JJM DINAMAP XL User manual

DINAMAP*

XL

Vital

Signs

Service

фобии

MEDICAL

Monitor

Manual

«фобии

INC.

^

“TRADEMARK

LIST

Part

776639A

776639B

U.

U.

U.

U

U

P

CAUTION:

sale

No./Rev.

S.

Patent

S.

Patent

S.

Patent

S.

Patent

S.

Patent

atent

by

Pending

or

OF

EFFECTIVE

4,349,034

4,360,029

4,501,280

4,543,962

4,546,775

Federal

on

the

Page

All

All

(U.S.A.)

order

No.

of a health

Date

Original

Revised

law

restricts

PAGES

of

Latest

(April

(April

this

care

practitioner.

Revision

1995)

1996)

device

a

to

The

content

drawings

Medical,

is

proprietary

Inc.,

maintenance

purposes

without

Photographs

may

©

JJM,

Printed

or

prior

incorporate

Inc.

1995.

in

U.S.A.

of

this

document

information

provided

or

repair,

publication

written

may

changes.

solely

and

consent

show

All

rights

or

design

including

for

purposes

dissemination

copying

by J & J Medical.

models;

reserved.

all

figures

of

Johnson & Johnson

for

thereof

production

and

of

operation,

other

is

prohibited

.

Já

ㆍ

units

>

SECTION

1.

INTRODUCTION

TABLE

=>

BOD

οσο

om

D

&

の

の

NN

ONA

N

NNN

>

Scope

Manual

Service

Product

=

HOOWWW

ROW

RRR ARR

PPPRA

OF

of

Manual

Changes

Policy

Extended

Assistance

Service

Service

Repair

Replacement

General

Physical

Controls

Storage

Product

Accessory

Specifications

Mechanical

Environmental

Electrical

Performance

Warranties

Loaners

Parts

Accessories

Description

Description

Description

and

Indicators

Battery

Reorder

Reorder

Specifications

CONTENTS

Information

Numbers

Specifications

Specifications

Specifications

må

må må

ο

ο

—A

må

må

an

ki

eni

e

ni

di

eki

ek

mh

do

leo

4k

di

‘

Co

À

À

À

En

3

O

NN NP

D

NO

©

ーーー

D

2

Fo

SECTION

PRINCIPLES

OPERATION

2.

OF

Introduction

Overall

Functional

Principles

System

Principles

Processor

Temperature

NIBP

System

Pneumatics

Power

Remote

Supply

Computer

of

Operation

of

System

System

Operation

Protocol

D D

D

ND

D

D

D

ND

上

'

一

№

VILLA

MODA

SECTION

3.

GENERAL

MAINTENANCE

=

Go

D

Co

一

D

CO

D

NO

Co

Co

čo

små

čo

Co

3.3.2

3.3.4

3.3.5

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.5.1

3.5.2

3.5.3

3.5.4

3.5.5

3.5.6

3.5.7

3.6

3.7

3.7.1

3.7.2

3.7.3

3.7.4

TABLE

OF

CONTINUED

Introduction

Changing

Replacement

Replacement

Calibration

Calibration

Calibration

Calibration

Calibration

Calibration

Periodic

Monitor

Care

Blood

Cuff

Overpressure

Temperature

Battery

Alignment

Five

Battery

Adjustment

Precision

Adjustment

Pressure

Overpressure

Overpressure

Temperature

Jumper

Troubleshooting

General

Blood

Temperature

Internal

Fuses

Modes

Mode

Mode

Mode

Mode

Mode

Maintenance

Cleaning

of

the

Storage

Pressure

and

Hose

Fast

and

Adjustment

Volt

Logic

Charger

Reference

Calibration

Options

Faults

Pressure

(800

Series)

(E00

Series)

Error

Charge

CONTENTS

of

Line

Power

of

Battery

of

Operation

1

2

3

4

5

Calibration

Pneumatic

Safety

Calibration

Supply

Float

Switch

PWA

Circuit

and

Fault

System

Alarms

System

Alert

(900

Fuse

Battery

Check

Check

Adjustment

Voltage

Voltage

Adjustment

Adjustment

Adjustment

Adjustments

Isolation

Codes

Series)

Fuses

Check

Leak

Check

Alarms

Check

3-34

3-36

3-37

3-37

3-38

3-40

3-41

iv

SECTION

-MODEL

.

ASSY

-

SECTION

-

MODEL

.

ASSY

SECTION

BEZEL

SECTION

BEZEL

4.

9300

5.

9340

6.

ASSY

7.

ASSY

TOP

TOP

332-213

332-220

4.1

4.2

4.3

5.1

5.2

5.3

6.1

6.2

6.3

7.1

72

7.3

TABLE

OF

CONTINUED

Introduction

Parts

Parts

List

Top

List

Assembly

Sub-top

Introduction

Parts

Parts

Introduction

Principles

Parts

Introduction

Principles

Parts

List

Top

List

List

List

Assembly

Sub-top

of

Operation

of

Operation

CONTENTS

354-456

Assembly

Assembly

351-067

354-464

351-076

ARB

ann

一

οσο

Oa

一

CO

ㅡ

IO

CO

SECTION

DISPLAY

-

438

8.

PWA

315-

8.1

8.2

8.2.1

8.2.2

8.2.3

8.2.4

8.3

Introduction

Principles

of

Operation

Seven-segment

Discrete

Display

Scan

Parts

List

Point

Data

Failure

Displays

LED

Displays

Transfer

Protection

Timing

and

Ghosting

SECTION

DISPLAY

439

9.

PWA

315-

TABLE

OF

CONTINUED

Introduction

Principles

Seven-segment

Discrete

Display

Scan

Temperature

Parts

of

Operation

Point

Data

Failure

Predictive

Tympanic

Isolated

Precision

Predictive

Thermistor

Predictive

and

Probe

Predictive

Selector

Voltage-to

Opto-isolators

List

CONTENTS

Displays

LED

Displays

Transfer

Protection

Conversion

Temperature

Temperature

Power

Reference

Supply

Temperature

Interface

Temperature

Type

Temperature

Frequency

Detector

Timing

and

Ghosting

Circuits

Conversion

Conversion

Voltage

Probe

Calibration

Channel

Converter

Supply

©

©

©

©

©

©

©

©

©

©

©

O

© © © ©

©

1

oh

ak

ak

a ' n ' '

3

NN

©

GR

Où

ὁ

©

CONN

vi

SECTION

CPU

PWA

10.

315-437

10.1

10.2

10.2.1

10.2.1

10.2.1

10.2.1

10.2.1

10.2.1

10.2.1

10.2.1.7

10.2.1.8

10.2.2

10.2.2.1

10.2.2.2

10.2.2.3

10.2.2.4

10.2.2.5

10.2.2.6

10.2.3

10.2.4

10.2.5

10.2.6

10.2.7

10.3

1

2

3

4

5

6

TABLE

OF

CONTINUED

Introduction

Principles

Microprocessor

Analog

Switchpanel

Display

Pneumatics

Failsafe

External

Parts

of

Operation

Master

Microprocessor

Gate

EPROM

RAM

A/D

Digital

Digital

Negative

Pressure

Automatic

Oscillation

Reference

Power

List

Clock

Array

Circuit

Converter

/O

Output

Subsystem

Supply

PWA

Timer

Communications

CONTENTS

System

Circuit

Circuit

Circuit

Circuit

Latch

Bias

Supply

Transducer

Zero

Setting

Channel

Voltage

Voltage

Interface

Interface

PWA

Interface

Circuit

Circuit

Circuit

Circuit

Circuit

Amplifier

Supply

Circuit

Monitors

and

Control

Circuit

vii

(A

TABLE

OF

CONTENTS

CONTINUED

|

|

|

|

SECTION

POWER

11.

SUPPLY

315-372

SECTION

12.

TRANSFORMER

ASSY

SECTION

TRANSFORMER

ASSY

320-432

13.

320-433

PWA

11.1

11.2

11.2.1

11.2.2

11.2.3

11.2.4

11.2.5

11.3

11.4

12.1

12.2

Introduction

Principles

Unregulated

Regulated

ON/OFF

Shutdown

Logic

Battery

Parts

Parts

Control

Introduction

Parts

Introduction

Parts

of

System

Charger

List

Power

List

Battery

Circuit

List

List

Control

Operation

Air

Pump

+5

and

+8

and

Master

Circuit

Supply

Charger

PWA

Supply

VDC

Low

Battery

Reset

PWA

Supplies

Circuit

SECTION

AC

POWER

ASSY

viii

14.

CONN

320-431

Introduction

Parts

List

SECTION

PNEUMATICS

315-317

SECTION

PNEUMATICS

315-480

15.

16.

