Jinma 200 Operator Manual

Jinma 200 series Tractor Users Manual

JINMA 200 Series

DOCUMENTATION

MCE 2004.01

Edited by: Steve Bradshaw

Malacat Enterprises

Cobble Hill, B.C.

Version 0.2 Page 1 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

Table of Contents

INTRODUCTION......................................................................................................................................7

Sources of data .................................................................................................................................7

PARTS..............................................................................................................................................7

Yancheng Tractor Factory..........................................................................................................................8

THE RULES..............................................................................................................................................9

Preventing Farm Machine Hazards..........................................................................................................11

AEX-593-91...................................................................................................................................11

Shear and Cutting Points................................................................................................................11

Pinch Points ...................................................................................................................................12

Wrap Points ...................................................................................................................................12

Crush Points ...................................................................................................................................12

Free-Wheeling Parts.......................................................................................................................13

Springs............................................................................................................................................13

Burn Points.....................................................................................................................................13

Hydraulic Systems..........................................................................................................................13

MATERIAL SAFETY DATA SHEETS.................................................................................................15

DISPOSAL OF POL WASTE........................................................................................................16

ENVIROMENTIAL LAW.............................................................................................................16

Controls and Instruments.........................................................................................................................17

Instruments (Standard)....................................................................................................................17

Amp meter:.....................................................................................................................................17

Water Temperature Gauge:.............................................................................................................17

Oil Pressure Gauge.........................................................................................................................17

Tachometer.....................................................................................................................................17

Turning Signal Switch....................................................................................................................17

Work Light Switch.........................................................................................................................17

Horn Button....................................................................................................................................17

Headlight Switch............................................................................................................................17

Starting Switch...............................................................................................................................18

Instruments (Optional).............................................................................................................................18

Amp meter......................................................................................................................................18

Water Temperature Gauge..............................................................................................................18

Tachometer/Hour Meter:................................................................................................................18

Oil Pressure Gauge.........................................................................................................................18

Fuel Gauge......................................................................................................................................18

OPERATING CONTROLS.....................................................................................................................19

Engine Shutoff Handle...................................................................................................................19

Compression Release......................................................................................................................19

Hand Throttle..................................................................................................................................19

Clutch Pedal....................................................................................................................................19

4WD Selector..................................................................................................................................19

Version 0.2 Page 2 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

Transmission Gear Selector............................................................................................................19

Hi-Lo Range Gear Shifting Lever..................................................................................................20

Left and Right Brake Pedals...........................................................................................................20

Foot Throttle Pedal.........................................................................................................................20

Parking Brake Lock Pawl...............................................................................................................20

Creeper Shifting Lever...................................................................................................................20

Hydraulic Control Lever.................................................................................................................20

Differential Lock Lever..................................................................................................................20

Hydraulic Speed Regulator.............................................................................................................20

Control and Operation of the Tractor.......................................................................................................21

Starting Engine...............................................................................................................................21

Warm weather over 32 Degrees F..............................................................................................21

Cold weather below 32 Degrees F ............................................................................................21

Operating the Tractor......................................................................................................................21

Driving the Tractor.........................................................................................................................22

Proper speed should be selected for best productivity. ..................................................................22

Stopping the Tractor.......................................................................................................................22

Tractor Operation Safety................................................................................................................22

Control and Operation of the Working Devices.......................................................................................23

Control and Operation of PTO............................................................................................................23

Control and Operation of Hydraulic Hitch System.............................................................................24

Position Control..............................................................................................................................24

Floating Control..............................................................................................................................24

Control of the Lowering Speed of the Implement..........................................................................24

Operation of Hitch System..................................................................................................................24

Adjusting of Longitudinal Level....................................................................................................24

Adjusting of Lateral Level..............................................................................................................25

Use of the Electrical Equipment..............................................................................................................26

Battery.............................................................................................................................................26

The Starter......................................................................................................................................26

Maintenance Schedule for the Tractor.....................................................................................................27

Daily Maintenance..........................................................................................................................27

50 Hour Maintenance (Every 50 Hours).........................................................................................27

250 Hour Maintenance (Every 250 Hours).....................................................................................27

500 Hour Maintenance (Every 500 Hours).....................................................................................27

1000 Hour Maintenance (Every 1000 Hours).................................................................................28

Maintenance for Long Term Storage..............................................................................................28

Tractor Adjustments.................................................................................................................................29

Adjustment of clutch.......................................................................................................................29

Adjustment of brake.......................................................................................................................30

Adjustment of disc brake................................................................................................................31

Free state adjustment of disc brake ...........................................................................................31

Travel adjustment of brake pedal...............................................................................................31

