Building essentials

Revised 8/7/2012. This information may have been updated. Please download the latest version at www.jmeagle.com/onesheets.

for a better tomorrow

SOLVENT WELD

SDR SERIES

MEETS ASTM D2241.

APPLICATIONS

JM Eagle Solvent Weld SDR Series pipes are suitable for use in pressurized

irrigation applications.

DESCRIPTION

JM Eagle’s PVC Solvent Weld pressure-rated pipes come in SDR 41 (100 psi),

SDR 32.5 (125 psi), SDR 26 (160 psi), SDR 21 (200 psi) and SDR 13.5 (315 psi).

The pipes are available in 20-foot lengths, bell end, in ½- to 12-inch diameters.

Solvent Weld joints are designed to provide a rigid (or restrained) joint connection, and the schedule-rated products are specifically engineered for use

in partial support systems above ground.

JM Eagle also manufactures this pipe in purple for reclaimed water systems.

BENEFITS

JM Eagle Solvent Weld SDR series pipe is cost-effective and long-lasting.

• It can be field-cut with a power saw or ordinary handsaw without the use of

expensive or complicated machinery.

• Easy to load, transport and handle, installers prefer it because it goes into

the ground quickly, saving installation costs.

• It maintains performance against tuberculation, corrosion and external galvanic soil conditions without lining wrapping, coating or cathodic protection.

• It keeps its smooth interior over long years of service with virtually no loss in

carrying capacity, allowing for savings in pumping costs, as well as savings

on the size of the pipe required.

• It can be connected directly to most plumbing and IPS fixtures without complicated procedures or adapters, as well as into CIOD fittings with adapters

and/or transition gaskets.

• A cured joint of JM Eagle Solvent Weld schedule series pipe offers a zeroleak joint that is structurally sound.

PLEASE CONTACT YOUR JM EAGLE REPRESENTATIVE OR VISIT WWW.JMEAGLE.COM FOR MORE INFORMATION.

Building essentials

Revised 8/7/2012. This information may have been updated. Please download the latest version at www.jmeagle.com/onesheets.

