Page 1

INSTALLATION MANUAL

R-22

OUTDOOR SPLIT-SYSTEM

AIR CONDITIONING

MODELS: 13 SEER

AY018-030 SERIES

1.5 TO 2.5 TONS

LIST OF SECTIONS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ORIFICE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LIST OF FIGURES

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Oil Trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation of Vapor Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Underground Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Heat Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Orifice Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LIST OF TABLES

Application Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 R-22 Saturated Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATIONS REQUIRING AN ADD-ON TXV KIT . . . . . . . . . . . .5

EVACUATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SYSTEM CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Outdoor Unit Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Typical Field Wiring (Air Handler / Electrical Heat) . . . . . . . . . . . . . . . .6

Thermostat Chart - Single Stage AC with PSC Air Handler . . . . . . . . .7

Thermostat Chart - Single Stage AC with PSC Air Handler . . . . . . . . .8

Thermostat Chart - Single Stage AC with PSC Furnace . . . . . . . . . . .9

Thermostat Chart - Single Stage AC with PSC Furnace . . . . . . . . . .10

LISTED

ISO 9001

Certified Quality

Management System

SECTION I: GENERAL

The outdoor units are designed to be connected to a matching indoor

coil with sweat connect lines. Sweat connect units are factory charged

with refrigerant for a matching indoor coil plus 15 feet of field supplied

lines.

The refrigerant charge may need to be changed for some indoor-outdoor unit combinations, elevation differences or total line lengths. Refer

to Application Data covering “General Piping Recommendations and

Refrigerant Line Length” (Part Number 036-61920-001).

SECTION II: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words DANGER,

WARNING , or CAUTION.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury

WARNING indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury

CAUTION indicates a potentially hazardous situation, which, if not

avoided may resul t in minor or moderate injury

alert against unsafe practices and hazards involving only property damage.

Improper installation may create a condition where the operation of

the product could cause personal injury or property damage.

Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual

for assistance or for additional information, consult a qualified contractor, installer or service agency.

.

.

. It is also used to

This product must be installed in strict compliance with the

enclosed installation instructions and any applicable local, state,

and national codes including, but not limited to building, electrical,

and mechanical codes.

INSPECTION

As soon as a unit is received, it should be inspected for possib le damage during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s delivery receipt. A separate request for

inspection by the carrier’s agent should be made in writing. See Local

Distributor for more information.

LIMITATIONS

The unit should be installed in accordance with all National, State and

Local Safety Codes and the limitations listed below:

1. Limitations for the indoor unit, coil, and appropriate accessories

must also be observed.

2. The outdoor unit must not be installed with any duct work in the air

stream. The outdoor fan is the propeller type and is not designed

to operate against any additional external static pressure.

3. The maximum and minimum conditions for operation must be

observed to ensure a system that will give maximum performance

with minimum service.

TABLE 1:

4. The unit should not be operated at outdoor temperatures below

Application Limitations

Ambient Air Temperature

on Outdoor Coil

Min. DB Max. DB Min. WB Max. WB

50 °F 115 °F 57 °F 72 °F

50° F without an approved low ambient operation accessory kit

installed.

Air Temperature on

Indoor Coil

347337-UIM-A-0408

Page 2

347337-UIM-A-0408

SECTION III: UNIT INSTALLATION

LOCATION

Before starting the installation, select and check the suitability of the

location for both the indoor and outdoor unit. Observe all limitations and

clearance requirements.

