Jinma JM300, JM354E Operator Manual

OPERATION MANUAL

Original Instruction

()

300E-354E

MADE IN CHINA

Preface

Contents

Chapter One Precautions for Safe Operations

Chapter Two General Description

-------------------------------------------------------------------------7

Chapter Three Some key Technical Specifications of the Tractors

3.1

Data of Whole Uni

3.2

Engine Parameter

3.3 Transmission System---------------------------------------------------------------------------------------10

3.4

Travel, Steering and Braking Systems

3.5

Working U nit

3.6

Ele ctr ical Sy stem

3.7

Liquid Filling Capacity

---------------------------------------------------------------------------------------------12

Chapter Four Operation of the Trac tor

4.1 The Fuel and Lubricating Oil of the Tractor ----------------------------------------------------------14

4.2 Water--------- --- --- ------- --- ---- --- --- ---- --- ------- --- --- ---- --- --- ---- --- ------- --- --- ---- --- --- ------- --1 4

4.3 Running-in --------------- ---- --- --- ---- --- --- ---- --- ------- --- --- ---- --- --- ------- --- ---- --- --- ---- --- --- --15

--------------------------------------------------------------------------------------8

-----------------------------------------------------------------------------------------9

------------------------------------------------------------11

----------------------------------------------------------------------------------------13

--------------------------------------------------------------------------------13

----------------------------------------------------------------14

-----------------------------------------------------1

---------------------------8

4.4

Steering Mechanism and Meters

4.5 Control and D riv e----- ---- --- --- ---- --- ------------- ---- --- --- ---- ------------- --- ---- --- --- ---- --- --------19

4.6

Operati on and Us e of th e Worki ng Units of Tra ct or

Chapter Five Technical Maintenance for the Tractor

5.1

Shift Technical Maintenance

5.2

I-grade Tec hnical Maint enance

5.3

II-grade Te chnical Maintenance

5.4

III-grade Technica l Maintenance

5.5

Technical Maintenance in Winter

5.6 Techincal M aintenan ce for Long-ter m Storag e--------- ------ ---------- ------- ------- ------ ------- ----29

--------------------------------------------------------------------17

-----------------------------------------22

-------------------------------------------27

-------------------------------------------------------------------------27

--------------------------------------------------------------------27

-------------------------------------------------------------------28

-----------------------------------------------------------------28

------------------------------------------------------------------29

1

Chapter Six Structure and Maintenance of the Tractor

s-------------------------------------31

6.1

Transm ission System

6.1.1 Clutc h--------- --- ------------- ---- --- --- ---- --- --- -------------- --- --- ---- --- --- ---- ----------------------31

6.1.2 Struct ur e an d Wor kin g P rin ci pa l of S ha ft C ou pl in g------ --- --- --- ---- --- ------------- ---- --- --- --3 4

6.1.3 Gear Box Assembly--------------------------------------------------------------------------------------35

6.1.4 Differ en tia l Ge ar a nd Dif fer en tia l L oc k----- ---- --- --- -------------- --- --- ---- ------------- --- ---- --3 6

6.1.5 Fina l Tr ans mission------------ --- ---- --- ------------- ---- --- --- ---- ------------- --- ---- --- --- ---- --------39

6.2

Travel& Steering System

6.2.1 Hydraulic Steering Control Unit (SCU)---------------------------------------------------------------40

6.2.2 Brake

6.2.3 Tw o -wheel Front Drivi n g A xle

6.2.4 Front Drivin g Axle--------------- -------------- --- --- ---- --- --- ---- ------------- --- ---- --- --- ---- --- -----47

6.2.5 Wheels------------ ------- ------ ------- ------- ------ ---------- ------- ------- ------ ------- ---------- ------- --51

6.3

Working U nit

6.3.1 Suspendin g S ys tem----- ---- --- --- -------------- --- --- ---- --- --- -------------- --- --- ---- --- ------------- 53

6.3.2 Structure and use of PTO Shaft------------------------------------------------------------------------58

6.4

Electric Installation

------------------------------------------------------------------------------------------------------43

---------------------------------------------------------------------------------------------53

-----------------------------------------------------------------------------------31

-----------------------------------------------------------------------------40

-----------------------------------------------------------------------45

-------------------------------------------------------------------------------------58

6.4.1 Engine----- ---- --- --- ----------------- ------------- ---- --- --- ---- --- ------------- ---- --- --- ---- --- --- ---- --5 8

6.4.2 Voltage Adju ste r--------- --- --- ---- --- --- ---- ------ ---- --- --- ---- --- --- ------- --- ---- --- --- ---- --- --- ---62

6.4.3 Battery----------------------------------------------------------------------------------------------------62

6.4.4 Starte r----- ---- --- --- ---- --- ------------- ---- --- --- ---- -------------------------- ---- --- --- ---- --- ---------64

6.4.5 Preh ea tin g P lu g--------- --- ------------- ---- --- --- ---- ------------- ----------------- --- --- ---- --- --------65

6.4.6 Fuse Box--------------------------------------------------------------------------------------------------65

6.4.7 Lig ht s a nd Si gn al D evi ce s--------- --- ------------- ---- --- --- ---- --- --- -------------- --- --- ---- --- --- --6 6

6.4.8 Gauges an d S w itc hes of E le ctr ica l E qu ip ment s--------------- ---- --- --- ---- --- ------------- ---- --- 67

6.5 Intake and Exhaus t S ys tem----- ---- --- ------------- ---- --- --- ---- --- --- -------------- --- --- ---- --- --- ---6 8

Chapt er Seven Main Tr oubles a nd The Solutions

7.1 Hard or Fail to Start the Diese l--------- ------------- --- ---- --- --- -------------- --- --- ---- ------------- --- 70

7.2 Self -stop of Di ese l----- ---- --- --------------------------- --- --- ---- --- --- ---- ------------- --- ---- --- --- ---7 0

7.3 Lack of Diesel Power------------------------------------------------------------------------------------71

-------------------------------------------------70

2

7.4 Abnorm al Exhau st Colo r----- ---- --- ------- --- --- ---- --- --- ---- --- ------- --- --- ---- --- --- ---- ------ ---- --7 1

7.5 Too High T empe rat ur e of Exh au st ed Wate r----- ---- --- --- -------------- ---------------- ---- --- --- ---- 72

7.6 Sudden Raise d S peed of Die se l (Fl ying D ie sel )----- ---- --- --- -------------- --- --- ---- --- --- ---------72

7.7 Abnormal Sound during Engine's Operating----------------------------------------------------------72

7.8 Too low pressure or Zero Pres su re of Diesel Oi l----- ---- --- --- -------------- --- --- ---- --- --- --------73

7.9 Brakes--------------- ---- --- --- ------- --- ---- --- --- ---- --- ------- --- --- ---- --- --- ------- --- ---- --- --- ---- --- -73

7.10 Clutch-----------------------------------------------------------------------------------------------------73

7.11 Hydraulic Suspending System--------------------------------------------------------------------------74

7.12 Electri c S ys tem----- ---- --- --- ---- --- ------------- ---- --- --- ---- --- --- -------------- --- --- ---- --- --- ---- --7 5

7.12.1 Starti ng Moto r----- ---- --- --- -------------- ---------------- ---- --- --- ---- --- --- ---- --------------------75

7.12.2 Bat ter y--------- --- --- -------------- ---------------- ---- --- --- ---- --- ----------------- ------------- --- ---- -7 6

7.12.3 Instrume nt s--------- ------------- --- ---- --- --- ---- ------------- --- ---- --- --- ---- --- ------------- ---- --- --7 6

7.12.4 Lights----- ---- --- --- ---- --- --- -------------- --- --- ---- --- --- ---- --- ------------- ---- --- --- ---- --- --- ---- -7 6

7.12.5 Si lic on Rect ifi cat io n G en er ator----- ---- --- --- ----------------- --------------------------------------77

Chapter Eight Appendix

Ele ctric Wir ing Map

8.1

8.2 Sizes of Suspending System

Spare Parts Along With the Machine

8.3

Tools Along With the Machine

8.4

-------------------------------------------------------------------------------------78

------------------------------------------------------------------------------------78

-----------------------------------------------------------------------------79

-------------------------------------------------------------80

--------------------------------------------------------------------81

3

Preface

Thank you for you r trust on our JINM A-35E and HHJM-35E seri es wheel tractors

(hereinafter JINMA-300E, HHJM-300E, JINMA-304E, HHJM-304E, JINMA-350E,

HHJM-350E and JINMA-354E, HHJM-354E). This series is reasonable in structure,

excelle nt in materia ls and complet ed in perfo rmance. I n order to help c ustomres operat e,

adjust , repair and maintain the products in a better way, and for better performance of

this series, we compile this operation manual. As for the operation & maintenance manue

of engines, please refer to diesel engine manual.

With tec hnical d evel opment a nd requi renment s from our cus tomers , descr iptions in

the manual may differ from the real structure of your tractors and the differences will be

involved in the next version. If what you want to know is beyond this book, plesease

contact the agent or the manufactuer.

“ ”

In this manual, this precaution symbol means some important safety information.

Seeing this symbol, you should read the contents below it carefully and inform other

operators to protect from possible hurts.

"

Warning

operations. Driver or stander-bys will be hurt or even die due to ignore.

"Important"

ignore can result in the damages to tractors or equipments.

Precaution Symbol

" and "

Attention

: These focus on correct steps or techniqus in operations. Your

": These focus on correct steps or techniqus in

Chapter One Precautions for Safe Operations

1.1 Only after reading the manual carefully, can the driver who has got special training and

driving licence with a full survey record operate the tractor. Tractor cannot be operated without

licenses.

1.2 This machine only can be operated, maintained and repaired by the perssons who are familiar

to its features and know the related safe operation rules.

1.3 Driver should pay especial attention to the precaution symbol on the machine.

1.4 It is forbid de n t o driv e tr a cto rs after being drun k, tired or takin g som e an tipsychotic.

1.5 1.5 During operating the tractor, driver should strictly complies with the informed steps

accrod ing to the presa ut ion sy mbo ls t o avo id acc ide nts. When t he symb ols ar e lo st, po lu ted or ab ra sed,

they should be replaced in time.( See Fig.1--1~Fig. 1-7 for precaution and operation symbols)

