ADO102 \ ADO104 automotive oscilloscope manual

ADO102 \ ADO104 automotive oscilloscope is a portable device developed and

produced by JH Company. This product is compact, portable, and flexible operation;

Using color TFTLCD and pop-up menus to display; to achieve its ease of use, greatly

improving the user productivity.

In addition, this product has superior performance and it is powerful, affordable, high

cost. The real-time sampling rate can be as high as 100MSa/S,can meet the capture

speed, market demand for complex signals and auto repair market; Support for USB

storage devices, users can upgrade via USB, Special test project and Universal

oscilloscope to meet different levels of customer needs.

Characteristic:

Model

Bandwidth

ADO 102

Dual channel

ADO 104

Four channel

—New ultra-thin design, small volume, light weight, convenient carrying

—Color TFTLCD display, 320*240 resolution, waveform display more clearly, stability

—Four analog channel (ADO102 for Dual channel)

—Can be convenient to realize the car corresponding module features one-button

operation

—Any interface screenshot (press F2 screenshot)

—Screenshot can preview

—Support for USB storage device

—Have the edge trigger function, under universal oscilloscope mode can automatically

detect the support (20Hz - 10MHz)

—Support time and voltage cursors

—Support A variety of waveforms mathematical sum

—Adding a variety of waveform math functions

—Support Chinese and English menu display

—A variety of display styles

—Backlight brightness can be adjusted

—Long standby: single cell battery can work continuously for 5 hours

—With a digital multimeter functions

General safety requirements:

The following safety precautions to avoid injury; And to prevent the product or any other

products connected from the damage. To avoid possible danger, be sure to use the

product in accordance with the provisions.

Attention: Do not using this oscilloscope (or multimeter)

measurements while connecting USB, as this may damage the

instrument!

Only trained personnel should perform service procedures.

1. Avoid fire and personal injury

● Correct plug

When the probe or test leads are connected to a voltage source Do not plug.

● Properly connected probe

The same probe wire and the ground potential,Do not connect the ground wire to a high

voltage. And during the test, do not touch exposed contacts and components.

● View all terminal ratings

In order to avoid the fire and impact of excessive current, Please check all rated the

product value and marking instructions. Please refer to the product description before

connect the products for more information about ratings.

● Do not open lid

If the cover or panel has been removed, do not operate this product.

● Avoid circuit exposed

After the boot, Do not touch exposed connections and components.

● Suspected product failure, do not operate

If you suspect that the product has failed, you can ask a qualified service personnel.

● To maintain adequate ventilation

● Do not operate in wet conditions

● Do not operate in the flammable, explosive environment

● Please keep the product surface is clean and dry

2. Security terminology and labeling

Terminology in this manual. The following terms may appear in this manual:

Terms on the Product: These terms may appear on the product

DANGER: Indicates that there is a direct risk of harm exists near the mark.

WARNING: Indicates a potential risk of injury near the mark.

Note: indicate a potential danger to the products and other property.

Symbols on the Product: These symbols may appear on the product

High voltage Protective ground Attention Measurement of ground

WARNING: Warning statements indicate conditions and

behavior which might endanger the safety of life .

Note: Note Statement Pointed out conditions and

behaviors that may cause this product and other

property damage .

Summary:

This manual describes the operation of ADO Series Handheld Digital Oscilloscope.

Manual includes the following chapters:

◆ Getting started: a brief introduction to digital handheld oscilloscope's front panel user

interface, functional check and probe compensation.

◆ Features and Operation: a detailed presentation for functions and operations of

universal oscilloscope and automotive oscilloscope and multimeter.

◆ The application example: provide some measurement example, for reader reference.

◆ System Tips and Troubleshooting.

◆ Service and Support

◆ Appendix

1

Catalog

Chapter 1 Getting Started .............................................................. 2

1.1 Preliminary understanding ADO front panel and user interface ............................ 2

1.2 Probe ...................................................................................................................... 3

Chapter 2 Describes of the function and operation ........................ 4

2.1 Automotive oscilloscope ......................................................................................... 5

1. Quick Operation Guide ...................................................................................... 5

2. Ignition function ................................................................................................. 5

3. The function of sensor ..................................................................................... 13

4. The Function of Actuator ................................................................................. 19

5. Bus .................................................................................................................. 22

2.2 Universal Oscilloscope this section features are described ................................ 23

1. Menus and Control buttons ............................................................................. 24

2. Connector ........................................................................................................ 25

3. Automatically set ............................................................................................. 25

4. Default settings................................................................................................ 26

5. Vertical Systems .............................................................................................. 26

6. Horizontal Systems ......................................................................................... 27

7. Trigger system ................................................................................................. 28

8. Math System ................................................................................................... 29

9. System Setup .................................................................................................. 30

10. The storage system ....................................................................................... 31

2.3 Multimeter function and operation ........................................................................ 32

Chapter3 Application Examples ................................................... 34

3.1 Singal measure ..................................................................................................... 34

3.2 Cursor measure .................................................................................................... 34

3.3 Capture the Single Signal..................................................................................... 35

3.4 Use Multimeter to Measure DC Voltage .............................................................. 36

Chapter 4 System Tips and Troubleshooting ............................... 36

4.1 Prompting Message ............................................................................................. 36

4.2 Troubleshooting .................................................................................................... 36

Chapter 5 service and support .................................................... 37

5.1 Warranty Description ............................................................................................ 37

Appendix A: Technical Specifications ........................................... 37

Appendix B: ADO 102/ADO 104 oscilloscope accessories .......... 39

Appendix C: routine maintenance and cleaning .......................... 39

2

Chapter 1 Getting Started

ADO handheld digital storage oscilloscope is a small, lightweight portable instrument,To

provide users with a convenient and easy to operate front panel, you can perform basic

tests.

This chapter explains how to perform the following tasks:

△ Preliminary understanding ADO front panel and user interface

△ Probe Compensation

△ Match the probe attenuation factor

1.1 Preliminary understanding ADO front panel and user interface

Before using ADO, We must first understand the operation panel. Following is a easy

description and presentation for the ADO series front panel operation and function, To

make use of you in the shortest possible time familiar with the oscilloscope.

ADO provide users with a clear and simple front panel, To facilitate the user to perform

basic operations. On the left and right side of the display panel is marked with various

function keys. Key to set the different options up and down through the menu. The red

substrate power button, press it, you can open the oscilloscope or shutdown. The other

pushbuttons are function buttons, through them, you can enter different function menus or

obtain a specific function application. As shown in Figure 1-1 and Figure 1-2.

Figure 1-1 ADO102 Figure 1-2ADO104

Channel 1-2

F1-F4

multi-selector

button

Channel1-4

RUN/STOP

Multimeter

Back

Move button

Zoom button

3

Figure 1-3 Interface is shown in Figure

1.2 Probe

1 Safety of probe

Set around the probe body protection to protect your fingers to prevent electric shock.

Before taking any measurements, make sure the probe is connected to the oscilloscope

and the ground terminal to ground.( Note: The oscilloscope probe and the attenuation

must be set the same gear)

2 Probe compensation (see probe manual)

In the first probe with any input channel connection, this needs to be adjusted to match the

probe to the input channel. Uncompensated probe calibration can cause measurement

error or errors. If you adjust the probe compensation, as follows:

(1) Set the Probe option attenuation to 10X in the channel menu, The switch on the probe

is also set to 10X,And oscilloscope probe connected to channel 1.If using the probe

hook-tip, ensure reliable contact with the probe.

(2)Connect the probe tip and the signal generator output connector, Grounding clip and

signal generator is connected to the ground connector, Display Channel, Then press the

"AUTO" (automatic) button.

(3)Check the shape of the waveform display. As Figure 1-4

Trigger

status

display

Channel 1 mark

Show vertical

volts / division

Display power

Horizontal

displacement

Show the amount of

the trigger position

Channel

operation

status

Show

horizontal

time / div

Display

level

Trigger

position

Corresponds to a different

function keys, menus will

vary

Frequency

waveform display

4

Under compensation Appropriate compensation over compensation

Figure 1-4

(4) If necessary, adjust the probe and repeat the operation if necessary.

Chapter 2 Describes of the function and operation

In order to use ADO Series oscilloscope effectively, you need to understand the main

functional framework of the oscilloscope.

This chapter is divided into three modules to introduce oscilloscope according to the

functional framework: automotive oscilloscope, general oscilloscope, multimeter.

5

2.1 Automotive oscilloscope

This section function of automotive oscilloscope is described below:

Ignition Sensor Actuator Bus

1.Primary

ignition

2.Secondary

ignition

3.Primary and

secondary

ignition

4.Primary

ignition

(current)

1. Crankshaft and

camshaft position

2. Vehicle speed

sensor

3. Oxygen sensor

4. Throttle position

sensor

5. Air flow meter

6. Manifold absolute

pressure

7. Knock sensor

8. Accelerator pedal

1. Electromagnetic

valve

2. Gasoline and

diesel fuel nozzle

3. Gasoline nozzle

(Current)

4. Gasoline nozzle

(Voltage and

Current)

1. CAN-high、

CAN-low

2. LIN-bus

3. FlexRay

NOTE: When signal voltage of measured signal is not clear, you can use multimeter first

(this series oscilloscopes are with multimeter), according to the measured value of the

multimeter, set the attenuation ratio of the oscilloscope and probe. The waveform pictures

of each functional test in text are from Dodge. Journey 2.4 L model cars, different models

measured different waveforms, so there will be differences.

1. Quick Operation Guide

Setting essentials:

1)Wave height adjustment (amplitude):Press the corresponding channel, and adjust

through the up and down keys

2)Waveform overall move:Press the corresponding channel, and then adjust through

the left and right keys

3)Waveform density adjustment (time base):Press time base key, and then adjust

through the up and down keys

4)Waveform shaking elusive:Press the trigger button, and then by moving left and right

keys, and then control the trigger arrow in the right of the screen, move red trigger arrow

to the appropriate location of waveform until the waveform stabilizes

5)Waveform freeze playback view: Press the start / stop button, then press the time

base key, and finally by moving left and right key to see if crankshaft has missing teeth

phenomenon

2. Ignition function

(1)Ignition introduction

1)Ignition System Category

6

Partakers boards conventional ignition system used on the car has a long history,

now has gradually been replaced by direct ignition system (DIS)

Direct ignition system is divided into three types:

▲dual ignition system using double-ended output ignition coil (DEC).

