Page 1

The

M

ALISTM

El

ectrosur ical

y em

Bi

olar

C®-III

Service Manual

~~

PROFESSI

RAYNHAM,

·

CMC

is I regisll<ed noarnarlt

ONAL, IN

MA

02767-0350 USA

~

if

•

01

JoMscn

.........."o/

Lecnln;ll.

& .Jotr\sorI

C.

Malis. IolD.

Proleucn:l~

II'IC.

Page 2

TABLE

' .0 Scope .......................

2.0

Warranty ..................

3.0

Service and Repair ....................................

4.0

Warnings

5.0

Funct

5.1 Product Description ................................ 1

5.2

5.3

5.4 Footpedal Controls ....................

5.5

5.6

6.0 Technical Description ................................. ... 4

6.1 Printed Circuit Boards ............................

6.2

6.3

6.4

6.5 Operational Performance ....... .............

6.6

6. 7

6.8

7.0 Replacing Internal Fuses ............................ 14

8.0 Maintenance .

9.0 Routine Cleaning ......•................................. 15

10.0 Sterilization ..... .......................... ................ 15

11

.0

Block

12.0 Schematics .........

13.0

PCB

Parts

14.0

OF

CONTENTS

........

.......................

...............................

..

..

IFe

IFe

IFe

and Cautions .............................

ional Description

of

Controls and Indicators .....................

Generator Controls ........................... ...... 1

Remote Control Set Controls .................. 2

__

Indicators ............. ............................ _ ... _

Connections ............................................ 4

Theory of Operation ................................ 5

Master List of Card

Connector Signals

Test

Points ............. ...............................

Calibration .......................................... .. 12

Technical Specifications ............. .......... 13

Trouble Shooting Guide ........................ 14

......

Diagrams ......................................... 16

Layouts and Assemblies ................... 34

List ...................................................

..

.............

......................... ............... 15

....

..................................

......

.....••..

IFe

_.

........... 2

..

..

10

11

..

12

20

46

3

4

1.0 SCOPE

This

manual

allow a qualified Service Techn ician to perform

maintenance

under

warranty, please refer to Section 2.0 .

contains the necessary information

and repair in

the

field.

If

the unit is still

to

mproper

i

IN LIEU

EXPRESS OR IMPLIED , INCLUDING ANY

RANTY

FOR

use

determined

for

incidental

1

3.0

For

tor

and

representative directly

Service,

The

Include with the unit a repair purchase order number,

the

serial

description

The

Replacements are

4.0

service.

OF

OF

A PARTICULAR

of

the

device for

THE

ABOVE WARRANTIES

ALL OTHER WARRANTIES, EITHER

MERCHANTABILITY OR FITNESS

PURPOSE

any

surgical procedure shall

by the

user

. Codman shall not be liable

or

conseque~tiaJ

. Suitability for

damages

SERVICE AND REPAIR

service

sales representative coordinates the return to:

Codman

c/o Johnson & Johnson Professional, I

4969

Philadelphia, PA

MAllS

Johnson

325 Paramount Drive

Raynham, MA 02767-0350

or

repairs

footpedal,

to

the

MALIS CMS-III genera-

contact

your local Cadman

or

through Cadman Customer

1-800-225-0460.

Repair Service

Wakefield

number of the generator,

of

the problem.

CMG-rrr Remote Control is not repairable.

& Johnson Professional, Inc.

Street

19144

and

available from:

WARNINGS AND CAUTIONS

4.1 WARNINGS

00

not

attemp

the

generator by using a 3-prong to 2-prong adaptor.

The

generator must be properly grounded to

operator

can

be achieved only

tacle

marked

Always

ate type and value fuse (see Technical Specifications).

The

user. Unauthorized modifications

cause

replace the

unit should not

it

t to bypass the grounding prong

and patient safety. Grounding reliability

when

connected

"Hospital

to

malfunction

Only"

system's

be

modified in any way

or

or

" Hospital Grade

fuse with the appropri-

to

fail in use.

the unit

WAR·

of any kind.

nc.

a written

ensure

to

a receJr

by

may

ARE

be

sales

on

".

any

2.0 WARRANTY

The

MALIS

(catalog no. 80-1170) is warranted for one full year

date

from

Set

which

CMC-1I1

materials and workmanship. This warranty

apply

failure

ing

to

unauthorized parts

abuse,

Bipolar Electrosurgical System CMC-III

of

purchase, except

is warranted for

is

warranted

where

to

the

service is required

operate

Instruction Manual, (ii) Buyer's use

misuse

to

be free from defects in both

or

maintain the Equipment accord-

or

consumables, (iii) accident,

, modification or misapplication,

the

six

months. The

due

Remote Control

to

MALIS

shall not

(i) Buyer 's

of

or

(iv)

4.2 CAUTIONS

Continuous power

remote control, must

a 4O-second rest period.

Close proximity of

Electrosurgical Units producing EXCESSIVE RF

CURRENT

produce

power

We

recommend the

CAL

electrosurgical device

RADIATION

voice annunciation and possibly output

.

SEPARATION

output

be

this

user

of

, by

either

footpedal

limited to

unit

and its cables with

may

insure MAXIMUM PHYSI·

this

unit from any other

and

its cables .

cause

20

seconds, with

this

unit

or

some

to

Page 3

5.0 FUNCTIONAL DESCRIPTION

OF CONTROLS

5.1

PRODUCT DESCRIPTION

The

MAUS

(catalog no. 8()'1170) includes:

1.

The

2. A wireless

settings

lation functions;

3. An Adapter Cable to allow the use

Irrigator

with the

The generator

footswitch (catalog no.

tootswitch (catalog no. 80-1149) both available

separately. The generator is equipped with a voice

synthesizer that provides an audible indication of

changes

option, it also announces the operating mode and

power

performed. With the exception of the generator,

above system components may also be ordered

separately.

MAUS

insulated and

separately, as

cords.

Irrigation

CODMAW

designed

and

the

In bipolar coagulation,

onty in

requirements.

should

so

all

current

of

the

no

current

ground.

dent

upon

meet, as

immersed.

lel.

and

major

shunting

bowed

blades

be

mainly

lowest

vides

the

tips

with

shunting.

The

MAUS

provides

cutting

shifting

automatically

the

high

Bipolar

Generator;

Remote

as

well

as

and/or a MALIS Bipedal Electric Footswitch

CMC-IJI

to

setting

Bipolar

The

Irrigator together.

the

be isolated

separated forceps.

The

well

the

or

are

possible

the

the

of

all

the

power

.

is

compatible with both a pneumatic

the

power settings. At the surgeon's

each

Cutting

non

are

System

Module

to

flow

the

angled

between

best

(catalog no. 80-1164).

Floorstand

accommodate

isolated output

The

flow

from

current

tip

size

as

the

11

the

forceps

forceps

in

the

so

still

well

generator

maintenance

least

decrease

Bipolar

higher

tissues

low

impedance

to

match

cut

AND INDICATORS

Electrosurgical System CMC-III

Control

operating

8(H173)

time cutting

Forceps

insulated

reusable

may

for

the

output

from

ground

takes

place between

either

geometry

and

medium

are

deep

saline.

the

tips

separated ,

the

tips

Electrosurgical System CMC-III

energy

, including

the

settings.

for

changing power

the

cutting

and

or

coagulation is

and

forceps

and

disposable bipolar

be

used

MALIS

the

CMC-III

electrical difference is

and

in the lower power

of

the

bipolar generator

as

There

the

blades

output

should

side

of

will now

angle

in which they are

are

in

saline,

If

the

almost

the

with

little shunting. The

impedance pro-

01

power

in coagulation

output

dense

of

the

micro cutting

power

requirements

and

of

a MALIS

an electric

standard

are available

with

the

MALIS

The

CMC-IIIIII is

Generator

much

as

possible.