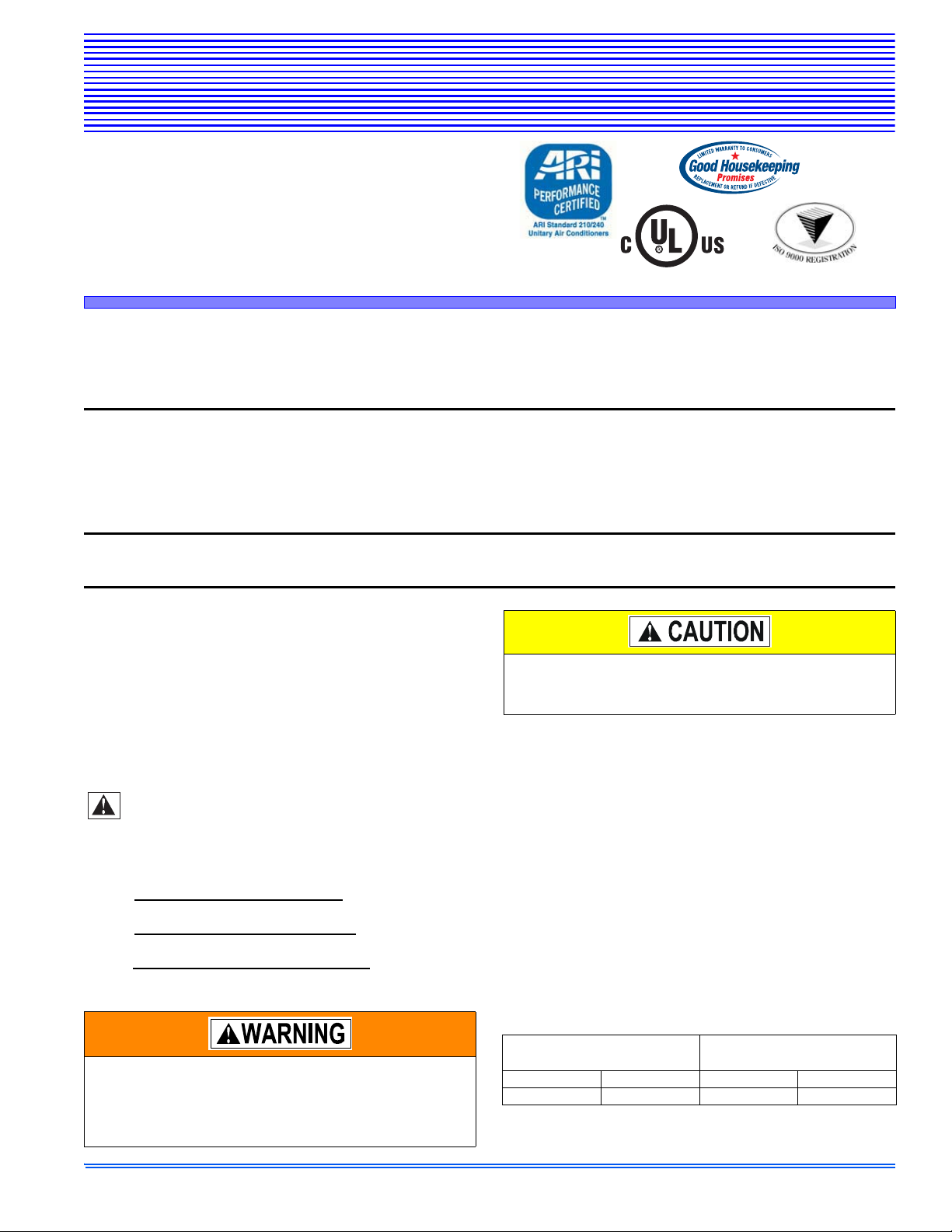

The outdoor unit must have sufficient clearance for air entrance to the

condenser coil, air discharge, and service access. See Figure 1.

NOTE: For multiple unit installations, units must be spaced a minimum

of 18 inches apart (coil face to coil face).

If the unit is to be installed on a hot sun exposed roof or a black-topped

ground area, the unit should be raised sufficiently above the roof or

ground to avoid taking the accumulated layer of hot air into the outdoor

unit.

Provide an adequate structural support.

MINIMUM 24” SERVICE ACCESS

CLEARANCE ON ONE SIDE

48” OVERHEAD

12” CLEARANCE

AROUND PERIMETER

CLEARANCE

WEATHERPROOF

DISCONNECT

SWITCH

ADD-ON REPLACEMENT/RETROFIT

The following steps should be performed in order to insure proper system operation and performance.

1. Change-out the indoor coil, if required, to an approved R-22 coil/

condensing unit combination with the appropriate metering device.

2. If the outdoor unit is being replaced due to a compressor burnout,

then installation of a 100% activated alumina suction-line filter

drier in the suction-line is required, in addition to the factory

installed liquid-line drier. Operate the system for 10 hours. Monitor

the suction drier pressure drop. If the pressure drop exceeds 3

psig, replace both the suction-line and liquid-line driers. After a

total of 10 hours run time where the suction-line pressure drop has

not exceeded 3 psig, replace the liquid line drier, and remove the

suction-line drier. Never leave a suction-line drier in the system

longer than 50 hours of run time.

THERMOSTAT

NEC CLASS 1 WIRING

TO FURNACE OR

AIR HANDLER

TERMINAL BLOCK

NOTE:ALL OUTDOOR WIRING

MUST BE WEATHERPROOF.

CONTROL ACCESS PANEL

FIGURE 1: Typical Installation

GROUND INSTALLA TION

The unit should be installed on a solid base that is 2” above grade and

will not shift or settle, causing strain on the refrigerant lines and possible

leaks. Maintain the clearances shown in Figure 1 and install the unit in a

level position. The base pad should not come in contact with the foundation or side of the structure because sound may be transmitted to the

residence.

The length of the refrigerant tubing between the outdoor unit and indoor

coil should be as short as possible to avoid capacity and efficiency

losses. Excessive spacing of the outdoor unit from the home can result

in the refrigerant lines being restricted by trampling or being punctured

by lawn mowers. Locate the outdoor unit away from bedroom windows

or other rooms where sound might be objectionable.

Adverse effects of snow or sleet accumulating on the outdoor coil can

be eliminated by placing the outdoor unit where the prevailing wind

does not blow across the unit. Trees, shrubs, corners of buildings, and

fences standing off from the coil can reduce capacity loss due to wind

chill effect.

Provide ample clearance from shrubs to allow adequate air to pass

across the outdoor coil without leaves or branches being pulled into the

coil.

NEC CLASS 2 WIRING

TO INDOOR COIL

SEAL OPENING(S) WITH

PERMAGUM OR EQUIVALENT

ROOF INSTALLATION

When installing units on a roof, the structure must be capable of supporting the total weight of the unit, including a pad, lintels, rails, etc.,

which should be used to minimize the transmission of sound or vibration into the conditioned space.

LIQUID LINE FILTER-DRIER

The air conditioning unit’s copper spun filter/dryer is located on the liquid line.

NOTE: Replacements for the liquid line drier must be exactly the same

as marked on the original factory drier. See Source 1 for O.E.M.

replacement driers.

Failure to do so or using a substitute drier or a granular type may

result in damage to the equipment.

R-22

Filter-Drier

Source 1 Part No.

029-22156-000 All Models

Apply with Models

AY

2 Johnson Controls Unitary Products

Page 3

347337-UIM-A-0408

PIPING CONNECTIONS

The outdoor condensing unit must be connected to the indoor evaporator coil using field supplied refrigerant grade (ACR) copper tubing that is

internally clean and dry. Units should be installed only with the tubing

sizes for approved system combinations as specified in tabular data

sheet. The charge given is applicable for total tubing lengths up to 15

feet. See Application Data Part Number 036-61920-000 for installing

tubing of longer lengths and elevation differences.

NOTE: Using a larger than specified line size could result in oil return

problems. Using too small a line will result in loss of capacity

and other problems caused by insufficient refrigerant flow. Slope

horizontal vapor lines at least 1" every 20 feet toward the outdoor unit to facilitate proper oil return.

