JL Audio M200/2 Owner's Manual

OWNER’S MANUAL

200W Marine 2-Channel Amplier

Thank you for purchasing a JL Audio amplifier for

your marine sound system.

Your amplifier has been designed and manufactured to exacting

standards in order to ensure years of musical enjoyment in your vehicle.

For maximum performance, we highly recommend that you have

your new amplifier installed by an authorized JL Audio dealer. Your

authorized dealer has the training, expertise and installation equipment

to ensure optimum performance from this product. Should you

decide to install the amplifier yourself, please take the time

to read this manual thoroughly so as to familiarize yourself

with its installation requirements and setup procedures.

If you have any questions regarding the instructions in this

manual or any aspect of your amplifier’s operation, please contact your

authorized JL Audio dealer for assistance. If you need further assistance,

please call the JL Audio Technical Support Department

at (954) 443-1100 during business hours.

PROTECT YOUR HEARING!

We value you as a long-term customer. For

that reason, we urge you to practice restraint in

the operation of this product so as not to damage

your hearing and that of others in your vessel.

Studies have shown that continuous exposure to

high sound pressure levels can lead to permanent

(irreparable) hearing loss. This and all other

high-power amplifiers are capable of producing

such high sound pressure levels when connected

to a speaker system. Please limit your continuous

exposure to high volume levels.

While driving, operate your audio system in

a manner that still allows you to hear necessary

noises to operate your vessel safely (horns,

sirens, etc.).

SERIAL NUMBER

In the event that your amplifier requires

service or is ever stolen, you will need to have

a record of the product’s serial number. Please

take the time to enter that number in the space

provided below. The serial number can be found

on the bottom panel of the amplifier and on the

amplifier packaging.

Serial Number:

INSTALLATION APPLICATIONS

This amplifier is designed for operation in

vessels with 12 volt, negative-ground electrical

systems. Use of this product in vessels with

positive ground and/or voltages other than 12V

may result in damage to the product and will void

th e w arra nty.

This product is not certified or approved for

use in aircraft.

Do not attempt to “ bridge” the outputs of this

amplifier with the outputs of a second amplifier,

including an identical one.