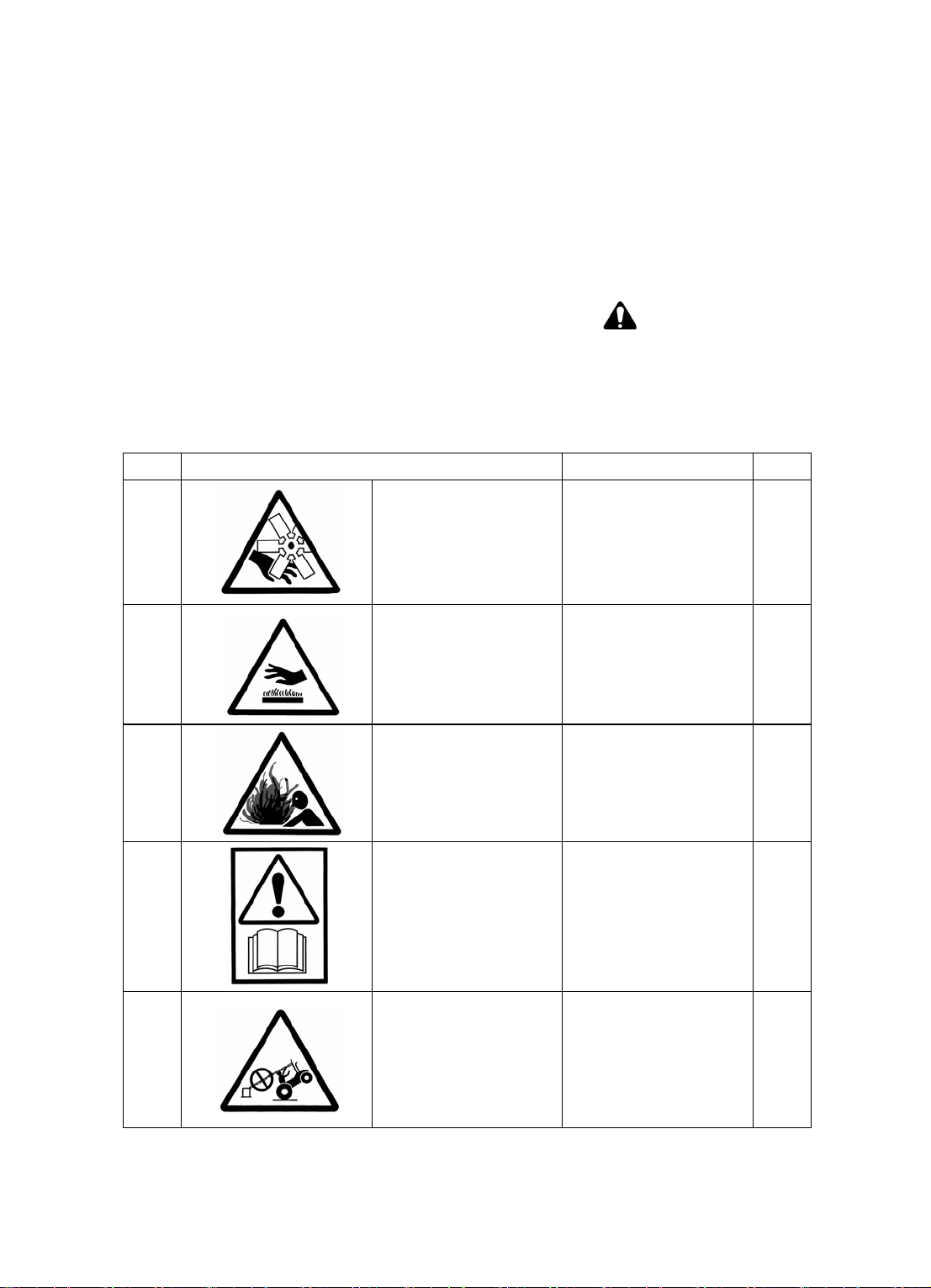

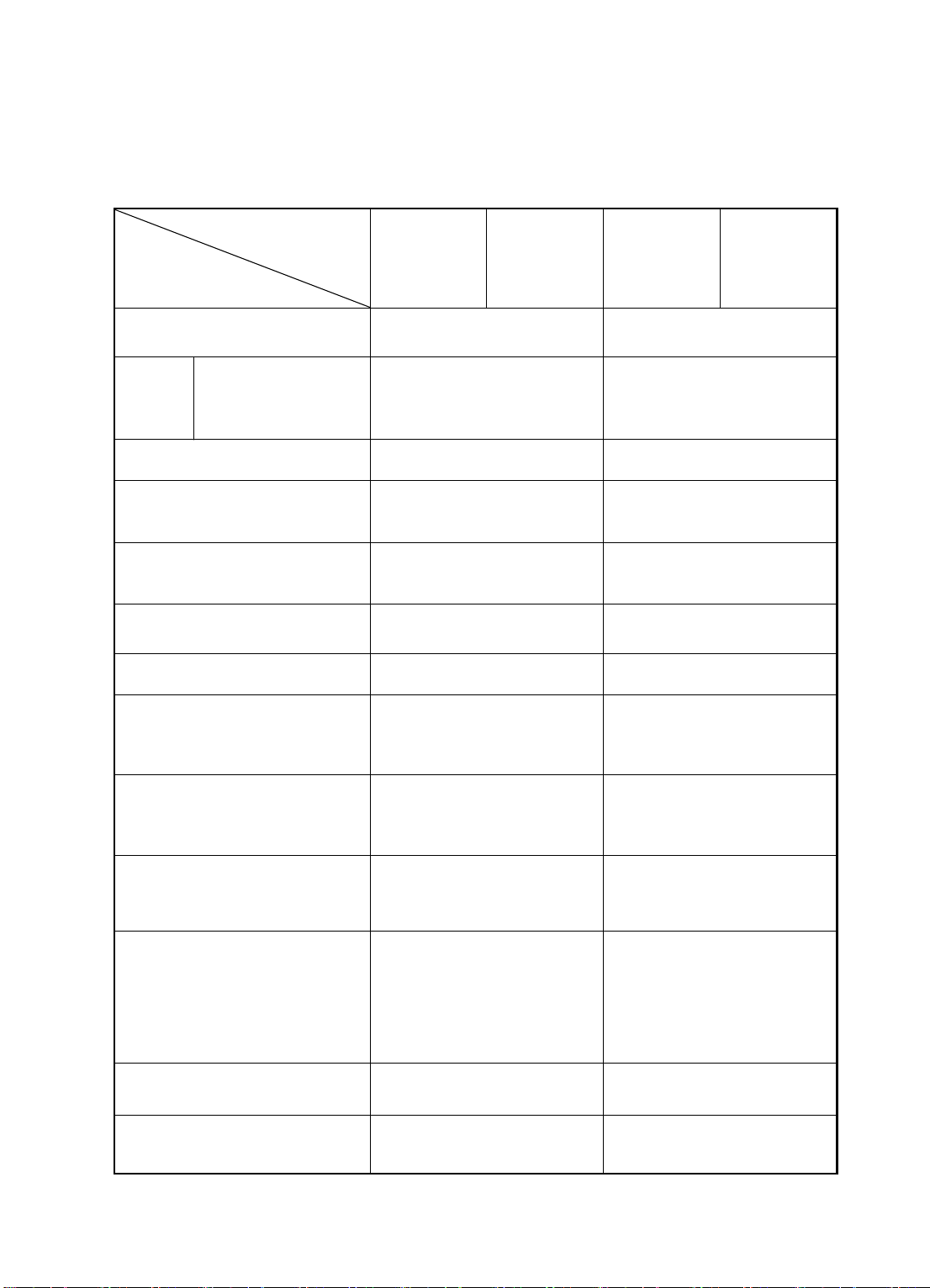

REF. MEANNING LOCATION Q.TY

1-1

:DANGER ENGINE

FAN

On the two sides of

radiator wind scooper

clearly.

2

1-2

1-3

1-4

1-5

:DANGER HOT

PARTS

DANGE R COOLING

SYSTEM UN DER

PRESSURE

CONSULT THE USER

MANUAL BEFORE

OPERATING THE

MACHINE

DO NOT US E CHAINS

OR ROPES JOINED

TO ROPS FOR

TOWING

:

1.On the two sides of

radiator wind scooper

clearly.

、2 Near to muffler.

On the position of fore

and lower part of

radiator.

On the PTO guard at the

back of the machine

On th e right insid e of

ROP.

2+1

1

1

1

1

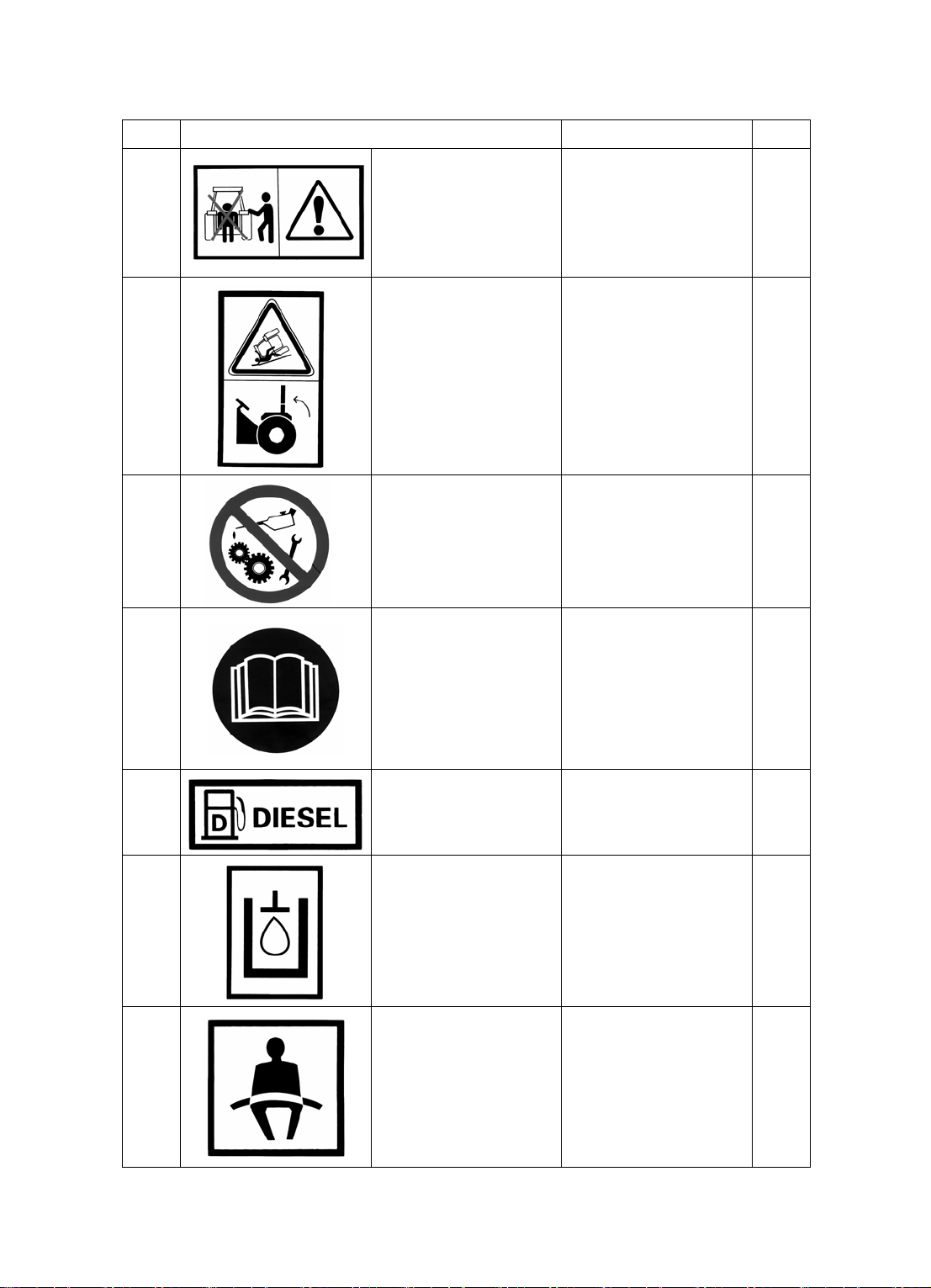

REF. MEANNING LOCATION Q.TY

DO NOT STAND

1-6

1-7

BETWEEN TRACTOR

AND EQUIPMENT

WHILE OPERATIING

HYDRAU LIC LIFT

ALWAYS LOCK ROPS

IN UPRIGHT

POSITION UNLESS IT

HAS TO BE FOLDED

DOWN TO ALLOW

OPERATION

UNDERNEATH

TREES OR BUSHES

At the central site of the

machine end.

On the left og the inside

of ROP

1

1

:PROHIBITION

1-8

1-9

1-10 DIESEL

1-11 HYDRAU LIC OIL On the oil tank 1

DO NOT LUBRICATE

MOVING PARTS

CONSULT THE

(MANUAL IF THE

MANUAL IS MISSING

,OR DAM A GED

CONTAC T THE

VEHICLE'S

On the two sides of

radiator wind scooper

clearly.

