Page 1

Subwoofer Specifi cations

8W6

32.5 Hz

0.466

0.511

5.500

3

ft

in.

83.6 dB

2

in

Dual 6 Ω

200 Watts

liters

mm

m

2.30 65.1

0.469 11.9

2

53.6 0.0346

Fs (free-air resonance):

Qts (total speaker “Q”):

Qes (electrical “Q”):

Qms (mechanical “Q”):

Vas (equivalent compliance):

Xmax (linear excursion one-way):

Effi ciency (1W/1m)*:

Sd (effective piston surface area):

Re (DC resistance):

Znom (nominal impedance):

Pt (continuous thermal power handling):

0.79 22.4

0.388 9.9

30.7 0.0198

10.6 Ω (in series)

*Effi ciency (1W/1m) is not an accurate indicator of a subwoofer’s output capability and should not be used as a

comparison to other subwoofers to determine which one is “louder”!

10W6

23.2 Hz

0.432

0.463

6.567

ft

in.

3

liters

mm

84.2 dB

2

in

10.8 Ω (in series)

Dual 6 Ω

300 Watts

5.73 162.3

0.438 11.1

2

82.5 0.0532

m

10.8 Ω (in series)

300 Watts

12W6

20.9 Hz

0.433

0.462

6.897

3

ft

in.