Troubleshooting guide for Diesel Engines...............................................................................................32

SERVICE ADVISORIES........................................................................................................................34

Version 0.2 Page 3 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

50 hour, Head Re-torque.................................................................................................................34

18-28 HP Jinma Tractor Hydraulic Fluid Intake Filter .................................................................36

Backhoe Hydraulic Fluid Intake Filter ..........................................................................................38

Injector Pump Oil ..........................................................................................................................40

Oil Drains .......................................................................................................................................41

Ignition Switch Retrofit .................................................................................................................42

Jinma 254 Specifications..........................................................................................................................43

Jinma Crate Tractor Assembly ................................................................................................................46

Jinma JW-03 Backhoe Info .....................................................................................................................50

PIVET PINS...................................................................................................................................50

Enlarge outrigger pads. ...............................................................................................................51

Strengthen lower sub-frame. .........................................................................................................51

Stiffen up rear mount ....................................................................................................................52

Version 0.2 Page 4 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

Index of Illustrations, drawings and photos.

Figure 1. A 254 at the factory......................................................................................................8

Figure 2. Yancheng City..............................................................................................................8

Figure 3. Old Factory with dirt floors..........................................................................................8

Figure 4. New factory machine shop...........................................................................................8

Figure 5. Engine assembly in the new plant................................................................................8

Figure 6. Map of Jiansu Province ...............................................................................................8

Figure 7. Shear Point....................................................................................................................11

Figure 8. Pinch Points..................................................................................................................12

Figure 9. Crush Points..................................................................................................................13

Figure 10. Spring dangers.............................................................................................................13

Figure 11. Old style instrument panel...........................................................................................17

Figure 12. Old style lower dash switches .....................................................................................17

Figure 13. New style electronic instrument cluster.......................................................................18

Figure 14. New style lower dash switches....................................................................................18

Figure 15. Driving Controls..........................................................................................................19

Figure 16. Ignition Switch ...........................................................................................................21

Figure 17. Clutch cut away diagram.............................................................................................29

Figure 18. Brake cut away diagram..............................................................................................30

Figure 19. TY-290 Engine............................................................................................................34

Figure 20. JM204 TY29 Engine with valve cover removed........................................................34

Figure 21. Close-up of JM-204 TY290 engine head.....................................................................34

Figure 22. Y385 Torque Sequence, used for JM254/284.............................................................35

Figure 23. TY20 Torque Sequence, used in JM184/204/224.......................................................35

Figure 24. Hydraulic Filter Assembly...........................................................................................36

Figure 25. Hydraulic filter disassembly........................................................................................37

Figure 26. Hydraulic Filter Parts...................................................................................................37

Figure 27. Hoe Hydraulic Oil Filter..............................................................................................38

Figure 28. Hoe Hydraulic Filter o-ring.........................................................................................38

Figure 29. Fuel Injector Oil filler (A) & Drain (C).......................................................................40

Figure 30. Fuel Injector Breather (A) and Cap (B)......................................................................40

Figure 31. Fuel Injector Assembly................................................................................................40

Figure 32. Fuel Injector Steel Balls..............................................................................................40

Figure 33. Transmission Oil Drain...............................................................................................41

Figure 34. Engine Oil Drain..........................................................................................................41

Figure 35. Hydraulic System Oil Drain........................................................................................41

Figure 36. JW-03 Backhoe showing modification points.............................................................50

Figure 37. Flat bar details.............................................................................................................50

Figure 38. JW-03 Pivot pins.........................................................................................................50

Figure 39. Enlarged Outrigger Pads..............................................................................................51

Figure 40. Hoe Frame showing heavy reinforcement ..................................................................51

Figure 41. Hoe frame damage.......................................................................................................51

Version 0.2 Page 5 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

Figure 42. Hoe frame reinforcement fwd view.............................................................................51

Figure 43. Hoe frame reinforcement after view............................................................................51

Figure 44. Hoe frame top link stabilizer.......................................................................................52

Version 0.2 Page 6 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

INTRODUCTION

This manual is a general guide to provide the user with general information with

respect to personnel and equipment safety, operational procedures and

maintenance of your machine.

This manual was developed to fill the requirement for a JINMA specific operations

and maintenance manual. While Jinma tractors come with a set of 4 manuals,

some of the language syntax is a little hard to follow.

Sources of data

Sources of data for this manual come from many places. They include , but are

not limited to the following:

http://www.johnstractor.homestead.com/, http://www.emerybuilt.com/

http://www.tractor-outlet.com/ http://www.china-tractors.com/

http://www.tractorpages.com/, http://chinabestproducts.com

Factory Engine Operations Manual,

Factory Tractor Operations and Maintenance Manual,

Factory Tractor Illustrated Parts Breakdown Manual,

Factory Engine Illustrated Parts Breakdown Manual.