▲single ignition system using single-ended output ignition coil (CPC).

▲Integrated ignition system using the integrated spark plug (COP).

The common feature of these three is the output of the ignition coil pass directly

to the spark plug without passing through the distributor plate

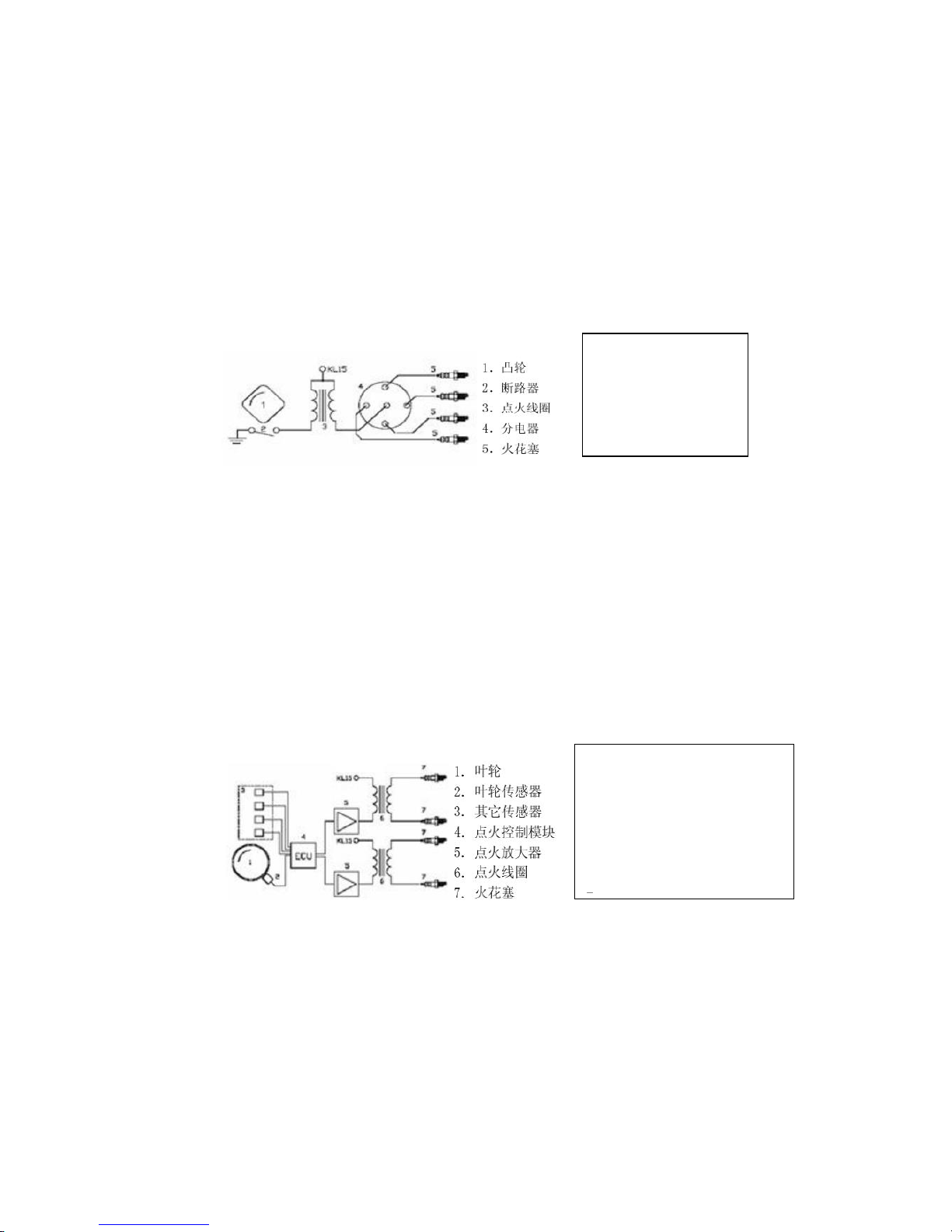

2)Traditional ignition system

Traditional ignition system consists of a battery, cam, breaker, ignition coil, distributor,

spark plugs. The effect of battery is to supply power of the ignition system require, cam

and the circuit breaker turn on or off ignition system power. Ignition coil store ignition

energy and turn battery voltage to ignition high voltage. The role of the circuit breaker is

turned on or off ignition primary circuit. The role of the distributor is to delivery ignition high

voltage produced by ignition coil to each spark plugs according to working order of engine.

Spark plugs lead ignition high voltage to cylinder combustion chamber, and produce spark

between the electrodes, Igniting the combustible mixture.

The advantage of this ignition system is relatively easy for detection service, one of

the disadvantage is mechanical parts and electrical contacts easy to wear, short life. And

the high-voltage connector portion also easily damaged.

3)Dual ignition system (DEC)

Dual ignition system entirely by electronics, with no mechanical parts. Each two

cylinder shared a ignition coil, two electrodes of coil secondary connect to a spark plug

respectively. It means that there are always two spark plugs igniting at the same time, one

of the cylinders in the normal ignition, the other cylinder is at the exhaust process (Ignition

spark "waste" in the exhaust gas), the pressure of cylinder in exhaust close air pressure,

only need very low ignition voltage, wasted little energy.

One of the advantages of dual ignition system is fewer faults, virtually no maintenance.

Another advantage is the good adjustability of the ignition system; wave radiation emitted

1. Cam

2. Breaker

3. Ignition coil

4. Distributor

5. Spark plugs

1. Impeller

2. Impeller sensor

3. Other sensor

4. Ignition control module

5. Ignition amplifier

6. Ignition coil

7

small, low fuel consumption. The disadvantage is still required high voltage and spark plug

connector, these places is very easy to go wrong.

4)Single Ignition System (CPC)and Integrated ignition system (COP)

Each cylinder has a separate ignition coil, is today's most advanced ignition system.

This ignition system is divided into two types: Single Ignition System (CPC), integrated

ignition system (COP). Integrated ignition system integrated ignition coil in the spark plug,

single ignition system is connecting ignition coil to spark plug with a high voltage wire.

5)Ignition principle

▲The electronic ignition

The electronic ignition system collect information related to the engine with a set of

sensors, such as speed, cooling temperature and engine load, etc. Position sensor and

speed sensor is the most important information required for the ignition system, the

information from the wheel sensors or camshaft sensor. Ignition control module calculates

ignition time and charging time based on the collected information, If a sensor is not

working properly, it will cause the output signal is incorrect, so modern control module

have to check whether the signal sent by the sensor is authentic, when there are

untrusted signal, it may not output any signal. Ignition control module output signal can not

directly drive the ignition coil, have to amplify by ignition amplifier. In fact, ignition amplifier

is mounted in ignition coil generally, in this case the primary ignition signal is

undetectable;Or mounted in the ignition control module,in this case the ignition control

module output signal is undetectable. Thus, detecting engine fault and performance

through the secondary ignition signal is important.

▲Mechanical ignition system

1. Impeller

2. Impeller sensor

3. Other sensor

4. Ignition control module

5. Ignition amplifier

6. Ignition coil

7. Spark plugs

1. Signal sensor

2. Ignition control module (ECU)

3. Ignition amplifier

4. Ignition coil

5. High voltage line and spark

plugs

8

Contact-driven

Sensor-driven

In the mechanical ignition system, the charging time and the ignition time is

controlled by the distributor camshaft. Electrical sensor (Hall or magnetic) or contacts is

as the role of the sensor. Contacts can directly drive the ignition coil, but telex can only

drive the ignition coil by ignition enlarge. In fact, ignition amplifier is mounted in ignition

coil generally,in this case the primary ignition signal is undetectable.

6)Sensor

Hall devices and magnetic induction coil are commonly used sensors.

Hall device output square wave 0-5 volts or 0-12 volts.

Magnetic induction coil output sine wave, the amplitude is related to rotational

speed. Ignition control signal.

Ignition control module output control signal 0-5 V or 0-12 V square wave.

7)Secondary ignition

When ignition, coil secondary generates a high voltage,when the voltage is

gradually increased to a certain value,the spark plug produce sparks,this voltage is

the ignition voltage. The voltage then drops rapidly to another voltage value and

maintained for some time,this voltage is the

combustion voltage, combustion time is the

time of voltage maintained at a combustion

voltage value. At the end of the burning time,

ignition coil energy is almost exhausted, the

remaining energy is formed damped

oscillation on the coil.

Observing this picture can analysis of

operation of the vehicle from details. Ideally,

this pattern is very stable, showing each

voltage of ignition combustion processes are

1. Electric shock

2. Ignition coil

3. Distributor / high voltage line /

spark plugs

1. Sensor

2. Ignition amplifier

4. Ignition coil

5. Distributor / high voltage line /

spark plugs

Closed section

Flashover segment

Shock attenuation

section

9

the same. Each cylinder pattern should be roughly the same. However, the actual

situation is not ideal, graphics assembly will be large or small jitter,such as ignition

or breakdown voltage fluctuated,combustion times may vary in length,these do not

necessarily indicate the engine failure. These may need us have experience

cumulation by time, combined with a comprehensive analysis of other graphics,but it

can be said, the ideal graphics may not been seen.

Ignition or breakdown voltage:If the ignition voltage is too high, even more than

the range of the screen, indicating that the resistance value is too high in secondary

ignition circuit. Open line,spark plug damaged,high-voltage or spark plug gap is too

large may have resulted in the phenomenon of high breakdown voltage,Conversely,

if the breakdown voltage is too low,It indicates that the resistance value in ignition

secondary circuit is lower than normal, spark plugs may be dirty or rupture,

high-voltage leakage and other reasons caused.

Combustion line and combustion time:if combustion line has too much clutter,

It represents cylinder misfire. Or due to premature ignition, injectors damaged, spark

plugs dirt and other reasons. The length of the combustion line duration is related to

mixed gas concentration in the cylinder. Typically, it means that the combustion time

exceeding 2ms gas mixture is too thick. Conversely, if combustion time is less than

0.75ms indicates too lean mixture.

