Page 1

Gardena, CA 90247

USA

2

MC

D I S T R I B U T E D BY PM I A U D I O G R O U P

1845 W. 169th Street

JOEMEEK

Stamp

Here

Joemeek User Guide

v i s i t u s o n t h e w e b a t j o e m e e k . c o m

Place

Page 2

JOEMEEK reborn – the legend grows

The Next Generation of Joemeek studio processors represents a quantum

leap in the history of the Joemeek legend. Long regarded for its “Big Sound”,

the original Joemeek gear was both revered and reviled for its somewhat

“quirky” nature. Now we have taken the best of what made the Joemeek

products sound great, refined it, distilled it, added to it and repackaged it.

Properly and robustly engineered for predictable, controllable performance,

the new range retains the famous Joemeek sound, with its wide, flat frequency

response extending from subsonic to ultrasonic. It also uses genuinely low

noise circuitry, with lots of headroom (immunity to overload). Accurate

calibration and metering, together with clear panel labelling, give you complete

confidence in what’s going on. While some equipment pays lip-service to

quality and “professional rules” but fails to deliver, the Next Generation of

Joemeek products are founded on good solid electronic and audio engineering,

and withstand direct comparison with the very best names in mixers and

outboard gear.

The Joemeek range provides everything you need to get your performance

onto tape/disc.

About the Designer

The Next Generation of Joemeek has been completely re-engineered by

renowned audio electronics consultant Allan Bradford. With his background

in physics and 30 years experience with the design of instruments, mixers,

processors and amplifiers, Allan’s unique range of expertise ensures that

Joemeek remains at the forefront of music technology.

3

fax: 310-323-9051

Gardena, CA 90247

marketed under the direction of:

PMI AUDIO GROUP

Joemeek is manufactured and

toll free: 877-563-6335

USA: 1845 W. 169th Street

email: info@joemeek.com

Babbacombe Road,

tel: +44 (0) 1803 329848

Torquay, Devon TQ1 3SY

Written by Allan Bradford, MSc

email: eusales@joemeek.com

UK: Unit 2 Babbacombe Business Park

Contents

mc2 Controls at a Glance..................................................4

Overview............................................................................6

Preamplifier........................................................................6

Insert Point..........................................................................6

VU Meter..............................................................................6

Compressor.......................................................................7

GR Meter.............................................................................9

GR Hold...............................................................................9

Stereo Width........................................................................9

Outputs......................................................................9

Using the mc2..................................................................10

Getting Connected.............................................................10

Using the Preamp...............................................................10

