Page 1

HAD0901001C2

Microwave Oven

NN-CT878SBJQ

JLFSMWC003

32L OEM

United Kingdom

Page 2

NN-CT878SBJQ JLFSMWC003 32L OEM

2

1 Contents

1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Inverter Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Feature Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

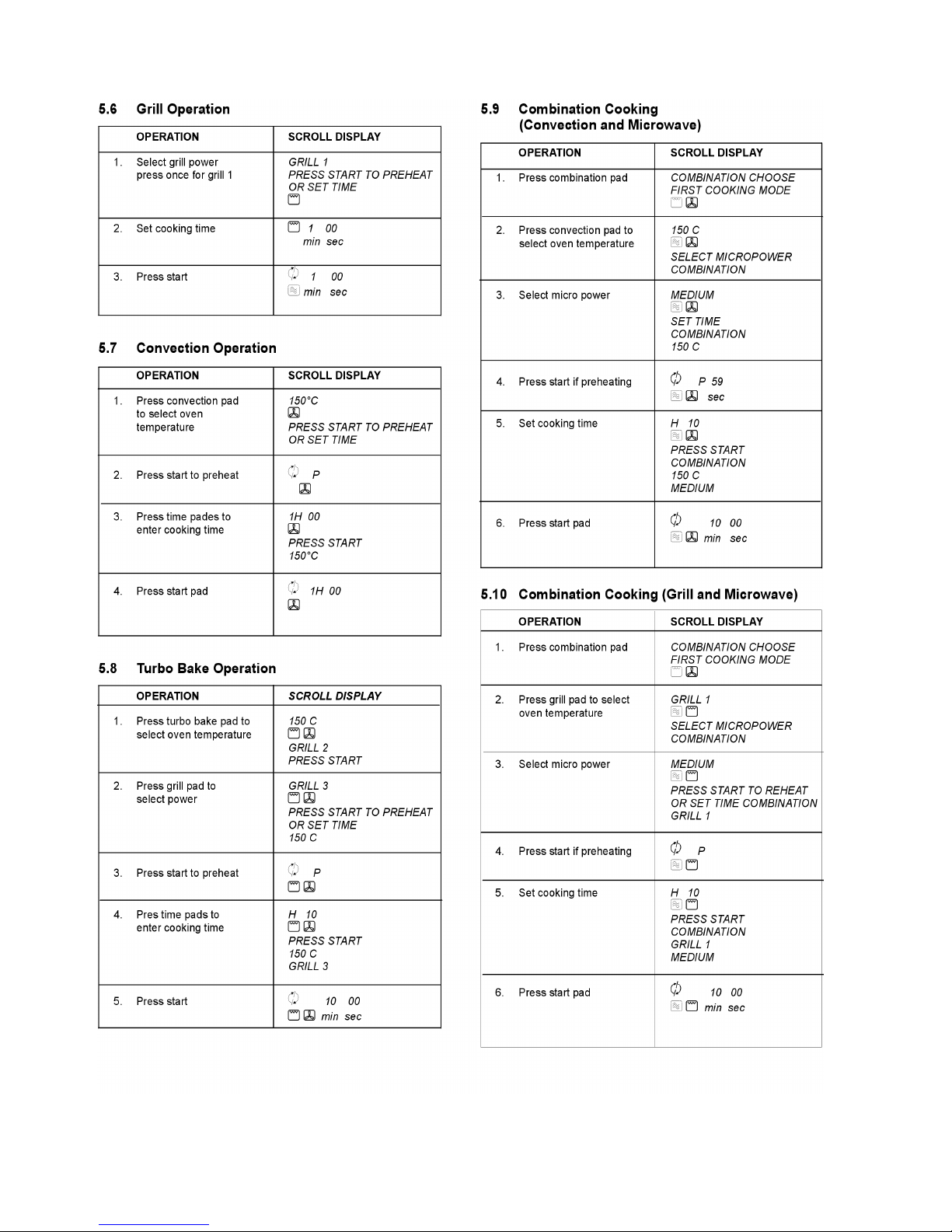

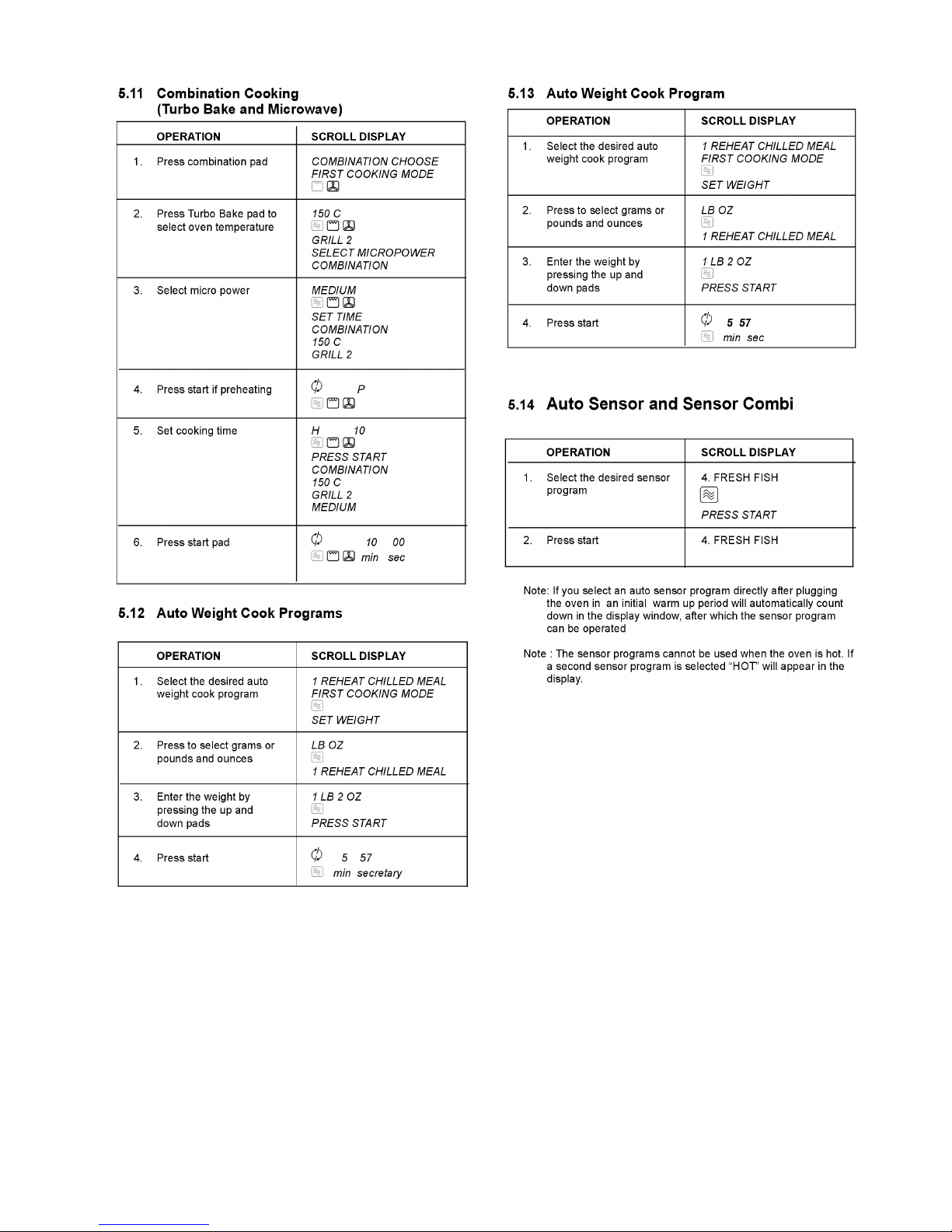

5 Operation And Digital Programmer Circuit Test Procedure . . . . . . . . . . . . . . . . . . . 5

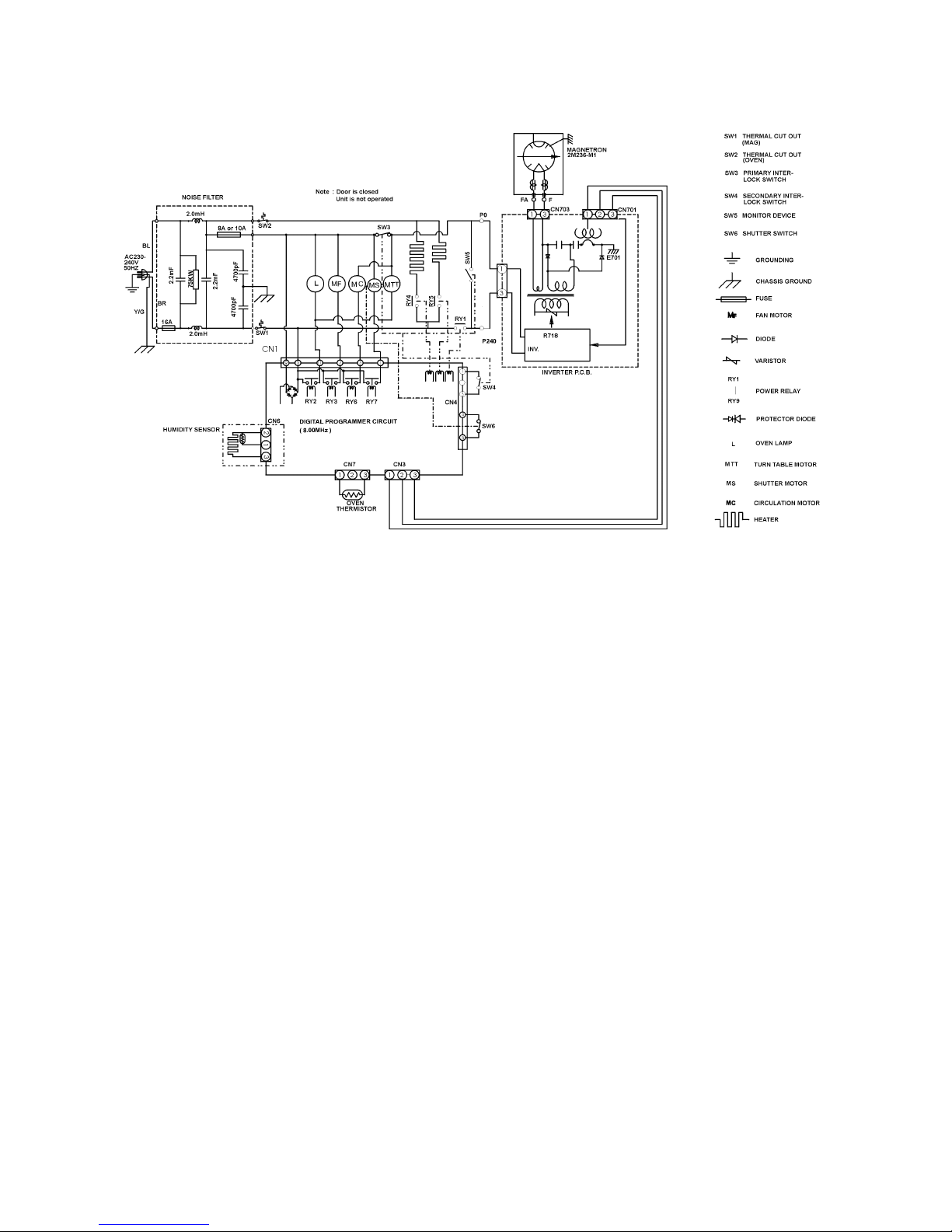

6 Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

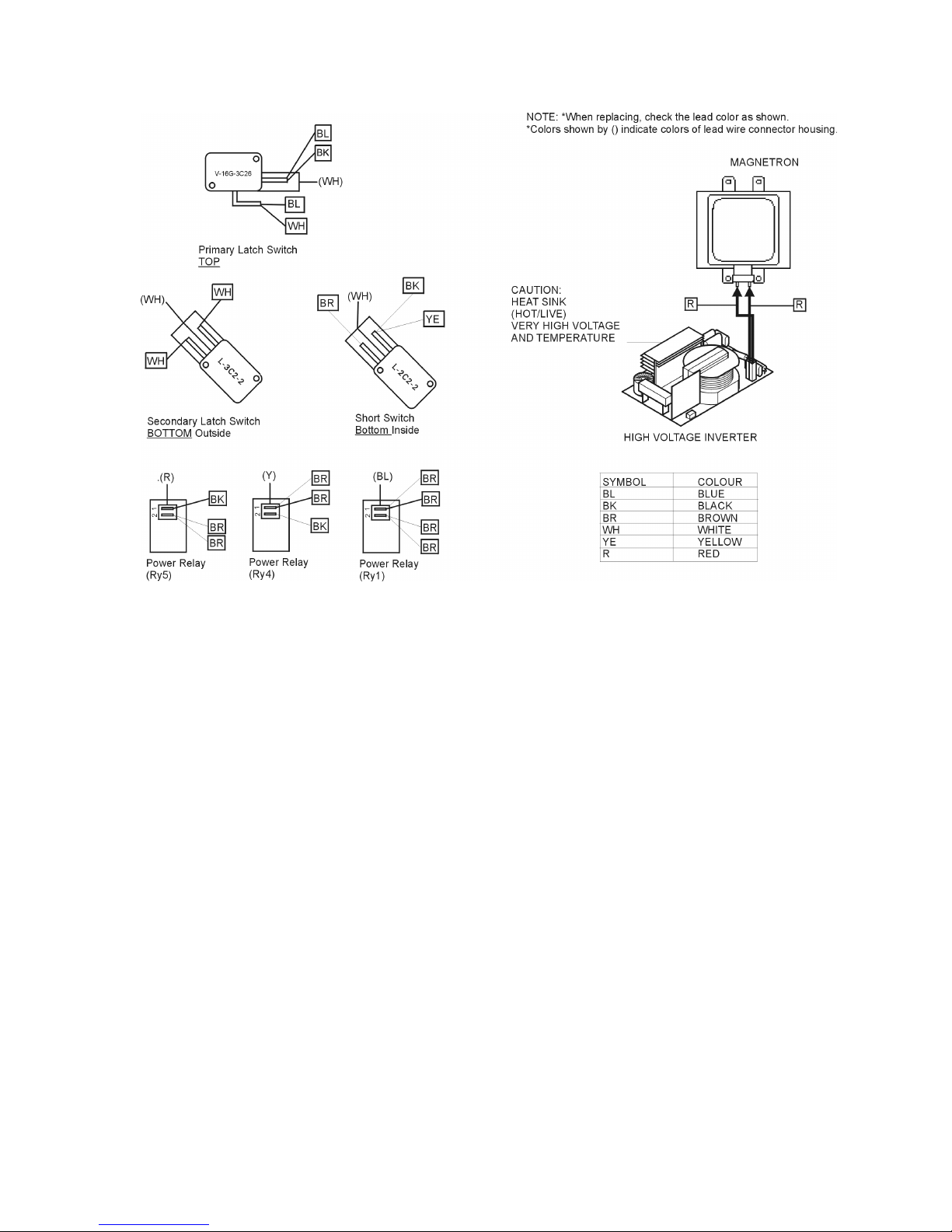

7 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Description of the Operation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9 Cautions to be Observed when Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10 Part Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Component Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12 Measurements and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

13 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14 Digital Programmer Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

15 Description of Operating instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

16 Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

17 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

18 Door Assy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

19 Escutcheon Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

20 Packing and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

21 Digital Programmer Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

22 Key Board Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

© Panasonic Home Appliance Division. 2008

Unauthorized copying and distribution is a

violation of law.