the

two

be

virtually

the

forceps

be

depen

at

which

virtualty paral-

there

will

forceps

meet

current

needed

are

while

flow

at

the

forceps

due

for

fibrous layers ,

coagu-

to

the tips

rapid

aU

tips

be

the

will

to

of

the

-

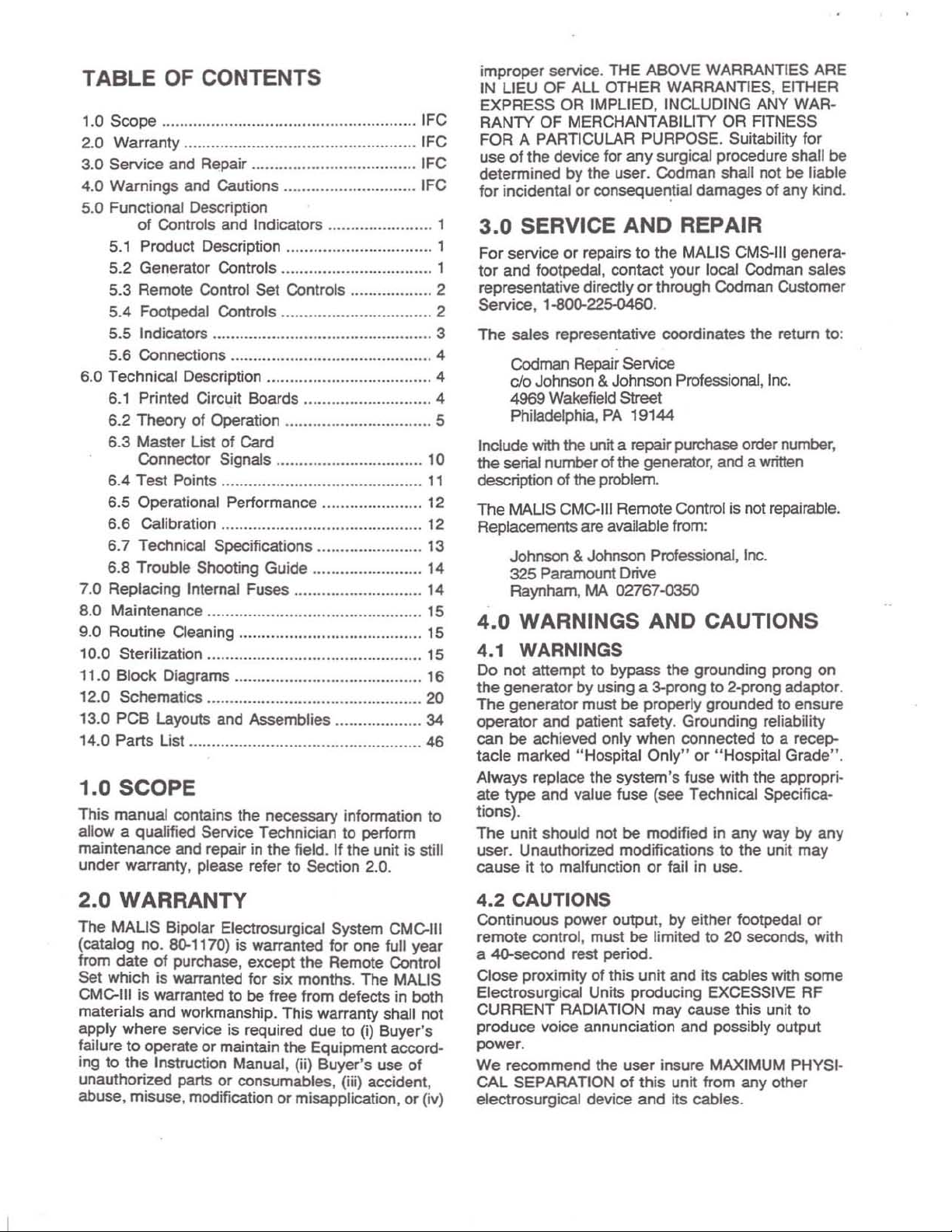

5.2 GENERATOR CONTROLS

and 2)

A.

Power

Controls

B.

Cutting

Used

cutting . (Cutting power control

located on

C.

Coagulation

Increases

coagulation. (Coagulation

also

D.

Tone

Used

indicate cutting

delivered

volume at

CMC-III ,

you

are

settings

Window

display

power setting.

Switch

the

power supplied

Power

to

increase

the

and

found on

Volume

to

control the

to

forceps.

any

except

using these controls,

appear

(Item V in

window

Control

or

decrease

remote control set.)

Power

decreases

the

remote control set.)

Control

volume

or

coagulation

time during

while cutting

in

the

Figure

again

--

CHe·1lI

--

--.

0 0 0

Switch

Control

the

power

of

You

can

the

Microcut

5).

shows

to

the

coagulator.

the

power

buttons

Switch

power

control

the

tones

power

change

operation

or

coagulating.

the

tone

Power

Afterwards,

the

actual

B C

-

]~

-..

0

0

A

Figure 1. Front Panel Controls (Items A through

E.

Voice

Volume

Used

to

increase or

voice synthesizer which

mode

being employed

settings.

volume at

during cutting

these controls.

the

Figure

shows

F.

By

the cutting

You

any

Microcut Power

5). Afterwards,

the

actual microcut

Cutting

pushing

Reset

this

power

Control

decrease

can

increase

time

while

or

coagulating.

the

voice

Display

Button

button ,

to

35

and

the

you

Malis

D

the

volume

announces

changes

or

decrease

using

the

While

volume

Window

display

power

can

immediately

Units

settings

window

setting.

the

in

CMC-III,

you

(or 9

(Figures

settings

are

also

settings

is

volume

E

I)

the

(Item V in

for

buttons

which

being

the

tone

of

the

Display

the

microcut

0

0

I

I

©.::.@I

of

the

operating

power

the

voice

except

are

using

appear

again

reset

watts).

1

for

are

While

"

I

in

1

Page 4

G.

Coagulation

You can quickly reset the coagulation power

Malis Units (or 9 watts) by pushing this button.

H.

Irrigation

When the

connected

and enable irrigation. An additional irrigator button

located

Mode Indicator (Figure

generator

regardless

I.

Watts

Press this button

watts. The

CC) illuminates whenever power settings show

watts.

J.

Voice

Used to prevent

ing the operating mode being employed and the

power settings

performed.

Indicator,

K. LED Test

When

illuminate

that does not illuminate,

attention .

L. Supply

Use this control

voltage as

MAUS

on

will illuminate when the irrigator is enabled,

Display

Mute

Item

you

press this button, all numeric LEOs should

as a self-diagnostic test. Any numeric LED

Voltage

the

Reset

Mode

to

the

the

remote control set.

of

which

to

Watts

Button

the

each

When

BS

Button

Sutton

Irrigator is properly set up and

CMC-III, push this button to disable

5,

of

the two switches is

Button

display the

Display Indicator (Figure 5, Item

voice synthesizer from announc -

time cutting or coagulating

the

voice is muted, the Mute

in Figure 5. illuminates.

Button

Selector

to

set the generator

power

receptacle you

=

to

The

Irrigation

Item AA) located on the

used

.

power

Signals a problem requiring

settings in

to

the

same

are

using.

K J

I

35

in

is

Coagulation

N.

By pressing this button. you

power to

pedal on the footpedal, Item S in Figure 4, also

controls this function.)

O.

is

Use this button

setting for coagulation.

Switch on the generator, Item C in Figure 1, controls

the

P.

Cutting

Increase

means

Switch on

the same function.)

Q.

lrrlgatlon

When

connected

and enable irrigation.

located on the generator.

Indicator (Figure 5,

tor

illuminates when the irrigator

less

be

Coagulation

same function.)

or

of

this button. (The Cutting

the generator, Item B in Figure

the

MAUS

of

which of the

Output

delivered

Power

to

increas~

Power

decrease the

Mode

Irrigator is property set

to

the

CMC-III, push this button

Button

cause

to

the forceps. (The Coag

Control

or

(The

Control

Button

Item AA) located on

two

Button

power

An

additional irrigator button is

The

switches is used.

coagulation

Button

decrease the power

Coag

Power

setting for cutting by

Power

Irrigation Mode

the

is

enabled. regard-

_-.,,'"