Using the Compressor.......................................................10

Using the GR Hold.............................................................11

Using the Stereo Width......................................................11

Using the Insert Point........................................................12

Troubleshooting..............................................................12

Technical Specification...................................................13

3

Page 3

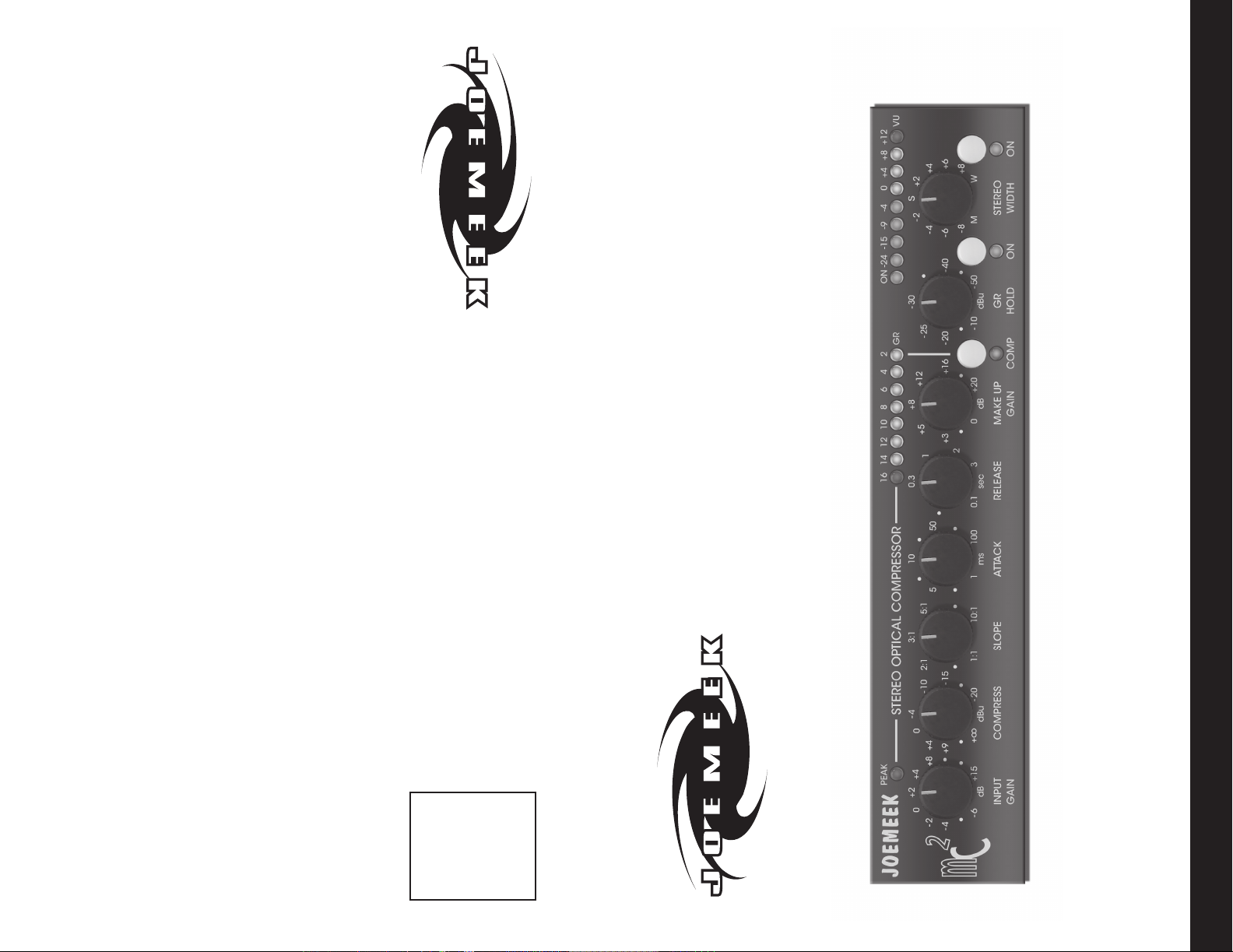

VU METER – 8-Led bargraph shows the output signal level in dB at

any given moment.

GR METER – 8-Led bargraph indicates the amount of gain reduction

in dB, which is taking place at any given moment.

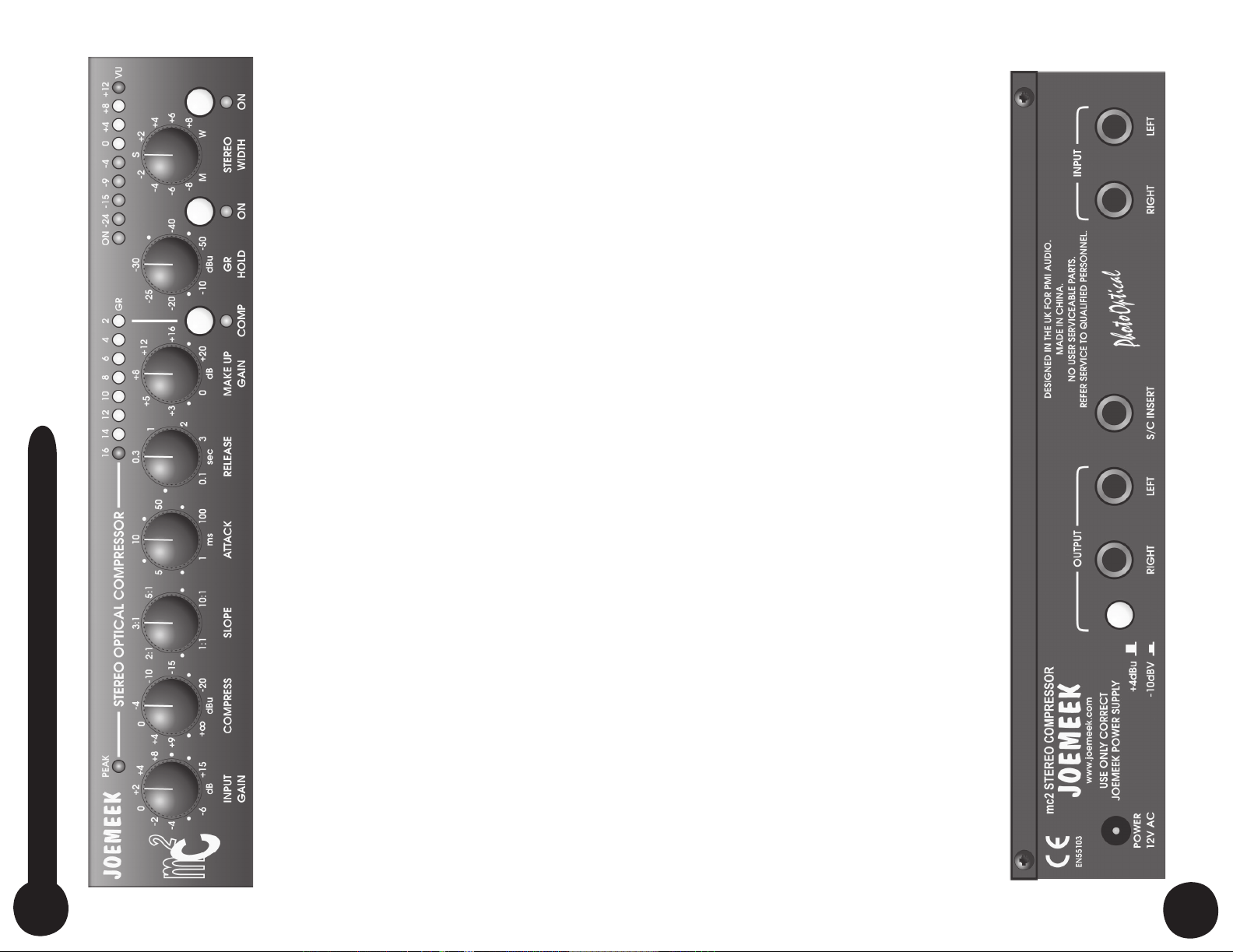

INPUTS – Balanced line level inputs on 1/4” TRS jacks.

S/C INSERT – unbalanced “Send and Return” jack allows you to patch

other pieces of equipment, into the compressor’s control circuitry

OUTPUTS – Balanced line level outputs on 1/4” TRS jacks.

