Mail: P.O. Box AA631

Evanston, IL 60204 USA

Ship: 1728 Brummel St.

Evanston, IL 60202 USA

THE JOHN HARDY COMPANY

Phone: 847-864-8060

Toll-free: 866-379-1450

Fax: 847-864-8076

www.johnhardyco.com

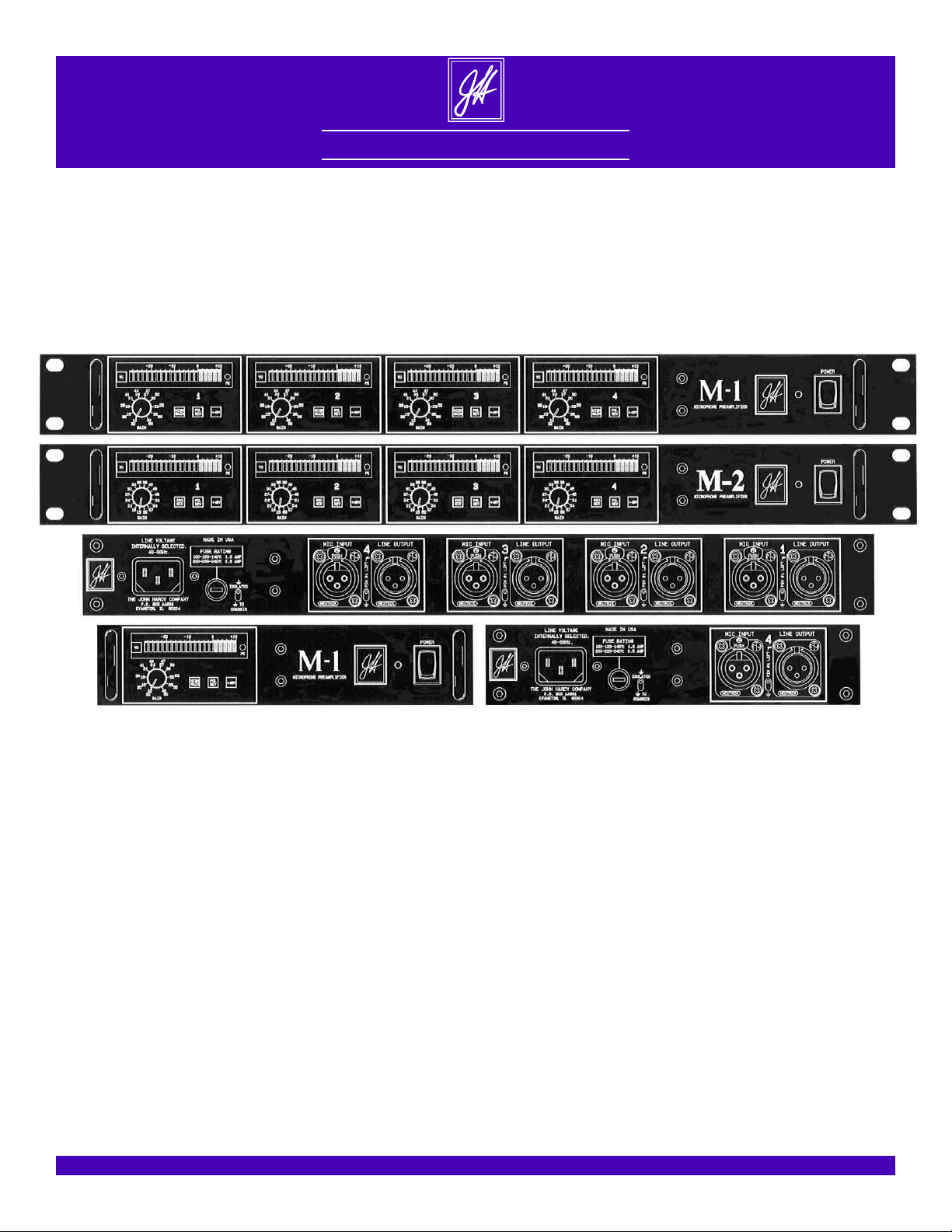

M-1 Mic Preamp

October 6, 2003

M-2 Mic Preamp

M-1 Personal Mic Preamp

The M-1, M-2 and M-1 Personal mic preamps are among the finest mic preamps in the world. They provide the accuracy

and transparency that is missing in other mic preamps. No matter what your application, they will provide superior

results. The world's best input transformer (Jensen JT-16-B), best op-amp (990C discrete class-A op-amp) and the

elimination of all coupling capacitors from the signal path combine to provide the highest performance.