2 | JL Audio - XD200/2 Owner’s Manual

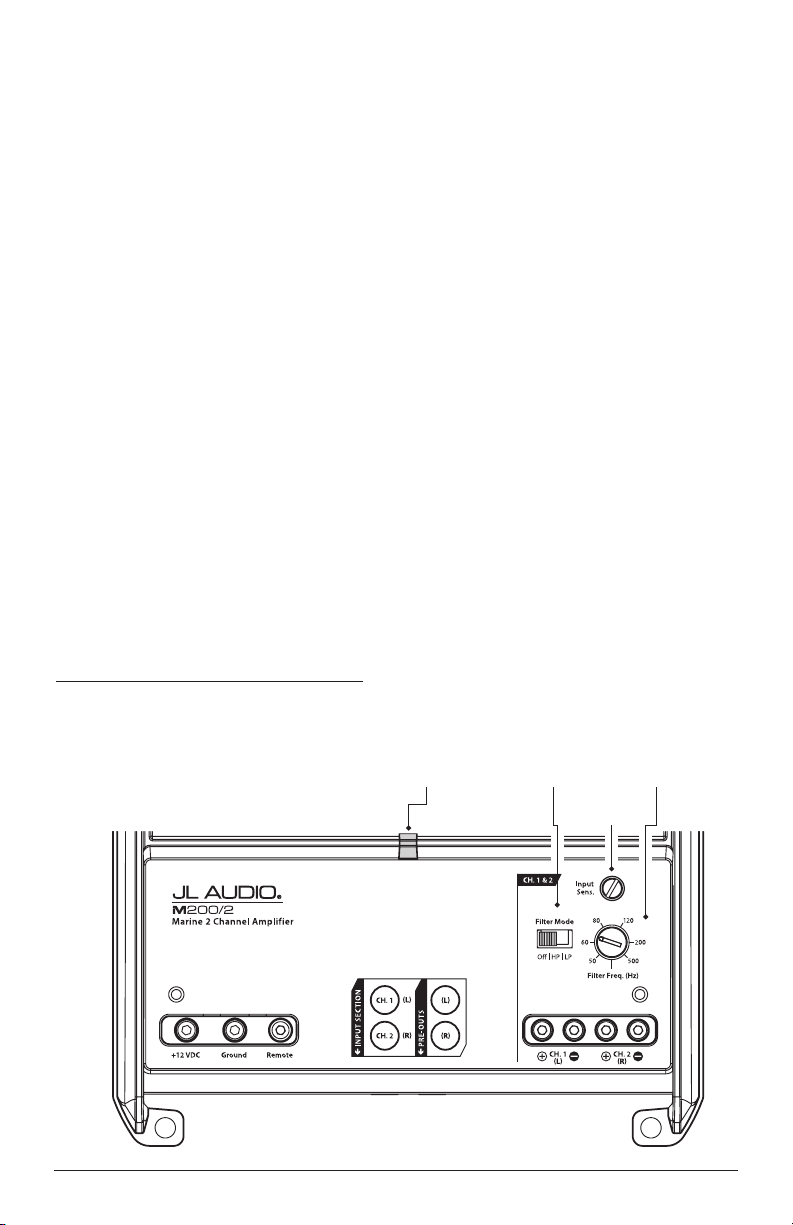

Status

LED

(pg. 11)

Ch. 1 & 2

Filter Mode

Selection

(pg. 8)

Ch. 1 & 2 Filter

Frequency

Ch. 1 & 2 Input

Sensitivity Control

(pg. 7)

Selector

(pg. 8)

PLANNING YOUR INSTALLATION

It is important that you take the time to read

this manual and that you plan out your

installation carefully. The following are some

considerations that you must take into account

when planning your installation.

Cooling Efficiency Considerations:

The outer shell of your JL Audio amplifier

is designed to remove heat from the amplifier

circuitry. For optimum cooling performance,

this outer shell should be exposed to as large a

volume of air as possible. Enclosing the amplif ier

in a small, poorly ventilated chamber can

lead to excessive heat build-up and degraded

performance. If an installation calls for an

enclosure around the amplifier, we recommend

that this enclosure be ventilated with the aid

of a fan. In normal applications, fan-cooling

is not necessary.

Mounting the amplifier upside down is

strongly discouraged.

Safety Considerations:

Your amplifier needs to be installed in a dry,

well-ventilated environment and in a manner

which does not interfere with your vessel’s factory

installed electronic devices. You should also take

the time to securely mount the amplifier using the

supplied screws so that it does not come loose in

the event of a collision or a sudden jolt to the vessel.

Stupid Mistakes to Avoid:

• Check before drilling any holes in your vessel to

make sure that you will not be drilling through

the hull, a fuel tank, fuel line, wiring harness or

other vital vessel system.

• Do not run system wiring outside or underneath

the vessel. This is an extremely dangerous

practice which can result in severe damage to

your vessel and person.

• Protect all system wires from sharp edges

(metal, fiberglass, etc.) by carefully routing

them, tying them down and using grommets

and loom where appropriate.

• Do not mount the amplifier in the engine

compartment or in any other area that will

expose the amplifier circuitry to the elements.