+4dBu/-10dBv – switch selects the operating level of the 1/4” jack

outputs, either to the professional +4dBu level, or to the -10dBv semi-

pro level.

mc2 Controls at a Glance

4

INPUT GAIN – sets the amount of audio amplification. Too little gain and

the resulting sound will be too quiet; too much and the signal could become

distorted.

PEAK LED – lights 6dB below clipping.

COMPRESS – sets the level of signal (or “Threshold”) above which the

signal starts to be compressed.

SLOPE – sets the compression ratio applied to signals above threshold.

ATTACK – sets how quickly the compressor responds to peaks above

threshold.

RELEASE – sets the time taken for the signal to return to its normal size

after compression. In general, the longer the time, the less obvious the

compression.

MAKE UP GAIN – restores the level of the signal after compression.

COMP – switch turns the compressor on. The LED lights when active.

GR HOLD – freezes Gain Reduction at a constant level during gaps in the

programme material (ie: prevents the compressor gain rising).

GR Hold ON – switch turns the GR Hold function on. The LED lights when

active and changes color to indicate Hold status.

STEREO WIDTH – varies the perceived with of the programme material

from Mono, to normal Stereo, to extra Wide.

Stereo Width ON – switch turns the Stereo Width function on. The LED

lights when active.

5

Page 4

Insert Point

Overview

and monitors, where the effect of transients is less critical. Normally you

should not hear a limiter operating but if it is driven hard constantly, it can

render a mix somewhat flat and lifeless.

4. Accommodation

The dynamic range of the human ear is phenomenal, extending from the

threshold of hearing (eg: a pin dropping onto soft carpet) to threshold of

pain (eg: standing next to a jet aircraft) - some 120dBA in all. By contrast,

vinyl, cassette tape and radio broadcasts all have a dynamic range of

about half that. Since the advent of the CD, the dynamic range of the

medium is far less of an issue and compressors are used more to give a

certain “feel” to a production. AM and FM radio however, is still very much

compressed to fit its restricted dynamic range.

5. Modification

A compressor can change the dynamics, or “envelope” of the track and it

is here that the Joemeek Compressor excels!

Types of Compressor

Most compressors work in essentially the same way: a volume-controlling

element or “gain cell” is inserted into the audio signal path. The level of

the signal at any given moment is measured and that information is used

to control the gain cell. So if the signal gets bigger, the volume is turned

down.

Various types of gain cell in common use include FETs, valves (tubes),

light-dependent-resistors (photoelectric), digital potentiometers and volt-

age-controlled-amplifiers, better known as VCAs.

The mc2 Compressor is a unique recreation of the sort of photoelectric

compressor used by record producer Joe Meek in the 1960’s. Using mod-

ern components for consistency and reliability, it nonetheless reproduces

faithfully the same punchy sound that was so characteristic of the pop

This is simply an unbalanced “Send and Return” jack on the rear panel.

It allows you to patch other pieces of equipment into the compressor’s

control side chain, such as an equalizer or filter. To use it you will need

a “Y” lead wired as follows:

Tip: send

Ring: return

Sleeve: ground

When no jack is inserted, the socket is internally linked, or “normalled”,

so that the control signal flows uninterrupted.

VU Meter

The LED VU Meter shows signal level at the outputs. It covers the range

-24dB to +12dB in eight steps. Note that this is relative to the selected

operating level of “+4dBU” or “-10dBv”. In other words if you have

selected “4dBu” and the meter reads “0”, then you have +4dBu coming

out of the output sockets. If you have selected “-10dBv” and the metere

reads “0”, then you have -10dBv coming out of the output sockets.

Compressor

The hardest device to understand, yet one of the most useful, the PhotoOptical

Compressor is what gives Joemeek products their unique character. Its job is to

make quiet sounds louder and loud sounds quieter, or in other words to reduce

the dynamic range of the programme material. It’s a bit like manually riding the

volume control, except the compressor does it automatically, responding far

quicker and more accurately than you ever could by hand. The compressor is

applied in several ways:

1. Make Sounds Stand Out

Because compressors make loud sounds quieter, you can boost the volume

of the quiet bits without the loud bits getting even louder. That means you can

raise the average level of an instrument or vocal in the mix, which has the

effect of lifting it and bringing it forwards. This can actually improve vocals for

example, bringing them out in front of a mix, making them sound denser, more

even, and more confident!

2. Crank Up The Volume

Raising the average volume of whole mixes means they can be heard in noisy

environments, such as vehicles and factories. Boosting the average level is

what makes radio stations sound LOUD and the same technique is used on

TV commercials too, which is why they always seem annoyingly louder than

the movie you were trying to watch!

3. Protection

Fast response times are generally used to control brief transients. In other

words if an occasional peak sticks its head above a maximum permitted

level, the compressor clobbers it; this is known as limiting and a compressor

The JOEMEEK mc2 is a professional studio-quality stereo compressor in a

compact half-rack format. Simple to use yet extremely powerful, the mc2 will

bring out the best in any line-level stero material and give the gloss of a pro-

fessional studio production to all your performances. It can be used both for

recording, mastering and live work.

Think of the stereo mc2 as three separate items of equipment:

• A line-level stereo Preamplifier.

• A stereo JOEMEEK Optical Compressor.

Preamp

The front end to the mc2 accepts any type of line level (ie: preamplified)

audio signal. The inputs are electronically balanced. Note: although the

Line inputs are not normally used directly with microphones, they may be

suitable for some high output unbalanced microphones, such as battery

powered Electret types.