PWA

PWA

15.1

15.2

15.2.1

16.2.2

15.2.3

15.3

16.1

16.2

16.2.1

16.2.2

16.2.3

16.2.4

16.3

16.4

TABLE

OF

CONTINUED

Introduction

Principles

Valve

Pump

Overpressure

Parts

introduction

Principles

Valve

Pump

Overpressure

Overpressure

Pneumatics

Overpressure

Drive

Drive

and

List

Drive

Drive

of

Operation

Circuit

Circuit

Safety

of

Operation

Circuit

Circuit

PWA

PWA

CONTENTS

Switch

Interlocks

PWA

and

Safety

315-480

Parts

Interlocks

Parts

List

List

15-1

15-2

15-2

15-3

15-3

15-4

16-1

16-1

16-2

16-3

16-4

16-5

16-6

16-8

Y

Y

Y

Y

Y

Y

LI

>

Y Y

Y

Y

0

n

—

ORAM

OON

LA

—

— =

0

LIST

Model

Rear

Model

Model

Pneumatics

Power

System

Temperature

NIBP

Pneumatics

Power

Typical

Typical

Typical

Pressure

Cuff

Connect

+5

Volt

Battery

Battery

Precision

Overpressure

Overpressure

Locations

System

System

OF

9300

Controls

Panel

9340

Controls

9300

System

and

Monitor

Controls

Monitor

Series

System

Distribution

Processor

System

Suppiy

Calibration

Calibration

Calibration

Calibration

Hose

Calibration

Logic

Charger

Charger

Reference

of

Processor

Processor

ILLUSTRATIONS

Maintenance

and

Indicators

and

Indicators

Maintenance

and

Indicators

System

Block

Block

Leak

Supply

Test

Float

Switch

PWA

R37

and

System

Simplified

Diagram

Block

Block

Diagram

Block

Diagram

Mode 1 Displays

Mode 2 Displays

Mode 3 Displays

Check

Check

Plug

Adjustment

Circuit

Voltage

Voltage

Adjustment

Adjustments

R42

PWA

Adjustments

Block

Schematic

Diagram

Diagram

Diagram

Setup

Setup

Adjustment

Test

Jumper

Diagram

Point

Options

1-8

1-11

1-13

2-2

2-7

2-11

2-15/16

2-17/18

2-19/20

2-21/22

2-23/24

3-8

3-10

3-12

3-17

3-19

3-22

3-25

3-26

3-27

3-28

3-31

3-33

3-35

3-36

3-45/46

LIST

CONTINUED

FO-4A

FO-4B | Sub-top

6-1

FO-6A

7-1

FO-8A

FO-9A

10-1

FO-10A

11-1

11-2

FO-11A

Top

Assembly

Model

Diagram

Bezel

Model

Diagram

Display

Display

System

and

System

Power

Battery

Power

9300

Assembly

9340

Jumper

Supply

PWA

Supply

OF

Assembly

PWA

PWA

Processor

Processor

Charger

315-369

ILLUSTRATIONS

354-456

Monitor

332-213

Monitor

315-438

315-439

Locations

Test

Control

PWA

351-067

Front

Front

Test

Points

PWA

315-437

Point

Location

Circuit

315-372

Panel

Panel

Schematic

Schematic

4-5

4-7

6-2

6-5

7-2

8-5

9-11

10-2

10-23

11-2

11-10

11-11

FO-12A

FO-13A

FO-14A

15-1

FO-15A

16-1

16-2

FO-16A

FO-16B

Transformer

Transformer

AC

Power

Pneumatics

Hose

Pneumatics

Pneumatics

Hose

Overpressure

Pneumatics

Overpressure

Assembly

Assembly

Connector

PWA

Connections

PWA

PWA

Connections

PWA

PWA

PWA

320-423

320-424

320-431

315-317

315-480

Connections

315-480

315-409

12-3

13-3

14-3

15-1

15-7

16-1

16-4

16-9

16-13

xi

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

2-1

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

LIST

Model

Rear

Model

Product

Accessories

Mechanical

OF

9300

Controls

Panel

Controls

9340

Controls

Reorder

Monitor

Monitor

Specifications

Environmental

Electrical

Performance

Host

Software

Calibration

Alignment

Battery

General

800

E00

900

Specifications

Specifications

Computer

Revision

Mode 5 Channel

and

Charger

Faults

Series

Series

Series

Alarms

Alarms

Alarms

TABLES

Maintenance

and

Indicators

and

Indicators

Maintenance

and

Indicators

Numbers

Specifications

Interface

Level

Adjustment

Load

Numeric

Selection

Equipment

Test

Codes

List

1-9

1-12

1-14

1-17

1-18

1-22

1-23

1-23

1-24

2-12

3-7

3-13

3-24

3-27

3-37

3-38

3-40

3-41

xii

Q

xiii

ο

NZ

payı

I

AT

LUS

xiv

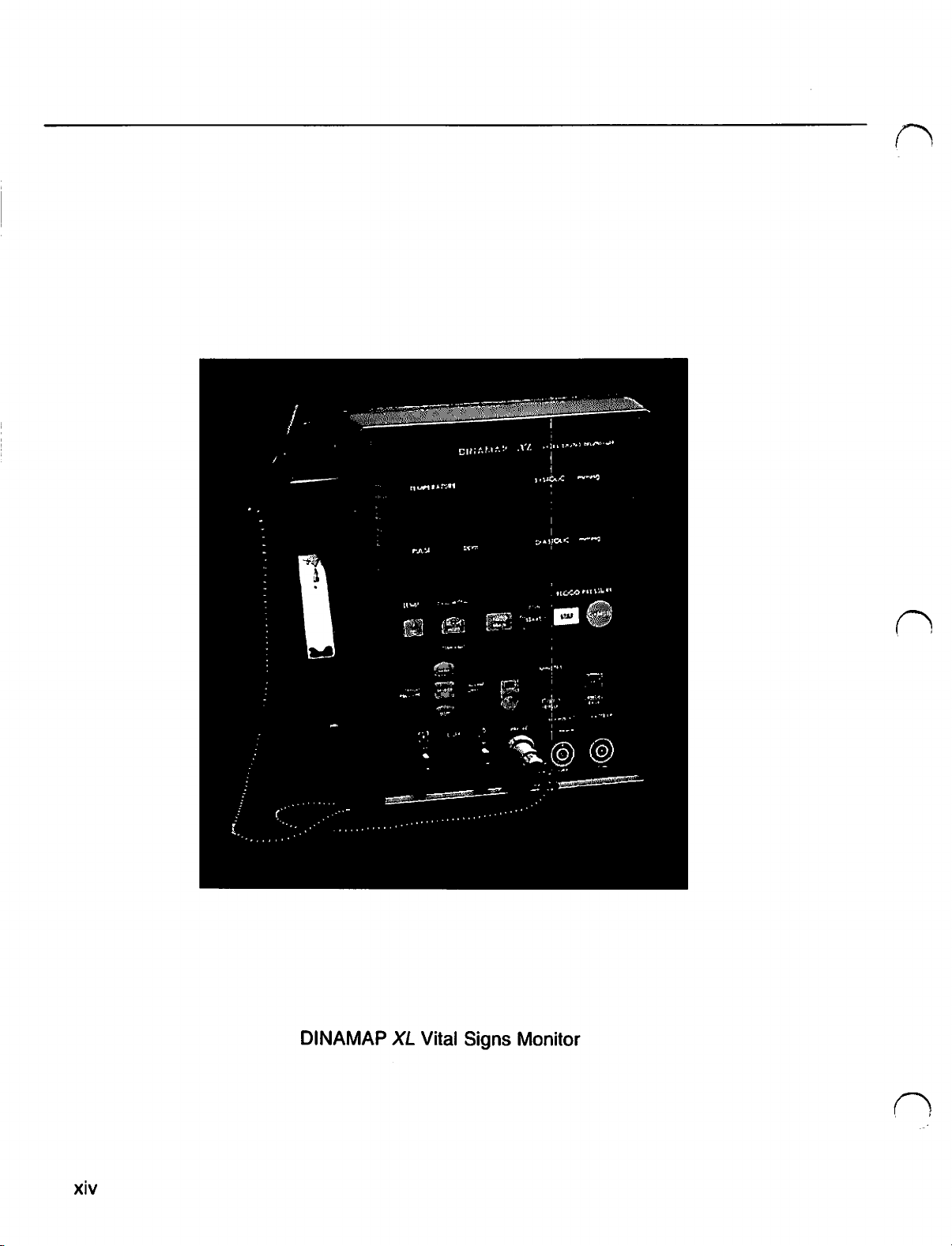

DINAMAP

XL

Vital

Signs

Monitor

1.1

SCOPE

OF

MANUAL

SECTION

This

Service

information

Monitor

variations.

service

devices

CAUTION

All

only

Voltages

unit.

supply

for

Models

This

technicians

and

unit

by

Take

Manual

DINAMAP

9300

manual

digital

and

To

reduce

shock,

or

back.

qualified

repairs

trained

dangerous

care

and

display

provides

XL

and

9340

is

intended

who

are

analog

WARNING

the

do

not

Refer

service

should

service

to

when

assembly.

1.

INTRODUCTION

service

Vital

and

familiar

circuit

risk

remove

and

parts

Signs

Monitors,

their

international

for

use

with

electromechanical

techniques.

of

electric

cover

by

servicing

personnel.

be

performed

technicians.

life

exist

servicing

in

power

repair

including

trained

to

this

For

information

environment,

DINAMAP

776-600

about

refer

XL

Vital

operating

to:

Signs

the

Monitor

Monitor

in a clinical

Operation

Manual

1-1

The

first

part

of

this

sections

that

Service

provide

general

Manual

service

consists

of

information

three

about

the

Monitor:

Section 1 describes

use

it.

