CI/SfB

John Guest Speedfit Limited

Horton Road, West Drayton, Middlesex UB7 8JL, England.

Tel: 01895 449233 Fax: 01895 420321. www.speedfit.co.uk

Technical Help Desk: 01895 425333

No.’s 95/3177

BS7291

KM39767

THE PUSH-FIT SOLUTION FOR

PLUMBING & HEATING SYSTEMS

53.0

Ih6

The company has a policy of continuous research

and development and reserves the right to amend

without notice the specification and design of all

products illustrated in this catalogue. John Guest

Speedfit reserve the right to change the colour and

shape of products. Photographs are for illustration

purposes only.

Subject to our Terms and Conditions

of Sale available on request.

, and are

trademarks of John Guest International

© Copyright 2007.

registered

Limited

AVAILABLE FROM:

UK PRODUCT RANGE AND

INSTALLATION GUIDE

October 2007

Z2105/217/10/07

Worldwide connections

THE PUSH-FIT SOLUTION FOR

PLUMBING AND HEATING SYSTEMS

The John Guest Group has a long

established reputation as a world leading

manufacturer of push-in fittings, tube and

other fluid control products. A

reputation built on producing consistently

high quality products with an ongoing

commitment to value engineering and

product development.

Quality Manufacture

A commitment to quality is at the heart of the John Guest Philosophy.

The strictest control is maintained by virtue of the fact that design and manufacture is carried

out in modern purpose built manufacturing centres in west London and at Maidenhead in

Berkshire.

Maintaining control over the whole process from initial tool design and tool making through

to final assembly and testing ensuring that only products of the highest quality are produced.

The company believe it is this commitment to quality that has led to it receiving prestigious

awards from many of the world’s leading testing and approvals organisations.

John Guest is a preferred supplier to many international companies.

British Gas

Service

JG Speedfit is a push-fit system suitable for the plumbing

of normal domestic hot and cold water services and

central heating applications, including pressurised and

combi systems.

Performance specifications are well within those required

for most normal domestic central heating and water

supply systems including:

• Mains fed and indirect cold water systems

• Vented and unvented hot water systems

• Vented central heating systems

• Sealed central heating systems provided

temperatures and pressures comply with

BS7291 Parts 1, 2 and 3 Class S.

• Underfloor heating

Technical Support

Our national team of Technical Support Engineers is

available to help you get the best from your

System. This includes a free underfloor heating estimate

and CAD design service.

TTeecchhnniiccaall HHeellpp DDeesskk:: 0011889955--44225533333

JJGG

The

to assist and advise on the aspects of the

System. The service is available 8:00am to 5:00pm

Monday to Friday.

SSppeeeeddffiit

t

Technical Advisory Service is available

3

SSppeeeeddffiit

SSppeeeeddffiit

The System is approved by the BRA and the WRAS.

Speedfit ‘PEM’ fittings and PEX and Polybutylene Barrier

Pipe are Kitemarked to BS7291 Parts 1, 2 and 3 Class S

Licence No KM39767.

Speedfit Fittings have been designed for use with both

Speedfit and copper pipe.

Extensive tests have shown that Speedfit products will

withstand temperatures and pressures well in excess of

normal working conditions.

JG Speedfit should be installed to conform with good

plumbing practice.

British Gas Service has accepted the John Guest Speedfit

System as being suitable for open vented and sealed

central heating systems and as eligible for acceptance

onto its service contracts.

t

t

01

Speedfit PEX Fittings

and Barrier Pipe.

K24076, K24077 and K24078

BS7291

No. KM39767

02

SYSTEM FEATURES

• All white system

• Truly demountable without damage to pipe or fitting

• Grip and seal connection

• Superseal Insert gives secondary seal

• Reduced pipe insertion force

• Lightweight and easy to handle on site

SYSTEM BENEFITS

• Installation time reduced by up to 40%

• Pipe flexibility permits the cabling of pipe through less

accessible areas

• No risk of fire or flames from a blowtorch

• Easier to work in confined places

• A permanent leak-proof connection

• Corrosion free

• No scale build up

• Lower thermal diffusivity maintains safer surface

temperature

• Pipe elasticity can reduce the possibility of bursting

under freezing conditions

• Lead free and non toxic

• Less noise from water flow and expansion/contraction

• Long pipe lengths reduce fittings required

GUARANTEE

As a result of long term test programmes and rigorous

quality standards, John Guest Speedfit Limited offer a 25

year guarantee against the defects in materials or

manufacturing of ‘PEM’, ‘PSE’ and ‘SFM’ Range

Plumbing Fittings and Speedfit Barrier Pipe

manufactured by John Guest.

