John Guest USA Marine Plumbing User Manual

The Push-Fit People

USA Marine Plumbing Catalog

& Price List

World Connections

The John Guest Group has a long established reputation as a world leading manufacturer

of push-in fittings, tube and other fluid control products. A reputation built on producing

consistently high quality products with an ongoing commitment to value engineering and

product development.

Quality Manufacture

Both design and manufacture are carried out in John Guest’s modern, purpose-built facilities in the United Kingdom.

Maintaining control over the entire process - from initial tool design and tool-making to final assembly and testing ensures that only products of the highest quality are produced.

It is this commitment to quality that has resulted in the Company receiving prestigious awards from many of the

world’s leading testing and approvals organizations.

John Guest is a preferred supplier

to many international companies.

Contents:

CTS TWIST & LOCK FITTINGS

LEAD FREE

BRASS FITTINGS

STANDARD BRASS

PIPE AND INSERTS

ACCESSORIES

p4-6

p6

p7

TECHNICAL CHECKLIST FOR PRODUCTS

LISTED ON PAGES 4-8 ONLY

POLYPROPYLENE FITTINGS

ANGLE STOP ADAPTER VALVES/

POLYPROPYLENE VALVES

ACCESSORIES

p9

p11-12

p13-14

BLACK CTS TWIST & LOCK FITTINGS

p8

TECHNICAL CHECKLIST FOR PRODUCTS

LISTED ON PAGES 11-14 ONLY

p15

The Push-Fit Solution

JG Speedfit® is an advanced push-fit fitting featuring John Guest Twist & Lock® technology that is suitable for Marine plumbing

applications. Speedfit Fittings have been designed for use with Copper Pipe, Speedfit PEX Pipe, CPVC, and PEX Pipe conforming to

US Plumbing Standards.

Performance specifications are well within those required for most normal water supply systems including:

• Hot and cold water distribution systems.

• Potable water distribution systems.

Extensive tests have shown that Speedfit products will withstand temperatures and pressures in excess of normal working conditions.

JG Speedfit® should be installed to conform with good plumbing practice.

Performance Benefits:

• John Guest Twist & Lock® for added security

• Approved for behind-the-wall installations

• No scale buildup

• Pipe exibility permits the cabling of pipe

through less accessible areas

• No blowtorch required

• A permanent leak-proof connection

• Lower thermal diffusivity maintains safer

surface temperature

• Pipe elasticity can reduce the possibility of

bursting under freezing conditions

• Lead and corrosion free

• Less noise from water ow and expansion/

contraction

• Long pipe lengths require fewer ttings

Installation Benefits:

• Works with Copper, CPVC, and PEX

• No tools required

• Installation time reduced by 40%

• Grip and seal connection

• Reduced pipe insertion force

• Disassemble without damage to pipe or tting

• Easy to use in conned spaces

www.jgspeedfit.com

1.

SPECIAL APPLICATIONS:

Boats: The flexibility of the Speedfit System ensures it can be

cabled easily around the interior and hidden from view.

RV: Speedfit is ideal for RV installations due to its flexibility and

its resistance to corrosion and freezing.

Exhibitions: The unique ability of the Speedfit System to be

easily disassembled and reused, together with its flexibility,

makes Speedfit ideal for this application.

Portable Buildings (offices, toilets): As with RV’s, Speedfit is

well suited for these applications.

Agricultural and Horticultural: Speedfit has many applications

in agricultural and horticultural environments.

HANDLING PIPE AND FITTINGS:

Ensure that the fittings and pipe are kept clean at all times by

keeping them in the bags and box provided.

Do not empty Speedfit products onto the floor area. Be sure to

keep the internal o-ring seals free from dirt and debris.

STANDARDS AND AFFILIATIONS

Speedfit complies with the applicable sections

of the latest edition of the Uniform Plumbing

Code® and the International Plumbing Code®,

including behind-the-wall installations. Refer

to the applicable code listings for the latest

information.