Information

functional

assistance

characteristics

in

properly.

Section 2 provides

including

functional

Section 3 provides

maintenance

The

rest

of

this

detailed

and

modules,

publication,

principles

service

and

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

diagrams

circuit

these

4

5

6

7

8

9

10

11

12

13

14

15

16

this

is

also

the

event

system

descriptions.

information

and

troubleshooting

manual

is

divided

of

operation,

about

PWAs

sections

Top

Assembly

Top

Assembly

Bezel

Bezel

Display

Display

CPU

Power

Assembly

Assembly

PWA

PWA

PWA

Supply

Transformer

Transformer

AC

Power

Pneumatics

Pneumatics

volume

and

provided

of

the

Monitor,

the

unit

fails

principles

about

into

component

each

of

the

of

the

Monitor.

consisted

354-456

354-464

332-213

332-220

315-438

315-439

315-437

PWA

Assy

320-432

Assy

320-433

Conn

PWA

PWA

Assy

315-317

315-480

telis

you

about

to

physical

and

how

function

of

operation

general

of

the

Monitor.

sections

that

information,

subassemblies,

At

the

time

of

the

following:

315-372

320-431

how

to

and

to

get

provide

of

1.2

MANUAL

CHANGES

If,

in

the

normal

omissions,

comments

complete

back

of

Johnson & Johnson

Technical

P.O.

4110

Tampa,

Changes

input

or

accomplished

Changes

through

pages.

your

manual,

or

incorrect

that

the

Publications

this

manual.

Publications

Box

31800

George

Florida

to

the

to

reflect

through

occurring

Change

If a Change

the

use

of

this

data,

may

help

improve

Submit

Medical,

Road

33631-3800

Service

Manual,

continuing

reissue.

between

Information

Information

manual

is

manual,

or

if

you can

Change

the

form

Inc.

either

product

reissues

Sheets

Sheet

correct

you

notice

suggest

this

manual,

Request

form

to:

in

response

improvements,

are

addressed

and

replacement

does

not

as

printed.

errors,

please

in

the

to

are

accompany

user

1.3

SERVICE

POLICY

The

warranty

the

shipper

must

be

performed

personnel.

Products

by

qualified

not

for

this

product

carton.

All

repairs

or

approved

Unauthorized

covered

electronics

by

service

is

enclosed

on

by

repairs

warranty

personnel.

with

products

Customer

will

void

should

be

the

under

Service

the

warranty.

repaired

product

in

warranty

only

1.3.1

Extended

Warranties

1.3.2

Assistance

Extended

Contact

If

the

service

Support.

to

attempt

accessories

problem.

checking

calling,

O

product

warranties

your

product

or

spare

Before

to

to

If

you

these

please

name

Sales

fails

duplicate

U a complete

If

the

asked

the

the

a

000

or

the

the

DD

repair

purchase

you

parts

to

provide

product

facility's

order

facility's J & J Medical

6-digit

may

Representative

to

function

parts

are

contacting

the

ensure

are

items,

be

that

unable

contact J & J Medical.

prepared

and

model

description

or

service

serial

number

complete

order

part

number

spare

number

parts

be

purchased

properly,

required,

Customer

problem

they

are

to

resolve

to

provide

number

of

the

problem

are

necessary,

name

if

the

and

account

for

spare

on

for

details

or

if

contact

Support,

and

to

check

not

the

the

problem

address

product

number,

or

replacement

most

products.

and

pricing.

assistance,

Customer

it

is

helpful

all

cause

you

is

of

Prior

to

will

to

be

if

possible

the

after

also

repaired

parts

be

1.3.3

Service

If

your

product

non-warranty

representative

repairs

must

provide

To

external

are

be

sent

you

facilitate

chassis

Customer

The

Customer

necessary

Authorization

repair,

you

requires

repair

will

provided

to

the J & J Medical

with

an

prompt

or

Support

Support

information and

Number.

must

have a Return

Call J & J Medical

1-800-237-2033

and

select

Monday

excluding

Parts,

through

holidays.

Friday,

warranty,

service,

assist

at

you.

no

charge;

call

Estimates

estimate.

service

case

in

cases

damage,

representative

representative

will

provide

Prior

to

at

Product

Service,

8:00

a.m.

extended

Customer

however,

Service

where

please

when

returning

Authorization

and

to

6:00

warranty

Support

for

non-warranty

the

Center

the

advise

you

call.

will

record

you

with a Return

any

product

number.

Customer

p.m.

or

and

product

in

order

product

the

all

for

Support

EST,

a

to

has

Packing

Follow

(J

these

Remove

ancillary

packs

O

Pack

only

place

product

O

Use

the

if

available.

If

the

original

O

Place

to

prevent

openings

O

Use a sturdy

tape

securely

O

Pack

with 4 to 6 in.

product.

Instructions

recommended

all

hoses,

products

from

the

monitor

the

accessories

them

in a separate

inside

original

the

shipping

shipping

the

product

loose

such

particles

as

corrugated

to

seal

packing

cables,

such

sensors,

as

printers

before

you

bag and

shipping

carton.

carton

carton

in a plastic

hose

is

not

or

materials

ports.

bag

container

the

container

of

padding

instructions.

power

and

external

packing.

are

requested

insert

and

the

packing

available

and

tie

or

from

to

ship

for

shipping.

on

all

sides

cords

battery

to

return;

bag

materials,

tape

entering

the

product;

of

the

and

and

the

the

bag

1-5

insurance

Insurance

damage

is

to

at

the

the

customer's

product

must

discretion.

be

initiated

Claims

by

the

for

shipper.

1.3.4

Service

1.3.5

Repair

Loaners

Parts

A

loaner

of

the

product

Medical.

shipped

O

J&J

loaner

the

warranty.

O

Shipping

product

customer.

O

Shipping

Medical,

All

loaners

the

specified

rental

Repair

fee

parts

Support

such

as

the

Customer

unit

is

provided

when

Within

to

your

Medical,

sent

to

charges

repairs

charges

Inc.

provided

time

will

be

can

or

via

FAX.

Circuit

Board

Support

at

the

repair

48

hours

facility.

Inc.

will

the

customer

for a loaner

not

under

for

the

will

be

paid

to

customers

stated

on

incurred.

be

ordered

Exchange

Assemblies

representative

no

of

your

pay

warranty

return

by

the

via

charge

service

during

is

performed

request, a loaner

shipping

for

sent

charges

product

to

the

will

repairs

be

of a loaner

the

customer.

must

be

returned

loaner

phone

agreement

to

Customer

replacement

also

are

available;

for

details.

the

service

by J &

will

be

for

a

under

customer

billed

to J &

to

J

for

the

within

or

a

assemblies

ask

life

J

1.3.6

Replacement

Accessories

Via

FAX

Please

order.

O

Facility's

Lj}

FAX

O

Your

O

Your J & J Medical

Replacements

purchased

at

1-800-255-2500.

----

allow

All

one

orders

complete

number

purchase

from

1-813-887-2892

such

Reorder/Product

purchase

order

and

or

working

must

order

as

day

include

name,

address,

number

account

hoses,

for

confirmation

the

following

number

sensors,

Johnson & Johnson

Please

Code

account

of

have

the

the

item

you

number

-2893

of

information.

and

phone

etc.

must

Health

Care

4-digit

wish

to

order,

available.

your

number

be

Systems

your

ON

1.4

PRODUCT

DESCRIPTION

1.4.1

General

Description

The

DINAMAP

noninvasive

measurement

arterial

or

adult/pediatric

battery

hospital

Emergency,

monitoring

of

blood

pressure

operated

acute

care

PACU,

Gl/Endoscopy,

The

units

described

basic

measurement

Model 9340

features.

versions

such

for

description

The

hospital-grade

Monitor

Within

that

as

the

Germany.

of

unit

operates

models:

of

Monitor

add a unique

code

Refer

DINAMAP

power

XL

Monitor

systolic

is a portable

of

patients

and

(MAP),

patients.

and

are

primarily

settings

Progressive

and

Medical/Surgery

in

this

the

noninvasive

adds

temperature

each

9302

to

model

version

paragraph

XL

from

AC power

cord,

device

and

automatic

diastolic

and

The

monitors

pressure,

pulse

intended

such

as

Same

Care,

Labor

Units.

manual

Model

9300

blood

are

available

Monitor

pressure

measurement

group,

digit

Monitor

to

of

the

1.4.5

there

the

group

Model

for a complete

product

using a standard,

or

from a battery.

used

mean

rate

for

neonatal

are

portable

for

use

Day

Surgery,

and

Delivery,

in

features

(NIBP);

are

international

product

9300

codes.

for

and

in

two

the

code,

Monitor

1.4.2

Physical

Description

Each

itself.

assembly

is

The

Model

Monitor

The

and

removed,

sub-top

and

pneumatics

muffler,

system

and

processor

includes

top

assembly

mounting

the

sub-top

assembly

consists

PWAs,

battery.