John Guest Underfloor Heating Products, which should

be installed and maintained in accordance with our

recommendations, carry a 2 year guarantee against

defects in materials and manufacture.

John Guest Plumbing and Heating Products are for use

with normal UK domestic plumbing and heating systems

and supplied in accordance with our Conditions of Sale.

SPECIAL APPLICATIONS

Boats. The flexibility of the Speedfit System ensures it can

be cabled easily around the interior and hidden from view.

Caravans. Speedfit is ideal for caravan installations due

to its flexibility and its resistance to corrosion and freezing.

Exhibitions. The unique ability of the Speedfit System to

be easily demounted and reused, together with its

flexibility, makes Speedfit ideal for this application.

Agricultural and Horticultural.

applications in agricultural and horticultural environments.

Portable Buildings (site cabins, toilets). As with caravans,

Speedfit is well suited to this application.

Spe e d fit h as m a n y

WORKING TEMPERATURES AND PRESSURES

Application Usual Working Maximum working Maximum working

Cold Water 20 20 12

(indirect and direct mains)

Central Heating 82 105, short term 3

Hot Water 65 95 6

(including unvented cylinders)

Speedfit fittings suitable for central heating systems can

withstand temperatures up to 114°C intermittently for

short periods.

Speedfit fittings shown as not suitable for central heating

systems are used primarily on the domestic hot and cold

water system accepting temperatures of up to 65°C.

temperature, ºC temperature, ºC pressure, bar

malfunction at 114

HANDLING FITTINGS AND PIPE

Ensure fittings and pipe are kept clean at all times by

keeping them in bags and boxes provided.

Do not empty Speedfit Products onto the floor area.

Ensure internal ‘O’ Ring seals are kept free from dirt and debris.

PRODUCT SELECTION AND INSTALLATION

John Guest fittings and related products are specifically

designed and manufactured by John Guest to the

Technical Specifications set out in the John Guest

Product Catalogues. All John Guest fittings and related

products should be selected, installed, used and

maintained in accordance with these Technical

Specifications. It is the customer’s / user’s responsibility

to ensure that John Guest fittings and related products

are suitable for their intended applications, are properly

installed and maintained and are used in accordance with

the Technical Specifications. It is also the customer’s /

user’s responsibility to provide it’s own customers with

any relevant technical information about John Guest

products it supplies them.

Speedfit should not be used for gas, fuel oil or compressed

air applications.

John Guest produce a push fit system of pipe and fittings

compressed air situations. See seperate literature for details.

for

Contents

PLUMBING AND HEATING

Plumbing and 09 - 10

Heating Fittings

Flexi Hoses 11 - 12

Brass Fittings 12

Valves 13

Pipe and 14 - 15

Accessories

UNDERGROUND FITTINGS

For connecting MDPE

Cold Water Service Pipe.

UNDERFLOOR HEATING

Designed to be quick and easy to install.

