Page 1

eBOX

Ethernet to Serial & GPI Interface

Users Manual

Page 2

eBOX and eBOX I/O are trademarks of JLCooper Electronics. All other brand

names are the property of their respective owners.

eBOX User’s Manual, Fifth Edition

Part Number 932095

2010 JLCooper Electronics, 142 Arena Street, El Segundo, CA 90245 USA

(310) 322-9990 ¬ (310) 335-0110 www.jlcooper.com

2

Page 3

Table of Contents

Introduction................................................................................... 6

Setup............................................................................................... 7

Unpacking................................................................................... 7

Connections................................................................................. 7

Operating Modes........................................................................... 8

Web Page Configuration......................................................... 8

eBOX Server Mode................................................................. 8

eBOX Client Mode ................................................................. 9

GPI to Serial Conversion ........................................................ 9

GPI to Ethernet Conversion .................................................... 9

Resetting eBOX Settings............................................................. 10

Initial Hardware Configuration ................................................ 11

eBOX Configuration Utility....................................................... 12

eBOX to Configure.................................................................... 13

eBOX Password Change........................................................... 13

eBOX Settings ........................................................................... 14

Configuration with Web Page Interface................................... 15

Operational Settings.............................................................. 17

eBOX IP Address.................................................................. 19

Port ............................................................................................... 20

Unused Switches................................................................... 20

GPI Outputs in GPI Conversion Modes ................................... 21

GPI Outs................................................................................ 21

3

Page 4

GPI Programmer Software........................................................ 22

eBOX GPI Tester Utility ............................................................ 25

eBOX Software for Apple Mac.................................................. 28

Installation ................................................................................ 28

Operation .................................................................................. 28

Preferences ............................................................................... 29

Password................................................................................... 30

Keysets ...................................................................................... 30

Programming Mode.................................................................. 31

Action Tabs ............................................................................... 32

MIDI Tab .................................................................................. 33

MIDI Machine Control (MMC)............................................ 33

Custom MIDI Messages ....................................................... 34

Special Tab................................................................................ 36

Delay Tab.................................................................................. 36

Keyboard Triggers.................................................................... 37

GPI Input Pins .......................................................................... 38

GPI Output Pins........................................................................ 38

GPI Preset Buttons ................................................................... 40

Serial Port Buttons.................................................................... 40

Serial Port Buttons.................................................................... 41

Serial Preset Buttons................................................................. 41

Serial Preset Buttons................................................................. 42

Live Mode.................................................................................. 43

Using the eBOX With a Router ................................................. 45

Using with eBOX I/O.................................................................. 46

4

Page 5

Technical Reference.................................................................... 47

Electrical Connections.............................................................. 47

Ethernet................................................................................. 47

Serial ..................................................................................... 48

GPI Port Pinouts ................................................................... 50

GPI Port Circuitry Details..................................................... 51

Power............................................................................................ 53

Troubleshooting .......................................................................... 54

Care and Service....................................................................... 55

Declaration of Conformity ......................................................... 56

RoHS Statement of Compliance ................................................ 57

JLCooper Electronics Limited Warranty ................................ 58

5

Page 6

Introduction

The eBOX is a general purpose interface box that converts 4 serial

communication ports and 24 GPI (General Purpose Interface)

inputs and outputs to 100/10baseT Ethernet. The serial ports can

be configured as EIA/TIA RS-232E (CCITT V.28) or as EIA/TIA

RS-422A ports. This can be performed easily in the field.

Additionally, the port direction can be configured as DTE or DCE

on each port independently.

The eBOX communicates over standard TCP/IP which allows is be

used with any host computer running any operating system that

uses TCP/IP protocol. The eBOX can also be connected to other

eBOXes to allow longer runs than traditional serial and GPI cables.

Since the eBOX uses TCP/IP, traffic can be routed over internal

LANs, wireless LANs, MANs, WANs and even over the public

Internet.

Most configuration can be accomplished through a web page

server built into the eBOX. Items such as port speed, parity, IP

address, remote IP address and TCP port are set using a standard

web browser. Settings are stored in nonvolatile memory.

Typically, the eBOX functions as a server, passively waiting for

client devices to connect to it. The device can be a computer or

another eBOX configured as a client. When the eBOX is

configured as a client, it will actively attempt to connect to the

server eBOX. Once this is accomplished, the either eBOX will

pass data received in the serial or GPI ports to the remote eBOX.

If there is no data received in the eBOX, the eBOX will not send

any TCP packets.

In addition, the eBOX can operate as a GPI to Serial Converter or

GPI to Ethernet Converter. In these modes, the eBOX will convert

GPI input triggers to deck commands.

6

Page 7

Setup

Unpacking

The eBOX package will contain the following items:

• eBOX

• Power Supply

• This Users Manual

• Four rubber feet

Connections

The eBOX connections are straightforward:

1. Plug the power supply into the eBOX.

2. Plug a network cable into the Ethernet jack.

3. Connect serial cables into ports 1-4.

4. Connect GPI cables into GPI ports.

7

Page 8

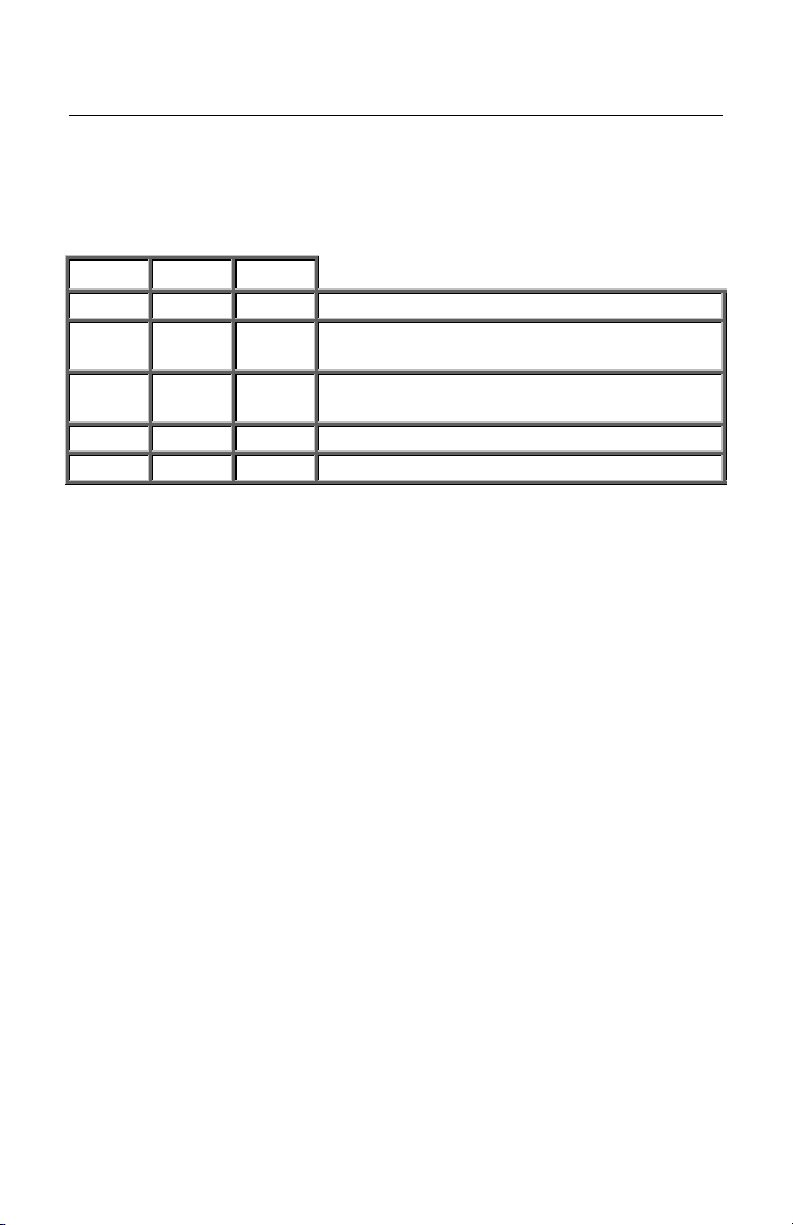

Operating Modes

The eBOX has five distinct modes of operation that are set by the

rear panel DIP switches. The DIP switches are read only at power

on so the eBOX must be power cycled for the changes to take

effect.