The Chinese Tractor Owner Association is a good place to lurk, ask questions and

get/give support from/to others.

http://www.ctoa.net

Please read this manual carefully and keep in a convenient place for future

reference.

Do not hesitate to contact your local dealer for any questions concerning

the tractor. Even if you obtained this tractor as a crate assembly project, a

tractor dealer can provide skilled personnel, spare parts and all tools and

equipment necessary for your service requirements. Most of all, a dealer will

have the experience of working with tractors and small diesel engines.

PARTS

Parts are readily available for JINMA series tractors. The Internet is a good place

to find sources of parts. http://www.jinmaparts.com is but one company selling

parts for your machine.

Any suggestions and or comments about this manuals contents, errors or

omissions are most welcome. Please email or mail:

Steven Bradshaw

1033 Braithwaite Drive

Cobble Hill, BC

Canada. V0R-1L0

brads@malacat.ca

Version 0.2 Page 7 of 52

Yancheng Tractor Factory

The Yancheng Tractor Factor is located, as you may guess, in the city of Yancheng, Jiangsu

province, China, and is about 100 miles north of Shanghai.

Yancheng is one of thirteen municipalities of Jiangsu province.

Yancheng is situated by the Yellow sea. With the coastal

marshland covering an area of 453,000 ha with rich resources,

Yancheng is an important production center for clams, prawns

and eels. The two natural protection regions of red-crowned

cranes and David' s dear have been set up in Yancheng. The

development of agricultural economy of the city is in full swing, making the city

a new commodity grain and cotton base in China. The local industrial structure

has been completed in Yancheng with industries like textiles, machinery,

electronics, chemical, pharmaceutical, food processing and construction materials

industries as its backbone. The arts and crafts, native and special products of the

Figure 2. Yancheng City

city are of unique styles.

Jinma 200 series Tractor Users Manual

MCE 2004.01

Figure 1. A 254 at the factory

Figure 4. New factory machine shop

The tractor factory

was originally built

about 50 years ago. As

you can see from figure

3, this factory was a

less than ideal

environment in which

to build. As of the

Figure 3. Old Factory with dirt floors

spring of 2002 all

tractors were being built in a new factory.

Figure 5. Engine assembly in the new plant

Figure 6. Map of Jiansu Province

Average wage per person in Jiansu Prov for 2003 was 9200 Yaun (Cdn $1400).

Pop. 70.2 Million

Area: 1.03 x 105 Km

Version 0.2 Page 8 of 52

2

Jinma 200 series Tractor Users Manual

MCE 2004.01

Read these safety rules and follow them closely. Failure to obey these rules

could result in loss of control of vehicle, severe personal injury to yourself

or bystanders, or damage to property or equipment. The triangle in the

text signifies important cautions or warnings which must be followed.

THE RULES

• Know the controls and how to stop quickly.

READ THIS MANUAL and instructions

furnished with attachments.

• Do not allow children to operate the machine.

Do not allow adults to operate the machine

without proper instructions.

• Do not carry passengers. Don't mow when

children and others are around.

• Clear the work area of objects (wire, rocks,

etc.) that might be picked up and thrown.

• Disengage PTO and shift into neutral before

attempting to start the engine.

• Disengage PTO and stop the engine before

leaving the operators position.

• Disengage PTO and stop the engine before

making any repairs or adjustments.

• Disengage PTO and lower all attachments

when not in use.

• Take all possible precautions when leaving the

vehicle unattended, such as disengaging the

PTO, lowering all hydraulic attachments,

setting the parking brake, stopping the engine

and removing the key.

• Reduce speed and exercise extreme cation on

slopes and in sharp turns to prevent tipping or

loss of control. Be especially cautious when

changing direction on slopes.

• Stay alert for holes, rocks, and roots in the

terrain and other hidden hazards. Keep away

from drop-offs.

• Use care when pulling loads or using heavy

equipment.

a) Use only approved draw bar hitch points.

b) Limit loads to those you can safely control.

c) Do not turn sharply. Use care when

backing.

d) Use counterweights or wheel weights when

suggested in this manual.

• Watch out for traffic when crossing or near

roadways.

• When using any attachments, never direct

discharge of material toward bystanders or

allow anyone near the vehicle when in

operation.

• Handle fuel with care.

• Do not stop or start suddenly when going uphill

a) Use approved container.

or downhill. Mow up and down the face of

slopes; never across the face.

b) Never remove the fuel cap of, or add to a

running or hot engine.