On th e right side o g

tractor instrument pa nel 1

)MANUFACTURER

On the front end of oil

tank

2

1

1-12 USE SAFET Y BELTS On th e right of the insid e

of ROP

2

1

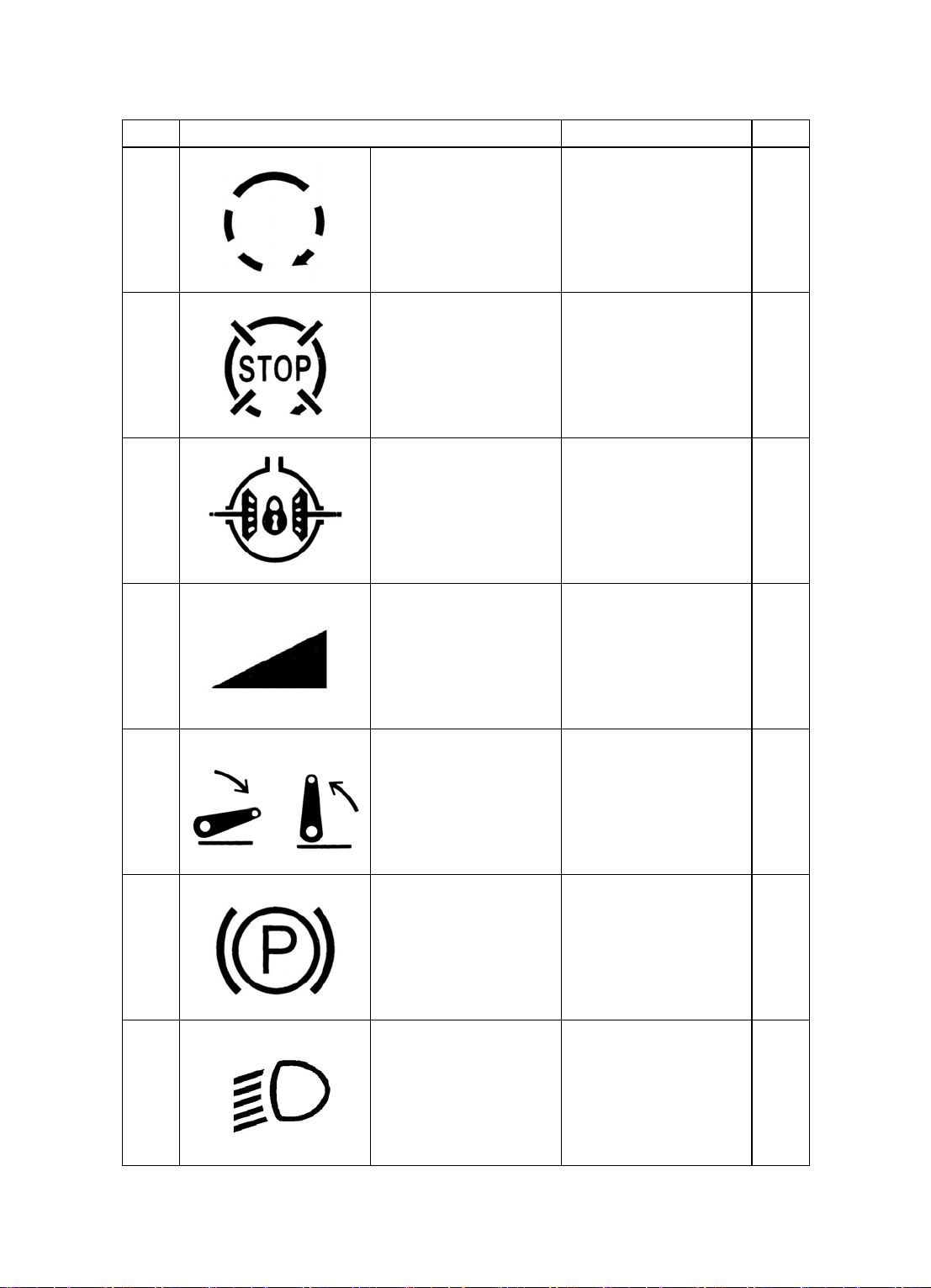

REF. MEANNING LOCATION Q.TY

1-13 STARTER CONTROL Abov e starting switch 1

1-14

1-15

1-16

1-17

ENGINE SHUT-OFF

CONTROL

DIFFERENTIAL LOCK

CONTROL

ENGINE ROTARY

VARIATIONS

THREE-OINTLIFTING

ECHAN ISM CONTROL

Above choke line 1

above ped al of

differential lock

On cover plate of hand

throttle assembly

At the starting and

ending positions of lifter

control lever

1

1

1

1-18

1-19

PARKING BRAKE

CONTROL

DIPPED-BEAM

HEADLAMPS

CONTROL

3

Near hand throttle

assembly

On the surface of head

lamps

1

1

REF. MEANNING LOCATION Q.TY

1-13 STARTER CONTROL Abov e starting switch 1

1-14

1-15

1-16

1-17

1-18

ENGINE SHUT-OFF

CONTROL

DIFFERENTIAL LOCK

CONTROL

ENGINE ROTARY

VARIATIONS

THREE-OINTLIFTING

ECHAN ISM CONTROL

PARKING BRAKE

CONTROL

Above choke line 1

above ped al of

differential lock

On cover plate of hand

throttle assembly

At the starting and

ending positions of lifter

control lever

Near hand throttle

assembly

1

1

1

1

1-19

DIPPED-BEAM

HEADLAMPS

CONTROL

4

On the surface of head

lamps

1

1.6 Befo re operation, a new tractor sho uld have a runnin g-in follow ing the related r egulations .

And then normal loaded work can be done.

1.7 Befo r the tractor moves, o n its path sh ould be no any ba rrier, and no p eople between the

tractor and th e rear impl e ment or trailer.

1.8 D on't leave driv er's seat to st art or c ontro l the tracto r. Ea ch ge ar sh ifter shou ld be p laced a t

the "n eutra l gear" before strating or gettin g off the tractor.

1.9 Don 't get on or off th e tractor duri ng its runnin g. Before rep airing the tracto r, the mach ine

should be stop ped an d the ke y s hould be taken off . R epa ir or che ck under the t ractor is fo r bi dden w he n

the engine runs.

1.10 To a vo id tu rn- over , onl y low gears c an be use d, espe cia lly goin g on h igh s lopes o r mu ddy

path. W hen going downslop e, clutch engaging or neutr al g ear is not a ll o w ed. Let th e running tactor not

too near to any ditch, to avoid damage due to broken trenches.

1.11 In transportat ion, the l eft and the r ight brake p edals shou ld be joined and locked togethe r.

Move PTO handle to the "Apart" position.

1.12 When the suspende d implemen t of the tracto r is transfer ed, hydrauli c lifter shou ld be at th e

positio n of " ne utr al" .

1.13 No sharp turn is permitted while driving at a hig speed. Sharp turn with the help of one side

brake is prohibited eitherto avoid turn-over or parts damaging .

1.14 You'd better check and fasten bolts of wheel radial plates and the bolts or nuts in other key

positions.

1.15 When transfering to another fiel d or operating with hung farm implements, high speed is

forbidden to avoid the damage to parts of lifting system and suspending system. Before leaving the

tractor, driver should drop down its farm implement first, stop the engine and take off the key to

prevent others from starting the tractor.

1.16 B efore st arting t he tracto r, you'd better c heck oi l duct, elec tric ci rcuit and cooling water.I n

any case, it is not allowed to fill the fuel that has not been precipitated or filtrated into tank.After

starting the machine, you'd better pay attention to all indicators and meters.

1.17 Be fore fillin g fuel int o tank, yo u'd bett er stop the engine; Smokin g is prohib ited dur ing fue l

filling and check & repair for fuel system.

1.18 W hen deep treade d tires work ing or transf ering in fiel ds, high speed is not allow ed; Deep

trea ded tires can't be used for transportation .

1.19 Tr act or can not b e u sed wi th ov er loa d to avoi d dam age t o or gans. Load lim it of t he trai ler is

3 tons.

1.20 Dirts should be eliminated from radiating water tank to guarantee its heat radiating

performa nce. When the water tank is too hot, you ca n't water the en gine or wat er tank with col d wate r

to avoid breaking the tank. You should reduce it s load and on l y af t er the wa ter is not so hot can cool in g

water be filled with the engine running.

1.21 You should te ll your nex t shift about any troubles of the trac tor. Dur ing opera tion in night,

fine lightings are necessary.

1.22 Wh en it wo rks bel ow 0 in winte r, exha us t all th e wate r in the ca se of idling op erat ion to

avoid organs freezing caused by remained water.

℃

5

1.23 M anufactur e r is n ot responsible fo r an y reduce d ra li a bility of the machin e, pe rsonnel hurt or

dama ged mac hine due t o any una uthorized ref orm on th e tractor.

1.24 Du ring running or w orking, if one of the tractor' s driving whe el is found seve re wheels pin,

you ca n use the differentia l lock fo llowing i ts instruct ion. The different ial lock is forbidden to use in

any other case to avoid machine dama gi ng or oth er accidents.

1.25 D uring h arvestin g or operati ng in f ield yard, a spark e xtingui sher s hould be insta lled on ai r

exhaust .

1.26 Exhaust elbow and muffler are high temperature components. within a half hour after

starting or stoping the engine, anyone is not allowed to get near to avoid burn.

1.27 Fa ulted tra ctor c anno t be pu t into use, e spe ciall y whe n oil p ressu re is z ero or too lo w , wate r

is too hot or abnormal sound or smell come. The machine should be stopped for check and the trouble

should be shot in time.

1.28 Only after taking earth wire off from the battery can electric parts be repaired.

1.29 Don ' t stop the tractor on a big slop. If so , it s park br a ke s should be us ed and a tria ng le s ho uld

be stuck under the real wheel s.

1.30 Th e protecti ng compon ents for dri ver is not in dispensabl e. However when install ing safet y

frame on the tractor , a seat belt is necess ary; when removin g the fram fro n the tractor, the sea t belt

should be removed too to avoid ues by mistake.

1.31 When working in fields or muddy area, you'd better remove the dirt from your shoes and

keep the pedals clean.Catcj the armrest carefull when getting on or off the tractor.

1.32 When driving along the road, you'd be tter follow the loc al traffic rules

1.33 In any c ase ki ds or no -drive rs sh ould be kept far away from the ma chine t o avoid hurts.

1.34 Before using PTO, a protecting cover need be installed.

1.35 Be fore operating th e tractor, ple ase read oper ation manua l; Please be sure to sit on the sea t

and fasten the seat belt, then you can start and operate the tractor.

1.36 It is forbidden to put down the roll bar when you are starting and using the tractor normally!

1.37 You can use the differential lock only when the tractor skid on the muddy road; when the

tractor skid s, ple ase press t he hand le of the d iffer ential l ock, th en t he d iff erenti al lo ck w orks , a nd i t

makes lef-right jaw o f the drive shaf t meshing to be o ne, and then makes t he tractor driv ing out of the

muddy road; At the same ti m e rele ase th e hand le back to the po sition!

6

Chapter Two General Description

JINMA-35E HHJM-35E series wheel tractors JINMA

、、

-304E HHJM-304E JINMA

developed by ourselves according to Europe farming machinery markets.

JINMA-35E HHJM-35E series wheel tractors are newly developed with kinds of new

technologies, new processes and new structures, together with years' production experiences .

The n ew series ha s more reas onable stru ctures and b etter improve d perform ance. Th ey are mo re

powerfu l, eco nom ical in o il cons um ption, high effic iency , n ice in a ppea rance , easy in o peratio n

and maintenance, conenient for being supported, economical in use and perfect in integrated

performa nce. T his serie s has got EC certificate in D ecemn er 20 07 (C ertificate N o. e1 1*2 005/67 *

0005*0 0) w h ile the certific ated typ es e xc lude any option al pa rts.

JINMA-35E HHJM-35E series wheel tractors are equipped with 30hp and 35hp vertical

and oil-saving diesels respectively. Direct transmission is used between the engine and the

transmission system and an 8-gear gear box is installed for the work of rototilling, ploughing,

harvesting, transportation and so on. They have a hydraulic suspending system with perfect

performance, low-pressure broad driving wheel tires with fine adhesion, and airbraking device

with reliable p erformance. Be sides, customers ca n select different types o f tractors according to

their own requirenme nts a nd economic situ atio ns. The series include sing le-a cting clu tch and dual

、(

、

、

、、

-350E HHJM-350E JINMA

、)

-354E HHJM -35 4E are a n ew se rie s

、、

-300E HHJM-300E JINMA

-acting clutch, 2-wheel driving and 4-wheel driving, mechanical steering and entirely hydraulic

steering.

Warning:

Manu facture r is n ot resp onsi ble fo r any reduced rel iabil ity of the m achine, pe rsonne l

1.

hurt or mac hin e da magi ng du e t o any unau th oriz ed ref or m on t he tra ct or or a ny o pe ratio n t hat

doesn't follow re lated technical re quirements.

2. You can only use the implements specially designed for this series.

Customers should try to avoid possible damages to the machines caused by the farm

implements that don't follow the configuring regulations.

