FOR:

PASSENGER CAR & LIGHT TRUCK WHEELS

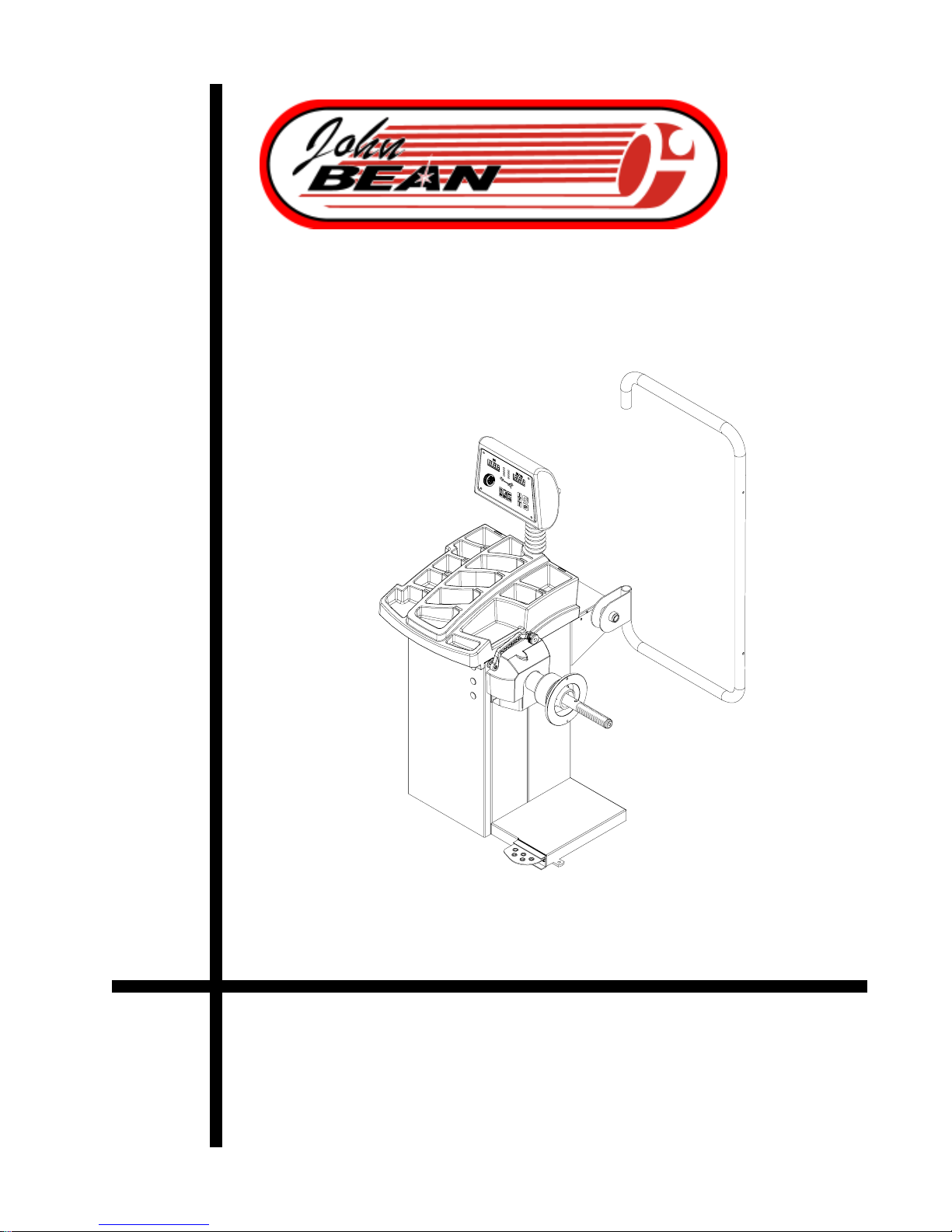

VPI SYSTEM I

COMPUTER WHEEL BALANCER

OPERATION INSTRUCTIONS

Form 5787-1

Rev 04/19/2001

SAFETY INFORMATION

For your safety, read this manual thoroughly

before operating the JBC VPI System I Wheel Balancer

The JBC VPI System I Wheel Balancer is intended for use by properly trained automotive technicians. The safety messages presented in this section and throughout the

manual are reminders to the operator to exercise extreme caution when servicing tires

with these products.

There are many variations in procedures, techniques, tools, and parts for balancing

tires, as well as the skill of the individual doing the work. Because of the vast number

of wheel and tire applications and potential uses of the product, the manufacturer cannot possibly anticipate or provide advice or safety messages to cover every situation.

It is the automotive technician's responsibility to be knowledgeable of the wheels and

tires being serviced. It is essential to use proper service methods in an appropriate and

acceptable manner that does not endanger your safety, the safety of others in the work

area or the equipment or vehicle being serviced.

It is assumed that, prior to using the Model VPI System I Wheel Balancer, the

has a thorough understanding of the wheels and tires being serviced. In addition, it is

assumed he has a thorough knowledge of the operation and safety features of the

rack, lift, or floor jack being utilized, and has the proper hand and power tools necessary to service the vehicle in a safe manner.

Before using the Model VPI System I Wheel Balancer, always refer to and follow the

safety messages and service procedures provided by the manufacturers of the equipment being used and the vehicle being serviced.

IMPORTANT !! SAVE THESE INSTRUCTIONS -- DO NOT DISCARD !!

operator

IMPORTANT SAFETY INSTRUCTIONS

When using this equipment, basic safety precautions should always be followed,

including the following:

1. Read all instructions.

2. Do not operate equipment with a damaged power cord or if the equipment has been

damaged - until it has been examined by a qualified authorized service technician.

3. If an extension cord is used, a cord with a current rating equal to or more than that

of the machine should be used. Cords rated for less current than the equipment

may overheat. Care should be taken to arrange the cord so that it will not be tripped

over or pulled.

4. Always unplug equipment from electrical outlet when not in use. Never use the

cord to pull the plug from the outlet. Grasp plug and pull to disconnect.

5. To reduce the risk of fire, do not operate equipment in the vicinity of open

containers of flammable liquids (gasoline).

6. Keep hair, loose fitting clothing, fingers and all parts of the body away from moving

parts.

7. Adequate ventilation should be provided when working on operating internal

combustion engines.

8. To reduce the risk of electric shock, do not use on wet surfaces or expose to rain.

9. Do not hammer on or hit any part of the control panel with weight pliers.

10. Do not allow unauthorized personnel to operate the equipment.

11. Do not disable the hood safety interlock system or bypass the intended operation.

12. Use only as described in this manual. Use only manufacturer’s recommended

attachments.