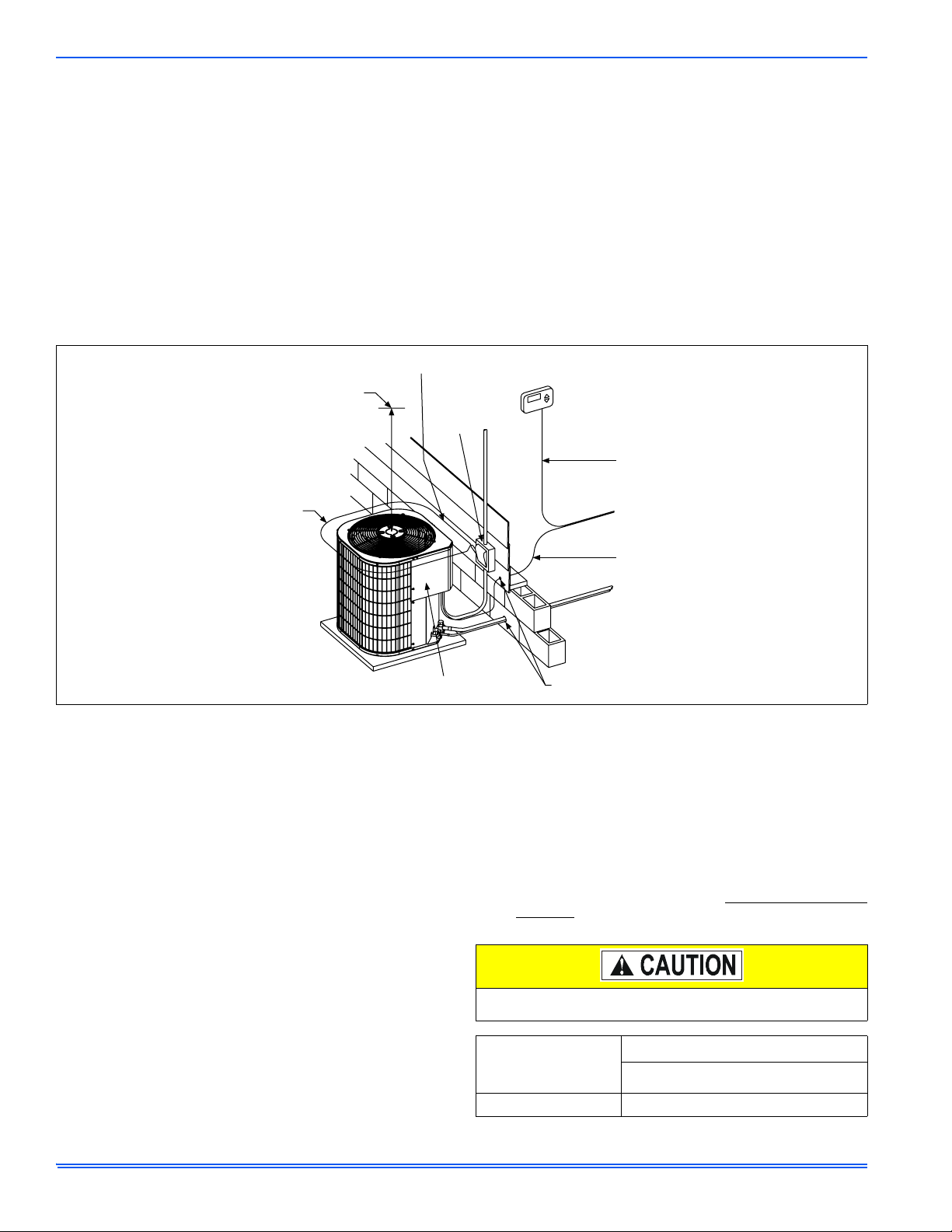

OIL TRAPPING

When the outdoor unit is above the indoor coil, oil trapping is necessary .

An oil trap should be provided for every 20 ft. of rise. See Figure 2.

OUTDOOR COIL

10 In.

20 Ft.

INDOOR

COIL

20 Ft.

6 In.

FIGURE 2: Oil Trap

PRECAUTIONS DURING LINE INSTALLATION

1. Install the lines with as few bends as possible. Care must be taken

not to damage the couplings or kink the tubing. Use clean hard

drawn copper tubing where no appreciable amount of bending

around obstruction is necessary. If soft copper must be used, care

must be taken to avoid sharp bends which may cause a restriction.

2. The lines should be installed so that they will not obstruct service

access to the coil, air handling system, or filter.

3. Care must also be taken to isolate the refrigerant lines to minimize

noise transmission from the equipment to the structure.

4. The vapor line must be insulated with a minimum of 1/2" foam rubber insulation (Armaflex or equivalent). Liquid lines that will be

exposed to direct sunlight, high temperatures, or excessive humidity must also be insulated.

5. Tape and suspend the refrigerant lines as shown. DO NOT allow

tube metal-to-metal contact. See Figure 3.

6. Use PVC piping as a conduit for all underground installations as

shown in Figure 4. Buried lines should be kept as short as possible

to minimize the build up of liquid refrigerant in the vapor line during

long periods of shutdown

7. Pack fiberglass insulation and a sealing material such as permagum around refrigerant lines where they penetrate a wall to reduce

vibration and to retain some flexibility.

8. For systems with total line length exceeding 50 ft., see APPLICATION DATA and worksheet "General Piping Recommendations

and Refrigerant Line Length" for vapor and liquid line sizing, calibration of liquid line pressure loss or gain, determination of vapor

line velocity, elevation limitations, orifice connections, system

charging, traps, etc.

Sheet Metal Hanger

Liquid

Line

Incorrect

Correct

Insulated Vapor Line

Tape

FIGURE 3: Installation of Vapor Line

TO OUTDOOR UNIT

Cap

Liquid Line

PVC

Conduit

TO INDOOR COIL

Insulated

Vapor Line

FIGURE 4: Underground Installation

PRECAUTIONS DURING BRAZING OF LINES

All outdoor unit and evaporator coil connections are copper-to-copper

and should be brazed with a phosphorous-copper alloy material such

as Silfos-5 or equivalent. DO NOT use soft solder. The outdoor units

have reusable service valves on both the liquid and vapor connections.

The total system refrigerant charge is retained within the outdoor unit

during shipping and installation. The reusable service valves are provided to evacuate and charge per this instruction.

Serious service problems can be avoided by taking adequate precautions to assure an internally clean and dry system.

Dry nitrogen should always be supplied through the tubing while it

is being brazed, because the temperature required is high enough

to cause oxidation of the copper unless an inert atmosphere is provided. The flow of dry nitrogen should continue until the joint has

cooled. Always use a pressure regulator and safety valve to insure

that only low pressure dry nitrogen is introduced into the tubing.