The M-1 and M-2 have a 19” wide rack-mount chassis (1.75”H x 19”W x 8”D) and can be ordered with one, two, three or

four channels. The M-1 Personal mic preamp has an 8” wide chassis with a capacity of one channel. There are two meter

options, and the best Jensen output transformer (JT-11-BMQ) is available as an option. These options and basic channels

can be easily added later.

The M-1 was introduced in 1987. The M-2, introduced in 1996, is a variation of the M-1. The first difference is the gain

controls: The M-1 has a two-section gain-pot providing continuously variable adjustment in two overlapping ranges of 12

to 40dB and 32 to 60dB. The “HIGH GAIN” switch changes ranges. The M-2 has a 16-position gain-switch with 1%

metal-film resistors, providing accurate and repeatable gain-settings from 15 to 60dB in steps of 3dB.

Further differences involve the push-button switch to the right of the gain-pot or gain-switch. The M-1 has a “HIGH

GAIN” switch as mentioned above. Since this switch is not required in the M-2, the p.c. board layout was modified to

allow that switch to be used in the M-2 as either a “20Ω MIC” switch, or a “20dB PAD” switch, depending on how the

board is assembled. The 20Ω MIC switch provides optimum matching of microphones with extremely low output

impedances. The 20dB PAD switch attenuates the input signal by 20dB prior to the JT-16-B input transformer, providing

a maximum input level of +29dBu.

1

Highlights

The Jensen JT-16-B Input Transformer is

Jensen's best mic-input model. Jensen is

known worldwide for their superior audio transformers. If you thought transformers were a compromise, you haven't

heard the JT-16-B!

The JT-16-B is a large, low impedance

ratio (150:600Ω) transformer made with

a proprietary 80% nickel (nickel-ironmolybdenum) core material. The large

size allows it to handle extremely high

signal levels of +12dBu at 30Hz and

above, +8dBu at 20Hz. The low ratio

provides less distortion, flatter frequency

response and more linear phase response

than more typical high-ratio transformers

(150:15kΩ). The proprietary 80% nickel

core material is far superior to, and much

more expensive than the steel often

found in other transformers.

The JT-16-B outperforms transformerless mic preamps because it eliminates

the input coupling capacitors that are required with transformerless designs. Capacitors degrade the audio signal because they have a property known as dielectric absorption, where some of the

signal passing through the capacitor is

absorbed by the dielectric of the capacitor, then released a short time later. This

smears the signal. Transformerless designs require these capacitors to keep the

phantom supply voltage from reaching

the circuitry of the preamp. Transformers inherently block DC voltages, eliminating the need for the capacitors.

The JT-16-B provides better common

mode rejection than transformerless designs, important in electrically noisy environments. It handles common mode

voltages as high as ±300V peak. Transformerless designs are usually limited to

maximum voltages equal to their power

supply voltages, typically ±15V to ±18V.

The 990 Discrete Op-Amp is faster, quieter, more powerful and better sounding

than the typical monolithic op-amps

found in other equipment. Each individual (discrete) transistor, resistor, diode,

capacitor and inductor of the 990 has

been carefully chosen for its task. This

provides a level of performance that is

not possible in a monolithic op-amp

where all components are fabricated on

the same tiny chip of silicon. The 990

operates from ±24V power supplies, al-

lowing output levels of greater than

+24dBu. It can drive long cables and

loads as low as 75Ω, something monolithic op-amps cannot do. See the 990

data package for further information.

Elimination of All Coupling Capacitors

from the Signal Path results in less degra-

dation of the audio signal. Two superior

techniques are used to accomplish this:

1. Input bias current compensation circuitry nulls out the small DC currents

(thus voltages) that flow from the inputs

of the 990 (or any op-amp), voltages that

could cause noise when operating the

gain controls. This circuitry also reduces

the DC offset voltage at the output of the

990. Most other mic preamps use coupling capacitors to block the input bias

currents, resulting in signal degradation.

2. DC servo circuitry nulls out the DC

offset voltage at the output of the 990,

eliminating the need for a traditional output coupling capacitor to block that voltage. The signal degradation caused by

that capacitor is also eliminated. See the

schematic on page 7 for details.