13. Always securely tighten the wing nut before spinning the shaft.

14. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

15. Balancer is for indoor use only.

SAVE THESE INSTRUCTIONS

Page 2

John Bean VPI System I Operators Manual

TABLE OF CONTENTS

General Safety Instructions Pages 1 & 2

1.0 Introduction Page 4

1.1 Safety Notice Page 4

1.2 Balancer Application Page 4

1.3 Specifications Page 5

1.4 Balancer Features Page 5

1.5 Standard Accessories Page 6

1.6 Optional Accessories Page 6

1.7 Dimensions Of The Machine Page 7

1.8 Installation Area Page 7

1.9 Installation Instructions Page 7

2.0 Shaft Adapter Installation Page 7

2.1 Wheel Guard Installation Page 8

2.2 Electrical Installation Page 8

2.3 Perform a User Calibration Page 8

3.0 Terminology Page 9

4.0 Balancer Operation Page 10

4.1 Inspection Check list Page 10

4.2 Wheel Mounting Page 10

4.2.1 Mounting of Standard Wheels Page 10

4.2.2 Mounting of Light Truck Wheels Page 11

4.3 Mode Selection Page 11

4.3.1 Weight Placement Modes Page 11

4.4 Selecting Operator Preferences Page 12

4.4.1 Fine Balance Mode Page 12

4.4.2 Ounce /Grams Conversion Page 12

4.4.3 Inch/Millimeter Conversion Page 12

4.4.4 Selection of Operator A/B Page 12

4.5 Entering Rim Parameters Page 13

4.5.1 Entering Distance (offset) with SAPE Page 13

4.5.2 Entering Rim Diameter Page 13

4.5.3 Entering Rim Width Page 13

4.5.3.1 Manual Distance Entry Page 13

4.6 Correcting the Imbalance Page 14

4.7 Verifying Results Page 14

4.8 Vibration Problems Page 14

5.0 Matching Program Page 15

6.0 Optimization Program Page 17

7.0 Alu-S Program Page 18

8.0 Spoke Mode Page 19

9.0 Split Weight Mode Page 20

10.0 User Shaft Calibration Page 21

11.0 Distance Gauge Calibration Page 22

11.0 Explanation of "F" Codes Page 23

12.0 Maintenance Page 23

13.0 Trouble Shooting Page 23

Page 3

1.0 INTRODUCTION

Congratulations on purchasing the VPI System I computer wheel balancer. This wheel balancer is

designed for ease of operation, accuracy, reliability and speed. With a minimum of maintenance and

care your wheel balancer will provide many years of trouble-free operation.

Instructions on use, maintenance and operational requirements of the machine are covered in this

manual.

STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE.

READ THIS MANUAL THOROUGHLY BEFORE USING THE MACHINE.

1.1 SAFETY NOTICE

This manual is a part of the balancer product.

Read carefully all warnings and instructions of this manual since they provide important information

concerning safety and maintenance.

1.2 BALANCER APPLICATION

The John Bean wheel balancer model VPI System I is intended to be used as a device to balance car,

and light truck wheels within the following range:

Maximum wheel diameter : 44” (1117mm)

Maximum wheel width : 16” (530mm)

Maximum wheel weight : 120lbs (54 kg)

This device is to be only used in the application for which it is specifically designed.

Any other use shall be considered as improper and thus not reasonable.

The manufacturer shall not be considered liable for possible damages caused by improper, wrong or

non reasonable use.

Page 4

John Bean VPI System I Operators Manual

1.3 VPI System I SPECIFICATIONS

Computerized digital wheel balancer for car, light truck

wheels.

Weight Imbalance Accuracy .1 oz / 2 grams

Weight Placement Resolution ± .7 degrees

Weight Imbalance Resolution:

Roundoff Mode .25 oz / 5 grams

Non-Roundoff Mode .05 oz / 1 gram

Max. Shaft Weight Capacity 120 lbs / 54 kg

Max.Tire Diameter 44" / 1117 mm

Rim Width Capacity 1.5"-15" / 76 mm - 406 mm

Max. Tire Width 19” / 482 mm

Rim Diameter Capacity 8"-20" / 152 mm-660 mm

Balancing Cycle Time. 7 seconds or less

Shaft Speed at calculation >100 RPM

Electrical 115vac, 1ph, 50-60Hz, 8A

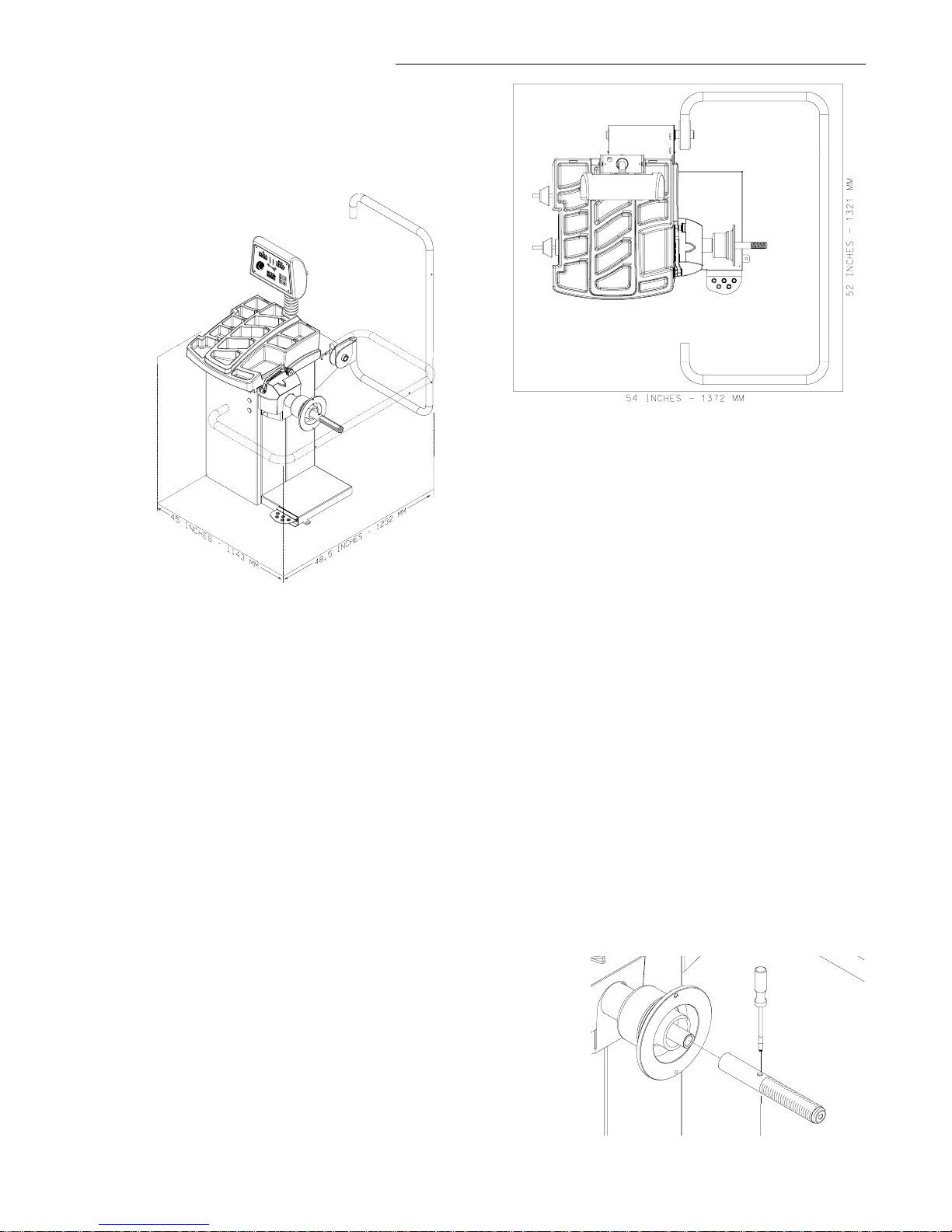

Required Work Area 54” x 52” (1372 x 1321 mm)

Shipping Weight, complete 325 lbs/147kg

Shipping Dimensions 52.75”h 41.5”w 37”d

Machine Dimensions 54”h 45”w 48.5”d

Actual Weight with Accessories 309 lbs / 140 kg

Operating Temperature Range 32-122F / 0-50C

1.4 FEATURES

ACCURACY

• Weight placement accuracy to as low as ± .7°

• Weight imbalance accuracy to 2 grams.

