Pipe and Equipment Insulations

Zeston

PVC Insulated Fitting Covers

Installation Instructions for Hot, Cold and USDA Piping Systems

®

Zeston® PVC Insulated Fitting Covers

Installation Instructions for Hot, Cold and USDA Piping Systems

Installation Instructions for USDA and FDA Piping Systems

The Zeston PVC/Perma-Weld® pipe jacketing

system consists of Zeston PVC fitting

covers, Zeston PVC jacketing (20 and 30 mil

[0.5 and 0.8 mm] material only) and Zeston

Perma-Weld solvent welding adhesive.

The Zeston/Perma-Weld protective jacketing

system meets USDA requirements for piping

systems in meat and poultry processing facilities.

It also meets FDA standards for other food

processing, beverage and pharmaceutical

facilities. In these and related applications, the

Zeston PVC/Perma-Weld system resists

contaminant infiltration and withstands repeated

washdowns while providing a clean, finished

appearance over bare or insulated pipe.

Installation Instructions for Cold Systems

Qualifications for Use

®

Install the appropriate Hi-Lo

insert by wrapping it completely around the pipe

fitting without overly compressing it or leaving

any voids. Ensure that the insulation insert covers

all exposed surfaces. The Zeston PVC fitting

cover should then be installed over the pipe fitting

and fiber glass insert by securing the throat using

either serrated tacks, Perma-Weld adhesive or

Zeston Z-Tape.

The following sequence describes the installation

of Zeston PVC jacketing and fitting covers with

Perma-Weld solvent welding adhesive.

Temp fiber glass

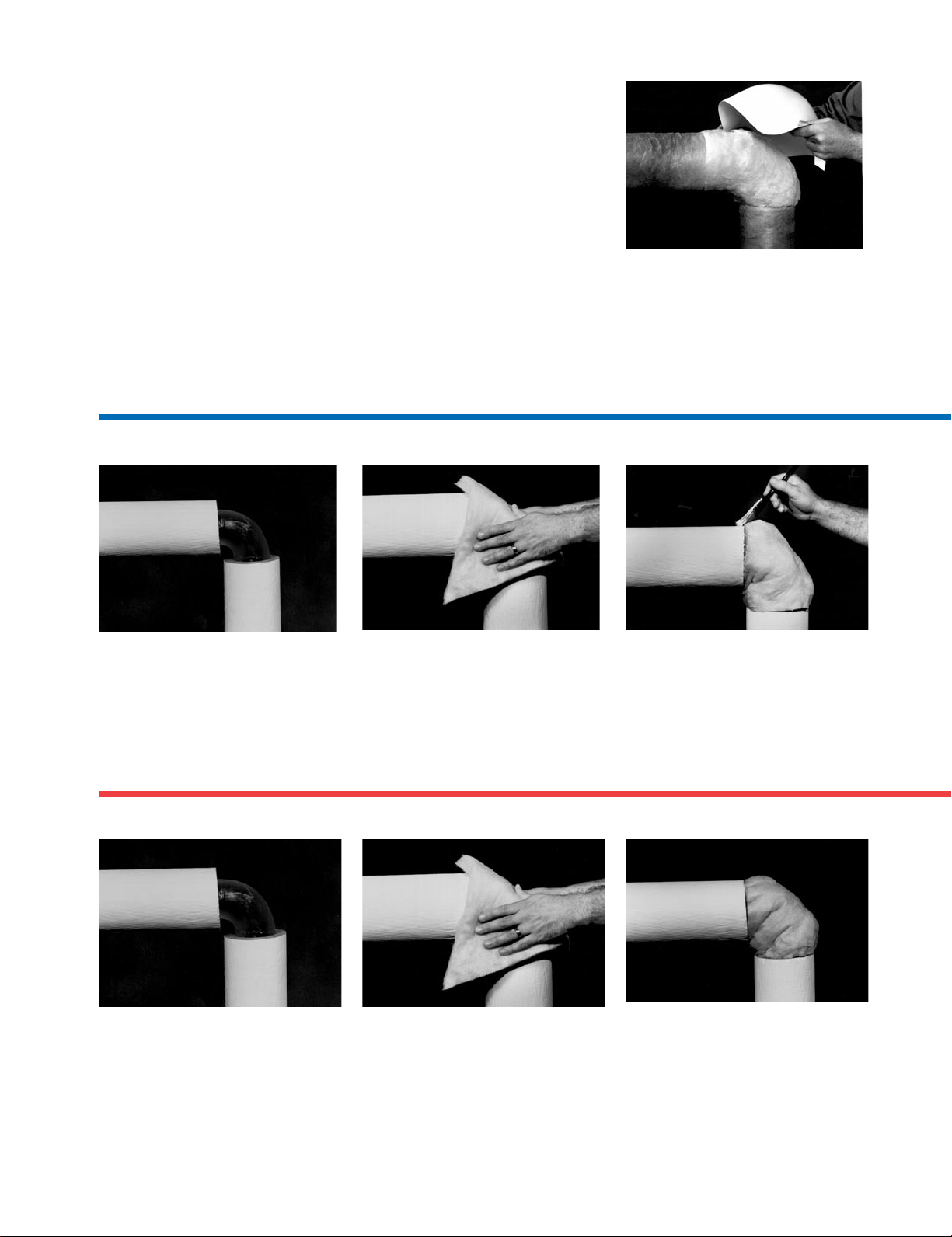

1. Position the Zeston PVC fitting cover

over the insulated fitting.

1. Zeston PVC insulated fitting covers are

quickly installed over ells, tees, valves

and other pipe fittings. Combined with

Micro-Lok

®

HP jacketed pipe insulation,

they provide a complete, color-coordinated system.

Installation Instructions for Hot Systems

1. Zeston PVC insulated fitting covers are

quickly installed over ells, tees, valves,

and other pipe fittings. Combined with

Micro-Lok

they provide a complete, color-coordinated system.

®

HP jacketed pipe insulation,

2. Position, tuck, and fold the fiber glass

insulation insert as described below in

steps 2 and 3 for hot systems.

2. Place the pre-cut fiber glass insert

around the fitting, positioning the points

of the insert on the inside radius of the

elbow. For applications with temperatures below 45°F (7°C) or above 250°F

(121°C), additional layers of insulation

may be required.* In such cases, the

first layer is secured by wrapping with

fiber glass yarn.

3. Apply a vapor barrier mastic around the

edges of the adjoining pipe insulation.

3. Butt the ends of the fiber glass insert

against the ends of the pipe covering.

Tuck and fold the insulation so that it

covers all bare surfaces. Keep the fiber

glass fluffed up to the thickness of the

adjacent pipe insulation to assure maximum thermal efficiency.

Loading...

Loading...