7

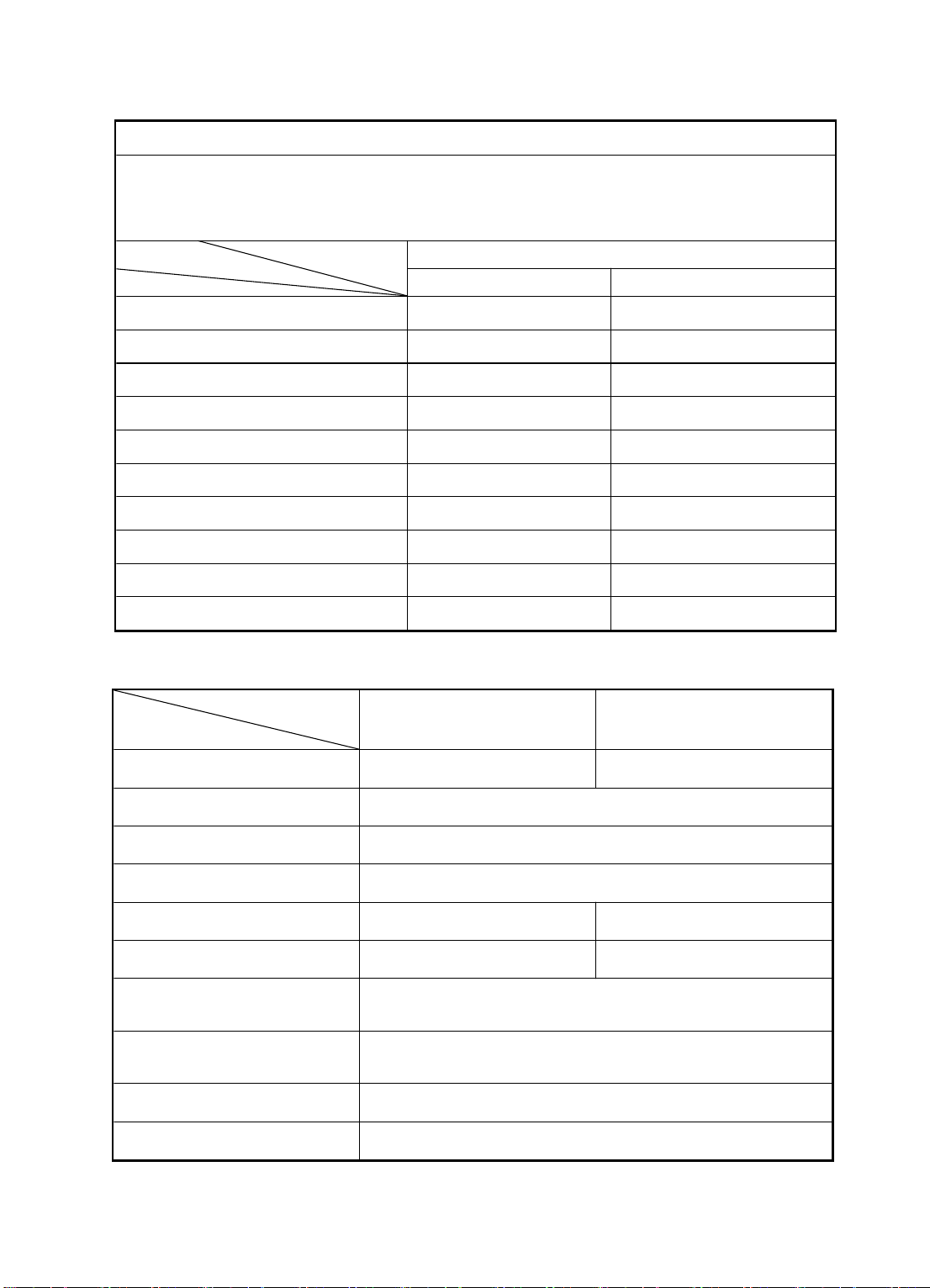

Chapter Three Key Technical Specifications of the Tractors

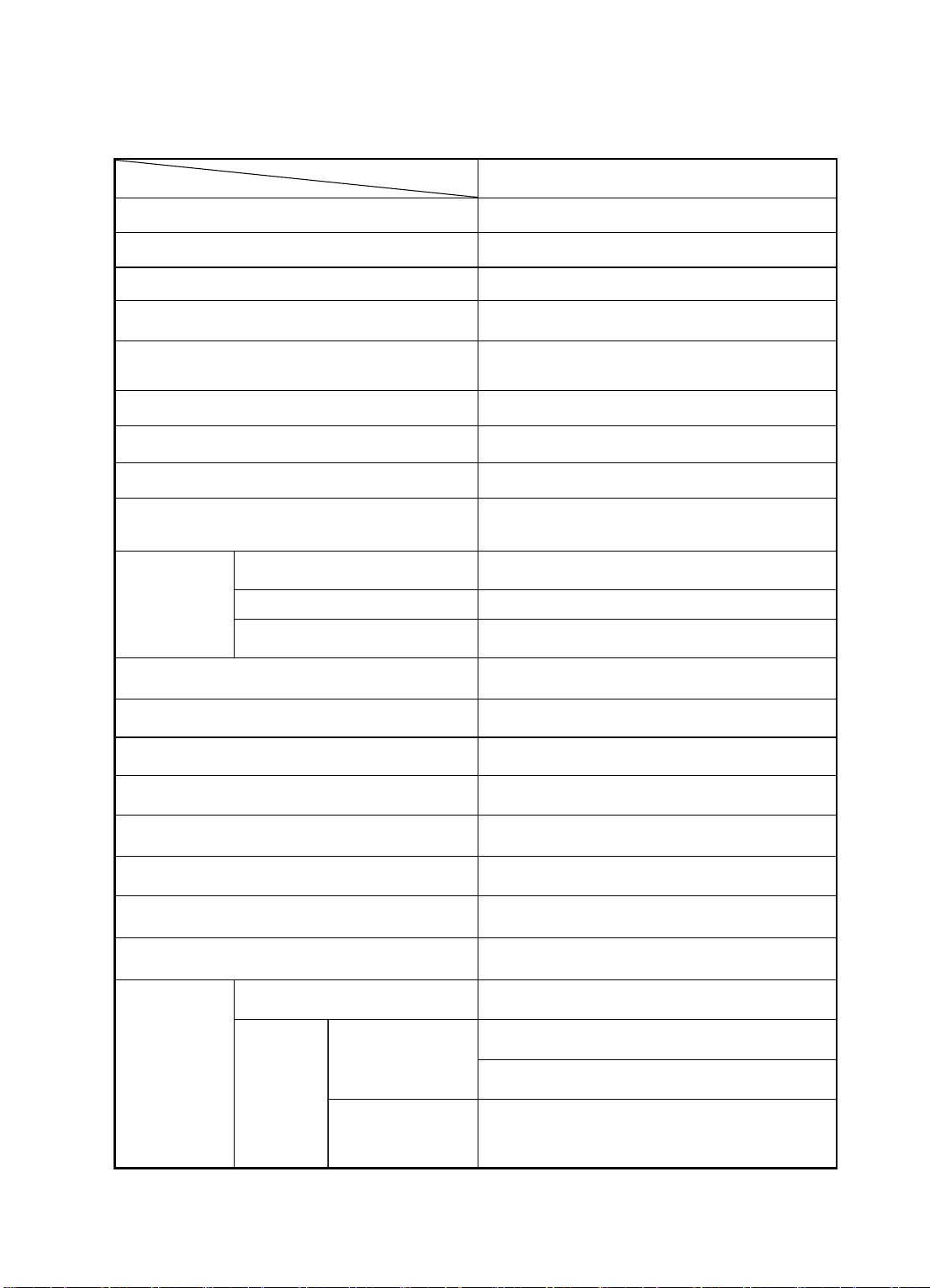

3.1 Data of whole uni

tractor type

Parameter

mode ×( )422WD ×( )444WD

external

size

mm

wheelbase mm 1776.5 1833.5

usual tread of front wheels mm

usual tread of back wheels mm

Min. ground clearance mm 350 292

radius of turning circle m 3.55 4.15

Min. use weight kg

fore axle kg

rear axle kg

L

W

H

JINMA/HHJM

300E

1050~1450(adjustable with

1200~1500(adjustable with

JINMA/HHJM

350E

3363

1485

2420

steps)

steps)

1735

695

1040

JINMA/HHJM

304E

1200~1500(adjustable with

JINMA/HHJM

354E

3353

1485

2420

1200

steps)

1935

845

1090

added mass (option) kg

fore axle kg

rear axle kg

allowed max. weight

fore axle kg

rear axle kg

pull mass kg

tow truck without braking

tow truck with independent braking

tow truck with inertiabraking

tow truck with hydraulic or

pneumatic braking

Noise by ear dB(A)

Vibration of the seat m/sec

∧

2

208

48

160

2400

850

1550

1200

/

/

/

85.6 85.9

1.15 1.20

8

208

48

160

2750

1050

1700

1500

/

/

/

:1.Rated engine speed 2350r/min

theoretical velocity km/h

:2.Tyre code of rear driving wheels 11.2-24

:3.Max. impetus radius of rear driving wheels 516mm

theoretical velocity

gear

ⅠL- 2.248 2.082

ⅡL- 3.008 2.628

ⅢL- 4.127 4.279

ⅣL- 6.258 6.785

ⅠH- 10.37 8.867

ⅡH- 13.875 11.182

ⅢH- 19.451 18.204

ⅣH- 28.867 28.867

ⅠR- 2.861 1.942

ⅡR- 13.2 8.265

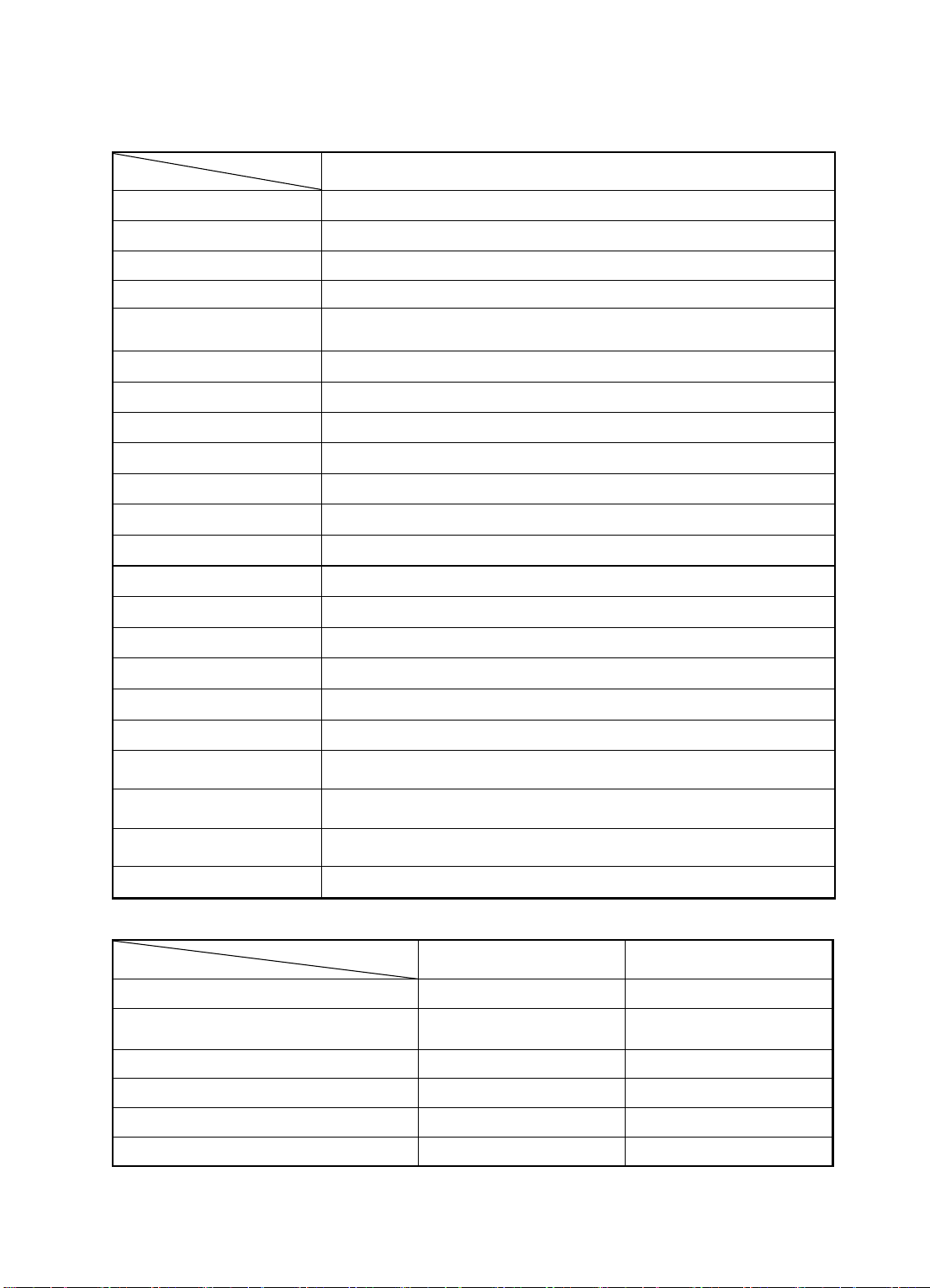

3.2 Engine Parameter

Type

Engine Data

tractor model

JINMA/HHJM-300E/304E/350E/354E

dual-acting clutch single-acting clutch

JINMA/HHJM-300E/304E JINMA/HHJM-350E/354E

Model 4L22T1 4L22T

Type Four-cylinder,In-line Water-cooled,Four-stroke,Swirl chamber

Bore of cylinder mm 85

Stroke of piston 95

Tated power/speed kW/rpm 22.2/2350 25.8/2350

Max. torpue/speed N·m/rpm 103.28/1650 120.57/1650

Maximum allowable

intake depression kPa

Maximum allowable

back pressure kPa

Compression ratio :22 1

Displacement L 2.156

9

3.6

10.2

Engine parameter

Type

JINMA/HHJM-300E/304E JINMA/HHJM-350E/354E

Oil

pressure

Valve

timing

phase

Valve

clearance

Model

Firing order

At idle speed kPa

At rated speed kPa

Intake valve open(before T.D.C)

Intake valve close (after B.D.C)

Exhaust valve open(before B.D.C)

Exhaust valve close(after T.D.C)

4L22T1 4L22T

1-3-2-4

≥ 50

~300 450

13 CA

29 CA

56 CA

12 CA

Intake valve mm ~0.20 0.30

Exhaust valve mm ~0.25 0.35

Cooled water ~75 85

℃Temperature

Oil ~85 95

Exhaust pipe ≤ 650

Starting method Electric starting

Lubricating method Pressure & splash

Cooling method Water cooling

××Overall dimension (L W H) mm ××757 494 620

Net weight kg 200

3.3 Transmission system

part names

Clutch

Gearbox ()×two-axial, direct teeth 4+1 2 combination type

Central Drive spiral taper gear

Differential two planetary gear teeth, bevel gear type (with differential lock)

