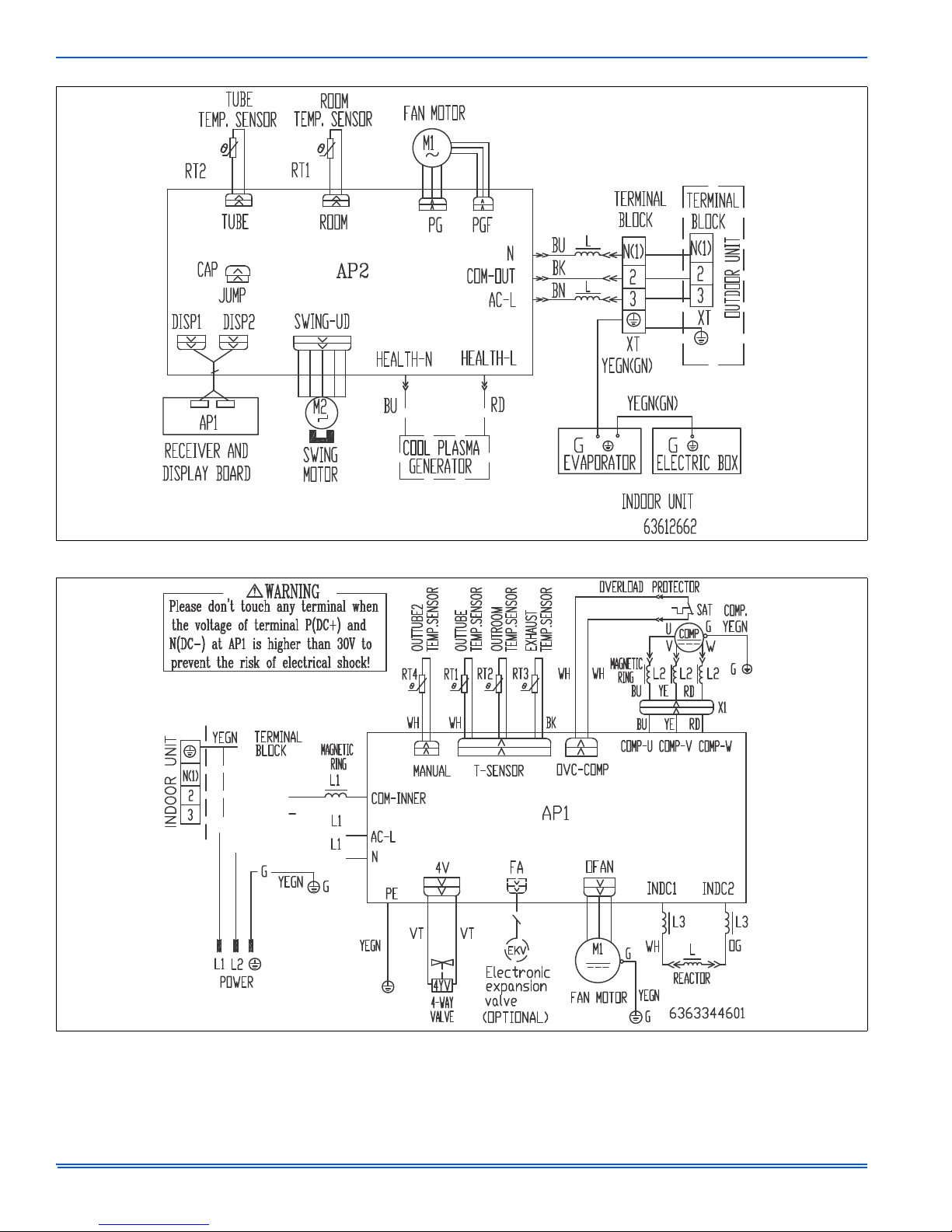

SECTION XXII: TYPICAL UNIT WIRING

DIAGRAM

The indoor unit wiring diagram is located on the inside of the cabinet by

the terminal block. It is necessary to remove the front panel from the

unit to see the diagram. The outdoor unit wiring diagram is located on

the underside of the outdoor unit control access cover.