8)Correct broken-line by broken wire needle.(all need to break the wire for

measurements except for secondary ignition)

10

(2)Ignition test

cross section of ignition coil(inside is secondary coil outside is

primary coil)

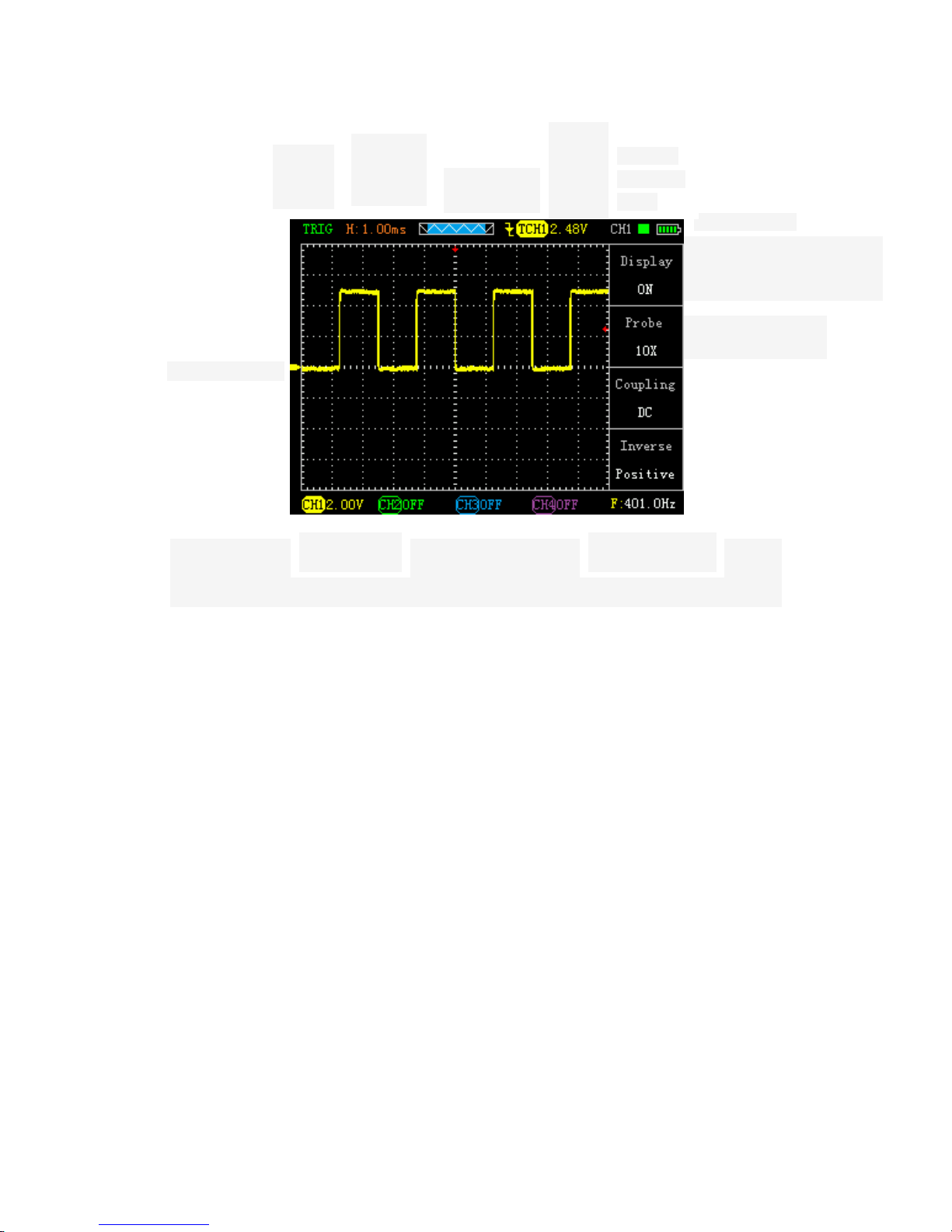

1)Primary ignition

①After the oscilloscope installed batteries,long press red power

button“ ”, let it go until you hear the buzzer,at this time

oscilloscope enter the main menu interface,as picture-1

②After entering the main menu interface , can select the

instrument operation mode through the up and down buttons,

then press “OK” button,default select the "ignition" into the ignition

function selection interface,then you can enter the user interface through up and

down keys to select the "primary ignition", as picture-2

③Connect the probe to CH1 and probe set to 10X,then connect

grounding clip to the signal ground or grounding.

④Since the primary ignition of oscilloscope has default settings

(Probe 10X,time base 1ms), Simply connect the ignition coil

to the probe needles can display waveform. As picture-1(when

the waveform shaking too fast to capture, you can set the trigger

Mode to single-shot then detect again)

⑤Press“CH1”,can view the values and configuration(configuration has default)

Picture-1

Picture-2

11

⑥Waveform display can be adjusted based on their own through the vertical

volts / division and trigger ways to meet your needs(Time base, vertical volts /

division and other specific operations, please refer to the operation of general

oscilloscope)

2)Secondary ignition

①Same as Primary ignition step 1

②After entering the main menu select "Ignition",then enter the sub-menu press

the up and down keys to select "secondary ignition",It will prompt "use

professional ignition probe" before entering the operating interface, wait a few

seconds to enter the oscilloscope interface.

③Independent ignition to be equipped with an ignition extension cord and high

voltage ignition probe must ignition sensing probe, connect ignition probe to

CH1.

④Since the secondary ignition of oscilloscope has default settings(Probe 10X,

time base 1ms)ignition system with sub-cylinder line, probe with capacitor

(small black squares )side is sandwiched with sub-cylinder line, the other side

connected to the ground or battery negative. If the car is an independent

ignition system,you need to buy "independent ignition extension cord"(one

side connect to ignition coil, one side connect to spark plug, the role is to

replace the sub-cylinder line)ignition probe in independent ignition extension

cord, Step as above.

⑤Same as Primary ignition step 5

⑥Same as Primary ignition step 6

3)Primary and secondary ignition

This function let the primary ignition, secondary ignition be realized through CH1

and CH2,observed and compared two waveforms more intuitively. Select”

Primary ignition, secondary ignition” Before entering into operation interface, it

Breakdown voltage

or ignition voltage

peak

arcing or burning

voltage

Burn line

Ignition coil begins

charging

Oscillation coil

Pic-1 Primary ignition

12

will prompt“CH1: standard probe for primary use,CH2: Ignition probe for

secondary use” Wait a few seconds to enter the oscilloscope interface,other

details, please refer to the above primary, secondary ignition function.

Note:CH1 is primary ignition, CH2 is secondary ignition pay attention to the

probe connected to the channel

4)Primary ignition (current)

①Same as Primary ignition step 1

②After entering the main menu select "Ignition",then enter

the sub-menu press the up and down keys to select the

"primary ignition (current)",before entering the operating

interface, it will prompt "must comply with the current

clamp using" wait a few seconds to enter the

oscilloscope interface.

③Connect current clamp to the oscilloscope CH1, since the

primary ignition oscilloscope is default setting (probe 1X,

time base 1ms), simply connect the current clamp to ignition

coil, then waveform can be visually displayed. As pic-2.

④Press“CH1”, you can view the value and configuration

(configuration has default)

⑤Displayed waveform can be realized through the self-regulating

group, vertical volts / division and trigger their needs

(time base, vertical volts / division and other specific operations,

please refer to the general oscilloscope operation)

Note: If the measured waveform inversed, change the direction of current clamp as

pic-3, the specific use of current clamp, please refer to the purchase

Instructions of the current clamp (To purchase current clamp can contact the

manufacturer for recommended)

Pic-2 Primary ignition current

Pic-3 use of current clamp

13

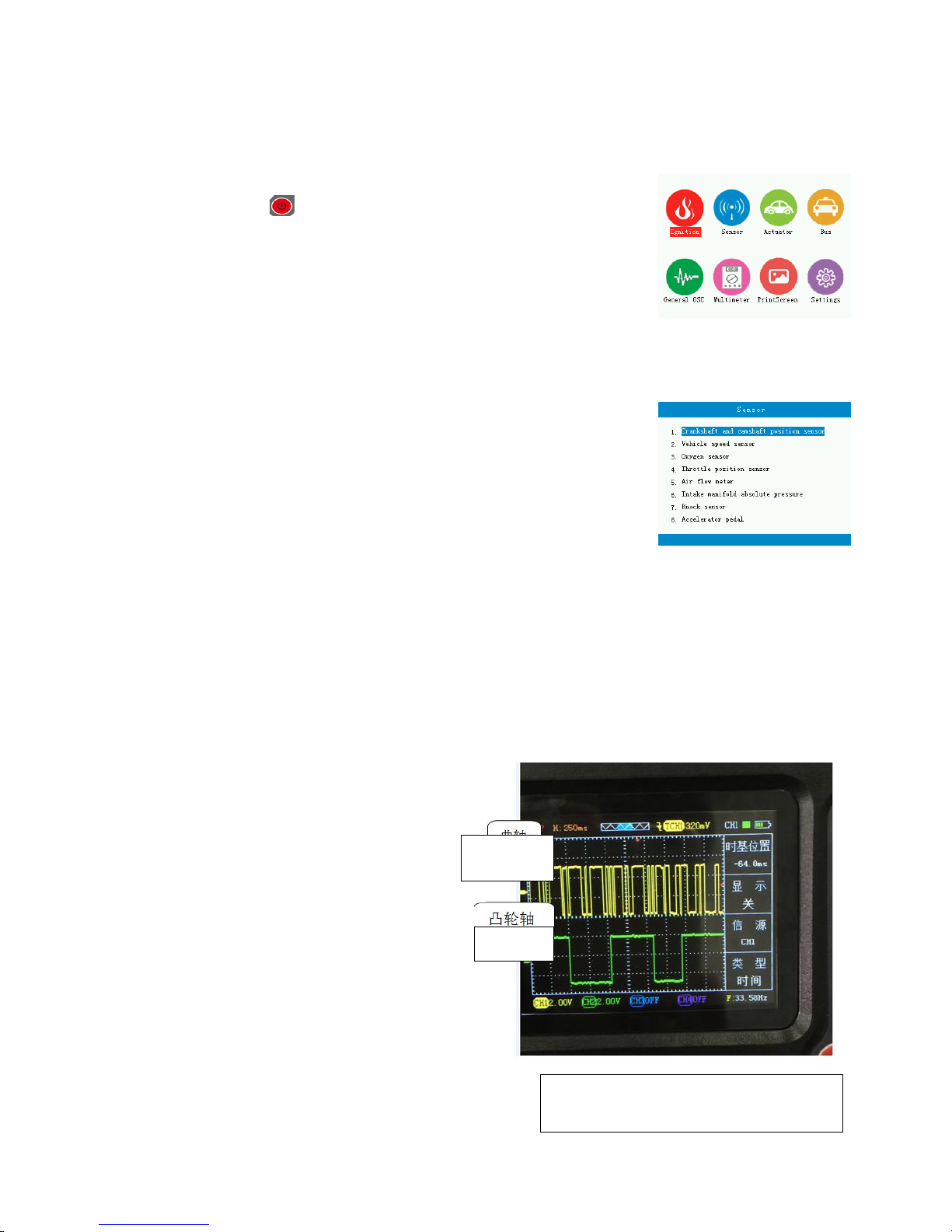

3. The function of sensor

1)Crankshaft and camshaft position sensor(magnetic-electric, Hall)