Speedfit Products are manufactured in

compliance with, ASTM F876, ASTM F877,

ESR # 1931

PMG 1033

NSF 14

NSF 61

CSA B137.5, ASSE 1061 and IGC188

pw-rfh

PEI Speedfit fittings & pipes have NSF/ANSI

Standard 14 which demonstrates compliance

with USA Plumbing Codes, cNSFus – which

complies with Canada and US Standards,

CSA – Canadian Standards, pw – potable

water, rfh – radiant floor heating, all have NSF

Standard 61 Certification for Drinking Water

System Components and Materials which

contact drinking water. Including Annex G

where applicable.

John Guest quality system is certified by BSI

to BS EN ISO 9001.

PRODUCT SELECTION AND INSTALLATION:

John Guest fittings and related products are specifically designed

and manufactured by John Guest to the technical specifications

set out in the John Guest Product Catalogs. All John Guest fittings

and related products should be selected, installed, used, and

maintained in accordance with these Technical Specifications.

It is the customer’s/user’s responsibility to ensure that John

Guest fittings and related products are suitable for their intended

applications, are properly installed and maintained, and are used

in accordance with the Technical Specifications. It is also the

customer’s/user’s responsibility to provide its own customers with

any relevant technical information about John Guest products it

supplies them.

Speedt® must not be used for gas, fuel oil or compressed air

applications.

John Guest produces a specially designed push fit system of

pipe and fittings for compressed air installations. See separate

literature for details.

Working pressures and temperatures:

Application Max. Working Max. Working

Pressure Temperature

The Genuine JG symbol represents our

commitment to our customers, and what the

John Guest name means to business: Quality,

Reliability, and Support.

WARRANTY:

As a result of long-term testing programs and rigorous quality

standards John Guest USA offers a 25-year warranty against

defects in materials or manufacturing of PEI, MWI, and PSEI

ranges of plumbing fittings and Speedfit PEX Pipe manufactured

by John Guest.

John Guest plumbing products are for use with normal domestic

plumbing systems and supplied in accordance with our terms

and conditions of sale.

Water 160 psi 73° F

Water 100 psi 180° F

Water 80 psi 200° F

2.

MAKING A GOOD CONNECTION

Push the pipe into the fitting and up to the pipe stop.

Pipe Insert

John Guest Twist and Lock® Fittings have a collet with stainless

steel teeth that grip the pipe when fully inserted, and an O-ring to

provide a permanent leak-proof seal. The additional benefit of the

Twist and Lock fitting is that a twist of the screw-cap gives greater

compression on the O-ring seal and locks the pipe in place for

greater security.

Main ‘O’ Ring Seal

Stainless Steel Teeth Grip PipeSpacer

PREPARE THE PIPE

Speedfit Pipe

No Gap (locked)

Twist the screw-cap until it touches the body flange.

This locks the pipe into position and increases the

o-ring seal around the pipe.

Pull to check that it is secure. It is good practice to test the

system prior to leaving the site or before use. Our recommended

test procedure is shown in our Technical Checklist.

TO DISCONNECT:

Ensure that the system is depressurized.

Pipe Cutter

JGTS

To prevent damage to the O-ring remove all burrs and sharp

edges. When using Speedfit® or other types of PEX Pipe, we

recommend the use of Pipe Insert.

HOW TO MAKE A CONNECTION

Fittings and pipe should be kept clean, bagged, and undamaged

before use.

TWIST AND LOCK FITTINGS

Gap Between Cap and Flange

The fitting should be in the ‘unlocked’ position. This is shown by a

small gap between the screw-cap and the body flange.

Pipe Stop ‘O’ Ring Collet

Spacer

Be sure to twist the screw-cap back to the unlock position.

Push the collet square against the face of the fitting by using

fingers. With the collet held in this position the pipe can be

removed.