The Line input jacks are balanced and wired as follows:

Tip: + (hot)

Ring: - (cold)

Sleeve: ground The “Input Gain” control covers a range of amplification from -6dB to +15dB.

This enables the mc2 to be matched to sound sources at both -10dBv to

+4dBu operating levels. The PEAK LED lights 6dB below clipping, so occa-

sional brief flashes are OK but if it’s on all the time you need to back the

• A stereo Width Processor

Input Gain off!

designed solely for this purpose is known as a Limiter. Limiters are primarily

records of that time.

used to protect recorders and monitor systems from overload, radio trans-

mitters from overmodulation, etc. The Joemeek compressor is not primarily

intended for this purpose as the Attack is not really fast enough to satisfy radio

station requirements, although it is generally good enough to protect recorders

6

7

Page 5

trol clockwise increases the ratio and makes the effects of compression

more dramatic. At maximum (10:1) the Joemeek compressor effectively

becomes a limiter.

‘ATTACK’ sets how quickly the compressor reacts to peaks above

threshold. Turn this control anticlockwise for a quick response. Slower

(clockwise) allows the fast leading edge of percussive sounds to pass

Compression Ratio

What?? OK, it’s simpler than it sounds. If the input gets 10dB louder but the

output only increases by 5dB then the compression ratio is “2 to 1”. If the

input goes up 10dB but the output only goes up 1dB, then the compression

ratio is “10 to 1”. In a theoretically ideal compressor, this ratio is the same

for any size of signal above the threshold but for that to be true, the gain cell

and its control circuitry must be perfectly linear over a very wide range. In

uncompressed for a moment, before the compressor reacts to control the

practice only compressors based on VCAs and digital potentiometers are

Outputs

CONNECTORS

Left and Right outputs are provided on TRS jacks. The adjacent switch

selects the output operating level to either +4dBu (suits most profes-

sional studio equipment) or -10dBv (suits semi-pro or hi-fi equipment).

Check with the handbook for whatever you are feeding, to find out

which level is required.

The jack outputs are balanced and wired as follows:

Tip: + (hot)

Ring: - (cold)

Sleeve: ground

Balanced or Unbalanced

To run the ¼” jack outputs unbalanced, just plug in mono jack plugs.

This increases the gain of the “+” signal by 6dB, so there is no drop in

level compared with balanced gear.

All outputs on all NextGen Joemeek products are properly balanced,

which is to say there is a signal on both pins! In this way the maximum

possible common-mode rejection of interference, can be achieved at

This control allows the width of the stereo image to be modified, from mono,

to normal stereo, to extra-wide stereo.

the receiving end.

Wide stereo gives the impression of a bigger sound stage and a greater

sense of space and depth to a mix. Depending on the mix, it may also

create a sense of improved clarity. The “Mid and Side” technique

employed widens stereo without the dreaded “hole in the middle” effect

(ie: loss of center or bass components). Stereo widened in this way

also remains mono compatible.

The ‘ON’ switch allows comparison between processed and unprocessed

‘RELEASE’ sets how long the compressor goes on squashing the

sound for, once the signal has dropped below threshold. If it stopped

instantly there would be very noticeable modulation or “pumping” of the

sound. So we may want it to stop compressing less abruptly and that

is what the Release control is for. Generally, the longer the Release

time, the less obvious is the compression. Of course some “pumping”

might actually be desirable as a special effect and that is another way

in which the envelope of a sound can be modified. The mc2 Release is

variable from 100mS up to 3 seconds giving a wide variety of effects.

‘MAKE UP GAIN’ sets a static amount of amplification, to restore the

level of the signal after compression. Correctly adjusted, there will be

no change in perceived volume as the ‘COMP’ in/out switch is operated.

How the compressor behaves actually changes with program content

and volume. So experiment with the controls with different kinds of ma-

terial to discover the range and depth of effects that can be achieved.

The ‘COMP’ in/out switch allows comparison between compressed and

gain. This example of “changing the envelope” of a sound exaggerates

the percussive nature of drums and other instruments. Settings around

midposition are used where the compression needs to be less obvious.

Vocals for example, require Attack times around 10msec for natural

sounding results. Faster attack times (anti-clockwise) in conjunction with

large amounts of compression, result in extreme “pumping” effects.

likely to behave in this way.

Some compressors have a control to set the ratio anywhere between 1:1

(ie: no compression), and 20:1 (which would be regarded as a “brick wall

limiter”). In the mc2 the “Slope” or “Compression Ratio” is variable from 1:1

(ie: no compression) to 10:1. Slopes around 3:1 are gentle for vocals while

higher slopes are hard for drums and guitars. However that’s not all there

is to it.

Variable Ratio

In the Joemeek optical compressor the compression ‘threshold’ is not clearly

defined and the compression ratio varies with the amount of compression

applied. Suppose the ‘Slope’ control is set to 5:1. For signals only just ex-

ceeding threshold, the ratio is little more than 1:1. As the compressor is

driven harder, the ratio rises to 5:1, at least up to a point. It is a feature of

the Joemeek compressor that the compression ratio actually reduces again

during large transients and, adjusted correctly, this helps to retain brightness

that is often lost with other types of compressor. This is why vintage com-

pressors often sound more lively than their modern counterparts.

Controls

‘COMPRESS’ sets the level of signal (the “Threshold”) above which the sig-

uncompressed sound (blue LED lights when active).

GR Meter

nal starts to be compressed. Turning the compression control clockwise low-

ers the compression threshold, and drives the compressor harder.