SW8 SW7 SW5

On X Off Web Page Configuration

Off Off

Off On

Off On On eBOX performs GPI to serial conversion

Off Off On eBOX performs GPI to Ethernet conversion

X = Don’t Care

Off eBOX is server at address specified on next

Off eBOX is client at address specified on next

Web Page Configuration

When DIP switch 8 is set to the ‘On’ position, the eBOX starts up

in the Web Page Configuration Mode. This allows the user to

configure the settings of the eBOX with a web browser such as

Internet Explorer 6. More information can be found in the section

‘Configuration with Webpage Interface’. The web page can be

found at the IP address set by DIP Switches 1, 2 and 3.

Note: The eBOX must be power cycled to switch to this mode.

page

page

Mode Configuration

eBOX Server Mode

When the eBOX is in the server mode, it waits for a client to

connect to it. The client can be another eBOX in client mode or it

can be a computer based application. The IP address and TCP port

of the eBOX is set by DIP switches 1, 2 and 3.

Note: The eBOX must be power cycled to switch to this mode.

8

Page 9

eBOX Client Mode

When the eBOX is set to client mode, it actively attempts to

connect to another eBOX in server mode. The IP address and TCP

port of the eBOX is set by DIP switches 1, 2 and 3.

Note: The eBOX must be power cycled to switch to this mode.

GPI to Serial Conversion

When the eBOX is in GPI to Serial Conversion Mode, it converts

GPI inputs into serial messages out to the four serial ports. The IP

address of the eBOX is set by DIP switches 1, 2 and 3 plus one.

The TCP port is fixed at 8000. The GPI Programmer Software

allows you to edit and upload the commands that are sent when

GPI inputs are triggered.

When the eBOX operates as a GPI to Serial Converter, it will send

to the to Serial Port A status requests on a periodic basis. Replies

from the deck will be used to establish the state of some of the GPI

Output pins, acting as tally lines. Refer to the section regarding

GPI Outputs in GPI Conversion Modes later in this manual.

Note: The eBOX must be power cycled to switch to this mode.

GPI to Ethernet Conversion

When the eBOX is in GPI to Ethernet Conversion Mode, it

converts GPI inputs into Ethernet messages specifically for Doremi

V1 and MCS video servers. The IP address of the eBOX is set by

DIP switches 1, 2 and 3 plus one. The TCP port is fixed at 8000.

The eBOX GPI Programmer Software allows you to edit and

upload the commands that are sent when GPI inputs are triggered.

When the eBOX operates as a GPI to Ethernet Converter, it will

send to the Doremi server status requests on a periodic basis.

Replies from the server will be used to establish the state of some

of the GPI Output pins, acting as tally lines. Refer to the section

regarding GPI Outputs in GPI Conversion Modes.

Note: The eBOX must be power cycled to switch to this mode.

9

Page 10

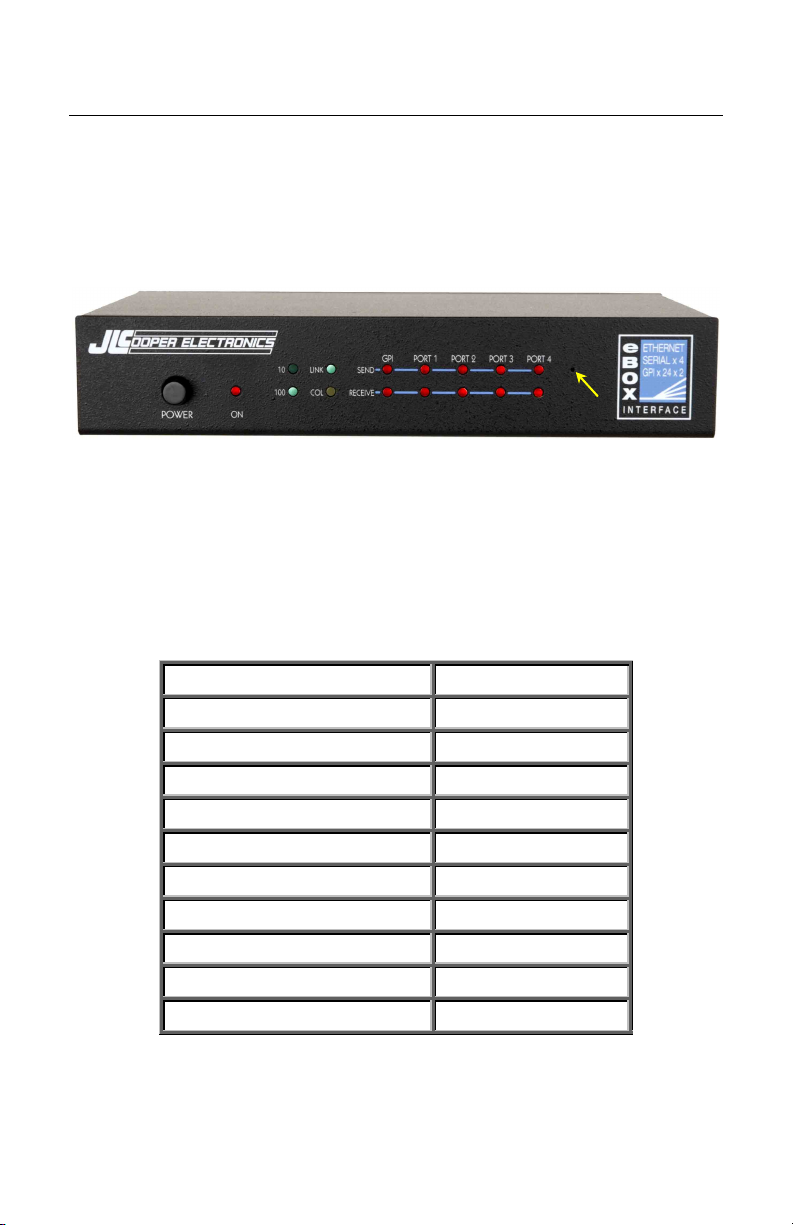

Resetting eBOX Settings

The eBOX settings can be forced to factory defaults by using the

reset button. The reset button is located behind the front panel. It

can be accessed via the small, unmarked hole to the right of the

Port 4 Send LED. The arrow in the picture below shows the

location of the hole for the reset button.

To reset the eBOX to factory defaults, simply press the button with

a long, thin object such as a paper clip and turn the power on. The

reset button can be released after the 5 Send and 5 Receive LEDs

stop flashing.

The eBOX factory defaults are:

IP Address 192.168.254.102

Subnet Mask 255.255.255.0

Gateway Address 192.168.254.198

TCP Port 23

Destination IP Address 192.168.254.103

Destination TCP Port 5000

Password

Serial Port Rate 38400 bits/sec

Parity Odd

Serial Port Timeout 5 mS

Maximum Buffer Size 128 bytes

password

eBOX Settings After Reset

After the eBOX settings are reset in this manner, you must power

cycle the eBOX to load those settings.