M-1: Dual Range Gain Control and “HIGH

GAIN” Switch. The overall gain adjust-

ment range is 12 to 60dB, a span of

48dB. Rather than cover the entire 48dB

in one revolution of the gain pot, there

are two smaller, overlapping ranges selected by the “HIGH GAIN” switch. The

low gain range provides adjustment of

12 to 40dB, the high gain range 32 to

60dB. This provides 28dB of adjustment

per range, with 8dB of overlap. The relatively small 28dB of adjustment per

range provides great feel and resolution,

with sufficient overlap to keep you “in

range” at all times.

There are two reasons for the great feel:

First, with fewer dB of adjustment per

revolution, it is easier to adjust the pot to

the desired gain setting. The second reason is a more technical one, and very important. A single 10kΩ pot covering the

entire 48dB range in a single revolution

could get a bit “touchy” as it approached

the maximum gain point (minimum resistance), due to contact resistance variation (CRV). The gain pot of the M-1 is

actually a two section pot having a 10kΩ

section and a 500Ω section. In high gain

Standard Features

applications where CRV would be a

problem with a 10kΩ pot, the 500Ω section of the pot is used. CRV is reduced

by a factor of twenty, virtually eliminating any touchiness. See page 5 for details.

The unusually low minimum gain of

12dB allows the M-1 to handle input levels as high as +12dBu before the output

is driven past its +24dBu maximum output level. The JT-16-B input transformer

can handle input levels of +12dBu at

30Hz and above, and +8dBu at 20Hz.

If you need infinite resolution so you can

set the mic preamp to any gain, or have

the ability to “ride gain” during a performance, the gain controls of the M-1 are

ideal.

M-2: 16-Position Rotary Gain-Switch with

1% metal-film resistors provides accurate

and resetable gain control from 15 to

60dB in steps of 3dB. For situations

where quick and exact gain-matching of

channels or exact resettability is required, the gain controls of the M-2 are

ideal.

M-2: “20Ω MIC” Switch provides optimum

matching with microphones that have a

20Ω output impedance. Note that the

Jensen JT-16-B mic-input transformer

does exceptionally well with just about

any low-impedance microphone, including those with a 20Ω output impedance,

but this switch provides further refinement. The switch takes the place of the

“HIGH GAIN” switch of the M-1.

M-2: “20dB PAD” Switch provides a 20dB

resistive pad before the input transformer. This increases the maximum input level to +29dBu for situations where

excessively high input levels are encountered. Most applications won't need a

pad, but for those that do, this option

provides it. This switch takes the place

of the “HIGH GAIN” switch of the M-1.

Note that you can get an M-2 channel

built with the “20Ω MIC” option or the

“20dB PAD” option, but not both. These

options take advantage of the fact that

the “HIGH GAIN” switch of the M-1 is

not needed in the M-2, and the p.c. board

was modified to allow that switch to be

used one of three ways.

2

M-1 and M-2 Common Features:

Polarity Reverse Switch (“POL REV”) re-

verses the signal polarity at a point immediately before the input transformer.

48V ON/OFF Switch (“+48V”) for phantom

power. The phantom supply has more

than enough current to handle any condenser microphone.

All Front Panel Switches are LED Illuminated. A custom clear plastic push button

was developed for the M-1 and M-2.

Each button's function is marked on the

front surface and is illuminated dimly

when off, brightly when on, each button

with its own LED color. The HIGH

GAIN switch of the M-1 (20Ω MIC or

20dB PAD for the M-2) uses a red LED,

the POL REV switch uses an amber

LED and the +48V switch uses a green

LED. No guessing about these switches!

Gold Plated XLRs for maximum reliability. Gold does not tarnish or oxidize. Silver plated XLRs are available on special

order.

Ground Lift Switch on Each Channel allows disconnection of the shield (pin 1)

of the output XLR. This can be helpful

in eliminating ground loops. This minitoggle switch is on the rear panel.

Toroidal Power Transformer with additional silicon-iron shielding eliminates

hum problems caused by stray magnetic

fields. Some manufacturers use a separate power supply chassis and umbilical

cord to keep the power transformer's

stray magnetic fields from interfering

with the audio circuitry. In the M-1 and

M-2, the stray magnetic fields are controlled at the transformer. Each transformer is carefully tested for stray magnetic fields under worst-case full-load

conditions. The optimum rotational position is determined, then the silicon-iron

shielding is added to assure hum-free

performance. Thanks to these extra details, the transformer can be built into the

M-1 or M-2 chassis. No separate chassis

and umbilical cord to deal with.