Final Drive external gearing direct teeth type

Fore Drive Axle —— whole-sealed bevel gear type

Transfer Case —— spur gear

Type

JINMA/HHJM-300E/350E JINMA/HHJM-304E/354E

single-acting, dry and constantly-engaged friction type

gual-acting, dry and constantly-engaged friction type

10

3.4 Travel, steering and braking systems

tractor type

parts and parameters

JINMA/HHJM-300E/350E JINMA/HHJM-304E/354E

Frame Type No Frame

Type of Fore Shaft(Fore

Drive Axle)

Inverted-U Pipe Epuilibrium

tri-sentor separable axisle shousing

of conic reducer

Fore Axle Tilt Angle ±°13 ±°12

Toe-in of Front Wheels mm 4~11 3~11

Toe-out of Front Wheel °2 °3

Tumble Home of Main

Shaft

°8 °8

tyre code 5.00-15-8PR 6.00-16-6PR 7.50-16-6PR

agricu

fore

wheels

air

pressure /

load

Pa/kg

tyre code

200/310 150/350 120/415

350/430 250/470 180/530

460/510 340/560 210/585

9.5-24 11.2-24

6PR 8PR 6PR 8PR 6PR 8PR 6PR 8PR

ltural

tyre

back

wheels

air

pressure/

load

120/

600

180/

765

120/600

200/810

120/

160/

120/745 120/600 120/600 120/745 120/745

745

200/1000 180/765 200/810 160/880

880

Pa/kg

210/

845

280/

1000

180/

240/1110 210/845

940

280/

1000

180/940

200/

1000

240/

1110

tyre code ×31 9.5-16-4PR

front

wheels

air

pressure /

load

lawn

tyres

back

wheels

Pa/kg

tyre code 13-20-6PR

air

pressure /

load

Pa/kg

model of hydraulic steering

device

model of constant flow

pump

brake disk brake

120/640

140/705

160/765

80/745

100/850

120/945

101S-1-100-12-AH

CBT-E306(coupling by levogyrate splines)

11

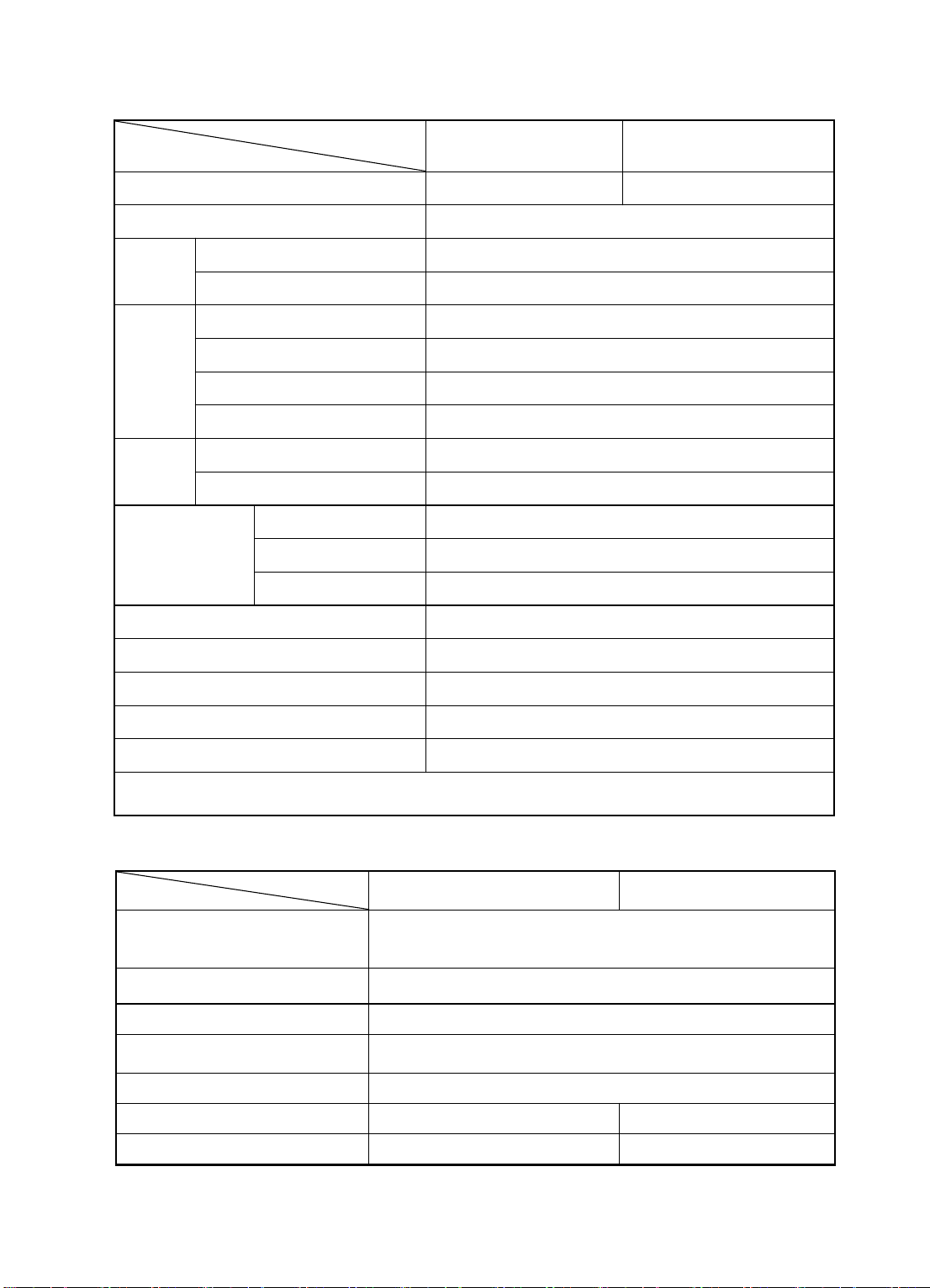

3.5 Working unit

parts and parameters

Tractor model

JINMA/HHJM-300E/304E/350E/354E

Lifter type Semi-divided positioned Type

Model of Gear Pump CBN-E314(coupling by dextrogyrate splines)

Model of Dispenser Outlaid Unload Control

(×)cylinder diameter stroke mm ×85 100

Safety Valve Type of System andOil Cylinder

Damping Valve Direct Action Type and Cone

System Pressure MPa 16

Opening Pressure of Safety Valve MPa 18

Plowing Depth Control combination control

Max Lift Force in the Position of 610mm back

from Lower Hook Station kN

Hydraulic-

pressure

Specification of Diameter ×M16 1.5

Quantity 1

4900/4900/5800/5800

Output Joint

Output Discharge l/min 12

Valve Direct Action

Type of Hanging Device REar Three-point Suspending

Hanging Connection Triangle mm W

Connecting Aperture of Upper Suspending Point mm Φ19

Connecting Aperture of Lower Suspending Point mm

Φ22

Mode of PTO Shaft combined type

speed r/min 540/1000

Circumrotation Direction Clockwise(Facing the head-ward of Tractor)

Shaft Extension ××I type/ square spline (6-35 28.91 8.69)

Diameter of Joint Pin mm Φ30

323.5

418.5

pull unit

20Ground

Clearance

Swing drawbar

of Joint Pin

(Midpoin

t) mm

Clevis 509

12

3.6 Electrical system

parts

electrical system minus earthsingle-wire system12V

starting motor QDZ157Y(12V,3.2kW)

generator

battery C603-6QA-90AH

gauges

head lamp C201-014

rear working lamp C203-005

front signal lights C202-007

tail lamp C203-002

rear license light C209-001

horn C502-50F

fuse box C703-003

combined switch 254E.48.012 & 254E.48.013

7-hole socket C604-001

starting switch C402-003

model

C110-015(oil pressure gauge, fuel gauge, water

JINMA/HHJM-300E/304E/350E/354E

ZFW13C1

thermometer,chronometer,speed indicator)

(14V,350W)

