Page 1

10W6v2-D4 12W6v2-D4 13W6v2-D4

Subwoofers

owner’s manual

Congratulations on your purchase of a JL Audio subwoofer component. Your JL Audio subwoofer is a

precision loudspeaker which has been engineered to produce the highest quality sub-bass performance

in your vehicle. Authorized JL Audio dealers have extensive technical information for many different

applications of your new speaker. They also have the knowledge, skills and tools to build a high-quality

enclosure that will maximize the performance of your speaker. We highly recommend that you have

your enclosure built by an authorized JL Audio dealer.

Inside you will find specifications and two recommended enclosures for your speaker; one is a sealed

enclosure, the other is a ported design. Both types of enclosures will give you excellent sound quality and

low-frequency extension. The sealed enclosure is a better choice if space is extremely tight, but the ported

enclosure will produce 3dB more output at the same power if you have the extra space to work with.

Page 2

SUBWOOFER SPECIFICATIONS

SUBWOOFER: 10W6v2-D4 12W6v2-D4 13W6v2-D4

Free Air Resonance (Fs): 28.5 Hz 25.0 Hz 24.3 Hz

Electrical “Q” (Qes): 0.497 0.480 0.464

Mechanical “Q” (Qms): 8.458 7.100 6.700

Total Speaker “Q” (Qts): 0.469 0.450 0.434

Equiv. Compliance (Vas): 1.18 ft3 2.82 ft

3

3.94 ft

33.4 litres 79.9 litres 111.6 litres

One-way, Linear Excursion: 0.60 in 0.65 in 0.85 in.

(Xmax)* 15.2 mm 16.5 mm 21.6 mm

Efficiency (1W/1m)**: 83.7 dB SPL 85.9 dB SPL 87.4 dB SPL

Effective Piston Area (Sd): 51.4 in2 77.8 in

2

100.4 in

0.0332 m2 0.0502 m2 0.0648 m

DC Resistance (Re)***: 6.30Ω 6.75Ω 6.50Ω

Nominal Impedance: Dual 4Ω Dual 4Ω Dual 4Ω

Power Handling (continuous): 600W 600W 750W

Mounting Depth: 6.9 in 7.6 in 9.2 in

175 mm 193 mm 234 mm

Mounting Hole Diameter: 9.0 in 11.0 in 12.5 in

229 mm 279 mm 318 mm

Driver Displacement: 0.068 ft3 0.090 ft

3

0.120 ft

1.9 litres 2.5 litres 3.4 litres

* Xmax specifications are derived via one-way voice coil overhang method with

no correction factors applied.

** Efficiency (1W/1m) is not an accurate indicator of a subwoofer’s output

capability and should not be used as a comparison to other subwoofers to

determine which one is “louder” !

*** Re (DC resistance) is mea sured with the voice coils in series , for parallel-

wired specification divide Re by 4. All other specifications remain the same.

3

• The W6v2’s employ a pole vent to remove heat and pressure from the inside of the

speaker. This vent is located around the JL Audio badge at the rear of the speaker. A

minimum distance of 3/4-inch (20mm) is required between the back of the speaker

and any wall of the enclosure to allow proper operation of the pole vent.

• The enclosure recommendations listed are external dimensions which assume the

use of 3/4" (19mm) thick material. If you are using 5/8" (16mm) thick material, subtract

2

1/4" (6.5mm) from each dimension. Do not use any material with a thickness of less

2

than 5/8" (16mm) as this may compromise the rigidity of the enclosure.

• All enclosure volumes listed are net internal volumes! Box volume displacement,

port displacement and brace displacement must be added to obtain the final gross

internal volume. All enclosure dimensions listed have already taken this into account.

• When using two subwoofers in a common enclosure simply double the

required volume and, in the case of a ported enclosure, use two times the

recommended port(s).

• We recommend the use of this speaker in a bi-amplified system using high-

quality satellite speakers and amplifiers. We do not recommend the use of this

3

subwoofer with a passive crossover (coil), as this type of device will adversely

affect performance.

