John Bean EEWH553A Series Operation Instructions Manual

High Performance Tire Changer

Operation Instructions

Form ZEEWH553AE

(BLANK PAGE)

COPYRIGHT NOTICE

The information contained in this document is property of Snap-on

Equipment division of Snap-on Incorporated. It or any of the information contained within shall not be used, copied, or reproduced without

express written consent of Snap-on Equipment or its holding company.

(BLANK PAGE)

Operation Instructions

SAFETY INFORMATION

For your safety, read this manual thoroughly

before operating the EEWH553A Tire Changer

The EEWH553A Series Tire Changers are intended for use by properly trained automo-

tive technicians. The safety messages presented in this section and throughout the

manual are reminders to the operator to exercise extreme care when changing tires

with these products.

There are many variations in procedures, techniques, tools, and parts for changing

tires, as well as the skill of the individual doing the work. Because of the vast number

of wheel and tire applications and potential uses of the product, the manufacturer cannot possibly anticipate or provide advice or safety messages to cover every situation.

It is the automotive technician’s responsibility to be knowledgeable of the wheels and

tires being changed. It is essential to use proper service methods and change tires in

an appropriate and acceptable manner that does not endanger your safety, the safety

of others in the work area or the equipment or vehicle being serviced.

It is assumed that, prior to using the EEWH553A Series Tire Changers, the operator

has a thorough understanding of the wheels and tires being changed. In addition, it is

assumed he has a thorough knowledge of the operation and safety features of the rack,

lift, or fl oor jack being utilized, and has the proper hand and power tools necessary to

service the vehicle in a safe manner.

Before using the EEWH553A Series Tire Changers, always refer to and follow the

safety messages and service procedures provided by the manufacturers of the equipment being used and the vehicle being serviced.

IMPORTANT !! SAVE THESE INSTRUCTIONS -- DO NOT DISCARD !!

- Page 5 -

SAFETY INSTRUCTIONS

IMPORTANT!! SAVE THESE INSTRUCTIONS

Overinfl ated tires or rims mounted on the wrong sized rims can explode produc-

ing hazardous fl ying debris.

Read Operator’s Manual before using this Tire Changer.

Never mount tire on rim with different sized diameter.

Never exceed maximum infl ation pressure listed on tire sidewall.

Always use safety restraint arm to hold wheel in place while

infl ating.

Always use attached air hose to infl ate tires.

Exploding tires can cause death or serious injury.

Risk of electrical shock.

Do not operate equipment with a damaged power cord or if the

equipment has been dropped or damaged, until it has been

examined by a qualifi ed service person.

If an extension cord is necessary, a cord with a current rating equal

to or greater than that of the equipment should be used. Cords

rated for less current than the equipment can overheat.

Unplug equipment from electrical outlet when not in use. Never

use the cord to pull the plug from the outlet. Grasp plug and pull to

disconnect.

Do not expose the equipment to rain. Do not use on wet surfaces.

Plug unit into correct power supply.

Do not remove or bypass grounding pin.

Contact with high voltages can cause death or serious injury.

Risk of electrical shock. High voltages are present within the base unit.

There are no user serviceable items within the unit.

Service on the unit must be performed by qualifi ed personnel.

Do not open any part of the base cabinet.

Turn power switch off and unplug the unit before servicing.

Contact with high voltages can cause death or serious injury.

Risk of crushing. Stand clear of bead breaker arm during operation.

- Page 6 -

Operation Instructions

Warning !

Warning !

Read and understand the operation instructions before using this

tire changer.

Become familiar with all controls before proceeding with operation.

Stand away from the bead breaker arm when in operation.

Apply air to breaker in bursts if necessary to control arm depth.

Keep all persons clear of tire changer.

Contact with moving parts could cause injury.

Risk of pinching or crushing hands and fi ngers when mounting and demounting.

Read and understand the operation instructions before using this

tire changer.

Keep hands and fi ngers clear of rim edge during demounting and

mounting process.

Keep hands and fi ngers clear of mount/demount head during opera-

tion.

Keep hands and other body parts away from moving surfaces.

Do not use tools other than those supplied with tire changer.

Do not bypass any safety features.

Use proper tire lubricate to prevent tire binding.

Contact with moving parts could cause injury.

Risk of eye injury.

seating and infl ation process.

Remove any debris from tire tread, wheel surfaces.

Remove excess tire lubricant before infl ating.

Wear approved safety glasses during mount and demount

procedures.

Debris, dirt, and fl uids can cause serious eye injury.

Risk of injury. Tools may break or slip if improperly used or maintained.

Read and understand the operation instructions before using this

tire changer.

Use only the mount-demount tire tool supplied with the tire changer.

Frequently inspect, clean, and lubricate (if recommended) where

designated.