• Self test check with every power up cycle.

• Fast operator calibration.

• Pre-programmed Error Codes indicate procedural

errors or safety concerns.

SPEED and DURABILITY

• Automatic distance entry. Simply touch the distance

arm to the wheel, the distance parameter is automatically entered.

• Quick clamp speed nut reduces wheel mounting time.

• Captured back spring eliminates having to handle the

backing spring.

• Quick cycle time.

• Automatic recalculation if weight positions are

changed. No need for re-spinning the wheel.

• Common 40 mm diameter mounting shaft.

• Weight pocket storage tray.

• Easy-to-Read Data display.

• Easy weight tray access.

SOFTWARE VERSATILITY

• Both dual weight Dynamic and single weight Static

capability.

• Match Balance program for reducing weight required.

• Built-in spin counter for monitoring balancer

productivity.

• Service code access to all Balancer electronic functions for fast, easy diagnosis.

• Operator selectable roundoff mode.

• 5 Aluminum Modes

• Alu-S mode

• Hidden Weight (Spoke) mode

• Split Weight mode

Page 5

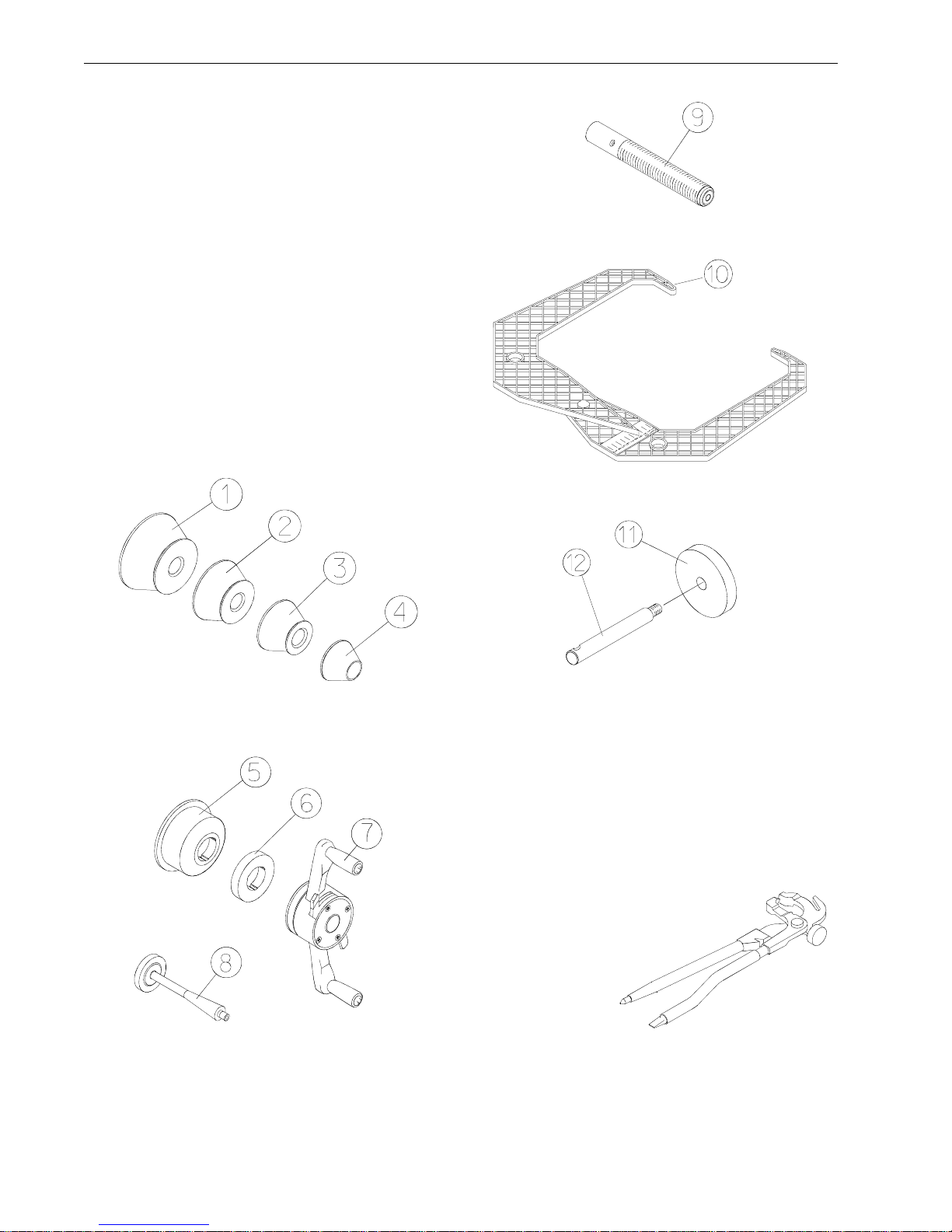

1.5 STANDARD ACCESSORIES

Standard accessories included with the VPI System I

are:

1 EAM0003J08A Cone, 85-132 mm / 3.3”-5.2”

2 EAM0003J07A Cone, 71-99 mm / 2.8”-3.9”

3 EAM0003J06A Cone, 56-84 mm / 2.2”-3.3”

4 EAM0003J05A Cone, 43-63 mm / 1.7” - 2.5”

5 8 - 02040A2 Cup - Pressure

6 8 - 02040A1 Disk - Pressure

7 8 - 02140A Quick Nut

8 EAM0005D40A Weight - Calibration

9 EAM0005D15A Stub Shaft

10 EAA0247G21A Caliper - Rim Width

11 EAC0060G02A Flange - Cover, Hook

12 EAM0006G01A Pin - Accessory

Figure 1

Figure 2

1.6 OPTIONAL ACCESSORIES

Weight Pliers P/N 26 (Figure3).

Versatile weight hammer/plier. In addition to hammering on weight and used weight removal, the

26

hammer/plier can be used to reshape worn weight

clips and trim weight to size.

model

Figure 3

Page 6

John Bean VPI System I Operators Manual

PRE-INSTALLATION CONSIDERATIONS

1.7 DIMENSIONS OF THE MACHINE

Figure 5 - Recommended Work Area

1.9 INSTALLATION INSTRUCTIONS

CAUTION! CAREFULLY REMOVE THE BALANCER

FROM THE PALLET.

Remove the hardware that secures the machine to

the pallet and slide the balancer onto the floor where

it is to be installed.

THE UNIT IS HEAVY AND THE WEIGHT IS NOT

EVENLY DISTRIBUTED.

Figure 4 - Actual Footprint Dimensions.