RECOMMENDED ENCLOSURES

SUBWOOFER SEALED ENCLOSURE PORTED ENCLOSURE

Volume External Dimensions Volume Enclosure External Dimensions Slot Port Internal Dimensions

(net int.) (Width x Height x Depth) (net int.) (Width x Height x Depth) (Slot W idth x Slot Height x Slot Length)

3

10W6v2-D4

17.7 litres 368mm x 305mm x 260mm 21.2 litres 559mm x 305mm x 273mm 32mm x 267mm x 762mm

12W6v2-D4

35.4 litres 457mm x 356mm x 324mm 42.5 litres 667mm x 356mm x 330mm 38mm x 318mm x 737mm

13W6v2-D4

46 litres 457mm x 406mm x 359mm 53.1 litres 479mm x 419mm x 473mm 44mm x 381mm x 702mm

CAUTION

!! !!

Prolonged exposure to sound

pressure levels in excess of 100dB can

cause permanent hearing loss. This highperformance speaker can exceed this level.

Please exercise restraint in its operation

in order to preserve your ability to enjoy

its fidelity.

When installing a subwoofer in your

vehicle, it is extremely important to secure

the enclosure firmly. We recommend

bolting the enclosure through the metal of

the floorpan or the frame of the

vehicle with large diameter washers for

reinforcement. If an enclosure is not firmly

attached, it can become a projectile in a

collision. This is particularly impor tant in

a hatchback, station wagon, sports utility

vehicle, or van.

2 JL AUDIO 10W6v2-D4/12W6v2-D410W6v2-D4/13W6v2-D4

0.625 ft

1.25 ft

1.625 ft

14.5" x 12" x 10.25" 0.75 ft

3

18" x 14" x 12.75" 1.50 ft

3

18" x 16" x 14.125" 1.875 ft

3

3

3

22" x 12" x 10.75" 1.25" x 10.5" x 30"

26.25" x 14" x 13" 1.5" x 12.5" x 29"

18.875" x 16.5" x 18.625" 1.75" x 15" x 27.625" 35.4 litres

“EL” (Port Extension Length):

10W6v2: 17.25" (438mm)

12W6v2: 16" (406mm)

13W6v2: 9.75" (248mm)

All specifications are subject to change without notice.