①After the oscilloscope installed batteries,long press red power

button“ ”,let it go until you hear the buzzer,at this time

oscilloscope enter the main menu interface, as picture-1

②After entering the main menu interface select “Sensor”, then

enter the sub-menu press the up and down keys to select

"Crankshaft and camshaft position sensor"(as picture-2),

enter the second sub-menu press the up and down keys to select "Magnetic

Electric"or" Hall ", press “OK”,

it will separately prompt "Amplitude with the speed of change"

and "0-5v or 0-12v" before entering operation interface, will

enter into oscilloscope interface after waiting several

seconds.(Note: Channels should be correspond with functions.

CH1: Crankshaft position sensor, CH2: Camshaft position

sensor)

③Connect two probes to CH1 and CH2 separately, and set probe

to 1X, then connect grounding clip to signal ground or grounding.

④Since the "magnetic-electric" and "Hall" function of oscilloscope has default

settings (probe 1X,time base 10ms),just need to connect two probes to corresponding

signals, then the waveforms can be displayed, as pic-4.( measured waveform is under

800 rpm)

⑤Press“CH1”or“CH2”, can view the values and configuration(configuration has

default)

⑥Displayed waveform can be realized the need through the self-regulating time base,

vertical volts / division and trigger type

(time base, vertical volts / division and

other specific operations, please refer to

the general oscilloscope operation)

Note: Considerations when

measuring magnetic-electric and

Hall waveforms

① Measuring range :

Magnetic-electric type time

base 1ms-500ms(Horizontal

ruled); voltage 500mv-50v

(vertical ruled); Hall type

time base 1-500ms

( Horizontal ruled) voltage

1v-10v(vertical ruled)

② The amplitude and frequency

of magnetic-electric type

Picture-1

Picture-2

pic-4 Crankshaft, camshaft position sensor

(Hall)

Crankshaft

Camshaf

14

changes with the speed(Similar with the principles of the generator), the

amplitude with fixed frequency of Hall type changes with the speed.

2) The vehicle speed sensor (magnetic, Hall,

photoelectric)

①The same as the crankshaft, camshaft position sensor

Step 1.

②Select "Sensor" after entering the main menu, then

enter the sub-menu press the arrow keys to select "speed

sensor" into the second sub-menu press the arrow keys to

select "magnetic-electric", "Hall" or "photoelectric", press

"OK" button to confirm to enter the oscilloscope user

interface (Note: before entering the electric and magnetic

Hall oscilloscopes prompts are "amplitude variation with

speed" and "0-5v or 0-12v" wait a few seconds to enter the

user interface )

③Connect the CH1 probe to the oscilloscope and set probe to 1X file transfer, then

connect the grounding clip to the signal ground or grounding.

④Since the oscilloscope "magneto electric", "Hall" and "photoelectric" function has

already default settings (magneto electric and HALL: Probe file 1X, time base 5ms,

photoelectric probe file 1X, time base 25ms), Just probe to the corresponding signal, To

intuitive display waveforms, as shown in Figure 5.

⑤Press "CH1", you can view the value and configuration (by default)

⑥waveform can be self-fulfilling their needs by adjusting the time base, vertical volts /

division and trigger mode (time base, vertical volts / division and other specific operations,

please refer to the Universal oscilloscope operation)

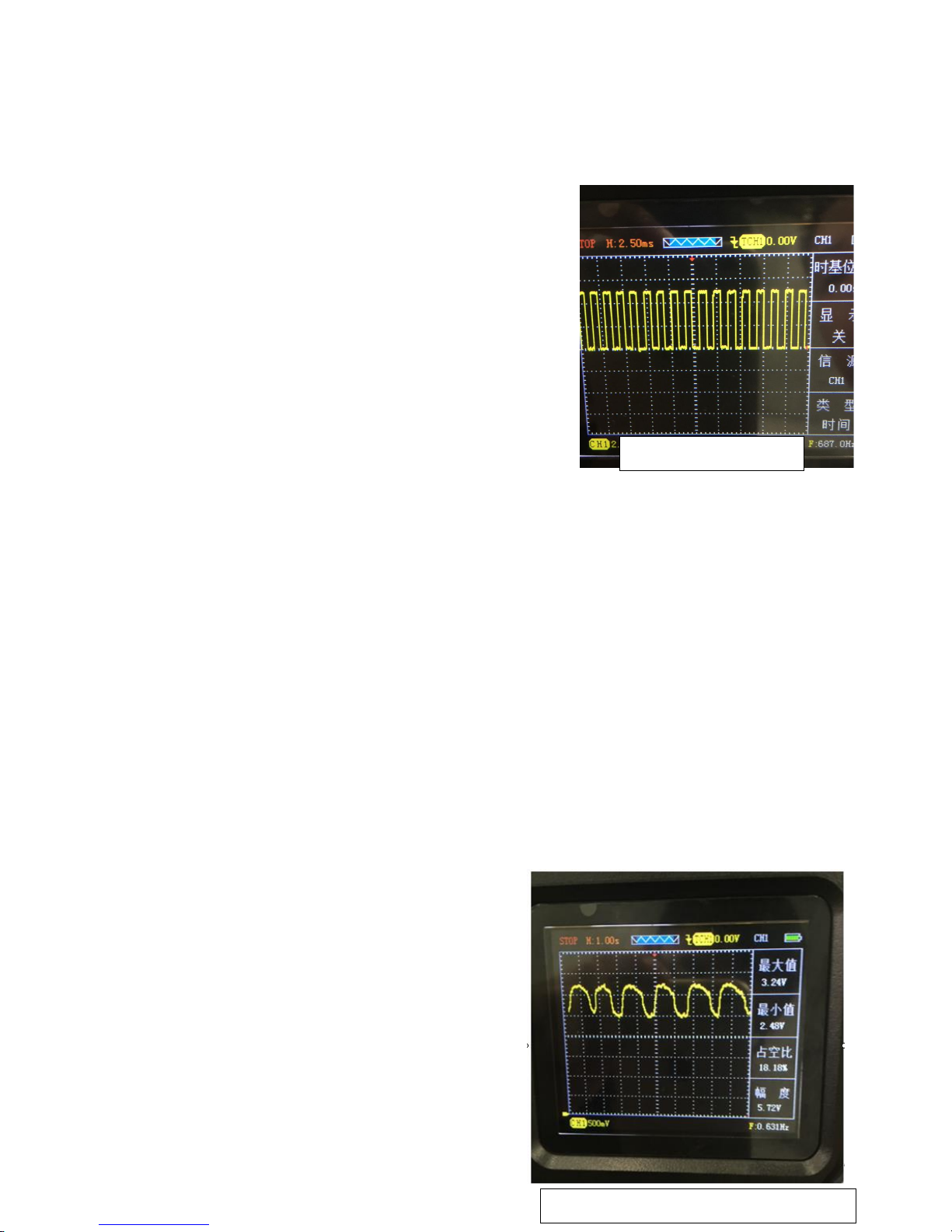

3) The oxygen sensor (zirconium-type, titanium type)

①The same as the crankshaft, camshaft position sensor Step 1.

②Select "Sensor" after entering the main menu, then enter the sub-menu press the arrow

keys to select "oxygen sensor" into the second sub-menu press the arrow keys to select

"zirconium-type” or "titanium type", press "OK" button to confirm to enter the oscilloscope

user interface.

③Connect the CH1 probe to the oscilloscope and set probe to 1X file transfer, then

connect the grounding clip to the signal ground or

grounding.

④Since the oscilloscope "Zirconium" and

"titanium" function has default settings (profiles

probe 1X, time base range 1s), just probe to the

corresponding signal, To intuitive display

waveforms, as shown in Figure 6. (Note: As in the

"SCAN" scan mode requires patience waveform

scanned)

⑤Press "CH1", you can view the value and

configuration (by default)

Pic-5 Hall speed sensor

Pic-5 Titanium oxygen sensor (idle condition)

15

⑥waveform can be self-fulfilling their needs by adjusting the time base, vertical volts /

division and trigger mode (time base, vertical volts / division and other specific operations,

please refer to the Universal oscilloscope operation)

Note:

The oxygen sensor, also known as the exhaust gas sensor, is a very important role in the

exhaust emission control of a vehicle equipped with a catalytic converter.

The oxygen sensor is arranged on the exhaust pipe and in front of catalytic converter. The

variation range of the voltage of the zirconium oxygen is 0-1V, and the voltage variation

range of titanium oxide is 0-5V, because the titanium oxygen sensor needs the power

supply voltage. A vehicle equipped with an oxygen sensor is referred to as a "closed loop",

meaning that the sensor will analyze the exhaust gas and re adjust the engine oil supply

according to the results after the fuel is burned.

No matter how many connection lines between the oxygen sensor and the engine control

module, the sensor output is always a black line.

Single Line: This line is used to produce the output voltage of the sensor itself, usually

black.

Two lines: one output line output and a ground line.