1.8 REQUIRED INSTALLATION AREA

Make sure that from the operating position the user can

see all of the machine and the surrounding area.

The operator should prevent non authorized persons

and/or objects from entering the area which may create potential hazards.

The machine should be installed on a stable level floor.

Do not install the machine on a uneven floor.

If the balancer is to be installed on a raised floor, the

floor must have a capacity of at least 110lbs per sq ft.

(5000 N/m² - 500 kg/m²).

It is not required to secure the machine to the floor.

Install the machine in a dry, covered area.

The installation of the machine requires a working area

of at least 54” x 52” (1372 x 1321 mm) (Figure5).

DO NOT LIFT THE BALANCER BY THE SHAFT.

DROPPING THE UNIT MAY CAUSE PERSONAL INJURY OR EQUIPMENT DAMAGE.

2.0 BALANCER INSTALLATION

Mounting the Shaft Adapter

IMPORTANT!

CHECK THAT THE SURFACES ARE PERFECTLY

CLEAN AND NOT DAMAGED. AN INCORRECT

MOUNTING MAY RESULT IN SIGNIFICANT IMBALANCE.

A. Mount the threaded shaft onto the arbor of the bal-

ancer. Tighten firmly using a screwdriver. (Figure 6).

Figure 6

Page 7

B. Install the accessory pins (Figure 7). Tighten firmly.

Figure 8

2.2 ELECTRIC INSTALLATION

ANY ELECTRICAL WIRING MUST BE PERFORMED BY LICENSED PERSONNEL.

ALL SERVICE MUST BE PERFORMED BY AN

AUTHORIZED SERVICE TECHNICIAN.

Figure 7

C. Place cones and other accessories onto the accessory pins.

2.1 HOOD GUARD INSTALLATION

The safety hood guard is standard equipment and

must be installed prior to use.

Refer to Figure 8 for hood guard installation.

Parts Required:

(1) Hood Guard Assembly

(1) 3/8” - 16 x 2” HHCS

(1) 3/8” x 16 Keps

Position the hood guard in the raised (up) position.

Slide the hood guard support tube over the frame pivot

shaft protruding from the right side of the balancer cabinet.

Line up the mounting holes in both the pivot shaft and

the guard support tube. Secure the guard with 3/8” hardware.

Check on the plate of the machine that the electrical

specifications of the power source are the same as the

machine. The machine uses 115VAC, 50-60Hz, 1Ph,

8.0 Ampere. 230VAC units are available if required.

NOTE:

Any electrical outlet installation must be verified

by a licensed electrician before connecting the balancer.

NOTE:

This machine performs a self-test routine on startup. There will be a delay of several seconds before

the display is activated.

2.3 USER CALIBRATION

Perform the user calibration procedures as instructed

on page 21 and 22 of this manual before placing the

machine in service.

Page 8

John Bean VPI System I Operators Manual

3.0 TERMINOLOGY

Figure 9

Before using the wheel balancer it is suggested that

you become familiar with the terminology and features

of the machine’s components. Refer to Figures 9 and

10 for identification and location.

1. Inside Weight Amount and Function Display

Window - Shows inside or left weight amount and

various operation messages.

2. Position Indicator LEDs - Displays the location

for wheel weight placement.

3. Outside Weight Amount and Function Display

Window Shows outside or right weight amount and

various operation messages.

4. Weight Mode and Placement Display - Displays

a pictorial reference of the chosen balance mode.

5. Function Button - Used to activate the various

functions. Press this button followed by pressing

the

up

or

down

arrow buttons until the desired number is displayed. Press the “Enter” button to active

the function.

6. Enter - This key activates whatever selection has

been requested, it also spins the wheel if guard

frame is down.

7. Up and Down Value - Buttons are used to raise or

lower displayed values for parameter entry or function code activation.

NOTE: Rotating the shaft in either direction will

also vary displayed values.

8. Cancel - Pressing this key interrupts any process.

9. Mode Selection - A series of placement locations

for custom weight location. Useful for the wide variety of custom wheels on today's market.

10. Rim Width - Press this key to enter the rim width.

Use the rim width calipers for measurement.

11. Rim Diameter - Enter the rim diameter after pressing this key. Read the size stated on the tire sidewall.

12. ALU-S and Spoke Mode - Activates the ALU-S or

Spoke Mode. Each time this button is pressed programming toggles between the two.

13. Rim Offset - This key is used to enter the rim offset

position using the numbers from the distance gauge.

14. Multi-Operator Selection - This key toggles between four operators designated as a, b, c, and d.

Wheel parameters are recalled upon command.

15. Display - Easy to read, user friendly display featuring large LEDs and one button functions.

16. Weight Storage Tray - Generous storage for a

variety of weight profiles and sizes as well as built

in storage pockets for the standard centering cones.

17. Accessory Storage - Four sturdy side mounted

pegs are supplied for storage of additional accessories.

18. Foot Operated Shaft Lock - A foot operated shaft

lock is used to stabilize the shaft during the weight

placement process.

19. Shaft Adapter - A common 40 mm size shaft is

used. The easily removable shaft can be replaced

for service or during use of certain wheel adapters.

20. Wheel Guard - The standard wheel guard is a

safety feature for prevention of operator injury in

the event of loose weights, debris or wheel mounting failure. The balancer is programed to spin upon

guard closure as well as brake when the guard is

raised.

21. Semi-Automatic Parameter Arm - Rim distance

is automatically input with the SAPE. The SAPE is

also used in several procedures for determining

accurate rim profiles.

Page 9

4.0 OPERATION OF THE BALANCER

WARNING: For operator safety please read

and follow the precautions outlined on

pages 1 and 2 of this manual.

NOTE: Read all instructions before proceeding with operation of the balancer.

Before starting any balancing procedure it is very important that the wheel is mounted on the machine with

the proper adaptors. An incorrect centering of the wheel

will result in considerable imbalance.

There are many types of wheels and John Bean supplies adaptors of good quality and durability for the large

majority. However if you meet special wheels which may

require a specific adaptor, call your authorized John

Bean distributor.

All balancer functions are input into the main computer

through the large easy to read touch panel. Although

each wheel tire assembly differ in some ways all balancing jobs require basically the same procedure. The

order of events to take place are:

1. Inspection of the wheel/tire assembly

2. Mounting wheel onto shaft or adapter

3. Selection of Balancing Mode and Preferences

4. Entry of wheel parameters

5. Spinning the wheel

6. Applying the recommended weight

7. Check spin if desired

8. Dismounting the wheel

The following operation instructions will follow the basic outline above.

4.1 CHECK LIST - INSPECTION

Observe Before Balancing Wheel

1. Check for proper air pressure. If not correct, inflate to

correct pressure.

Rims may be divided into these major groups:

1. Car rims with a true center hole.

2. Car rims without a center hole.

3. Car rims with an untrue center hole.

4. Light truck rims.

4.2.1 Standard Wheels (back cone mount)

Mount the wheel as detailed below in Figure 11:

2. Check for any foreign material inside tire. If present,

remove before balancing tire.

WATER IS FOREIGN MATERIAL!

3. Remove old weights — old weights may be improper

value or in wrong location.

4. Be sure tire and wheel are free of excessive dirt, rust

and large stones. Use wire brush on back side of wheel

if necessary.