Only a small flow is necessary to displace air and prevent oxidation.

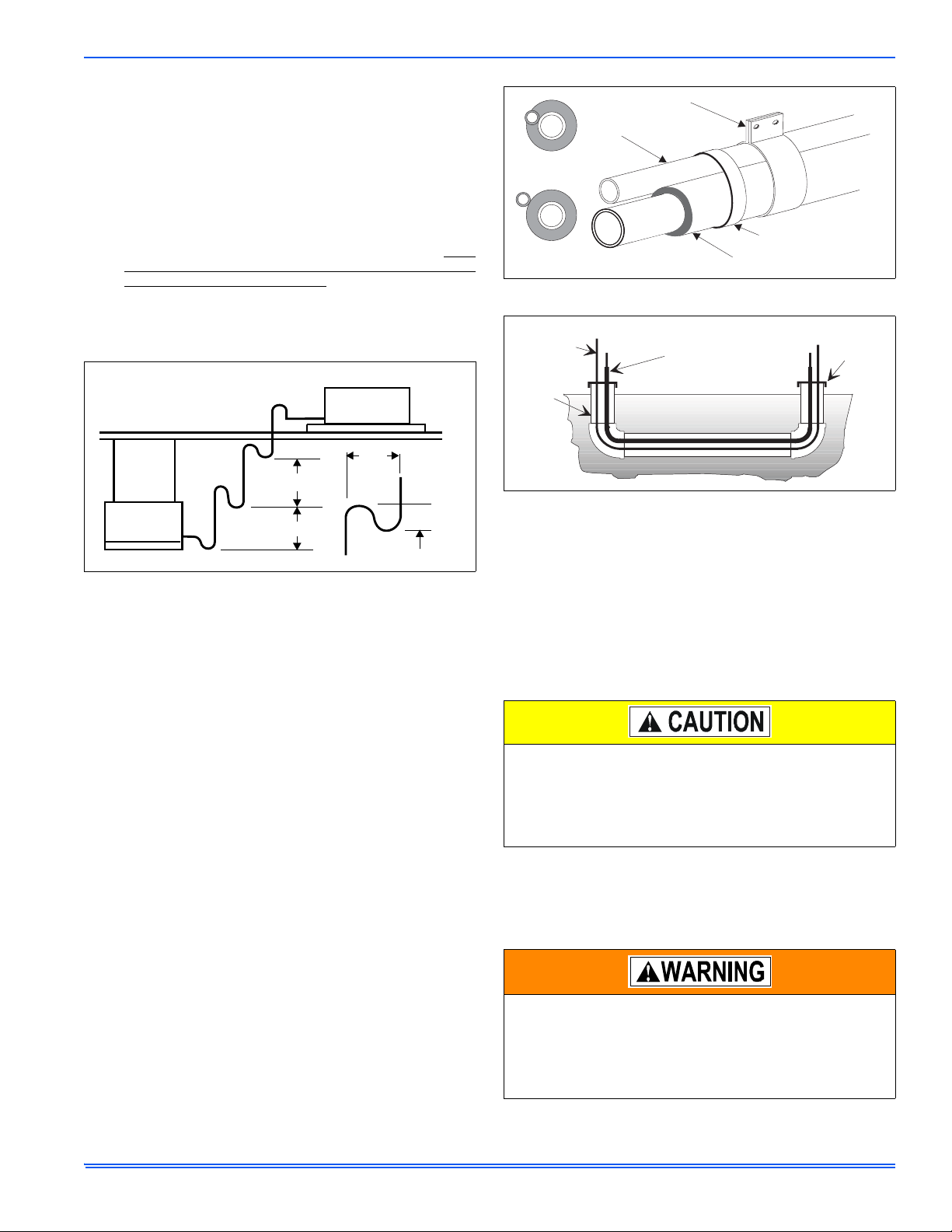

PRECAUTIONS DURING BRAZING SERVICE VALVE

Precautions should be taken to prevent heat damage to service valve

by wrapping a wet rag around it as shown in Figure 5. Also, protect all

painted surfaces, insulation, and plastic base during brazing. After brazing, cool joint with wet rag.

This is not a backseating valve. The service access port has a

valve core. Opening or closing valve does not close service access

port.

If the valve stem is backed out past the chamfered retaining wall,

the O-ring can be damaged causing leakage or system pressure

could force the valve stem out of the valve body possibly causing

personal injury.

Valve can be opened by removing the plunger cap and fully inserting a

hex wrench into the stem and backing out counter-clockwise until valve

stem just touches the chamfered retaining wall.

Johnson Controls Unitary Products 3

Page 4

347337-UIM-A-0408

Connect the refrigerant lines using the following procedure:

1. Remove the cap and Schrader core from both the liquid and vapor

service valve service ports at the outdoor unit. Connect low pressure nitrogen to the liquid line service port.

2. Braze the liquid line to the liquid valve at the outdoor unit. Be sure

to wrap the valve body with a wet rag. Allow the nitrogen to continue flowing.

3. Carefully remove the plugs from the evaporator liquid and vapor

connections at the indoor coil.

FIGURE 5: Heat Protection

Do not install any coil in a furnace which is to be operated during

the heating season without attaching the refrigerant lines to the coil.

The coil is under 30 to 35 psig inert gas pressure which must be

released to prevent excessive pressure build-up and possible coil

damage.

4. Braze the liquid line to the evaporator liquid connection. Nitrogen

should be flowing through the evaporator coil.

5. Slide the grommet away from the vapor connection at the indoor

coil. Braze the vapor line to the evaporator vapor connection. After

the connection has cooled, slide the grommet back into original

position.

6. Protect the vapor valve with a wet rag and braze the vapor line

connection to the outdoor unit. The nitrogen flow should be exiting

the system from the vapor service port connection. After this connection has cooled, remove the nitrogen source from the liquid fitting service port.

7. Replace the Schrader core in the liquid and vapor valves.

8. Go to “SECTION V” or “SECTION IV” for orifice or TXV installation

depending on application.

9. Leak test all refrigerant piping connections including the service

port flare caps to be sure they are leak tight. DO NOT OVERTIGHTEN (between 40 and 60 inch - lbs. maximum).