10

Page 11

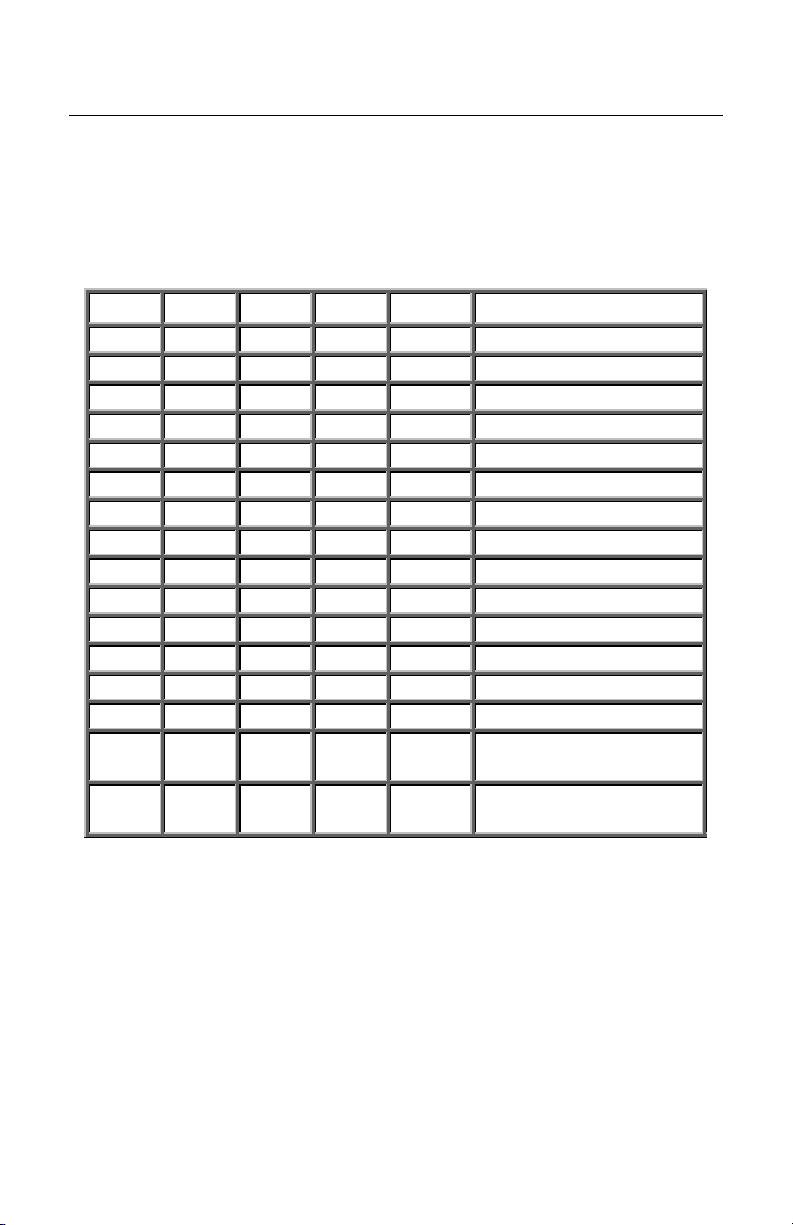

Initial Hardware Configuration

IP Address

The IP Address of the unit depends on the position of DIP switches

1, 2 and 3. This is detailed in the table below. The address box

can accommodate numeric (nnn.nnn.nnn.nnn) or alphanumeric

(domain.name.com) network locations.

SW3 SW2 SW1 SW7 Mode IP Address

Off Off Off Off Server 192.168.254.102

Off Off Off On Client 192.168.254.103

Off Off On Off Server 192.168.254.104

Off Off On On Client 192.168.254.105

Off On Off Off Server 192.168.254.106

Off On Off On Client 192.168.254.107

Off On On Off Server 10.0.0.128

Off On On On Client 10.0.0.129

On Off Off Off Server 10.0.0.130

On Off Off On Client 10.0.0.131

On Off On Off Server 10.0.0.132

On Off On On Client 10.0.0.133

On On Off Off Server 172.16.0.128

On On Off On Client 172.16.0.129

On On On Off Server Set by user,

Default=192.168.254.102

On On On On Client Set by user,

Default=192.168.254.102

IP Address Configuration for eBOX

11

Page 12

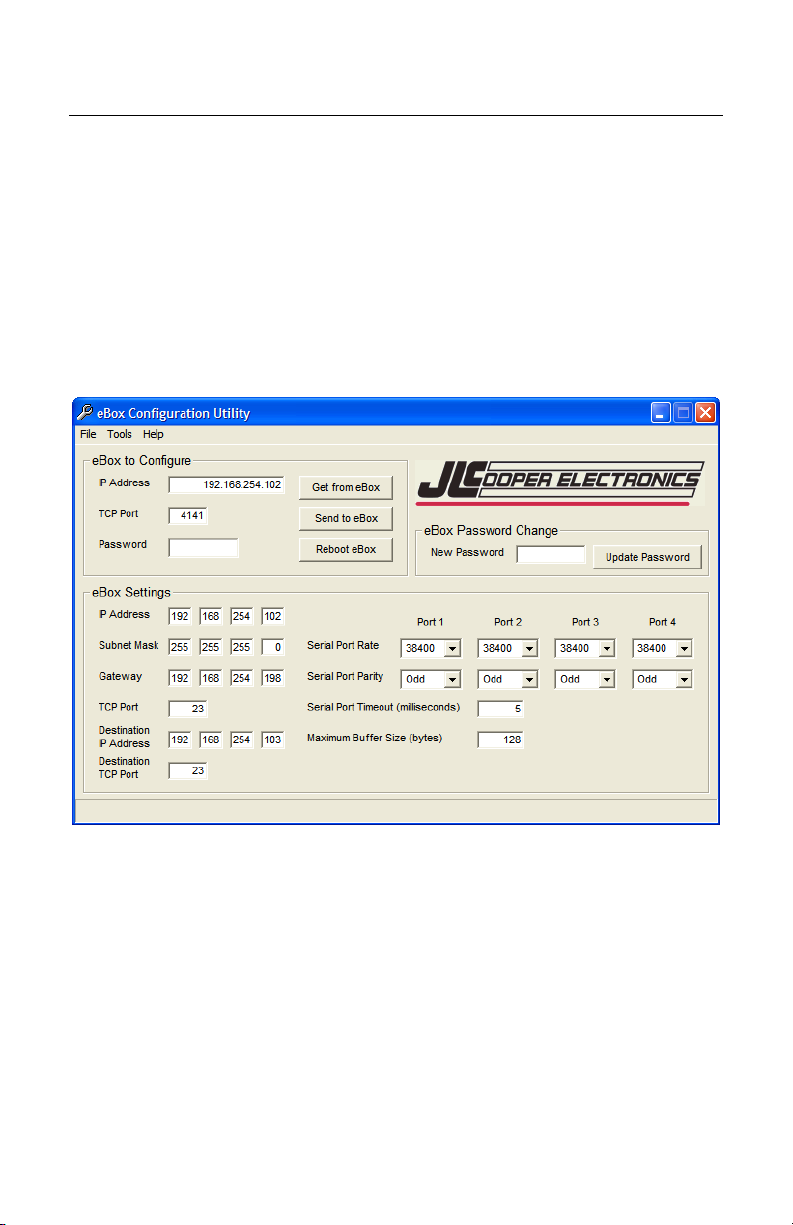

eBOX Configuration Utility

Beginning with version 1.09 firmware, a second TCP connection

was added. This allows the eBOX to be configured while the

eBOX is in use and avoids any compatibility issues with web

browsers. This is the recommended way to configure the eBOX.

To allow easy configuration of the eBOX, JLCooper has provided

a small Windows utility. The eBOX Configuration Utility is

shown below.

To use the utility, simply install and launch it.

12

Page 13

eBOX to Configure

In this section, enter the IP Address, TCP Port and Password of the

target eBOX that you wish to configure.

IP Address

This is IP Address of the target eBOX to configure.

TCP Port

This is the TCP Port of the target eBOX to configure. The TCP

Port for configuration is fixed at 4141. In most circumstances, you

will never have to change this however, if the eBOX is behind a

router using port forwarding, you may have to specify a different

port.

Password

If DIP switch 6 is set to the down position, the eBOX uses a

password to prevent unauthorized access. The default password is

‘password’.

Note: If the Password box contains any text, the eBOX Configuration

Utility will pad out the password with spaces and truncate the

password to 8 characters. If the Password box is empty, the eBOX

Configuration Utility will send no password.

eBOX Password Change

This section allows you to change the password of the eBOX.

Remember, if DIP switch 6 is set to the down position, the eBOX

requires the correct password in the ‘eBOX to Configure’ section.

The default password is ‘password’.

New Password

This is the area to enter a new password. The password can be up

to 8 characters in length.

Update Password

Clicking on this button sends the new password to the eBOX.

Note: The eBOX Configuration Utility will pad out the password with

spaces and truncate the password to 8 characters even if the Password

box is empty.

13

Page 14

eBOX Settings

This section allows you to change the operational settings of the

eBOX Ethernet and serial ports. These settings are identical to the

settings that appear on the configuration web page.

Device IP Address

IP address of this eBOX when SW1, SW2 and SW3=On.

Subnet Mask

The mask is a binary pattern that is matched up with the IP address

to turn part of the host ID address field into a field for subnets.

Gateway Address

IP address of gateway router that connects to other networks.

Port Number

TCP port of this eBOX when SW1, SW2 and SW3=On.