Page 3

NN-CT878SBJQ JLFSMWC003 32L OEM

3

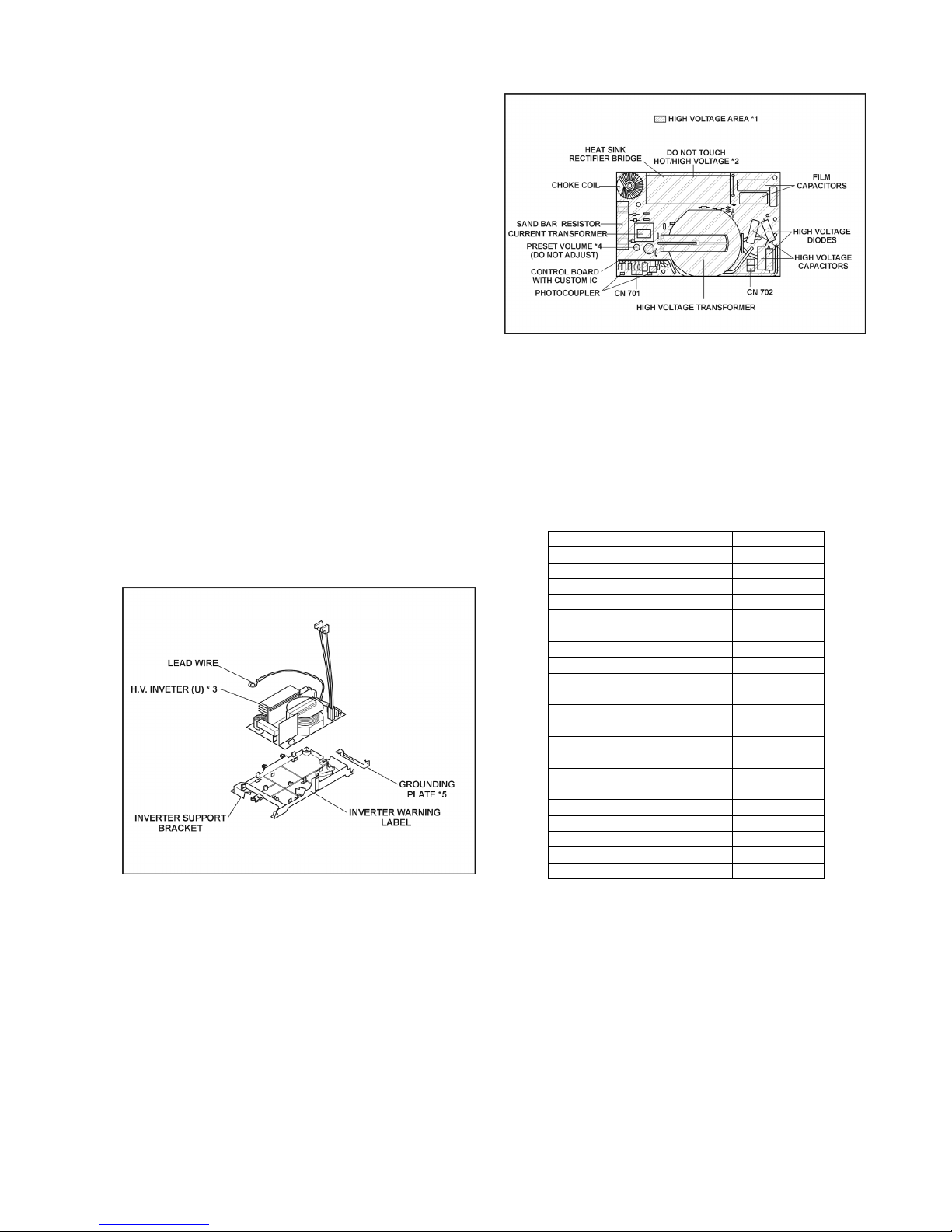

2 Inverter Warning

The inverter board looks like a regular PCB, however, this PCB

drives the magnetron tube using very high voltages and current.

It has

1. Very high voltage and high current

2. An Aluminium heat sink that becomes very hot

3. The capacitors on the inverter circuit will contain a high

voltage charge even when the oven is not operating.

Do not

1. Do not touch the circuitry as it contains very high voltages. When replacing the board please take extreme

care to avoid possible electric shock. High voltages may

remain in the circuit.

2. Do not touch the aluminium heat sink as it will become

very hot. It also contains high voltages.

3. Do not attempt to repair the inverter PCB as this can be

very dangerous. Replace the high voltage inverter circuit

as a complete unit. Return the old unit fully repacked

in the original shipping box and completed paper

work.

4. Do not adjust or tamper with the preset volume on the

inverter board. It is very dangerous to adjust this preset

without proper test equipment.

5. Do not test the oven while the inverter grounding strip or

screws are loose. It is very dangerous to operate the

inverter circuit board without a proper ground connection.

