Page 1

!

!

CSD Series Current Devices—Split Core

24- 10345- 34, Rev. E

Installation Instructions

CSD-CF0A0-1

CSD-CF0J0-1

CSD-CA1G0-1

Refer to the QuickLIT website for the most up-to-date version of this document.

Part No. 24-10345-34, Rev. E

Issued March 2016

Applications

The Current Switch Device (CSD) Series of digital

output switches are nonintrusive devices designed to

detect current flowing through a cable or wire. A cost

effective solution for monitoring on and off status or

proof of operation, these units are ideal for monitoring

small current loads on motors driving fans and blowers,

heating coils, and lighting.

These units provide a universal solid state output and

do not require a power supply. Completely

self-powered, these units draw their po wer from current

induced from the monitored cable or line.

IMPORTANT: The Current Switch Device (CSD)

Series Current Devices are intended to provide an

input to equipment under normal operating

conditions. Where failure or malfunction of the CSD

could lead to personal injury or property damage to

the controlled equipment or other pr op er ty,

additional precautions must be designed into the

control system. Incorporate and maintain other

devices, such as supervisory or alarm systems or

safety or limit controls, intended to warn of or protect

against failure or malfunction of the CSD.

IMPORTANT : Le Current Switch Device (CSD)

Series Current Devices est destiné à transmettre

des données entrantes à un équipement dans des

conditions normales de fonctionnement. Lorsqu'une

défaillance ou un dysfonctionnement du CSD risque

de provoquer des blessures ou d'endommager

l'équipement contrôlé ou un autre équipement, la

conception du système de contrôle doit intégrer des

dispositifs de protection supplémentaires. Veiller

dans ce cas à intégrer de façon permanente

d'autres dispositifs, tels que des systèmes de

supervision ou d'alarme, ou des dispositifs de

sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de

défaillance ou de dysfonctionnement du CSD.

IMPORTANT: Install the CSD Series Current

Devices only on the input side of a variable speed

drive. Otherwise excessive wear may occur on the

controlled equipment, as well as premature failure of

the CSD Series Current Devices.

Installation

WARNING: Risk of Electric Shock.

Disconnect the power supply before

making electrical connections. Contact with

components carrying hazardous voltage

can cause electric shock and may result in

severe personal injury or death.

AVERTISSEMENT : Risque de

décharge électrique.

Débrancher l'alimentation avant de réaliser

tout branchement électrique. T out cont act

avec des composants conducteurs de

tensions dangereuses risque d'entraîner

une décharge électrique et de provoquer

des blessures graves, voire mortelles.

WARNING: Risk of Personal Injury.

Do not touch the relay while power is

applied to the relay. The relay surface is

hot during use, and may cause a serious

burn upon contact.

AVERTISSEMENT : Risque de

blessure.

Ne pas toucher le relais lorsque le relais

est sous tension. La surface du relais

devient extrêmement chaude durant son

utilisation et risque de provoquer des

brûlures graves en cas de contact.