27 - 28

TECHNICAL CHECKLISTS

Plumbing and Heating 29

Underfloor Heating 30

22 - 26

03

Underground Fittings 30

04

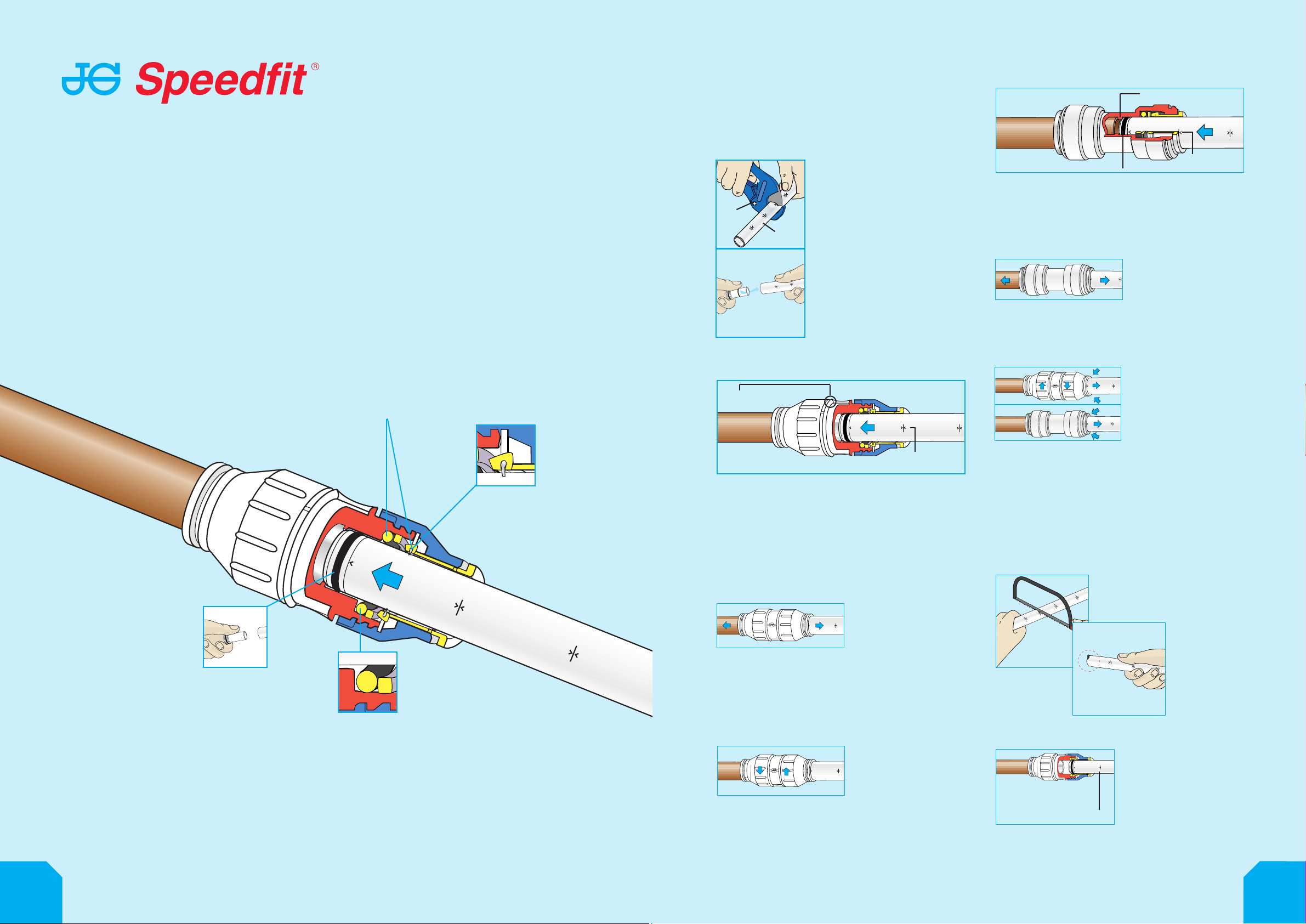

MAKING A GOOD CONNECTION

STANDARD SPEEDFIT FITTINGS

HOW SPEEDFIT WORKS

Speedfit Fittings have a unique grip then seal construction made up of a collet with stainless

steel teeth to grip the pipe and an ‘O’ ring to provide a permanent leak proof seal.

Use of the Superseal Pipe Insert ensures a double ‘O’ ring seal.

An ‘O’ ring at the head of the insert and the shape of the stem, provide a secondary seal against

the bore of the fitting. A combination of this and the main ‘O’ ring ensure a good connection.

The stem of the insert gives greater rigidity of the length of pipe within the fitting, reducing the

chance of leaks if a side load is applied.

The head of the insert has been designed for ease of insertion.

The additional benefit of Twist and Lock Fittings is that a twist of a screwcap locks the pipe in

position and gives increased compression on the ‘O’ ring for even greater security.