Version 0.2 Page 9 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

• Open doors if the engine is run a confined

space – exhaust fumes are dangerous. Do not

run the engine indoors.

• Keep the vehicle and attachments in good

operating condition, and keep safety devices in

place and in working condition.

• Keep all nuts, bolts and screws tight to be sure

the equipment is safe to operate.

• To reduce the risk of fire, keep the engine and

exhaust system free of grass, leaves or

excessive grease.

• The vehicle and attachments should be stopped

and inspected for damage after striking a

foreign object, and damage should be repaired

before restarting and operating the equipment.

• Do not change the speed governor setting or

over speed the engine.

• When welding, make sure that hoses are

properly protected as sparks or molten material

may puncture or weaken the tubes and sleeves,

resulting in leakage or of oil, cooling liquid,

etc.

• Avoid spillage when transferring used engine

cooling liquids, engine and transmission

lubricants, hydraulic oils, etc. Never mix used

fuel oil with lubricants. Store safely until

suitable disposal can be arranged according to

national legislation or local regulations.

• Modern anti-freeze liquids and solutions, e.g.:

anti-freeze and other additives must be replaced

every two years. They must not be left to be

absorbed into the ground, but must be collected

and disposed of in a suitable manner.

• Any leakage or defect in the engine cooling or

hydraulic systems must be repaired

immediately.

• Do not increase the pressure in pressurized

systems, as this may cause component parts to

burst.

• When welding, make sure that hoses are

properly protected as sparks or molten material

may puncture or weaken the tubes and sleeves,

resulting in leakage or of oil, cooling liquid,

etc.

• Avoid using unsuitable, pressurized filling

systems or fuel cans when filing tanks, as these

may cause considerable spillage and leakage of

liquids.

• As a general rule, do not allow liquid fuels,

lubricants, acids, solvents, etc. to come into

contact with the skin. The majority of these

products contain substances that are potential

health hazards.

• Modern lubricants contain additives. Do not

burn contaminated fuel oils and/or oils used in

conventional heating systems.

Version 0.2 Page 10 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

Preventing Farm Machine Hazards

AEX-593-91

Thomas L. Bean

Each year, 2,600 farm residents are killed and 230,000 disabled in farm-related injuries, many due to

farm machinery. Farm machinery uses mechanical power to do work. This creates a number of possible

hazards for both operators and bystanders. Even though manufacturers take many steps to make

machinery safe, all hazards cannot be removed. Some machine parts cannot be completely shielded and

still do their job. For instance, a totally enclosed cutting blade could not cut.

Many machinery-related accidents result from human error. The operator either forgot something, took

a shortcut or a risk, ignored a warning, wasn't paying close attention, or failed to follow safety rules. In

addition, guards removed for maintenance often aren't replaced.

There are many different kinds of farm machinery: mowers, tractors, shredders, harvesters, grinders,

blowers, augers, balers, etc. They all have similar characteristics and hazards. You can be cut, crushed,

pulled in or struck by an object thrown by these machines. They have cutting edges, gears, chains,

revolving shafts, rotating blades, pinch points and other hazards. You can also be injured if you fall

while working on or near any of these machines.

Accidents with farm machinery are often serious, even fatal. It is important to recognize and be alert for

machine hazards and to take precautions to avoid injury.