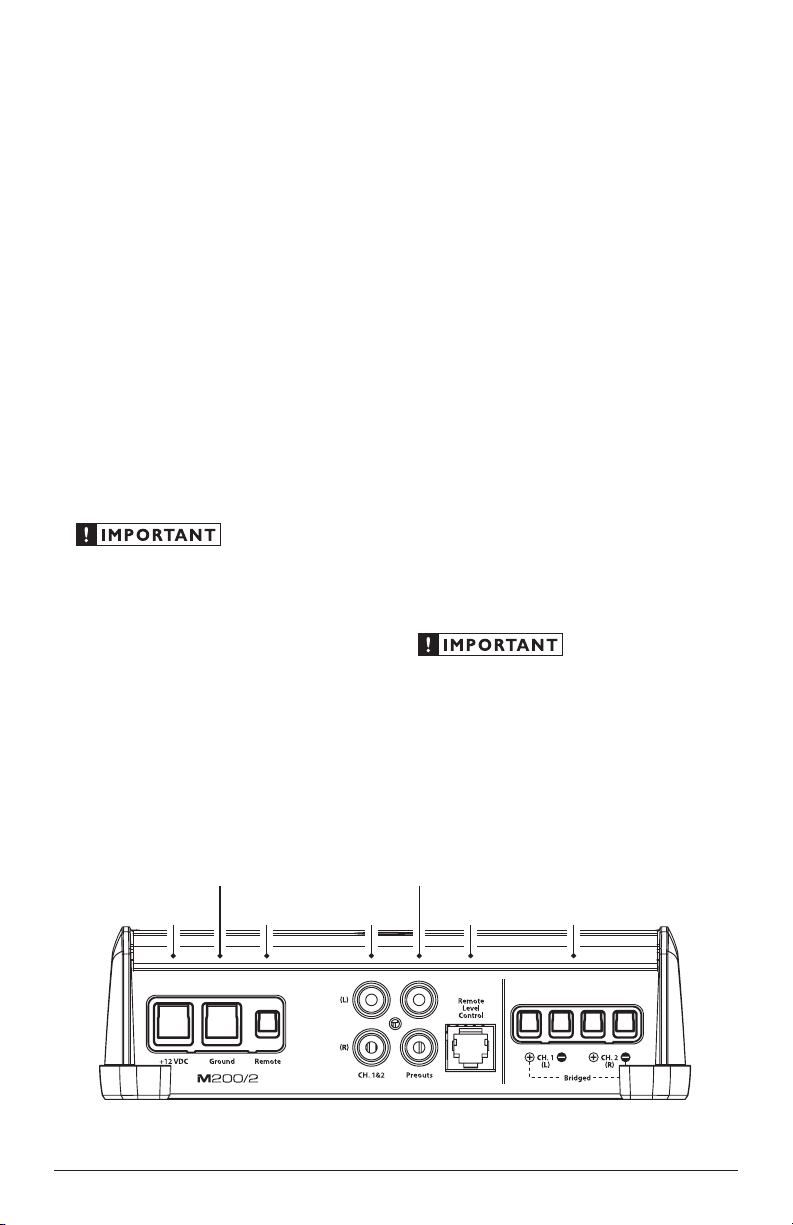

Chassis Ground

+12 V Power

Connector

(pg. 5)

Connector

(pg. 5)

Remote Turn-On

Connector

(pg. 6)

Left & Right Preamp

Output Jacks

Channels 1 & 2

Preamp Input Jacks

(pg. 6)

While this amplifier is specially designed

for marine applications, it is not waterproof

and it should not be mounted where it is

likely to get wet.

(pg. 9)

Jack for

Remote Level

Control Knob

(pg. 9)

Channels 1 & 2

Speaker Outputs

(pg. 10)

3

PRODUCT DESCRIPTION

The JL Audio M200/2 is a two-channel,

full-range audio amplifier utilizing JL Audio

NexD™ ultra-high speed switching technology to

deliver outstanding fidelity and efficiency.

The M200/2 can be operated with a wide

variety of source units and system configurations.

TYPICAL INSTALLATION SEQUENCE

The following represents the sequence for a

typical amplifier installation, using an aftermarket

source unit. Additional steps and different

procedures may be required in some applications.

If you have any questions, please contact your

authorized JL Audio dealer for assistance.

1) Disconnect the negative batter y post

connection and secure the disconnected cable

to prevent accidental re-connection during

installation. This step is not optional.

2) Run 8 AWG (minimum) power wire from the

battery location to the amplifier mounting

location, taking care to route it in such a

way that it will not be damaged and will not

interfere with vessel operation. Use 4 AWG

or larger power wire and a power distribution

block if additional amplifiers are being

installed with the M200/2.

3) Connect power wire to the positive battery

post. Fuse the wire with an appropriate fuse

block (and connectors) within 18 inches (45

cm) wire length of the positive battery post.

This fuse is essential to protect the vessel. Do

not install the fuse until the power wire has

been securely connected to the amplifier.

4) Connect negative power wire to the negative

battery post. Use the same size power

wire as the wire connected to the “+12V ”

connection (minimum 4 AWG).