and

an

accessory

is

comprised

hardware.

assembly

is

identified

of

the

bezel,

transformer,

When

display

the

AC

bezel

PWAs

kit

and

of a sub-top

When

is

exposed.

by

unique

pump,

power

power

is

removed,

are

the

monitor

the

top

assembly

code

supply

connector,

the

exposed.

for

and

unit

each

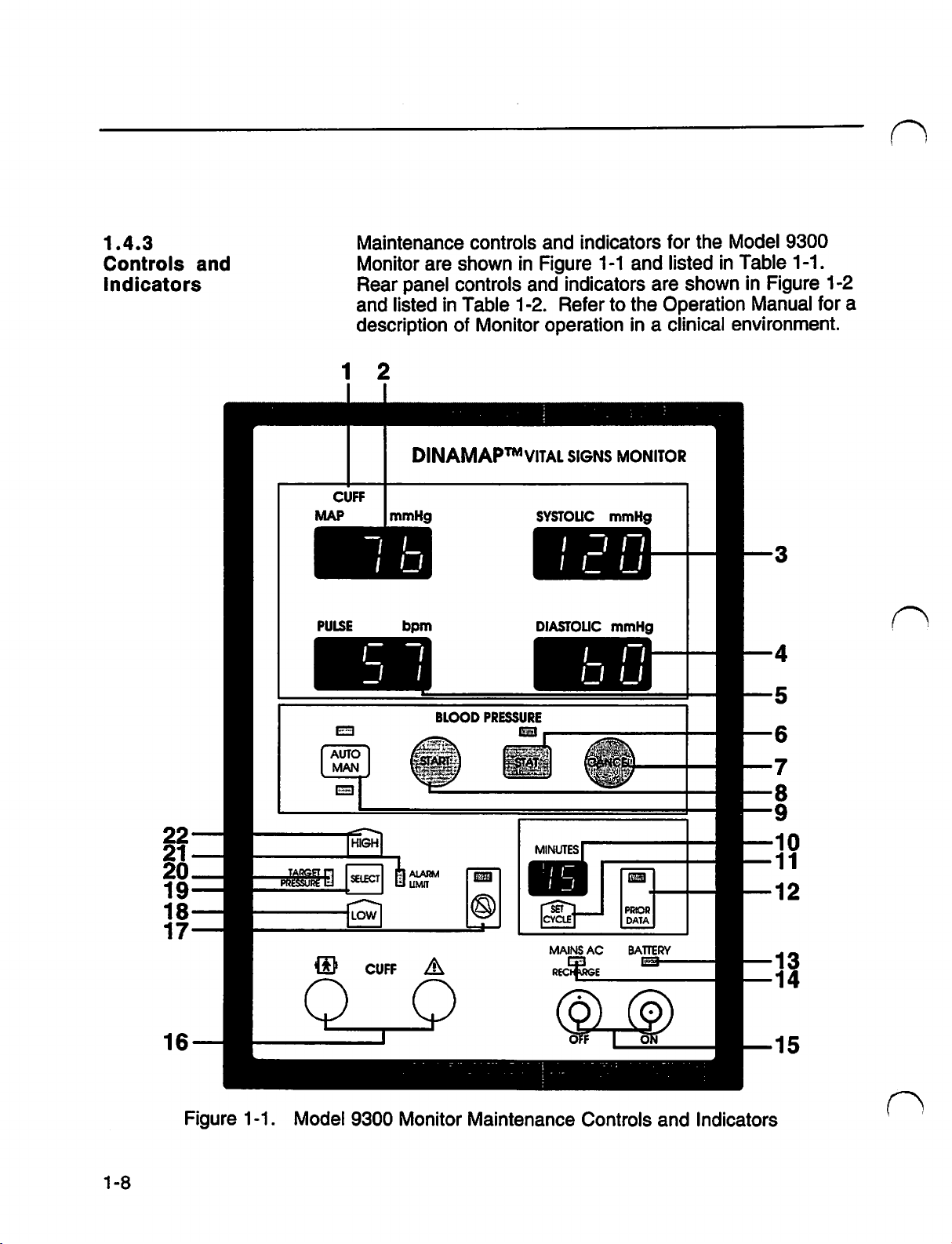

1.4.3

Controls

indicators

and

Maintenance

Monitor

Rear

and

description

1

wt

panel

listed

2

DINAMAP™

mmHg

are

shown

controls

in

Table

of

BLOOD

controls

in

Figure

and

1-2.

Monitor

VITAL

SYSTOLIC

DIASTOLIC

μπι

PRESSURE

|

and

indicators

1-1

indicators

Refer

operation

to

SIGNS

mmHg

MONITOR

for

the

Model

and

listed

are

the

Operation

in a clinical

in

Table

shown

environment.

+i

9300

1-1.

in

Figure

Manual

4

5

6

1-2

for

a

1-8

22

21

2

18

18

16

Figure

1-1.

Model

9300

Monitor

Maintenance

MINUTES

u

at

區

MAINS

AC

©

ΦΦ

i

Controls

les

BATTERY

ο

Ἡ

and

Indicators

7

8

9

10

12

1

3

15

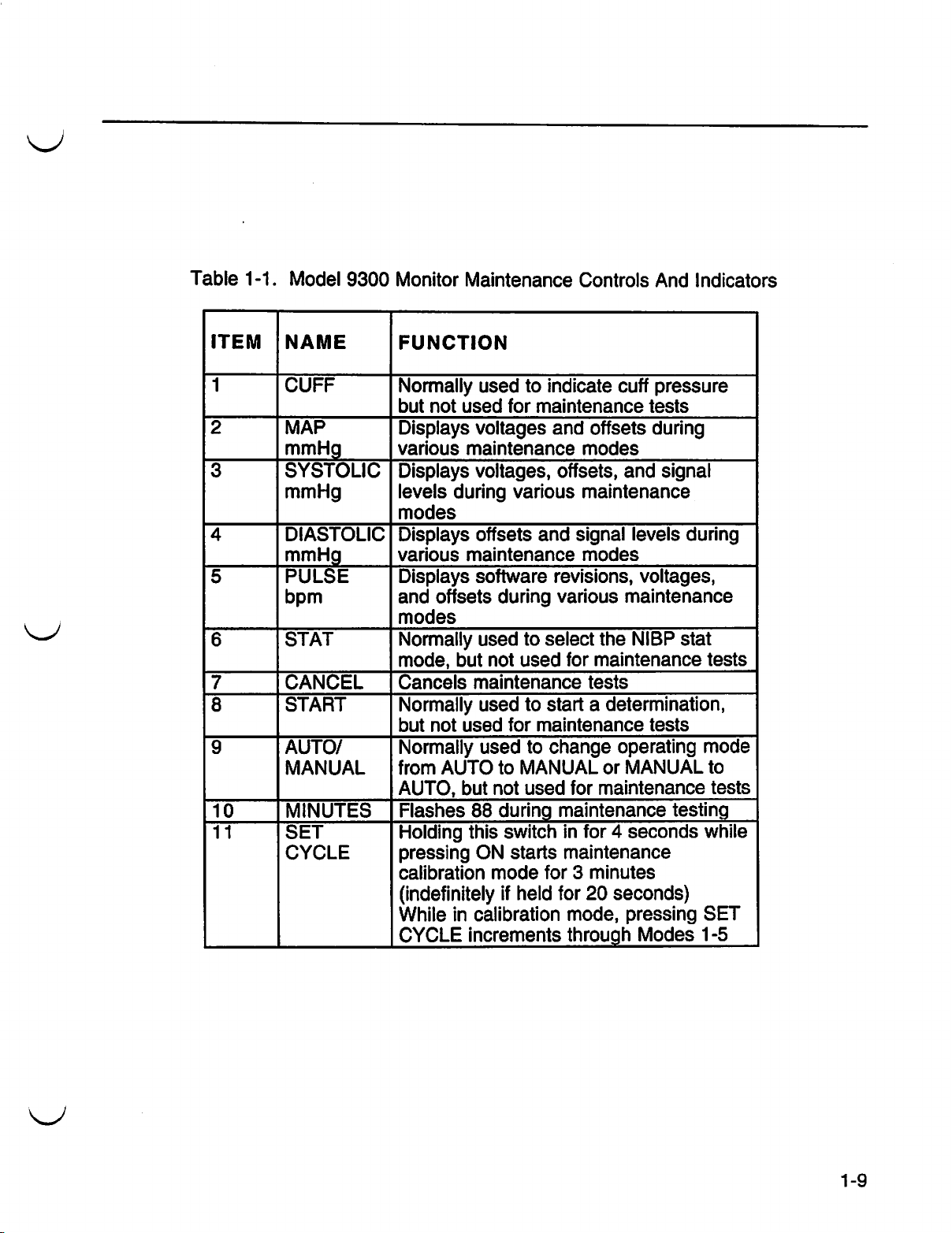

Table

1-1.