--

=

~

-

-

Mali,-

<><C. m

p

"""",&

~

~

Control

Control

1,

controls

up

and

to

genera-

N

a

o

disable

LJ

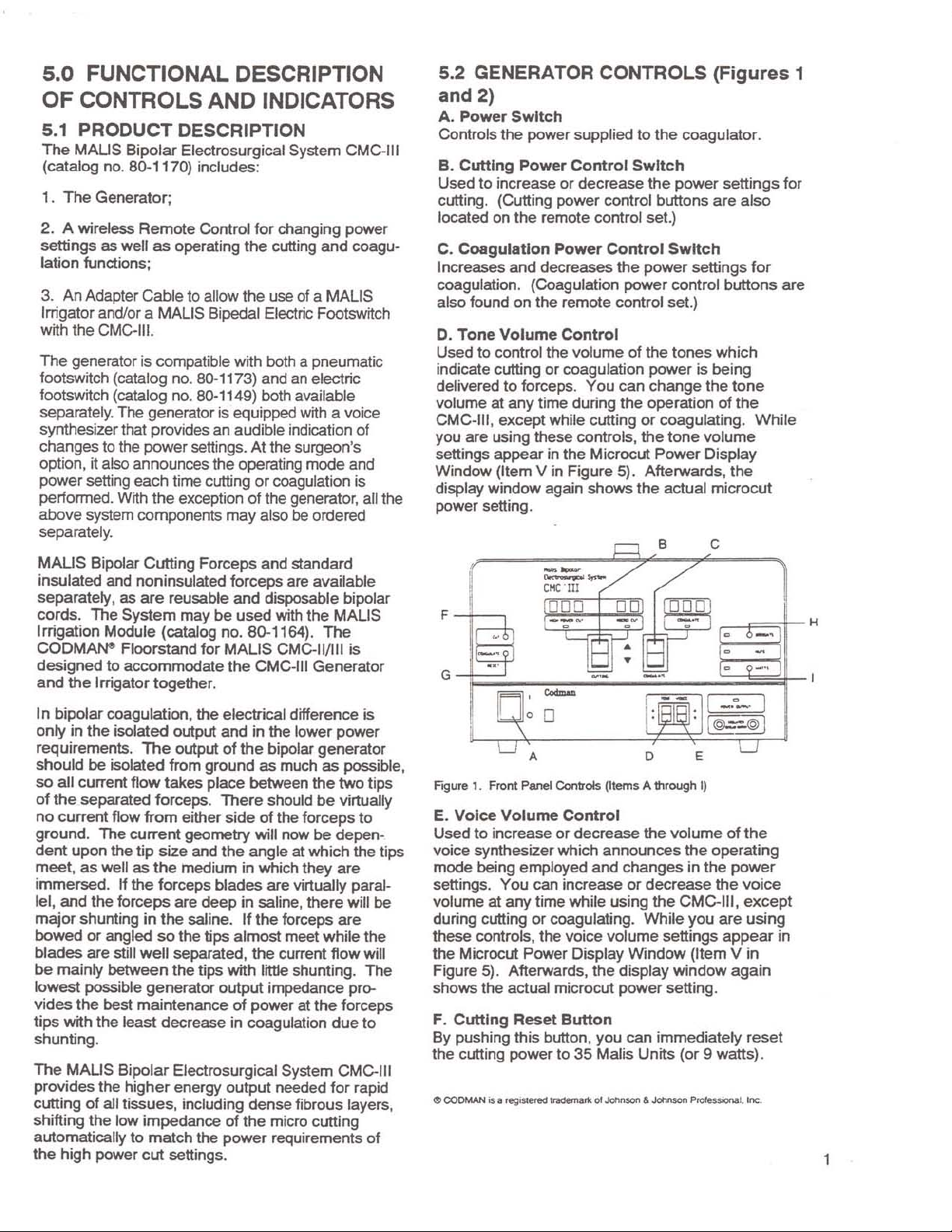

Figure 2.

Bad<

Panel Controls (Items J through L)

LJ

5.3 REMOTE CONTROL SET CONTROLS

(Figure 3)

M.

Cutting

When you

ered

Item R

Output

press

to

the forceps. (The Cut pedal on

in

Figure 4, also controls this function.)

Button

this

button, cutting power

is

the

footpedal.

deliv-

FIgUre

3. Remote Control pte

ms

M through Q)

5.4 FOOTPEDAL CONTROLS (Figure

R.

Cutting

When you depress this pedal. cutting power

delivered to the forceps. (The

remote control,

controls this function.)

Output

Item M

Pedal

Cut

button on the

as

shown in Figure 3, also

is

4)

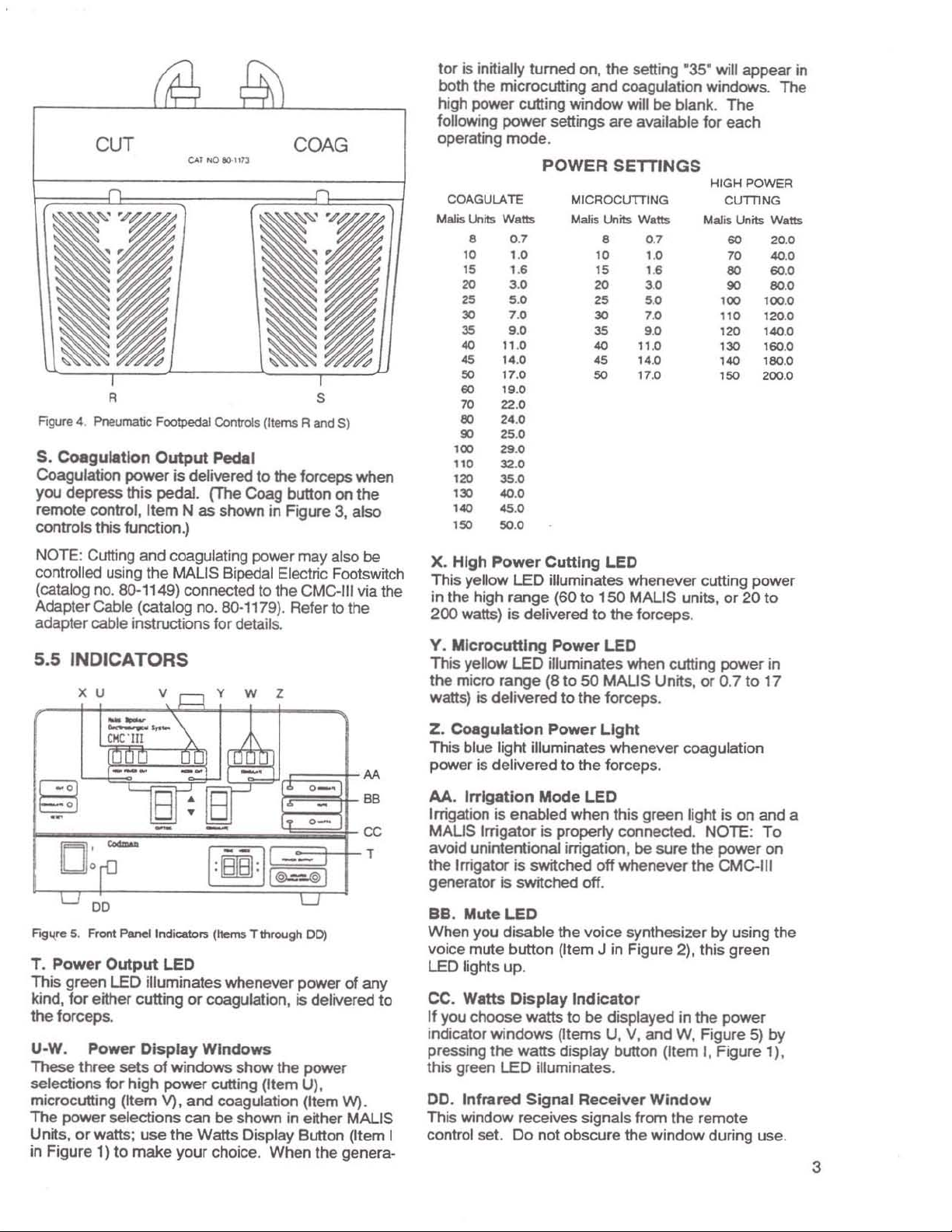

Page 5

CUT

R $

Fig

ure

4.

Pneumatic

S.

Coagulation

Coagulation

you

depress

remote control,

controls this function.)

FootpedaJ

Output

power

this pedal. [The Coag button on the

is delivered to the forceps when

Item

COAG

Contr

ols (Items R and

Podol

N as shown in Figure

S)

3,

also

lor

is initially turned on, the setti

both the microcutting

high power cutting

following

operating

power

mode

POWER

COAGULATE

Malis Units Watts Malis Lklits Watts

0.7

•

10

15 I .•

20

25 5.0

30 7.0

35 9.0

40

45

SO

60

70

80

90

100

110

120

130

140

150

11

14.0

17

19

22

24

25

29

32

35

"'

45

SO

1.0

3.0

.0

.0

.0

.0

.0

.0

.0

.0

.0

.0

.0

.O

and

window

settings

.

are

MICAOCUTTING

•

10

15

20

2$

30

35

'"

..

50

coagulatkm windows. The

will be blank.

available

SEmNGS

0.7

1.0

I .•

3.0

5.0

7.0

9.0

11.0

14

.0

17

.0

ng

-35

- will appear in

for

MarIS

The

each

HIGHPOWEA

ClfTilNG

Units Watts

60

20

70

"'

80

60

90

100

110

120

130

''''

150

80

100

120

140.0

160.

180

200

.0

.0

.0

.0

.0

.0

.0

.0

0

NOTE: Cutting

controlled

(catalog no. So-" 49) connected to the

Adapter Cable (catalog no. 80-1179

adapter cable instructions for detail

and coagulating power

using

the

MALIS

Bipedal

).

s.