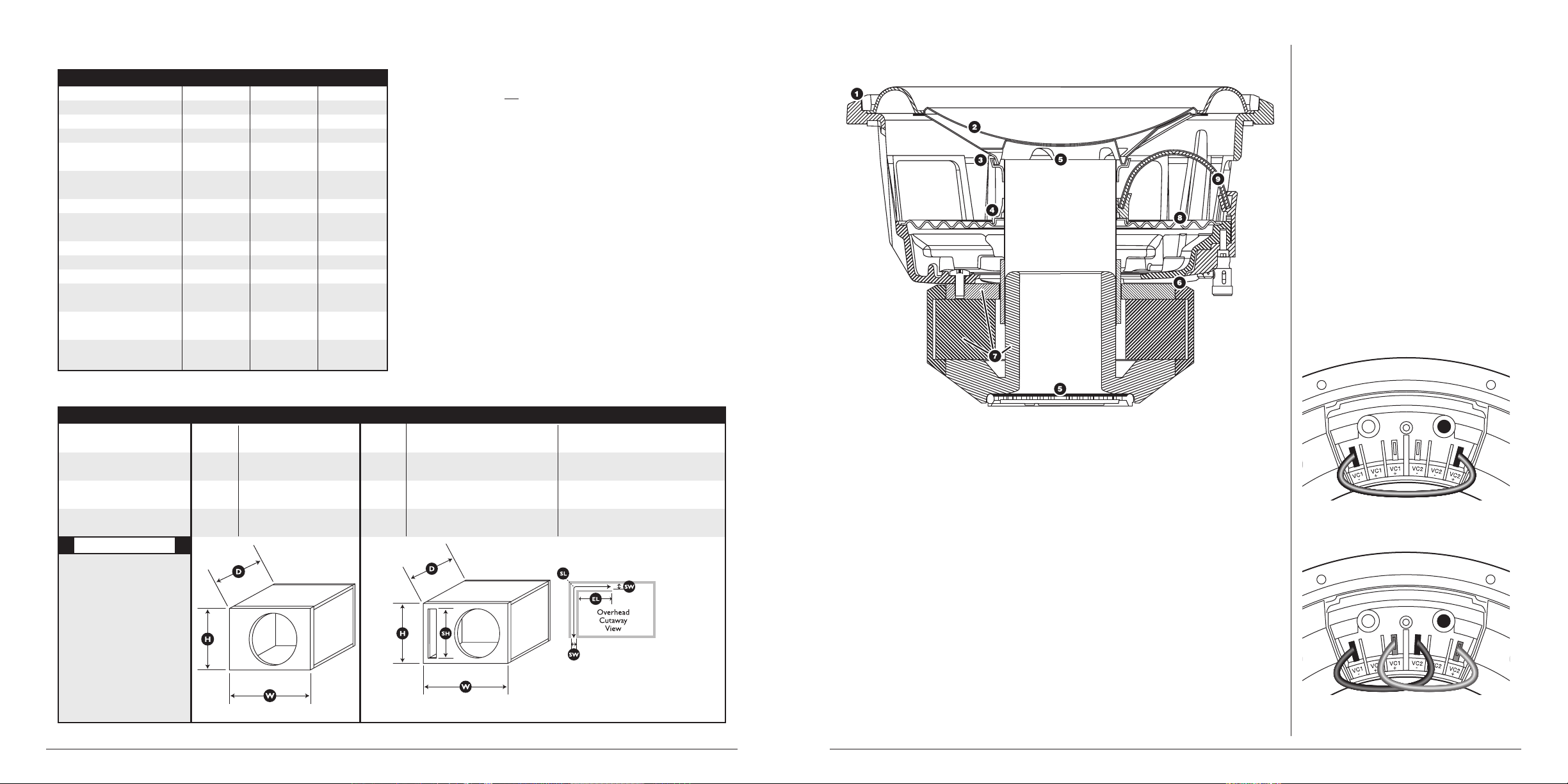

W6v2 TECHNOLOGIES W6v2 TERMINAL JUMPER SYSTEM

Please note that the W6v2 is a dual voice coil driver.

BOTH voice coils must be connected to the amplifier

(in series or parallel) for the speaker to operate

properly. To accomplish this, each W6v2 features a

pair of main input connection push-terminals and

four voice coil configuration tab terminals. These are

located behind the main input connectors and are

used to interconnect the dual voice coils in one of

two ways: Diagram A shows a series connection (8Ω

nominal impedance per speaker). Diagram B shows

a parallel connection (2Ω nominal impedance per

speaker) and is the way the speaker is configured at

the factory. After verifying that the tabs are properly

configured using the supplied jumper(s), connect

the amplifier’s output wires to the W6v2’s main

input push-terminals and install the speaker into the

enclosure.

Warning! Failure to properly connect the

configuration tabs will result in no output and may

damage the speaker.

1 - Customizable Trim Ring: (U.S. Patent

#D480,709) This removable ring can be painted to

match the installation theme, if desired.

2 - W-Cone™ (U.S. Patent #6,496,590) The

W-Cone™ unit-body cone assembly delivers

astonishing cone-stiffness with minimal mass.

3 - Floating-Cone™ Attach Method

(U.S. Patent #6,501,844): This unique assembly

technique ensures proper surround geometry in the

assembled speaker for better excursion control

and dynamic voice coil alignment.

4 - Plateau-Reinforced Spider Attachment

(U.S. Patent #6,118,884): A derivative of JL Audio's

famous VRC technology, this bulletproof suspension

attachment relieves stress from the spider material

at high excursions for enhanced reliability.

5 - Pole and Cone Venting (Patent-Pending):

Vents at the neck of the lower cone body work in

conjunction with the pole vent at the rear of the

motor structure. These vents effectively remove hot

air during high power operation to improve sound

quality and reliability.

JL AUDIO 10W6v2-D4/12W6v2-D4/13W6v2-D4 3

6 - Forced-Air-Cooled Aluminum Alloy Frame

(U.S. Patent #6,219,431, #6,229,902 and

#D472,891): Cool air is directly pumped onto the

voice coil of the speaker through slots between the

frame and top-plate. This enhances power handling

and sound quality by minimizing dynamic parameter

shifts and power compression.

7 - Highly Optimized Motor Systems:

Highly linear, FEA-optimized motors reduce audible

distortion and improve transient behavior for

superior sound quality and dynamic stability.

8 - Large, Progressive-Roll Spiders:

Optimized to control the long excursion of the

W6v2's without limiting it.

9 - Engineered Lead Wires and Connectors:

Connections for both voice coils terminate in a

unique configuration block on one side of the

basket.The extruded lead wire casing and

carefully engineered attachments ensure controlled

behavior and improved reliability under extreme

excursion demands.

Diagram A: Series Connection (8Ω):

Use one jumper from “VC1–” to “VC2+”

Diagram B: Parallel Connection (2Ω):

Use two jumpers... one from “VC1–” to “VC2–” and

one from “VC1+ to “VC2+”.