Model

ITEM

1

2

3

4

圖

5

6

7

8

9

10

11

{NAME

CUFF

_

MAP

mmHg

SYSTOLIC | Displays

mmHg

DIASTOLIC | Displays

mmH

PULSE

bpm

STAT

CANCEL

START

ーー

AUTO/

MANUAL _ |

MINUTES

SET

CYCLE

9300

_

_ |

___|

Monitor

FUNCTION

Normally

but

Displays

various

levels

|

modes

various

Displays

and

modes

Normally

mode,

Cancels

Normally

but

Normally

from

AUTO,

|

Flashes

Holding

pressing

calibration

(indefinitely

While

CYCLE

Maintenance

used

not

used

voltages

maintenance

voltages,

during

offsets

maintenance

software

offsets

not

AUTO

during

used

but not

maintenance

used

used

used

to

but

not

88

during

this

ON

mode

if

in

calibration

increments

for

for

switch

starts

Controls

to

indicate

maintenance

and

offsets

modes

offsets,

various

to

used

to

to

MANUAL

used

held

maintenance

and

signal

modes

revisions,

various

select

start a determination,

maintenance

change

for 3 minutes

the

for

maintenance

tests

or

for

maintenance

maintenance

in

for 4 seconds

maintenance

for

20

mode,

through

And

cuff

pressure

tests

during

and

signal

levels

voltages,

maintenance

ーー

NIBP

tests

operating

MANUAL

seconds)

pressing

Modes

Indicators

during

stat

tests

mode

to

tests

testing

while

SET

1-5

1-9

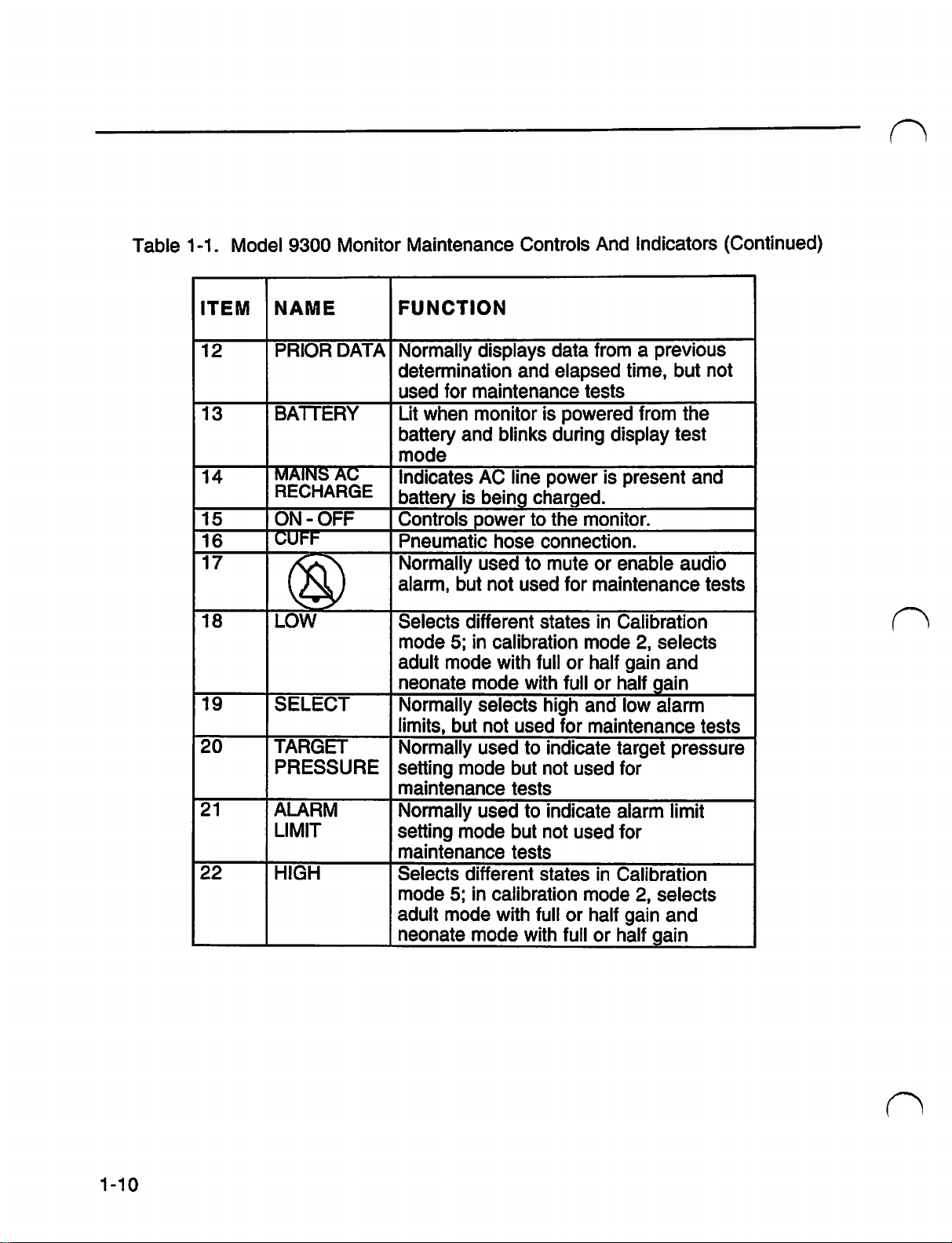

Table

1-1.

Model

ITEM

12

13

14

15

16

17

18

19

20

21

22

9300

|NAME

PRIOR

BATTERY

MAINS

Monitor

DATA|

AG

RECHARGE | battery

ON - OFF

CUFF

LOW

SELECT

TARGET

PRESSURE

ALARM

LIMIT

HIGH

Maintenance

FUNCTION

Normally

determination

used

for

Lit

when

battery

mode

Indicates

maintenance

and

is

Controls

Pneumatic

Normally

alarm,

Selects

mode

adult

neonate

Normally

limits,

Normally

|

setting

maintenance

Normally

setting

maintenance

Selects

mode

adult

neonate

but

different

5;

in

mode

mode

but not

mode

mode

different

5;

in

mode

mode

Controls

displays

monitor

blinks

AC

being

power

hose

used

not

calibration

with

selects

used

used

calibration

with

data

and

elapsed

is

during

line

power

charged.

to

the

connection.

to

mute

used

states

full

with

high

used

to

indicate

but

not

tests

to

indicate

but

not

tests

states

full

with

And

Indicators

from a previous

time,

tests

powered

monitor.

for

mode

or

half

full

and

for

maintenance

used

used

mode

or

half

full

from

display

is

present

or

enable

maintenance

in

Calibration

2,

selects

gain

or

half

gain

low

alarm

target

for

alarm

for

in

Calibration

2,

selects

gain

or

half

gain

(Continued)

but

not

the

test

and

audio

tests

and

tests

pressure

limit

and

1-10

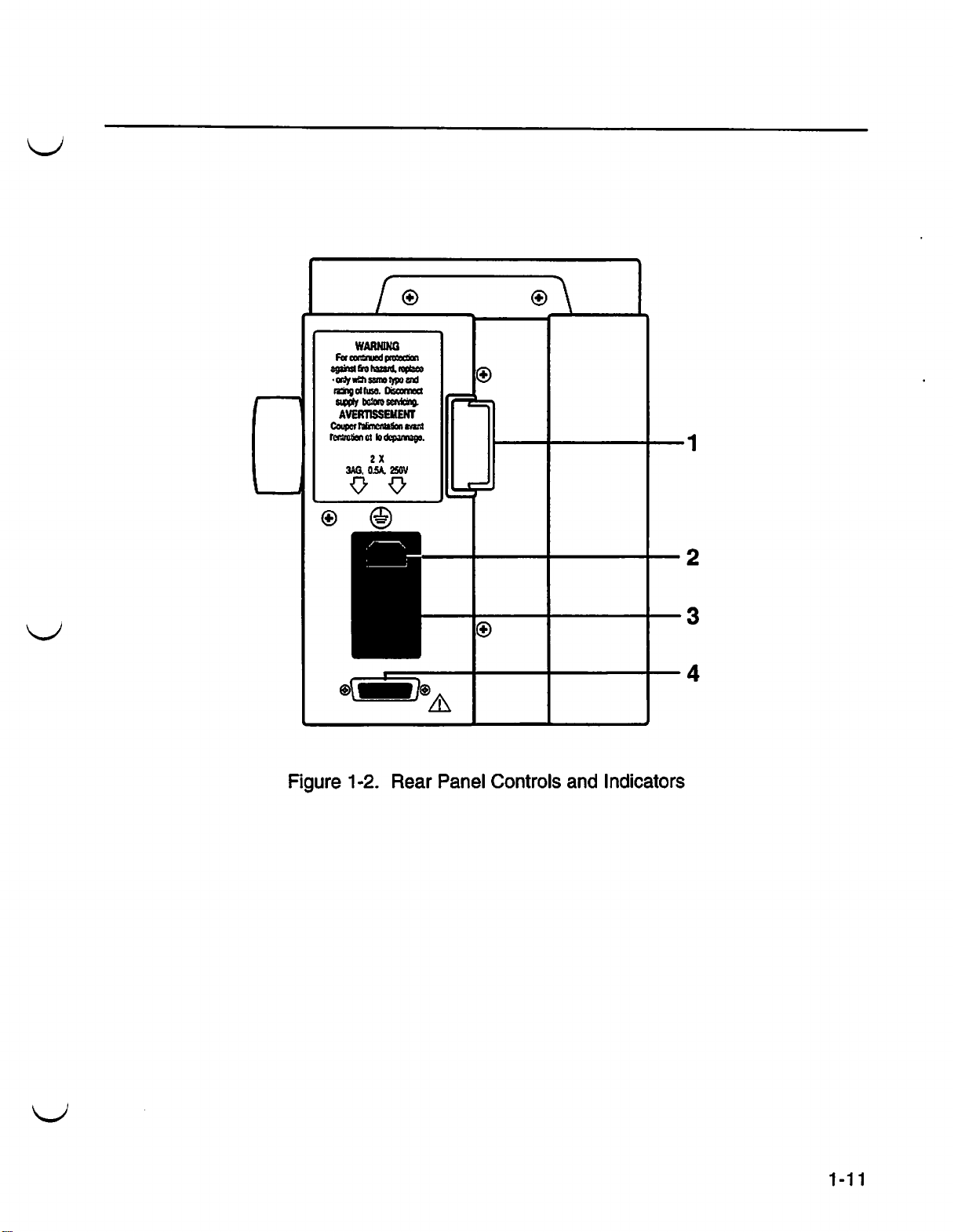

Figure

1-2.