Toroidal power transformers inherently

have lower stray magnetic fields than

conventional EI-core transformers. They

are also smaller and lighter. They are

also much more expensive!

Universal Power Supply. An internal

switch provides six primary voltage

choices: 100, 120, 140, 200, 220 and 240

volts. The power cord is detachable, with

a line filter included in the input connector. These features allow the preamps to

be easily adapted for use anywhere in the

world. The supply accommodates

over/under voltage situations easily.

Chassis Ground Isolation Switch allows

the chassis ground to be isolated from

the signal ground, or tied to it. This can

be helpful in eliminating ground loops in

certain situations. This mini-toggle

switch is on the rear panel.

Built to Order, the way YOU want it. Start

with only one basic channel if you wish.

Additional channels, meters and output

transformers can be easily field-installed.

The mainframe is ready for all four

channels, with blank panels provided for

unused channels. Have it your way!

VU-1 Meter Card is a very accurate and informative meter that directly monitors the

output level of the MPC-1 mic preamp

card. There is no need to monitor the input

level of the MPC-1 because the output will

clip before the input transformer saturates.

The VU-1 provides a 20 segment LED bargraph display and separate "peak" LED (labeled “PK” on the front panel) to indicate

extremely high signal levels. An LED-illuminated front panel switch (green LED)

gives a choice of “Peak” or “VU” meter

ballistics. The “Peak” ballistic provides a

fast attack time for the bargraph so that

transients are fully indicated. The “VU”

ballistic provides a slower attack time, similar to a standard mechanical VU meter.

The meter scale accurately covers -28 to

+10dB in linear steps of 2dB (15 yellow

LEDs, 5 red LEDs). Easy calibration of the

meter's 0VU operating level is accomplished by moving an internal plug-in

jumper to one of four positions: 0dBu,

+4dBu, +8dBu or Adjustable (the adjustable position covers -10 to +12dBu via

a 25-turn trim pot). Standard setting is

“+4” (0VU on the meter scale equals a

+4dBu output level).

The firing point of the separate peak (PK)

LED is calibrated via a 25-turn trim pot for

output levels of 0 to +22dBu. The standard

Options

setting of +22dBu provides at least 2dB of

warning prior to clipping. Jumpers are provided to choose BAR mode (cumulative

LEDs) or DOT mode (one LED at a time)

for the display.

Circuitry includes a full-wave rectifier,

peak detector, Peak and VU ballistics, and

a temperature compensated log/linear converter. The circuitry is DC coupled and

uses high-speed, precision op-amps with

extremely low DC offset voltage and drift

(better op-amps than you find in the signal

path of many consoles!). All of these features guarantee accurate performance over

a wide temperature range, and for years to

come. On-card voltage regulation for the

op-amp power supplies, and isolated

grounding for the 5 volt LED power supply

assure that the VU-1 will not interfere with

the mic preamp circuitry.

PK-1 Meter Card provides a peak LED function only. It uses the same full-wave rectifier, peak detector, 25-turn trim pot for firing

point calibration, on-card voltage regulation and isolated grounding for the 5 volt

LED power supply that is used on the VU1 card.

JT-11-BMQ Output Transformer is the best

Jensen line-output transformer. It compliments the outstanding line driving capabili-

ty of the 990 by providing a balanced,

floating, isolated output. Ground loop

problems are eliminated because the signal

is coupled magnetically rather than directly, something that transformerless circuits

cannot do. Your application may not require an output transformer, but if you need

one, the JT-11-BMQ is the best.

PIN 2 or PIN 3 HIGH? There are two polarity

standards in use today for XLR connectors.

The official IEC, SMPTE and AES standards state that pin 2 is high (relative to pin

3), while the unofficial standard states that

pin 3 is high (relative to pin 2). The M-1

and M-2 make it very easy to deal with

this. A pair of plug-in jumpers is located

next to each XLR, allowing you to quickly

change from “PIN 2 HIGH” to “PIN 3

HIGH”, or vice-versa. It is very important

to verify the polarity of the equipment that

will be used with the mic preamp, and to

maintain correct polarity when connecting

the mic preamp. Possible problems range

from an audible change due to an inadvertent reversal of polarity, to slight degradation of the signal if a transformer-coupled

output is driving an unbalanced input of

the opposite polarity, to possible damage to

the 990 in a direct-output configuration

driving an unbalanced input of the opposite

polarity (driving a short-circuit!). Please

specify PIN 2 HIGH or PIN 3 HIGH!