speed sensor C304-005

oil mass sensor C302-006

oil pressure sensor C303-002

water-temperature

sensor

starting interlock

switch

braking interlock

switch

cigarette lighter C801-001

C301-003

C402-007

C402-008

3.7 Liquid filling capacity

parts and parameters

fuel tank L 40 40

gearbox, rear axle, final transmission of

dispenser L

front driving axle L —— 6.6

hydraulic steering L 2.5 2.5

lifter L 8.8 10

cooling liquid L 7.2 7.2

tractor model

JINMA/HHJM-300E/350E JINMA/HHJM-304E/354E

18.5 20.2

13

Chapter Four Operation of the Tractor

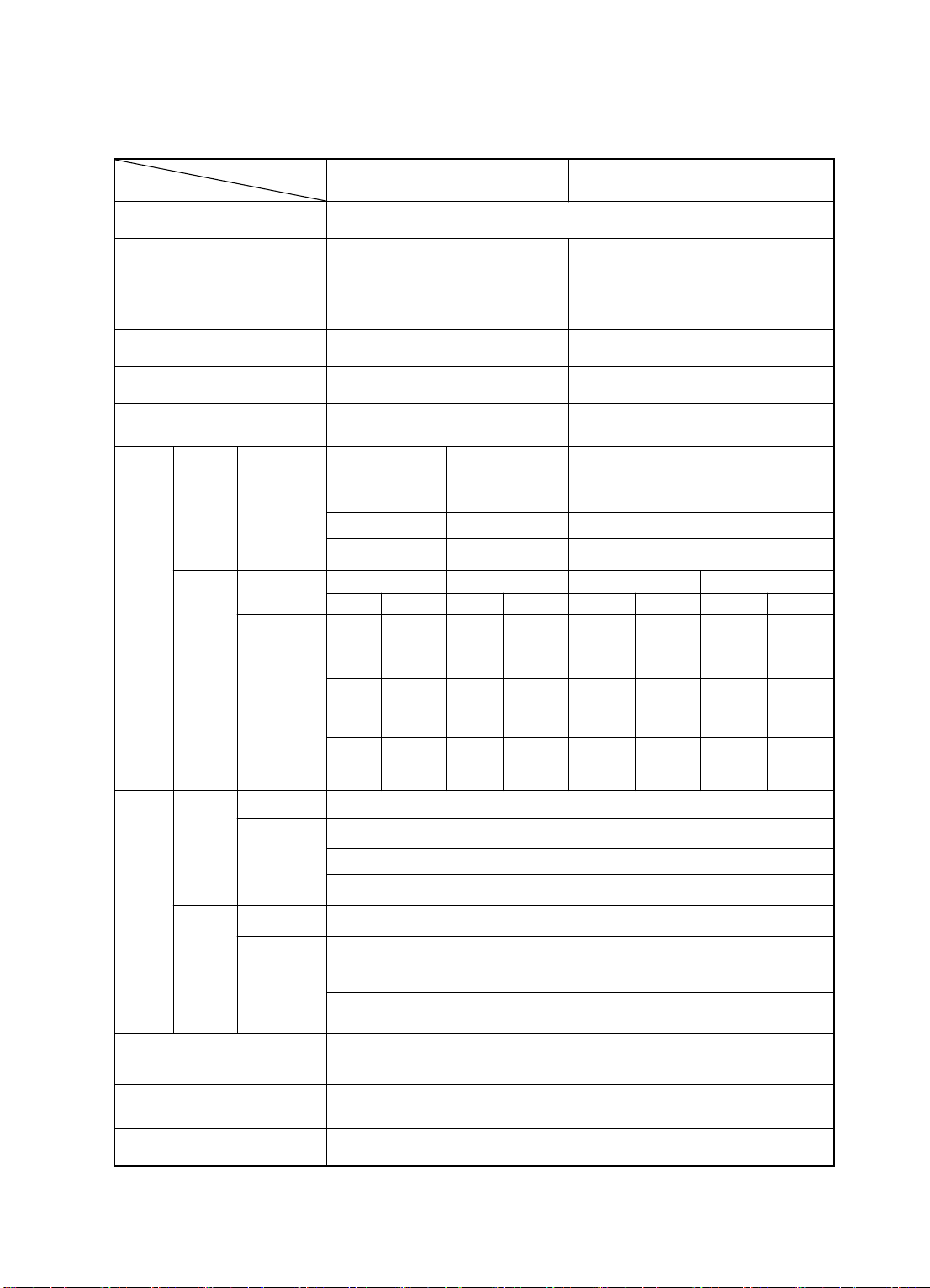

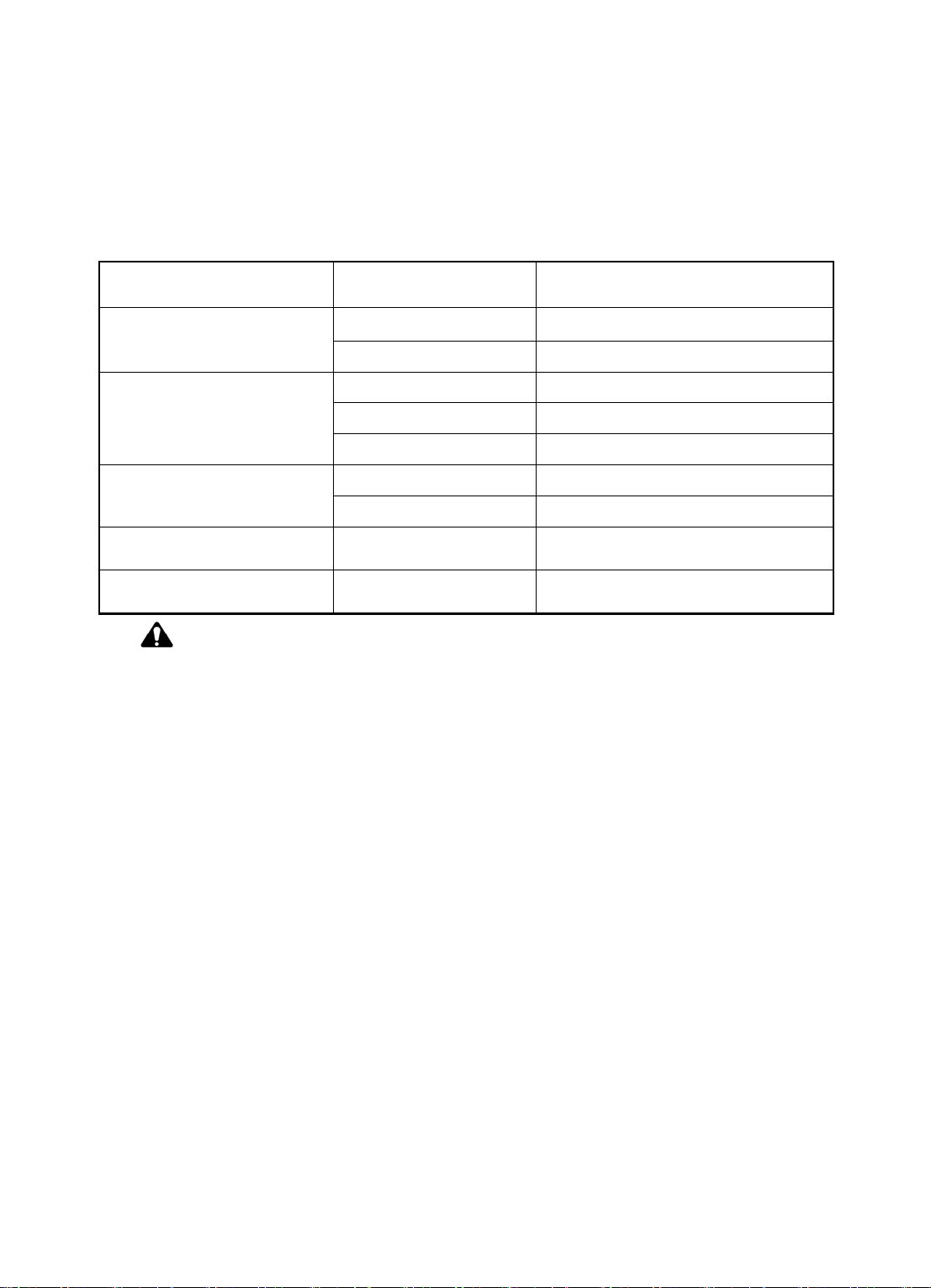

4.1 The fuel and lubricating oil of the tractor

See Fig. 4-1 for The fuel and lubricating oil of the tractor.

Fig. 4-1 The fuel and lubricating oil of the tractor

Site

Fuel Tank

Oil pa n of engin e, hydraulic-

pressure steering gear of lifter,

oil pan of air filter, and

injection pump

Gear box, transfer case, front

driving axle, mechanical

steer ing device

Each grease nipple

engine, starter, bearing6203-E For all seasons

Warning:

1. Before fill ing fuel int o tank , you 'd bett er st op the engi ne; Sm oking is no t all owed durin g

fuel filling and check & repair for fuel system.

2. In no case can gasoline or alcohol be filled in diesel oil. This mixture can lead to fire or

exp losion b ecause it is m ore deto nable than pu r e g as o l i ne in fuel tank. Differen t gr ade oil can't be

mixed for use.

●

Important:

1. Only very clear fuel can be used. Fuel should be precipitated for above 48 hours and then only

the middle and top fuel can be filled into the tank with a filter. No full fuel for volatilization and screw

down the tank cover after filling.

2. Fill fuel before the tank is empty. To fill fuel after the oil is used out in the supplying system, air

must b e exha usted from th e supply ing system firstl y.

3. Do use a clean filling tool. Don t wash or wipe with diesel oil. Wipe the overflowed diesel oil

at once.

4. Wash fuel tank regularly, discharge precipitated oil, and wash diesel oil filter.

’

5. Don t use open oil drum to transport fuel.

6. Put all cloth with oil into containers with covers. No dog-end can touch it.

’

7. You d better check the engine oil on each lubricated site very often. Fill oil at the sites in time.

Fill grease into grease nipples regularly.

Season and Envirenmental

Temperature

(℃)Summer Above 10

(℃)Winter Below 10 ()-10# solar oil GB/T 252-2000

℃Below 0 ()20# 40# diesel oil GB/T 5323-1994

℃℃ Between 0 -25 ()30# diesel oil GB/T 5323-1994

℃Above 25 ()40# diesel oil GB/T 5323-1994

(℃)Summer Above 10 ()40# diesel oil GB/T 5323-1994

(℃)Winter Below 10 ()30# diesel oil GB/T 5323-1994

For all seasons

’

ZFG2# complex calcium lubricating

grease(SH0370-1992)

ZFG2# complex calcium lubricating

grease(SH0370-1992)

Oil Specification

()0#, -10 # solar oil GB/T 252-20 00

4.2 Wate r

4.2.1 Only clear and soft water can be filled into water cooling tank to avoid inefficient

14

performance caused by scale incrustation.

4.2.2 Hard water(in well, spring and so on) should be softened and then be used. Follow the steps

below to soften the hard water:

1. Boil up hard water, precipitate and filter it.

2. Use causti c soda to tre at har d wat er at a rate of 1.5g/ l

Working in cold areas, anti-icing fluid can be used for cooling water.

Attention:

When the engine works or just after it is stopped, the water tank has a high temperature, so

it is dan gerous to open the t ank cover a t that time. Only after the tank is c ooled down can it b e

opened. To open it , you can loose the cover first to release its inside air pressure.

●

Important:

1. Dirt should be eliminated from radiating water tank to guarantee its heat radiating performance.

When the water tank is too hot, you can't water the engine or the tank to avoid breaking the tank. You

should reduc e its l oad an d onl y aft er th e water is not so h ot can cooli ng water be filled with the e ngin e

runnin g. Ch eck cooli n g w ater in t h e tank that shoul d be kept ful l. C o oling wate r can t be less th an 2/3

of the tank volume.

2. When the water in tank is over 100 , stop the engine immediately. Have a necessary check and

repair on the water tank after it is cooled.

3. When op erat ion in th e col d ar ea wi th a t em perat ure unde r 0 is o ver , you sho uld d isc harge all

the water with tractor idling.

’

℃

℃

4.3 Runni ng-in

To put into use, new tractors or heavily repaired tractors must run in first, because newly

manufactured parts have more or less tool marks on the surfaces. If you use the tractor with a heavy

load without running-in, abrasion on the parts will be more severe and the parts can even be stuck and

dama ged to shorten the tractor life.

4.3.1 Prep aration befo re Running-i n

1. Wash the housin g of the en gine.

2, Check and tighten the external bolts and nuts.

3. Check the oil level in each lubricating bo x, refi ll oil if not en ough.

4. Fill grease to every oil site.

5. Fill fuel and cooling water.

6. Check the toe-in of front wheel (4-11mm); Check air pressure of the front and the rear tires and

adjust the pressure to the rated value.

7. Check batteries and connections of the electric circuit in electric system.

8. Put shift er at neut ral gear, hand throttle in idle- speed position and hydraulic hand in dropping

position.

4.3.2 Running-in of the engine without load

After connecting farm implements to the suspending mechanism, control the lift& drop handle

with the engine running at a rated rev to make the suspending unit lift and drop equably for 10 minutes

and a t least 20 times. Don t drop or lift th e farm implements on hard ground to avoid da mage. After

running-in, its oil pump should be stopped from working.

better find out their causations. Only after all troubles are disposed, can the running-in go on.

’

15

4.3.3 Running-in of Hydraulic System

After connecting farm implements to the suspending mechanism, control the lift& drop handle

with the engine running at a rated rev to make the suspending unit lift and drop equably for 10 minutes

and a t least 20 times. Don t drop or lift th e farm implements on hard ground to avoid da mage. After

running-in, its oil pump should be stopped from working.

4.3.4 Travel running-in without load for 2 hours

Start and move the tractor according to stipulations and do running-in following the steps and

rules below:

III-gear 20min.

IV-gear 30min.

V-gear 30min.

VI-gear 30min.

Reverse I-gear 10min.

During the travel of free running-in, do steering operations and use the brake suitably. Pay

attention to the following items:

1) Watch and listen carefully to the operations of its engine, transmission system and travel &

steering.

2) Watch and see if clutch, brake and gear shifting work normally an d smoothly.

3) See if indicators and electric units work well.

When abnormal things or troubles happen, you d better find out their causations. Only after

shooting the troubles can load running-in be done.

4.3.5 Running-in with load for 48 hours

The running-in of the tractor with load is to make the tractor operating with a certain load from a

small load to heavy one and at speed from low gear to high gear.

See Fig. 4-2 for Loaded running-in and load

’

’

Fig. 4-2

time (h)

load

basic configuration 150kg

(1/4 load)

basic configuration 300kg

(1/2 load)

basic configuration 450kg

(3/4 load)

When abnormal things or troubles happen, you d

4.3.6 After the running-in is finished, do the following maintenance and then the tractor can be

put into use.

1. After the machine is stopped, discharge the lubricating oil from the oil pan of diesel engine.

Wash oil pan, engine oil filter cloth and engine oil cleaner, and fill new lubricating oil to rated level.

2. Disch arge the lubric ating oi l from gea r box, hy draul ic system and fron t drivin g axle wh en it i s

hot. Fill in some diesel oil, travel for 2-5minutes at II-gear and reverse I-gear, wash it, let out the

gear

3 4 5 6 total approximate traction value for reference

345517

355518

355 13

16

pull 2-wheel trailer, transport on roads with

loadof 2 tons

tow a 2-plowshare plough with a ploughing

width of 60 cm and a dep t h of 12 cm.

tow a 3-plowshare plough with a ploughing

width of 71 cm and a dep t h of 15 cm.

’

washing oil and fill in new lubricating oi.

3. Wash diesel oil cleaner (including the filter cloth in fuel box) and air filter.

4. Discharge cooling water, wash the cooling system of the engine with clean water.

5. Check and adjust the free travels of the clutch pedal and brake pedal, and the operating of the

brake.

6. Check and tighten the bolts and nuts at every key connecting sites.

7. Check oil nozzle and valve clearance. Adjust them if necessary.

8. Check th e work of elect ric system.

9. Check and adjust toe-in of the front wheels.

10. Fill lubricating grease to every grease nipple sites.

●:

Important

1. See if the operation of engine is right.

2. See if clutch ad justment normal and its separation is thoro ugh.

3. See if gear shifting of gear box including front driving handle, crawling gear shifting are

flexible and easy. Pay attention to possible spontaneous out-of-gear or failure interlock.

4. See if brake adjustme nt is proper and t he performance is reliable.

5. See if steering control is flexible.

6. See if electric uni ts and meters work normally an d reliably .

4.4 Steering M echanism and meters

(1)Prehea ti ng st a rtin g co ntr ol un it (Fi g. 4-1 , part 1)

Inse rt key into the switch, posi tion OFF” mean s t he elect ric circuit n ot through ; turn clockwise

to the position ON”, all electric circuits except starting and warming-up electric circuits are

energiz ed ( aft er sta rting, the k ey sh ou ld b e ke pt in th is p os itio n) ; tur n to po sition H”, heater plug is

energized; turn to the position of ST , starting

circuit is alive. Turn anti-clockwise to the position

“”

ST and it can be started directly.

(2)Control Mechanism of Hand Throttle (Fig. 4-3

Parts 11)

Push ahead, and the oil supply will be increased;

pull ha ck, it will be red uced.Hand thro ttle is forb idden

for road traveling.