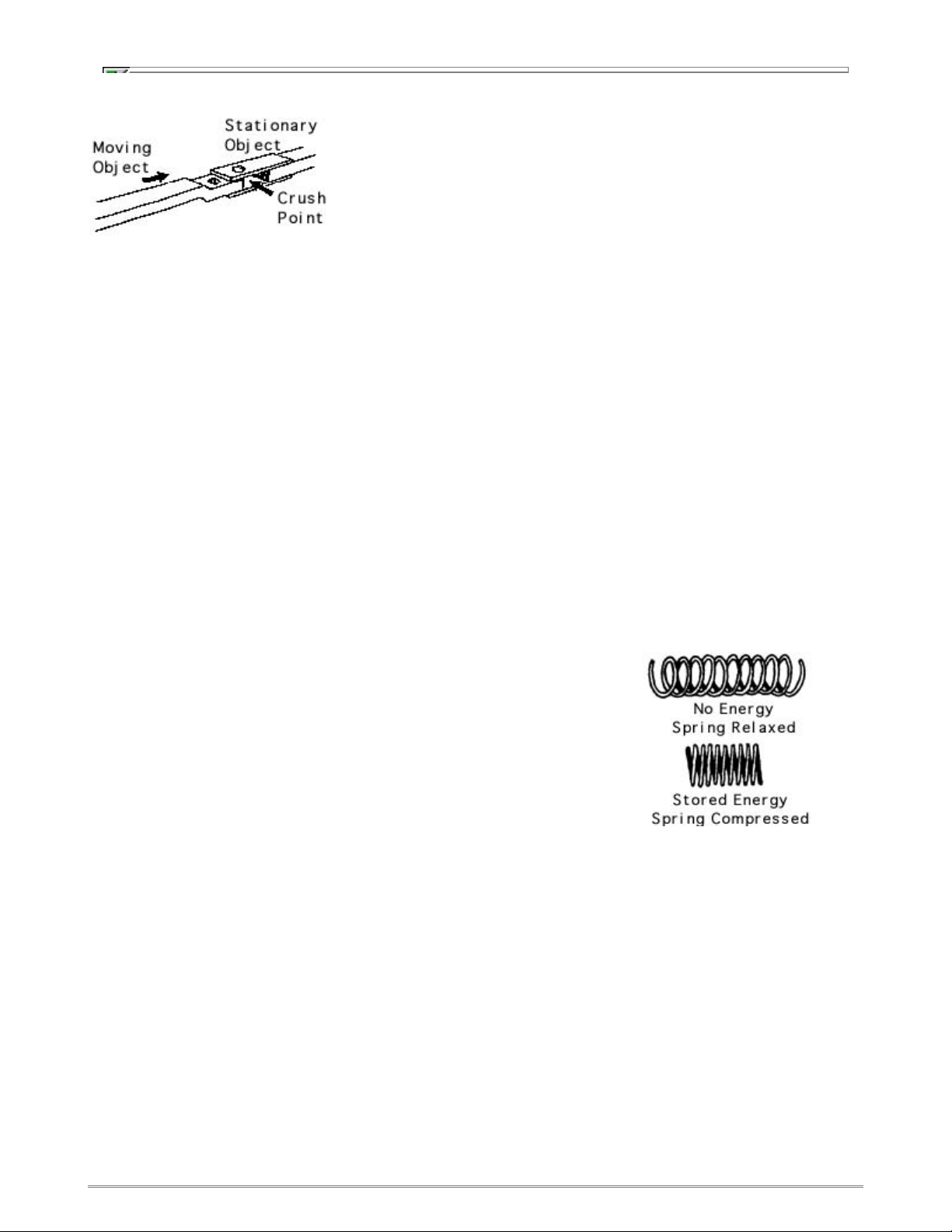

Shear and Cutting Points

Shear points (Fig. 1) are created when the edges of two objects are moved

together closely enough to cut a soft material, as with a pair of shears or an

auger. Cutting points are created when a single object moves forcefully or

rapidly enough to cut, as with a rotary mower blade.

Figure 7. Shear Point

Both shear and cutting points are created on machinery designed to cut, such as

harvesters, and on those that are not designed to cut, such as augers. They are hazardous because of

their cutting force and they often move so rapidly that they may not be visible, so it is easy to forget

they are operating or to underestimate the hazard.

Because some shear and cutting points cannot be guarded, it is important to be aware of their hazard

and stay alert when they are operating. It is also important to warn others and to look out for their

safety. This is especially true if there is a danger of thrown objects while using cutting-type equipment.

Version 0.2 Page 11 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

Pinch Points

Pinch points are another hazard of farm machinery (Fig. 2). Pinch points

(which should be more appropriately named mangled or maimed points) are

formed when two rotating objects move together and at least one of them

moves in a circle. For example, the point at which a belt runs into a pulley is

a pinch point. Belt drives, chain drives, and gear drives are other sources of

pinch points in power transmission devices. Feed rolls, gathering chains and

similar equipment designed to draw crops into the machine also create pinch

Figure 8. Pinch Points

points.

Fingers, hands and feet can be caught directly in pinch points, or they may be drawn into the pinch

points by the inertia of the moving part or loose clothing that becomes entangled. Contact may be made

by falling or brushing against unshielded parts. You can become entangled in pinch points if you take

chances and reach or work near rotating parts. Machines move too fast to get out of a pinch point once

you become caught.

To avoid injury from pinch points, be aware where pinch points occur and avoid them. Wear clothing

that fits well and is not loose or floppy. Never reach over or work near rotating parts. Turn off

machinery to work on it. Always replace shields removed for maintenance.

Wrap Points

Rotating shafts are the most common source of wrap-point accidents, although any exposed machine

part that rotates can be a wrap point. A cuff, sleeve, pant leg, long hair or just a thread can catch a

rotating part and result in serious injury. Entanglement with a wrap point can pull you into the machine,

or clothing may become so tightly wrapped that you are crushed or suffocated. In other cases, you

could be thrown off balance and fall into other machinery parts.