3

A few Important Details

Factory Selection of Critical Parts. R2 and

R3, the 6.81kΩ resistors in the phantom

supply network, are matched to 0.1% tolerance for the best performance.

1% 100ppm Metal Film Resistors are

used instead of the more common 5%

200ppm carbon film resistors. They

provide greater initial accuracy, better

long term stability, and higher stability at extremes of temperature.

Polycarbonate Capacitors are used in critical timing circuits instead of cheaper mylar or polyester capacitors. They are much

more stable, and have a more linear

impedance, important parameters in timing circuits such as the ballistics circuits

of the meter cards.

Electrolytic Capacitors with a 105°C Temperature rating are used instead of the

more common 85°C rated parts. This

higher temperature capability means that

they will last much longer than the lower

rated parts. They will also have better,

more linear performance over a wider

temperature range. Electrolytic capacitors

are more failure prone than most other

components (a good thing to remember

when troubleshooting older equipment).

Sometimes they allow small amounts of

DC current to pass through (leakage current), causing pots and switches to be

noisy when operated. (NOTE: in the M-1

and M-2 there are no capacitors in the signal path, so this problem cannot exist).

Other capacitors will short-circuit, or lose

most of their capacitance. Whatever the

failure mode, you have a problem, even in

equipment that never approaches an operating temperature of 85°C. But not with

these mic preamps!

XLR Connectors are Soldered Directly to

the P.C. Card, minimizing the number of

interconnections for better reliability and

better sound quality.

Fully Sealed Potentiometer and Trim Pots

for long, trouble-free life.

Central Point Grounding and Power Distribution. Rather than use a “motherboard”,

wiring harnesses are used to deliver power

supplies and grounds to each channel individually. This provides the least interaction between channels.

The KNOB. A knob is a basic device that

should provide three basic things:

1. Good VISUAL indication of setting.

2. Good TACTILE indication of setting.

3. Good TRACTION for your fingers.

Most knobs don't meet all three of the requirements. Some don't meet any of the

requirements! In addition to these basic

requirements, a knob should look good

and feel good.

Plastic knobs look like . . . well . . . plastic

knobs! Plain round knobs don't give any

tactile indication of which way they are

pointing. Knobs with pointers or bars

sticking out do tell by feel which way they

point, but the protrusion is often so big

that it gets in the way. Some knobs have

an indicator line on top, but the typical

decorative metal finish causes light reflections from the top like spokes of a wheel.

Which is the indicator line and which are

the spokes?

This knob was developed to meet all requirements. It is machined out of solid

aluminum, with a nonreflective black anodized finish. A laser-cut white ceramic

insert is added to create visual and tactile

indication of the knob's setting. The insert

appears as an indicator line on the top of

the knob, and protrudes just enough

(.025”) beyond the side of the knob so that

you can feel it, yet it doesn't get in the

way. Traction is provided by a fine diamond knurl with sharp, fully formed teeth.

The diamond knurl provides traction for

rotary motion, and for vertical motion to

keep your fingers from slipping “up” and

off of the knob. Straight knurls can only

provide rotary traction. Also, there is a

certain amount of tradition in a diamond

knurl. The knob looks great, feels great,

and works great!

An Extruded Aluminum Chassis was developed for the front, rear and sides of the M1 and M-2 chassis. It solves a number of

packaging problems, providing a neater,

stronger and more efficient package. The

brushed and black anodized finish looks

great, and provides optimum thermal

emission properties. Rack-handles are provided for easy installation and handling.

Stainless steel threaded inserts are used

for long life and the ability to withstand

repeated assembly & disassembly. Rackmount handles are provided for ease of

handling.

CONDENSED SPECIFICATIONS (0dBu = 0.775V)

E.I.N., 20-20kHz unweighted, 150Ω source: -129 dBu

Maximum input level, M-1 >30Hz: +12 dBu

Maximum input level, M-2 >30Hz: +9 dBu

Maximum input level, M-2 with pad >30Hz: +29 dBu

Maximum output level at 990 outpu t 75Ω load: +24 dBu

CMRR 100Hz: 100 dB

Deviation fro m linear phase 20Hz-120kHz: <2 deg

THD, JT-16-B, (below saturation) 20Hz 0.036 %

THD, JT-16-B & 990:

60dB gain, 10kΩ load, +2 4dBu output 10kHz: 0.005 %

40dB gain, 600Ω load, +24dBu output 10kHz: 0.003 %

40dB gain, 75Ω load, +24dBu output 10kHz: 0.030 %

DC offset <100 µV

0Ω source: -132 dBu

10kHz: 80 dB

30Hz: 0.022 %

50Hz: 0.010 %

1kHz: 0.003 %

1kHz: 0.004 %

1kHz: 0.003 %

1kHz: 0.005 %

4

Contact Resistance and Contact Resistance Variation

The most familiar specifications for potentiometers are: resistance value, tolerance

and taper. Even these simple specs will

vary with temperature, time, applied voltage, number of rotations, etc., but they are

pretty straight forward. However, contact

resistance (CR), and contact resistance

variation (CRV), are specifications that

are unfamiliar to many people.

A pot has a moving contact, or “wiper”,

and it is positioned along the surface of a

resistance element. The key to understanding the problems of CR and CRV is to realize that the resistance element has a

small but measurable thickness to it, and

the current flow is not always occurring

exactly at the surface of the element. This

is because the current flow follows the

path of least resistance created by the imperfect blend of conductive and non-conductive materials used to make the element. There is a measurable amount of

distance, therefore resistance, between the

contact and the nearest point of current

flow. This contact resistance (CR) can be

as much as 2% of the pot's resistance value, and will vary as the contact is moved

from one position to the next (CRV). If

the current is flowing near the surface of

the element at the contact position, CR is

low. If the current is flowing far below the

surface at the contact position, CR is high.

For example, if the pot measured exactly

10kΩ from end to end, and if you could

find the exact electrical midpoint of the resistive element, it could measure 5200Ω

from either end to the contact sitting at the

midpoint. It takes 5000Ω to get to the

midpoint of the resistive element, and an

additional 200Ω to get to the surface of

the element where the contact is, assuming

a worst-case CR of 200Ω.

When a pot is used as a rheostat, as it is in

the gain control of the MPC-1 mic preamp

card, the CR must be added to the basic

element resistance when making gain calculations. The gain pot of the MPC-1 card

is configured so that a reduction of resistance causes an increase of gain.

For the following example let's assume a

single section 10kΩ pot is used, covering

the entire 48dB adjustment range (12 to

60dB) in a single revolution. Due to the

logarithmic nature of audio, it takes almost a 2kΩ reduction of resistance (10kΩ

to 8kΩ) to provide a 1dB increase of gain

when going from 12 to 13dB of gain,

while it takes a mere 10Ω reduction of resistance (70 to 60Ω) to provide a 1dB increase when going from 47 to 48dB of

gain. The worst-case CR of 200Ω (2% of

a 10kΩ pot) would be insignificant in the

first instance (resistance change from

10kΩ to 8kΩ for a gain change of 12 to

13dB), since a CR of 200Ω is small compared to the 2kΩ change in gain pot resistance. But if you were increasing the gain

from 47 to 48dB by changing the gain pot

setting from 70 to 60Ω, a CR of 200Ω

could definitely be a problem, compared

to the desired 10Ω change in gain pot re-

sistance. Imagine a worst-case situation: at

the theoretical 70Ω position, contact resistance might happen to add 10Ω, while at

the theoretical 60Ω position, contact resistance might happen to add 200Ω. Instead

of going from 70Ω to 60Ω, you would actually be going from 80Ω to 260Ω. The

resistance goes up instead of down, and

the gain is decreased by more than 8dB instead of the 1dB increase you planned on!

The next nudge of the control could have

just the opposite effect. It is highly unlikely that CRV would be that bad, but it is

unpredictable and undesirable.

The gain pot of the MPC-1 mic preamp

card is actually a two section pot (RV1A

and RV1B on the schematic on page 7),

with a 10kΩ section and a 500Ω section.

In the low-gain mode (12 to 40dB), the

HIGH GAIN switch shorts across the

500Ω section of the pot, leaving just the

10kΩ section active. The CR of a 10kΩ

pot is not a problem at lower gains, as

mentioned earlier. In the high-gain mode

(32 to 60dB), the HIGH GAIN switch

shorts across the 10kΩ section, leaving

just the 500Ω section active. Contact resistance would be a problem at these higher gains if you were still using the 10kΩ

pot, but the worst-case CR is just 10Ω

with the 500Ω pot, compared to 200Ω

with the 10kΩ pot. This reduces the CRV

problem by a factor of twenty. The result

is a much smoother, more consistent and

higher resolution gain control.

5

678

Loading...

Loading...