The fitting can be used again without the need for replacement

parts. (Ensure the fitting is clean before every use).

WHAT NOT TO DO

• Do not use damaged or scored pipe

• Do not use a hacksaw to cut the pipe

• Do not leave burrs on the end of the pipe

• Do not forget to push the pipe fully into

the fitting, past both the collet (gripper) and the O-ring.

• Do not insert fingers into the fitting as the stainless steel teeth

may cause injury.

Remember to pressure test the completed installation according

to the recommendations in our Technical Checklist.

www.jgspeedfit.com

3.

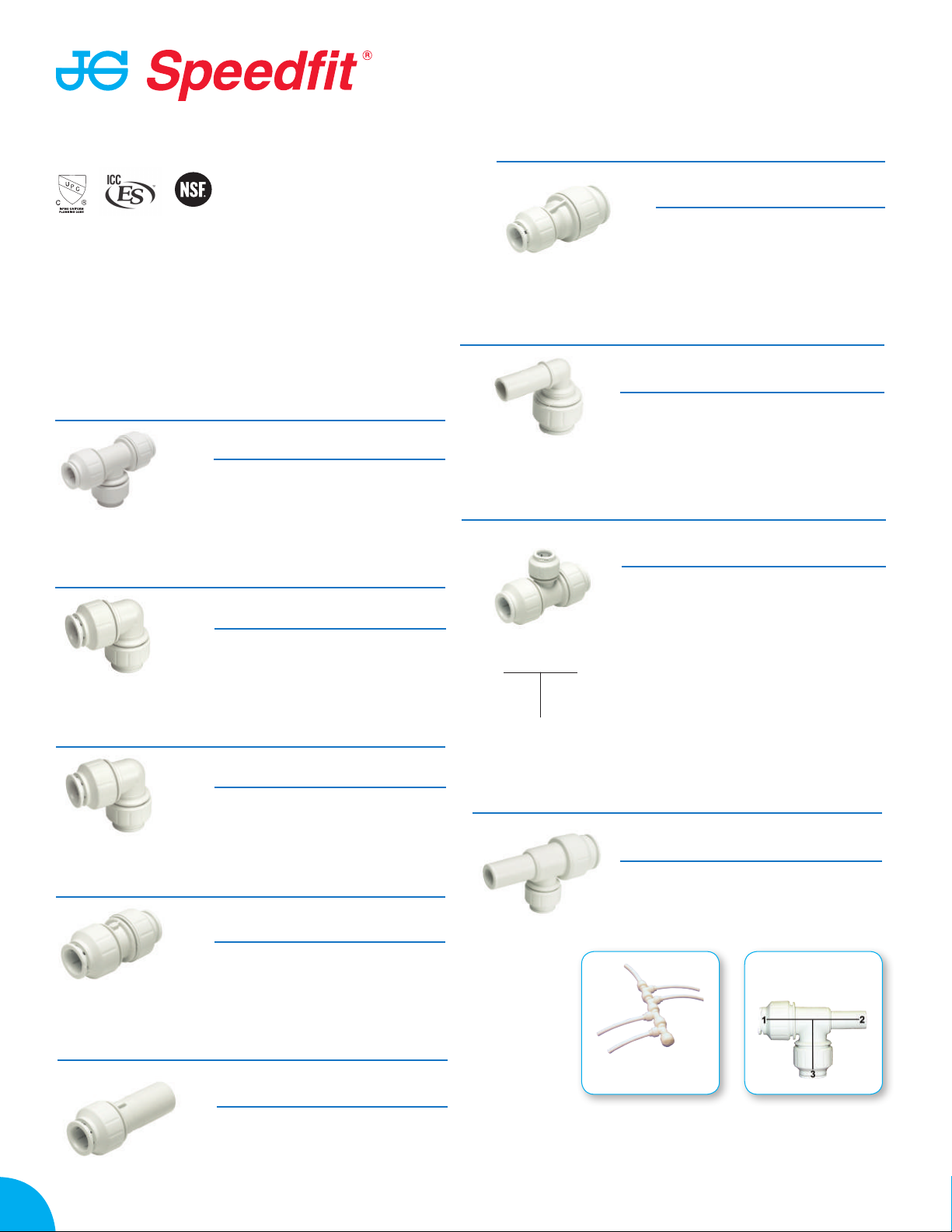

CTS TWIST & LOCK FITTINGS

FOR USE WITH COPPER, PEX AND CPVC PIPE

ESR # 1931

The PEI Range of JG Twist & Lock® Fittings is offered in 3/8”, 1/2”,

3/4” and 1” CTS sizes. The fittings are manufactured from high

quality engineered plastic with EPDM O-Rings. Speedfit Push-in

System is suitable for hot and cold water plumbing applications.

NSF 61

REDUCING COUPLER

PART NO. SIZE BAG BOX PRICE

CTS QTY QTY $

PSEI202016

PEI202820

PEI203628

1/2” x 3/8” 10 80 9.00

3/4” x 1/2” 5 30 6.53

1” x 3/4” 5 15 9.62

Refer to page 9 for detailed technical specification

Prices subject to change without notice.

TEE

PART NO. SIZE BAG BOX PRICE

CTS QTY QTY $

PSEI0216

PEI0220

PEI0228

PEI0236

3/8” 5 50 12.50

1/2” 5 25 6.04

3/4” 2 10 10.07