Three lines: one output line and two-line heating device (power line and ground line).

Interior heating means to raise the temperature at cold start to make the cars quickly

brought under control.

Four-wire: a signal line and a signal ground. Two other heating device lines.

Zirconium oxygen sensor needs to reach more than 300 degrees Celsius temperature in

order to work properly, this kind of oxygen sensor normal output feedback voltage change

between 0 ~ 1V. 0.5V above the output indicates that the mixture is too thick; 0.5V output

indicates that the appropriate balance between lean and too thick; 0.5V the following

output indicates that the mixed gas is too thin. The output voltage variation indicates that

the engine control module changes the air fuel ratio

(the ratio of air to fuel, the concentration of the mixture).

Normal zirconia’s oxygen sensor output voltage

waveform should meet the 3 elements: the maximum

voltage, the minimum voltage, response time (voltage

from high to low change of time). In general, the

allowable range is the maximum voltage value > 850mV,

the minimum voltage is 75 ~ 175mV, and the response

time is less than 100ms. For the change of the amplitude

of the waveform is in the idle state of the 10s amplitude

of the waveform is not less than 8 times as shown in

figure 7.

Start the engine and keep the engine speed

1500-2000rpm, after 3 minutes, until the engine reaches

normal working temperature, because the engine must

reach normal working temperature and into the closed

loop, oxygen sensor signal readout instrument is

correct.

Pic-7 Zirconia oxygen sensor

Note: 1、The axis is a peak-to-amplitude

2、Peak to trough for the two amplitudes,not one

Wavelength

Amplitude

Amplitude

One amplitude

16

If the oxygen sensor is detected, the oxygen sensor has power supply, but not see the

waveform change, then the cause of the failure may be as follows:

● poor connection

● oxygen-sensor fault

● engine vacuum leak

● poor fuel mixture ratio control

4) Throttle Position Sensor

①The same as the crankshaft, camshaft position sensor Step 1.

②Select "Sensor" after entering the main menu, then enter the sub-menu press the arrow

keys to select "Throttle Position Sensor”, press "OK" button to confirm to enter the

oscilloscope user interface.

③Connect the CH1 probe to the oscilloscope and set probe to 1X file transfer, then

connect the grounding clip to the signal ground or grounding.

④Since the oscilloscope "throttle position sensor" function has already default

settings (profiles probe 1X, time base range 500ms), just probe to the

corresponding signal, to intuitive display waveforms, as

shown in Figure 8. (Note: As in the "SCAN" scan mode

requires patience waveform scanned)

⑤Press "CH1", you can view the value and configuration

(by default)

⑥waveform can be self-fulfilling their needs by adjusting

the time base, vertical volts / division and trigger mode

(time base, vertical volts / division and other specific

operations, please refer to the Universal oscilloscope

operation).

Note:

Open the ignition switch, do not start the engine, to detect

the throttle position sensor signal, slowly open to close the

throttle, observe the waveform has no sudden or irregular

changes in the situation. When the throttle position sensor is analyzed, it is possible to find

out the abnormal signal waveform in any signal waveform, for example, the instantaneous

voltage drop may indicate the error of the sensor itself, damage, or dirty. And this

abnormal signal waveform, but also easy to cause the error of the oscilloscope, so that the

vehicle fault. Most of the solar term door position sensor, when idling, the voltage value

should be all below 1.25V, and the throttle valve is fully open, the voltage value should be

more than 3.4V, and the voltage should be smooth without any change, or surge voltage

drop situation.

When the ignition switch is turned on, the engine does not start, detecting the throttle

position sensor signal, if not see the waveform with the throttle opening variation, the

failure may be as follows:

● poor connection

● bad sensor itself

5) Air flow meter sensor

Pic-8 Throttle Position Sensor

The throttle

fully open

Throttle

Close

Throttle

Close

17

①The same as the crankshaft, camshaft position sensor Step 1.

②Select "Sensor" after entering the main menu, then enter the sub-menu press the arrow

keys to select "air flow meter sensor" into the second sub-menu press the arrow keys to

select "high frequency" or "low frequency", press "OK" button to confirm to enter the

oscilloscope user interface.

③Connect the CH1 probe to the oscilloscope and set probe to 1X file transfer, then

connect the grounding clip to the signal ground or grounding.

④Since the oscilloscope "air flow meter sensor" function has already default settings

(High Frequency: Probe file 1X, time base range 100us, low frequency: probe profiles 1X,

time base range 10ms),Just probe to the corresponding signal, To intuitive display

waveforms, as shown in Figure 8. (note: As in the "SCAN" scan mode requires patience

waveform scanned)

⑤Press "CH1", you can view the value and configuration (by default)

⑥waveform can be self-fulfilling their needs by adjusting the time base, vertical volts /

division and trigger mode (time base, vertical volts / division and other specific operations,

please refer to the Universal oscilloscope operation).

Note:

air flow meter is generally divided into analog air flow meter and digital air flow meter:

●Analog air flow meter

The function of the air flow meter is to measure the air flow into the throttle valve. The air

flow into the throttle valve is different with the speed of the engine. Analog air flow meter

will detect the flow of air into the change of 0-5V between the voltage signal transmitted to

the oscilloscope. Start the engine, step on the accelerator pedal, then the air flow signal,

should be with the throttle valve opening bigger and the higher the value.

In the idle speed should be kept stable, when the throttle valve is fully open, the signal will

be increased to the maximum value.

Watch the waveform signal in the abnormal phenomenon, such as: if the waveform

smoothly, no surge occurred suddenly, waveform distortion, usually said oscilloscope

between sensor and circuit, has the situation bad, bad line or the sensor itself.

Sensor voltage output signal, usually at idle speed when the minimum and with the

increase of the engine load, the average idle speed is about 800mv, when the throttle

valve is fully open, about 4.5V.

● Digital air flow meter

The function of digital air flow meter is to measure the air flow into the throttle body. Air

flow into the throttle body varies with the speed of the engine. Digital air flow meter

converts the detected air flow into the frequency signal. When the higher frequency signal,

the greater the amount of air. Start the engine, at this time will be displayed on the screen

square wave graphics, without any waveform display. You may have entered the analog

air flow meter.

The observed signal waveform anomalies, for example, whether a square wave at right

angles to change, or whether the surge occurs and the like. Sensor signal waveform

sudden change in frequency usually indicates that there is a bad contact between the

oscilloscope and the sensor, or the sensor itself is poor.

Digital waveform generated by air flow meter square wave signal neat, when the ignition

18

key is turned on and tap the sensor when the engine does not start, this time waveform if

a difference, said air flow meter sensor itself is bad, or there is a short circuit or line

breaking situation.

Air flow meter sensor generates a signal to a frequency signal, the frequency of the

number of so-called square-wave signal appears every second, the normal air flow meter

sensor fixed to the engine speed signal values to produce little change in frequency, if the

fluctuation range is too large, it means that poor air flow meter sensor. If the detected air

flow meter, air flow meter power supply, but the changes seen in the waveform, the failure

may be as follows:

●The oscilloscope has not received the signal transmitted from the air flow meter

●sensor itself is unstable

6) Intake manifold absolute pressure sensor

①The same as the crankshaft, camshaft position sensor Step 1.

②Select "Sensor" after entering the main menu, then enter the sub-menu press the arrow

keys to select "intake manifold absolute pressure

sensor" ,press "OK" button to confirm to enter the

oscilloscope user interface .

③Connect the CH1 probe to the oscilloscope and

set probe to 1X file transfer, then connect the

grounding clip to the signal ground or grounding.

④Since the oscilloscope "intake manifold absolute

pressure sensor" function has already default

settings (profiles probe 1X, time base range 500ms),

just probe to the corresponding signal, to intuitive

display waveforms, as shown in Figure 9. (Note: As

in the "SCAN" scan mode requires patience

waveform scanned)

⑤Press "CH1", you can view the value and configuration (by default)

⑥waveform can be self-fulfilling their needs by adjusting the time base, vertical volts /

division and trigger mode (time base, vertical volts / division and other specific operations,

please refer to the Universal oscilloscope operation).

7) Knock sensor

①The same as the crankshaft, camshaft position

sensor Step 1.

②Select "Sensor" after entering the main menu, then

enter the sub-menu press the arrow keys to select

"knock sensor”, press "OK" button to confirm to enter

the oscilloscope user interface.

③Connect the CH1 probe to the oscilloscope and set

probe to 1X file transfer, then connect the grounding

clip to the signal ground or grounding.

④Since the oscilloscope "knock sensor" function has

Pic-9 Intake manifold absolute pressure sensor

Idling

Pic-10 Knock Sensor

19

already default settings (profiles probe 1X, time base range 500us),Just probe to the

corresponding signal and then use a small stick percussion cylinder, To intuitive display

waveforms, as shown in Figure 10. (note: As in the "scan" scan mode requires patience

waveform scanned)

⑤Press "CH1", you can view the value and configuration (by default)

⑥waveform can be self-fulfilling their needs by adjusting the time base, vertical volts /

division and trigger mode (time base, vertical volts / division and other specific operations,

please refer to the Universal oscilloscope operation).

8) Accelerator pedal

①The same as the crankshaft, camshaft position sensor Step 1.

②Select "Sensor" after entering the main menu, then enter the sub-menu press the arrow

keys to select "accelerator pedal" ,press "OK" button to confirm to enter the oscilloscope

user interface .

③Connect the CH1 probe to the oscilloscope and set

probe to 1X file transfer, then connect the grounding clip to

the signal ground or grounding.

④Since the oscilloscope "accelerator pedal" function has

already default settings (profiles probe 1X, time base

range 250ms), just probe to the corresponding signal, to

intuitive display waveforms, as shown in Figure 11. (Note:

As in the "SCAN" scan mode requires patience waveform

scanned)

⑤Press "CH1", you can view the value and configuration

(by default)

⑥waveform can be self-fulfilling their needs by adjusting

the time base, vertical volts / division and trigger mode (time base, vertical volts / division

and other specific operations, please refer to the Universal oscilloscope operation).