Inverter Grounding

Figure 1

Inverter PCB layout

Figure 2

3 Feature Chart

Function NN-A883

Microwave 6

Grill 3

Convection 17

Combination YES

Sensor reheat 2

Sensor cook 2

Sensor combination 4

Sensor crisp Weight defrost 3

Weight combination 8

Weight reheat Weight cook Memory cook Weight crisp Stage cooking 3

Delay/Stand YES

More/Less YES

Kg-> lb/oz YES

Clock 12H

Word prompt English

Step by Step LED

Page 4

NN-CT878SBJQ JLFSMWC003 32L OEM

4

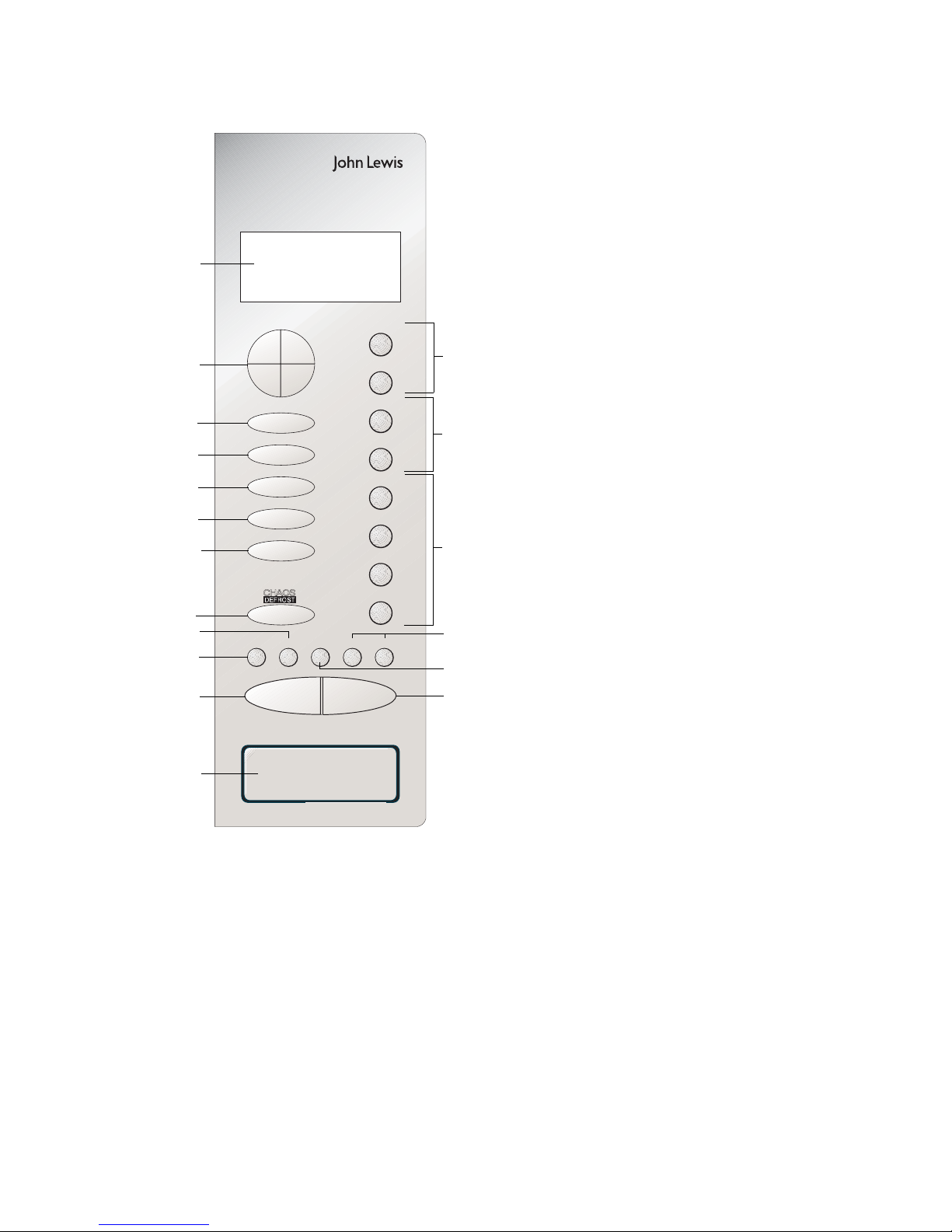

4 Control Panel

Potatoes

Micro Power

Grill 1-2-3

Convection

Turbo-Bake

Combination

CHAOS

g/

lb

oz

Delay/

Stand Clock more less

Stop/Cancel

Start

Reheat

Meal

Pastry/

Cake

Crispy

Top

Meat

Chicken

Roast Veg

Veg/Fish

JLFSMWC003

AUTO SENSOR

SENSOR COMBI

AUTO WEIGHT

10

min

1

min10sec

1

h

(1) Display Window

(2) Time Pads

(3) Auto Sensor Microwave

Programs

(4a) Auto Sensor Combination

Programs

(4b) Auto Weight Combination

Programs

(5) Auto Weight Defrost Programs

(6) Microwave Power Pad

(7) Grill Pad

(8) Convection Pad

(9) TURBO-BAKE Pad

(10) Combination Pad

(11) Delay/Stand Pad:

This can be used to delay a

cooking program for up to 9 hrs

99 mins., or used to time or for

standing (non-cooking) time.

(12) Clock Pad:

Refer to page 15 for setting the

clock.

(13) lb/oz Conversion Pad

(14) More/Less Pads

(15) Stop/Cancel Pad:

Before Cooking:

one press clears your instructions.

During Cooking:

one press temporarily stops the

cooking program. Another press

cancels all your instructions and

the time of day will appear in the

display.

(16) Start Pad:

Press to start operating the oven.

If during cooking the door is

opened or Stop/Cancel Pad is

pressed once, Start Pad has to

be pressed again to continue

cooking.

(17) Door Release Pad

(1)

(2)

(15)

(12)

(13)

(14)

(16)

(6)

(7)

(8)

(9)

(10)

(5)

(11)

(3)

(4a)

* The design of your control panel may

vary from the panel displayed (depending

on colour and shape of pads or buttons),

but the words relating to the pads will be

the same, and function in the same way.

(4b)

(17)

Page 5

NN-CT878SBJQ JLFSMWC003 32L OEM

5

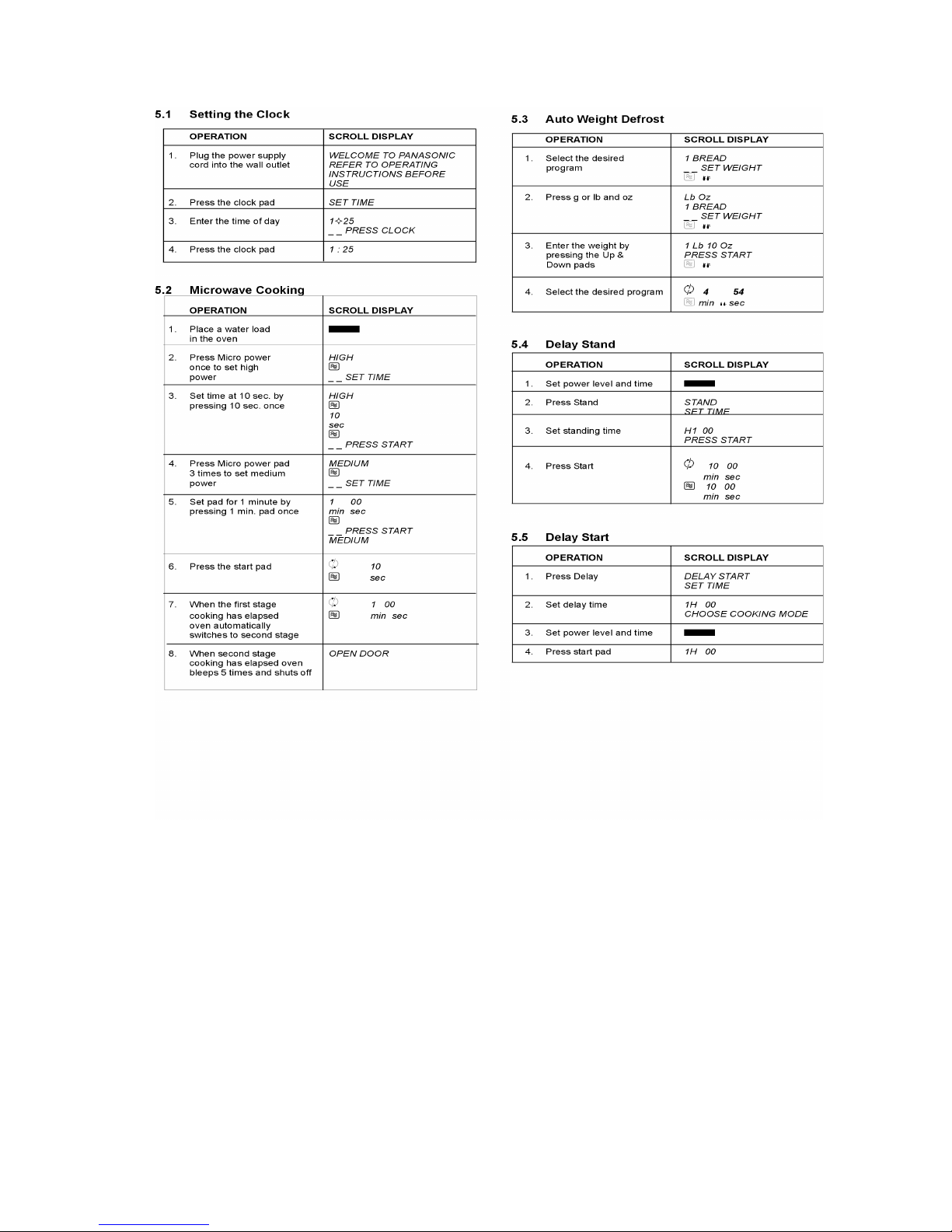

5 Operation And Digital Programmer Circuit Test Procedure

Page 6

NN-CT878SBJQ JLFSMWC003 32L OEM

6

Page 7

NN-CT878SBJQ JLFSMWC003 32L OEM

7

Page 8

NN-CT878SBJQ JLFSMWC003 32L OEM

8

6 Schematic Diagram

Page 9

NN-CT878SBJQ JLFSMWC003 32L OEM

9

7 Wiring Diagram

Page 10

NN-CT878SBJQ JLFSMWC003 32L OEM

10

8 Description of Operating instruction

8.1. Variable power cooking control

The HIGH VOLTAGE INVERTER POWER SUPPLY controls

the output power by a signal from the digital Programmer circuit

DPC. The power relay (RY1) turns on to supply power to the

inverter circuit. The level of output power is controlled by the

drive signal level from the inverter circuit.