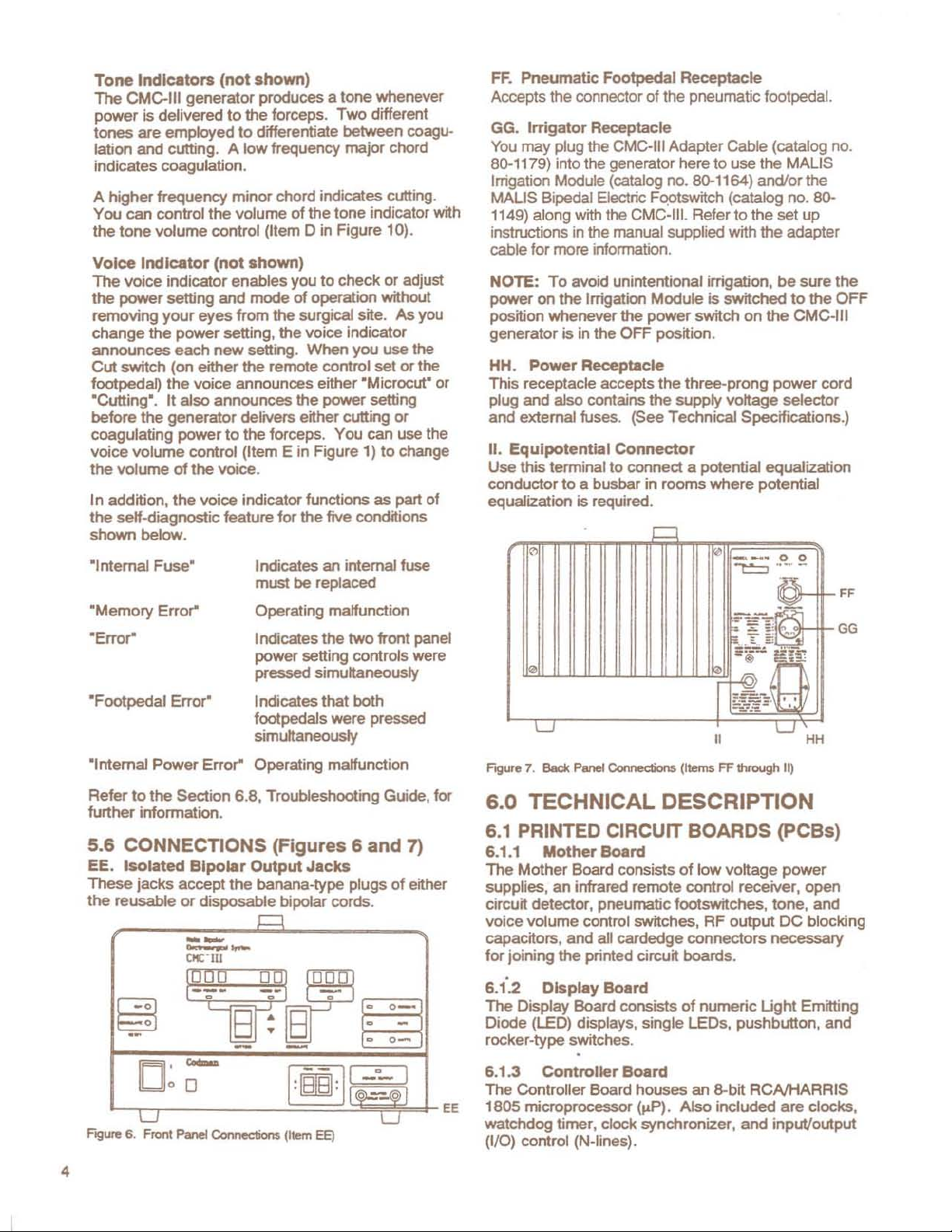

5.5 INDICATORS

x u

........

--

O!C'

~-.

I11

V,

~~

.\

i=\

-.

v

w z

-

§

U

:~

D:

;-

LJ

DO

FJgl(re

S. Front Panellndicator.i (Items Tthrough

T.

Power

This

kind,

the

forceps

U-W. Power Display Windows

These

selections

microcutting (Item V).

The

Units,

in Figure 1) to

Output

green

LED illuminates whenever power

for

either cutting

.

three

for

power

selections can

or

watts;

sets

high

make

of

use

[;IEiI

Ei

I

; I

I

~~

LED

or

coagulation, is delivered

windows

power

and

the

your

show

the power

cutting (Item

coagulation (Item W) .

be

shown in either MALIS

Watts

Display Button (Item I

choice.

When

may

also be

Electric Footswitch

CMC·JIJ

Refertothe

0 _

via the

AA

BB

-

0 _

cc

T

1

LJ

DO)

of

any

to

U)

I

the

genera-

X.

High

Power

This yellow

in the high

200 watts) is delivered

Y.

Mlcroeuttlng

This yellow

the

micro

watts) is delivered to the forceps .

Z.

Coagulation

This blue light illuminates

power is

AA.

Irrigation is enabled

MAUS

avoid unintentional irrigation , be

the

generator is switched

BB.

When

voice mute

LED

CC.

If

you

indicator

pressing

this green

DO.

This window receives signals from

control set.

delivered

Irrigation

Irrigator is property connected.

Irrigator is switched

Mute

you

lights up.

Watts

choose

windows

the

Infrared

LED

range

LED

range

Cutting

illuminates whenever cutting

(60 to

Power

illuminates

(8

Power

Mode

to

to

when

LED

150

to

the forceps .

LED

50

MALIS

Light

whenever

the

forceps.

LED

this

off

whenever

off

.

MALIS

when

Units, or

green

sure

LED

disable

button

Display

LEO illuminates.

the

voice

synthesizer

(Item J in Figure 2), this green

Indicator

watts to be displayed in the

(Items U, V, and W. Figure

watts

display button (Item I. Figure 1),

Signal

Do

Receiver

not obscure the

Window

window

units,

or

cutting

the

power

0.7

coagulation

light

is

NOTE: To

the

power on

the CMC-III

by

power

remote

during use.

power

20

to

in

to

17

on

and a

using the

5)

by

3

Page 6

Tone

Indicators

The

CMc..1II

power

tones

lation and cutting. A

indicates coagulation.

A higher frequency

You

the

Voice

The

the

removing

change

announces

Cut

footpeda/)

"Cutting·. It also

before

coagulating

voice

the

In addition,

the setf·diagnostic feature

shown

"Memory

"Internal

is delivered

are

can

control

tone

volume

Indicator

voice

power

your

the

switch

the

volume

volume

below.

Error"

Power

employed

indicator

setting

(on either

the

generator

the

(not

shown)

generator produces a

to

the forceps.

to

differentiate between coagu-

low

minor

the

volume

control (Item 0 in Figure 10).

(not

shown)

enables

and

mode

eyes

from

power

each

01

setting. the voice indicator

new

setting. When you use the

the

voice announces either "Microcut"

announces

delivers either cutting

power

to

the forceps.

control (Item E in Figure 1)

the

voice.

voice

indicator functions

Indicates an internal

must

Operating

Indicates

power

pressed simuttaneousty

Indicates

footpedals were pressed

simultaneousty

Error" Operating malfunction

tone

whenever

Two

different

frequency major chord

chord indicates cutting.

of

the

tone

indicator with

you to

check

of

operation without

the surgical site.

remote control set

the

power

You

for

the five conditions

be replaced

maffunction

the

setting controls were

that

or

As

or

setting

or

can use the

to

change

as

part

fuse

two

front panel

both

adjust

you

the

of

or

FF.

Pneumatic

Accepts the connector

GG.

Irrigator

You may plug the CMC·III Adapter Cable (catalog no.

80-1179) into the generator here to use the MALIS

Irrigation Module (catalog no. 80-1164)

MAliS

1149) along with the

instructions in the manual supplied with the adapter

cable

NOTE:

power

position

generator is in the

HH.

This receptacle accepts

plug and also contains the

and external fuses . (See Technical

II.

Use

conductor

equalizabon

Bipedal Electric Foptswitch (catalog no.

for more information.

To

on the Irrigation

whenever

Power

Equipotential

this terminal to connect a potential equalization

Footpedal

Receptacle

CMC·111.

avoid unintentional irrigation,

the

OFF

Receptacle

Connector

to

a busbar in rooms

is required.

Receptacle

of

the pneumatic footpeda!.

Refer

to

Module

power

position.

the

is

switched

switch

three-prong

supply

voltage

Specifications

where

and/or

the

set

be

on

the

power

selector

potential

the

80-

up

sure

to

the

CMC·III

cord

c:

__

11"11

""t::::::l

·00

~ -~

-

AL

~-.~

..

:ii:i: ...

, "

:::;

11011

~!=

Fi~

f

-:".":.

",

LJ

HH

LJ

Figure 7. Back Panel

Corlnedion$

liE·

"

(Items FF through II)

the

OFF

.)

FF

GG

to

the

Refer

further

Section

information.

6.8, Troubleshooting Guide,

5.6 CONNECTIONS (Figures 6 and 7)

EE.

These

the

reusable

lsolated

jacks accept

Bipolar

or

disp0sa.b4e bipotar cords.

--

OC·1lI

--

Output

the

banana·type plugs

~

Jacks

T~@

I.ffill

~ I ~.

4

L,,-------==="''-'=-

6.

LJ

Front

Panel

F'9ure

Connections (Item EE) (I/O) control (N.lines).

..

of

for

either

6.0 TECHNICAL DESCRIPTION

6.1

PRINTED CIRCUIT BOARDS (PCBs)

6.1.1

The

supplies,

circuit detector, pneumatic footswitches, tone, and

voice

capacitors,

for

6.12

The

Diode (LED)

rocker·type switches.