Rear

Panel

Controls

and

Indicators

1-11

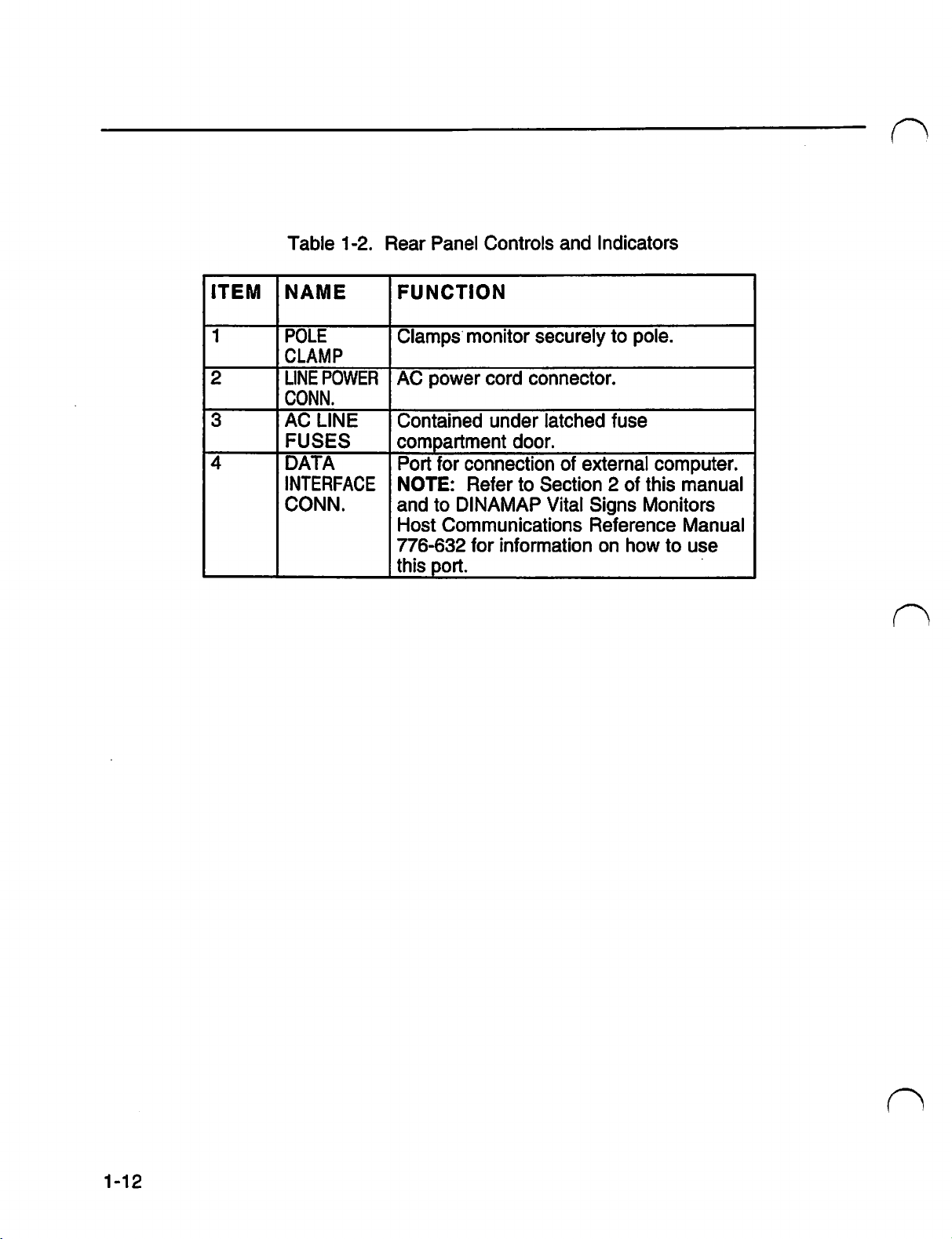

Table

ITEM | NAME

1

2

3

4

POLE

CLAMP

LINE

CONN.

AC

FUSES

DATA

INTERFACE | NOTE:

CONN.

1-2.

POWER |

LINE

Rear

Panel

FUNCTION

Clamps

_

AC

power

Contained

compartment

Port

for

and

to

Host

776-632

this

port.

Controls

monitor

cord

under

connection

Refer

DINAMAP

Communications

for

and

securely

connector.

latched

door.

of

external

to

Section 2 of

Vital

Signs

Reference

information

Indicators

to

pole.

fuse

computer.

this

Monitors

on

how

to

manual

Manual

use

|

1-12

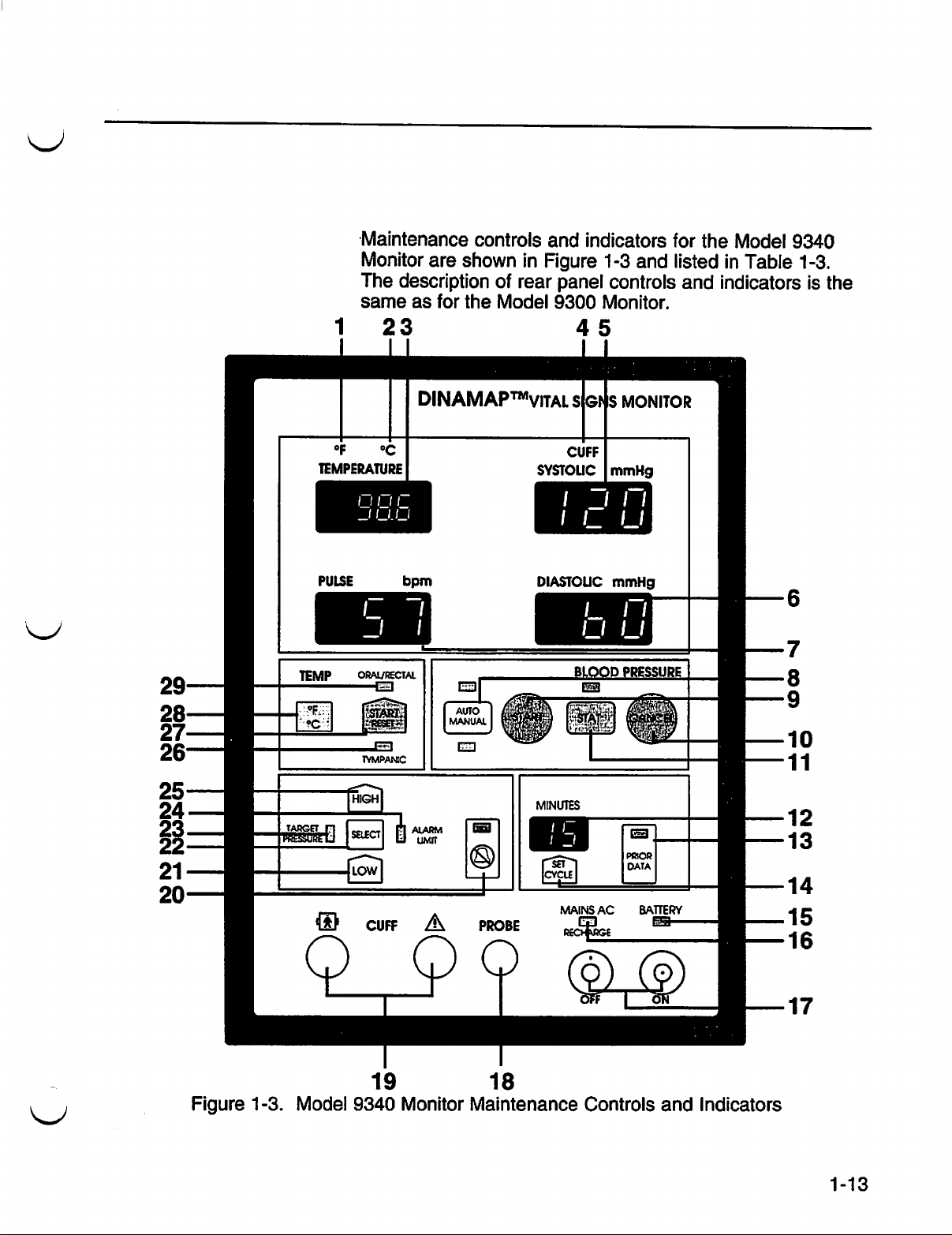

‘Maintenance

Monitor

The

same

1

°F

TEMPERATURE

23

°С

controls

are

shown

description

as

for

DINAMAPTMVITAL

the

of

Model

and

indicators

in

Figure

rear

panel

9300

45

СУЕР

SYSTOLIC | mmHg

DIASTOLIC

for

1-3

and

controls

Monitor.