5) Run signal cables and remote turn-on wire

from the source unit to the amplifier

mounting location.

6) Run speaker cable from the speaker systems

to the amplifier mounting location.

7) Securely mount the amplifier.

8) Connect the positive and negative power

wires to the amplifier. A fuse near the

amplifier is not necessary if the M200/2 is the

only device being run from the fused main

power wire. If the fused main power wire is

shared by the M200/2 and other amplifiers

or devices, fuse each amplif ier/device

within 12 inches (30 cm) of wire length,

via a fused distribution block or multiple

individual fuse blocks/on-board fuses.

9) Connect the remote turn-on wire

to the amplifier.

10) Connect the input cables to the amplifier.

11) Connect the speaker cables to the amplifier.

12) Carefully review the amplifier’s control

settings to make sure that they are set

according to the needs of the system.

13) Install the power wire fuse (20A for a

single M200/2) and reconnect the negative

battery post terminal. Install the fuse (20A)

near the amplifier (if applicable).

14) Turn on the source unit at a low level

to double-check that the amplifier is

configured correctly. Resist the temptation

to crank it up until you have verified the

control settings.

15) Make necessary adjustments to the input

sensitivity controls to obtain the right

overall output and the desired balance

in the system. See Appendix A (page 12)

for the recommended input sensitivity

setting method.

16) Enjoy the fruits of your labor with your

favorite music.

4 | JL Audio - XD200/2 Owner’s Manual

POWER CONNECTIONS

Before installing the amplifier, disconnect the

negative (ground) wire from the vessel’s battery.

This will prevent accidental damage to the system,

the vessel and your body during installation.