NOTE1: The ON/OFF time ratio does not correspond with

the percentage of microwave power since approximately 2

seconds are required for heating the magnetron filament.

NOTE: 2 If microwave cooking is over 8 minutes on HIGH

power, the fan motor rotates for 1 minute after cooking to

cool the oven and electrical components.

Duty cycles for microwave cooking

8.2. Grill Cooking

The digital programmer circuit controls the grill power by operating the power relay RY4 in the sequence shown in the table

below

Duty cycles for Grill Cooking

8.3. Auto weight defrost, Auto

weight Cook

When an auto control feature is selected and the start pad

pressed:

1. The digital programmer circuit determines the power level

and the cooking time and indicates the operating state in

the display. The table shows the corresponding cooking

times for each category and its respective weight.

2. When the cooking time in the display window has

elapsed, the oven turns off automatically via the control

signal from the digital programmer circuit.

Note: After auto cooking if the oven temperature is

over the predetermined temperature the fan motor

rotates to cool the oven and its components.

Defrost Menu’s

Weight Menu’s

Output Duty ON/OFF

ON time OFF time

High 1000W 22” 0”

Defrost 440W 16” 6”

Medium 600W 22” 0”

Low 440W 22” 0”

Simmer 440W 15” 7”

Warm 440W 8” 14”

Duty ON/OFF

ON Time OFF Time

Grill 1 66” 0”

Grill 2 54” 12”

Grill 3 42” 24”

Category 1st Touch Weight Cooking Time

Turbo Defrost 500g 8m 20s

Category 1st Touch Weight Cooking Time

1. Whole Chicken 1000g 18m 20s

2. Chicken Pieces 300g 9m 30s

3. Beef / Lamb 500g 14m 40s

4.Casserole 800g 56m 40s

5. Pastry 600g 15m 00s

6. Cake 400g 11m 40s

Page 11

NN-CT878SBJQ JLFSMWC003 32L OEM

11

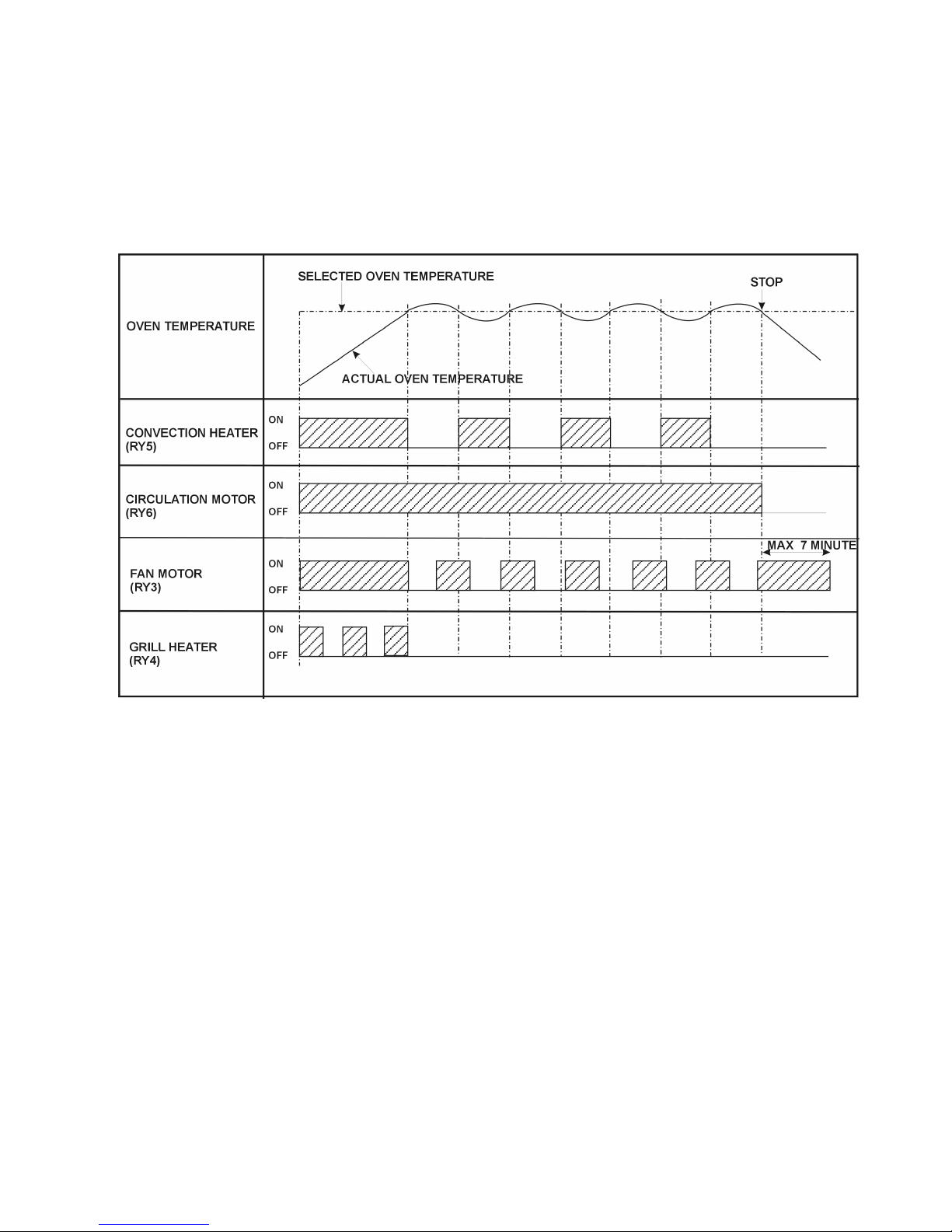

8.4. Convection Cooking

1. The digital programmer circuit operates the power relays

RY3,RY5 and RY6 in the sequence as shown in the figure

below.

2. When the oven reaches a predetermined temperature the

digital programmer circuit stops supplying power to relay

RY5, resulting in the convection heater turning off.

3. When the temperature drops below the predetermined

temperature, the digital programmer circuit supplies

power to power relay RY5 resulting in the convection

heater turning on.

Note: After the convection process, if the oven temperature is higher than the predetermined temperature, the

fan motor rotates to cool the electronic components and

the oven.

Convection Cooking Duty Cycles

Figure 1

Page 12

NN-CT878SBJQ JLFSMWC003 32L OEM

12

8.5. Combination Cooking

Combination cooking is achieved by operating the microwave

and heater modes together during one cooking cycle. There

are three combination modes.

1. Combination (convection and microwave)

2. Combination (grill and microwave)

3. Combination (grill, convection and microwave)

The digital programmer circuit operates the power relays as

shown in the figures below.

When the oven temperature reaches the predetermined temperature, the digital programmer circuit stops supplying power

to relay (RY5) resulting in the convection heater turning off.

During this time the digital programmer circuit continues to

operate relay (RY1) so that microwave activity continues at the

duty cycle selected. The inverter control signal level is also

maintained. The microwave activity continues to cycle until the

entire cooking program is completed.

When the oven temperature drops below the selected temperature, the digital programmer circuit operates power relay (RY5)

switching on the heater elements.

In the case of grill combination the sequence applies with the

digital programmer circuit switching power relay (RY4) to control, the grill elements.

With convection, grill and micro power combination. The grill

elements and convection elements are operated alternatively

whilst the oven temperature is above the selected level.