FIGURE 43: 09K & 12K 115V Outdoor Air Conditioners

Johnson Controls Unitary Products 19

Page 20

898841-UIM-B-0113

FIGURE 44: 09K & 12K Outdoor Air Conditioners

FIGURE 45: 18K & 24K 115V Indoor Air Conditioners

20 Johnson Controls Unitary Products

Page 21

898841-UIM-B-0113

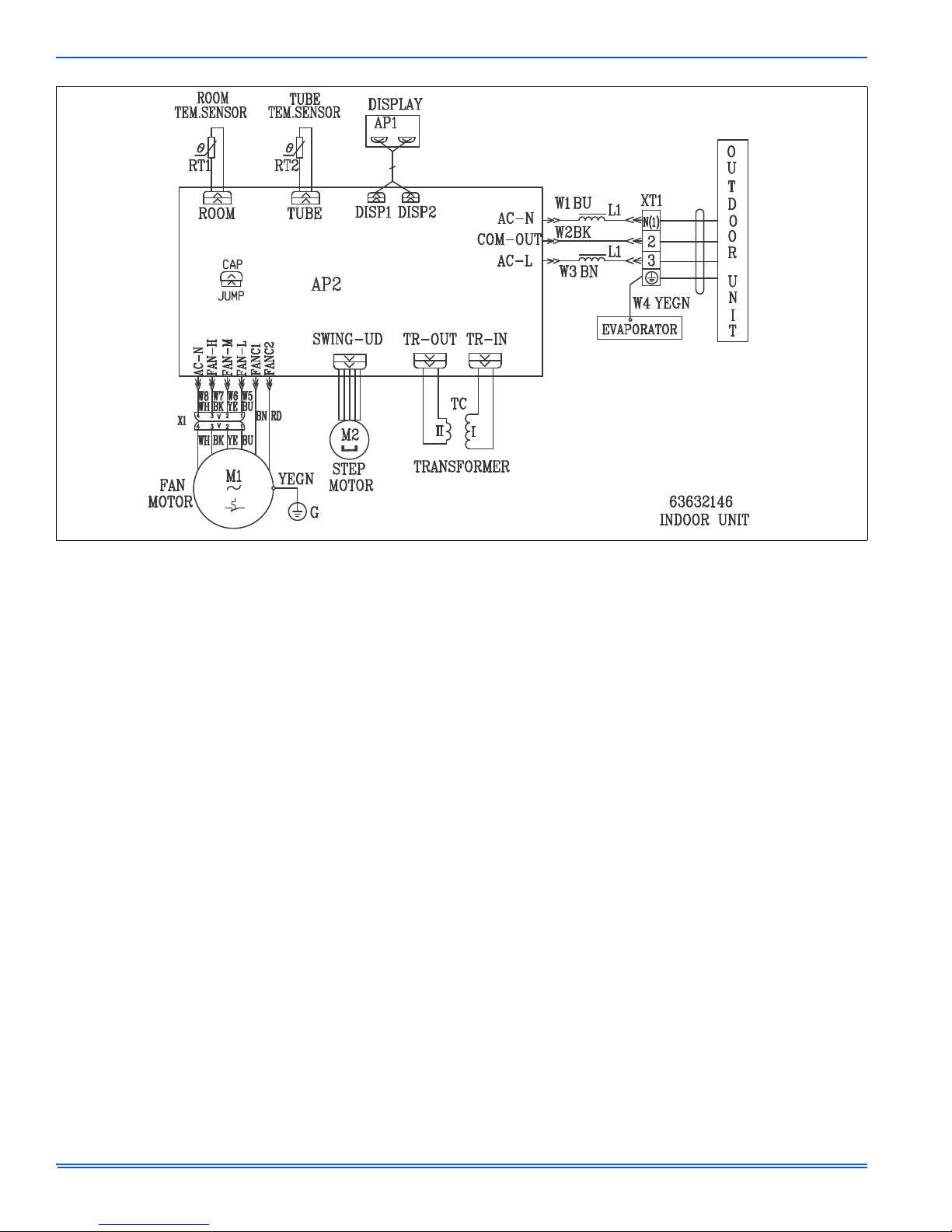

FIGURE 46: 18K & 24K Indoor Air Conditioners

FIGURE 47: 18K Outdoor Air Conditioners

Johnson Controls Unitary Products 21

Page 22

898841-UIM-B-0113

FIGURE 48: 18K Indoor Air Conditioners

FIGURE 49: 24K Outdoor Air Conditioners

22 Johnson Controls Unitary Products

Page 23

898841-UIM-B-0113

FIGURE 50: 24K Indoor Air Conditioners

FIGURE 51: 36K Outdoor Air Conditioners

Johnson Controls Unitary Products 23

Page 24

898841-UIM-B-0113

FIGURE 52: 36K Indoor Air Conditioners

FIGURE 53: 09K & 12K 115V Outdoor Heat Pumps

24 Johnson Controls Unitary Products

Page 25

898841-UIM-B-0113

FIGURE 54: 09K & 12K Outdoor Heat Pumps

FIGURE 55: 18K & 24K 115V Heat Pumps

Johnson Controls Unitary Products 25

Page 26

898841-UIM-B-0113

FIGURE 56: 18K & 24K Indoor Heat Pumps

FIGURE 57: 18K Outdoor Heat Pumps

26 Johnson Controls Unitary Products

Page 27

898841-UIM-B-0113

FIGURE 58: 18K Indoor Heat Pumps

FIGURE 59: 24K Outdoor Heat Pumps

Johnson Controls Unitary Products 27

Page 28

898841-UIM-B-0113

FIGURE 60: 24K Indoor Heat Pumps

FIGURE 61: 30K Outdoor Heat Pumps

28 Johnson Controls Unitary Products

Page 29

898841-UIM-B-0113

FIGURE 62: 30K Indoor Heat Pumps

FIGURE 63: 36K Outdoor Heat Pumps

Johnson Controls Unitary Products 29

Page 30

898841-UIM-B-0113

FIGURE 64: 36K Indoor Heat Pumps

30 Johnson Controls Unitary Products

Page 31

898841-UIM-B-0113

72

HEAT INDICATOR

COOL INDICATOR

TEMPERATURE*

RUN

DEHUMIDIFY

MODE

INFRARED

SIGNAL

RECEIVER

* The temperature readout (either

temperature setpoint or indoor ambient)

will be replaced by an error code if there

is a malfunction. If multiple errors are

detected, the display will alternate

between each error code.

NOTE:

No history is kept on past error codes.