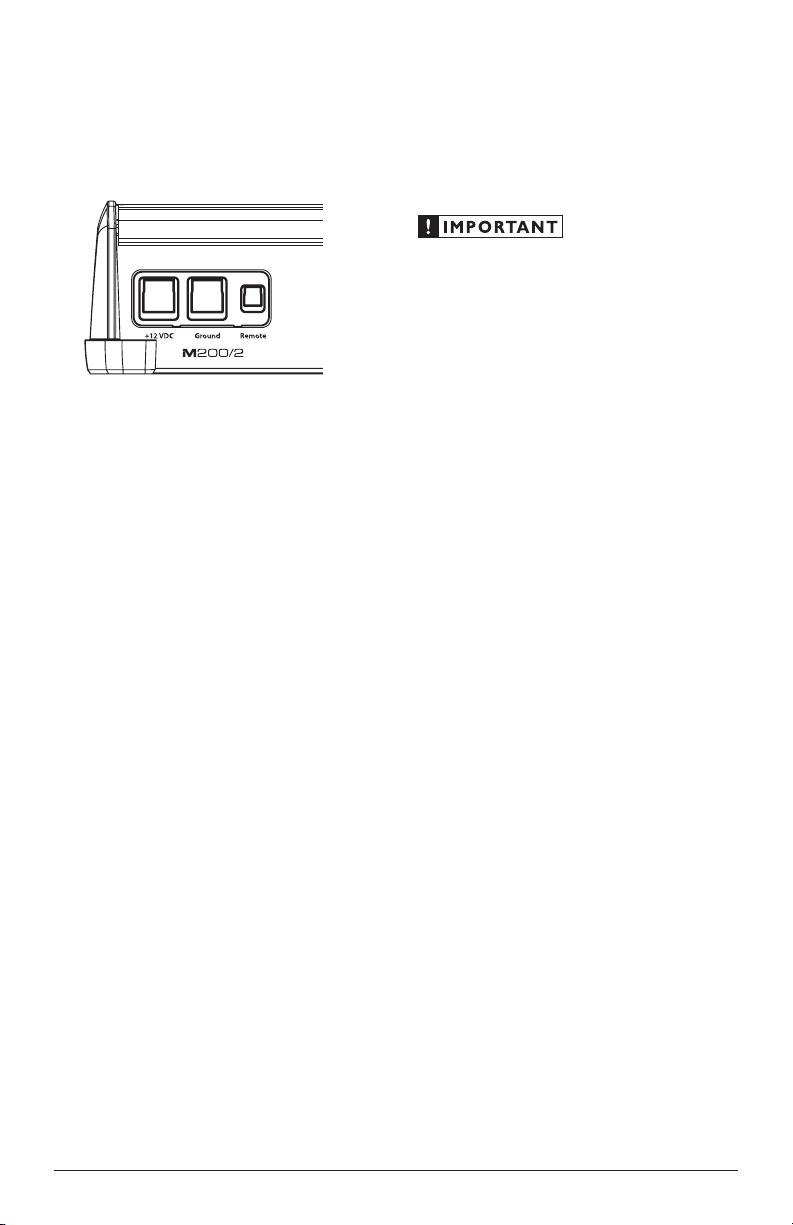

The M200/2’s “+12 V DC” and “Ground”

connections are designed to accept 8-4 AWG

power wire. 8 AWG is the minimum required

wire size for this amplifier.

If you are installing the M200/2 with other

amplifiers and wish to use a single main power

wire, use 4 AWG, 2 AWG or 1/0 AWG main

power wire (depending on the overall current

demands of all the amplifiers in the system).

This large power wire should terminate into a

fused distribution block mounted as close to

the amplifiers as possible (within 12 inches /

30cm of wire length). The fused output of the

distribution block will connect to the M200/2

with 8 or 4 AWG power wire. JL Audio ECS

fused distribution blocks are recommended

(XD-FDBU-2 and X D-FDBU-4)

Note: Smaller AWG numbers mean bigger

wire and vice-versa (1/0 AWG is the largest, 2

AWG is smaller, then 4 AWG, then 8 AWG, etc.).

Any wires run through barriers must

be protected with a high quality rubber

grommet to prevent damage to the

insulation of the wire. Failure to do so

may result in a dangerous short circuit.

Some vessels employ small (10 AWG -

6 AWG) wire to connect the alternator's

positive connection to the batter y. To prevent

voltage drops, these wires should be upgraded

to 4 AWG when installing amplifier systems

with main fuse ratings above 60A.

It is also common for the alternator to be

grounded through its chassis to the engine and

for the engine to be grounded to the battery or a

ground stud via a dedicated wire or strap. This

wire or strap should also be upgraded to 4 AWG or

larger when installing amplifier systems with main

fuse ratings above 60A.

FUSE REQUIREMENTS

It is absolutely vital that the main power

wire(s) to the amplifier(s) in the system be

fused within 18 inches (45 cm) of the positive

battery post connection. The fuse value at each

power wire should be high enough for all of the

equipment being run from that power wire. If

only the M200/2 is being run from that power

wire, we recommend a 20A fuse be used.

If fusing the amplif ier near its power

connections (when more than one amp is being

run from the main power wire), use a 20A fuse.

MAXI™ plastic-body fuses are recommended.

To connect the power wires to the amplifier,

first back out the set screw on the top of the

terminal block, using the supplied 2.5 mm hex

wrench. Strip 1/2 inch (12 mm) of insulation from

the end of each wire and insert the bare wire into

the terminal block, seating it firmly so that no

bare wire is exposed. While holding the wire in

place, tighten the set screw firmly, taking care not

to strip the head of the screw.

The ground connection should be made using

the same gauge wire as the power connection.

5

TURNON LEAD

The M200/2 uses a conventional +12V remote

turn-on lead, typically controlled by the source

unit's remote turn-on output. The amplifier will

turn on when +12V is present at its “Remote”

input and turn off when +12V is switched off. If

a source unit does not have a dedicated remote

turn-on output, the amplifier’s turn-on lead can

be connected to +12V via a switch that derives

power from an ignition-switched circuit.

The M200/2’s “Remote” turn-on connector is

designed to accept 18 AWG – 12 AWG wire. To

connect the remote turn-on wire to the amplifier,

first back out the set screw on the top of the

terminal block, using the supplied 2.5mm hex

wrench. Strip 1/2 inch (12mm) of wire and insert

the bare wire into the terminal block, seating it

firmly so that no bare wire is exposed. While

holding the wire in the terminal, tighten the set

screw firmly, taking care not to strip the head of

the screw and making sure that the wire (not the

insulation) is firmly gripped by the set screw.