NOTE: Line set and indoor coil can be pressurized to 250 psig with dry

nitrogen and leak tested with a bubble type leak detector. Then

release the nitrogen charge.

NOTE: Do not use the system refrigerant in the outdoor unit to purge or

leak test.

10. Evacuate the vapor line, evaporator, and liquid line to 500 microns

or less.

11. Replace cap on service ports. Do not remove the flare caps from

the service ports except when necessary for servicing the system.

12. Release the refrigerant charge into the system. Open both the liquid and vapor valves by removing the plunger cap and with an

allen wrench back out counter-clockwise until valve stem just

touches the chamfered retaining wall. See Page 3 "PRECAUTIONS DURING BRAZING SERVICE VALVE".

13. Replace plunger cap finger tight, then tighten an additional 1/12

turn (1/2 hex flat). Cap must be replaced to prevent leaks.

Never attempt to repair any brazed connections while the system is

under pressure. Personal injury could result.

See "System Charge” section for checking and recording system

charge.

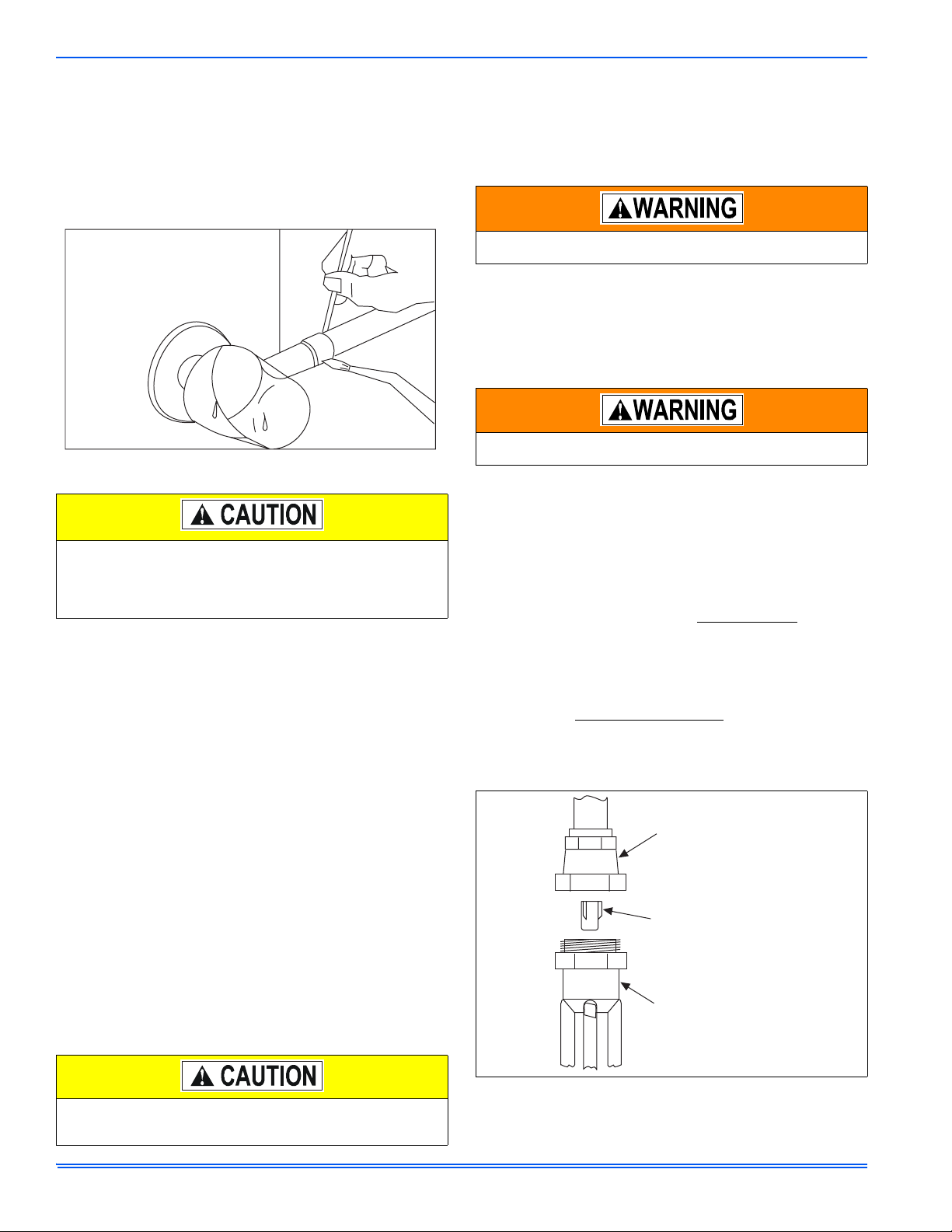

Supplied with the outdoor unit is a Schrader Valve Core and Orifice for

highest sales volume indoor coil. The valve core must be installed in

equalizer fitting of the indoor coil.

SECTION IV: ORIFICE INSTALLATION

Failure to install Schrader Valve Core on orifice applications could

result in total refrigerant loss of the system!

Install Schrader Valve Core as follows:

1. Slide indoor coil out of cabinet far enough to gain access to equalizer fitting on the suction line.

2. After holding charge is completely discharged remove black plastic cap on equalizer fitting.

3. Install Schrader Valve Core supplied with the outdoor unit into

equalizer fitting using a valve core tool.

4. Loosen and remove the liquid line fitting from the orifice distributor

assembly. Note that the fitting has right hand threads

5. Install proper size orifice supplied with outdoor unit. Refer to supplied Tabular Data Sheet for specific orifice size and indoor coil

match up.

6. After orifice is installed reinstall the liquid line to the top of the orifice distributor assembly. Hand tighten and turn an additional 1/8

turn to seal. Do not over tighten fittings.

7. Leak test system.

8. Replace black plastic cap on equalizer fitting.

9. Slide indoor coil back into cabinet.

LIQUID LINE

SWIVEL COUPLING

(This fitting is a right-hand thread,

turn counter-clockwise to remove)

ORIFICE

DISTRIBUTOR

.