Destination IP Address

IP address of remote eBOX when SW1, SW2 and SW3=On. This

is used when eBOX is configured as a client (SW7=On).

Destination Port Number

TCP port of remote eBOX when SW1, SW2 and SW3=On. This is

used when eBOX is configured as a client (SW7=On).

Password

Eight character alphanumeric password that is embedded in the

Ethernet packet that prevents unauthorized eBOXes from passing

unintended packets. If the password protection feature is enabled

(SW6=Off) on either eBOX, then both eBOXes must have the

same password.

Baud Rate

Sets the port speed of the individual serial ports.

Parity and Parity Type

Enables or disables parity and sets parity type of the serial ports.

Serial Time Out

Sets the time that the eBOX will wait for data from the serial ports.

Max Buff Size

Sets the maximum buffer size of the serial ports.

14

Page 15

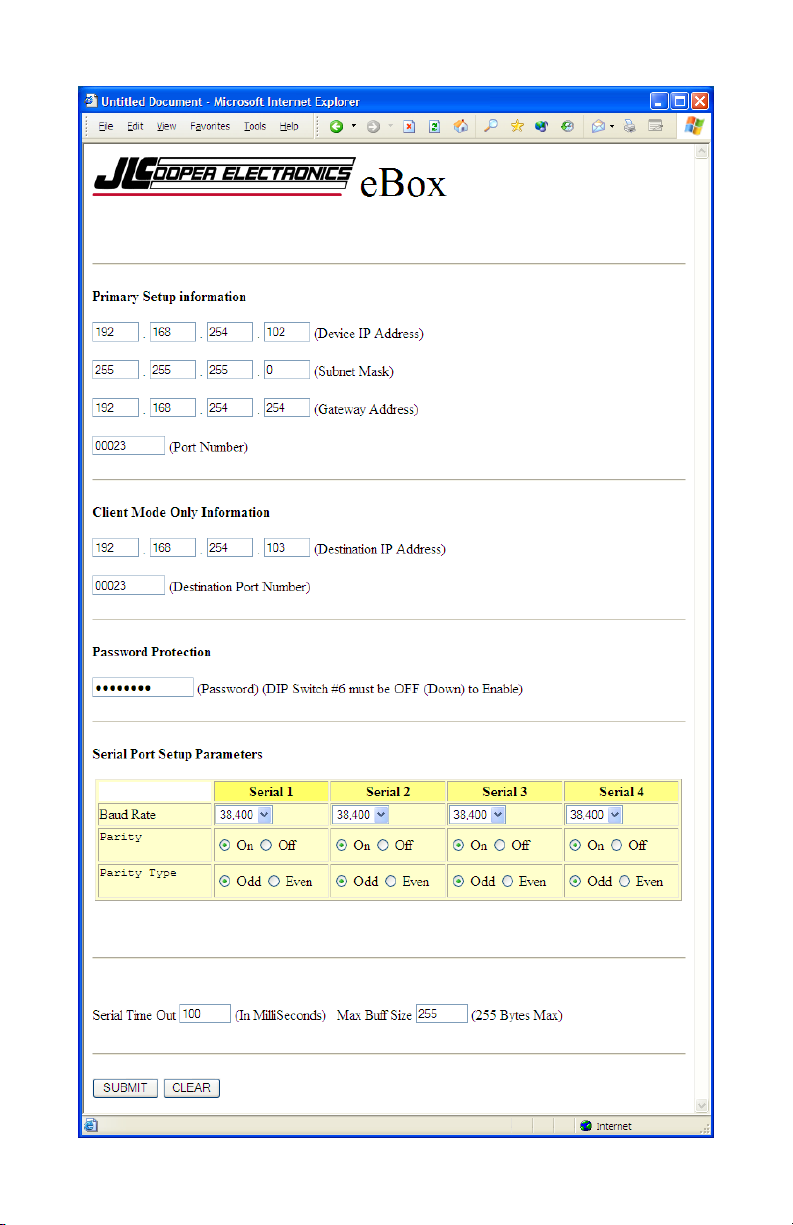

Configuration with Web Page Interface

Note: Beginning with version 1.09 firmware, the ability to configure the

eBOX with the eBOX Configuration Utility while the eBOX is in use

was added. For this reason, using the eBOX Configuration Utility to

configure the eBOX is the recommended method to configure the

eBOX.

When SW8 is set in the ‘On’ position, the eBOX allows access to

the configuration web page. On this page, various settings such as

port rate and parity, IP addresses and ports, and password can be

modified.

Note: The eBOX will not send Serial/GPI messages when the eBOX is

set to configuration mode.

This page is accessed by setting SW8 to the ‘On’ position and

typing

time, the normal operation of the eBOX is suspended. Make any

changes that are necessary for your system and click on SUBMIT.

These changes are stored in nonvolatile memory and are loaded at

power up.

Switch SW8 to the ‘Off’ position and power cycle the eBOX so the

changes are loaded.

The configuration web page is shown on the next page.

http://192.168.254.102 into your web browser. During this

Note: The configuration web page is always set to 192.168.254.102

regardless of the state of the DIP switches.

Note: In the configuration mode, the subnet mask is set to

255.255.255.0. This means that the eBOX will only see traffic from

computers with and IP address of 192.168.254.nnn. You will need to

change your computers IP address to 192.168.254.nnn where nnn =

any number except 0, 102 and 255. This will allow your computer to

access the configuration page of the eBOX.

15

Page 16

16

16

Page 17

Operational Settings

Device IP Address

IP address of this eBOX when SW1, SW2 and SW3=On.

Subnet Mask

The mask is a binary pattern that is matched up with the IP address

to turn part of the host ID address field into a field for subnets.

Gateway Address

IP address of gateway router which connects to other networks.

Port Number

TCP port of this eBOX when SW1, SW2 and SW3=On.

Destination IP Address

IP address of remote eBOX when SW1, SW2 and SW3=On. This

is used when eBOX is configured as a client (SW7=On).

Destination Port Number

TCP port of remote eBOX when SW1, SW2 and SW3=On. This is

used when eBOX is configured as a client (SW7=On).

Password

Eight character alphanumeric password that is embedded in the

Ethernet packet that prevents unauthorized eBOXes from passing

unintended packets. If the password protection feature is enabled

(SW6=Off) on either eBOX, then both eBOXes must have the

same password.

Baud Rate

Sets the port speed of the individual serial ports.

Parity and Parity Type

Enables or disables parity and sets parity type of the serial ports.

Serial Time Out

Sets the time that the eBOX will wait for data from the serial ports.

Max Buff Size

Sets the maximum buffer size of the serial ports.

17

Page 18

eBOX Security

The eBOX contains a basic security mechanism that prevents

unintended hosts or eBOXes from passing data through a secured

eBOX. An eBOX can be protected with password that is set on the

configuration web page. The password is stored in nonvolatile

memory and, is read upon power up.

When password protection is enabled, the sending eBOX embeds

the password in the transmitted IP packet. At the remote end, the

receiving eBOX must have password protection enabled AND

have a matching password.

The DIP switches are read only at power on so the eBOX must be

power cycled for any changes to take effect.

This security mechanism is only used in eBOX Server and eBOX

Client modes. SW6 should be set to the off position when used in

the GPI to Serial and GPI to Ethernet modes.

SW6

On Disable password protection

Off Enable password protection

Security Configuration

The effect of SW6 takes place immediately.

Note: If an eBOX has password protection is disabled, it will ignore the

password and act on any packets sent to it.

18

Page 19

eBOX IP Address

The IP address of the eBOX can be set by the rear panel DIP

switches or by the internal web page. As above, the DIP switches

are read only at power on so the eBOX must be power cycled for

the changes to take effect.

Here is a table of how IP address and the TCP port are set with the

DIP switches in eBOX Server and eBOX Client modes.

SW3 SW2 SW1 SW7 Mode IP Address Port

Off Off Off Off Server 192.168.254.102 23

Off Off Off On Client 192.168.254.103 23

Off Off On Off Server 192.168.254.104 23

Off Off On On Client 192.168.254.105 23

Off On Off Off Server 192.168.254.106 23

Off On Off On Client 192.168.254.107 23

Off On On Off Server 10.0.0.128 23

Off On On On Client 10.0.0.129 23

On Off Off Off Server 10.0.0.130 23

On Off Off On Client 10.0.0.131 23

On Off On Off Server 10.0.0.132 23

On Off On On Client 10.0.0.133 23

On On Off Off Server 172.16.0.128 23

On On Off On Client 172.16.0.129 23

On On On Off Server Set by user

On On On On Client Set by user

IP Address Configuration for eBOX Server and eBOX Client

modes

19

Page 20

Here is a table of how IP address and the TCP port are set with the

DIP switches in eBOX GPI to Serial and GPI to Ethernet

conversion modes.