CSD Series Current Devices—Split Core Installation Instructions 1

Page 2

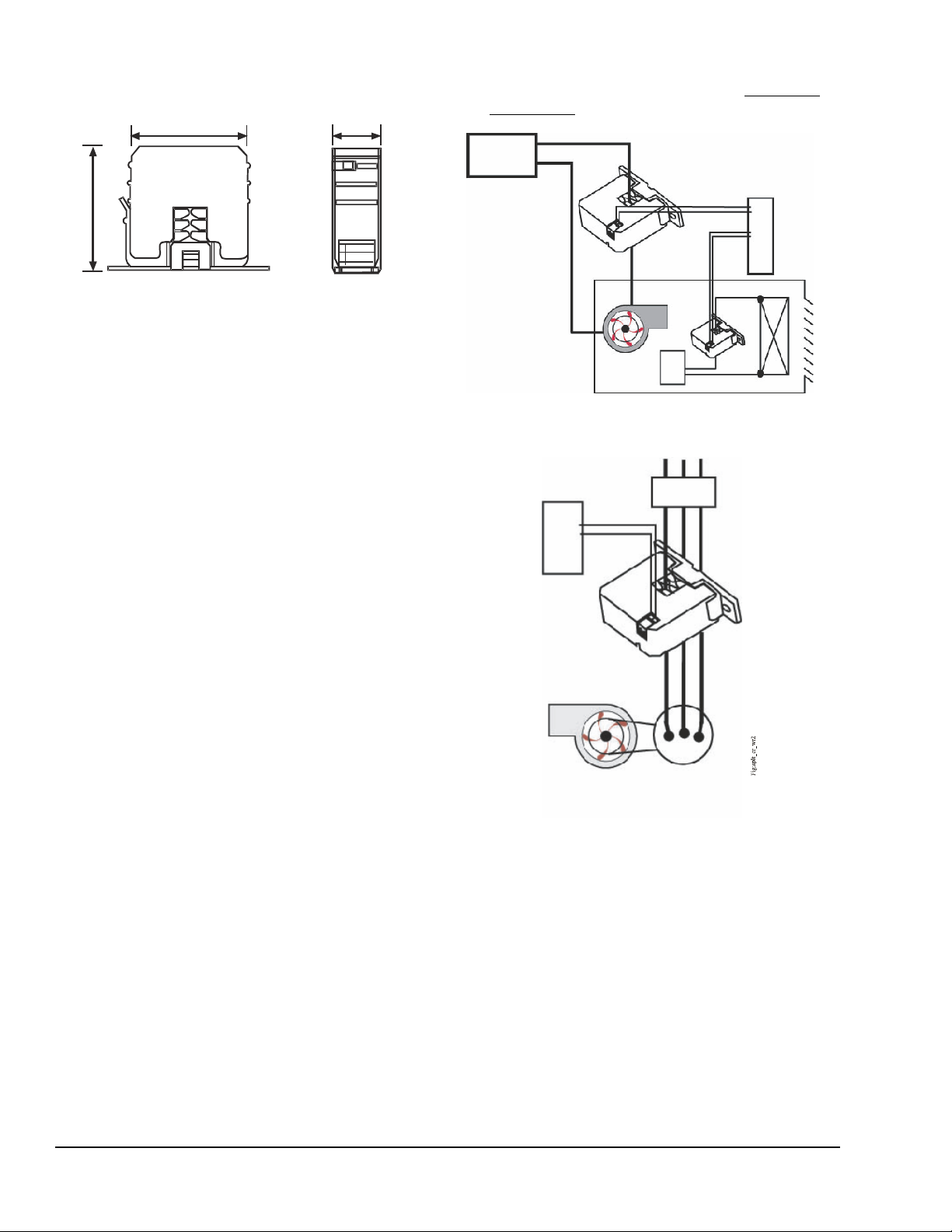

Dimensions

Figure 1: CSD Dimensions, mm (in.)

27 (1-1/16)

Fig:sc_sde

65 (2-9/16)

69 (2-23/32)

Fig:splt_cre_frnt

Figure 2: Model CSD-CF0A0-1/CSD-CF0J0-1

Power

Source

Building Automation

Controller

Heating Element

Fan or Pump

DI

DI

Power

Source

F

I

g

:

s

c

_

w

r

e

Figure 3: Model CSD-CA1G0-1

Contactor

DI

Motor

Fan or Pump

Mounting

1. Using the two screws (included), attach the

mounting bracket to the back of the electrical

enclosure.

2. Snap the CSD into place on the mounting bracket.

Wiring

1. Disconnect power to the conductor cable from the

power source.

2. Snap the split core around the power conductor

cable, and close the core until the core snaps shut.

Note: The switch contacts are solid state and they

work just like dry contacts. When the switch is closed,

less than 1 ohm is present; when the switch is open,

more than 1 megohm is present.

5. Calibrate Model CSD-CA1G0-1 (see Setup and

Adjustments).

3. Wire CSD output terminals to the control box

Digital Input (DI) terminal (30 V maximum terminal

voltage).

4. Reconnect the power conductor cable. (For wiring

example, see Figure 2 and Figure 3.)

If the measured current is too low to be detected or

is higher than the maximum current rating of the

CSD, use the following methods to increase or

decrease current.

CSD Series Current Devices—Split Core Installation Instructions2

Page 3

If Measured Current Is Too Low to Be Dete cted

Figure 4: CSD Shown with Four Turns

Figure 5: CSD with CT Transformer

F

i

g

:

s

p

c

_

w

c

t

Figure 6: Status Open, LED On

Status

Status

Open Setpoint

Closed

F

i

g

:

s

c

_

s

t

a

t

_

o

p

n

Figure 7: Status Open, LED Off

Status

Status

Open Setpoint

Closed

F

i

g

:

s

c

_

s

t

a

t

_

c

l

s

d

Wrap the conductor (wire) through the sensing hole

and around the CSD body to produce multiple turns to

increase the measured current.

Measured current = actual current times the number of

turns (see Figure 4).

s

n

r

t

_

c

s

:

g

i

F

IMPORTANT: Failure to derate the current cap acity

could result in damage to the CSD when using

multiple turns to increase measured current. Use the

the following formula to determine the new

maximum current:

New Maximum Current = CSD Current Rating/

number of turns. For example,

Model CSD-CA1G0-1 with 4 turns = 135 A/4 = 33.8,

new maximum current.

Setup and Adjustments

Calibration

Position the CSD so the status output panel faces you.

Confirm the monitored load (for example, a motor or

heater) is running, and use the following methods to

calibrate the CSD.

Under Current Status Condition (Belt Loss, Coupling Shear, Fan, and Pump Status)

1. Turn the setpoint screw clockwise until the Status

Closed Light-Emitting Diode (LED) turns off and

the Status Open LED turns on.

2. Slowly turn the setpoint screw counterclockwise

until the Status Closed LED turns on and the

Status Open LED turns off.

To Monitor Currents Exceeding the Maximum Current Rating of the CSD

For currents > 135 A (Model CSD-CA1G0-1), > 200 A

(Model CSD-CF0A0-1 or Model CSD-CF0J0-1).