YELLOW LED

GREEN LED

RED LED

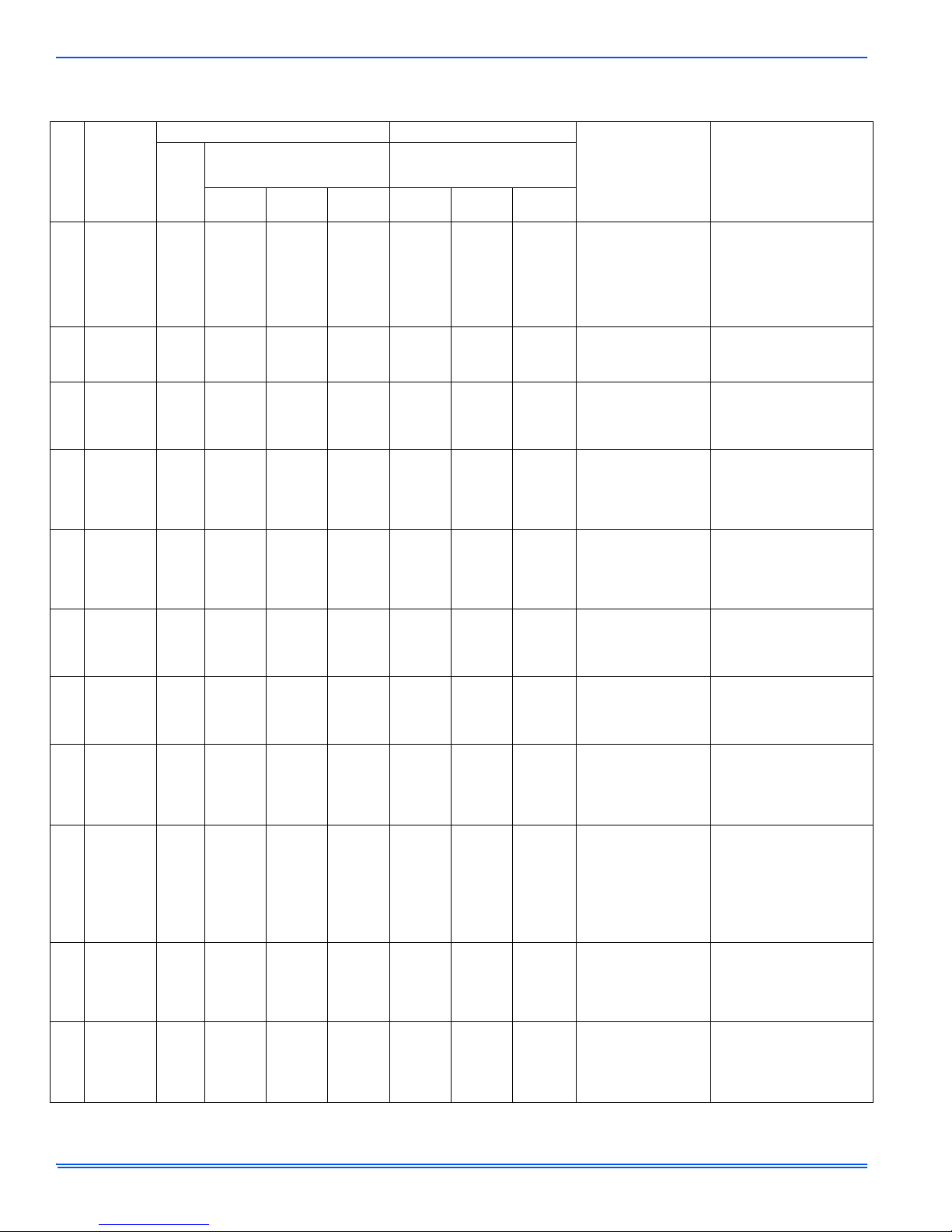

SECTION XXIII: INDOOR AND OUTDOOR UNITS ERROR CODES

This section identifies error codes that appear on the front panel of the indoor unit or outdoor unit control. Many of the error codes w ill automatically

clear themselves when the error no longer exists. However some error codes may require disconnecting power to the system at the unit disconnect

switch or circuit breaker in order to clear them and to resume normal system operation.

FIGURE 65: Indoor Unit Front Panel Indicators

FIGURE 66: Control Board

Johnson Controls Unitary Products 31

Page 32

898841-UIM-B-0113

INDOOR UNIT ERROR CODES

TABLE 12:

No.

1

2

3

4

5

6

7

8

9

10

11

Error Codes - 09K 12K

Malfunction

Name

High

pressure

protection of

system

Antifreezing

protection

System block

or refrigerant

leakage

High

discharge

temperature

protection of

compressor

Overcurrent

protection

Communi-

cation

Malfunction

High

temperature

resistant

protection

EEPROM

malfunction

Limit/

decrease

frequency

due to high

temperature

of module

Malfunction

protection of

jumper cap

Gathering

refrigerant

Dual 8

Code

Display

Display Method of Indoor Unit Malfunction

Indicator Display

ON 0.5s and OFF 0.5s)

Operation

Indicator

OFF 3s

E1

and blink

once

OFF 3S

E2

and blink

twice

OFF 3S

E3

and blink

3 times

OFF 3S

E4

and blink

4 times

OFF 3S

E5

and blink

5 times

OFF 3S

E6

and blink

6 times

OFF 3S

E8

and blink

8 times

EE

EU

OFF 3S

C5

and blink

15 times

OFF 3S

F0