Follow procedures when instructed in this manual.

Tools that break or slip can cause injury.

Flying debris, dirt, and fl uids may be discharged during bead

IMPORTANT !! SAVE THESE INSTRUCTIONS -- DO NOT DISCARD !!

- Page 7 -

Tires and Rims that are not the same diameter are mismatched.

NEVER attempt to mount or infl ate any tire and rim that are mismatched.

ALWAYS check to see that tire and rim diameters are the same.

A mismatched tire and rim will explode causing death or serious personal injury

Over-pressurized tires can explode causing fl ying debris.

Read and understand Operator’s Manual before operating.

Keep bystanders away from work area.

ALWAYS wear Safety Goggles.

ALWAYS check to see that Tire and Rim diameters are the same.

NEVER attempt to mount or infl ate any Tire and Rim with different

diameters.

Inspect tires, NEVER infl ate tires that are damaged, rotten or worn.

NEVER infl ate ‘Split Rim Wheels’ on this tire changer, remove them and

use only an approved safety infl ation cage designed for this purpose.

Lock turntable Clamp on inside of rim before attempting to infl ate tire.

Use approved tire bead lubricant before removing or installing tire on

rim.

ALWAYS position the “Safety Restraint Arm” over the wheel to hold it

to the turntable while infl ating if so equipped.

If a tire explodes on this tire changer, STOP using it until the "Safety

Restraint Arm" has been replaced, which must be done even if no

damage is seen.

NEVER place head or body over a tire during infl ation process.

Use short bursts of air to seat tire beads, check tire air pressure

frequently. NEVER exceed tire manufacturer’s pressure limits.

NEVER attempt to bypass or alter the built in air pressure limiter. Only

infl ate tire with air hose supplied with tire changer. NEVER use shop

infl ation hose to infl ate a tire.

Tire Changer must be anchored to concrete fl oor if equipped with a

“Safety Restraint Arm”

Exploding Tires can cause serious injury.

- Page 8 -

Operation Instructions

TABLE OF CONTENTS

SAFETY STATEMENTS Page 5-8

TABLE OF CONTENTS Page 9

1.0 Introduction Page 10

1.1 Specifi cations and Features Page 10

1.2 Nomenclature Page 10

1.3 Dimensions of the Machine Page 12

1.4 Standard Accessories Page 12

1.5 Optional Accessories Page 13

1.6 General Precautions Page 14

2.0 Installation Page 14

2.1 Electric Installation Page 14

2.2 Bead Breaker Installation Page 15

2.3 Air Installation Page 15

3.0 Controls Page 16

4.0 Mounting and Demounting-precautions Page 17

4.1 Demounting Tubeless Tires Page 17

4.2 Mounting Tubeless Tires Page 20

4.3 Infl ating Tubeless Tires Page 21

5.0 Demounting Tube T ype Tires Page 23

5.1 Mounting Tube T ype Tires Page 23

5.2 Infl ating T ube Type Tires Page 24

6.0 Mounting/Demounting Motorcycle Tires Page 24

7.0 Maintenance Page 25

8.0 Optional Bead Assist Attachment Page 26

- Page 9 -

1.0 INTRODUCTION

Congratulations on purchasing the JBC EEWH553A electric/air tire changer. This tire changer is designed for ease

of operation, safe handling of rims, reliability and speed.

This combination of features means more profi t and added

versatility for your shop, enabling you to work with aluminum

or magnesium alloy wheels without damaging customer’s

rims. With a minimum of maintenance and care your JBC

EEWH553A T ire Changer will provide many years of troublefree operation.

Please read this manual thoroughly before operating the unit.

Instructions on use, maintenance and operational requirements of the machine are covered in this manual.

1.1 SPECIFICATIONS

Operation temperature range +41/+122 F (+5/50 C)

Tire changers for car , light commercial vehicle and motorcycle

tires designed for one-piece rims.

EEWH553A Series

Shipping Weight - EEWH553A 517 lbs.

Rim Clamping Capacity-outside: 10” to 20”(254-508mm)

Rim Clamping Capacity-inside: 12” to 22”(305-559mm)

Maximum Rim Width: 15” (381mm)

Maximum Tire Diameter: 40” (1016mm)

Turn Table Operation Dual Speed with Reverse

Turn Table Torque (lb - ft) 885

Turn Table Speed (RPM) 7 and 14 CW / 7 CCW

Bead Breaker Force: 3,300 lbs. @ 150 PSI

Bead Breaker Opening:* ADJ. (2.5”-12.5”) or (3” - 15”)

Air Pressure Required: 110 to 170 psi (8-12bar)

Electrical Requirements: 230V 60Hz 1 ph 12A

*Tire profi le may effect machines ability to completely break

bead. Specifi cation given is opening between breaker pad

and breaker blade only.