Use a 5 A Current Transformer (CT) to reduce the

current passing through the CSD as shown in Figure 5.

Run the current transformer secondary wire through

the sensing hole. Terminate th e two secondary wires of

the 5 A current transformer to each other, and then

install the 5 A current transformer on the monitored

conductor.

Current > 135 A

3. Turn the setpoint screw an ad ditional 1/4 turn

counterclockwise to create a deadband to prevent

hunting.

The CSD is now calibrated to signal current flows

below normal full load amperes.

Output Status:

• Normal: Output Closed

• Alarm: Output Open

Over Current Status Condition (Locked Rotor, Seized Impeller)

1. Turn the setpoint screw counterclockwise until the

Status Open LED turns off and the Status Closed

LED turns on.

CSD Series Current Devices—Split Core Installation Instructions 3

Page 4

Note: This is the default factory setting.

Figure 8: Status Closed, LED On

Status

Status

Open Setpoint

Closed

F

i

g

:

s

c

_

s

t

a

t

_

c

l

s

d

Figure 9: Status Ope n, LED On

Status

Status

Open Setpoint

Closed

F

i

g

:

s

c

_

s

t

a

t

_

o

p

n

2. Slowly turn the setpoint screw clockwise until the

Status Closed LED turns off and the Status Open

LED turns on.

3. Turn the setpoint screw an additional 1/4 turn

clockwise to create a deadband to prevent hunting.

The CSD is now calibrated to signal current flows

above normal load amperes.

Output Status:

• Normal: Output Open

• Alarm: Output Closed

Accessories

See Table 1 for acce sso ries .

Table 1: CR-01200-0 and CR-02400-0 Command

Relays

Product Code Product Description

CR-01200-0 12 VAC/VDC Single-Pole,

Single-Throw (SPST), Normally

Open (N.O.) Relay

CR-02400-0 24 VAC/VDC Single-Pole,

Single-Throw (SPST), N.O. Relay

Repair Information

If the CSD Series Current Device fails to operate within

its specifications, replace the unit. For a replacement

CSD, contact the nearest Johnson Controls®

representative.

Troubleshooting

Table 2: Troubleshooting

Symptom Action

CSD solid state output does

not function.

Setpoint screw keeps

turning.

Motor is turned on and switch

does not close.

Verify the maximum amperage range has not been exceeded. Voltages or currents above

the rated levels may damage the CSD.

The setpoint screw has a slip clutch to prevent damage at either end. To return the LED to

its original setting, turn the setpoint screw 20 full turns counterclockwise and start the

calibration procedure again.

Insufficient current to the load leads (for example, a motor or heater) to reach the setpoint

threshold. To turn the switch on, wrap the cable multiple times through the sensing hole

(see Figure 4).

CSD Series Current Devices—Split Core Installation Instructions4

Page 5

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2016 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Technical Specifications

Split Core Models CSD-CF0A0-1, CSD-CFOJO-1, and CSD-CA1G0-1

Product Code CSD-CF0A0-1 CSD-CF0J0-1 CSD-CA1G0-1

Amperage Range 0.15–200 A 1.5–200 A 1.25–135 A

Switch Setpoint Fixed Fixed Adjustable

Output Relay No

Actuation Coil No

Switch LED Indication No No Yes

Relay LED Indication No

Trip Setpoint Value 0.15 A 1.5 A 1.25-135 A

Current Switching Mode Under Current Sensing Under Current Sensing Over/Under Current

Sensor Supply Voltage Induced from power conductor cable.

Wire Size 2.1–0.6 mm (12–22 AWG) Diameter Recommended

Status Output Switch Normally Open.

Switch Load Capacity 1 A at 30 VAC/42 VDC Maximum

Isolation Voltage 600 VAC rms

Temperature Range -15 to 60°C (5 to 140°F)

Frequency Range 50/60 Hz

Humidity Range 0–95% Noncondensing

Screw Torque 0.5 N·m (4 lb·in.)

Dimension 69 x 65 x 27 mm (2-23/32 x 2-9/16 x 1-1/16 in.)

Aperture (Sensing Hole) Size 18 x 20 mm Diameter (0.72 x 0.78 in. Diameter)

Compliance United States UL Listed, File E310692, CCN NRNT, Under UL 508, Industrial Control Equipment

Canada UL Listed, File E310692, CCN NRNT7, Under CAN/CSA C22.2 No. 14-M91

Industrial Control Equipment

Europe CE Mark – Johnson Controls, Inc., declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive and the Low

Voltage Directive.

Shipping Weight 0.16 kg (0.35 lb)

The performance specifications are nominal and conform to acceptable industry standards. For application of conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

Sensing

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

Published in U.S.A. www.johnsoncontrols.com

JOHNSON CONTROLS

507 E MICHIGAN ST

MIL WAUKEE WI 53202

USA

CSD Series Current Devices—Split Core Installation Instructions 5

JOHNSON CONTROLS

C/O CONTROLS PRODUCT

MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

Loading...

Loading...