(3) Control mechanism of foot throttle (Fig. 4-1,

Parts 7)

Step it dow n to increase oil pully; rele ase pedal

to reduce oil supply.

(4)Shut-off control mechanism (Fig. 4-1, Parts2)

Pull the leve r backwa rd an d the en gine w ill be s hut

down. Then the lever will be rush into the original

position for next sta rting.

(5)Clutch contro l mechanism (Fig. 4-1, Parts 3)

Step down the clutch pedal forward for releasing

“

。

“

“

“”

Fig. 4-1 control unit 1

1-preheating starting switch

2- flameout handle

3-clutch pedal 4- assistant

gear-shifting lever

5-key gear-shifting lever 6-

braking pedals

7-foot accel pedal

17

clutch and the pedal to keep the clutch

engaged.

()

6 Key and assistant gear-shifting

control mechanism (Fig. 4-1, Parts 4, 5)

Control key and assitant gearlevers for

8 forward gears and 2 reverse gears. Before

the key and the assistant gearlevers, clutch

pedal should be stepped down first.

()

7 Control mechanism of foot

brake (Fig. 4-1, parts 6)

Step down left-right braking pedal for

brakin g. Before that, clutch pedal should be

stepped down first. In emergent case,

braking and clutch pedals can be stpped

down at the same time.

()

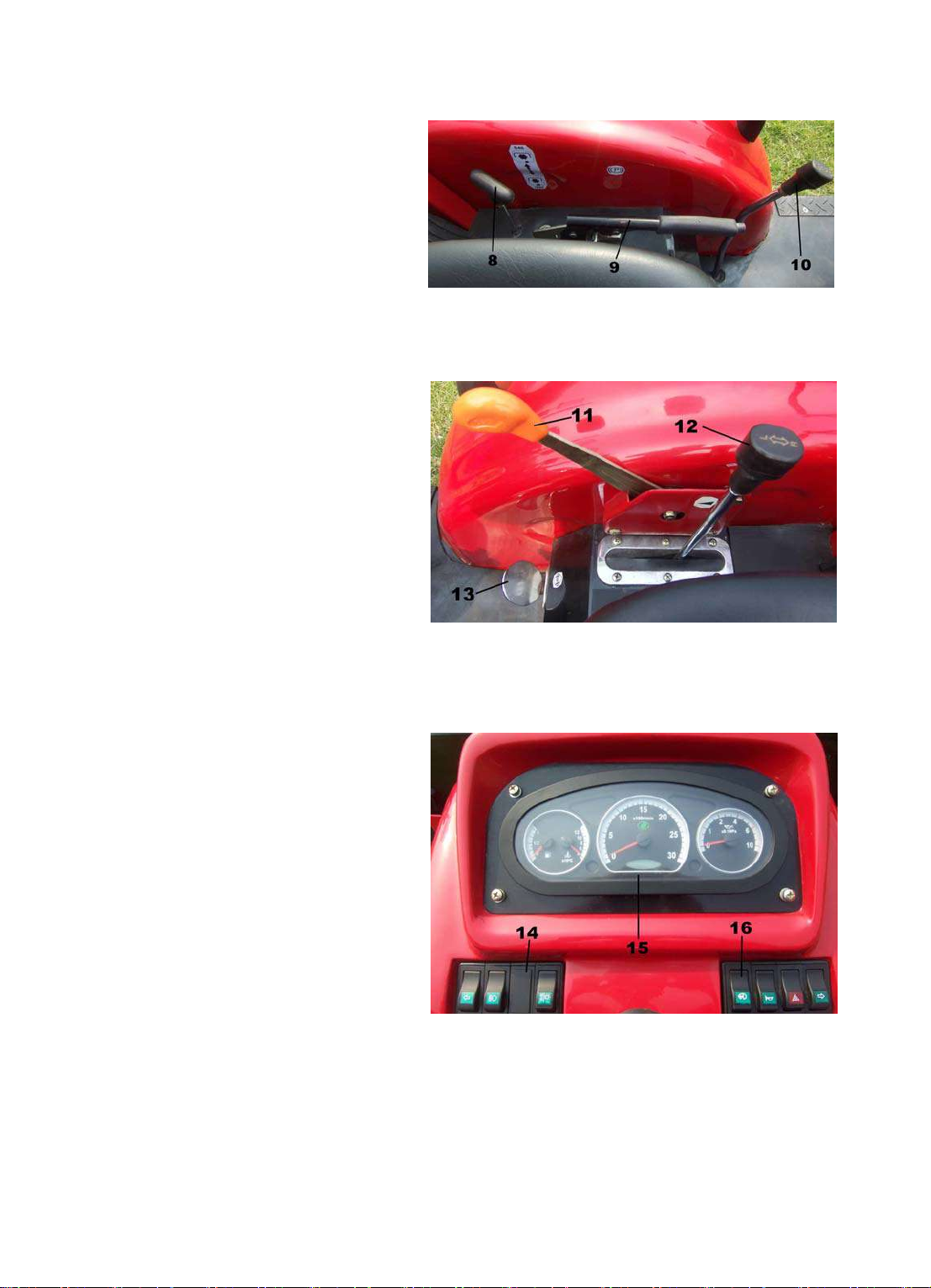

8 Control mechanism of hand

brake (Fig. 4-2, Part 9)

Pull hand brake handle upward for

emergent braking or park braking. Before

starti ng th e vehic le, check the han d brake to

see if it is in the separated position.

(9) Con trol mechanism o f differentia l

lock(Fig. 4-3, Part 13)

Step differential lock pedal down and

the diff erential gear will lose the di fferen tial

function. After the operation is over,

rerlease the pedal to its original position.

(10) Front driving control mechanism

(Fig. 4-2, Parts 10)

As for 4-WD tr actors, pu sh the contro l

lever forward for 4-wheel driving; pull the

control lever backward, separate 4-WD.

Before oper ation, th e clut ch peda l should be

stepped down first.

(11)Control mechanism of hydraulic

system (Fig. 4-2, Parts 12)

Control modes of hydraulic

suspending system has three types of

combination control, position control and

floatin g control. These are operat ed through

lifter control lever, force-control spring

assemb ly , rig ht press p late of lifting axle, middle ro d w eldment, link lev er, feedba ck li n k an d such ot he r

parts.

8-PTO handle 9-hand braking assembly

14-triad switch 15-combined guag es assembly

Fig. 4-2 control unit2

10-front-driving handle

Fig. 4-3 control unit3

11-hand throttle 12-lifter control

13-differential lock pedal

Fig.4 -4 combined gauges and switches

16-quad switches

18

(12) Control mechanism of PTO (Fig. 4-2, Part 8)

Pull PT O control handle upw ard to reali ze PTO of 540 r/min; pr ess PTO con trol handle d own to

realize PTO of 10 00r/min. M iddle p osition is in saperate d situati on, no PT O. Every tim e the spe ed is

changed, the clutch pedal should be stepped down first..

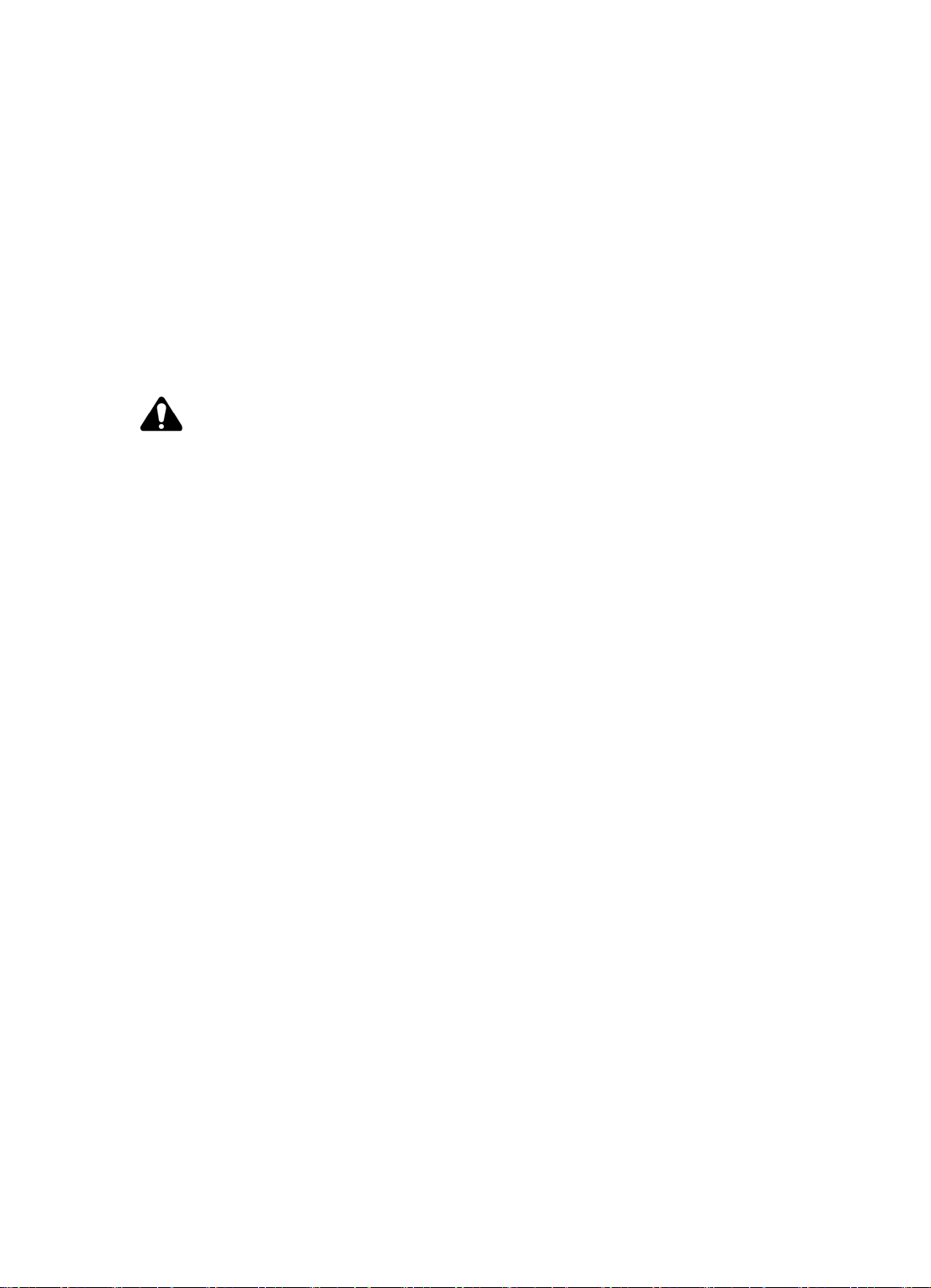

(13)Combi ned gau ges and switches (Fig. 4-4, Part 14, 15 and 16)

Combine d gauges include oil-p ressure g auge, oil vol ume indicat or, water-t emperature i ndicator,

chronometer, rotation speed gauge, warming light and indicator light.

Combine d sw itch es in cl ude : d ippe d he adlig ht s witch of head lam p, s witch of front tu rn lig hts,

switch of rear turn lights, switch es of the front signal li ght and the front licen se light, the rear sig nal

light and license light, switches of rear working lights, horn button, switch of emergent light.

4.5 Contr ol and Drive

Warn ing:

1. Only after readin g the manual carefully, ca n the driver who has got speci al traini ng and

drivin g license with a full survey record can op erate the tracto r. Tractor can not be opera ted

without license s. Overload is forbi dden.

2. drivers should pay especial attention to the safety & warning symbols and understand

them correctly.

3. It is forbidden to drive tractors after being drunk, tired or taking some an tipsychotic.

4. Don t leave driver s seat to start or control the tractor. Bef ore starting th e tractor,

every gear shift lever should be placed in the position of neutral gear . To get off the tractor,

every gear shift lever should be placed in th e position of neutral gear .

5. Before the tractor moves, its path should be no any barrier, and no people between the

tractor and the rear implement or trailer.

6. Don't g ett in g on o r o ff th e t ra cto r wh en it is running. No re pair o r c he ck und er t he tractor

is allowed when the engine runs. People are forbidden to sit on the fender apron. Casualty

accident can happen when it parks, so parking brake is necessary.

7. To go on an abrupt slope, you d better select a proper gear. It is not allowed to shift

gears on an abrupt slope. When going down the slope, it is forbidden to stop the engine or out-ofgear or turn sharply. For emergency stop, you should step down the clutch pedal and the brake

pedal at the same time. Don t just step down the brake pedal , or some mechanical parts will be

damaged.

8. For transportation operation, the right and the left brake pedals should be locked

together. For high-speed d riving or full-lo ad operation, i t is strictly forb idden to use unilate ral

brake to get a sharp turn.