4.2 WHEEL MOUNTING

Nearly all standard wheels and many alloy wheels have

accurately machined center holes, and they should be

mounted with center cones. Accurate balancing depends on accurate mounting of the wheel and correct

seating of the cone in the pilot hole. Insure that the wheel

is centered on the shaft exactly as it will be mounted to

the vehicle.

Page 10

Figure 11

1. Mount proper cone against spring plate.

2. Mount wheel on shaft in the same manner as you

would on the car.

3. Mount pressure cup on shaft and place against

outside of wheel, follow with the Quick-nut.

4. Tighten Quick-nut securely with both hands. To

operate the Quick-nut pull the lock-unlock lever

(Figure 12). Slide the Quick-nut on the threaded

shaft. When in contact with the rim, release the

unlock lever and tighten firmly. To assist in

centering the wheel properly, rotate the wheel on

the shaft while tightening the quick nut.

John Bean VPI System I Operators Manual

Figure 12

!

FAILURE TO TIGHTEN WING NUT SECURELY

MAY RESULT IN SERIOUS PERSONAL INJURY.

DO NOT USE A HAMMER TO TIGHTEN THE

QUICK NUT.

TO RELEASE THE QUICK NUT, UNSCREW A

FEW TURNS TO REDUCE THE AXIAL PRESSURE, THEN PRESS THE UNLOCK LEVER AND

SLIDE AWAY FROM THE SHAFT.

4.3 MODE SELECTION

The majority of balancing takes place in the default 2plane dynamic mode which is displayed as "2 PL"

(location 1). Hammer-on clip weights will be placed on

both inside and outside of the rim edge. If required,

select an optional weight placement mode by pressing

the

Mode

button until the appropriate placement mode

is displayed.

4.3.1 WEIGHT PLACEMENT MODES

Before spinning the wheel (although it may be done afterwards) choose the appropriate balancing mode for

the wheel. To select the various placement modes press

the Mode button until placement LEDs indicate desired

placement position.

Indicator LEDs

Mode Button

5. Check that the wheel rotates true by turning the wheel

several revolutions while noting any excessive runout.

4.2.2 CENTERING LIGHT-TRUCK WHEELS

An optional offset spacer may be required for some light

truck wheels and reverse-offset wheels that must be

moved away from the balancer mounting flange. The

extension adaptor is often used with the 5-1/4 inch diameter light truck cone.

Install the spacer on the mounting flange, then mount

the wheel, using the front cone method (Figure 13)

The balancing modes available are:

A. DYNAMIC (two planes), suggested for all steel rims.

In this case the wheel weights must be clipped onto the

rim edges. This function is selected as a default and

the LEDs corresponding to the wheel weight location

are lit on (Figure15).

Figure 14

Figure 15

B. STATIC (single plane - Figure16). Suggested for nar-

row rims (3" or less). Use a single corrective weight

placed in the center of rim as illustrated in Figure 16.

Figure 13

Figure 16

Page 11

C. ALUMINUM MODES. Balancing using a combination of hammer-on and adhesive weights as shown in

Figures 17 thru 21.

Figure 17 ALU 1

Figure 18 ALU 2

4.4 SELECTING OPERATOR PREFERENCES

4.4.1 FINE BALANCING MODE

This balancer measures with the maximum precision

available all the time, 1g / 0.05 oz, however values below 5g / 0.25 oz are shown as zero while in the normal

operating mode. Values exceeding 5g / 0.25 oz are

rounded to the amount of the nearest commercial wheel

weight.

Press the F button followed by the

button to toggle the display resolution between 5g /

0.25 oz and 1g / 0.05 oz.

4.4.2 OUNCE/GRAMS CONVERSION

When the machine is first turned on it is preset to display the imbalance in ounces.

If the display in grams is desired, press the F button

followed by the

displayed”.

Repeat the procedure for converting back to ounces.

4.4.3 RIM DIAMETER IN MILLIMETERS

UP

or

Down

UP

or

Down

arrow

arrow button until “P 3” is

Figure 19 ALU 3

Figure 20 ALU 4

Figure 21 ALU 5

TO RETURN TO THE

ANY OF THE

cel/Stop.

ALU

PROGRAMS, JUST PRESS Can-

DYNAMIC

PROGRAM FROM

The rim diameter is normally displayed in inches, however if the value in millimeters is desired, press the

button followed by the

“P 7” is displayed”.

Repeat the above operation to convert back to inches.

Example: “dIA ICH” = inches

“dIA ---” = millimeters

4.4.4 OPERATOR SELECTION

Select the desired operator designated A,B,C,or D. The

EEWB304A Balancer can store wheel parameters of

four operators. The Operator button toggles between

the four operators with each depression.

UP

or

Down

arrow button until

F

Page 12

John Bean VPI System I Operators Manual

4.5 ENTER RIM PARAMETERS

4.5.1 Rim Distance (offset) - Move the rim off-

set arm to the edge of the rim, touch the pointer to

the rim edge as illustrated in Figure 22 and hold

steady for about a second. The beeper will sound

when the distance values are calculated and entered automatically. Return the arm to its fully in

and down position on the balancer. Do not allow

the measurement arm to "dangle" down in front of

the balancer.

4.5.3 Measure Rim Width using rim width

calipers. Measure wheel where corrective clip-on

weight would be applied, Figure 24. Enter the

measured width by pressing the

UP

or

Down

arrow button until the desired value appears in the

center display.

Figure 24

Figure 22

4.5.2 Rim Diameter Entry - Select the Manual

Diameter button (#11 page 9). Read the rim diameter marked on the sidewall of the tire (Figure

23). Enter the measured rim diameter by pressing

the

Diameter

row button until the desired value appears in the

button followed by the

UP

or

Down

ar-

right display.

4.5.3 Manual Parameter Entry

In the event of automatic gauge failure, the distance values can be input manually.

4.5.3.1 Manual Distance Entry - Move the distance gauge arm to touch the inner edge of the

wheel where weights are to be placed and observe

the reading on the scale of the distance gauge.

Press manual Wheel

followed by pressing the

Offset

UP

button (#13 page 9)

or

Down

arrow button

until value is displayed in the left display window.

NOTE: For a more precise balancing of perfor-

mance wheels, an “ALU-S” Mode is available for

precision determination of wheel parameters. This

feature allows exacting placement of corrective

weights as well. See

Page 18

for detailed instruc-

tions.

NOTE: The parameter arm must be in the Home

rest position when the balancer is powered up.

Thisestablishes the arm starting position.

Figure 23

Page 13

4.6 CORRECTION OF THE IMBALANCE

NOTE: Before spinning the wheel make sure proper

eye protection is worn by all personnel in the vicinity of

the balancer.

A. Spin the wheel by lowering the wheel guard or by

pressing the

is completed the wheel will stop automatically and the

imbalance values will appear on the LED’s.

Enter

button. When the balancing cycle

NOTE: If this situation is repeated, your machine may

be out of calibration and a calibration operation might

be required as instructed on page 21.

ALU

D. If an

weights have been placed in accordance to the program chosen.

E. Check that the quick nut is tight and that the wheel is

not slipping against the backing collar.

function was selected ensure that the wheel

NOTE: Do not use the foot operated shaft lock as a

brake, it is intended to be used only to prevent shaft

rotation while placing corrective weights.