Even a perfectly round shaft can be hazardous if there is enough pressure to hold clothing against the

shaft. Hazards increase with shafts that are not round. Clothing is more likely to catch if there is dried

mud or manure on the shaft, or if the shaft is nicked. Ends of shafts that protrude beyond bearings are

also dangerous. Universal joints, keys and fastening devices can also snag clothing.

Check all equipment for potential wrap points and, if possible, shield those that can be shielded.

Replace any damaged manufacturer-installed warning labels and place warnings on equipment parts not

previously labeled. In addition, consider painting them a bright color, perhaps with wide stripes. Be

aware of wrap points and be alert to their danger.

Crush Points

Crush points are created when two objects move toward each other or one object moves toward a

stationary object. For example, hitching tractors to implements (Fig. 3) creates a potential crush point.

Hitch accidents most commonly occur to fingers placed at the hitching point. Wait until the tractor has

Version 0.2 Page 12 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

stopped before stepping into the hitching position. If possible,

arrange the hitch point so that the tractor can be backed into position

without anyone between. Always know what the other person is

doing.

Figure 9. Crush Points

Failure to safely block up equipment can result in a fatal crushing injury. A jack may slip, a hose or

overhead support may break, or the equipment may roll. Take extra precautions when working with

machinery that is raised for any reason. The operator's head or chest can be crushed between the

equipment and a low beam or other part of a farm building. These accidents usually occur when the

machine is being operated in reverse. Tree limbs are also potential hazards when working with tractors

and other machinery.

To prevent being crushed or pinned, recognize and avoid potentially dangerous situations. Block all

machinery securely if you must work under it. If an implement can roll freely, block its wheels so it

cannot roll.

Free-Wheeling Parts

Many machine parts continue to spin after the power is shut off, including cutter heads of forage

harvesters, hammer mills of feed grinders, rotary mower blades, fans and flywheels. Never touch these

parts until they have stopped moving. This could take 2 to 21/2 minutes.