SW3 SW2 SW1 IP Address Port

Off Off Off 192.168.254.103 8000

Off Off On 192.168.254.105 8000

Off On Off 192.168.254.107 8000

Off On On 10.0.0.129 8000

On Off Off 10.0.0.131 8000

On Off On 10.0.0.133 8000

On On Off 172.16.0.129 8000

On On On Set by user 8000

IP Address Configuration in GPI conversion

modes

Unused Switches

Switch 4 is currently not used.

20

Page 21

GPI Outputs in GPI Conversion Modes

GPI Outs

When the eBOX operates as a GPI to Serial or GPI to Ethernet

Converter, it will send to the Doremi server or to Serial Port A

status requests on a periodic basis. Replies from the server or deck

will be used to establish the state of some of the GPI Output pins,

acting as tally lines. The pins are presently defined as:

Pin Tally Function Pin Tally Function

1 Ground 14 Jog

2 Play 15 Shuttle

3 Record 16 -

4 Fast Forward 17 Servo Lock

5 Rewind 18 A1

6 - 19 A2

7 Stop 20 TC

8 - 21 -

9 Standby 22 Video

10 Cue Up 23 Assemble

11 Still 24 Insert

12 Forward Direction 25 -

13 Varispeed

GPI Tally Outputs in GPI Conversion Modes

Note: by default, the GPI Input pins are active low or 0 volts. That is,

events are triggered when the GPI Inputs are connected to ground or

driven to zero volts. This behavior can be modified with the eBOX GPI

Programmer Software.

21

Page 22

GPI Programmer Software

The GPI Programmer Software pictured below allows you to

program custom messages and behaviors when the eBOX is in

either eBOX GPI to Serial and GPI to Ethernet conversion mode.

eBOX IP address

This is the IP address of the eBOX you want to configure.

eBOX TCP Port

This is the TCP port of the eBOX you want to configure. The

eBOX TCP port in the GPI to Serial and GPI to Ethernet

conversion modes is fixed to TCP port 8000.

Connection State

This window shows the status of the connection to the eBOX you

want to configure.

Connect / Disconnect

This allows you to establish or break the connection to the eBOX

you want to configure.

22

Page 23

Status Window

This window shows additional status messages of the connection

to the eBOX you want to configure. In addition, you will also see

the firmware version of the connected eBOX.

eBOX Programming

The parameters in this box are settings that will be downloaded

into the eBOX.

eBOX IP address

This will be the IP address of this eBOX when SW1, SW2 and

SW3=On.

Subnet Mask

This will be the subnet mask of the eBOX.

Gateway Address

This will be the IP address of gateway router which connects to

other networks.

Port Number

This will be the TCP port of this eBOX when SW1, SW2 and

SW3=On.

Destination IP Address

IP address of remote eBOX when SW1, SW2 and SW3=On. This

is used when eBOX is configured in the GPI to Ethernet mode or

the eBOX is in client mode.

Destination Port Number

TCP port of remote eBOX when SW1, SW2 and SW3=On. This is

used when eBOX is configured in the GPI to Ethernet mode or the

eBOX is in client mode.

Auto Calculate Checksum

Automatically appends a Sony type checksum to the end of each

message.

Suppress Header and Status Request

This disables Doremi message headers and VTR status requests.

Doing this allows you to use the eBOX in applications that do not

involve a VTR.

Serial Ports Baud Rate

Sets the port rate of the individual serial ports.

23

Page 24

Serial Ports Parity / Type

Enables or disables parity and sets parity type of the individual

serial ports.

GPI Pins

These are the pins on the GPI Input connector.

Commands

These are the commands that are sent when the GPI input is

triggered. The command can be triggered on either transition

which is set by the invert checkbox described below. Each byte

must be a two digit hexadecimal number.

Invert

Normally messages are triggered when a GPI input pin is shorted

to ground. Checking this box allows the messages to be triggered

when a GPI input pin is opened or is driven to +5 volts.

Send to Ports

This allows you to specify which serial port(s) the commands are

sent.

Send to eBOX

Clicking this button downloads all the parameters to the eBOX.

During the download, the eBOX will momentarily stop responding

to GPI inputs. This is normal. The serial messages and serial port

routings will be effective immediately. However, changes to the

IP settings and serial port settings take effect after a power cycle.

24

Page 25

eBOX GPI Tester Utility

The GPI Tester Utility pictured below allows you to perform basic

tests with your eBOX, eBOX I/O (if equipped) and connected

customer equipment. This is intended to be a diagnostic tool to aid

you in setting up a server eBOX. The GPI Tester Utility can be

used to connect to an eBOX configured for server mode.

The GPI Tester Utility can not connect to an eBOX:

• When configured as a client eBOX,

• When configured as a GPI to Serial converter,

• When configured as a GPI to Ethernet converter or,

• When connected to another eBOX or application.

25

Page 26

eBOX IP address

This is the IP address of the eBOX you want to test.

eBOX TCP Port

This is the TCP port of the eBOX you want to test. The eBOX

TCP port in the server mode is TCP port 23 by default. This can

be configured for any TCP port.

Connection State

This window shows the status of the connection to the eBOX you

want to test.

Connect / Disconnect

This allows you to establish or break the connection to the eBOX

you want to test.

Status Window

This window shows additional status messages of the connection

to the eBOX you want to test. In addition, you will also see the

firmware version of the connected eBOX.

GPI Inputs

These checkboxes indicate the state of the input pins on the GPI

Input connector. A check mark indicates that the corresponding

pin is in the active state (logic low or 0 volts). The absence of a

check mark indicates that the corresponding pin is in an inactive

state (logic high or 5 volts). Clicking on a checkbox will cause the

eBOX GPI Tester Utility to send a GPI Query command to update

the state of the checkbox.

GPI Outputs

Sets selected GPI Output to active state (logic low or 0 volts). All

other GPI Outputs are set to inactive state (logic high or 5 volts).

All Off

Sets all GPI Outputs to inactive state (logic high or 5 volts).

26

Page 27

Test All

Sets all GPI Outputs to the inactive state (logic high or 5 volts) and

sets each GPI Outputs to the active state (logic low or 0 volts) one

by one in succession as shown below.

1 → 2 → 3 … 22 → 23 → 24 → 1 → 2 → 3 …

Clicking the button again will stop the sequence.

Query GPI

An eBOX sends a GPI Status message in any of the following

cases:

• whenever any of its GPI Inputs change states,

• periodically every 5 seconds or,

• when a GPI Query command is received.

Clicking the Query GPI button sends a GPI Query command to the

connected eBOX causing the eBOX to immediately return the

states of its GPI Inputs. Clicking the Query GPI button is a good

way to verify that the eBOX GPI Tester Utility is still connected to

the eBOX under test.

Note: The eBOX GPI Utility does not use the Password protection

feature of the eBOX so that feature will have to be disabled by setting

DIP switch 6 to the ‘ON’ position.

27

Page 28

eBOX Software for Apple Mac

Installation

The installer puts the folder eBox in the /Applications folder. This

folder contains the eBox Control Center application and the eBox

Uninstaller. The installer also places eBox_StartupItem in

/Library/StartupItems and eBoxMidiDriver in /Library/MIDI

Drivers.

To uninstall run the eBox Uninstaller located in

/Applications/eBox. Select the items to uninstall, then click on the

Uninstall button.

NOTE: Currently the uninstaller is unable to remove the eBox Control

Center application.

Operation

After restart run eBox Control Center. This application serves as

the editing application just like the applications for our control

surfaces. However, it also can be used as a front end for the eBox.

You switch between these two modes of operation with the

Programming / Live Mode switch located just above the logo.

28

Page 29

Preferences

The preferences are where you set the IP Address, port and the

optional password.

NOTE: The password feature is not currently implemented.

There are several IP Addresses and Ports built in to the eBox.