‘SLOPE’ sets the average compression ratio applied to signals above

threshold. Lower settings (anti-clockwise) have less effect. Turning the con-

The LED GR Meter provides an accurate reading of gain reduction in dB,

sound (LED lights when the ‘STEREO WIDTH’ control is active).

at any given moment.

GR Hold

A problem with all compressors is that when the signal level falls below the

compression threshold, the gain rises to that set by the ‘MAKE UP GAIN’

control. The result is that during gaps in the music, any background noise

will be amplified, and may become noticeable and even downright annoy-

ing! This could be counteracted by using a noise gate or expander gate but

such devices introduce their own problems. The mc2’s ‘GR HOLD’ control

works by freezing gain reduction at the level it was at just before the signal

dropped below the compression threshold. In this way there is no overall

increase in gain and the noise floor is preserved.

The adjacent ‘ON’ switch enables this feature and the LED lights when

active. This LED also changes color to indicate the status of the GR Hold.

Green means a usable signal is present and the compressor is responding

to the program material. Red means that the input signal has fallen below

the selected threshold and the gain reduction is now frozen at its most

recent level.

Stereo Width

8

9

Page 6

POWER SUPPLY

Connect the mc2 Power Supply to the AC connector on the rear panel

Using the mc2

and switch on the mains supply. NB: Use only the 12V ac mains adap-

tor supplied. Use of any other power supply may damage the mc2 and

will invalidate the warranty.

GETTING CONNECTED

The figure shows the mc2 being used in a typical recording setup:

Using the Preamp

Turn the ‘INPUT GAIN’ control to minimum and connect the input source.

Another thing to note is that this feature uses an analogue “sample and

hold” circuit to freeze the control voltage to the compressor. As with all

such circuits, the stored voltage will eventually decay away, then the com-

pressor s gain will increase and the noise will again become apparent.

However this process will take several minutes – long enough the cover

the noisy gaps in the program material, or between tracks of an album

At the end of the recording, remember to fade out the signal before the

noise comes back!

Using the Stereo Width

With the STEREO WIDTH control centered, normal stereo is main-

tained. So with a stereo signal you should hear no difference. Turning

the control fully anticlockwise results in mono, ie: identical signals come

out of both left and right outputs.

Turning the control fully clockwise widens the soundstage to extra-

wide stereo.

Use the adjacent ON switch to make comparisons between processed

and unprocessed sound. When widening the stereo image you may find

Turn up the ‘INPUT GAIN’ until the sound registers on the VU Meter,

adjusting it so that the meter reads between “0” and “+4” on sound

peaks. When the red LED (labeled “Peak”) lights, the mc2 is within 6dB

of clipping. Occasional flashes are OK but if it is on all the time, turn the

Input Gain down!

Using the Compressor

Start with the Compressor off and adjust the INPUT GAIN so that the VU

Meter reads around 0dB.

Set ‘COMPRESSION’ and ‘ATTACK’ fully anti-clockwise, with ‘SLOPE’

and ‘RELEASE’ at mid-position. Press the ‘COMP’ switch and turn up

the ‘COMPRESSION’ control until the compressor GR meter starts to

read 4dB or 6dB on audio peaks. You should now be able to hear the

compressor working as the volume diminishes. Use the ‘MAKE UP

GAIN’ control to restore the signal to its previous (uncompressed) level

Alter the SLOPE and listen to how the severity of the gain reduction

changes. Try changing the Attack and listen for percussive sounds get-

ting louder. Reducing the Attack and Release times should emphasize

this even more and the compressor should start to “pump” audibly.

The overall result of compression depends on the combined settings

of the Compress, Slope, Attack and Release controls. Experiment with

combinations to discover what best suits the material you wish to compress.

Watch the GR meter and don’t overdo things - it’s possible to apply 20dB of

gain reduction before you realize it!

Use the ‘COMP’ switch to make comparisons between compressed and

uncompressed signals.

Using the GR Hold

Note that this works only in conjunction with the Compressor – it has no effect

on its own. It is for use with a noisy original signal, such as from cassette

tape, guitar amplifiers or live recordings where a lot of unwanted background

noise is present.

With a signal present, set the compressor to give a moderate amount of gain

reduction and wait for gaps between the music or program material. You

should then hear the noise increase as the compressor’s gain returns to the

level set by the ‘MAKE UP GAIN’ control. Next switch on the GR Hold and

• The insert point is being used to divert the compressor control signal through

an external graphic equalizer, for “frequency conscious” compression.

• If you have a mixer with L-R Master sends and returns, this is a good place

to connect the mc2, for both mastering and live work.

repeat that section of the program. Adjust the ‘GR HOLD’ control until the LED

that “less is more” and it s better to keep the effect subtle.

just changes from green to red when the music stops. Red means that the

input signal has fallen below the selected threshold and the amount of gain

reduction is being held constant. Green means that the noise is still above the

Using the Stereo Width

selected threshold and the compressor is still working, so raise the threshold

by turning the control clockwise.

If the results are not obvious, try increasing the compressor s Release time.

If the gain reduction releases too quickly, the GR Hold may not capture it

before the gain starts to rise again. Keep repeating the process until the

desired effect is obtained and there is no increase in noise during gaps in

the program.

10

11

Page 7

Troubleshooting

1) No Power (no lights work)

• Is the power supply plugged in (both ends)?

• Is the mains power on?

• Has a mains fuse blown?

2) The Inputs don’t work

• Is the source connected to the jack inputs on the back of the unit?

• Is the ‘Input Gain’ control turned up?