for a better tomorrow

SOLVENT WELD

SDR SERIES

SUBMITTAL AND DATA SHEET

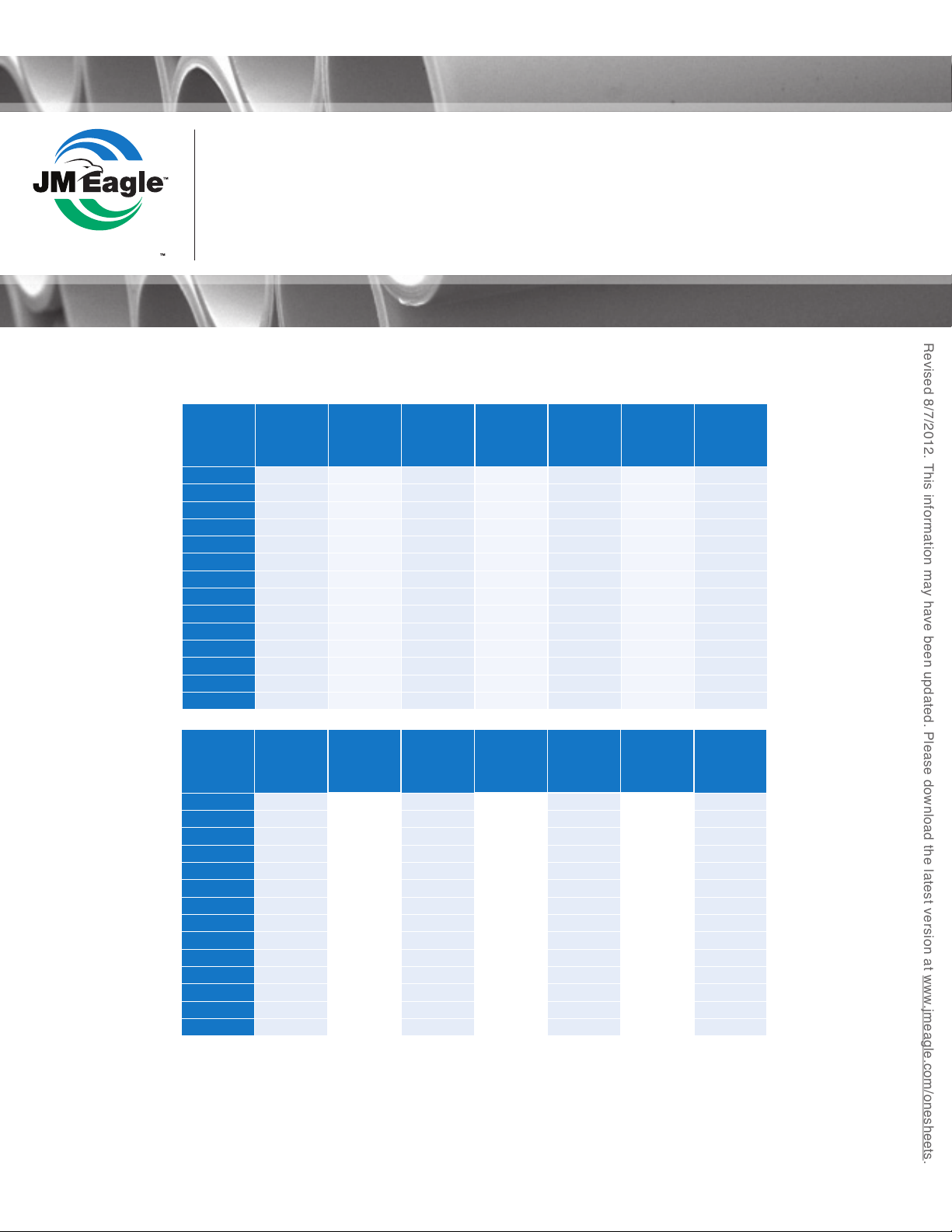

JM EAGLE™ PVC SOLVENT WELD PRESSURE RATED PIPE

Specifications: ASTM D2241 : :

NOM.

PIPE SIZE

(IN)

1/2

3/4

1

1-1/4

1-1/2

2

2-1/ 2

3

4

5

6

8

10

12

NOM.

PIPE SIZE

(IN)

1/2

3/4

1

1-1/4

1-1/2

2

2-1/ 2

3

4

5

6

8

10

12

O.D.

(IN)

0.840 — — — — — —

1.050 — — — — — —

1.315 — — — — 0.060 1.188

1.660 — — 0.060 1.533 0.064 1.524

1.900 — — 0.060 1.773 0.073 1.745

2.375 — — 0.073 2.220 0.091 2.182

2.875 — — 0.088 2.688 0.110 2.642

3.500 0.085 3.320 0.108 3.271 0.135 3.214

4.500 0.110 4.267 0.138 4.207 0.173 4.133

5.563 0.136 5.275 0.171 5.200 0.214 5.109

6.625 0.162 6.282 0.204 6.193 0.255 6.084

8.625 0.210 8.180 0.265 8.063 0.332 7.921

10.750 0.262 10.195 0.331 10.048 0.413 9.874

12.750 0.311 12.091 0.392 11.919 0.490 11.711

O.D.

(IN)

0.840 — — — — 0.062 0.709

1.050 0.060 0.923 0.062 0.919 0.078 0.885

1.315 0.063 1.181 0.077 1.152 0.097 1.109

1.660 0.079 1.493 0.098 1.452 0.123 1.399

1.900 0.090 1.709 0.112 1.663 0.141 1.601

2.375 0.113 2.135 0.140 2.078 0.176 2.002

2.875 0.137 2.585 0.169 2.517 0.213 2.423

3.500 0.167 3.146 0.206 3.063 0.259 2.951

4.500 0.214 4.046 0.265 3.938 0.333 3.794

5.563 0.265 5.001 0.327 4.870 0.412 4.690

6.625 0.316 5.955 0.390 5.798 0.491 5.584

8.625 0.410 7.756 0.508 7.548 — —

10.750 0.511 9.667 0.632 9.410 — —

12.750 0.606 11.465 0.750 11.160 — —

100 PS I/

SD R 41†

MI N. T.

(IN)

200 PSI /

SDR 21

MI N. T.

(IN)

NOM. I.D.

(IN)

NOM. I.D.

(IN)

Listed : ANSI/NSF - Standard 61, Standard 14

125 P SI/

SDR 32.5†

MI N. T.

(IN)

250 PSI/

SD R 17

MI N. T.

(IN)

NOM. I.D.

(IN)

NOM. I.D.

(IN)

160 PS I/

SDR 26

MI N. T.

(IN)

315 PS I/

SDR 13.5

MI N. T.

(IN)

NOM. I.D.

(IN)

NOM. I.D.

(IN)

Product Standard:

Pipe Compound:

Certifications:

End Finish:

Pipe Length:

Installation:

ASTM D2241 Pressure Pipe

ASTM D1784 Cell Class 12454

ANSI/NSF Standard 61

ANSI/NSF Standard 14

Plain End or Belled End

20 feet overall

JM Eagle™ Installation Guide

: : Standard Color: White, Standard Length:

20' Overall, Belled End Only. Purple Color for Reclaim,

contact your sales rep for availability.

† Available in Western Region Only.

* Prior to ordering or specifying, please consult

JM Eagle™ for product and/or listing availability.

Loading...

Loading...