They are set using the dip switches on the back of the eBox. Refer

to the eBox manual for details. You need to set the software to use

the same address and port as the hardware. The available ports are

listed in the popup menu. With the correct dip switch settings, and

by choosing Custom from the popup, you can define your own IP

address and port.

29

Page 30

Password

If you check the Use Password checkbox, you can define an eight

character password that will be sent as part of every message to

and from the eBox. This must match the password set in the eBox

hardware. Refer to the eBox manual for setting up the password.

Keysets

This software uses keysets like our control surface software.

Different keysets can be set up for different applications, for

example, a keyset for Pro Tools and another one for FCP. In Live

Mode the eBox, software will automatically use the correct keyset

for the front application.

To create a new keyset, go to New Keyset in the File menu. In the

dialog that opens up, navigate to the application that the keyset will

be used with, such as Pro Tools, FCP, etc. and click on Open.

30

Page 31

Use the Keysets menu to switch between the various keysets that

you have created.

When the eBox Control Center is in the background or not

running, the eBox driver checks to see what application is in front

then uses the keyset created for that application. If an application

has no keyset, then the eBox driver uses a permanent keyset named

Global. Although the Global keyset can be programmed just like

keysets for specific applications, it is probably best to leave it

blank. Otherwise, you might start your tape machines playing

while browsing in Safari :)

Keysets, and any changes you make to them, are stored

automatically in the eBox's preference file. There is no need to

Save or Open on a regular basis. If you want to make a copy of

your work for backup or to move to another Mac, use Open

Archive and Save As Archive in the File menu. These commands

store and retrieve all of your keysets in a single file.

Programming Mode

In programming mode, you click on a button, and its information

appears in the Inspector window. Here, you can give the control a

name and a set of actions to perform when it is clicked.

31

Page 32

You set up an action in one of the tabs (for example, GPI, MIDI,

Special, Delay) then click on Add Action. You can keep adding

as many actions as you want. They will be performed in order

when the button is pressed in Live Mode.

Action Tabs

The tabs in the inspector window vary slightly depending on what

type of control is selected. All controls will have the MIDI,

Special and Delay tabs. GPI Output buttons and GPI Preset

buttons will have a GPI Tab, and Serial Port and Serial Preset

buttons will have a Serial Tab.

32

Page 33

MIDI Tab

The MIDI tab is where you can assign MIDI message to a control.

These messages will be received by any running MIDI application

that is connected to the eBox Software. The procedure for

connecting MIDI applications varies from application to

application and will be covered in those applications’ manuals.

MIDI Machine Control (MMC)

You can assign one of several common MIDI Machine Control

(MMC) messages by clicking on the MIDI Machine Control radio

button and selecting a message from the popup menu.

33

Page 34

Custom MIDI Messages

By clicking the Custom radio button, you can define your own

MIDI message. The different message types will appear in a

popup menu.

34

Page 35

Depending on the type of message you choose, other editing

controls will appear. If the message type you have chosen has a

channel, you can either type a number from 1 - 16 in the Channel

field, or use the up and down arrows next to it. If the message also

includes one or two data bytes, the data byte editors will appear.

You can type a number from 0-127 or use the up and down arrows.

If you check Follows Control, then pressing a button in Live

Mode will cause that data byte to have a value of 7Fhex (127

decimal) and releasing the button will give it a value of 00hex,

In this example, one MMC Command and one Custom MIDI

Command have been assigned to a control.

35

Page 36

Special Tab

The Special Tab is not currently implemented.

Delay Tab

You can use the Delay Tab to set a delay between two actions.

Simply move the slider from 0 to 2 seconds then hit the Add/Insert

button.

If a GPI Preset button was programmed as in the following

example, pressing it in Live mode would close some GPI contacts,

wait, send a Record Strobe to all connected MIDI applications,

wait then send another MIDI message.

36

Page 37

Keyboard Triggers

For any buttons that trigger an output (actually, all buttons except

for the GPI IN buttons), you can also choose a keyboard trigger

that will perform the same actions as clicking on the button. The

trigger can optionally be passed on to the front application, with or

without a delay. The delay can be from 0 - 1 second. This lets you

do things like hit the space bar in Pro Tools to start playback, but

have the eBox turn off the studio monitors and wait a half a second

before sending the space bar to Pro Tools.

To set a keyboard trigger, click in the field next to Trigger with

Keystroke then type the trigger Character, modifier keys and all.

At any time, you can change the modifier keys by clicking on the

modifier checkboxes.

Because the keyboard triggers are assigned to specific applications,

they only operate when those apps are in front. Therefore, they

will not interfere with Microsoft Word, or your billing software.

NOTE: Keyboard triggers are disabled in the Global Keyset to prevent

unwanted interference with other applications.

All buttons can be either latched or momentary, and you can

choose to have them repeat their actions while the button is down.

37

Page 38

GPI Input Pins

The top group of buttons each represents Individual GPI pins.

There are three rows of input pins and three rows of output pins.

For the Input pins, you can program what happens when an

individual input pin is changed by some external hardware.

Currently the GPI Input pins can generate MIDI Messages and

Delays.

GPI Output Pins

Each GPI Output pin button can change the state of its pin, without

affecting the other pins. In the GPI tab, you can create a GPI

action that closes the contact when the button is pressed and opens

it when released. If you click on the Invert check box, then it

opens the contact on the button press and closes it on release.

Currently the Special Tab is not implemented. But even without it

you have the ability to do something like turn on a contact then

delay up to 2 seconds then turn it off again, plus send a MIDI

message to an application, and this can be triggered by a keystroke

that also does something useful in another program, like Pro Tools.

38

Page 39

Unlike serial ports, where the input and output signals are carried

over the same cable, and are usually going to the same device, GPI

inputs and outputs are separate entities. They may or may not be

connected to the same device. This is why they can be

programmed independently. However, when an input and output

pin is connected to the same device and you want them both to

perform the same actions, you can program the GPI Output pin

first, then click on Apply to GPI In. This will transfer the output

pin’s settings to the corresponding input pin.

39

Page 40

GPI Preset Buttons

The four GPI Preset buttons are similar to the GPI Output buttons,

except that they allow you to affect all of the GPI outputs at once.

In the GPI tab you can choose for each Pin, whether to have it

follow the button state, invert the button state, toggle with each

button press, or do nothing.

40

Page 41

Serial Port Buttons

Each of the four Serial Port buttons lets you send a message to a

serial port. It can be a Sony 9-Pin serial command, or any arbitrary

string that you can type in. The serial message can be combined

with MIDI and Delay actions. The Special tab is not currently

implemented.

The custom messages can be entered and displayed in either

decimal, hex or ASCII notation. The notation style is chosen with

the radio buttons at the bottom of the window.

Since the Serial Port buttons only send one command, they are

most useful if you have a single command that you send to a port

frequently. They are also useful displaying the name of the device

the port is connected to.

41

Page 42

Serial Preset Buttons

The Serial Preset buttons are more flexible. There are four banks,

each bank containing five F-Keys and five transport buttons.

There are four Gang buttons above each bank. These buttons let

you direct the bank’s output to one or more serial ports.

While more than one of the five F-Keys can be active at once, the

transport buttons act like “radio” buttons. That is, only one can be

active at once. Sorry, you can’t Record in Rewind. It’s a feature.

If that’s actually a problem, let us know.

42

Page 43

Live Mode

In live mode, the Inspector window is hidden, and the main

window’s appearance changes slightly.

The GPI Input Buttons change to indicators to show the state of

the GPI Inputs. They are not clickable since GPI Input actions are

only initiated by the external hardware.

In Live Mode, the GPI Output, GPI Preset, Serial Port and

Serial Preset buttons all initiate the actions they were assigned in

Programming mode.

Activity indicators also appear next to the GPI Output Buttons and

the Serial Port Buttons, since there are times when the state of a

GPI pin or serial port might be different from the state of the

button.

43

43

Page 44

In Programming mode, only one button (the one being

programmed) ca

be active. The exception is the Serial Preset Transport Controls.

Within each preset bank, each transport control is mutually

exclusive.

W

hen the eBox Control Center is the front application in Live

mode, you determine which keyset is active using the Keyset

menu. If the eBox Control Center is in th

ru

nning at all, the eBox driver automatically switches keysets

based on the front application. If there is no keyset for the

frontmost application, then the driver uses the Global keyset.