B. Read the imbalance value on the outer display. Values are displayed in ounces but can be displayed in

grams if required and are automatically rounded to the

nearest commercial wheel weight.

4.6.1 PLACING THE CORRECTIVE WEIGHT

Raise the wheel guard and turn the wheel until the displays of the outer plane imbalance position indicator

are illuminated green. Apply the wheel weight at twelve

o’clock position. Use the foot operated shaft lock to prevent shaft rotation while placing weights.

C. Correct the imbalance on the inner plane in the same

manner.

4.7 VERIFICATION OF THE RESULTS

Lower the wheel guard to spin the wheel again and

check that the readout is “0.00” “0.00” If a residual

imbalance is displayed:

A. Check the rim parameters, if entered value is incorrect, correct as needed. Imbalance values will be recomputed after re-spinning wheel.

B. Check if the balancing mode selected is the most

appropriate. If not, choose the right mode and respin.

C. The wheel weight could have been placed at a wrong

position. To check this, position the wheel at the correction position for the outer plane. If the wheel weight

previously attached is in sector ‘L’ or ‘R’ ( Figure25),

move the wheel weight up about 1” (2.54cm).

If the wheel weight is in sector ‘D’ cut a piece of the

wheel weight of an approximate value corresponding

to the value shown on the right display, or replace the

wheel weight with a lighter one.

If the wheel weight is in sector ‘U’ add a weight of value

indicated by the display or replace the wheel weight

with a heavier one. Repeat the same operation for the

inner plane.

F. Check that the wheel and adaptors are clean.

Figure 25

4.8 VIBRATION PROBLEMS

If vibration is still present after balancing, check the following possible sources of vibration:

1. Stones caught in the tire tread.

2. Tire slippage on the wheel.

3. Incorrectly mounted wheel.

4. Imbalanced wheel covers.

5. Excessive radial or lateral runout in the tire or

wheel.

6. Damaged wheel bolt holes.

7. Worn universal joints.

8. Imbalanced brake rotors or drums.

9. Worn or damaged balancer accessories.

Page 14

John Bean VPI System I Operators Manual

5.0 TIRE MATCHING PROGRAM - F90

Tire matching assists the user in determining the best

possible mating of the tire and rim. The mating of tire

and wheel normally allows the least amount of additional weight required for balancing and total runout.

The matching program is helpful when:

• Excessive radial runout is noticed.

• The balancer calls for weights in excess of 2 oz. on

either plane in the

The VPI System I computer wheel balancer features a

matching program capable of two levels of resolution:

Dynamic

for optimum rim and tire matching.

Static

rectional tread and cannot be reversed on the rim.

INSTRUCTIONS:

, to rotate

, when the tire has an ornate sidewall or di-

Dynamic

and

mode.

reverse the tire on the rim

Figure 26 - Step 1, valve top, press "F"

1. Press the "F" button dollowed by pressing the

Down

release the "F" button.

When activated the machine displays "--- ACH" for one

second followed by "VAL tOP". This instructs the operator to rotate the wheel so the inflation valve is at 12

o'clock. See

position, the display will then read "SPN 1 ".

NOTE: The F button can be pressed more than once,

every time the F button is pressed, the valve position is

remembered by machine as a reference point.

2. Lower the wheel guard to spin the wheel, when the

shaft reaches the balancing speed, the display reads

"ACH 1" accompanied with a short beep.

3. After spinning the shaft brake engages and the display reads "tur tir" and "CrS tOP" alternatively.

(1) The operator should turn the wheel and mark an X

at the 12 o'clock when the valve is at the 6 o'clock position.

arrow button until the display reads "F" “90”,

Figure

Figure

27

26. Press "F" to store the valve

UP

or

Figure 27 - Step 2, valve at bottom,

mark top of tire with X, press "F"

(2) Remove the wheel assembly from the balancer and

deflate and rotate the tire on the rim so the valve points

to the cross mark on tire as shown in

4. After inflating the tire and remounting on shaft, press

F Button. The machine displays "VAL tOP" again. Op-

erator should turn the wheel so the valve is at 12 o'clock.

Press the "F" button to program the valve position.

Figure

28

Figure 28 - Step 3, rotate tire on wheel so the valve and

X mark line up. Rotate assembly to TDC, press "F".

Page 15

NOTE: The "F" button can be pressed as often as necessary, with every press the machine updates the

memory of the valve position.

5. The machine displays "SPN 2 ". Lower the wheel

guard to spin the wheel, when the shaft reaches the

balancing speed, machine displays "ACH 2" along with

a beep.

6. Once the spin cycle is complete, the display reads

"CAL CUL" for one second. Machine calculates the

results based on the previous two spins.

From this point, there are three possible procedures to

conclude the match balance routine. These 3 procedures are quite different depending on the results of

calculation.

Procedure 1

The imbalance measured in spin 2 has been reduced

to an acceptable amount, less than 2 oz, and it will not

be necessary to continue match balance. The display

reads "ACH FIN" for one second, and then proceeds

to the normal two-plane balancing mode and displays

the weight imbalance amount and its position for both

planes.

Figure 29

Figure 30

Procedure 2

Due to a large amount of remaining imbalance the operator can continue match mount. Machine displays

"CrS” “r" and "tur” “tir" alternatively. This instructs the

operator to turn the wheel and make a double cross

mark (XX) on the right side of the tire at 12 o'clock position when the right center position LED turns to green.

See Figure 29.

NOTE: If you do not intend to continue minimization,

you can press the Cancel/Stop Button

If the Cancel/Stop Button is pressed now, machine displays "Qit Qit" for one and half second to remind operator whether he wants to quit optimization or not. If

one presses Cancel/Stop Button immediately, the program goes to procedure 1. If not, after one and half

second, machine returns to the optimization procedure.

To continue with optimization: Deflate the tire and then

turn the valve to point the XX mark on the tire. Remount

tire/wheel onto shaft, press "F" when ready to continue.

1. The machine displays "VAL tOP". Turn the wheel

so the valve is at top position. (12 o'clock) and then

press F Button. The machine stores the valve position.

See Figure 30.

2. The machine displays "SPN 3 ". Lower wheel guard

to spin shaft. Machine displays "ACH 3 ".

Page 16

John Bean VPI System I Operators Manual

3. Display will read "ACH CHC" for one second. Balancing results are checked whether or not the matching balancing has been achieved.

4. There are two results that could been given by the

previous step:

1 -

Match Balance failure

"FAI L " for one second and then goes to idle state.

2 -

Match Balance is successful

"ACH FIN" for one second and then goes to normal

two plane balancing mode. Machine displays the

recalculated weights and their position taking the

matching results into account.

Procedure 3

1. Machine displays "CrS L" and "FLP tir" alterna-

tively. When the left center position LED turns to green

this instructs the operator to turn the wheel and mark a

XX on the left side of the tire at 12 o'clock position.

2. If the tire cannot be flipped, press the Cancel/Stop

Button to force machine to procedure 2.

Calculations may not allow continuation of the matching process. If this is the case, machine displays "NO

NO " for one and half second. If the operator does not

respond the machine returns to above state after one

and half second.

