Page 1

OWNER’S MANUAL

6.50-inch (165 mm) Component Woofer

Page 2

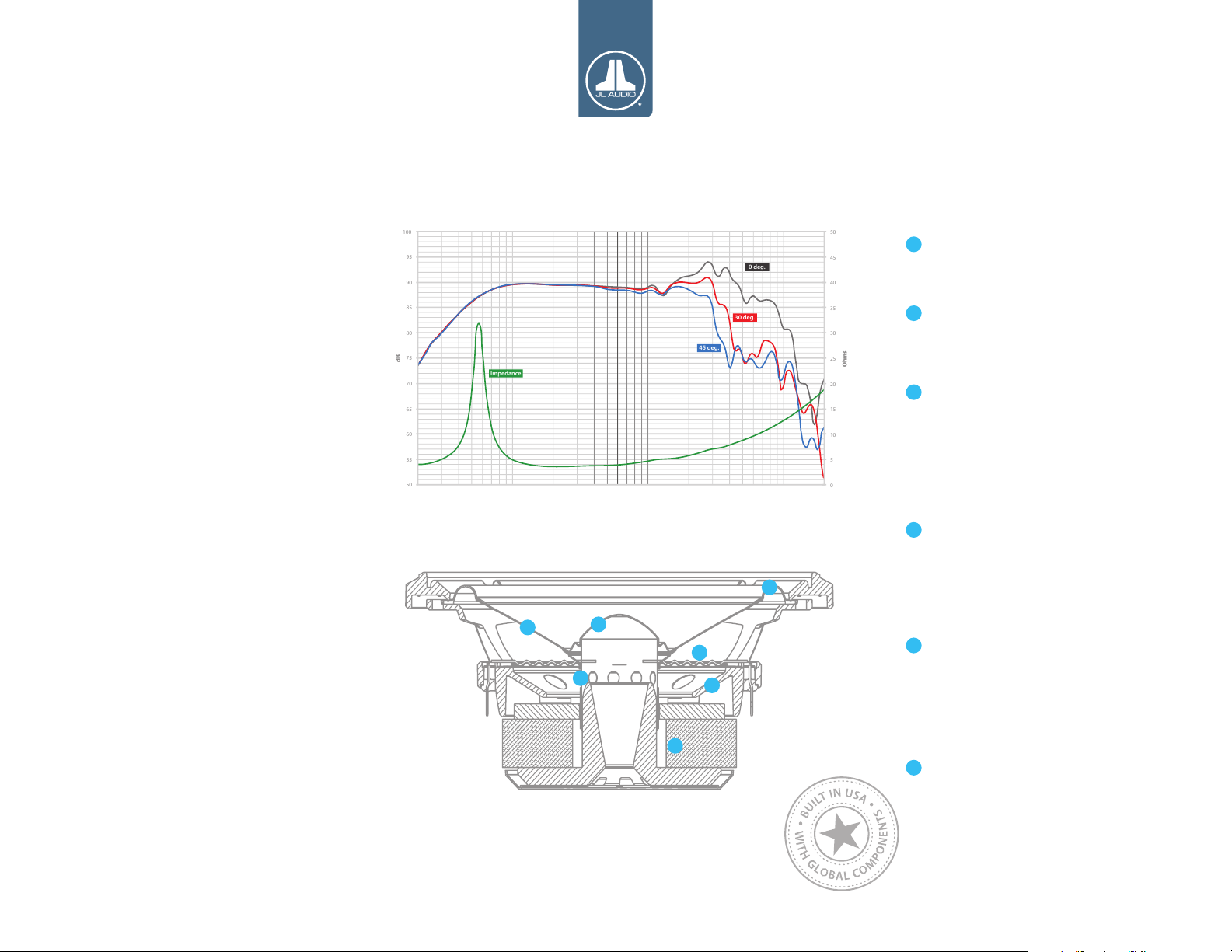

C7-650cw: 6.5-inch (165 mm) Component Woofer

0

5

10

15

20

25

30

35

40

45

50

50

55

60

65

70

75

80

85

90

95

100

OOhhmmss

ddBB

0 deg.

30 deg.

45 deg.