W

hen the eBox Control Center is not the front application, you can

use the keyboard triggers you defined in Programming Mode to

initiate the actions you assigned to the various buttons.

If

the eBox Control Center is visible in the background, and in

Live Mode, then its indicators will still display the states of the

GPI Input and Output Pins and the Serial Port Inputs.

n be active at once. In Live mode, any button can

s

e background, or not

44

Page 45

sing the eBOX With a Router U

p

p

In this section, we will explain how to configure the eBOX to work

with a router. In this example, we will show how to configure two

eBoxes behind a router. This same information also applies

normal ope

ration of the eBOX with different port numbers.

to

The TCP Port that the eBOX uses for configuration is fixed at

4141. However, if the eBOX is behind a router and the router i

configured to use Port Forwarding to remap the TCP connectio

the eBOX, you may have to use a different port. A good exam

of this is if you have 2 eBOXes at a remote site. In the exam

s

n

ple

ple

below, there are two eBOXes behind a router. The router is

onfigured to pass configuration packets coming to the router at IP

c

Address 12.34.56.78, TCP Port 4141 to the first eBOX at IP

Address 192.168.254.102, TCP Port 4141. Additionally, the route

is also configured to pass configuration packets coming

uter at IP Address 12.34.56.78, TCP Port 4142 to the second

ro

to the

eBOX at IP Address 192.168.254.103, TCP Port 4141.

IP Address = 12:34:56:78

TCP Port = 4141

IP Address = 12:34:56:78

TCP Port = 4142

Router

Port Forwarding Table

4141→192.168.254.102:4141

4142→192.168.254.103:4141

IP address = 19

2.168.254.102

ort = 4141

TCP

eBox #1

eBox #2

IP address = 192.168.254.102

TCP

ort = 4141

r

45

Page 46

Using with eBOX I/O

The eBOX GPI inputs and outputs are CMOS compatible circuits.

The CMOS GPI inputs require that the input signals be 0 to 5 volts

and referenced to ground. The CMOS GPI outputs can deliver 0

5 volts at up to +/- 6mA and referenced to ground.

In many cases, this will be compatible with your equipment.

However, in some cases, there will be the end user equipment ma

not be compatible with 0 to 5 volt requirements of the eBOX GPI

inputs and outputs. In this case, the eBOX I/O must be used. Each

eBOX I/O buffers 8 inputs and 8 outputs. The inputs are buffered

with an optoisolators while the outputs are buffered with a dr

relay contact. Up to three eBOX I/Os can be used with a single

eBOX.

3 1 2 4

eBOX I/O #1

GPI 1-8

3 1 2 4

eBOX I/O #2

GPI 9-16

3 1 2 4

eBOX I/O #3

GPI 17-24

to

y

y

46

Page 47

Technical Reference

Electrical Connections

Ethernet

This eBOX port is just like an Ethernet port on a computer, to

connect it to a hub, switch or router, use a straight through cab

To connect it to another eBOX or computer, use a crossover cable.

The eBOX supports IEEE 802.3u clause 28 Auto-Negotiation

which automatically senses the Ethernet port speed & duplex

operation and chooses the highest performance settings.

In addition, four LEDs on the front panel that indicate various

operating

conditions of the Ethernet port. These LEDs are:

• Link

• 100BaseT activity

• 10BaseT activity

• Collision

le.

47

Page 48

Serial

The four serial ports along the to

connectors which can be configu

operation. I

to appear as

n RS-422 mode, the eBOX direction can be configured

a Controller or a Device. In RS-232 mode, the eBOX

appears as a DCE or DTE.

p of the rear panel are 9 pin D-Sub

red for RS-232C or RS-422A

Mode RS-232C RS-232C RS-422A RS-42

Direction

Left SW

Right SW

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

To Device To Computer To Deck To Controller

Out In Out In

In In Out Out

not used not used not used not used

Receive Transmit Receive A Transmit A

Transmit Receive Transmit B Receive B

not used not used Ground Ground

Ground Ground Ground Ground

not used not used Ground Ground

not used not used Receive B Transmit B

not used not used Transmit A Receive A

not used not used not used not used

2A

Serial Port Configuration

48

Page 49

Older versions of the eBOX used DIP switches to configure the

the ports. In RS-232 mode, the RS-422 ICs must be mode of

removed. These ICs are marked 89C22.

Mode RS-232C RS-422A RS-422A

Direction

SW1

SW2

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

X = Don’t Care

To Computer To Deck To Controller

On Of Of

X On Off

not used not used not used

Transmit Receive A Transmit A

Receive Transmit B Receive B

not used Ground Ground

Ground Ground Ground

not used Ground round G

not used Receive B Transmit B

not used Transmit A eceive A R

not used not used not used

f f

Serial Port Configuration

49

Page 50

GPI Port Pinouts

The GPI ports on the rear of the eBOX ar

onnectors. The GPI In connector has 24 TTL/CMOS compatible

c

e 25 pin D-sub

inputs with internal pull-ups to +5 volts. The GPI Out connector

has 24 TT S c ut th , pin 1

is the g n -25 GP

L/CMO ompatible o puts. On bo connectors

round refere ce and pins 2 are the I signals.

When eBOXes connected together in a nt/server ner

clie man

establish a connection, both client and server eBOXes will send the

state of its n ports to ch other s an be sho n the GPI

Out port on the remote After that, changes to a GPI In port

will cause OX to send a GPI message to the remote eBOX.

Additiona eBO end ssa

GPI I ea o it c wn o

eBOX.

an eB

lly, the Xes will s a GPI me ge every 5

seconds to keep the connection alive and to refresh the state of the

GPI outpu

ts.

A packet is sent whenever a change to the GPI In is sensed. At

present, it is sampled a ry 20 onds. This can be

bout eve millisec

changed via the configuration web page.

LSB

Byte1 Pin 9 Pin 8 Pin 7 Pin 6 Pin 5 Pin 4 Pin 3 Pin 2

Byte2 P Pin 16 Pin Pin Pin 10 in 17 Pin 15 14 Pin 13 12 Pin 11

Byte3 P Pin 24 Pin 23 Pin 22 Pin 21 Pin 20 Pin 19 Pin 18 in 25

MSB

eBOX GPI In/Out Pinouts

50

Page 51

GPI Port Circuitry

The eBOX GPI input and output circuits are detailed in th

Details

e

following section.

The inputs of the eBOX GPI ports are CMOS inputs. The input

circuitry has a 4700 ohm pullup resistor to +5 volts as refere

pin 1 of the GPI Input Port.

to

nced

Note: Because the inputs are CMOS, the input voltage MUST be

limited to voltage levels between 0 and 5 volts. If this is not possible,

consider using the eBOX I/O.

5 Volts

4700Ω

74HC244

Detail of GPI Input

he internal pullup resistor insures that the input pin is set to a

T

nown st he d fault s ate of e GPI nputs +5 vo ts or

k ate. T e t th I is l a

stat 1’ G es it T ter ull

logic e of ‘ in the PI m sage b map. he in nal p up

or a o m ‘dry con o

resist lso all ws a si ple switch or tact’ t be

cte e P t d d o th

conne d betw en a G I Inpu pin an groun as sh wn in e

example below.

5 Volts

4700Ω

2

1

GPI Input Example with Pushbutton Switch

74HC244

51

Page 52

The outputs of the eBOX GPI ports are also CMOS. The output

signal is referenced to pin 1 of the GPI Output Port. The GPI

Outputs are rated to +/- 6mA. If this is not sufficient for you

application, conside

r using the eBOX I/O.

r

Note: Because the inputs are CMOS, the output voltage MUST be

limited to voltage levels between 0 and 5 volts. This can occur if

driving a circuit that is powered by

this is not possible, consider using

74HC

a voltage higher than 5 volts. If

the eBOX I/O.

374

The exampl

Detail of GPI

Output

e circuits below shows a GPI Output driving an LED.

5 Volts

74HC374

GPI Output Example #1 with LED

74HC374

2

1

2

1

GPI Output Example #2 with LED

52

Page 53

Power

The eBOX requires a 9 volt DC, center positive power supply

capable of delivering at least 500 milliamps. The unit com

a

power supply appropriate for the country in which the unit was

sold. If you need a power supply specific to your location, please

tact your local distributor or JLCooper Electronics.

con

Location JLCooper Part

North America PSDC117

Europe PSDC230

Approved Power Supplies

Warning: Using a power supply other than the units specified in the

above table can result in damage to the eBOX and/or other equipment

which is not covered by the JLCooper Factory Warranty.