. Machine displays:

. Machine displays:

7. Lower the wheel guard to spin the shaft. Machine

displays "ACH 3 " while collecting data. Do not disturb

the machine while it is acquiring data.

8. When balancing is complete, the machine displays

"ACH CHC" for one second. Machine processes the

balancing results to check whether or not the matching

balancing has been achieved.

9. There are two results could been given by the previous step.

1.

Matching balancing failure

"FAI L " for one second and then goes to idle state.

2 -

Match Balance is successful

"ACH FIN" for one second and then goes to normal

two plane balancing mode. Machine displays the

recalculated weights and their position taking the

matching results into account.

. Machine displays:

. Machine displays:

6.0 OPTIMIZATION ROUTINE- F91

The Optimization Routine is very similar to that of the

Match Mount Program (F90). The main difference is

that operation begins with a bare rim instead of a rimtire assembly. Follow instructions as detailed for in chapter 5.0 for F90.

If the Cancel/Stop Button is pressed within one and half

second, machine will display "Qit Qit" for one and half

seconds indicating cancelation of optimization returning the machine to normal balancing modes.

If optimization is to be continued with flipping tire, proceed as described below.

3. Deflate the tire then flip, turning the valve to point the

XX mark on the tire (as in procedure 2).

4. Inflate the tire and mount it to shaft again. Press the

“F” Button.

5. The machine displays "VAL tOP". Turn the wheel to

make valve at top position. (12 o'clock) and then press

"F" button. The machine will store the valve position.

6. The machine displays "SPN 3 ".

NOTE: The F Button can be pressed as often as nec-

essary, with every press the machine updates the

memory of the valve position.

Page 17

7.0 ALU-S MODE

This is a mode similar to ALU mode 2 and 3. The difference is that the distance and width parameters are accurately defined for a more exacting weight placement,

therefore improving the likelihood of a single spin balance. Follow the procedures below:

1. Press the Alu-s/Spoke button to activate the ALU-S

mode, the display will read " ALU - S".

2. Extend the rim offset gauge arm and touch the position of the left weight position. See Figure 31. The

display will read “d - I”. The high tone will sound when

dimension is entered. Return the gauge arm to the rest

position, a low pitch tone will indicate when it is OK to

proceed.

3. Move the parameter arm to the right weight position, the machine displays “d - 2” as the arm is moved.

See Figure 32. The high tone will sound when dimensions are entered. Return the gauge arm to the rest

position, a low pitch tone will indicate when it is OK to

proceed.

Figure 31

4. Enter the measured rim diameter by pressing the

Diameter

button or by rotating the shaft until the desired value

appears in the right display.

5. Lower the wheel guard or press “Enter” to spin the

wheel. The display will read “ALU” during the spin cycle.

6. After spinning, the machine displays both the left

and right plane imbalance weight and position with its

color LEDs.

Rotate the wheel until the left Green LED indicates correct position for the left correction weight.

7. Extend the gauge arm. The left display shows the

weight amount to be applied, the right display shows

the distance the gauge arm has to travel to get to the

correction plane. A high beep will sound when the correct position is reached, at the same time the right display will read “0“ when the proper position is attained.

A reading of “- - -“ in the distance window means the

gauge arm is over extended. Apply the weight amount

indicated in the left window using the tape weight applicator mounted on the SAPE extension.

Return the gauge arm to its home position.

8. The right plane correction weight will be applied next

as in step 7 above. The steps outlines are:

button followed by the

UP

or

Down

arrow

- Extend the arm until “0” is indicated in left window.

Figure 32

- Position the wheel in the weight application position

- Apply the displayed weight.

NOTE: Returning the gauge arm to the “Home” posi-

tion toggles between the left and right correction plane.

NOTE: To exit ALU-S mode and return to two plane

DYN (dynamic) mode press “Mode” button. The machine displays "ALU OFF" for one second and then

enters idle state in the 2-pl DYN mode

NOTE: Inspect the rim and available weights and use

good judgement in your selection. Weights should not

interfere with any suspension parts or make contact

during rotation. If a weight does make contact, use an

alternate location and select an appropriate mode.

Page 18

John Bean VPI System I Operators Manual

8.0 Spoke Balancing Mode

A standard dynamic balance places compenstation weight in two

planes, inner and outer, at the top dead center 180 degrees of

each plane of calculated imbalance. Sometimes the outide weight

placement may be unsightly on a custom wheel. See Figure 33.

The Spoke Mode is designed to “hide” outer plane corrective

weight by placing the required weight behind selected spokes in

order to retain the esthetic appeal of the wheel.

1. Press the Alu-s/Spoke button until “SPO” is displayed, the

display will read " SPO " when activated.

2. Enter left plane distance using the SAPE as you would a

dynamic 2-plane or ALU-S balance.

Figure 33

3. Move the parameter arm to the right weight position, the

machine displays “d - 2” as the arm is moved.

4. Enter the measured rim diameter by pressing the

Down

arrow button or by rotating the shaft until the desired value

appears in the right display.

5. Press Enter, or, lower hood guard. The display will read

“SPO” while spinning. After Braking to a stop rotate the shaft to

the inside plane top dead center position indicated by the center

green LED. Extend the SAPE until the right reading says “0”,

place indicated weight in the position directed by the SAPE.

6. Rotate the wheel to the outside plane top dead center position indicated by the center green LED, press the "F" button to

indicate top dead center.

NOTE: Mark the tire to assist in referencing the corrective weight

top dead center.

7. The display will read "SPO I “. Locate the first spoke nearest to top dead center and rotate the wheel so that spoke is at

top dead center. See Figure 34. Press P to store first position.

8. The display will read “SPO 2 “. Locate the second closest

spoke to top dead center and rotate the wheel to the top dead

center position, press F Button again to store the position. See

Figure 35.

UP

or

X

Figure 34

X

Figure 35

9. The display will read “P -2” on its left window and the balance weight amount in right window. Place the weight amount

displayed at “position 2” behind the spoke, then rotate the wheel

to locate position 1. See Figure 36.

10. When position 1 is located, the balancer will beep. The display will read “P -1” in the left window and the weight amount on

right window. Place the weight amount displayed at “position 1”

behind the spoke.

11. Perform a check spin if desired.

X

Figure 36

Page 19

9.0 Split Weights - P92

The “Split Weight” function is used to split one large

weight to two smaller weights with 60% of original weight

and 33.6° away each direction from the original position. For instance, if the original unbalance weight is 3

oz, the weight is split into two 1.75 oz weights and placed

56.4° and 123.6° from the original larger value located

top dead center at 90 degrees. The minimum weight to

activate this function is 2 oz. The procedure is described

below. See Figure 37.

1. After balancing, the weight amounts are displayed

in left and right windows.

2. Enter F92, machine will display “SPL -L- “ or “SPL

-R-“ meaning which plane should be split.

3. Press the “STOP” button alternately to toggle between the left and right plane.

4. Once the desired plane is chosen, press the "F"

button. The machine splits the weight into two parts.

The split weight is 60% of the original weight. The

position is 33.6° from each side the original position.

Figure 37

5. If the displayed weight is less than 2 oz (56.7

grams), the machine will display “ NOT AVL” for

one second, and then resumes the normal display.

6. Pressing “STOP” cancels the split weight mode

and operation returns to normal. The operator can

check if the position of original weight is between

the two smaller weights.