Impedance

INTRODUCTION

Thank you for choosing JL Audio C7 loudspeakers

for your automotive sound system. C7 is the

pinnacle of JL Audio loudspeaker design, benefitting

from patented technologies and our most advanced

development tools.

The C7-650cw is a component woofer capable

of operating in a 3-way system, with a midrange

and tweeter, or with only a tweeter in a 2-way

configuration. It has exceptional linear excursion

capability and outstanding linearity, resulting

in solid mid-bass and pure, precise mid-range

performance. Distortion and non-linearities have

been minimized through critical optimization of

dynamic motor and suspension behaviors.

We do not recommend the use of passive

crossover networks with C7 loudspeakers. Instead,

we recommend a high-quality tuning DSP and a

dedicated amplifier channel for each C7 loudspeaker

in the system. Precise setup of equalization, delay

and crossover filters will ensure optimal in-vehicle

performance.

Should you have any questions regarding the

instructions in this manual, please contact your

1

2

3

authorized JL Audio dealer for assistance, or contact

the JL Audio Technical Support Department.

INCLUDED COMPONENT & PARTS

• One (1) C7-650cw 6.50-inch (165 mm) woofer

• One (1) die-cast aluminum grille tray

• One (1) fine mesh steel grille

• One (1) spiral steel grille

• One (1) 6.35 mm female crimpable connector

• One (1) 4.7 mm female crimpable connector

• Eight (8) #8 x 1.25-inch (32 mm) sheet metal screws

2

5

6

4

3

DESIGN & TECHNOLOGIES

Cone and Dust Cap:

Vacuum-formed, mineral-filled polypropylene

1

material offers excellent damping and low mass.

The cone body features a gentle curvilinear

profile to optimize response.

A specially shaped dust cap attaches to the cone

2

body and the voice coil former to improve high

frequency behavior.

Suspension Design:

The moving assembly is suspended and

3

damped via a large-diameter, linear profile

spider formed from a Nomex®/polycotton

blend, and a positive-roll, rubber surround. The

two combine to provide optimum damping

without prematurely restricting the C7-650cw’s

outstanding excursion capability.

Motor Design:

The C7-650cw employs a high-density magnetic

4

circuit with a high-grade Y35 Strontium-ferrite

magnet, and a specially machined, T-Yoke motor

topology. Motor magnetics have been precisely

optimized utilizing advanced FEA tools to

reduce distortion and provide linear motor force

throughout the driver’s performance range.

A 32 mm (1.27 inch) diameter, overhung voice

5

coil is employed, wound with copper wire onto

a fiberglass voice coil former. The oversized

voice coil offers extended power handling

capability, minimizing thermal compression

and distortion at higher listening levels.

Chassis Design:

A purpose-engineered cast alloy basket is

6

employed, featuring thin spokes to maximize

rear open area, and our Patented Elevated

Frame Cooling technology.