MONITOR

mmHg

the

listed

in

and

indicators

Model

Table

9340

1-3.

is

the

26

25

2

2

21

20

dl

SELECT

LOW

cur

А

=-

8

м

19 18

Figure

1-3.

Model

9340

Monitor

Maintenance

MAINSAC

Controls

DATA

BATTERY

and

Indicators

1-13

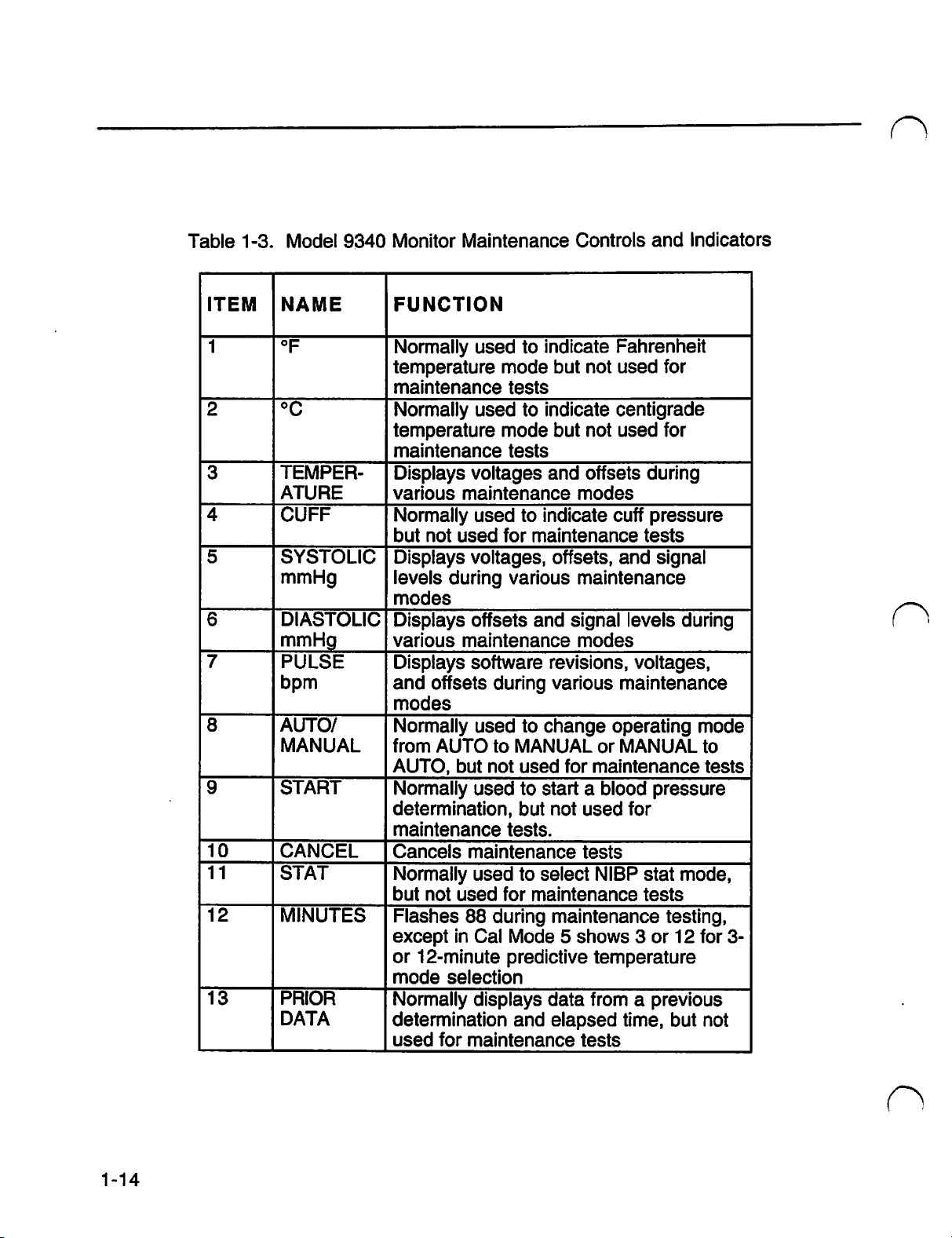

Table

1-3.

Model

ITEM | МАМЕ

1

2

3

4

5

6

7

8

9

10

11

12

13

SF

°C

TEMPER-

ATURE

CUFF

SYSTOLIC | Displays

mmHg

DIASTOLIC | Displays

mmHg

PULSE

bpm

_

AUTO/

MANUAL

START

CANCEL

STAT

MINUTES

PRIOR

DATA

9340

______ | maintenance

__|

__

__

__|

Monitor

FUNCTION

Normally

temperature

maintenance

Normally

temperature

|

Displays voltages

various

Normally

but

levels

|

modes

various

Displays

and

modes

Normally

| from

AUTO,

Normally

determination,

maintenance

Cancels

Normally

|

but

|

Flashes

except

or

mode

Normally

determination

used

Maintenance

used

used

maintenance

used

not

used

voltages,

during

offsets

maintenance

software

offsets

AUTO

not

12-minute

for

during

used

to

but not

used

maintenance

used

used

88

during

in

Cal

selection

displays

maintenance

to

mode

tests

to

mode

tests

to

for

maintenance

various

and

to

MANUAL

used

to

but

tests.