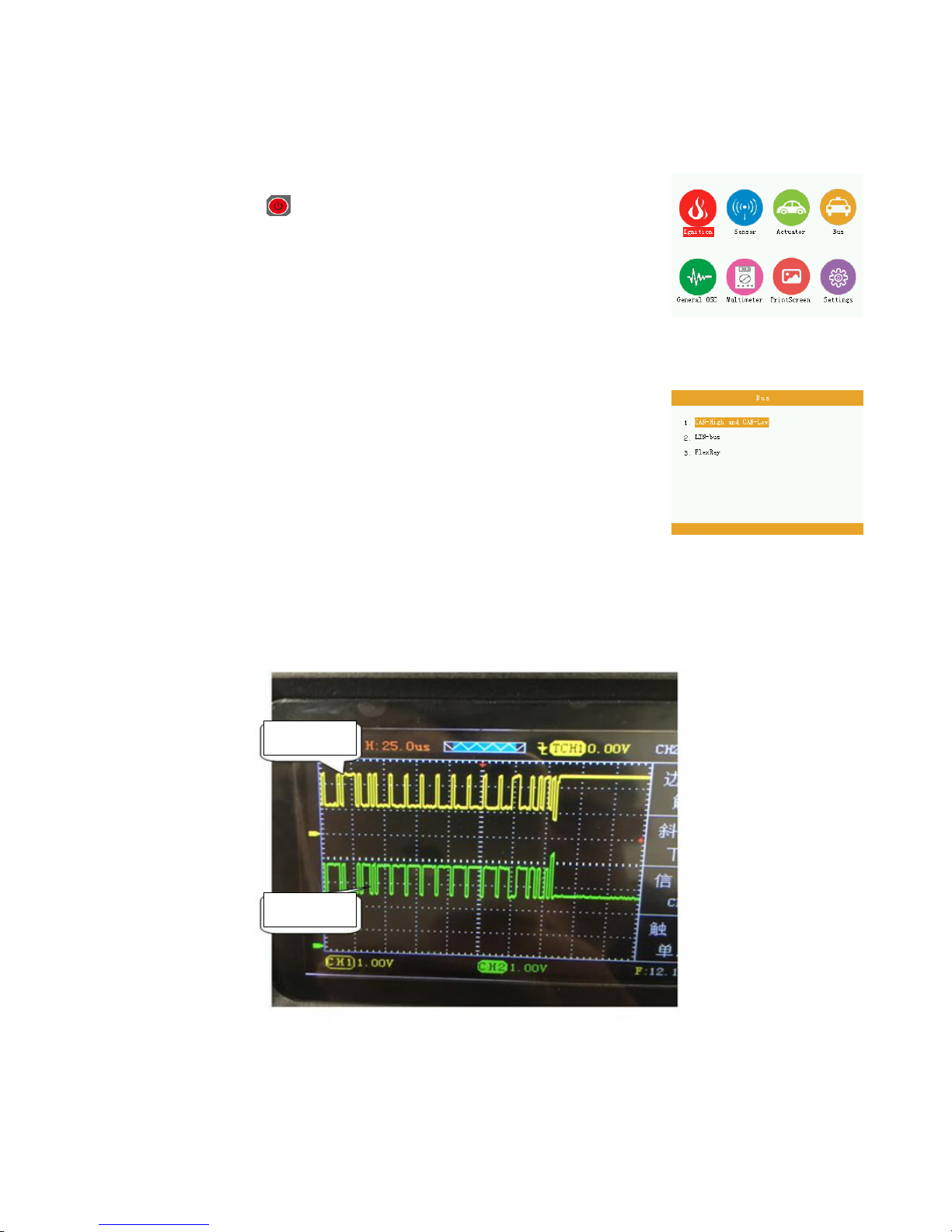

4. The Function of Actuator

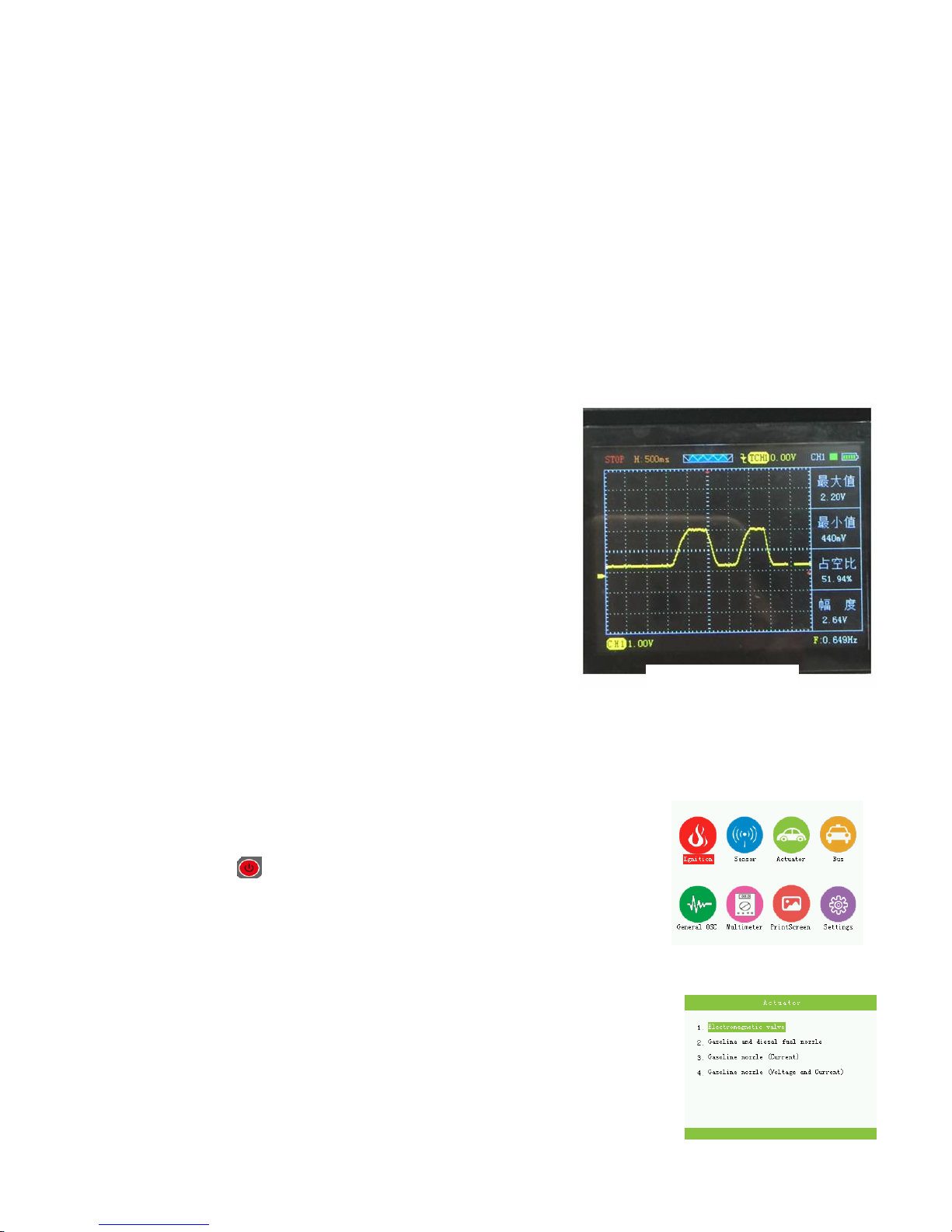

1)Electromagnetic valve

①After the oscilloscope installed batteries,long press red power

button“ ”, let it go until you hear the buzzer,at this time

oscilloscope enter the main menu interface, as picture-1

②After entering the main menu interface select “Actuator”, then

enter the sub-menu press the up and down keys to select "

Electromagnetic valve ",press “OK” button, after confirmation, entering oscilloscope

operation interface, as picture -2

③Connect the probe to CH1 and probe set to 1X,then connect

grounding clip to the signal ground or grounding.

④Since the “Electromagnetic valve” Function of oscilloscope has

default settings (Probe 1X,time base 25ms),simply connect the probe

to the corresponding signal can display waveform. As picture-12

Picture-1

Picture-2

Pic-11 Accelerator

20

⑤Press“CH1”,can view the values and configuration(configuration has default)

⑥Waveform display can be adjusted based on their own through the vertical volts /

division and trigger ways to meet your needs(Time base, vertical volts / division and

other specific operations, please refer to the operation of general oscilloscope)

2)Gasoline and diesel fuel nozzle

①Same as Electromagnetic valve step 1

②After entering the main menu interface select “Actuator” , then enter the

sub-menu press the up and down keys to select " Gasoline and diesel fuel nozzle ",

press “OK” button, after confirmation, entering oscilloscope operation interface

③Connect the probe to CH1 and probe set to 10X,then connect grounding clip to

the signal ground or grounding.

④Since the “Gasoline and diesel fuel nozzle” Function of oscilloscope has default

settings ( Probe 10X , time base 1ms ) ,simply connect the probe to the

corresponding signal can display waveform.

⑤Press“CH1”,can view the values and configuration(configuration has default)

⑥Waveform display can be adjusted based on their own through the vertical volts /

division and trigger ways to meet your needs(Time base, vertical volts / division

and other specific operations, please refer to the operation of general oscilloscope)

Note: there is a rectangular concave on waveform, the width of the rectangle is the

actual fuel injection pulse width, after the engine entering the closed-loop control,

fuel injection pulse width is generally 1.5ms-2.9ms. If bigger than this value, there

are clogging or excessive intake and other issues of nozzle.

3) Gasoline nozzle (Current)

①Same as Electromagnetic valve step 1

Pic-12 Electromagnetic valve

21

②After entering the main menu interface select “Actuator” , then enter the

sub-menu press the up and down keys to select " Gasoline nozzle (Current) ",

press “OK” button, after confirmation, before entering oscilloscope operation

interface, it will prompt "must comply with the current clamp using " Wait a few

seconds to enter the oscilloscope interface

③Connect current clamp to CH1,since the “Gasoline nozzle (Current)” Function of

oscilloscope has default settings (Probe 1X,time base 1ms),simply connect the

probe to the corresponding signal can display waveform.