3) The compressor doesn’t work

• Is the ‘Comp’ switch in (LED on)?

Using the Insert Point

This unbalanced “Send and Return” jack allows you to patch other pieces

of equipment, such as a graphic equalizer into the compressor’s control

circuitry, for “frequency conscious” compression.

If you boost certain frequencies with an external equalizer, those frequen-

cies are going to cause the compressor to respond more, ie: squash the

program material more. If you cut certain frequencies, the compressor will

respond less to those frequencies. Uses for this can be either creative or

corrective.

• Is the ‘Compress’ control turned up enough?

• Is there enough signal, as set by the ‘Input Gain’ control, to drive the

compressor?

• Is the ‘Slope’ control turned up enough?

4) Too little or too much compression

• Turn the ‘Input Gain’ control up or down respectively, to adjust the

signal level to the compressor.

• Turn the ‘Slope control up or down respectively.

5) The Stereo Width doesn’t work

• Is the ‘ON’ switch in (LED on)?

• Is only one input connected?

• Is the programme material mono?

Imagine you are trying to even out the vocals in a mix, but the mix is

bassheavy with the result that each bass note squashes the vocals. A mod-

est amount of bass-cut on the external equalizer will make the compressor

respond less to the bass, allowing it to do its job of controlling the vocals.

On the other hand, you might want to have a vocal or a drum beat deliber-

ately “duck” the rest of the mix for special effect. Tune the external equalizer

to the frequencies of the instrument you want to emphasize, then adjust

the ‘COMPRESS’ control so that the compressor only operates when those

frequencies are present.

Note that none of this external equalization is audible as such.

Technical Specification

Input impedance Line: 20kohm

Pre-amp overall gain -6dB to +15dB

Common mode rejection 70dB

Equivalent input noise -95dBu (unweighted)

Distortion 0.001% (below Compressor

threshold)

Frequency response 10Hz to 70kHz (-3dB)

Maximum input before clipping +19.5dBu

Headroom before clipping +19.5dBu

Compression threshold -6dBu to +22dBu (variable)

Compression ratio 1:1 to 10:1 (variable)

Compressor attack time 1 msec to 100 msec

(adpative)

Troubleshooting continued...

6) Too much noise

• Is the ‘Input Gain’ control too high (eg: the input signal is too small)?

• Is the noise already present in the input signal? (Try removing the input).

• Is the ‘Make Up Gain’ control too high (eg: when lots of compression is

being used)?

• Try using the GR Hold function to compensate for compressor accentuated

noise.

7) Sounds distorted

• Is the ‘Input Gain’ control too high?

• When using the compressor, is the Release control set too low?

• Is the GR Hold on with the control set too low? Troubleshooting

Compressor release time 0.1 sec to 3 sec (adaptive) GR Hold rhreshold -10dBu to -50dBu (variable)

Stereo Width range Mono / stereo / wide stereo

(variable)

GR Meter 8 segment bargraph

VU Meter 8 segment bargraph

Nominal output levels +4dBu/-10dBv

Output impedance 75ohm

Output Level switch 12dB attenuation

Noise Floor -95dBu (typical, with 0dB

Input and Make Up gain)

Power supply 12V ac mains adaptor

Power consumption 12W

Mechanical 220W x 44H x 180D (overall)

Weight 1 kilo

12

13

Page 8

IMPORTANT SAFETY AND ENVIRONMENTAL INFORMATION

Audio Group will work with disposal and recycling partners

working within the EU. The waste electric and electronic

equipment can then be turned over to a disposal and recy-

cling companies in the countries concerned.

Business to Customer products: emerging electric and

electronic equipment will be disposed of by local authorities’ collection systems.

Dual Use products: this equipment wi ll be di sposed of by local authorit ies’

collect ion system s.

CAUTION: TO REDUCE THE RISK OF ELECTRIC

Important Safety Information

SHOCK, DO NOT REMOVE COVER. NO USER-SER-

VICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

The lightning ash with arrowhead symbol, within equilateral triangle, is

SHOCK HAZARD, DO NOT EXPOSE THIS

The exclamation point within an equilateral triangle is intended to alert

intended to alert the user to the presence of uninsulated “dangerous volt-

age” within the product’s enclosure that may be of sufcient magnitude

the user to the presence of important operating and maintenance (servic-

to constitute a risk of electric shock to persons.

WARNING: TO AVOID FIRE OR ELECTRIC

ing) instructions in the literature accompanying the appliance.

APPARATUS TO WATER, RAIN OR MOISTURE.

Important Safety Instructions

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water. Do not expose to drips or splashes. Do

not place any objects lled with liquids, such as vases, on the apparatus.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Do not install this apparatus in a con-

ned space such as a book case or similar unit. Install only in racks designed for

the purpose and in accordance with manufacturers’ instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or

other apparatus (including ampliers) that produce heat.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A po-

larized plug has two blades with one wider than the other. A grounding-type plug

has two blades and a third grounding prong. The wide blade or the third prong are

provided for your safety. If the provided plug does not t into your outlet, consult

an electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched particularly at plugs,

convenience receptacles, and the point where they exit from the apparatus.

11. Only use attachments/accessories specied by the manufacturer.

12. Use only with a cart, stand, tripod, bracket, or table specied

by the manufacturer, or sold with the apparatus. When a cart is

used, use caution when moving the cart/apparatus combination to

avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when unused

for long periods of time.