Built in USA with Global Components

Page 3

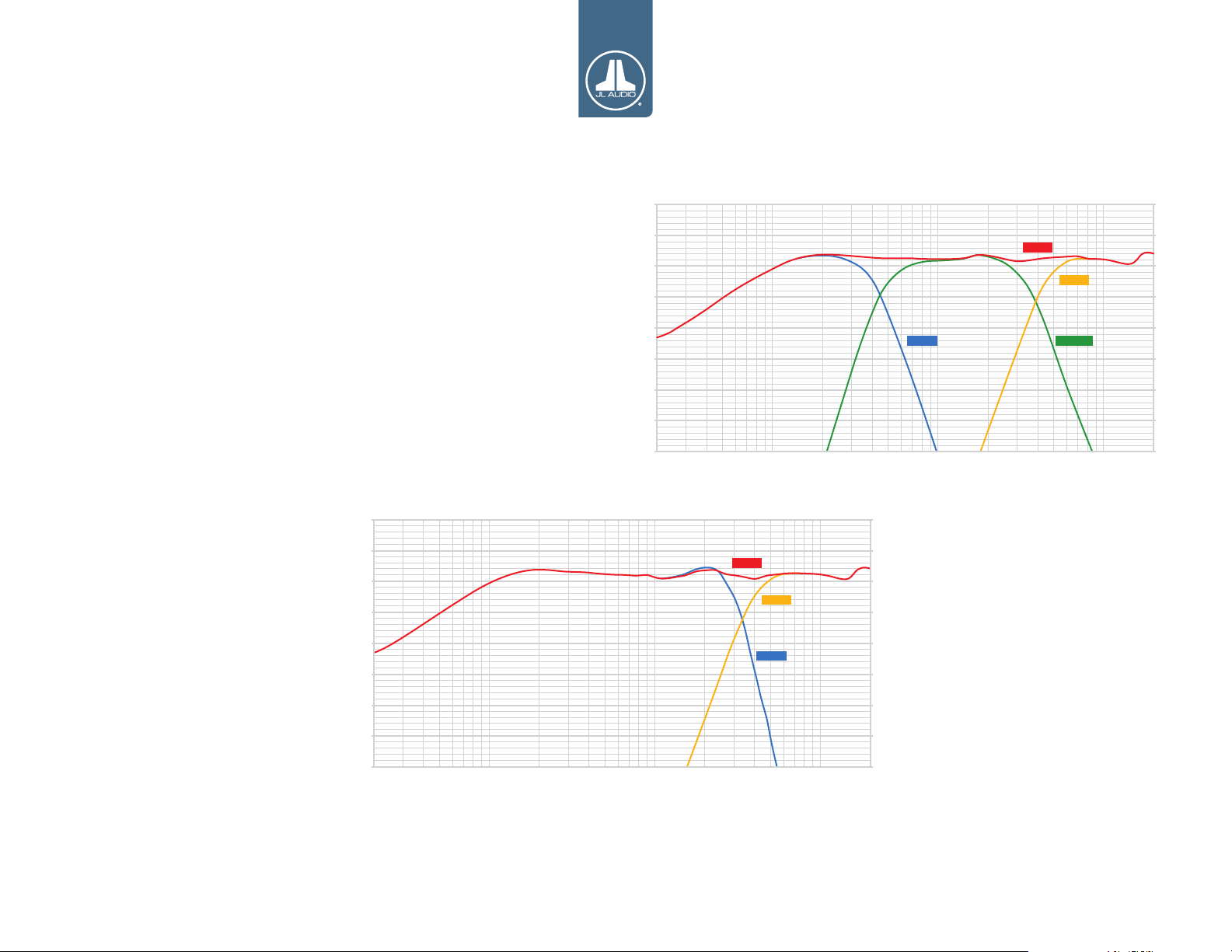

C7-650cw: Specifications and Crossover Setting Guidelines

95

dB SPL

C7650cw SPECIFICATIONS

Speaker Type: Component Woofer

Nominal Diameter: 6.5 in. (165 mm)

Nominal Impedance (Znom): 4 ohms

Continuous Power Handling: 125 W

Recommended Amplifier Power: 50-175W (RMS)

Net Weight: 3.28 lbs. (1.49 kg)

Driver Rear Displacement: 0.0135 cu.ft. (0.382 liter s)

Min. Recommended Sealed Enclosure:

0.424 cu.ft. (12 liters)

Parameters:

Voice Coil Resistance (Re): 3.11 4 oh ms

Free Air Resonance (Fs): 54.5 Hz

Reference Efficiency (no): 0.304%

Efficiency: 87.0 dB @ 1W/1m | 93.0 dB @ 1W/0. 5m

Sensitivity: 90.0 dB @ 2.8 3V/1m

Electrical “Q” (Qes): 0.669

Mechanical “Q” (Qms): 6.265

Total Speake r “Q” (Qts): 0.605

Equivalent Compliance (Vas): 0.461 cu.ft. (13.05 liters)

Moving Mass (Mms): 17.67 9 g

Mechanical Compliance (Cms): 0.000482 m/N

Magnetic Strength (BL): 5.31 N /A

Effective Piston Area (Sd): 21.4 sq.in. (0.013807 sq. m)

One-Way Linear Excursion (Xmax): 5 mm

Design Bandwidth:

With 48 dB/oc tave filters: 50 Hz - 5 kHz

With 24 dB/octave f ilters: 60 Hz - 5 kHz

With 12 dB/octave filters: 70 Hz - 5 kHz

C7 3-Way Speaker System

Low-Pass: 24 dB/octave Linkwitz-Riley @ 400 Hz

High-Pass: 24 dB/octave Linkwitz-Riley @ 480 Hz

Low-Pass: 24 dB/octave Linkwitz-Riley @ 3500 Hz

High-Pass: 24 dB/octave Linkwitz-Riley @ 4500 Hz

Please note: These are recommended starting points

for tuning. In-vehicle measurements should be made to

optimize the crossover for speaker placement and vehicle acoustics.