Grips before it seals

Pipe insert gives

secondary seal

Main ʻOʼ Ring Seal

Stainless steel teeth

grip the pipe

PREPARE THE PIPE

Fittings and pipe should be kept clean bagged and undamaged

before use.

Ensure the pipe is free of score

marks. Cut the pipe square.

When using Speedfit Barrier Pipe

cut along an insertion mark. We

Pipe Cutter

JG TS

NEW TWIST AND LOCK FITTINGS

Gap between Cap

and Flange

The fitting should be in the ‘unlocked’ position, this is

shown with a small gap between the screwcap and the

body flange.

Push the pipe fully into the fitting, up to the pipe stop. If

the Speedfit Pipe has been cut correctly the insertion

mark on the pipe will be level with the collet head. The ‘O’

ring on the Superseal Pipe Insert provides a secondary

seal against the bore of the fitting. A good connection

has been made.

Pull to check it is secure. It is good practice to test the system

prior to leaving the site or before use. Our recommended

test procedure is shown in our Technical Checklist.

ADDED BENEFIT TWIST AND LOCK

Speedfit

Barrier Pipe

recommend the use of JG Pipe

Cutters.

To prevent damage to the ‘O’ ring

remove all burrs and sharp edges.

When connecting Speedfit Pipe

use a Superseal Pipe Insert. A

twisting motion will aid insertion.

The insert should only be used

with Speedfit Pipe.

Pipe mark indicates

full insertion

If you are not using collet

clips, ensure that the

screwcaps are in the

locked position.

Twist the screwcap until it

touches the body flange.

This increases the ‘O’ ring

seal around the pipe and

locks the pipe into position.

Push pipe up to stop

Secondary Seal

Standard Speedfit connections are made in the same way

as Twist and Lock.

Push Pipe up to Pipe Stop. If the Speedfit Pipe has been

cut correctly the insertion mark on the pipe will be level

with the collet head.

Pull to check connection

is secure and test the

system. Our recommended

test procedure is shown

in our Technical Checklist

on page 29.

TO DISCONNECT

Ensure that the system

is depressurised.

The screwcap on Twist

and Lock Fittings will

need to be turned back

to the unlocked position.

Push the collet square against the face of the fitting by

using fingers or with the help of our collet release tool.

With the collet held in position the pipe can be removed.

The fitting can be used again without the need for

replacement parts.

WHAT NOT TO DO

Don’t use hacksaws to cut the

pipe or leave burrs on the end of

the pipe.

✗

Pipe mark indicates

full insertion.

Don’t use

damaged or

scored pipe.

✗

Don’t forget to push the

pipe fully into the fitting,

✗

Fitting may be gripped but not

sealed if pipe is not fully inserted.

past both the collet (gripper)

and the ‘O’ ring.

05

Do not insert fingers into the fitting as the stainless steel

teeth may cause injury.

Remember to pressure test the completed installation

according to the recommendations in our Technical Checklist.

06

PIPE STOP DISTANCES

Stops are located at the following distances from the end

of the fitting:

size 10mm 15mm 22mm 28mm

stop distance 20mm 30mm 35mm 44mm

COLLET COVERS

Use a collet cover or collet clip to provide added security

against pipe disconnection, e.g. the fitting coming into

contact with rigid surfaces and behind dry-lining walls.

Collet covers for use with standard Speedfit fittings, are

available in white or in red or blue to allow colour coding of pipes.

Collet cover

STOP END

The unique feature of the

Speedfit Concept, the ability

to disconnect the fitting

should you want to, means

the Speedfit Stop End not

only provides a permanent

leakproof seal, but can be

readily removed to allow

work to restart or to allow

an extension to a system.

Stop end

Stop ends are also useful when pressure testing a system

before appliances are connected.

Thus, the fitting is especially

useful to allow water to be

turned back on, overnight for

instance, or if a job has to be

interrupted for another reason.

STEM ELBOW

Designed to simplify pipe connection

in restricted spaces. The Speedfit

Stem Elbow provides an instant swivel

fitting so pipe can be orientated in

any direction.

A special 10mm version gives a neat

connection from concealed plumbing

a radiator.

to

TAP CONNECTORS

Speedfit manufacturer a wide range of connectors

including conventional straight and bent tap connectors.