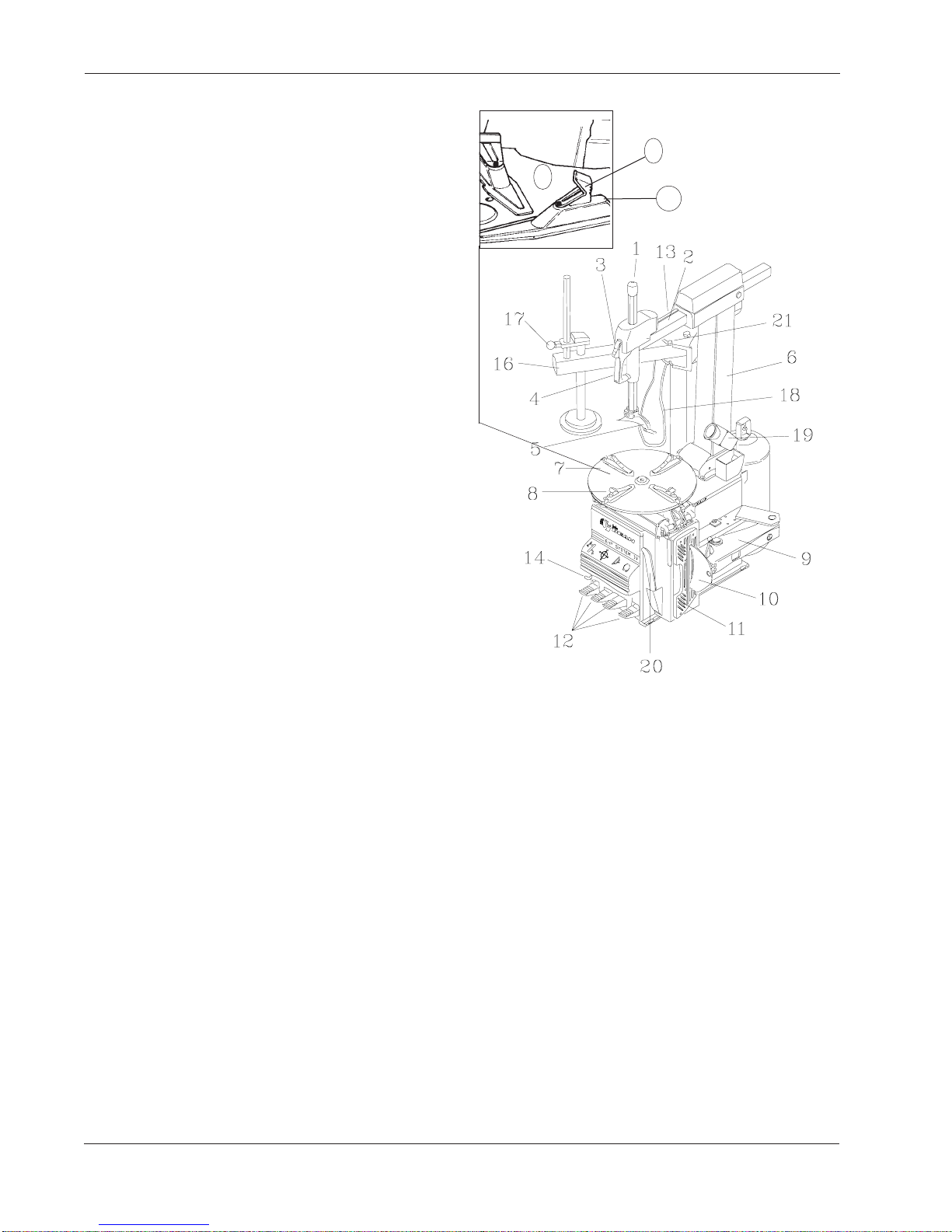

1.2 NOMENCLATURE

Before installing and using the JBC EEWH553A T ire Changer

it is suggested that you become familiar with the nomenclature

of the machine’s components.

Jaw and Air

Jet Detail

8

7

15

827a

Figure 1

1 Vertical slide

2 Diameter Slide

3 Diameter Lock Button

4 Diameter Slide Handle

5 Mount/demount head

6 Tower or column

7 Turntable

8 Clamping Jaws

9 Bead breaker arm

10 Bead breaker blade

11 Bead breaker pads

12 Foot pedal controls

13 Infl ation gauge

14 Bead seater/infl ator pedal

15 Infl ation jets

16 Safety restraint arm

(Optional)

17 Safety restraint positioning knob

(Optional)

18 Infl ation hose

19 Lube bottle

20 Mount/Demount Tool

21 Safety Restraint Arm Anti-rotation Lock

- Page 10 -

Loading...

Loading...