90

85

80

75

dB SPL

70

65

60

55

C7-650cw Woofer

Level Offset: 0 dB

C7-350cm Midrange

Level Offset: 0 dB

C7-100ct Tweeter

Level Offset: -1.0 dB

95

90

85

80

75

70

65

60

55

Sum

Tweeter

C7 2-Way Speaker System

Sum

Tweeter

MidrangeWoofer

20 kHz10 kHz5 kHz1 kHz 2 kHz100 Hz50 Hz 200 Hz 500 Hz20 Hz

C7-650cw Woofer

Low-Pass: 24 dB/octave Linkwitz-Riley @ 2700 Hz

Woofer

Level Offset: 0 dB

C7-100ct Tweeter

High-Pass: 24 dB/octave Linkwitz-Riley @ 4000 Hz

Level Offset: -1.0 dB

Please note: These are recommended starting points

for tuning. In-vehicle measurements should be made to

optimize the crossover for speaker placement and vehicle acoustics.

20 kHz10 kHz5 kHz1 kHz 2 kHz100 Hz50 Hz 200 Hz 500 Hz20 Hz

3

Page 4

C7-650cw: Dimensions

7. 20 i n.

183 mm

0.98 in.

25 mm

6.12 in.

156 m m

4

5.56 in.

141 mm

6.50 in.

165 mm

3.94 in.

100 m m

2.77 in.

70 mm

Page 5

C7-650cw: Installation

CROSSOVER CONSIDERATIONS

Passive crossover networks are not included with

C7 drivers, as they are designed for active systems.

Actively configured systems allow all filtering and/or

equalization to be configured prior to reaching the

amplifier, thus avoiding the technical compromises

of passive crossover networks. The result is

linear, crystal clear audio output and minimal

distortion. For optimum performance, we strongly

recommend the use of a high-quality DSP and a

dedicated amplifier channel.

SPEAKER WIRING

If you will be using the factory speaker wires, it

may be necessary to change the terminations. This

may be accomplished by using an adaptor plug

or simply by cutting the factory connector off and

using the supplied crimp connectors to terminate

the speaker wires. The larger connector is for the

positive terminal and the smaller connector is for the

negative terminal of the C7-650cw.

If you choose to run new speaker wires, protect

all wiring from sharp edges by carefully routing

them, securing them and using grommets and loom

where appropriate. If you are running wires into a

door, use existing factory wiring boots whenever

possible. If you are drilling new holes, file their edges

and install rubber grommets into each hole. Wires

running into car doors should be covered with a

protective, flexible PVC sleeve. Make sure that the

wires will clear door hinges and other structures in

the door.

SPEAKER INSTALLATION

The speakers should be installed in one of the

following ways depending on location:

Factory Location: Your new speakers have been

designed to install, without modifications, into most

vehicles that accept a 6.50-inch (165 mm) speaker.

Most factory 6.50-inch speakers use four mounting

screws which will line up with the mounting holes

on your woofers.

It is absolutely vital that the speaker frame fits into

the mounting hole cleanly. This must be checked

prior to tightening the screws. Do not force the

frame into a hole that is too small. Do not tighten the

speaker onto an uneven mounting surface. This will

damage your speakers. The speaker should also fit so

that air does not leak around the mounting flange.

Air leaks will cause a severe degradation in sound

quality. Seal any air leaks with an automotive-grade

sealant material. Hand-tighten the screws evenly in

a criss-cross pattern to avoid bending the speaker

frame or stripping the mounting screw holes. (See

Diagram C).

Custom Location: Select a desired mounting

location with an even surface. Tightening a

speaker onto an uneven mounting surface can

damage it. Mark the center and the outline of the

speaker’s mounting hole. Before drilling or cutting

on your interior panels, use a utility knife to cut

any fabric, vinyl or leather from hole locations.