14. Refer all servicing to qualied service personnel. Servicing is

required when the apparatus has been damaged in any way, such as power-sup-

ply cord or plug is damaged, liquid has been spilled or objects have fallen into the

apparatus, the apparatus has been exposed to rain or moisture, does not operate

normally, or has been dropped.

15. Apparatus designed with Class-I construction must be connected to a mains

socket outlet with a protective earthing connection (the third grounding prong).

16. This apparatus may be equipped with a single-pole, rockerstyle AC mains

power switch. If so this switch is located on the front panel and should remain

readily accessible to the user.

17. The manufacturer reserves the right to change the technical specication of

the product without prior notice.

Please read this information carefully and keep for future reference. For further information please visit: www.pmiaudio.com

Statement of RoHS Compliance

PMI Audio Group man ufactures comple te electronic products which

are covered by the European Union’s “Removal of Hazardous Sub-

stances” directive 2002/95/EC (RoHS). This directive seeks to elimi-

nate toxic substances from the manufacturing process, such that when

equipment is disposed of at the end of its life cycle, the materials it

contains do not contaminate the environment and pose health risks.

Banned substances are lead, mercury, cadmium, hexavalent chro-

mium, polybrominated biphenyls (PBB) and polybrominated diphenyl

ethers (PBDE). Lead is used together with tin in solder connections

to reduce the melting point of solder. Lead-free solder requires higher

soldering temperatures which in turn places greater thermal stress on

components.

PMI Audio Group takes seriously its obligations under the RoHS directive and insists

that its factories use only components that are certied RoHS compliant, as well as

leadfree solder. In a very few cases the necessary components may not yet be available

to the world market but we work continuously to eliminate any such exceptions at the

earliest opportunity. Our printed Circuit Boards (PCB’s) and all soldered joints have been

lead-free since 2005.

This appliance has a serial number located on the rear panel. Please record the model

number and serial number and retain them for your records.

Model number

Serial number

NOTE — This apparatus does not exceed the Class A/Class B (whichever is applicable)

limits for radio noise emissions from digital apparatus as set out in the radio interference

regulations of the Canadian Department of Communications.

ATTENTION — Le présent appareil numérique n’ émet pas de bruits radioélec-

triques dépassant las limites applicables aux appareils numériques de class A/de class B

(selon le cas) prescrites dans le réglement sur le brouillage radioélectrique édicté par les

ministere des communications du Canada.

These limits are designed to provide reasonable protection against harmful interference

in a commercial/residential installation respectively. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications.

There is no guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television equipment reception, which

can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by any combination of the following measures: (1) Relocate

or reorient the receiving antenna (2) Increase the separation between the equipment

and the receiver (3) Plug the equipment into an outlet on a circuit different from that to

which the receiver is connected (4) Consult your dealer or experienced radio/television

technician for additional assistance.

CAUTION — Changes or modications to this equipment not expressly approved by

the party responsible for compliance could void the user’s authority to operate this

Statement of WEEE Policy

PMI Audio Gr oup manufactures ma ny complete electronic products which are

covered by the European Union’s “Waste Electric and Electronic Equipment” directive

2002/96/EC (WEEE). This directive seeks to ensure that waste electric and electronic

equipment is disposed of in an environmentally responsible manner, at the end of its life

cycle. PMI Audio Group takes seriously its obligations under this directive to take back

WEEE-affected products and, from 13th August 2005, will mark all such products with the

crossed-out wheeled bin symbol.

Business to Business products: PMI Audio Group will cost-neutrally take back WEEE-

affected electric and electronic equipment in this category, from 1st January 2006. PMI

equipment.

Page 9

Joemeek Limited Warranty

replacement by Purchaser of any Product or part thereof shall extend

the warranty period as to the entire Product. The specific warranty on

THIS PRODUC T IS FOR PROFESSION AL USE ONLY

the repaired part only shall be in effect for a period of ninety (90) days fol-

lowing the repair or replacement of that part or the remaining period of

the Product warranty, whichever is greater.

PMI Audio Group warrants that all products will be free from defects in mate-

rial or workmanship:

A: For a period of (3) three years from the date of purchase (hereinafter the

2. Exclusive Remedy: Acceptance: Purchaser’s exclusive remedy and

labor warranty period), PMI Audio Group will repair or replace this Product if

PMI’s sole obligation is to supply (or pay for) all labor necessary to

repair any product found to be defective within the warranty period

determined to be defective. After the expiration of the labor warranty period,

and to supply, at no extra charge, new or rebuilt replacements for

defective parts. If repair or replacement fails to remedy the defect, then

and only in such an event, shall PMI exchange to Purchaser a new or

the Purchaser must pay labor charges.

B: In addition, PMI Audio Group will supply, at no charge, replacements for

reconditioned unit. Purchaser’s failure to make a claim as provided in

paragraph 1 above or continued use of the product shall constitute an

defective parts for a period of (three years) from the date of purchase. During

the labor warranty period, to repair the Product, Purchaser must return the

unqualified acceptance of such Product and a waiver by Purchaser of

all claims thereto.

defective Product, freight prepaid, or deliver it to PMI Audio Group Service

Center. The product to be repaired is to be returned in either its original car-

3. Exceptions to Limited warranty: PMI shall have no liability or obligation

to Purchaser with respect to any Product subjected to abuse, improper

ton or a similar package affording an equal degree of protection. PMI Audio

Group will return the repaired Product freight prepaid to the Purchaser. PMI

use, negligence, accident, modification, failure of the end-user to follow

the operating and maintenance procedures outlined in the users manual,

attempted repair by non-qualified personnel, operation of the unit

outside of the published environmental and electrical parameters, or

if such products original identification (trademark, serial number) markings

have been defaced, altered, or removed. PMI excludes from warranty

coverage, Products sold AS IS and/or WITH ALL FAULTS and excludes

used products which have not been sold by PMI to the Purchaser. PMI

also excludes from warranty coverage consumables such as fuses and

batteries, tubes, etc.