Mother

Mother

an

volume

joining

Display Board

Display Board consists

Board

Board consists

infrared remote control receiver. open

control switches.

and

all cardedge

the

printed circuit boards.

displays,

• I 6.1.3 Controller Soard

The Controiler Board houses an

''''F'ir'-J-

U

EE

1805 microprocessor

watchdog

timer, clock synchronizer,

single

(JtP).

of

low

voltage

RF

output

connectors

of

numeric

LEOs, pushbutton,

B-M

Also

included are clocks,

power

DC

necessary

Ught

RCNHARRIS

and

inpuVoutput

blocking

Emitting

and

Page 7

6.1.4

The

EPROM

audio fitters, amplifiers,

controls for voice and

6.

The

switching-type

principle of voltage transfer and isolation from

line (mains) sources.

6.1.6 AF Power

The

amplifier, coagulation waveform generator,

output steering, short circuit detection, and isolated

bias supplies.

Sound

Sound Board consists of a Digitaiker™,

, digital tone generators, steering logic,

1.5

High

High Voltage

RF Amplifier Board consists

Board

Voltage

Power

power

Amplifier

and

two electronic volume

tones

.

Power

supply utilizing the f1yback

Supply

Supply Board is an

Board

of

a bridge-type RF

Boord

RF

off

-line

power

6.2 THEORY OF OPERATION

NOTE

: Refer

schematic, Sections 8.0 and 9.0, respectively.

6.2.1

6.2.1.1

Four

low voltages are supplied

(a)

+5

VDC @ 2 Amps (regulated);

(b)

+15

(e)

+18 VDC @ 1 Amp (unregulated);

(d)

·18

VDC@O

6.2.1.2 Infrared Remote Control Receiver

The

Infrared Remote Control Receiver monitors

aaivity

transmitter,

processing.

from

Mother

Low

VOC@

the

and

to

each board's block diagram

Board

Voltage Power Supplies

on

the mother board:

1 Amp (regulated) ;

and

,

.l Amp (unregulated).

infrared remote control handheld

sends the

serial

data to the

and

IlP

for

6.2.1.6

The

primarily

elements

The

high cutting voltage duri

tips from breaking down components in

It

also

This circuit

mode.

Operation is

A small (

Khz is generated

wave, buffered by

transformer TS02

signal. The primary

form a parallel resonant circuit . Signal 20KHZlN

path to a filter, buffer U603B, detector,

comparator U603A. Providing there is essentially an

open across

open), the parallel resonant circuit acts

the

flow

20

KHZlN. During

U603A toggles

to

U503

off RF power

under 5000 ohms, the secondary winding of T502

acts to reflect

winding of T502 and lower

resonant circuit, thereby

wave to

signal level is detected by

comparator

amplifier to operate.

Open Circuit Detector

Open Circuit Detector circuitry is located

on

the Mother Board, with interfacing

on

the

RF Power Amplifier

open circuit detector helps prevent excessively

ng

periods of

eliminates the occurrence of

is

active only during the high power cut

as

follows:

<3

V p oP) audio signal of approximately

by

U602 in the form

Q600

and

capacitor coupled to

and

C529. This is

of

TS02 and capacitor C529

the

secondary winding of TS02 (forceps

of

the

20

Khz

sine wave from

this

period

on

and asserts the

on

the RF Amplifier Board, thereby shutting

If

the forceps should see resistance

this

impedance back

pass from

U603A

20

KHZOUT

to change state and allow

of

the

Q of

aflowing the

0600

Board

.

open

forceps

the

RF path .

AF

interference.

01

a sine

the

20KHZOUT

is

and

threshold

to

impede

20KHZOUT

open forceps,

?WRDIS

to

the

the

20

to

20

KHZIN.

and 0601, causing

signal

primary

parallel

Khz

sine

the

This

20

RF

a

to

6.2.1.3 Pneumatic Footswitches

Air

pressure

preSSUriZe their respective

sent

to

6.2.1.4 Tone

The

Tone and Voice Volume Control Switches are

located

through

these

switches are sent

6.2.1.5

A capacitive

of

the

RF Amplifier and the forceps

circulatory current that occurs during cutting

coagulating to prevent muscle tissue react ion.

from

the cut and coag footpedals

air

the

J.l.P

for

processing .

and Voice

on

the

front

of

the front panel

DC Blocking Capacitors

DC

block is inserted between the

Volume

the

Mother Board, protruding

of

the

to

the

switches. Signals are

Control Switches

CMC·1I1.

"p

Signals from

for processing.

to

limit DC

or

output

Time delay is built into

continuous application

periods of open circuit. After approximately

seconds of open circuit at the forceps, RF power is

extinguished.

L504 and C530,

series resonant circuit that acts

RF power waveform from saturating

with

interfering

6.2.2

6.

LED101 through LE01

through U108, respectively . Data from

Display

2.2.1

Oata Bus

from control signals supplied

Ulll

. The latched information is decoded (hexa-

decimal to 7 segments) and drives the numeric LED

displays.

the

Front Panel Numeric LEOs

(D8{O

..

the

detector circuit to allow

of

RF power during short

on

the

RF Amplifier

low level detection circuitry.

Board

08

are driven by U101

1}) are

la1ehed

by

Board

to

prevent the 1

T502

the

into

Ul0l·Ul08

Ul09, Ul10, and

0.5

, is a

Mhz

and

808ft

5

Page 8

Steering

suppty control signals to U101 through

N1 signal

and

Microcut and

significant

displays.

The N1. N2.

combine,

LED display.

and

numeric

requested.

6.2.2.2 Front Panel Single LEOs

The

are combined, selectively,

LPCUT.

FTPoON

RF

signal turns

requested.

LED

signal turns

display

6.2.2.3

The UP/DN

control rocker switches,

CUTSTRB

control switch,

produced by

5102.

Irrigator control

is produced

CUTRST

switch .

the

6.2.

LPop

CGop

klgic

, consisting of

selects

Coag

displays, the decimal points used on the

bytes

respectively, to select

FTPOON

LED

HPCUT. LPCUT. COAG. and FTPDON. signals

or

COAG

signal

output

power

when

irrigation is requested. The WATTS LED

mode

Front

signal

The

IRIGSW

the

Coag

displays, as well

on

the Cut, Microcut, and Coag

HPCUT

The

signals

display when RF

on

The

on

is

signal

the

. LPCUT. and COAG signals

HPCUT. LPCUT. COAG. BLINK.

mode display

turns on the Generator LED when

is

requested.

the

Mute LED when voice muting is

IRGLEo

the

Watts

requested.

Panel Switches

is produced

is produced by

5101

.

Coag RF

signal is produced by the

switch

by

the

watts

signal is produced

S105.

Coag

2.4

High

microcut

High

coag decimal poi

The

Reset

On-Card

switch,

going

decimal point

going

COAGRSTsignai

Signals

signal indicating seled.ion of the

signal indicating

Ul09

through

U1

most

significant byte of the Cut

as

the

the

proper numeric

combine to flash the selected

power

to

tum

signal

LEO

when the watts

by

5101 and

The

COAGSTRB signal is

pO¥ler

,

5103

. The

switch,

by

5106

.

nt

output is

on

the HPCUT,

LED~amp

The

MUTELEo

turns

on

the

RF power

5102.

the

Cut RF power

control switch,

WATISW

SlO4

. The

the

Cut

Reset

is produced by

seledion

08.

.

the

The

Ull1,

The

two

The

Irrigate

signal

of

least

the

6.2.3.2 Memory

The memory

addressing

consists

2805 EEPROM (O.5k-bytes)

the

J.lP.

during

latched tnto U207

provide enabling/disabling signals

devices

6.2.3.3 Clock Generator

clock generator includes a

The

and

two

dividing provides continual.

4

from

proximately eight

controller board.

6.2.3.4 Watchdog Timer

The

watchdog timer, U206,

the

J.lP

(a)

power

(b)

no

signal.

within 1

This guards against unit matfunctioning due

hang·ups

tions.

6.2.3.5 Clock Synchronizer

The

f,1P

the external clock generator. A flip-flop, U231 B,

whose output changes only with a rising clock edge

the

on

The

clock frequency

timer signals a ·clear'"

(U231B) and

Mhz

starts running synchronously with

generator.

6.2.3.6 Select

clock input.

500

and 500

circu;t

to

of

one

Upper

the

Timing Pulse A (TPA)

to

avoid conflicting with

ripple dividers, U202

Mhz

to .25Hz in divide--by·two steps. Ap-

when one

up; or,

to

to

2.5 seconds, continuaJly.

and

internal

Khz clock

the

Khz

has

fully demultiplexed 16-bit

allow 64k-bytes

27128

8-M

U206

temporary low supply voltage condi·

clock

of

EPROM (16k-bytes).

addressing

and

U208.

taps

are used

of

the

following

, pin 6,

divider is synchronized with

is

supplied with a

is

the equivalent

the

J.lP.

to

.p.

the

clocks are aligned

Out

and

and

phase

provides

watchdog

When

both

the

rising

of

data. Memory

a fl4.byte RAM in

(of

16

period

U201D

to

one

stable a Mhz

U203. RipP'e

coherent division

by

devices

occurs

of

the

synchro

edges

the

one

bits) occurs

, and is

and

U233C

all

the

memory

another.

crystal

on

the

a reset pulse

:

input

(WDI)

to

IJP

500

Khz

clock.

the

intemal

watchdog

circuit

of

both the 4

and

the

IJ.P

master clock

to

6.2

.3

Controller

6.2.3.1 Microprocessor

The

microprocessor has

bus

(OB{O

..