④Press“CH1”,can view the values and configuration(configuration has default)

⑤Waveform display can be adjusted based on their own through the vertical volts /

division and trigger ways to meet your needs(Time base, vertical volts / division

and other specific operations, please refer to the operation of general oscilloscope)

4)Gasoline nozzle (Voltage and Current)

①Same as Electromagnetic valve step 1

②After entering the main menu interface select “Actuator”, then enter the

sub-menu press the up and down keys to select " Gasoline nozzle (Voltage and

Current) ",press “OK” button, after confirmation, before entering oscilloscope

operation interface, it will prompt " CH1:using probe,CH2:using current clamp"

Wait a few seconds to enter the oscilloscope interface

③Connect the probe to CH1 and probe set to 10X,then connect grounding clip to

the signal ground or grounding. Connect the current clamp to CH2

④Since the “Gasoline nozzle (Voltage and Current)” of oscilloscope has default

settings ( CH1:Probe 10X, time base 1ms; CH2: Probe 1X, time base

1ms),simply connect the probe to the corresponding signal can display waveform,

as picture 13

⑤Press“CH1” and “CH2”,can view the values and configuration(configuration has

default)

⑥Waveform display can be adjusted based on their own through the vertical volts

/ division and trigger ways to meet your needs(Time base, vertical volts / division

and other specific operations, please refer to the operation of general

oscilloscope)

Pic-13 Gasoline nozzle (Voltage and Current)

Voltage

Current

22

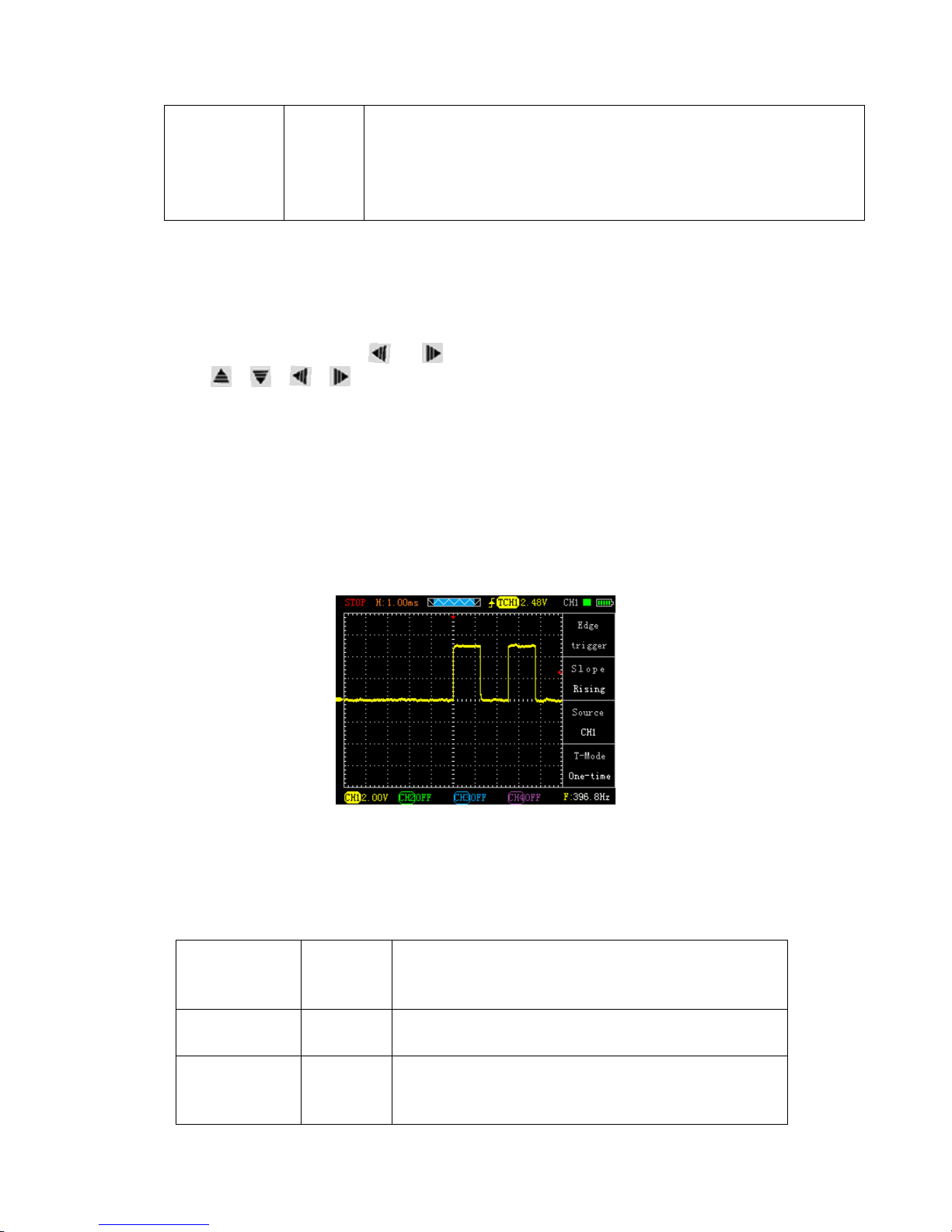

5. Bus

1)CAN-high、CAN-low

①After the oscilloscope installed batteries,long press red power

button“ ”, let it go until you hear the buzzer,at this time

oscilloscope enter the main menu interface,as picture-1

②After entering the main menu interface select “Bus”, then enter

the sub-menu press the up and down keys to select " CAN-high、

CAN-low ",press “OK” button, after confirmation,

entering oscilloscope operation interface, as picture -2

③Connect the two probes to CH1 and CH2, probe set to 1X, then connect

grounding chipotle signal ground or grounding

④Since the “CAN-high、CAN-low” function of oscilloscope has

default settings (CH1,CH2:Probe 1X,time base 25us),simply

connect the probe to the corresponding signal can display

waveform, as picture 14

⑤Press“CH1” and “CH2”,can view the values and configuration

(configuration has default)

⑥Waveform display can be adjusted based on their own through

the vertical volts / division and trigger ways to meet your needs

(Time base, vertical volts / division and other specific operations, please refer to the

operation of general oscilloscope)

Pic-14 CAN-high, CAN-low

Picture-1

Picture-2

CAN-high

CAN-low

23

2) LIN-bus

①Same as CAN-high、CAN-low step 1

②After entering the main menu interface select “Bus”, then enter the sub-menu press

the up and down keys to select " LIN-bus ",press “OK” button, after confirmation,

entering oscilloscope operation interface

③Connect the probe to CH1 and probe set to 1X,then connect grounding clip to the

signal ground or grounding

④Since the “LIN-bus” Function of oscilloscope has default settings (CH1:Probe 1X,

time base 500us),simply connect the probe to the corresponding signal can display

waveform.

⑤Press“CH1” and “CH2”,can view the values and configuration(configuration has

default)

⑥Waveform display can be adjusted based on their own through the vertical volts /

division and trigger ways to meet your needs(Time base, vertical volts / division and

other specific operations, please refer to the operation of general oscilloscope)

3) FlexRay

①Same as CAN-high、CAN-low step 1

②After entering the main menu interface select “Bus”, then enter the sub-menu press

the up and down keys to select " FlexRay ",press “OK” button, after confirmation,

entering oscilloscope operation interface

③Connect the two probes to CH1 and CH2, probe set to 1X, then connect

grounding clip to the signal ground or grounding

④Since the “FlexRay” Function of oscilloscope has default settings (CH1,CH2:Probe

1X,time base 10us),simply connect the probe to the corresponding signal can display

waveform.

⑤Press“CH1” and “CH2”,can view the values and configuration(configuration has

default)

⑥Waveform display can be adjusted based on their own through the vertical volts /

division and trigger ways to meet your needs(Time base, vertical volts / division and

other specific operations, please refer to the operation of general oscilloscope

2.2 Universal Oscilloscope this section features are described

Below:

▲ Menus and control systems

▲ Connector

▲ automatically set

▲ The default setting

▲ Vertical System

▲ Horizontal System

▲ Trigger system

▲ Math system

▲ System Settings

▲ Storage System

24

1. Menus and Control buttons

As shown in the following figure:

ADO102 control button ADO104 control button ADO General Button

All models

CH1、CH2

CH3、CH4

Channel 1, Channel 2 , Channel 3, Channel 4 settings menu

Press the "Return" to return to the previous menu

Press the "Multimeter" mode to enter the multimeter

On / Off

AUTO

Automatically sets the oscilloscope controls, press this key to achieve 20HZ-10MHZ a key

trigger function, Channel 1-Channel 4 can be used

TRIG

Show "Trigger" control menu

HORI

Show "Horizontal" control menu

Continuously acquires waveforms or stops the acquisition. Note: In the stop mode, the

waveform vertical scale and horizontal base can be adjusted within a certain range,

equivalent to extend the signal on the horizontal or vertical direction.

MENU

Function menu interface, the first press of waveform storage interface, the second press to

display settings interface, press three times for the system setup interface

To enlarge, shrink waveform, or move the displayed cursor in oscilloscope mode. Used to

adjust the range, in the multimeter functions.

Can be used to move the waveform display or move the cursor in oscilloscope mode;

select the type of test used in the multimeter functions.

25

OK

Function Confirm

F1、F2、F3、

F4

Corresponding to the selected setting in the Options menu 1,2,3,4

2. Connector

ADO102 ADO104

Figure 2-1 Figure 2-1

Figure 2-1 CH1-CH2: Input connectors for waveform display, the left is CH1,

the right is CH2, "COM" and "VΩ" is used to connect the black and red pen.

Figure 2-2 CH1-CH4: used to display the input waveform connection. "COM"

and "VΩ" is used to connect the black and red pen.

3. Automatically set

ADO has an automatic setting function. According to the input signal,

automatically adjusting the voltage stall, time base, and triggering the best way

to form display.

"AUTO" for automatically setting.

● If there is more than one channel signal, the channel with the lowest

frequency signal as the trigger source.

● Found no signal, connect the channel 1 to a signal, press "AUTO" button. As

shown in figure 2-3:

Figure 2-3

VΩ

COM

CH4 CH3 CH2 CH1

VΩ

COM

CH2 CH1

26

4. Default settings

The oscilloscope is set at the factory for routine operations, which is the default

setting. There oscilloscope main menu "System Settings" in the "factory

restore mode" operation by the arrow keys to select "Factory" and press the

"OK" button to confirm, the instrument off to save and restore the factory

settings, the instrument can be used after restart.