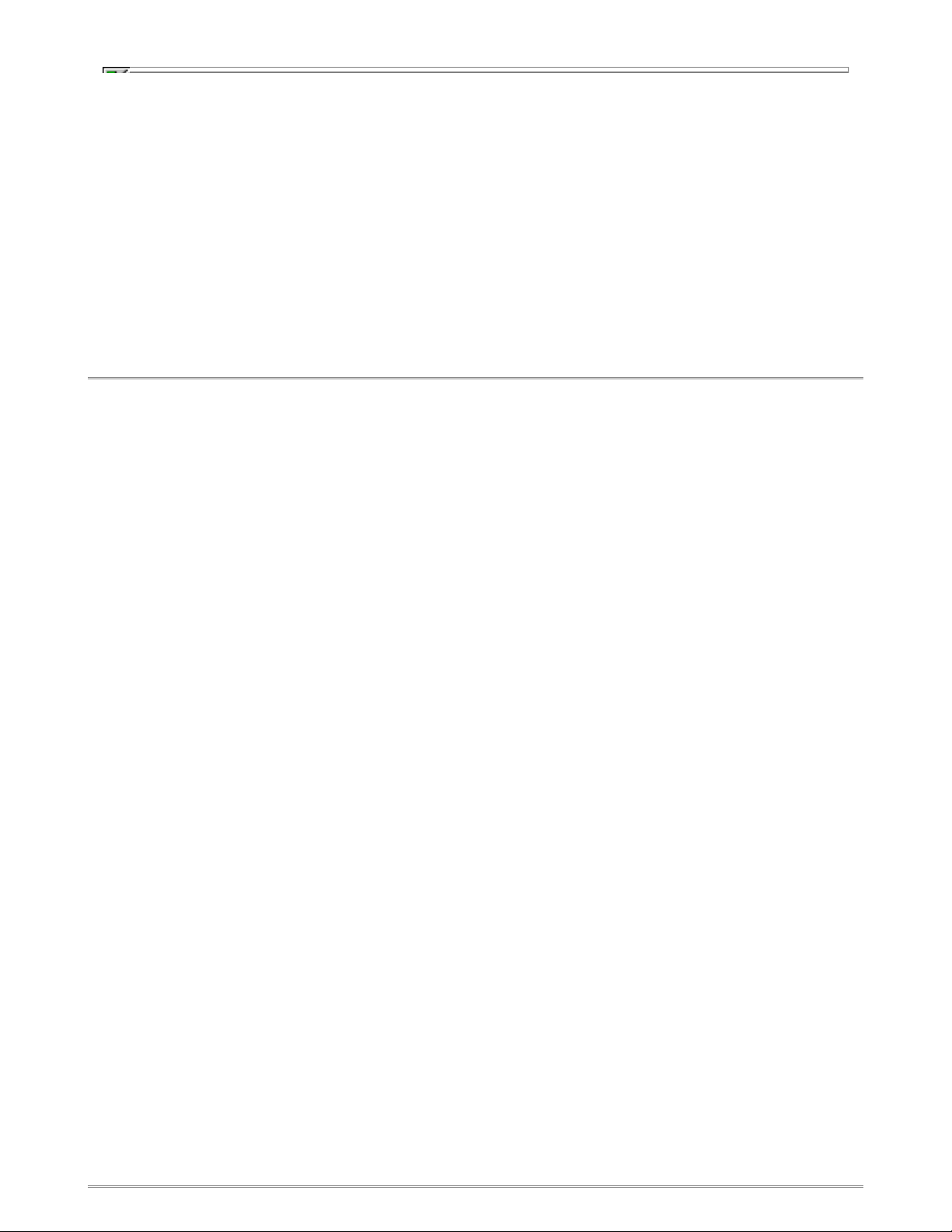

Springs

Compressed springs (Fig. 4) will expand with great force when

released, and springs that are stretched will contract rapidly when

released. Know what direction a spring will move and how it might

affect another machine part when released, and stay out of its path.

Figure 10. Spring dangers

Burn Points

Be aware of burn points: mufflers, manifolds and even gear cases under adverse climatic conditions.

They may not be severe enough to seriously maim, but they can startle the operator enough to cause

him or her to "jump" into more deadly danger.

Hydraulic Systems

Hydraulic systems contain fluid under extreme pressure. Before loosening, tightening, removing or

otherwise working with any fittings or parts, relieve this pressure. Jet streams from even pinhole leaks

can penetrate flesh. In addition, the liquid is often hot.

Version 0.2 Page 13 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

Before attempting any service on hydraulic systems, shut off the engine that powers the hydraulic

pump. Lower the implement to the ground and relieve the pressure. Follow instructions in the

operator's manual because the specific procedures for servicing the systems are very important to your

safety.

Funded in whole or in part from Grant Number U05/CCU506070-01, "Cooperative Agreement

Program for Agricultural Health Promotion Systems," National Institute for Occupational Safety and

Health.

Reviewed by Dr. Randall Wood and Dr. Warren Roller

Version 0.2 Page 14 of 52

Jinma 200 series Tractor Users Manual

MCE 2004.01

MATERIAL SAFETY DATA SHEETS.

MSDS is a widely used abbreviation for Material Safety Data Sheet. A MSDS contains

details of the hazards associated with a chemical, and gives information on its safe use. MSDS helps

with the electronic management of the material safety data sheets.

You will be using many different types of petroleum, oils and lubricants during the

operation and maintenance of your machine.

READ THE MSDS SHEETS FOR

THE MATERIAL YOU ARE USING

The MSDS sheet will provide you with technical information about the product including but not

limited to Product and Company Identification

• Information on ingredients.

• Emergency overview. What the material is.

• Stability and Reactivity. What not to mix it with.

• Toxicological Information. What it will do to you if you touch, breath, ingest this material.

• Accidental Release Measures. What to do if you release it into the environment.

• Handling and Storage.

• Personal Protective Equipment. Do as it says.

• Immediate Health Effects.

• First Aid Measures, and

• Firefighting measures.

You can find MSDS information on any product sold in North America. Vendors MUST provide them

on request. The following is an example of a MSDS sheet for Simple Antifreeze.