9. High spee d is no t allowed whe n operatin g or transferrin g to other fie ld with hun g farm

impleme nts. Lift t he workin g units o f farm impl ements out of the e arth to av oid damag es to the

parts of lifti ng s ystem an d su spending s ystem. W hen leaving the trac tor, driver shou ld drop farm

implements to the ground, stop the engine and take off the keys to avoid others starting tractor.

10. For em ergency park ing, you should ste p down the clut ch pedal and br ake pedal at th e

same time. Don t only step down the brake pedal , or the brake will be damaged.

11. D riving on road, you should follow the local traffic rules.

’’

“”

“”

’

’

’

’

19

Attention:

1. Carefully check and listen to the engine and all parts of the tractor when they are working

to see if there are abnormal sound and noise, especially check the technical situations of clutch

and brake, check and tighten the bolts and nuts at every key site of the tractor. Check air

pressure of the tires, aerate the tires if necessary.

2. When the mac hine is turnup d uring op eration , shift to a lo w gear , release t he clut ch and

discharge the load to avoid lengthways turn-over.

3. When en gine is over sp eed , u nl oa din g is no t a llo we d. You d be tte r im m ed iately pul l shutdown lev er, and tu rn th e de com p re ssion rod to th e d ec omp ression po si tion or ke ep air away from

entering engine or cut off the oil way.

4. Watch the color of the exhausted air. Too much black smoke is not allowed to avoid

overload of the engine. If the clutch slides or cannot separate thoroughly or brake doesn t work

well, the machine should be stopped for check.

Operat ions duri ng nights need complete lighting e q uipments.

6. Wh en 4-whe el driv ing tra ctors tr avel with out loa d or ar e engage d in tr ansportat ion, the

front driving lever sho uld be placed in the neutral position.

7. To avo id tur n-ov er, es pec ially tr avel o n st eep sl ope and mu ddy road s. On ly lo w g ear s are

allowed. When going down the slope, it is forbidden to step down the clutch and slide with neutral

gear.

8. To avoid the pollution caused by the exhaust gas don t start the diesel in a room that is

closed witho ut fine ventilat ed conditions. Wh en a diese l transfers, keep hum an and an imals far

away from the exhaust gas.

4.5. 1 Startin g the Engi ne

Before a new shift be gins to wo rk and st art t he e ngine , they shou ld do sh ift tec hn ical m aint ena nce f irs t

(detailed description is below). Dispense its troubles and do the following work before starting the

engine:

1. Release the switch of fuel tank.

2. Pum p t he oil with hands, fill fuel into fuel sys tem, and e xh aust the air in the sy ste m .(T hi s st ep can be

omitte d gener a ll y. )

3. Check and see if every gear shift lever in the neutral position.

4. Hand throttle should be pulled into the position of fully opened .

5. Insert the key into the switch of preheat starting.

6. Turn the dec om pressio n handle t o t he decomp ression po sition ( de com p ression ca n be omitted i n

hot weather)

Finishing the above steps, you can start the engine as the following steps:

()

1 Starting Preheated Machine

Turn the preheat st arting switc h anti-clock wise until you can hear the sound of ig nition and then

return to th e po si tion ON i mmedi ate ly. P ut th e ha nd thro ttle in th e low -spe ed p osi tion. A ttenti on:

If the e ngine has been starte d while th e startin g switch is still kept in the s tarting pos ition, the motor

will be burned in several minutes.

“”

“”

’

’

’

() :

2 Starting Cold Machine

20

Turn t he crank shaft with e ngine cran k handle f or 5-10 roun ds, turn the preheat starting s witch

clockw ise to th e po sition H and sta y the re f or ab out 1 0 sec onds, th en tu rn to the posi tion ST

and stay th ere for 5 secon ds. And then res et the compr ession ha ndle. Afte r ignition, the starti ng switc h

will be re set t o the midd le pos iti on O N and put the ha nd thr ott le to the poiso n of sm all oil sup ply.

Startin g the engine costs ov er 15 second s and the eng ine isn t alive ye t. The storag e battery shoul d

rest for 10 seconds and then have another try to start.

3. When it is hard to start due to a temperature of below 5 , usually you need a engine oil

preheater that will be energized for 15 minutes, fill some 20~30 water , and the engine can be started.

Or you can fill some 80~90 water, discharge switch should be on at the beginning to discharge some

cold wa ter unt i l th e wa te r fro m th e en gi ne is 40~50 and the turn of f t he dis charge swit ch. At the same

time, th e engine oil w ill be heat ed to 60~70 and be filled in to the engi ne (slowly ch urning dur ing

heating ). It is n ot al lowed to br ake the oil pan of the engine with fire, or t he machine bo dy will b e

damaged.

4.5.2 Start to Move

1. Step do wn the clutch pedal thor oughly, and shift the main an d assista nt gear shifti ng levers t o

needed gear steadily and slowly.

2. Relea se the clutc h peda l slow ly and at the same time g radua lly ge ar up to mak e the tr actor star t

movi ng slow ly and stably.

3. Gear selection: Select a proper gear to get a high production and

4.5. 3 Driving Tr actor

1. Turn the steering wheel to get a direction change. Sharp turn is allowed under low gear. singleside braking can be used to minus the turning radius during field operations (especially in paddy fields)

to raise its flexibility and production; however when it operates with

high speeds or transports on roads, single-side braking cannot be

adapte d for shar p tu rn to avo id tur n-ov er. 2. Wh en the tra ctor is en gage d

in transportation or travel on roads, the left and the right brake pedals

should be interlock ed. When th e tractor is par ked, especi ally when it i s

stoppe d o n a slop e, you mus t us e a fixe d ja w to lo ck th e br akes t o av oi d

automatical moving.

3. Gear selection: Select a proper gear to get a high production and

economic performance. See Fig.4-3 for the speeds and uses of every

gear.

I-gear and II-g ear can no t be use d to plou gh and har row, or be use d

as the p ull force. Or th e transmissio n system will h ave severe overload

to avoid damage. During working the tractor should be kept from

overload. Follow the steps below to distinguish:

1). V -gear is adapted for wo rki ng. Put the thro tt l e in the semi-o pen

positio n to let the tractor w ork with loads, and th en push the thrott le to

the fu lly-op en p ositi on. I f now the trac to r spee d is incr ease, it m eans n o

over load, while if it slows down, it means over load.

2). When V-gear is used for working and engine sounds heavy with

black smoke, it means overload. Change to IV-gear. Every time you

shift gears, clutch pedal should be stepped down fully first to avoid breaking gears.

“” “ ”

“”

’

℃

℃

℃

℃

℃

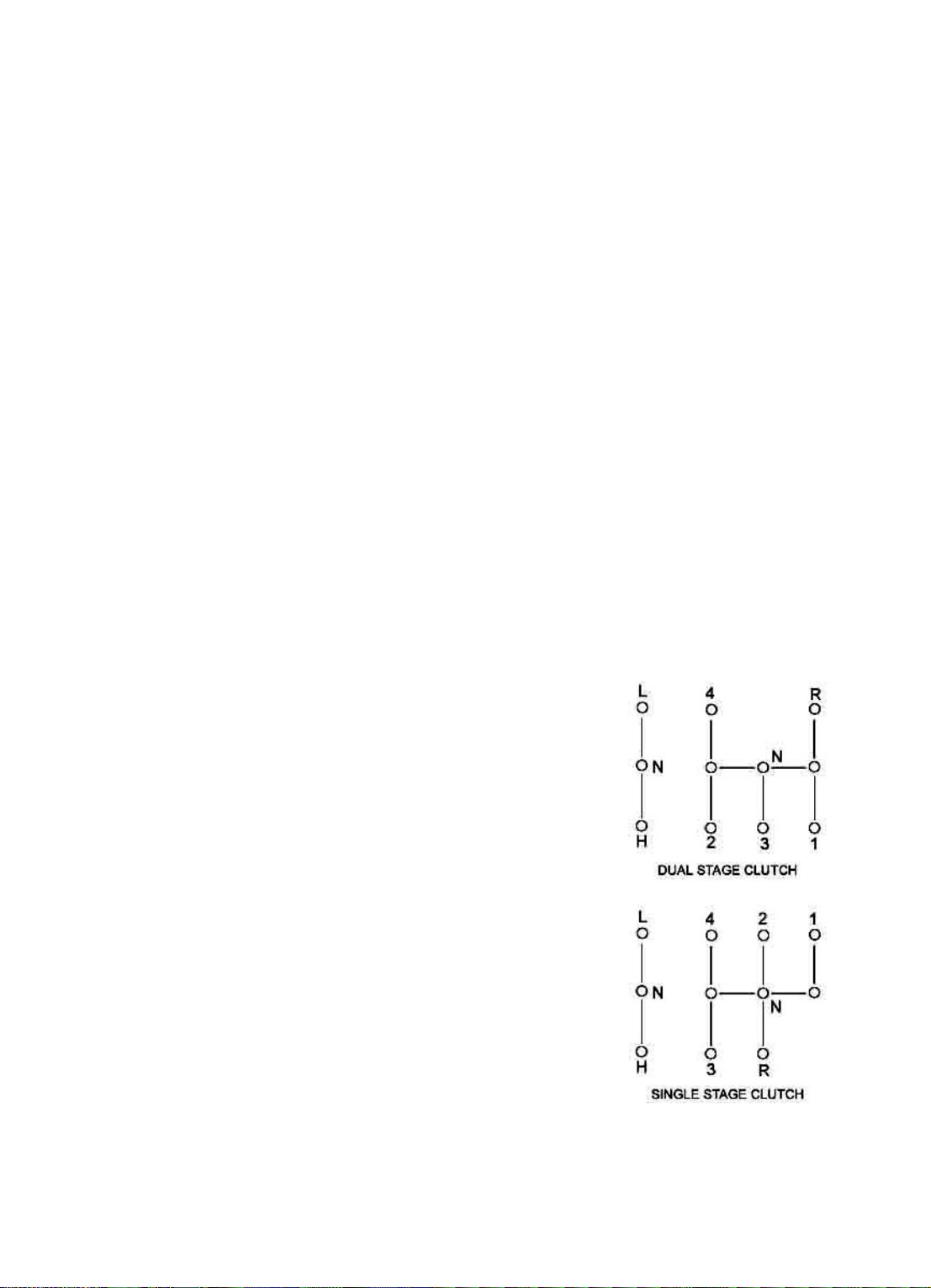

Fig.4-5 gears distribution

21

4.5.4 Parking

g

1. Lower down the gear for a slower moving

2. Step down the clutch pedal and push the main gear shifting lever to the neutral position.

3. Release the cl utch pedal to make th e engine fre ely run with a low sp eed.

4. To red uc e the water temperature an d o i l te m pe rature slowl y, engine sh ould be kept r un nin g for a

while at a slow speed. It is forbidden to stop the engine under a high temperature.

5. Push the hand throttle to the position of closed

6. Pull out the shu t-down lever

7. Turn off the oil tank switch after stopping the tractor.

8. To preve nt the c oolin g water from being frozen in winter that can cause frost crack, you should

turn on the two discharge switches and open the water tank to discharge all the water.

theoretical

gear grade action

F1 rototilling,replanting 2.248(2.082) F5

velocity

()km/h

“”

Table 4-3

gear action

ploughing, harrowing,

and seedi ng

theoretical

velocity

()km/h

10.37(8.867)

F2 rototilling,replanting 3.008(2.628) F6

F3 harvesting 4.127 (4.279) F7 roa d t ransportation 19 .451(18.204)

ploughing,

F4

Speeds in () match si ngle-acting clutch

●

Important:

1. Whe n working in fields or muddy area, you'd better remove the dirt from your shoes and

keep the pedals clean. Catch the armrest careful when getting on or off the tractor.

2. Watch readings of every gauges. During normal operation, engine oil has a pressure

range of 300~450kPa and a water temperature range of 70~90 . When readings on gauges have

malfunctions, repair or replace them. Don't use it any longer.

3. You should tell your next shift about the troubles and malfunctions you found.

4. Try to avoid barrie rs on roads when drivi ng tractors.

5. Driving on roads, farm implements cannot be put into use.

harro w ing, an d

seedin

6.258(6.78 5) F8 road transportat ion 28.86 7(28.86 7 )

ploughing, harrowing,

and seedi ng

℃

13.875(11.182)

4.6 Operation and Use of the Working Units of Tractor

4.6. 1 Operati o n and use of PTO shaft

Rev of PTO shaft is the combination of 540r/min. and 1000r/min

1. Push the cont rol hand le of PTO shaf t to the m iddle neutr al positi on, take down the p rotectin g

cov er of PTO shaft and connect th e worki n g mech anism and PTO shaft.

2. Step d ow n th e clutch ped al to the botto m , pu t th e handle of the driving PTO s ha f t to the position

“”

conjun ction , and the n pu t the h an dl e of P TO sha ft to nee ded gears a cco rd ing to the re qu irements of

workin g mech anism

:

22

Loading...

Loading...