to

for

maintenance

Mode 5 shows 3 or

predictive

and

Controls

indicate

but

indicate

but

and

indicate

offsets,

revisions,

various

change

for

start a blood

not

select

maintenance

data

elapsed

Fahrenheit

not

used

centigrade

not

used

offsets

modes

cuff

and

maintenance

signal

modes

tests

levels

voltages,

maintenance

operating

or

MANUAL

maintenance

used

for

tests

_

NIBP

temperature

from a previous

time,

and

Indicators

for

for

during

pressure

tests

signal

during

mode

to

tests

pressure

stat

mode,

tests

testing,

12

for

but

not

3-

1-14

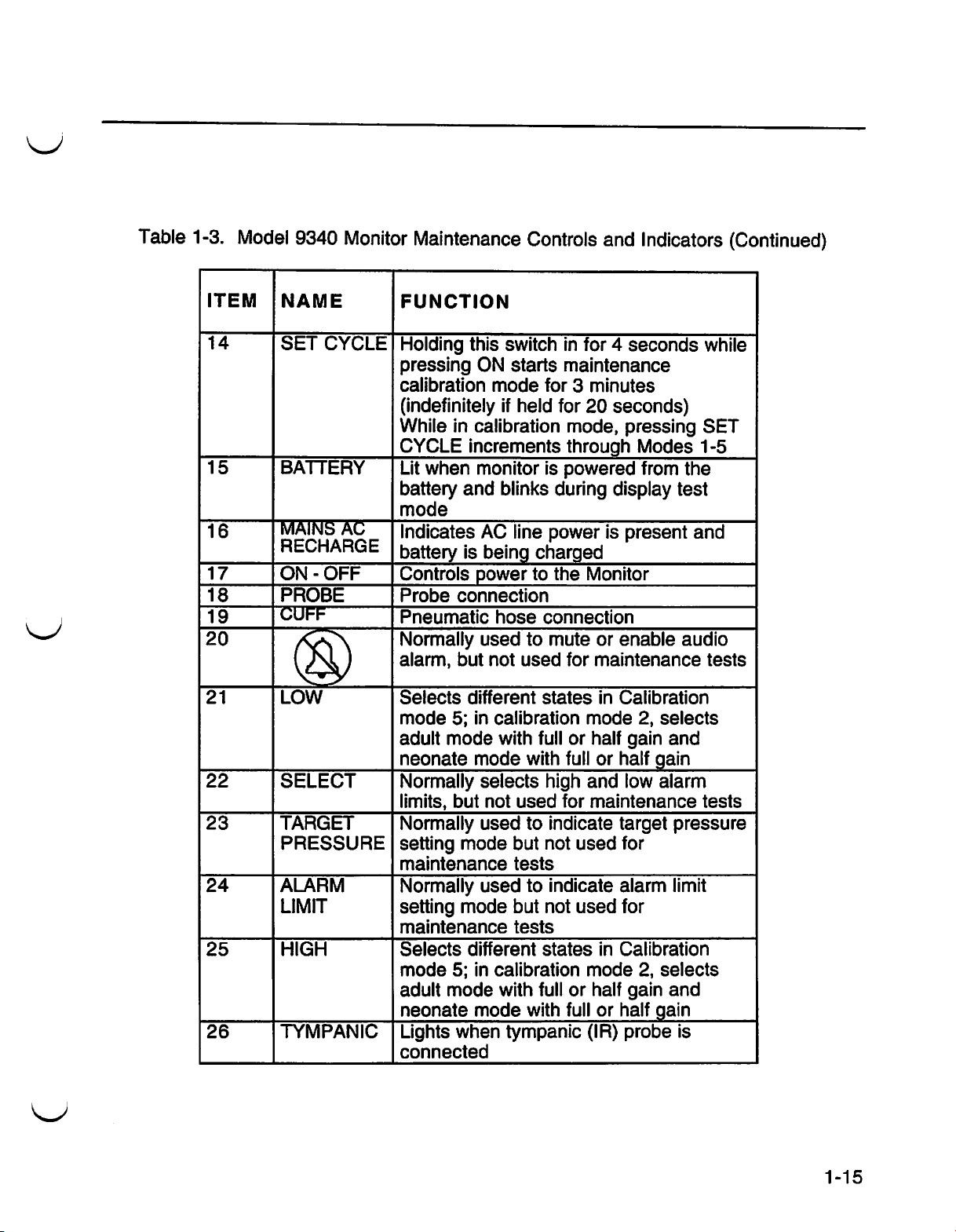

Table

1-3.

Model

ITEM

14

15

16

17

18

19

20

21

22

23

24

25

26

9340

|NAME

SET

BATTERY

MAINS

RECHARGE | battery

ON-OFF

PROBE

CUFF

LOW

SELECT

TARGET

PRESSURE

ALARM

LIMIT

HIGH

TYMPANIC

Monitor

CYCLE | Holding

|

AC _ |

_

_

Maintenance

FUNCTION

this

pressing

calibration

(indefinitely

While

CYCLE

Lit

battery

mode

Indicates

|

Controls

Probe

Pneumatic

Normally

alarm,

Selects

mode

adult

neonate

Normally

limits,

Normally

|

setting

maintenance

Normally

setting

maintenance

Selects

mode

adult

neonate

|

Lights

connected

in

increments

when

and

is

connection

but

different

5;

mode

but not

mode

mode

different

5;

mode

when

Controls

switch

ON

starts

mode

if

calibration

monitor

blinks

AC

line

being

power

hose

used

not

in

calibration

with

mode

selects

used

but

tests

used

but not

tests

in

calibration

with

mode

tympanic

in

maintenance

for 3 minutes

held

for

mode,

through

is

powered

during

power

charged

to

the

connection

to

mute

used

for

states

full

or

with

full

high

used

for

to

indicate

not

to

indicate

states

full

or

with

full

and

Indicators

for 4 seconds

20

seconds)

pressing

Modes

from

display

is

present

Monitor

or

enable

maintenance

in

Calibration

mode

half

and

maintenance

used

used

mode

(IR)

2,

selects

gain

or

half

gain

low

alarm

target

for

alarm

for

in

Calibration

2,

selects

half

gain

or

half

gain

probe

and

pressure

limit

and

(Continued)

while

SET

1-5

the

test

and

audio

tests

tests

is

1-15

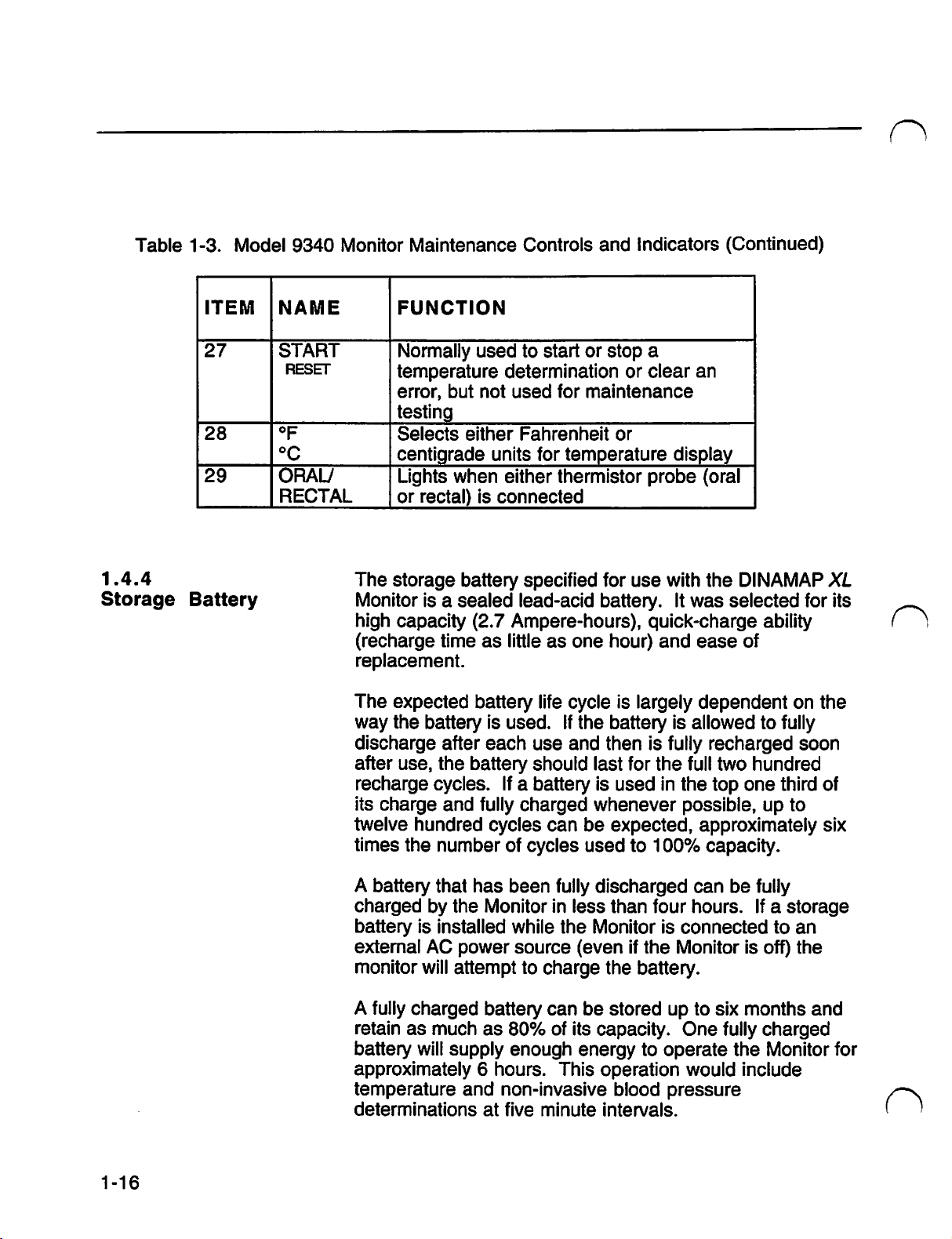

Table

1.4.4

Storage

1-3.

Model

ITEM

27

28

29

Battery

9340

|NAME

START

RESET

°F

°C

ORAL/

RECTAL

Monitor

Maintenance

FUNCTION

Normally

temperature

error,

testing

Selects

centigrade

Lights

or

rectal)

The

storage

Monitor

high

(recharge

replacement.

is a sealed

capacity

used

but

not

either

when

is

battery

(2.7

time

as

Controls

to

start

determination

used

and

or

for

maintenance

=

Fahrenheit

units

for

temperature

either

connected

Ampere-hours),

little

thermistor

specified

lead-acid

as

battery.

one

indicators

stop

a

or

clear

or

probe

for

use

quick-charge

hour)

and

an

display

(oral

with

the

It

was

ease

(Continued)

DINAMAP

selected

of

for

ability

XL

its

~~

The

expected

way

the

battery

discharge

after

use,

recharge

its

charge

twelve

times

A

charged

battery

external

monitor

A

retain

battery

approximately 6 hours.

temperature

determinations

hundred

the

battery

by

is

AC

will

fully

charged

as

will

battery

is

used.

after

each

the

battery

cycles.

and

number

that

the

installed

attempt

much

supply

If a battery

fully

cycles

of

has

been

Monitor

power

battery

as

80%

enough

and

non-invasive

at

five

life

use

should

charged

can

cycles

while

source

to

charge

can

minute

cycle

If

the

and

last

is

whenever

be

used

fully

discharged

in

less

the

Monitor

(even

be

of

its

capacity.

energy

This

is

largely

battery

then

used

expected,

than

the

stored

operation

blood

intervals.

is

is

fully

for

the

in

the

to

100%

four

is

connected

if

the

Monitor

battery.

up

to

operate

pressure

dependent

allowed

recharged

full

possible,

approximately

capacity.

can

hours.

to

One

would

to

two

hundred

top

one

up

be

fully

If a storage

is

off)

six

months

fully

charged

the

include

fully

third

to

Monitor

on

soon

to

an

the

and

the

of

six

for

^

1-16

Loading...

Loading...