and blink

1 times

(during blinking,

Cool

Indicator

OFF 3S

and blink

6 times

OFF 3S

and blink

1 times

Heating

Indicator

OFF 3S

and blink

15 times

OFF 3S

and blink

6 times

Indicator has 3 kinds of display

status and during blinking, ON 0.5s

Indicator

OFF 3S

and blink

OFF 3S

and blink

OFF 3S

and blink

OFF 3S

and blink

OFF 3S

and blink

11 times

Yellow

3 times

7 times

5 times

6 times

and OFF 0.5s

Red

Indicator

OFF3S

and blink

9 times

Green

Indicator

OFF

A/C Status Possible Causes

During cooling and drying

operation, except indoor

fan operates, all loads

stop operation. During

heating operation, the

complete unit stops.

During cooling and drying

operation, compressor

and outdoor fan stop while

indoor fan operates.

The Dual-8 Code Display

will show E3 until the low

pressure switch stop

operation.

During cooling and drying

operation, compressor

and outdoor fan stop while

indoor fan operates.

During heating operation,

all loads stop.

During cooling and drying

operation, compressor

and outdoor fan stop while

indoor fan operates.

During heating operation,

all loads stop.

During cooling operation,

compressor stops while

indoor fan motor operates.

During heating operation,

the complete unit stops.

During cooling operation:

compressor will stop while

indoor fan will operate.

During heating operation,

the complete unit stops.

During cooling and drying

operation, compressor will

stop while indoor fan will

operate; During heating

operation, the complete

unit will stop.

All loads operate normally,