7}),

appropriate

MRW\), a

flag-line inputs (EF1 to EF4), extemal interrupt

(INTIJ, internal countdown time

random

U205,

(N1

to

timing

device

access

provides

N7).

Board

an

a·bit bidirectional data

16-bit memory addressing

indicators (TPA,

1/0 selection

memory (RAM).

one-ot-eight operation of I/O devices

lPB, MRD

(N

.lines), 4 extemal

r,

and

An

N-line decoder,

6

(641<)

64-byte

\.

and

Data

to

be

output

into U212.

MRo

6.2.3.7 Select

Data

through U216.

when

chronous.

U213. U214

. and

TPB

to

be

input

U217

the

N3, N5. N6, and MWR

from

the 8-bit

, and

signals are

In

to

the

8-bit data

. U218. U219.

data

bus

U215

when

synchronous

bus

are transmitted

U237. and

signals

are latched

the NS, N6,

.

U238

are syn-

Page 9

6.2.3.8 Digital-to-Analog Converter (CAC)

The

OAe

takes information from

to

and converts it

the

High

Voltage Power Suppty . Eight bits of hexa-

decimal data corresponds to

as

is

data,

into the

synchronous.

output

wtth

6.2.3.9 Randomizer Control

While pseudorandomization

coagulation)

the

EPROM

the

~P

by the

S-bit

counter, U225. U225 is clocked

Therefore, each

inputs represents a delay

increments

The

delay is

tion waveform bursts. When U225 is finished down-

counting a given

EFl

applied to the

DAC

from

N=hexadecimal value input to

by

providing delays not otherwise obtainable

~P

itself. When

data

bus are loaded into an 8-bit binary down-

(j.LS)

flag line input.

analog voltage information used by

DAe

when the N4 and

The

value of the 4.

the

DAC

will be (NJ256)'

is primarily maintained by a data table in

and

controlled by the

N7

data

byte latched into the counter

in one-microsecond

(e.g.; hex 10=10

used

to

control

data

byte, it signals the

the

S-bit data bus

256

units of decimal

.

HEX

data are loaded

MRD

\ signals are

75

vec reference

(4

.75 VDC).

CAe

.

data

(necessary for

~p,

U225 assists

is asserted, data from the

down

at 1 Mhz.

J.lS,

hex

the

start

38=59

of

the coagula-

~P

)lS).

via the

When

the

U229

divider ratio is

by a 488 Hz clock , the output

is 8 Mhz ,

division of the shifted 8 Mhz

the

Mhz

Mhz

6.2

The

(FETs) require a 1 Mhz signal . However, due

tum

what

to

prevent both halves of the bridge

at

the

from the 8

two

by

The

together through

and

Mhz

and

01Mhz

edges are

bridge amplffier operation.

6.2

.3.13 On-Card Signals

± 4% at a change

1

Mhz

Split-Phase Dead

shifter circuit is locked

during the cutting mode .

.3.12 1

AF

off delay propagation

shorter duty

outputs of U230A and

U2348. They are combined (ORed) with the 1

and 1MhZ\ outputs

U232C to form

Mhz

Split-Phase

Power

same time and reducing efficiency. Eight

through U230A, U230B,

and

Amplifier bridge field -effect-transistors

cyde

(37% on,

Mhz

shifter circuit

U2330

of

two

37%

0\1Mhz

shifted

. The

1SOO

from

changed

of

the

rate

of

waveform

Zone

to

one

Dead

nature

of

63%

is

sequentially divided

and

U230B

and delayed through U234A

U231A

duty

cycle waveforms,

C1Mhz

each

other for proper

and shifted

PLL

VCO, U228,

488

Hz. Further

is handled by

Generator. The 8

frequency near 8

Zone

Generator

FETs

, a some-

off)

is required

from

turning on

U231A

are

through U232A

and

to

ANDed

0\1

Mhz

to

the

Mhz

1 Mhz.

rising

RF

6.2.3.10 Coagulation Waveform Control

The

coag

waveform

shift registers,

form a

the

control,

a

input).

mined by

U227. The final digital waveform

Power

waveshape .

(a) 2.0

(b)

(e)

(d) 1.0

U226

mode

6.2.3.11 8

16

-bit

word

ShiM...oad input (pin 15)

U226

0.5

J.lS

rate

(due

The

logic level of

the

fixed

Amplifier

liming

'"

low;

0.5

'"

",low;

'"

and

since

high;

high;

U227

they are

Mhz

1.5

generator consists of

U226

and U227, wired together to

. After receiving a start pulse

from

the randomizer

and

U227 output pulses from pin 13 at

to

a 2 Mhz signal

the

output pulses is deter·

inputs (A through

is

to

form a damped coagulation

is as follows :

(e)

1.0",

(Q

1.0

(g)

0.5

are

locked out during the cutting

not

required.

Shifter

two

to

the clock

H)

of U226 and

used

by

low;

'"

high;

",low.

S-bit

the RF

The coagulation waveform requires that the base

frequency

The base

locked-loop (PLL), U228 ,

oscillator (VCO)

8 Mhz from the

fed back

second reference input is connected

reference

signed

of 1 Mhz

waveform

to

one

clock. The

to

divide

be

shifted approximatety ± 4%.

is synthesized with a phase-

whose

output is approximately 8 Mhz .

veo

is divided down by U229 and

reference input of

U229 divider has been de-

at

a ratio that provides a near 62.5

voltage controlled

the

PLL

The

to

a 62.5

Khz

Khz output.

to

The

Low

EFI

EF2

ME\

N4

N5

N6

N7

RLYDLY

TPA

TPB

6.2.4

6.2

The

U301, pin 4, from N3 and simultaneous data from

8-bit data

determines which word is

word

U203

buffered and filtered

6.2

Tone

One

modes

tone

whenever there is no

Digitalker is accessed.

Sound

.4.1

Digitalker, U301, is

list.

. Digital voice aud io

.4.2

generators consist of

tone,

. U30SC determines which of the two other

oscillators are used.

going signal

troller, U225, to external flag 1 input on

Low

going signal

external flag 2

Low going signal to

of internal

1/0 select

64

of

I/O select

select

I/O

Output select

High

going signal, after

voltage relay

high

High going signal

tion of high order

High going signal

tion of low order

Board

Digitalker

bus

. Information written

The

word list

by U303.

Tone

Generator

390

Hz, is shared

from

the randomizer con-

from A to

mput

on

IlP

~p

indicating selection

byte

RAM

DAC

or

ADC

of

randomizer

delay

from

~P

indicating selec-

memory

from

memory

started

to

be

is

stored in

from

U305,

by

The

footpedaJ activity

address bytes

IlP

indicating selec-

address bytes

by a write pulse

to

the

sel

ected

the

U301, pin 39, is

U306, and U307 .

both cut and coag

tones

are squelched

0 converter

controller

, to control

Digitalker

from the

EPROM ,

or

the

~P

to

to

the

7

Page 10

6.2.4.3 Volume Control

U309 and

devices.

detennine selection of either

(voice). The

direction

signal strobes

function.

U304

The

power-up to quiet down

generators. U301, pin 6, generates an interrupt

extemal flag line

oigitalker

6.2.5

6.2.5.1

U310

are electronic volume control

The

TONEVOL

VOLUPoN

of

volume: either up

U309 and U310

The

outputs of U309 and

for

final amplification to the speaker.

oL

Y signal provides a small time delay upon

3,

and TALKVOL signals

U309 (tone) or U310

signal determines the

or

down. The N3\

for

the

oigitalker and tone

EF3,

of

the

J.l.P

volume control

U31

0 are fed to

when the

is active.

High

Voltage

General

Power

Supply

Board

to

oAC

vottage (from the controller board) is first

buffered by U404B, and then

locations: U404A and U401

6.2.5.2 Voltage Sensing

U4018

DC voltage from C405. The·reSultant output signal

from

flip-flop U405A.

the PWM

U40SA is lhen applied

input.

DAC reference voltage causes shutdown of the PWM

controller,

preclude sporadic duty cycle pulses from occurring

and causing premature shutdown

6.2.5,3 Current Sensing

compares DAC voltage and scaled down high

U401

B,

VCNTl,

controUer, U403, The output

Scaled down high DC voltage that exceeds

U403. Synchronizing (SYNC)

is applied

VCNlL

to

is applied

B.

to

is combined with

U403, pin 9,

the

of

to

data

of

the

U403.

two

input on

SYNC

flip-flop

shutdown

is

used

to

from

the

K401

Relay

voltages

auto-switch mechanism is employed

connection

K400 has a

primary of

when

voltage is presented

08400,

When

energizes and forces

capacitors C401 and

doubler system. Relay K400 initially defaults to the

220/240 mode

inrush current limiting. R400 and R401 provide

voltage balancing due

C401 and C402. R402 provides a shorter discharge

time for C401 and C402 when

Unloaded off-line voltage is approximately 330 VOC.