Convection And Microwave Combination Duty Cycles

Grill And Microwave Combination Duty Cycles

Grill Convection And Microwave Combination Duty Cycles

Convection Heater Micropower

100 - 250 C DISPLAY OUTPUT ON OFF

440 360W 66 0

250 360W 48 18

100 360W 21 45

Grill Heater Micropower

ON OFF DISPLAY OUTPUT ON OFF

Grill 1 51 15 440 360W 66 0

Grill 2 42 24 250 360W 48 18

Grill 3 28 38 100 360W 21 45

Convection

Heater

Grill Heater Micropower

100 - 250 C ON OFF OUTPUT ON OFF

Grill 1 51 15 440 360W 66 0

Grill 2 42 24 250 360W 48 18

Grill 3 28 38 100 360W 21 45

Page 13

NN-CT878SBJQ JLFSMWC003 32L OEM

13

8.5.1 convection and microwave duty cycles

Figure 1

Page 14

NN-CT878SBJQ JLFSMWC003 32L OEM

14

8.5.2 grill and microwave duty cycles

Figure 2

Page 15

NN-CT878SBJQ JLFSMWC003 32L OEM

15

Figure 3

8.5.3 Grill,Convection and microwave duty cycles

Page 16

NN-CT878SBJQ JLFSMWC003 32L OEM

16

8.6. One touch Auto sensor cooking

Auto sensor cook is a revolutionary way to cook by microwave

without setting a power level or selecting a time. All that is necessary is to select an auto sensor program before starting to

cook.

Understanding Auto sensor cooking

As food cooks, a certain amount of steam is produced. If the

food is covered, this steam builds up and eventually escapes

from the container. In auto sensor cooking, a carefully designed

instrument, called the humidity sensor element, senses the

escape of steam. then, based upon the auto sensor program

selected, the unit will automatically determine the correct power

level and the proper length of time it will take to cook the food.

NOTE: Auto sensor cooking is successful with the foods

and recipes found in the auto sensor cooking guide.

Because of the vast differences in food composition, items

not mentioned in the cooking guide should be prepared in

the microwave oven using the power select and time features. Please consult variable power microwave cook book

for procedures.

Explanation of the auto sensor cooking process

1. The shaded columns in figure 1 indicate when the humidity sensor heater is on.

2. During the 30 second period there is no microwave activity. When calculating the T2 time by using the formula

below, make sure this 30 seconds is subtracted from the

T0 time.

3. T1 time T0 time - 30 seconds

4. T2 time when the steam escapes from the cooking container placed in the oven, the humidity sensor detects it

and the microprocessor calculates the balance of cooking

time. This T2 time is then shown in the display and begins

counting down.

Balance of cooking (T2 time)

The balance of cooking time which is called T2 time, can be

calculated by the following formula.

T2 time (in sec.) = T1 time x K factor

NOTE: Remember, the T1 time starts after the start pad is

tapped. The coefficient K is programmed into the microprocessor memory and they are listed in the following

tables along with the P1 and P2 power.

NOTE: When “More“ or “Less” pad is selected, the K factor

varies resulting in T2 time to be increased or decreased.

Calculating the T2 time

Example 1: If the t1 time is measured to be 2 minutes and 40

seconds, and the auto sensor program selected is sensor

reheat. Fish (Program 4)

T2 = T1 x K

= 2 min. and 40 sec. X. 0.3

=48 sec.

Auto sensor cooking

Figure 1

Category P1 POWER P2 POWER K FACTOR

STANDARD

1. Chilled meal HIGH HIGH 1.6

2. Frozen meal MED HIGH 0.9

Page 17

NN-CT878SBJQ JLFSMWC003 32L OEM

17

9 Cautions to Be Observed When Troubleshooting

Unlike many other appliances, the microwave oven is a high

voltage, high current device. Although it is free from danger in

ordinary use, extreme care should be taken during repair.

Caution

Servicemen should remove their watches whenever

working close to or replacing the magnetron.

9.1. Check the grounding

Do not operate on a two wire extension cord. The microwave

oven is designed to be used when grounded. It is imperative,

therefore, to ensure the appliance is properly grounded before

beginning repair work.

9.2. Inverter Warnings

DANGER, HIGH VOLTAGE AND HIGH TEMPERATURE

(HOT/LINE) OF THE INVERTER POWER SUPPLY (U)

This high voltage inverter power supply handles very high

voltage and very high current for the magnetron tube.

Though it is free from danger in ordinary use, extreme care

should be taken during repair. As you can see, it looks like a

TV flyback transformer, however, the current is extremely

large and is therefore, dangerous due to this high current

and high voltage.

The aluminium heat sink is also energized with high voltage

(HOT), so do not touch when the AC input terminal is connected. The power devices (Collector) is directly connected

to the aluminium heat sink.

The aluminium heat sink may be (HOT) due to heat energy,

therefore, extreme care should be taken during servicing.

WARNING FOR INVERTER POWER SUPPLY (U) GROUNDING

Check the high voltage inverter power supply circuit grounding. This high voltage inverter power supply circuit board

must have a proper chassis ground, the inverter grounding

bracket must be connected to the chassis. If the inverter

board is not grounded it will expose very high voltages and

cause extreme DANGER! Be sure that the inverter circuit is

properly grounded via the inverter earth bracket.

HV Inverter warning

Figure 1

Page 18

NN-CT878SBJQ JLFSMWC003 32L OEM

18

WARNING! DISCHARGE THE HIGH VOLTAGE CAPACITORS

For about 30 seconds after the oven is turned off, an electric charge remains in the high voltage capacitors in the

inverter power supply circuit board.

When replacing or checking parts, remove the power plug

from the outlet and short the inverter output terminal of the

magnetron filament terminals to the chassis ground with an

insulated handle screwdriver to discharge. Please be sure

to touch the chassis ground side first and then short to the

output terminals.

WARNING

There is high voltage present with high current capabilities

in the circuits of the primary and secondary windings, choke

coil and heat sink of the inverter. It is extremely dangerous

to work on or near these circuits with the oven energized.

DO NOT measure the voltage in the high voltage circuit

including the filament voltage of the magnetron.

WARNING

Never touch any circuit wiring with your hand nor with an

insulated tool during operation.

Inverter Grounding

Figure 2

Discharging the high voltage capacitors

Figure 3

Page 19

NN-CT878SBJQ JLFSMWC003 32L OEM

19

9.3. When parts must be replaced,

remove the power plug from

the outlet.

9.4. When the 10A fuse is blown

due to the operation of the

short switch:

WARNING

When the 10A 250V fuse is blown due to the operation of

the short switch, the primary latch switch and short switch

must be replaced. It is also important to change the power

relay 1 (RY1) when the continuity test shows shorted contacts.

1. This is mandatory. Refer to “adjustments and measurements” for the location of these switches.

2. When replacing the fuse, confirm that it has the appropriate rating for these models.

3. When replacing faulty switches, be sure the mounting

tabs are not bent, broken or deficient in their ability to hold

the switches.

9.5. Avoid inserting nails, wire etc.

through any holes in the unit

during operation.

Never insert a wire, nail or any other metal object through the

lamp holes on the cavity or any holes or gaps, because such

objects may work as an antenna and cause microwave leakage.

9.6. Confirm after repair

1. After repair or replacement of parts, make sure that the

screws of the oven, etc. are neither loose nor missing.

Microwaves might leak if screws are not properly tightened.

2. Make sure that all electrical connections are tight before

inserting the plug into the wall outlet.

3. Check for microwave energy leakage. (Refer to procedure for measuring microwave energy leakage).

CAUTION MICROWAVE RADIATION

DO NOT BECOME EXPOSED TO RADIATION FROM THE

MICROWAVE GENERATOR OR OTHER PARTS CONDUCTING MICROWAVE ENERGY

IMPORTANT NOTICE

The following components have potentials above 250V

while the appliance is in operation.

• Magnetron

• High voltage transformer (Located on inverter (U))

• High voltage diodes (Located on inverter (U))

• High voltage capacitors (Located on inverter (U))

Pay special attention in these areas.

