Page 1

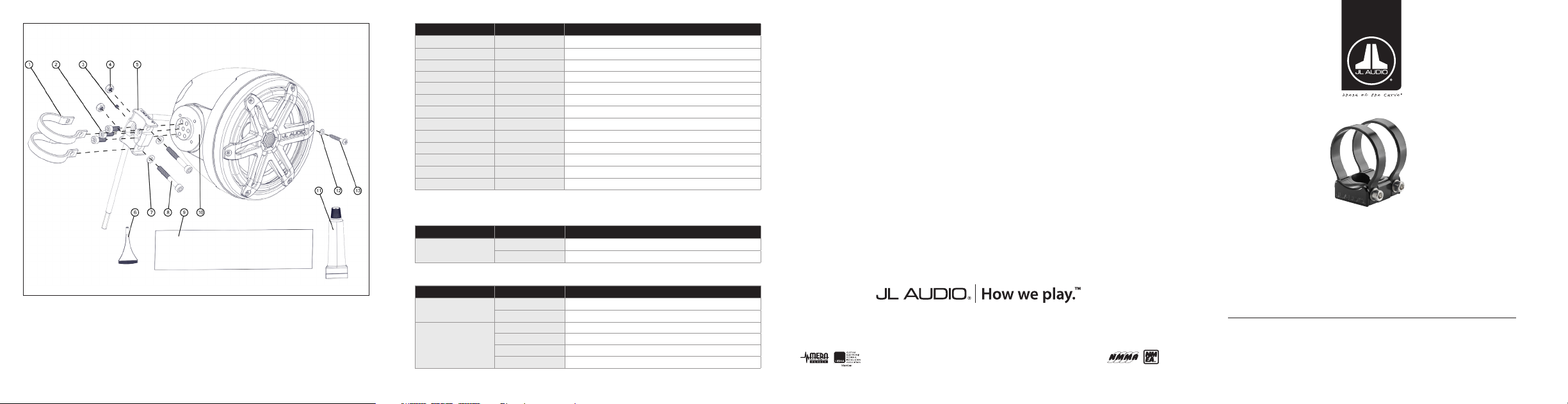

Included Hardware:

(hardware pictured for one)

Mounting Fixture is made in the USA by Axia Alloys

Protected by US Patents #8,136,771 & #8,398,035

NOTE: The PS-SWMCP-B-2.000 Fixture and PS650-VeX-SG-TMB Enclosed Speaker

System are used in this manual for illustrative purposes only. The fixture installation

steps are the same for all PS650-VeX Enclosed Speaker Systems and all PS-SWMCP

swivel fixtures for round pipes.

BOM ID Quantity Description

1 4 Axia Alloys Strap Clamp

2 6

3 2 M4 x 4 mm Set Screw (pre-installed)

4 4 M6 Nylon Insert Locknut

5 2 Clamp Receiver

6 1 Loctite® Red read-Locking Compound

7 4 M6 Flat Washer

8 4 M6 x 45 mm S ocket Cap Machine Screw

9 1 Plastic Strip

10* 2 Fixture Base

11* 1 Silicone Adhesive

12* 12 #8 Flat Washer

13* 12 #8 x 1-1/4” Pan Head Screw

* Included with VeX™ speaker enclosures.

M6 x 16 mm Socket Cap Machine Screw

For Standard Models:

Wire Size Wire Label Use

16 AWG

“+”

N/A

Speaker Negative (–)

For Premium Models:

Wire Size Wire Color Use

16 AWG

20 AWG

Note: Not all wires may be used in normal applications.

Red/Stripe Speaker Positive (+)

Black/Stripe

Red Not Used

Green Not Used

Blue LED Positive (+)

Yellow LED Negative (–)

Speaker Negative (–)

Speaker Positive (+)

LIMIT ED WARRAN TY MARIN E PRODUCT S USA

JL AUDIO war rants this pr oduct to be free of de fects in mater ials and work manship for a per iod of two (2) years fro m the

origi nal date of purch ase.