86.9 dB

2

in

Dual 6 Ω

mm

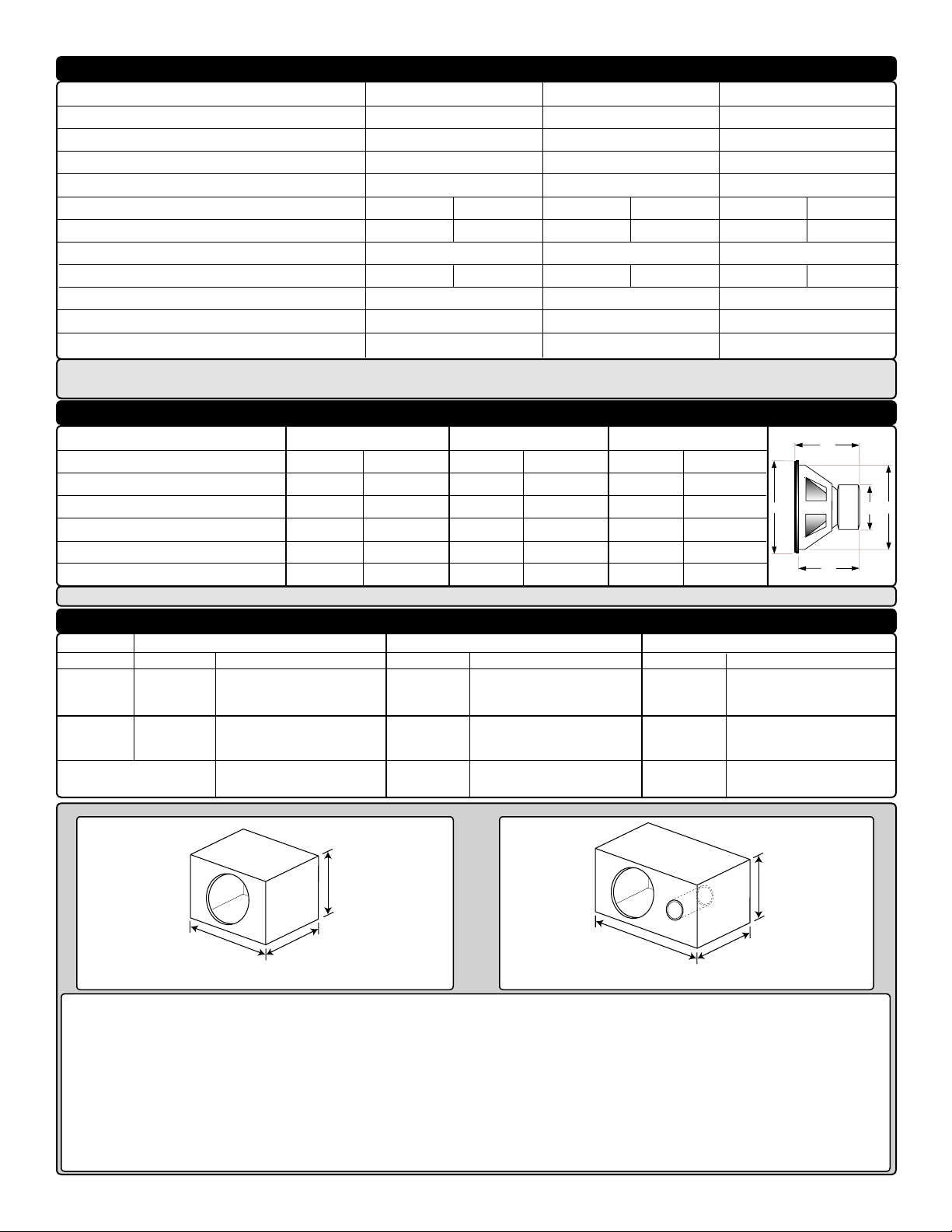

Physical Dimensions

8W6

Frame Diameter (A):

Mounting Hole Diameter (B):

Mounting Depth (C):

Overall Depth (D):

Magnet Diameter (E):

Displacement:

8.25

7

4.25

4.6875

4.875

0.035

in.

in.

in.

in.

in.

ft

3

209.55

177.8

107.95

119.06

123.82

0.989

mm

mm

mm

mm

mm

liters

10.125

9.125

4.875

0.06

Be sure to allow 0.75 inches (19mm) for pole vent clearance on this driver.

10W6 12W6

5.5

6.5

in.

in.

in.

in.

in.

ft

257.17

231.77

123.82

139.7

165.1

3

1.696

mm

mm

mm

mm

mm

liters

11.0625

12.25

5.625

6.5

6.5

0.085

in.

in.

in.

in.

in.

ft

311.15

280.98

142.87

165.1

165.1

3

2.403

mm

mm

mm

mm

mm

liters

D

A

C

liters

m

E

2

B

Normal Recommended Enclosures (single driver)

Model

Sealed

Enclosure

Ported

Enclosure

0.375 ft

10.6 l

0.625 ft

17.7 l

Port

(inside dia. X length)

Sealed Enclosure

•Enclosure dimensions listed are external dimensions which assume the use of 0.75 inch (19mm) thick material. If you are using

0.625 inch (16mm) thick material, subtract 0.25 inches (6.5mm) from each dimension. Do not use material with a thickness of

less than 0.625 inches (16mm).

•Enclosure volumes listed are NET internal volumes. Driver displacement, port displacement and brace displacement must be

added to obtain the fi nal gross volume. The dimensions listed have already taken this into account.

•When using two subwoofers in a common enclosure simply double the required volumes and use two of the recommended ports

(when needed). Likewise, when using three subwoofers in a common enclosure simply triple the required volume and number

of ports (when needed).

8W6

width X height X depthVolume (Net Int.)

3

3

16” x 9” x 8”

406mm x 229mm x 203mm

15” x 10” x 12.25”

381mm x 254mm x 311mm

2.5” X 15.4”

64mm X 391mm

W

D

10W6

width X height X depthVolume (Net Int.)

17.7 l

28.3 l

3

3

18” x 11” x 9”

457mm x 279mm x 229mm

17” x 12” x 13.75”

432mm x 305mm x 349mm

1.25 ft

35.4 l

2.25 ft

63.7 l

0.625 ft

1.00 ft

3” X 18.6”

76mm X 472mm

H

W

Ported Enclosure

12W6

3

3

width X height X depthVolume (Net Int.)

18” x 13” x 13.75”

457mm x 330mm x 349mm

20” x 14” x 17.75”

508mm x 356mm x 451mm

TWO 2.5” X 13.6”