When the appliance is operated with the door hinges or

magnetron fixed incorrectly, the microwave leakage can

reach more than 5mW/cm

3

. After repair or exchange, it is

very important to check if the magnetron and the door

hinges are correctly fixed.

9.7. Sharp Edges

Caution

Please use caution when unpacking, installing or moving

the unit, as some exposed edges may be sharp to touch

and cause injury if not handled with care.

Page 20

NN-CT878SBJQ JLFSMWC003 32L OEM

20

10 Parts Replacement Procedure

10.1. Magnetron

1. Discharge the high voltage capacitors on the inverter circuit.

2. Remove the five screws shown in figure 1

3. Disconnect the two high voltage leads from the magnetron

4. Remove the four screws holding the magnetron as shown

in figure 2

NOTE: After replacing the magnetron, tighten the mounting screws making sure that there is no gap between the

waveguide and the magnetron to prevent microwave leakage.

Caution

When replacing the magnetron, ensure that the antenna

gasket is in place.

Note

The magnetron used for this model is unique for the inverter

power supply system. Make sure to use the magnetron as

listed in the parts list.

Removal of the magnetron

Figure 1

Page 21

NN-CT878SBJQ JLFSMWC003 32L OEM

21

10.2. Inverter power supply (U)

1. Discharge the high voltage capacitors

2. Unplug the H.V. Lead wires from the magnetron

3. Remove the connector CN701 and CN702 from the

inverter PCB

4. Remove the two screws holding the inverter base to the

chassis (See figure 3)

5. Remove the one screw holding the inverter earth wire to

the oven chassis.

6. Carefully remove the inverter PCB and support base from

the oven.

7. Remove the air guide E by un-clipping the catch hooks

8. Remove the four screws holding the PCB to the inverter

support base.

Caution when replacing the inverter power supply (U)

1. Make sure that grounding plate is in place

2. Securely tighten the grounding screw through the side of

the chassis (Base).

3. Securely connect the 3 lead wire connectors

4. Make sure that the heat sink has enough space (gap)

from the oven. Take care not to touch any lead wire to the

aluminium heat sink because it is hot.

Screws to remove the magnetron

Figure 2

Removal of the inverter PCB

Figure 3

Page 22

NN-CT878SBJQ JLFSMWC003 32L OEM

22

10.3. Digital Programmer Circuit

(DPC) and membrane key

board.

NOTE: Ground any static electric built up on your body before

handling the DPC.

1. Disconnect all connectors from the DPC.

2. Remove the four screws holding the escutcheon base

and slide the escutcheon base upward slightly. removal is

easier with the door open.

3. Release the flat cable.

4. Remove the six screws holding the DPC DU assembly

5. Remove the door lever

6. Remove the nine screws holding the DPC AU assembly

To remove escutcheon pad

1. Remove the escutcheon bracket from the escutcheon

base by freeing the 4 catch hooks on the escutcheon

base.

2. Peel away the display window from the inside of the base.

3. Remove the membrane assembly by pushing from the

inside of the base and then peeling away from the outside

surface.

NOTE:

1. The escutcheon key board is attached to the escutcheon

base with double faced adhesive tape. Therefore, applying hot air such as using a hair dryer is recommended for

smoother removal

2. When installing a new escutcheon key board, make sure

that the surface of the escutcheon base is cleared sufficiently so that problems such as, shorted contacts and

uneven surfaces can be avoided.

10.4. Low voltage transformer and/

or power relays

Note

Be sure to ground your body to discharge any static

before handling the DPC.

1. Using a solder wick or a de soldering tool and a 30W soldering iron, carefully remove all solder from the terminal

pins of the low voltage transformer and/or power relays.

2. With all of the terminal pins cleaned and separated from

the DPC contacts, remove the defective transformer/

power relays and install the new components making

sure that the terminal pins are inserted completely. Carefully re solder all terminal contacts carefully.

Note

Do not use a soldering iron or de soldering tool of more

than 30 watts on DPC contacts

Disconnecting the PCB lock connector

Figure 4 Removal of DPC DU and DPC AU

Figure 5

Page 23

NN-CT878SBJQ JLFSMWC003 32L OEM

23

10.5. Fan Motor

1. Disconnect the two lead wires from the fan motor terminals

2. Remove the power cord by removing the two wires from

the noise filter and the ground connection from the oven

chassis.

3. Remove the noise filter

4. Remove the two screws holding the orifice assembly

5. Remove the two screws holding the fan motor assembly

6. Detach the orifice assembly and the fan motor assembly

from the oven assembly.

7. Remove the fan blade from the fan motor by pulling outward.

10.6. Door disassembly

1. Remove door C from door E by carefully pulling outward

starting from the upper right hand corner using a flat

blade screwdriver.

2. Remove four screws holding the door E to the door A

assembly

3. Replace the door A and screen B as a complete unit.

4. Remove the door key and spring from the door E

After replacement of the defective component parts of the

door, reassemble it and follow the instructions below for

proper installation and adjustment so as to prevent excessive microwave leakage.

1. When mounting the door to the oven, be sure to adjust

the door parallel to the bottom line of the oven face plate

by moving the upper hinge in the direction necessary for

proper alignment.

2. Adjust so that the door has no play between the inner

door surface and the oven front surface. if the door

assembly is not mounted properly, microwave power may

leak from the clearance between the door and oven.

3. Perform the microwave leakage test.

10.7. Turntable Motor

1. Remove the motor cover by breaking off at the 8 spots

indicated by the arrows.

2. Disconnect the two lead wires connected to the turntable

motor

3. Remove the turntable motor by removing the two screws

Removing the fan motor

Figure 6

Disassembly of the door

Figure 7

Page 24

NN-CT878SBJQ JLFSMWC003 32L OEM

24

Note: After breaking off the motor cover, make sure that

cut-off portions are properly trimmed off or bent inside so

that no sharp edges are exposed.

Note: To secure the motor cover use a 4 x 6 screw.

10.8. Quartz Heater

1. Remove the sensor cable from the DPC connector CN7.

2. Remove the exhaust guide A by removing the two screws

shown in figure 10.

3. Disconnect the cables to the grill heater

4. Remove the grill cover by removing the 5 screws in figure

11

5. Remove the two screws holding the grill heater

(Figure12).

6. Loosen the 2 screws holding the ceramic grill holders,

turn the holders to release the grill element.

7. Remove the heater bracket D by using a flat blade screw

driver to lever back the tabs.

8. The grill element can now be removed from inside the

oven.

Removing the exhaust guide and grill cover

Figure 10

Removing the Turntable motor cover

Figure 8

Two screws to remove the turntable motor

Figure 9

Page 25

NN-CT878SBJQ JLFSMWC003 32L OEM

25

Removing the screws holding the grill heater

Figure 11

Removing the grill element

Figure 12

Page 26

NN-CT878SBJQ JLFSMWC003 32L OEM

26

10.9. Convection Element And Circulation Fan Motor

1. Remove one screw to remove the exhaust guide D. Figure 13.

2. Remove the rear heater cover by removing the three screws. Figure 13

3. Remove the temperature sensor by removing the two screws. Figure 14

4. Remove the power cord.

5. Remove the wire terminals from the circulation fan motor and the convection heater element.

6. Remove the four screws from the oven base. Figure 15

7. Carefully place the oven onto its base and remove the backplate.

8. Remove the nut holding the circulation fan. Figure 16

9. Remove the circulation fan by removing the three screws. Figure 16

10. Remove the convection element by removing the two screws. Figure 16

Removing the rear heater cover

Figure 13

Page 27

NN-CT878SBJQ JLFSMWC003 32L OEM

27

Removing the oven back plate

Figure 14

Removing the base plate

Figure 15

Page 28

NN-CT878SBJQ JLFSMWC003 32L OEM

28

Removing the circulation motor

Figure 16

Page 29

NN-CT878SBJQ JLFSMWC003 32L OEM

29

11 Component Test Procedure

Caution

1. High voltage is present at the high voltage terminal of the

inverter unit, including the aluminium heat sink.