Number

es with

53

Page 54

shooting Trouble

If for some reason the eBOX does not give you the expected

results, take a moment to do some investigating. The most

important concept is that you have your eBOX connected properly

as outlined in Installation and Use. Take a moment to double

check your setup.

• W ate o

hat is the st f the DIP switches?

• Do the 10 red LEDs flash alternately at power up?

• Do the Link and 100 (or 10) LEDs light up?

• In any mo

(ping 192.168.254.102)?

• If you are using the password protection feature, is

enabled in both eBOXes?

• In webpage configuration mode, can you

with it using the web page?

• In normal client or server mode, can you communicate

with it using the eBOX Configuration Utility?

• The ARP Cache in the host application may have the

incorrect entry for the eBOX's IP address. Try clearing

the ARP cache (arp -d in Windows).

• In normal server mode, if you telnet to the eBOX, do

you see a short packet of unprintable characters every 5

seconds as shown in the screenshot below?

de, can you ping it

it

communicate

54

Page 55

If you are using the eBOX C

the eBOX for the settings to

A common problem is forgetting to turn the power switch on

turning the unit on after the software application has launche

In addition, the JLCooper website (www.jlcooper.com

contain up to date in

tr

oubleshooting.

If all el f ent

at: serv @

se ails, you can contact the JLCooper Service Departm

ice jlcooper.com

formation on drivers, applications and

onfiguration Utility, be sure to reboot

take effect

or

d.

) will

.

Care an

If prope

troublefree OX is built in a rugged

metal e lo

Clean w h

foreign ma

There are n

JLCooper E the last page

for deta d

d Service

rly cared for, your eBOX should provide years of

performance. While the eB

nc sure, please avoid dropping the eBOX.

it a soft, damp cloth. Do not allow liquids, dust or other

tter to get inside the unit.

o user-serviceable parts in the eBOX. Please refer to the

lectronics Limited Factory Warranty on

ile warranty and service information.

55

Page 56

Declaration of Conformity

JLCooper Electronics declares that the product named below conforms to:

Low Voltage Directive (LVD) 2006/95/EC

(Superceded LVD73/23/EEC) on 16th January 2006.

Low Voltage Directive

(Directive 73/23/EC has recently been the subject of a codifica

requiring a new number)

Warning: The installer is responsible for protection against personal contact

with all live connections to power supplies, w

Company Address:

142 Arena Street

El Segundo, CA, 90245 U.S.A.

Product Name: eBOX I

roduct Type: Network Interface

P

Model Number: eBOX

Date of Issue: 16 September 2009

Authorized by:

Title of Authority: Quality Assurance

Declaration Reference: CE/EEC2007TLL

(LVD) 73/23/EEC

tion,

eBOX

hich contain hazardous voltages.

nterface

56

Page 57

nce RoHS Statement of Complia

June 28, 2006

Re: eBOX

This is a declaration that the items described (herein as RoHS “Class 1”) do not

contain one or more than one:

RoHS restricted substances above the homogeneous material concentration limit

hreshold Level) per the EU/RoHS directive effective July 1, 2006 and

(T

amendi

ng document(s).

JLCoop r Electronics products will meet MIL-I 45208. The Company is

current 0, after which feasibility

researc

R

H

Cadmium (Cd) 100ppm (0.01%)

Lead (Pb) 1000ppm (0.1%)

M

Hexavalent Chromium

Polybrominated B

Polybrominated Diphenyl Ethers

Supplier evidence of compliance on

requirements of ISO 9000:2000. Whe

ISO 9000:2000 Quality an

S

Thomas L. Lowry

Quality Assurance Department

e

ly implementing procedures for ISO 9000:200

h will begin for ISO 14000 considerations.

oHS Class 1 OEM Products:

azardous Substance Allowed PPM Level

ercury (Hg) 1000ppm (0.1%)

(CrVI) 1000ppm (0.1%)

iphenyl's (PBB's) 1000ppm (0.1%)

(PBDE's) 1000ppm (0.1%)

file meets or exceeds trace ability

re feasible, JL Cooper seeks suppliers with

d ISO 14000 Environmental Certification.

incerely,

57

Page 58

rranty JLCooper Electronics Limited Wa

JLCooper Electronics ("JLCooper") warrants this product to be free of defects in materials or

w

orkmanship for a period of 12 months from the date of purchase. This warranty is non-

transferable a

warranty, c

9990 and talk to a service technician. If necessary, a Return Authorization number may be

issued. For our customers outside th

our Dealer or Distributor, since they may offer their own service or support policy. If local

y

support is not obtainable, please send a FAX to JLCooper's Service Department at +1 310 335

0110 with a detailed description of the service required. Upon issuance of return authorization,

the product should be packed in the original shipping materials and shipped pre

insured to: Service Departm

0245. Please include the following: copy of the sales receipt, your name and address (no P.O.

9

Boxes, please), a brief description of the problem, and any other related items discus

the service department and considered necessary to evaluate the product or effect a repair. T

return authorization number must be clearly written on the outside of the package. JLCoop

ill at its option, without charge for parts or labor, either rep

w

r unit. Carriage, insurance, customs duties, impounds, tariffs, taxes, surchanges, brokerage

o

fees and other shipping costs are not covered by thi

ound time at the factory is approximately 15 business days from receipt of product to

ar

shipping. Your actual turn around time will include return shipping. Actua

will vary depending upon many factors including the repeatability of th

complaint, the availability of parts required for repair, the availabilit

needed to evaluate the product if necessary. Priority services are availab

These should be discussed with the service technician at the time the r

issued. This warranty provides only the benefits specified and does not co

needed as result of acts beyond the control of JLCooper including but n

failure to operate in accordance with the procedures outlined in this ow

cover damage from accident, negligence, using incorrect power supply, modification,

it

alteration, improper use, unauthorized servicing, tampering, ingress of foreign mat

damage from natural or man-made events such as, but not limited to flooding

electrostatic discharge, tornadoes, earthquake, fire, civil unrest, war, terrorism, etc.

HE DURATION OF ANY OTHER WARRANTIES, WHETHER IMPLIED OR EXPRESS,

T

INCLUDING

MERCHANT D

WARRANTY HEREIN. JLCOOPER HEREBY EXCLUDES INCIDENTAL AND

CONSEQUENTIAL DAMAGES, INC UDING BUT NOT LIMITED TO: LOSS OF TIME,

INCONVENIENCE, DELAY IN PERF MANCE OF THIS WARRANTY, THE LOSS OF

USE OF THE PROD

EXPRESS OR IMPLIE

ABILITY APPLICABLE TO THIS PRODUCT OOPER SHALL NOT BE LIABLE FOR

DAMAGES OR LOSS RESULTING FROM THE NEGLIGENT OR INTENTIONAL ACTS

OF THE SHIPPER OR HIS CONTRACT FFILIATES. THE CUSTOMER SHOULD

CONTACT THE SHIPPER FOR PROPER CLAIMS PROCEDURES IN THE EVENT OF

DAMAGE OR LOSS RESULTING FROM SHIPMENT. THIS WARRANTY SHALL BE

GOVERENED BY THE LAWS OF THE STATE OF CALIFORNIA.

nd the benefits apply only to the original owner. Proof of purchase in the form of

ales receipt is required for warranty coverage. To receive service under this

d san itemize

ustomers in the United States should contact the JLCooper factory at (310) 322-

e United States, it is recommended that you first contact

ent, JLCooper Electronics, 142 Arena Street, El Segundo, CA

air or replace the defective part(s)

s warranty. JLCooper's normal repair turn

l turn around time

e customer's reported

of related products

y

le at additional cost.

eturn authorization is

ver defects or repairs

ot limited to: abuse,

ner's manual; nor does

BUT NOT LIMITED TO THE IMPLIED WARRANTY OF

ABILITY, IS LIMITE TO THE DURATION OF THE EXPRESS

L

UCT OR COMMERCIAL LOSS, AND FOR BREACH OF ANY

OR

D WARRANTY OF MERCHANT-

. JLC

A

paid and

sed with

ter; nor for

, lightning,

he

er

58

Loading...

Loading...