This wa rranty is not t ransferabl e and applies onl y to the origina l purchaser f rom an authori zed JLAUDIO deale r. Should servi ce

be neces sary under t his warra nty for any reason d ue to manufact uring defec t or malfunc tion, JL AUDIO wil l (at its discret ion),

repair o r replace the defe ctive product w ith new or remanu factured pro duct at no charge. D amage cause d by the followin g is not

covered un der warrant y: accident, m isuse, abuse , product modif ication or neg lect, failu re to follow inst allation in struction s,

unautho rized repai r attempts, mi srepresentat ions by the selle r. This warra nty does not cover i ncidental or con sequential d amages

and does no t cover the cost of rem oving or reinst alling t he unit(s). Cosmetic d amage due to acci dent or normal wea r and tear is not

covered un der warrant y.

Any applic able implied wa rranties a re limited in du ration to the pe riod of the expre ss warrant y as provided here in beginn ing

with t he date of the orig inal purcha se at retail, a nd no warrant ies, whether e xpress or impli ed, shall appl y to this produc t

therea fter. Some state s do not allow lim itations on impl ied warrant ies, therefor e these exclusi ons may not apply to you. T his

warra nty gives you sp ecific lega l rights, and y ou may also have ot her rights whic h vary from st ate to state.

For Service Information in the U.S.A. please call

JL Audio Customer Service: ( 954 ) 4 43-11 00

9:00 AM – 5: 30 PM (Eastern Time Zon e)

10369 North Co mmerce Pkwy.

Miramar, FL 33025, USA

Product s purchased outs ide the United States o f America are covere d only

©2016 JLAudio, Inc. • For more de tailed inform ation please vi sit us online at www.jlaudio.com. Due to o ur policy of con tinuous produc t developmen t, all specif ications are subj ect to change wi thout notice.

JL Audio® and the JL Aud io logo are regist ered trademark s of JL Audio, Inc. “Ahe ad of the Curve” and i ts respective l ogo is a trademark o f JL Audio, Inc.

International Warranties:

by that countr y’s distributo r and not by JL Audio, Inc .

w w w . j l a u d i o . c o m

JL Audio, I nc

SKU# 011498

Printed in U.S.A. • 092817

Installation Instructions for all

PS-SWMCP

swivel fixtures for round pipes

PIPE MOUNTING FIXTURES (SWIVEL)