FIGURE 6: Orifice Installation

Do not connect manifold gauges unless trouble is suspected.

Approximately 3/4 ounce of refrigerant will be lost each time a standard manifold gauge is connected.

4 Johnson Controls Unitary Products

Page 5

SECTION V: INSTALLATIONS REQUIRING

AN ADD-ON TXV KIT

For installations requiring a TXV kit, refer to the Installation Instructions

accompanying the TXV kit.

Schrader valve core MUST NOT be installed with TXV installation.

Poor system performance or system failure could result.

SECTION VI: EVACUATION

It will be necessary to evacuate the system to 500 microns or less. If a

leak is suspected, leak test with dry nitrogen to locate the leak. Repair

the leak and test again.

To verify that the system has no leaks, simply close the valve to the vacuum pump suction to isolate the pump and hold the system under vacuum. Watch the micron gauge for a few minutes. If the micron gauge

indicates a steady and continuous rise, it’s an indication of a leak. If the

gauge shows a rise, then levels off after a few minutes and remains

fairly constant, it’s an indication that the system is leak free but still contains moisture and may require further evacuation if the reading is

above 500 microns.

SECTION VII: SYSTEM CHARGE

The factory charge in the outdoor unit includes enough charge for the

unit, a 15 ft. line set, and the smallest indoor coil match-up. Some

indoor coil matches may require additional charge. See tabular data

sheet provided in unit literature packet for charge requirements.

Do not leave the system open to the atmosphere.

The “TOTAL SYSTEM CHARGE” must be permanently stamped on the

unit data plate.

Total system charge is determined as follows:

1. Determine outdoor unit charge from tabular data sheet.

2. Determine indoor coil adjustment from tabular data sheet.

3. Calculate the line charge using the tabular data sheet if line length

is greater than 15 feet.

4. Total system charge = item 1 + item 2 + item 3.

5. Permanently stamp the unit data plate with the total amount of

refrigerant in the system.

Use the following charging method whenever additional refrigerant is

required for the system charge.

347337-UIM-A-0408

Refrigerant charging should only be carried out by a qualified air

conditioning contractor.

Compressor damage will occur if system is improperly charged. On

new system installations, charge system per tabular data sheet for

the matched coil and follow guidelines in this instruction.

If a calibrated charging cylinder or accurate weighing device is available, add refrigerant accordingly. Otherwise, model-specific charging

charts are provided on the access panel of the unit. If mix matched TXV

indoor coils are used with these models, the following subcooling charging method must be used. Superheat charging charts are not valid with

TXV equipped systems.

SUBCOOLING CHARGING METHOD - MIXED MA T CH

COILS

The recommended subcooling is 10°F

1. Set the system running in the cooling mode by setting the thermostat at least 6°F below the room temperature.

2. Operate the system for a minimum of 15-20 minutes.

3. Refer to the tabular data sheet for the recommended airflow and

verify this indoor airflow (it should be about 400 SCFM per ton).

4. Measure the liquid refrigerant pressure P and temperature T at the

service valve.

5. Calculate the saturated liquid temperature ST from Table 2.

6. Subcooling temperature TC = Saturated T emperature (ST) - Liquid

Temp (T).

Example: The pressure P and temperature T measured at the liquid service port is 196 psig and 90°F, respectlvely. From Table 2,

the saturated temperature for 196 psig is 100°F. The subcooling

temperature TC = 100°-90°=10°F

Add charge if the calculated subcooling temperature TC in Step 6 is

lower than the recommended level. Remove and recover the refrigerant

if the subcooling TC is higher than the recommended level. See Table

2.

Check flare caps on service ports to be sure they are leak tight. DO

NOT OVERTIGHTEN (between 40 and 60 inch - lbs. maximum).

TABLE 2:

Pressure

R-22 Saturated Properties

PSIG

80 48 110 64 140 78 170 91 200 101 230 111

82 49 112 65 142 79 172 91 202 102 232 112

84 50 114 66 144 80 174 92 204 103 234 112

86 51 116 67 146 81 176 93 206 103 236 113

88 52 118 68 148 82 178 94 208 104 238 114

90 54 120 69 150 83 180 94 210 105 240 114

92 55 122 70 152 84 182 95 212 105 242 115

94 56 124 71 154 84 184 96 214 106 244 115

96 57 126 72 156 85 186 97 216 107 246 116

98 58 128 73 158 86 188 97 218 107 248 117

100 59 130 74 160 87 190 98 220 108 250 117

102 60 132 75 162 88 192 99 222 109 252 118

104 61 134 76 164 88 194 99 224 109 254 118

106 62 136 77 166 89 196 100 226 110 256 119

108 63 138 78 168 90 198 101 228 111 258 119

Temp °F

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

Johnson Controls Unitary Products 5

Page 6

347337-UIM-A-0408

CONTACTOR

IT IS UNLAWFUL TO KNOWINGLY VENT, RELEASE OR DISCHARGE REFRIGERANT INTO THE OPEN AIR DURING

REPAIR, SERVICE, MAINTENANCE OR THE FINAL DISPOSAL

OF THIS UNIT.

WHEN THE SYSTEM IS FUNCTIONING PROPERLY AND THE

OWNER HAS BEEN FULLY INSTRUCTED, SECURE THE

OWNER’S APPROVAL.

SECTION VIII: ELECTRICAL

CONNECTIONS

GENERAL INFORMATION & GROUNDING

Check the electrical supply to be sure that it meets the values specified

on the unit nameplate and wiring label.

Power wiring, control (low voltage) wiring, disconnect switches and over

current protection must be supplied by the installer. Wire size should be

sized per NEC requirements.

All field wiring must USE COPPER CONDUCTORS ONLY and be

in accordance with Local, National, Fire, Safety & Electrical Codes.

This unit must be grounded with a separate ground wire in accordance with the above codes.

The complete connection diagram and schematic wiring label is located

on the inside surface of the unit service access panel.

FIELD CONNECTIONS POWER WIRING

1. Install the proper size weatherproof disconnect switch outdoors

and within sight of the unit.

2. Remove the screws at the top and sides of the corner cover. Slide

corner cover down and remove from unit.