TWO 64mm X 345mm

H

D

Page 2

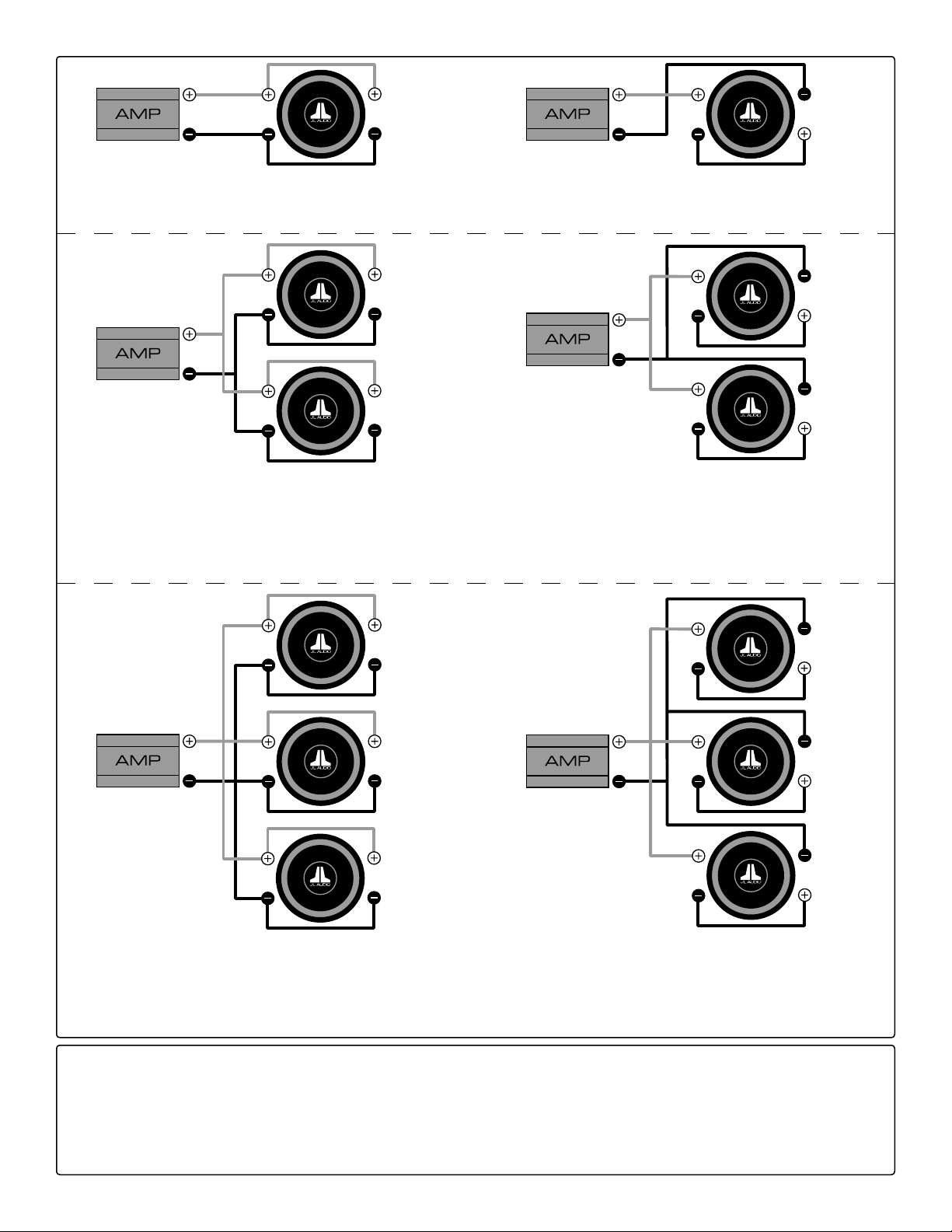

With coils wired in parallel, a dual 6Ω speaker will present a 3Ω load.

With coils wired in series, a dual 6Ω speaker will present a 12Ω load.

With coils AND speakers wired in parallel:

2 dual 6Ω speakers (D6) will present a 1.5Ω load.

With the coils wired in series and the speakers wired in parallel:

2 dual 6Ω speakers (D6) will present a 6Ω load.

With coils AND speakers wired in parallel:

3 dual 6Ω speakers (D6) will present a 1Ω load.

With the coils wired in series and the speakers wired in parallel:

3 dual 6Ω speakers (D6) will present a 4Ω load.

•Do NOT use different impedance speakers when using multiple subwoofers!

•JL Audio recommends using subwoofers as part of a bi-amplifi ed system using high quality satellite speakers like our Evolution line

of coaxial and component speakers. We do not recommend the use of passive crossover components (coils) on subwoofers. These

components may adversely affect the performance of a subwoofer.

•When dealing with exceedingly long port lengths, we recommend the use of JL Audio’s Flex-Port System. The Flex-Port tubing is

fl exible, allowing it to fi t in otherwise tight locations. The Port mouths provide not only a convenient method of securing the port,

but a smooth, rounded edge for the port termination as well.

Loading...

Loading...