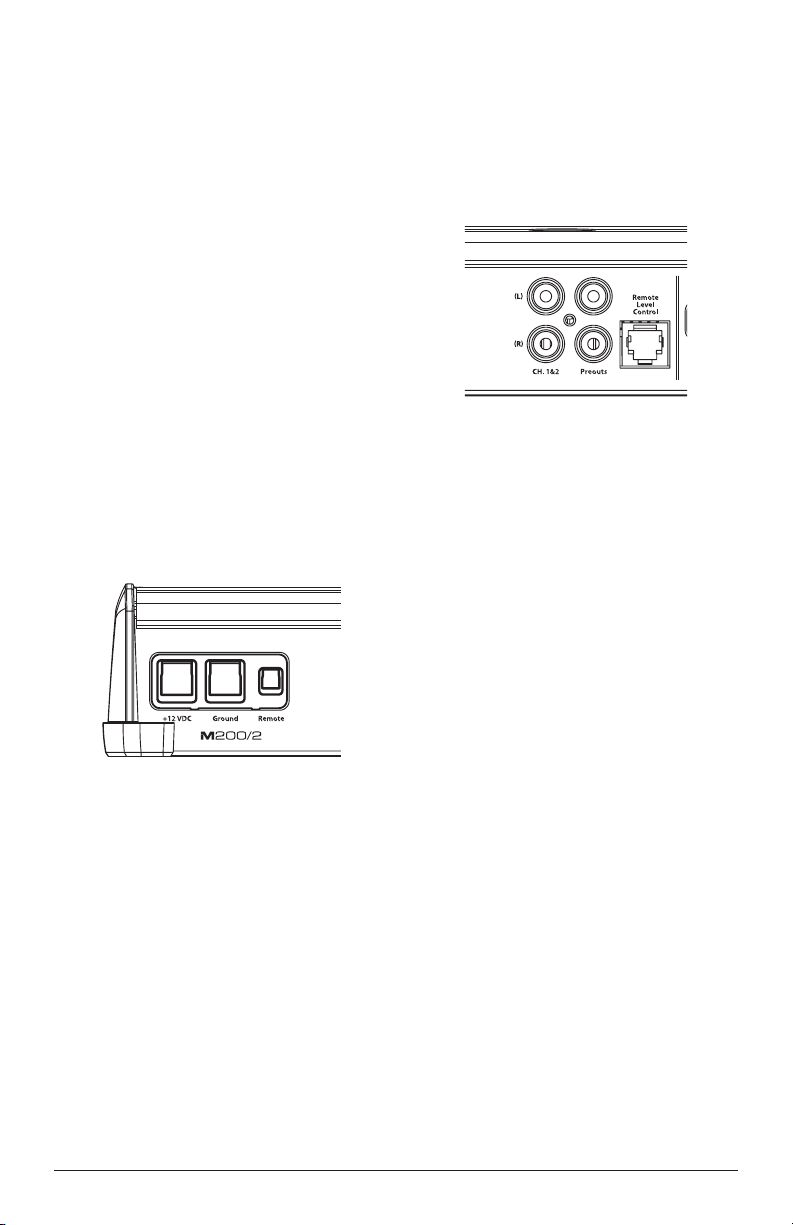

INPUT SECTION

The M200/2’s input section allows you

to send signals to the amplifier section

through the use of two differential inputs.

Input connections are via up to one pair of

traditional RCA-type jacks.

Input Voltage Range:

The M200/2’s input sections are designed to

accept signal voltages from 100mV – 4V. This

will accommodate all preamp level signals and

many speaker level signals.

To use speaker-level sources, simply splice

the speaker output wires of the source unit

onto a pair of RCA plugs. (or use JL Audio part

XD-CLRAIC2-SW) No “line output converter” is

needed in most cases.

If you find that the output cannot be reduced

suff iciently with a direct speaker level signal

applied to the amplifier, you may use a “line

output converter” to reduce the signal level.

6 | JL Audio - XD200/2 Owner’s Manual

Loading...

Loading...