7. Pressing the “STOP” button again, returns the

machjine to idle mode without weight amount or position display.

8. For a check spin, lower the hood guard or press

“SPIN” button.

Page 20

John Bean VPI System I Operators Manual

10.0 USER CALIBRATION

The VPI System I Balancer features a user calibration

program which requires only a few minutes to complete.

Perform this procedure when the balancer has been

moved, disturbed, or whenever accuracy is questioned.

Occasional field calibration will ensure years of reliable

service.

Follow these 3 simple steps:

1. Activate Calibration.

Press the F Button (#1 Figure 38) then press the UP/

Down buttons (#2 Figure 38) until the display reads "F"

“14”.

• Once F14 activates, the display will read

"CAL" " GAN" for one second.

• The display will then read "SPN" " 1 ".

• Mount a balanced wheel/tire to the shaft.

See Figure 39.

2. Spin shaft with balanced wheel only.

Lower the wheel guard or press enter to spin the shaft

with wheel/tire assembly. See Figure 39

• Displays "CAL" " 1 " as the machine is collecting

data and performing calculations. After taking data,

the shaft is automatically braked to a stopped.

• The display will read "SPN" " 2".

Figure 38

2

1

3. Spin shaft with calibration slug on the left side.

Mount calibration slug to inside edge of shaft mounting

plate as shown in Figure 40.

• Lower the wheel guard or press enter to spin the

shaft with slug and wheel/tire assembly.

• Displays "CAL" " 2" as the balancer is doing its

calculations. When complete, the shaft is automatically braked to a stop.

• The display will read "CAL" "FIN " when the second

step of calibration is FINished.

• If for some reason the calibration detected an error,

the display will read: "---" "---" after the shaft brakes.

NOTE: The balancer will not function until a valid calibration has been performed. Error messages will be

displayed in the event problems occur during the calibration process.

Figure 39

Figure 40

Page 21

Figure 40

Figure 41

11.0 Distance Gauge Calibration F80

1. Make sure the SAPE arm is in the home

position as shown in (Figure 40). NOTE:

Weight tray must be installed.

2. Press the “F” button followed by pressing the

“Up”

or

“Down”

button until the

display reads “F” “80”, press “EN-

TER” to continue.

3. The display will read “CAL ” “SAP” for

one second. This means CALibration of

SAPE. The display will then read “SAP”

“OUT”.

4. Gently pull the SAPE arm OUT until it is

fully extended, (Figure 41) hold it steady

for about 1 second or until beep.

5. Display will read “H” “POS” followed by

a beep. Return the arm to the home position (Figure 40). The display will read

“CAL End”.

Page 22

John Bean VPI System I Operators Manual

12.0 EXPLANATION OF PROGRAM CODES

Various functions and features can be programmed to

enhance operation. These programs are referred to as

“F Codes”. Activate the “F Code” programs by pressing and holding the

down arrow buttons or by turning the shaft until the desired number is displayed on the right display window.

User Codes are explained as follows:

F1 Toggle between normal and fine mode.

F3 Toggle switch between gram and ounce display

F7 Toggle switch of millimeter and inch for diameter

measurement

F12 The balancer has 4 counters that keeps track of total

number of cycles for a certain parameter. The balancer will automatically cycle through the counters

after P12 is pressed. The order of the counters are:

1. Display “Ctr ALL” for one second.

Counter number of all spins.

2. Display “Ctr CAL” for one second.

Counter number of spins since last calibration.

3. Display “Ctr SrV” for one second.

Counter number of service spins.

4. Display “Ctr USR” for one second.

Counter number of user spins.

F14 Shaft User Calibration by user

F18 ALU-S mode (press balancing mode button to exit

and back to DYN mode)

F43 Read or reset operator counters, reads or allows re-

set of all four operators. (A, B, C, D)

F44 Read or reset productivity of user. Display counter

number of default user only.

F90 Tire Matching mode

F91 Optimization

F Button

while depressing the up/

13.0 MAINTENANCE

!

BEFORE ANY MAINTENANCE OR REPAIRS ARE ATTEMPTED THE MACHINE

MUST BE DISCONNECTED FROM THE

ELECTRIC SUPPLY.

This balancer does not require any special maintenance,

but the following precautions are required:

A. Periodically wash all plastic parts with a glass

cleaner. Wipe with a dry cloth.

B. Clean all adapters regularly with a nonflammable liquid detergent all. Lubricate with a thin layer of oil.

C. Periodically perform a routine calibration as outlined

on pages 21and 22 of this manual.

14.0 TROUBLE SHOOTING

TROUBLE CAUSE REMEDY

When turning the machine on, No electric power Check the input voltage

the displays do not light Defect in the electric/electronic system Call the Equiserv service center

for assistance

The machine gives random readouts. Machine unstable on the floor Check that machine is stable

Water in the tire Remove water from tire.

Loose adaptor Tighten the adaptor firmly

Defective electronic board Call the Equiserv service center

for assistance

The machine does not stop after Defective electronic component Stop using the machine immedi

balancing cycle ately and call the Equiserv service

center for assistance

The balancer is slow to display when This machine performs a self-test routine This is a normal characteristic

powering machine up. on start-up. There will be a delay of several of the machine

seconds before the display is activated.

If the parameter arm ceases to Malfunction of the Parameter arm from Replace the Parameter arm or

properly measure rim distance either a failure of the electrical system manually enter the parameters

causing machine lockup. or harness connection failure. to continue operation.

Page 23

NOTES:

USA

John Bean

309 Exchange Avenue

Conway, Arkansas 72032

Tel.: (800) 362-8326 or (501) 450-1500

Fax: (501) 450-1585

FRANCE

John Bean

Snap-On Equipment France

Z.A. Du Vert Galant

15, rue de la Guivernone

BP 7175

95310 Saint Ouen L’Aumone

Tel: (33) 1-3448-5878

Fax: (33) 1-3448-5879

CANADA

John Bean

6500 Millcreek Drive

Mississauga, Ontario

Canada L5N 2W6

Tel: (905) 814-0114

Fax: (905) 814-0110

GERMANY

John Bean Auto Service Gerate

Division to Sun Electric Deutschland GMbH

Gewerbepark Sinn

D-35764 Sinn Herborner Str. 7-9

Tel: (49) 2772-9404-0

Fax: (49) 2772-94042-23

UNITED KINGDOM

Snap-On Equipment Ltd.

John Bean Equipment Group

Old Medow Road

Kings Lynn

Norfork

PE30 4WJ

Notice: The information contained in this document is subject to change without notice. John Bean

makes no warranty with regard to this material. John Bean shall not be liable for errors contained

herein or for incidental consequential damages in connection with furnishings, performance, or use of

this material.

This document contains proprietary information which is protected by copyright and patents. All rights

are reserved. No part of this document may be photocopied, reproduced, or translated without prior

written consent of John Bean.

is a registered trademark of Snap-on Technologies

Form 5787-1...pn ZEEWB504A....04/19/2001..wdc... copyright 2001 Printed in the USA

LATIN AMERICA

Snap-on Tools International, Ltd.

2801 80th Street

Kenosha, WI 53143

Tel: (262) 656-5003

Fax: (414) 656-1403

Loading...

Loading...