3. Run power wiring from the disconnect switch to the unit.

4. Route wires from disconnect through power wiring opening provided and into the unit control box as shown in Figure 6.

5. Install the proper size time-delay fuses or circuit breaker, and

make the power supply connections.

GROUND

LUG

LOW

VOLTAGE

BOX

REVERSIBLE HIGH

VOLTAGE CONDUIT PLATE

DUAL

RUN/FAN

CAPACITOR

“FINGERED”

BUSHING

FIGURE 7: Outdoor Unit Control Box

FIELD CONNECTIONS CONTROL WIRING

1. Route low voltage wiring into bottom of control box as shown in

Figure 6. Make low voltage wiring connections inside the low voltage box per Figures 7-9.

2. The complete connection diagram and schematic wiring label is

located on the inside surface of the unit service access panel.

3. Replace the corner cover removed in Step 2.

4. All field wiring to be in accordance with national electrical codes

(NEC) and/or local-city codes.

NOTE: A Start Assist Kit is available and recommended for long line set

applications or in areas of known low voltage problems.

5. Mount the thermostat about 5 ft. above the floor, where it will be

exposed to normal room air circulation. Do not place it on an outside wall or where it is exposed to the radiant effect from exposed

glass or appliances, drafts from outside doors or supply air grilles.

6. Route the 24-volt control wiring (NEC Class 2) from the outdoor

unit to the indoor unit and thermostat.

NOTE: To eliminate e rratic operation, seal the hole in the wall at the

thermostat with permagum or equivalent to prevent air drafts

affecting the operation of in the thermostat.

ALL FIELD WIRING TO BE IN ACCORDANCE WITH ELECTRIC CODE (NEC) AND/OR LOCAL CODES

POWER WIRING

CONTROL WIRING

FACTORY WIRING

*

GND.

LUG

POWER WIRING

208/230-1-60

CONTACTOR

TERMINALS

COIL

CONDENSING UNIT

ALL OUTDOOR WIRING MUST BE WEATHERPROOF. USE COPPER CONDUCTORS ONLY.

24 VOLT CONTROL WIRING

MINIMUM 18 GA. WIRE

(NEC CLASS 2)

*

TERMINAL W IS ONLY

REQUIRED ON SYSTEMS

WITH HEAT.

FURNACE OR AIR HANDLER TERMINAL BLOCK

CYRGW

YRGW

ROOM THERMOSTAT

FIGURE 8: Typical Field Wiring (Air Handler / Electrical Heat)

6 Johnson Controls Unitary Products

Page 7

347337-UIM-A-0408

For additional connection diagrams for all UPG equipment refer to “Low Voltage System Wiring” document available online at www.upgnet.com in the

Product Catalog Section.

AC 1A Single Stage Air Conditioner – PSC Air Handler

ID MODELS

AHP

SHP

THERMOSTAT

*PP11C70224

MA

PSC

AIR HANDLER

SINGLE STAGE

SINGLE STAGE

AIR

AIR CONDITIONER

CONDITIONER

Y

Full Stage Compressor

RH

24 – Volt Hot

(Heat XFMR)

G

Fan

RC

24 – Volt Hot

(Cool XFMR)

W

Full Stage Heat

HM1

Humidistat

Clipping Jumper W914 for

electric heat on thermostat

is not necessary

24VAC Humidifier

(Optional)

24VAC

Electronic Air Cleaner

(Optional)

PSC

AIR HANDLER CONTROL

COM

24 – Volt Common

Y/Y2

Second or Full

Stage Compressor

R

24 – Volt Hot

G

Fan

W2

Second Stage Heat

Single Stage Compressor

if humidistat is to be used.

Refer to AH documentation

Y1

O

Reversing Valve

Energized in Cool

X/L

Malfunction Light

W1

First Stage Heat

HUM

Humidity Switch

Open on Humidity Rise

HUM OUT

(24 VAC out)

Humidifier

EAC(24 VAC out)

Electronic Air Cleaner

Move HUM STAT

jumper to “YES”

for W1 and W2 electric

heat staging options.

SINGLE STAGE

1

SINGLE STAGE

AIR CONDITIONER

AIR CONDITIONER

C

24 – Volt Common

Y

Y

Compressor

Compressor Contactor

Other Part Numbers:

Part Numbers:

SAP = Legacy

SAP = Legacy

265902 = 031-09167

159480 = 031-09156

2

1

FIGURE 9: Thermostat Chart - Single Stage AC with PSC Air Handler

Johnson Controls Unitary Products 7

Page 8

347337-UIM-A-0408

AC 1B Single Stage Air Conditioner – PSC Air Handler

THERMOSTAT

THERMOSTAT

ID MODELS

AHP

SHP

MA

*BN11C00124

C

24 – Volt Common

Y

Full Stage Compressor

RH

24 – Volt Hot

(Heat XFMR)

G

Fan

RC

24 – Volt Hot

(Cool XFMR)

W

Full Stage Heat

2

Thermostat Installer Setup

1-System Type-must be

set to 0

Thermostat Installer Setup

15-Compressor Protection

must be set to 5

*BP11C50124

*BN11C01124

*DP11C40124

*DN11C00124

C

24 – Volt Common

Y

Full Stage Compressor

RH

24 – Volt Hot

(Heat XFMR)

G

Fan

RC

24 – Volt Hot

(Cool XFMR)

W

Full Stage Heat

External Humidistat

(Optional)

Open on Humidity Rise

Selection of GAS/ELEC

switch on thermostat

is not necessary

24VAC Humidifier

(Optional)

24VAC

Electronic Air Cleaner

(Optional)

PSC

AIR HANDLER

PSC

AIR HANDLER CONTROL

COM

24 – Volt Common

Y/Y2

Second or Full

Stage Compressor

R

24 – Volt Hot

G

Fan

W2

Second Stage Heat

Single Stage Compressor

if humidistat is to be used.

Refer to AH documentation

Y1

O

Reversing Valve

Energized in Cool

X/L

Malfunction Light

W1

First Stage Heat

HUM

Humidity Switch

Open on Humidity Rise

HUM OUT

(24 VAC out)

Humidifier

EAC(24 VAC out)

Electronic Air Cleaner

Move HUM STAT

jumper to “YES”

for W1 and W2 electric

heat staging options.