2. It is not necessary or advisable to attempt to measure this

high voltage.

3. Before touching any oven components, or wiring, always

unplug the oven from its power source and discharge the

high voltage capacitors.

11.1. Primary Latch Switch, Secondary Latch Switch and power

relay B interlocks.

1. Unplug the lead connectors to power relay B and verify

the continuity of the power relay B 1-2 terminals.

2. Unplug the lead connectors to the primary latch switch

and secondary latch switch.

3. Test the continuity of the switches with the door open and

closed with an ohm meter on the lowest scale.

Normal continuity readings should be as followed.

11.2. Short Switch and Monitor Circuit

1. Unplug the lead wires from the HV inverter primary terminals.

2. Connect the test probes of the ohm meter to these leads

3. Test the continuity of the short switch with the door open

and the door closed using the lowest ohm scale.

11.3. Magnetron

Continuity checks can only indicate an open filament or a

shorted magnetron. To diagnose an open filament or shorted

magnetron.

1. Isolate the magnetron from the circuit by disconnecting

the HV leads

2. A continuity check across the magnetron filament terminals should indicate one ohm or less

3. A continuity check between each filament terminal and

the magnetron case should read open.

11.4. Push Button Keyboard

Check the continuity between the switch terminals, by tapping

an appropriate pad on the keyboard. The keypad matrix is

shown on Page 50.

Door Open Door Closed

Primary Latch Switch infinite Ω(Open) 0Ω (Close)

Secondary Latch

switch

infinite Ω(Open) 0Ω (Close)

Power relay B infinite Ω(Open) infinite Ω (Close)

Door Open Door Closed

Monitor switch 0Ω

infinite Ω

Page 30

NN-CT878SBJQ JLFSMWC003 32L OEM

30

11.5. Inverter Power Supply

Caution

DO NOT try to repair this inverter power supply. Replace as a whole H.V. Inverter Unit.

Inverter power supply diagram

Figure 3

11.6. Inverter Power Supply Unit

Warning

Do not attempt to make any measurements in the high voltage circuitry of the inverter or magnetron.

See troubleshooting of the inverter circuit and magnetron on

page 27 to determine if the inverter power supply is still functioning.

11.7. Temperature Sensor

A temperature sensor is mounted on the rear of the oven. The

resistance reading across the thermistor should read 300K ohm

within a temperature range of 10 to 30 degrees centigrade. This

would be the temperature range within a kitchen environment.

If the resistance measured is outside this range the thermistor

is defective and should be replaced.

NOTE: When measuring the resistance of the thermistor disconnect the connector from the digital programmer circuit.

NOTE: If the microwave oven has been operated allow to cool

to room temperature before attempting to measure the thermistor resistance.

11.8. Humidity sensor and digital

programmer circuit.

1. Check the resistance across the sensor heater terminals.

Normal cold resistance should read approximately 4.5

ohms.

2. Check the voltage across the sensor heater terminals. It

should read approximately 2.5VDC

3. In order to determine if the auto cooking by humidity sen-

sor is working, perform the following test.

1. Place a water load (150cc) in the oven.

2. Press the auto reheat panel.

3. Press the start pad

4. The humidity sensor detects steam about 2 to 4 minutes

after the start pad has been pressed.

5. The auto cooking (T1) automatically switches to cooking

time. (T2)

6. The remaining cooking time T2 appears in the display

window. If 48s -1min 36 secs appears in the display, the

humidity sensor function is normal.

Page 31

NN-CT878SBJQ JLFSMWC003 32L OEM

31

12 Measurements and Adjustments

Warning

• For continued protection against radiation hazard, replace

only with identical parts.

• When the 10 amp fuse is blown due to the operation of the

short switch, you must replace the primary latch switch and

short switch. Then follow the installation procedures below.

• Interlock switch replacement - In replacing faulty switches,

be sure mounting tabs are not bent, broken or otherwise

deficient in their ability to hold the switches.

• Refer to the schematic and wiring diagram to ensure proper

connection

12.1. Installation of primary latch

switch, secondary latch switch

and short switch.

1. When mounting the primary latch switch, secondary latch

switch and short switch to the door hook assembly. Follow the instructions in figure 1.

NOTE: No specific adjustment during the installation of

each switch into the door hook is necessary.

2. When mounting the door hook assembly to the oven

assembly, adjust the door hook assembly by moving it in

the direction of the arrow in figure 1. Ensuring the door

does not have any play in it. Check for play by pulling the

door assembly. Make sure that the latch keys move

smoothly after adjustment is completed. Completely

tighten the screws holding the door hook assembly to the

oven assembly.

3. Reconnect the short switch, primary switch and secondary latch switches and check the continuity of the monitor

circuit and latch switches by following the component test

procedures on page.

12.2. Measurement of microwave

output

The output power of the magnetron can be determined by performing the IEC standard test. However, due to the complexity

of the IEC test procedures, it is recommended to test the magnetron using the simple method outlined below.

Necessary equipment:

• 1 litre beaker

• Glass thermometer

• Wrist watch or stop watch

NOTE: Check the line voltage under load. Low voltage will

lower the magnetron output. Take the temperature readings

and heating time as accurate as possible.

1. Fill the beaker with exactly one litre of tap water. Stir the

water using the thermometer and record the beakers temperature (Recorded as T1)

2. Place the beaker on the center of the glass cook plate.

3. Stir the water again and read the temperature of the beaker (Recorded as T2)

4. The normal temperature rise at the high power position

for each model is shown in the table. (Figure 2)

Adjustment of latch switch assembly

Figure 1

TABLE (1L - 1min test)

RATED OUTPUT TEMPERATURE RISE

1000W 8°C

Page 32

NN-CT878SBJQ JLFSMWC003 32L OEM

32

13 Troubleshooting Guide

Page 33

NN-CT878SBJQ JLFSMWC003 32L OEM

33

Fuses are not blown

Fuses are blown

Page 34

NN-CT878SBJQ JLFSMWC003 32L OEM

34

6A5BPQ

Other problems

Inverter circuit troubleshooting

6A5BPQ

Alternative method for toubleshooting, the inverter circuit

Page 35

NN-CT878SBJQ JLFSMWC003 32L OEM

35

14 Digital Programmer Troubleshooting Guide

Page 36

NN-CT878SBJQ JLFSMWC003 32L OEM

36

Page 37

NN-CT878SBJQ JLFSMWC003 32L OEM

37

15 Description of Operating instruction

15.1. Auto weight defrost, Auto

weight Cook

When an auto control feature is selected and the start pad

pressed:

1. The digital programmer circuit determines the power level

and the cooking time and indicates the operating state in

the display. The table shows the corresponding cooking

times for each category and its respective weight.

2. When the cooking time in the display window has

elapsed, the oven turns off automatically via the control

signal from the digital programmer circuit.

Note: After auto cooking if the oven temperature is

over the predetermined temperature the fan motor

rotates to cool the oven and its components.

Auto Weight Defrost

Category 1st Touch Weight Cooking Time

Bread 100g 45s

Meat Items 200g 3m 40s

Meat Joints 400g 6m 20s

Category 1st Touch Weight Cooking Time

Whole Chicken 1000g 18m 20s

Chicken Portions 300g 10m 00s

Beef / Lamb 500g 14m 40s

Casserole 800g 56m 40s

Chilled Crispy Top 300g 10m 00s

Frozen Crispy Top 300g 14m 00s

Pastry 600g 15m 00s

Cake 400g 11m 40s

Loading...

Loading...