4. Proof of purchase: The dealer’s dated bill of sale must be retained as

evidence or the date of purchase and to establish warranty eligibility

Conditions

Audio Group is not obligated to provide Purchaser with a substitute unit dur-

ing the warranty period or at any time.

1. Notification of claims: Warranty Service: If Purchaser discovers that the

Product has proven defective in material or workmanship, then written notice

with an explanation of the claim shall be given promptly by Purchaser to PMI

but all claims for warranty service must be made within the warranty period. If

after investigation PMI determines that the reported problem was not covered

by the warranty, Purchaser shall pay PMI for the cost of investigating the

problem at its then prevailing time-and-materials rate. No repair or

Notes

Page 10

Notes

Notes

Page 11

Notes

Notes

Page 12

Audio MIDI

❏

Pro Sound News

❏

O F P UR C H A SE

change without notice

Owners Registration Card

Disclaimer of Warranty

Y O U R RE G I ST R AT I O N

R E TA IN F O R Y O U R R E CO R D S

T O B E C O M P L E T E D A T TI M E O F P U RC H AS E

Name _____________________________________________

Date of Purchase ____________________________________

Serial Number ______________________________________

Dealer’s Name ______________________________________

P L E A S E D I S P A T C H A N D R E T U R N

T O J OE M E EK W I T H IN 1 4 D AY S

Specifications and model numbers are subject to

Recording

❏

Pro Audio Review

❏

Product Registration Information

Sound on Sound

❏

Please Fill in the Below Sections and Return

EQ

❏

What magazines do you read to influence your buying decision: (please check all that apply)

Limitation of Liability

Electronic Musician

❏

MIX

Name:

Address:

City: State: Zip Code:

Telephone Number: email Address:

Model Purchased: Date Purchased:

Serial Number: Dealer:

EXCEPT FOR THE FORGOING WARRANTIES, PMI HEREBY DISCLAIMS AND EXCLUDES ALL

OTHER WARRANTIES, EXPRESS OR LIMITED, INCLUDING, BUT NOT LIMITED TO ANY/OR ALL

IMPLIED WARRANTIES OF MERCHANT ABILITY, FITNESS FOR A PARTICULAR PURPOSE AND/

OR ANY WARRANTY WITH REGARD TO ANY CLAIM OF INFRINGEMENT THAT MAY BE PROVED

IN SECTION 2-312(3) OF THE UNIFORM COMMERCIAL CODE AND/OR IN ANY COMPARABLE

STATE STATUE. PMI HEREBY DISCLAIMS ANY REPRESENTATIONS OR WARRANTY THAT

THE PRODUCT IS COMPATIBLE WITH ANY COMBINATION OF NON-PMI AUDIO PRODUCTS

PURCHASER MAY CHOOSE TO CONNECT TO THE PRODUCT.

THE LIABILITY OF PMI, IF ANY, AND PURCHASER’S SOLE AND EXCLUSIVE REMEDY FOR

DAMAGES FOR ANY CLAIM OF ANY KIND WHATSOEVER, REGARDLESS OF THE LEGAL

THEORY AND WHETHER ARISING IN TORT OR CONTRACT, SHALL NOT BE GREATER THAN

THE ACTUAL PURCHASE PRICE OF THE PRODUCT WITH RESPECT TO WHICH SUCH

CLAIM IS MADE. IN NO EVENT SHALL PMI BE LIABLE TO PURCHASER FOR ANY SPECIAL,

INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND INCLUDING, BUT

NOT LIMITED TO, COMPENSATION, REIMBURSEMENT OR DAMAGES ON ACCOUNT OF THE

LOSS OF PRESENT OR PROSPECTIVE PROFITS OR ANY OTHER REASON WHATSOEVER.

Info rmati on in thi s User G uide is su bject to chang e withou t notice . No part of this User Guid e may be re produced

or transm itted in any form or by any means, elec tronic, mech anical or by any other mea ns, for any purpos e,

with out the express written per missi on of PMI Au dio Gro up.

PMI Audio G roup may h ave trad emarks, cop yrights or other int ellec tual proper ty rights cov ering the sub ject

matt er of t his U ser Guide. Exce pt as expr essly provide d in any writte n agr eement from PMI A udio Group, the

furn ishin g of this Us er Gui de is provide d for the so le use of t he auth orized User [or Service Agent where appli -

cabl e] and d oes n ot give the Us er an y lice nse t o use an y tra demarks, copyr ights or o ther intell ectual proper ty

of P MI Audio Gro up.

PMI , PM I A UDIO , T ED FLE TCHE R, MEE QUALIZ ER, ST UDIO P ROJE CTS, J OEMEEK , TO FT A UDIO

DES IGNS , C URRENT SENSE, ME EKROPH ONE, TR AKPAK, an d ( If it So unds Ri ght... It i s R ight!) a re

eith er regi stered tr adema rks o r trade marks of PM I A udio Grou p in the U .S.A. and /or o ther count ries. Copy right © 200 5 PM I Audi o Group . All ri ghts re served.

Comments:

❏

Loading...

Loading...