1” 1 5 18.90

ELBOW

PART NO. SIZE BAG BOX PRICE

CTS QTY QTY $

PSEI0316

PEI0320

PEI0328

PEI0336

3/8” 10 80 9.50

1/2” 5 40 5.89

3/4” 5 20 8.86

1” 1 10 14.87

REDUCING ELBOW

PART NO. SIZE BAG BOX PRICE

CTS QTY QTY $

PEI212820 3/4” x 1/2” 5 25

PEI213628 1” x 3/4” 1 10

COUPLER

PART NO. SIZE BAG BOX PRICE

CTS QTY QTY $

PSEI0416

PEI0420

PEI0428

PEI0436

3/8” 10 80 8.00

1/2” 5 40 5.14

3/4” 5 25 6.76

1” 1 15 13.11

STEM ELBOW

REDUCING TEE

10.40

18.38

Sizes are listed in the

following order

1 2

3

STACKABLE TEE

PART NO. SIZE BAG BOX PRICE

STEM x CTS QTY QTY $

PEI222020

PEI222828

1/2” x 1/2” 10 60 4.13

3/4” x 3/4” 5 25 5.78

PART NO. SIZE BAG BOX PRICE

CTS QTY QTY $

PEI3028A

PEI3028B

PEI3028C

PEI3028D

PEI3036A

PART NO. SIZE BAG BOX PRICE

CTS QTY QTY $

3/4” x 3/4” x 1/2” 5 15 9.57

3/4” x 1/2” x 1/2” 5 20 8.83

1/2” x 1/2” x 3/4” 5 20 8.83

3/4” x 1/2” x 3/4”

1” x 1” x 3/4”

5 15

1 10

9.57

11.35

PEI532020

PEI532820

PEI532828

1/2” x 1/2” x 1/2” 5 30 7.55

3/4” x 3/4” x 1/2” 5 20 9.88

3/4” x 3/4” x 3/4” 1 15 10.73

Sizes for Stackable Tee are

listed in the following order

4.

REDUCER

PART NO. SIZE BAG BOX PRICE

STEM x CTS QTY QTY $

PSEI062016

PEI062820

PEI063628

1/2” x 3/8” 10 50 6.34

3/4” x 1/2” 10 50 5.80

1” x 3/4” 5 30 7.68

For use with Copper, PEX and CPVC Pipe

Ideal for multi-port manifold

Loading...

Loading...