The range also offers a special and

unique Tap Connector that only

requires a simple hand tightening to

connect up a terminal tap, mixer or

float valve. An integral seal within the

fitting avoids the need for further

sealant. The connectors are useful

when replacing existing brassware or

in other confined spaces.

Coupling up to a supply is easy. The

pipe is simply pushed home into

the Sp eedfit con nection and is

instantly secured, without the need

for specialist tools.

FLEXI HOSES

SPEEDFIT MANIFOLD

Speedfit have introduced an innovative 22mm x 10mm 4

way manifold. Departing from the usual manifold design,

this new product has 4 in-line 10mm outlets, offering a

neater envelope size and therefore a much smaller

installation space.

Other benefits include better flow characteristics and a

more even distribution of hot water.

The 22mm and 10mm Speedfit push-fit connections make

for a fast and easy installation, even in confined spaces.

Whilst designed as a heating product, the manifold can

also be used in a mains pressure hot or cold domestic

plumbing system, to feed bathroom or kitchen taps and

mixers. This allows for a more efficient installation as

every terminal fitting has its own dedicated supply.

APPLIANCE TAP

The Speedfit range includes an Appliance Tap for

the permanent connection of washing machines and

dishwashers, thus enabling complete water isolation to

the appliance.

COLLET CLIPS

Collet clip

Collet clips are available in grey and white for use with

standard fittings to prevent accidental pipe

disconnection.

Red or blue collet clips provide colour coding of pipe on

twist and lock fittings.

They are not designed to prevent accidental release and

should be fitted when the fitting is in the locked position.

RELEASE AID

The action of pressure in a system could increase the grip

of the collet. The release aid allows a firmer grip on the

collet whilst removing the pipe.

Release aid

07

SERVICE VALVE

Speedfit x Speedfit

Mechanism twists out of sight

The Speedfit range of brass

chromium plated service

valves can be used on both

hot and cold water services

and central heating. Push fit

connections mean much

reduced installation time,

especially in confined spaces.

The valves, in 10 to 22mm,

have a 1/4 turn open/close

mechanism operated by a

screwdriver slot or a lever.

Tap connector patterns have

a uni o n n u t to co nn ect

direct to a tap or floatvalve.

Lever

operated valves are

supplied

and a red indice.

The ability of Speedfit products

to twist whil s t i n si t u

allows

operating valve to be turned

out of sight,

unauthorised tampering.

with both a blue

the sc re wdriver slot

helping to avoid

Manufactured to a quality you would expect from Speedfit,

our range of Flexi Hoses has 40 different patterns.

Available in lengths from 150mm to 1,000mm, ends are

either push fit to union nut or push fit to push fit,

hoses with an integral

screwdriver slot.

Apart from being aesthetically

hoses offer more flexibility and a larger through bore

for better flow characteristics.

More specialist patterns

have been designed to help

the installation of monobloc

mixers to a 15mm supply.

Sold in pairs, each hose in

the pair has a different

spanner location to ease

connection of the threaded

end into the monobloc’s

inlets.

The hoses are suitable for cold water up to 10 Bar and

hot water (65˚C max) up to 6 Bar and approved by WRAS.

service valve operated by a 1/4 turn

pleasing the new white

including

A simple push fit connection of the supply pipe and a

plastic thread on the outlet to marry well with the plastic

thread on the hose means the Speedfit Appliance Tap is very

easy to install. The large round handle is easy to grip and turn.

SUPERSEAL PIPE INSERT

The Superseal Pipe Insert has been developed to be used

with Speedfit Barrier Pipe and Speedfit Fittings to provide

an extra line of defence when installing a Speedfit Push

Fit System.

The insert has it’s own ‘O’ ring which, with a stem sliding

within th e inside of th e pipe, give s a secondar y seal

against the inside of the fitting.

The Speedfit Connection, when made with the insert, has

a number of design features.

Sliding the stem of the insert into the pipe gives greater

compression of the main ‘O’ ring on the pipe and greater

rigidity of the length of pipe within the fitting, reducing the

chance of leaks if a side load is applied.

A connection is easier to make because the head of the

insert has been designed for ease of insertion.

Superseal Inserts are listed on page 14.

08

Loading...

Loading...