High DC voltage monitoring is provided by optoisolator

are maintained: isolated for off-line; and earth, for

post-off-line

Unregulated high

off-line side (isolated) to

ground referenced) via FET

transformer

modulation (PWM) controller,

T400

by PWM at

flyback energy

T400's isolated secondary winding, R404, R405,

C403, and

prevent destructrve voltages from destroying

Flyback energy

C405, Regulated

RF Power Amplifier. R449 and

snubber protection for 0402.

Input

to

several sources, and combined before being input

U403, pin 9.

voltage regulation from several

breaks both the AC and off-line DC

simultaneously for safety. A line voltage

to

select proper

to

low

Tl01

operates

TI01

U400.

C404

the

PWM

either 1001120

120

VAC coil connected across the

voltage transformer, T701,

is operated

to

as

a full wave bridge rectifier.

is operated

the

C402 to operate

for

safely. RT400 and RT401 provide

to

Two

separate

and

chassis.

DC voltage is transferred from the

T400,

0400

125

Khz, During O4oo's off time,

is transferred from T

comprise

is

rectified by

DC

voltage is now available to the

controller, U403, is derived from

The

purpose of U403 is to maintain

or

220/240 VAC. Relay

at

2201240 VAC, no AC

K400; and

at

100/120 VAC, K400

diode bridge, 08400, and

unequal leakage currents

the

is controlled

two

the

d~

as

a voltage

K401

is de-energized.

DC

grounding systems

post-oft-line side (earth

0400

and flyback

by

pulse width

U403, and pulses

4OO's

primary to

snubber circuits

0402

and filtered by

C440 provide

volts to

as

225VDC.

8

so

that

bridge,

0400.

much

to

as

DC pulse current through

and monitored through current transformer, T

and then

the reference set by the

controller, U403, is shutdown. Comparator U401A's

trip point is modified by

voltages up to 3

voe,

prevent excessive high

periods of light or

are less

applied to U401A. If peak current exceeds

VOC, U404A acts linearty; above 3

U404A clamps.

no

than

125

vec. With

vec (greater than 125 vec at

overshoot problem is minimal.

Additional over-current protection is provided by

U409. When current exceeds

in

of

the high vottage power supply,

U403, shuts down and a signal, SCMONI, is transmit-

ted

to

the

j.lP

for error control handling (error code

02). The purpose of this additional circuit

prevent destruction of

Amplifier.

6.2.5.4

The PWM controller's

voltage for

drives U406,

~Iation

•

A'

T402,

isolation.

6.2.5.5 Normal

The

discontinuous mode for light loads.

primary current starts at zero, and secondary current

drops to zero during each cycle. The flyback

former operates in the continuous mode

or

to

transient load conditions,

operation

at

the start of each cycle, where

immediately steps up, then ramps

on pedestal waveform).

lsolaled FET

FET

driver, U402, Clock signal, SYNC,

Q404, and T403.

between off-line and post-oft-line sides.

drive signal from the output

U402, and FET

Operation (Flyback Mode)

ftyback transformer, T400, operates in

is

characterized by nonzero primary current

0400

and

T400

oAC

voltage,

U404A

The

purpose of this circuit

DC

voHage overshoot during

load while output

DAC

the

10

the

power supply and RF

(0400)

clock provides an isolated bias

0400.

Drive

T403

of

T402 also provides

the

At

oAC

voltages above 3

output) ,the

amps

the

PWM controller,

provides

U403 drives 0401 ,

That

The

continuous mode

the

primary current

linearly (i.e., ramp

is isolated

PWM

reference

DC

voltages

at

the

is

to

the

is, T400's

for

heavier

401

,

is

output

The

trans-

to

of

Page 11

62.5.6

ACIN_ 120/240

DACOUT Buffered

PWM Pulse wktth modu lated signal from PWM

SYNC Buffered clock signal from

VCNTL Signal

+15V/ISO Isolated 15 vott bi

6.2,6

6.2.6.1

The RF Bridge

Each vertical

driven at 1 Mhz. The drive signals ate

0 \1 Mhz. (See description under Controller Board).

Each

bottom

supplied from the coag waveform generator to

top

haff-legs

marked

horizontal bridge across

vertical elements.

62

.6.2 Coag Waveform Generator

voltage

DC

controlkld by

0501

rated and allows pass·through of the voltage from

the High

mode,

Controller Board) modulates the

High Voltage Power Supply. The modulated DC

the

voltage

C509 into a decaying

forming

RF bridge amplifier.

bridge amplifier

PWRDIS signal under conditions

circuit at the forceps.

6.2.6.3 RF Output Steering

The RF

saturating

series with

comprises two sepatate windings; one

ance

cut modes

power cut

ing secondary windi

K502, and the

high power

with the coag/low power cut winding

desired higher impedance.

On-Catd Signals

VAC

input to diode bridge

DAC

output voltage

controller

ler

, U403

comparator

FET

RF

Power

RF Bridge Amplifier

Amplifier is

hatf·leg

alternate half-leg (i.e

leftltop

BRIDGE .

. When in

the

is

right) is driven in phase. Voltage is

of

the

to

power the

the

Voltage

coag waveform signal (see description in

filtered by L501 , L502, L503, C508, and

to power

from output of voltage sense

driver

Amplifier

of

the "H" is an

bridge

The

load, T501 , is placed

the

coag waveform signal driving

the

cut mode, 0501 is fully satu-

Power

Supply. During

DC

FET

PWM

as

supply

Board

of

the "

.,

top left/bOttom right;

amp

~op

middle of

RF

Bridge Amplifier is

voltage waveform, thus

for

H"

bridge design .

FET

01

left;

the

voltage supplied by

the damped sinusoidal signal through

Cut

-off of DC voltage to

is

provided by U503 and the

of

short and open

output transformer , T501 ,

by a

DC

blocking capacitor, C528 , in

the

primary winding. T501's secondary

is

prevented from

low imped-

and

one high impedance. Coag

ate very low impedance

is somewhat higher

ngs

CUmL

cut

secondary wind ing is added

Y signal. When required,

«300

is controlled by relays K501 ,

and

«20

ohms). Switch.

to

achieve the

control-

power

suitably

Mhz

and

the

top

right),

as

the

two

the

coag

the

the

RF

low power

ohms); high

the

in

series

in

The high power cut winding added

coa9'low power cut winding, instead of a tap-type

connection. limits the amount

generated in the high power cut winding when

coagulation

energy

and outside

coag

noise filtering is

consisting

The coag noise filter also provides proper matching

between

cord, and

former TS02

the

Open

Mother Board description.

62

.6.4

Two short circuit detection circuits are used; one

each

for

Current through the forceps

coagflow

The sense current , in the form

rectified, filtered , and detected by opto-isolators

U513

outputs

in

U514

as

long

The outputs

signal

to

the RF bridge amplifier

the

100

again

until

the

signal

An

LED marked "short circuit" is used during testing

to confirm operation.

detection is

from destroying the RF Power Amplifier and forceps.

6.2.6.5

Isolated Bias Supplies of 7.5 VOC are required for

the upper hatves

coag waveform generator. These stages

respect

have

the

6.2.6.6

BRIDGE

ISO+7V(n) Isolated

ISOGND(n) Isolated grounds

PWRDIS Signal from output

mode

is used. This excessive noise

can

create interference problems both inside

the

metal

case

pro*d

01

L505

, L506, L507, C531 , and C532.

RF output transformer T501 .

biologlcalloading at

and L504, C529 and C530 are part of

Circuit Detector, and

Short

Circuit Oetection

coagllow power cut and high power cut.

power

or

U515 when the threshold is exceeded. The

of

to

as

PWRDIS. During the

ms

for

a shorted condition.

short circuit is removed.

is

also shared by the Open Circuit Detector.

cut, or RS24 for high power cut.

U513

or

U515 cause

operate at 100 millisecond (ms) intelVais

excessive short circuit current

of

U514 are ORed together

period, RF power is restored

The purpose of short circuit

to

prevent excessively high

Isolated Bias Supplies

of

the RF bridge amplifier and the

to

earth ground when operating, and must

Isolated Bias Supplies.

On

-Card Signals

Modulated DC vottage (during coag)

from coag waveform generator fitter to

RF

bridge amplifier

7.5 vec bias power supplies

to

RF bridge amplifier and coag

waveform generator

plies to

waveform generator

detectors to disable

RF

of

of

the

the

is

sensed by R525 for

of

100

is

cut

This

of

bridge amplifier and coag

series with the

high voltage energy

the

CMC-1I

by

a low

forceps. Trans-

is

explained in the

a small voltage,

the

ms

off

. At

The

bias power sup-

of

RF

1.