FOR PS650VeX™ ENCLOSED SPEAKER SYSTEMS

Page 2

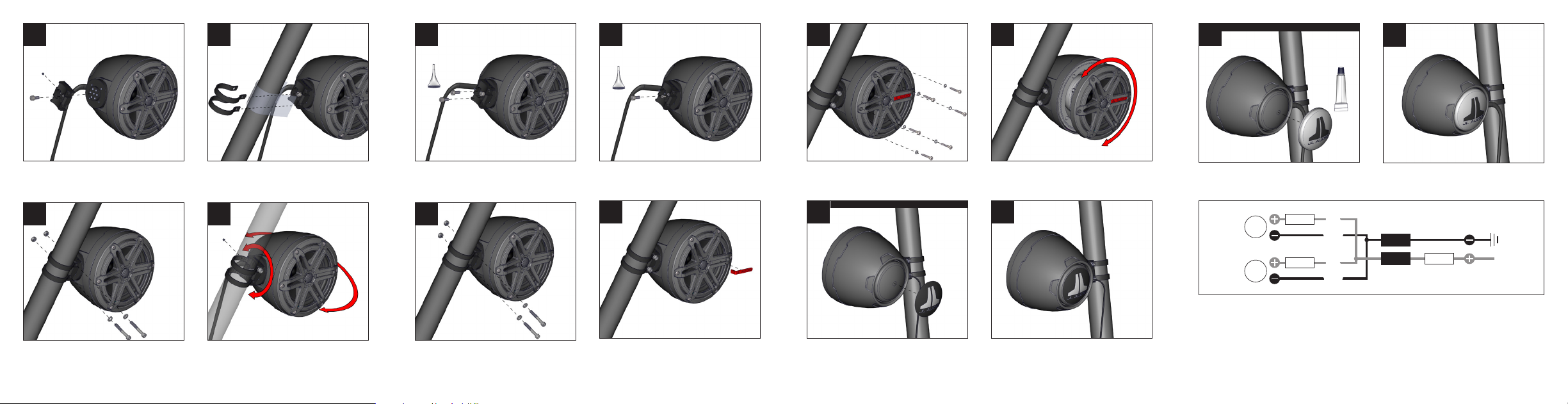

1

2

5

6

9

10

Steps 13-14 are for Premium Models Only

13

14

Loosen the pre-installed M4 x 4 mm Set Screw in the

clamp receiver. Slide an M6 x 16 mm Machine Screw

through the center hole of the clamp receiver, into the

center hole in the xture base, and hand tighten.

3

Secure the clamps to the clamp receiver using a pair of

M6 x 45 mm Machine Screws, M6 Flat Washers, and M6

Locknuts as illustrated. e locknut should be installed

into the hex shaped recess on one end of each clamp.

Hand-tighten, allowing just enough freedom to rotate the

enclosure around the pipe.

Place the supplied plastic strip around the pipe to

prevent scratching. Push the clamps over the pipe

(remove the plastic strip). Align the clamps with the

clamp receiver on the enclosure.

4

Position the enclosure at the desired location, tightening

the M6 x 45 mm Machine Screws as necessary. Fully

tighten the pre-installed M4 x 4 mm Set Screw in the

clamp receiver to hold its position. Mark the location

of the clamps on the pipe, then remove the enclosure

from the pipe.

Apply Loctite® red thread-locking compound to two M6

x 16 mm Machine Screws, slide them through the slots

in the clamp receiver, into the appropriate holes in the

xture base, and fully tighten.

7

Realign the clamps with the clamp receiver on the

enclosure, and secure them to the clamp receiver using a

pair of M6 x 45 mm Machine Screws, M6 Flat Washers,

and M6 Locknuts as illustrated, and fully tighten. Note:

e locknut should be installed into the hex shaped

recess on one end of each clamp.

Remove the center M6 x 16 mm Machine Screw from the

clamp receiver, apply Loctite® red thread-locking

compound, reinstall, and fully tighten.

8

Remove adhesive backing and install the JL Audio logo

badge.

If you wish to rotate the speaker’s grille/logo badge

alignment, remove the six #8 x 1-1/4” speaker mounting

screws and #8 Flat Washers.

Steps 11-12 are for Standard Models Only

11

Remove the backing from the rear logo appliqué. With

the logo positioned at the desired angle, attach the

appliqué to the back of the enclosure.

Rotate the speaker to the desired angle. Reinstall the

speaker and speaker mounting screws and washers.

Hand-tighten in a criss-cross pattern.

12

Gently press on the appliqué from the center out to

remove any air pockets.

Clean the inside of the aluminum cap with acetone (not

included) prior to attaching it to the enclosure. Apply a

circular bead of silicone adhesive to the inside of the

aluminum logo cap, 1/2-inch (13 mm) from the outer edge.

Blue

Blue

LED

LED

• For marine installations, do not connect the speaker’s LED lights to the vessel’s navigational lighting circuits.

• For short-circuit protection, install a supplied fuseholder onto EACH speaker’s BLUE (+12V) LED power connection lead.

• Connect all BLUE (+12V) leads together (parallel) and connect to a switched +12V supply. Connect all YELLOW (GND)

leads together and connect to a negative ground or to the NEGATIVE battery post.

• We recommend activating the speakers’ LEDs thru a lighting circuit that supplies +12V via an existing switch. If an

existing switched circuit is not available, you may install a dedicated toggle/rocker style switch that will supply positive

(+12V) power. Fuse this connection according to how many LED circuits you have (LED circuits x 150 mA).

Fuse

Fuse

Yellow

Yellow

Blue

Blue

Yellow

Yellow

Align the aluminum logo cap to the desired angle of

rotation, and press it onto the back of the enclosure.

Apply masking tape (not included) to hold the cap in

place until the silicone cures (at least 24 hours).

Example: One speaker pair of

LED circuits connected in parallel.

[GND ]

[+12V ]

Fuse

Loading...

Loading...