These materials can easily be snagged by a drill or

a saw, causing damage to the panel and possible

bodily injury. Drill a pilot hole in the center of the

proposed speaker mounting hole. Then, using

an appropriate cutting tool, make the circular

cut out for the speaker. File any rough edges.

After cutting the hole, check to see that

the speaker frame fits into its mounting

hole cleanly. Do not force the frame into a hole

that is too small. Once the speaker is in place, use

the holes on the speaker’s mounting flange to

mark the panel where the four mounting screws

will be positioned (See Diagram D). Remove the

speaker and drill 1/8-inch (3 mm) holes at each

mark. Connect the speaker wires, observing correct

polarity, and secure the speaker and grille tray to the

panel by evenly tightening by hand the provided #8

x 1.25 inch (32 mm) mounting screws. Make sure the

speaker is secured so that air does not leak around

the mounting flange. Air leaks will cause a severe

degradation in sound quality. Seal any air leaks with

an automotive-grade sealant material.

Finally, select your preferred grille style and

insert it into the grille tray, pressing around

its edge until seated firmly in the tray.

5

Page 6

Diagram C:

!!

Factory Location Speaker Installation

C7-650cw: Installation

Diagram D:

Custom Location Speaker Installation

WARNING

Hand-tighten the screws evenly in a

criss-cross pattern to avoid bending

the speaker frame or stripping the

mounting screw holes.

6

Page 7

C7-650cw: Installation Notes

7

Page 8

C7-650cw-MAN 012518

Limited Warranty

JL AUDIO warrants this speaker to be free of defects in materials and

workmanship for a period of one (1) year from the original date of purchase.

This warranty is not transferrable and applies only to the original purchaser

of the product from an authorized JL AUDIO dealer. Should service be necessary

under this warranty for any reason due to manufacturing defect or malfunction,

JL AUDIO will, at its discretion, repair or replace the defective product with new

or remanufactured product at no charge.

Damage caused by the following is not covered under warranty: accident,

misuse, abuse, product modification or neglect, failure to follow installation

instructions, unauthorized repair attempts, misrepresentations by the seller.

This warranty does not cover incidental or consequential damages and does not

cover the cost of removing or reinstalling the unit(s). Cosmetic damage due to

accident or normal wear and tear is not covered under warranty.

Any applicable implied warranties are limited in duration to the period of

the express warranty as provided herein beginning with the date of the original

purchase at retail, and no warranties, whether express or implied, shall apply

to this product thereafter. Some states do not allow limitations on implied

warranties, therefore these exclusions may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from

state to state.

If you need service on your JL AUDIO product:

All warranty returns should be sent to JL AUDIO freight prepaid through an

authorized JL AUDIO dealer and must be accompanied by proof of purchase

(a copy of the original sales receipt). Direct returns from consumers or nonauthorized dealers will be refused unless specifically authorized by JL AUDIO

with a valid return authorization number. Warranty expiration on products

returned without proof of purchase will be determined from the manufacturing

date code. Coverage may be invalidated as this date is previous to purchase

date. Return only defective components. Non-defective items received will be

returned freight-collect. The customer is responsible for shipping charges and

insurance in sending the product to JL AUDIO. Freight damage on returns is not

covered under warranty. Always include proof of purchase (sales receipt).

For Service Information in the U.S.A. please call:

JLAudio customer service: (954) 443-1100 during

normal business hours (Eastern Time)

JLAudio, Inc

10369 North Commerce Parkway, Miramar, FL 33025

International Warranties:

Products purchased outside the United States of America are covered only by

that country’s distributor and not by JLAudio, Inc.

www.jlaudio.com

10369 North Commerce Parkway • Miramar, Florida • 33025 • USA

“How we pla y.”, “Ahead of the Curve ”, “JLAudio” and the J LAudio logo are regi stered tradem arks of JLAudio, In c.

©2017 JLAudio, Inc. • For mo re detailed in formation ple ase visit us onlin e at www.jlaudio.com. Due to our polic y of continuous pr oduct develo pment, all spe cification s are subject to cha nge without no tice.

“C7” and it s respective l ogo are trademar ks of JLAudio, Inc .

Loading...

Loading...