Further

pass

filter

the

forceps

one-shot timers

is

present.

to

form the

period, voltage

the

end

of

to

test

cycle continues

PWRDIS

RF

currents

"'float" with

short circuit

output

is

9

Page 12

SCRES1

Short circuit current through R525 to IRRIG Low going signal from 1/0 indicating

of

input

coagllow power cut short circuil selection

detector

SCRES2

SCRES3

SCRES4

Short circuit current through R525 to selection

input

01

coag/low

detector

Short circuit current through A524 to

input

of

high power cut short circuit

detector

power

Short circuit current through A524

input

of

high power cut short circuit

detector

6.3 MASTER LIST OF CARD CONNEC·

TOR SIGNALS

o

to

5

vec

AlDIN

BUNK

COAG

COAGFTSW

COAGRST

COAGSTAB

COAGWVFM

CUOFTSW

CUTRST

CUTALY

CUTSTAB

DAC

DB[O

EF3

FTPDON

HPCUT

HVRLY

IRIGLED

IRIGSW

IRRECV

10

digital converter (ACC)

1

Hz

High going signal from I/O indicating

selection of

Low

going signal

depression of coag footswitch

Low

going signal to 1/0 indicating

depression of

Low

going signal

selection of coag power switch

Digital signal

(RFAMP) representing the coagula·

tion waveform

Low

going signal

depression

Low

going signal to I/O indicating

depression of

Low

going signal from 1/0 indicating

seledion

of

T501 via cut control relays

Low

going signal

selection of cut power switch

o

to

5 VOC signal from the digital to

analog

..

7]

Bidirectional

Low

going signal from Digitalker to

external flag 3 input on

High

going signal from I/O indicating

depression of any footpedal

High going signal from 1/0 indicating

selection

Low

going signal from 1/0 indicating

selection

located

High

going signal from 1/0 indicating

selection

Low

going signal

depression of

Digital signal from infrared receiver

to

f.1P

signal to the analog to

signal; 75% on, 25% off

roag

mode

to

1/0 indicating

the

coag reset switch

to

1/0 indicating

to

RF Power Amplifier

to

I/O indicating

of

cut footswitch

the

cut reset switch

of high power cut winding phase

to

1/0 indicating jacks

converter (DAC)

8-8it

Data Bus

of

high power cut mode

of

high voltage mains relay,

on

the

HVPS

of

irrigate LED

the

board

to

I/O indicating

irrigation switch

cut short circuit

to

to

the HVPS

f.1P

of

external irrigator

LPCUT

LT

MRD

MUTELED High going signal from 1/0 indicating

MUTESW

MWR High going signal

NOHV

N1·N2 Output select

High going signal from 1/0 indicating

01

Jow

power

Low going signal

indicating selection

High going signal

a memory read function

selection of

Low going signal

depression

a memory write function

Low going signal to 1/0 indicating

unregulated htgh voltage

present on the High

Supply (HVPS) board

mute

of

the

for

cut

mode

to

Display board

of

LED

test mode

from

,...p

indicating

LED

to

I/O

indicating

mute

switch

from

IlP

indicating

DC

is

Voltage

displays on display

Power

board

N3

OCMONI

PWMON Low going signal to

PWADIS Additional low going signal from

Q1MHZ

Output select

volume controls; input

Low going signal to 1/0 indicating

open forceps condition

selection

(PWM)

supply

output

AMP

Digital 1

to

of

to

for

Digitalker

select

HVPS

of

pulse width modulator

IC

to

stan

output voltage

RFAMP

open circuit

disable

Mhz

signal with a 37% ·on-

RF

detector

output

and

for

indicating

to

I/O

RF

duty cycle

Q\1MHZ

RFPWR1 RF output

RFPWR2 RF output

SCMONI

TALKVOL

TONEDN

TONEUP

TONEVOL

UP/DN Signal

Same

as

Q1

MHZ

, but 180"'

power

power

jacks

Low going signal

overcurrent condition

Low going signal

on Sound board indicating selection

of voice volume control

Low going signal

depression of

Down switch

Low going signal to 1/0 indicating

depression of

switch

Low going signal

on

Sound board indicating selection

of tone

cut or ceag

and

volume control

to

1/0 indicating selection

low for

the

the

power

down

to

patient output

to

patient output

to

I/O

to

volume

to

1/0 indicating

Tone

Tone

to

volume

control; high

out

indicating

on

the

controls

Volume

Volume

controls

of

HVPS

Up

of

for

an

an

up

Page 13

VOICEDN

VOICEUP

VOLUPDN Digital signal to volume controls on

WATTS LED High going signal from

WATTSW

20KHZIN 20 Khz (approximate) sine wave from

20KHZOUT

+200V 0

Low going signal to I/O indicating

depression of the Voice Volume Down

switch

L

ow

going signal to I/O indicating

depression of the

switch

Sound board representing volume

direction

selection of watts LED

Low going signal to I/O indicating

depression of the Watts switch

of

output

20

input

to

to

RF AMP

open circuit detector filter

Khz (approximate) sine wave

of

open circuit detector

225

VDC @ 2 Amps from HVPS

Voice Volume Up

110

indicating

10

fiNer

6.4 TEST POINTS

Eleven test points are available to facilitate trouble

shooting.

of

the controller board on P203 (Figure 8). Activate

test functions by grounding (momentarily or constantly, refer

ate pin. Note that some test points provide dual

function capability.

6.4.1

Momentarily grounding this pin provides a complete,

sequential test

For

All test pins are easily accessed al the top

to

each section for details) the appropri-

Pin

*1

Power

Up,

Display

of

see

Test/Power

aU

LEOs, lamps, and numeric LEOs.

6.4.4, Calibrate On/Off.

Up

Its purpose is to zero out the high voltage available to

RF

the

DC, however, remains on the High Voltage Power

Supply board and must

Removing the ground turns off LED

announces "output power is on".

6.4.4 Pin

Grounding this pin enables the calibration function by

announcing "calibrate output power

Section 6.6, Calibration, for details.

6.4.5 Pin

This test point can

problem with the EEPROM. This can occur during

first time power-up with a blank

the

grounded, the unit announces "recycle memory" and

reprograms the

in

nounces "memory is correct" (assuming no EEPROM

problems) and then reinitializes the CMC·III. With

error condition, the unit announces "internal memory

error" and flashes "01" in the microcut display.

6.4.6 Pin

Grounding this test point causes an instantly

lated checksum of the EEPROM

the checksum stored within the

compared values show

coag displays.

unit announces "internal memory is correct." When

this test point is ungrounded, the unit reinitializes.

6.4.7 Pin #7

Grounding this test point causes the unit

"internal power recycle on." This mode is available

for factory use only. It is recommended that this test

point NOT BE ACCESSED.

Power Amplifier. Unregulated high voltage

be

approached with caution.

201

and the unit

#4

Calibrate

#5

Factory

be

EEPROM malfunctions. When momentarily

EEPROM. Transferring data is seen

the coag display. When finished, the unit an-

#6

RAM

If

the compared sums are equal, the

Factory

ON/OFF

".

Refer

to

Profile

activated only when there is a

EEPROM, or when

Read

calcu-

to

be compared with

EEPROM. The

on

the high power cut and

Test

to

announce

an

Figure 6. Controller Board Layout

6.4.2

Momentarily grounding this point provides a complete.

sequential test of

voice/tone volume control1unctions. For

Down,

6.4.3

Grounding this point turns off the PWM controller IC

on the High Voltage Power Supply. The message

·output power is

on. This test mode allows full functioning of the

CMC-III except for output power.

Pin

#2

Sound

all Digitalker words, tones, and

see

Calibrate On/Off.

Pin

*3

Deactivate

off'

Test/Power

PWM

announces and LED

Down

Power

201

turns

6.4.8 Pin #8 DAC

Voltmeter test point. OAC reference input voltage

should be 4.75

6.4.9 Pin

Voltmeter test point. DAC output voltage. When

calibrate mode, this voltage can be compared against

the displayed

display. The

display/255} * (DAC reference voltage).

#9

DAC value shown on the numeric LED

DAC output

6.4.10 Pin #10 ACC

Not used.

6.4.11

Grounding this test point allows operation of the

CMC-lll with the High Voltage

removed.

Supply board connectors, J403 and P404, be can·

nected together to provide

voltage power supply transformer,

point must

the High Voltage Power Supply connected.

Pin

#11

It requires that the two High Voltage Power

be

ungrounded for normal operation with

Reference

VOC, ± .05 volts.

DAC

Output

VOltage

Input

NOHV

Bypass

Power

AC

power to the low

should be [DAC

Supply board

T70l.

This test

in

11

Page 14

6.5 OPERATIONAL PERFORMANCE

The

MALIS

may

be

ohm

and

ammeter

test set

values

that

these

may

vary

tolerances,

Bipolar

tested

400

or

equivalent

up

in the accompanying figure shows typical

for

each power setting. It should be noted

are

depending

and

--