Page 3

RECOMMENDED CONTINUOUS (RMS) POWER RANGE FOR ONE SUBWOOFER DRIVER:

MINIMUM

OPTIMUM MAXIMUM

LEGEND:

WARRANTY VOID

12W6v2

13W6v2

10W6v2

75W 150W 300W 600W 1000W

MEDIUM GRAY (MINIMUM):

From a reliability standpoint, this zone represents

a very comfortable operating power range for

each driver. This level of power will not stress the

woofer but will not extract all of its performance

potential, either.

Use of less than the minimum power level will

not dama ge the woofer, but may resul t in

unsatisfactory performance.

JL Audio offers an extensive line of high-performance subwoofer drivers to fit a wide variety of enclosure and power applications. When designing systems with our drivers, it is very important

to achieve a good power match between the subwoofer amplifier and the subwoofer driver's capabilities. The power levels listed in the above chart represent continuous (RMS) amplifier power

per woofer and assume that the user will regularly make full use of that power without drastically overdriving the amplifier(s). Make sure you factor system impedance and the total

number of subwoofers into your calculations. Adhering to these power recommendations will result in systems that are both reliable and enjoyable.

LIGHT GRAY (OPTIMUM):

This zone rep resents the best co mpromise

between long-term reliability, high-out put and

low-distortion performance. This power level is

lower than the woofer’s continuous power rating

(as publish ed in its s pecif ications) , but you will still

be taking advant age of the woof er’s, low-disto rtio n

performance range without undue risk of failure.

DARK GRAY (MAXIMUM):

Slightly more SPL will be gained by pushing the

power into this zone, but typically not more than

2dB, compared to the light gray zone. The subwoofer

driver is designed to operate safely up to this power

range, but not beyond. Operate with caution.

BLACK (WARRANTY VOID):

We do not recommend operating woofers at

this level of power. In this zone, there is a very high

probability that the driver will fail due to excessive

heat and/or mechanical stress.

Subwoofer drivers operated at these levels of

power are NOT covered under warranty.

JL AUDIO LIMITED WARRANTY (USA)

Automotive Subwoofer Components

JJL AUDIO warrants this speaker to be free of defects in materials and

workmanship for a period of one (1) year from the original date of purchase.

Damage caused by the following is not covered under warranty: accident, misuse,

abuse, product modification or neglect, failure to follow installation instructions,

unauthorized repair attempts, misrepresentations by the seller. This warranty does not

cover incidental or consequential damages and does not cover the cost of removing

Any applicable implied warranties are limited in duration to the period of the

express warranty as provided herein beginning with the date of the original purchase

at retail, and no warranties, whether express or implied, shall apply to this product

thereafter. Some states do not allow limitations on implied warranties, therefore these

exclusions may not apply to you. This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

or reinstalling the unit(s). Cosmetic damage due to accident or normal wear and tear

is not covered under warranty.

This warranty is not transferable and applies only to the original

purchaser of the product from an authorized JL AUDIO dealer.

Warranty is voided if the factory-applied product serial number is

removed or defaced.

Should service be necessary under this warranty for any reason due to

manufacturing defect or malfunction, JL AUDIO will, at its discretion, repair or replace

the defective product with new or remanufactured product at no charge.

If you need service on your JL AUDIO product:

All warranty returns should be sent to JL AUDIO freight prepaid through an

authorized JL AUDIO dealer and must be accompanied by proof of purchase (a

copy of the original sales receipt.) Direct returns from consumers or non-authorized

dealers will be refused unless specifically authorized by JL AUDIO with a valid

return authorization number. Warranty expiration on products returned without

proof of purchase will be determined from the manufacturing date code. Coverage

may be invalidated as this date is previous to purchase date. Return only defective

components. Non-defective items received will be returned freight-collect. Customer

is responsible for shipping charges and insurance in sending the product to JL AUDIO.

Freight damage on returns is not covered under warranty. Always include proof of

purchase (sales receipt).

JL Audio customer service: (954) 443-1100 during normal business hours (Eastern Time)

For Service Information in the U.S.A. please call:

10369 North Commerce Parkway, Miramar, FL 33025

Printed in USA JLAW6v2_MAN_05_08_011080

Products purchased outside the United States of America are covered only by that countr y’s distributor and not by JL Audio, Inc.

JL Audio, Inc

International Warranties:

Loading...

Loading...