Version 0.2 Page 15 of 52

Jinma 200 series Tractor Users Manual

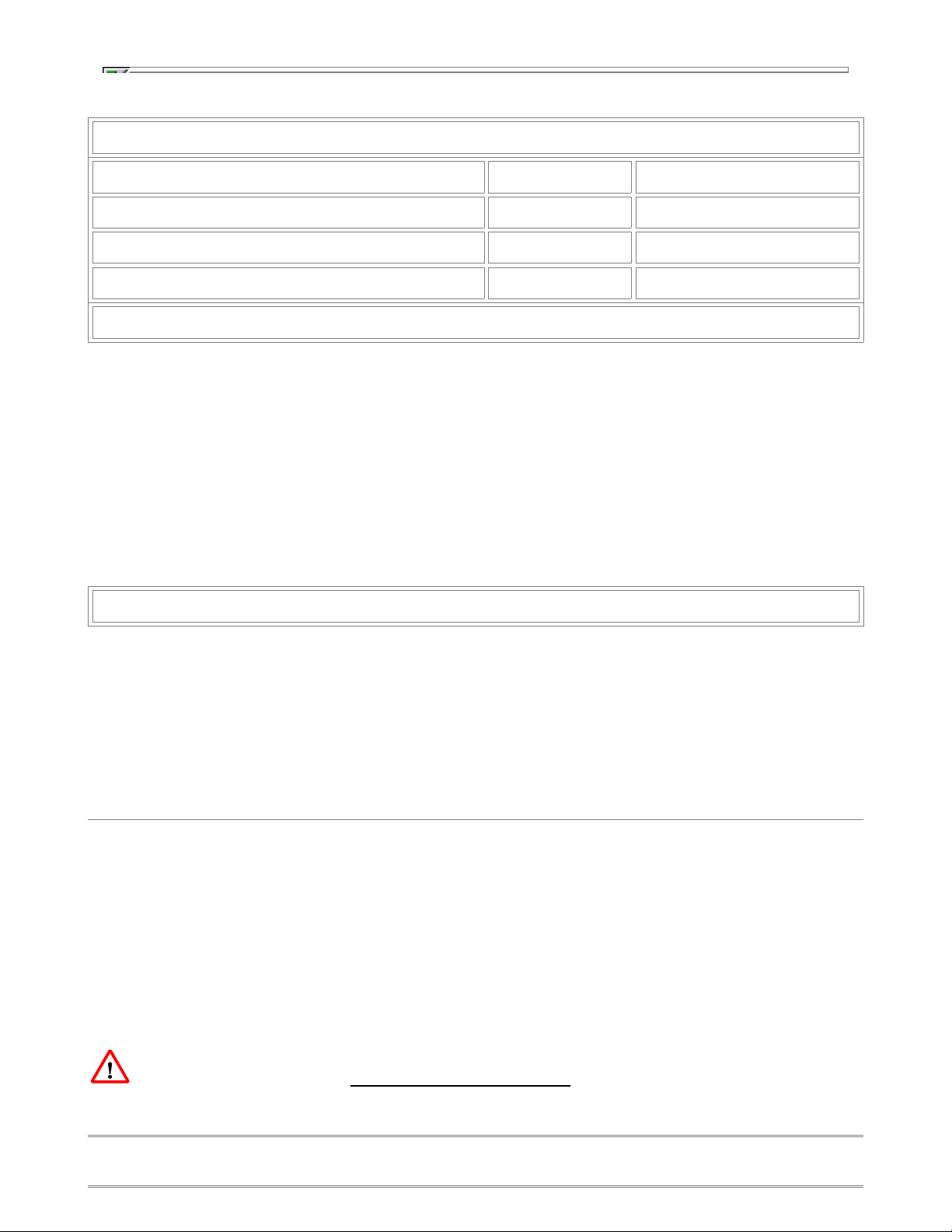

SECTION 2 COMPOSITION/ INFORMATION ON INGREDIENTS

COMPONENTS CAS NUMBER AMOUNT

MCE 2004.01

Ethylene Glycol

Diethylene glycol

Sodium 2-ethylhexanoate

SECTION 3 HAZARDS IDENTIFICATION

107-21-1 80 - 95 %weight

111-46-6 1 - 5 %weight

19766-89-3 1 - 5 %weight

EMERGENCY OVERVIEW

- HARMFUL OR FATAL IF SWALLOWED

- CAUSES EYE IRRITATION

- CONTAINS MATERIAL THAT MAY CAUSE ADVERSE REPRODUCTIVE EFFECTS BASED ON ANIMAL DATA

- POSSIBLE BIRTH DEFECT HAZARD - CONTAINS MATERIAL THAT MAY CAUSE BIRTH DEFECTS BASED ON ANIMAL DATA

- MAY CAUSE DAMAGE TO:

- KIDNEY

SECTION 4 FIRST AID MEASURES

Eye: Flush eyes with water immediately while holding the eyelids open. Remove contact lenses, if worn, after initial flushing, and

continue flushing for at least 15 minutes. Get medical attention if irritation persists.

Skin: To remove the material from skin, use soap and water. Discard contaminated clothing and shoes or thoroughly clean before

reuse.

Ingestion: If swallowed, get immediate medical attention. Do not induce vomiting. Never give anything by mouth to an unconscious

person.

Inhalation: Move the exposed person to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Get

medical attention if breathing difficulties continue.

DISPOSAL OF POL WASTE

Do not dispose used oil, coolant by dumping it onto the ground. The effect on the environment is cumulative over

time. Return used oil and glycol to your local recycling depot.

ENVIROMENTIAL LAW

You can be held accountable for the pollution you cause by improper disposal of POL and other materials

hazardous to the environment. THE BUCK STOPS WITH YOU.

Version 0.2 Page 16 of 52

Loading...

Loading...