SINGLE STAGE

AIR

CONDITIONER

1

SINGLE STAGE

AIR CONDITIONER

C

24 – Volt Common

Y

Compressor Contactor

Other Part Numbers:

2

Part Number:

S1-2HU16700124

Part Numbers:

SAP = Legacy

SAP = Legacy

265902 = 031-09167

159480 = 031-09156

2

1

FIGURE 10: Thermostat Chart - Single Stage AC with PSC Air Handler

8 Johnson Controls Unitary Products

Page 9

AC 5D Single Stage Air Conditioner – Single Stage PSC Furnace

ID MODELS

THERMOSTAT

G*(8/9)S

G*9F

L(Y/M)8S

G8C

GF(8/9)

LF8

TG(8/9)S

(G/T)GLS

347337-UIM-A-0408

*PP11C70224

Y

Full Stage Compressor

RH

24 – Volt Hot

(Heat XFMR)

G

Fan

RC

24 – Volt Hot

(Cool XFMR)

W

Full Stage Heat

HM1

Humidistat

24VAC Humidifier

(Optional)

SINGLE STAGE

PSC

FURNACE

SINGLE STAGE PSC

FURNACE

C

24 – Volt Common

Y/Y2

Full Stage Compressor

R

24 – Volt Hot

G

Fan

W

Full Stage Heat

SINGLE STAGE

AIR

CONDITIONER

1

SINGLE STAGE

SINGLE STAGE

AIR CONDITIONER

AIR CONDITIONER

C

24 – Volt Common

Y

Y

Compressor

Compressor Contactor

Clipping Jumper W914 for

electric heat on thermostat

is not necessary

Other Part Numbers:

SAP = Legacy

265901 = 031-09166

1

FIGURE 11: Thermostat Chart - Single Stage AC with PSC Furnace

Johnson Controls Unitary Products 9

Page 10

347337-UIM-A-0408

AC 5E Single Stage Air Conditioner – Single Stage PSC Furnace

G*(8/9)S

G*9F

THERMOSTAT

*BN11C00124

THERMOSTAT

*BP11C50124

*BN11C01124

*DP11C40124

*DN11C00124

L(Y/M)8S

G8C

SINGLE STAGE

ID MODELS

PSC

FURNACE

GF(8/9)

LF8

TG(8/9)S

(G/T)GLS

SINGLE STAGE

AIR

CONDITIONER

C

24 – Volt Common

Y

Full Stage Compressor

RH

24 – Volt Hot

(Heat XFMR)

G

Fan

RC

24 – Volt Hot

(Cool XFMR)

W

Full Stage Heat

24 – Volt Common

Full Stage Compressor

24 – Volt Hot

(Heat XFMR)

Fan

24 – Volt Hot

(Cool XFMR)

Full Stage Heat

External Humidistat

2

(Optional)

Open on Humidity Rise

RH

RC

SINGLE STAGE PSC

FURNACE

C

Y

G

W

24VAC Humidifier

(Optional)

C

24 – Volt Common

Y/Y2

Full Stage Compressor

R

24 – Volt Hot

G

Fan

W

Full Stage Heat

1

SINGLE STAGE

AIR CONDITIONER

C

24 – Volt Common

Y

Compressor Contactor

Thermostat Installer Setup

1-System Type-must be

set to 0

Thermostat Installer Setup

15-Compressor Protection

must be set to 5

Selection of GAS/ELEC

switch on thermostat

is not necessary

Part Number:

2

S1-2HU16700124

Other Part Numbers:

SAP = Legacy

265901 = 031-09166

1

FIGURE 12: Thermostat Chart - Single Stage AC with PSC Furnace

10 Johnson Controls Unitary Products

Page 11

347337-UIM-A-0408

INDICATIONS OF PROPER OPERATION

Cooling

1. The outdoor fan should be running, with warm air being discharged from the top of the unit.

2. The indoor blower (furnace or air handler) will be operating, discharging cool air from the ducts. Coils or other parts in the air circuit should be cleaned as often as necessary to keep the unit

clean. Use a brush, vacuum cleaner attachment, or other suitable

means.

3. The vapor line at the outdoor unit will feel cool to the touch.

4. The liquid line at the outdoor unit will feel warm to the touch.

Instructing the Owner

Assist owner with processing warranty cards. Review Owners Guide

and provide a copy to the owner and guidance on proper operation and

maintenance. Instruct the owner or the operator how to start, stop and

adjust temperature setting.

When applicable, instruct the owner that the compressor is equipped

with a crankcase heater to prevent the migration of refrigerant to the

compressor during the “OFF” cycle. The heater is energized only when

the unit is not running. If the main switch is disconnected for long periods, do not attempt to start the unit until 8 hours after the switch has

been connected. This will allow sufficient time for all liquid refrigerant to

be driven out of the compressor.

The installer should also instruct the owner on proper operation and

maintenance of all other system components.

Maintenance

1. Dirt should not be allowed to accumulate on the outdoor coils or

other parts in the air circuit. Clean as often as necessary to keep

the unit clean. Use a brush, vacuum cleaner attachment, or other

suitable means.

2. The outdoor fan motor is permanently lubricated and does not

require periodic oiling.

3. If the coil needs to be cleaned, it should be washed with Calgon

Coilclean (mix one part Coilclean to seven parts water). Allow

solution to remain on coil for 30 minutes before rinsing with clean

water. Solution should not be permitted to come in contact with

painted surfaces.

4. Refer to the furnace or air handler instructions for filter and blower

motor maintenance.

5. The indoor coil drain pan should be inspected and cleaned regularly to prevent odors and assure proper drainage.

Johnson Controls Unitary Products 11

Page 12

NOTES

Subject to change without notice. Printed in U.S.A. 347337-UIM-A-0408

Copyright © 2008 by Johnson Controls, Inc. All rights reserved. Supersedes: 259715-UIM-A-0606

Johnson Controls Unitary Products

5005 York Drive

Norman, OK 7306

Loading...

Loading...