5. Vertical Systems

Channel and its settings

Operation menu of the channel, indicating Table 2-1 below: Table 2-1

Coupling

AC

DC

Blocking the DC component of the input signal.

The ac and dc component of the signal.

Probes

1X

10X

100X

According to the probe attenuation factor to select one of the

values in order to maintain the correct reading of the vertical

deflection factor. There are three types: 1X, 10X, 100X

Display

Open

Close

Open display waveforms

Close display waveforms

Frequenc

y

/

Automatically displays the current input signal frequency

peak-to-

peak value

/

Automatically displays the current waveform peak-to-

peak value.

Duty Cycle

/

automatically displays the current input signal duty

Cycle

/

automatically displays the current input signal cycle

1). Set the channel coupling

To signal applied to the oscilloscope channel, for example, the measured signal is a

square wave signal containing AC component.

●Main menu, select "Universal oscilloscope" press "OK" button to enter the oscilloscope

screen. Press "CH1" → "Coupling DC", press “F3”set to DC coupling. DC and AC

components of the input signal to pass through.

As Figure 2-4

● Press "CH1" → "Coupling AC", press “F3” set to AC coupling. DC component of the

input signal is blocked. As Figure 2-5

● Press "CH1" → "Inverse" and press the SELECT function key "F4" to anti opposite way.

Inverting the signal display. Figure 2-6

Figure 2-4 Figure 2-5 Figure 2-6

2).Probe scale setting

27

To cope with the attenuation factor of the probe set, User need adjust the probe

attenuation scale factor in channel operation menu. If the probe attenuation coefficient

ratio is 10:1, Oscilloscope input channel ratio should be set to 10X, and so on. To avoid

the display of information and measurement data errors occur. Take the CH1 for example:

● Press "CH1" → "F2" to set the probe ratio for 10X.

3).Vertical volts/division adjustment setting

When adjusting the vertical volts/div, the range is 100mV/div-50V/div (probe 10X),

Stepping way to 1-2.5-5, or 10mV/div-5V/div (probe 1X), 1V/div-500V/div (probe 100X).

Take the CH1 for example:

● If you set the vertical direction 2.00V/div,press"CH1"→ " "or " " to adjust the

vertical volts / division, press " " or " "to move up and down the entire waveform. As

Figure 2-7

● If you set the vertical direction 1.00V/div, the steps in the above example. As Figure 2-8

Figure 2-7 Figure 2-8

6. Horizontal Systems

Use the control buttons to change the level of the horizontal scale (time base), trigger

horizontal position (trigger position) in memory. Changing the horizontal scale causes the

waveform relative to the screen center expansion or contraction, Change the horizontal

position relative to the change point of the waveform trigger position.

Table 2-2 Main Menu of horizontal time base

Master

time

base

Horizontal main time base setting is used to display the waveform

Master

time

base

cursor

state

Display

Set cursor display or not display

Source

Select cursor measurement signal source (CH1-CH4)

Type

There are two types of time and voltage

Cursor

display

Cursor1

Cursor 2

Time base offset relative to the main vector

28

● Horizontal scale: Adjust the main group; press the "HORI" button, Press" "or" " to

change the scale of the level. To zoom in or out waveform. If you want to stop waveform

acquisition, press the "RUN" key can be realized. As Figure 2-9, Figure 2-10

Figure 2-9 Figure 2-10

● Horizontal Position: adjust the horizontal position of the waveform (trigger position

relative to the center of the screen).Press the "HORI" button, Through " " or " "to

move the waveform left or right. The key resolution varies according to time base. Press

"AUTO" key can make the horizontal position return to zero.

●Cursor measurement: adjust the measurement, press the "time base" keys, press

"F2-F4" to select the corresponding function (display, source, type), and then press the

"time base" on the cursor key to enter the display interface, and then " " " " or " ",

" " key to adjust the cursor position.

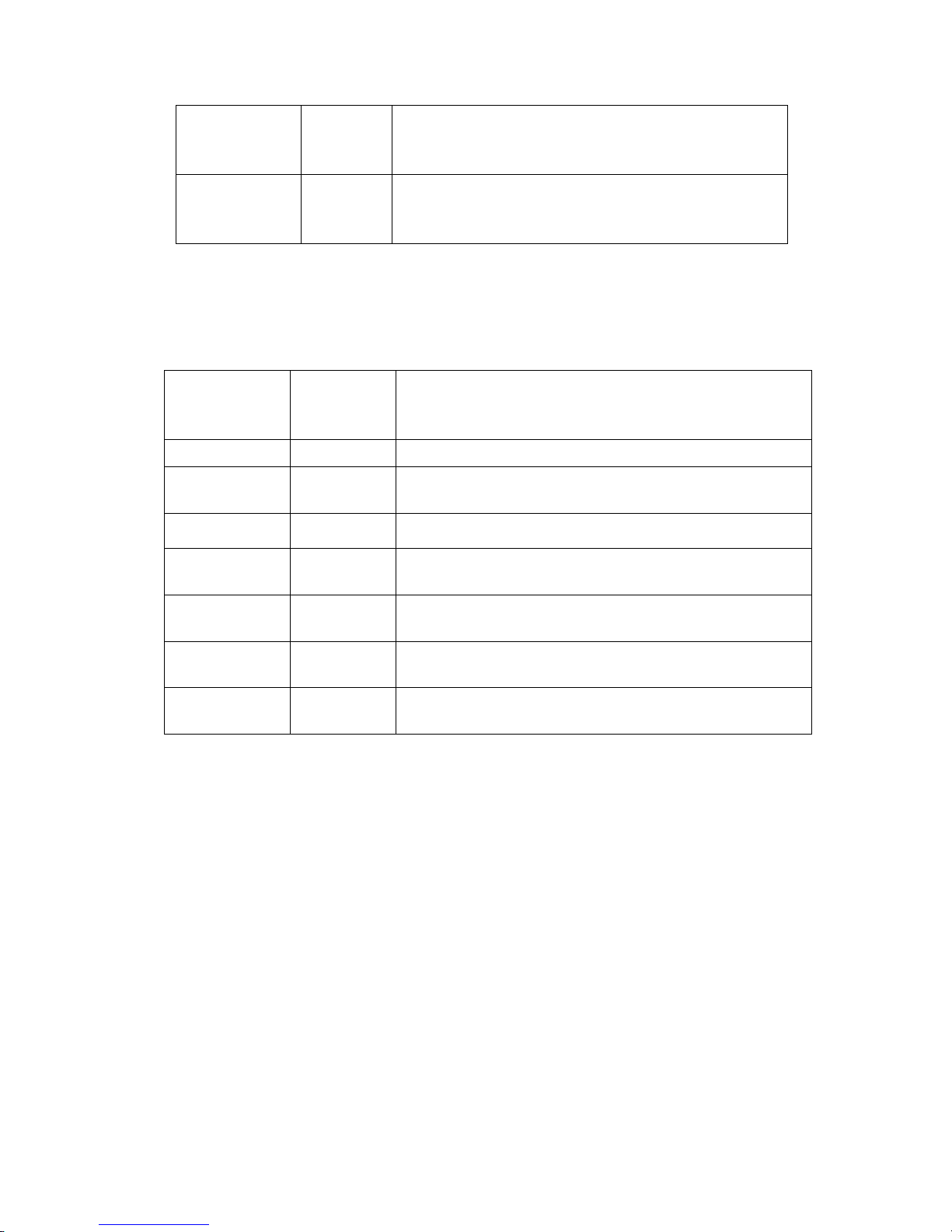

7. Trigger system

The trigger determines when the oscilloscope starts to acquire data and display

waveforms. Once the trigger is set up correctly, it can convert the unstable display into

meaningful waveforms. Trigger Control menu button" TRIG".

● Trigger Control

Trigger: The oscilloscope trigger mode is edge triggered.

● Edge Trigger: When the edge of the trigger signal reaches a given level,

Trigger occurs. Edge trigger is triggered on the input signal edge trigger threshold. When

"Edge”, that is input at the rising edge, falling edge triggered.

Table 2-3 Edge trigger function menu

Source

oscillosc

ope

Set CH1 as trigger source. (CH2-CH4 empathy)

Slope

UP

DOWN

Select the trigger signal to trigger on the rising edge

Select the trigger signal to trigger on the falling edge

Incremental

Cursor 2 - Cursor 1

29

Trigger mode

Auto

Normal

Single

Set in the absence of detectable also can collect waveform trigger

conditions Set only a triggering

condition is satisfied only waveform

Set capture a waveform when a trigger is detected, then stop

Instructions:

Set the source:

1).Main menu, select "Universal oscilloscope" press "OK" button to enter the oscilloscope

screen. Press the "TRIG" button to display the trigger menu, according to the signal input,

press the "F3" key to select CH1-CH4.

2).Press "CH1", then press" "or" "adjusts channel 1 mark. Press the "TRIG", then

press" "" "or" "" "adjust the trigger flag arrow, According trigger flag each cell

voltage value represents the relative position and the current channel a flag vertically to

set the trigger level size.

Set slope:

3).Press the "F2" key to select slope "up" or "down."

Set trigger mode:

4).Press the "F4" key to select "Auto", "normal" or "single."

Auto: Set in the absence of detectable also can collect waveform trigger conditions

Normal: Set only a triggering condition is satisfied only waveform Single: Set capture a

waveform when a trigger is detected, then stop As Figure 2-11

Figure 2-11

8. Math System

Math function is to display CH1, CH2, CH3, CH4 two two-channel waveform additions,

subtraction functions

Table 2-4 Math Functions

Menu

Settings

Comments

Setting

Description

Arithmetic

Functions

/

Source A

Settings

Source

CH1-CH4

Set CH1, CH2, CH3, CH4 as source B

30

Source B

Settings

Source

CH1-CH4

Set CH1, CH2, CH3, CH4 as source B

Operation

A+B、A-B

or NULL

Be A + B or A-B operation according to the source A,

Source B is set above

▲Press the "operation" button then press the "F4" select operation mode and turn on the

display.

9. System Setup

Table 2-5 System Functions menu

Menu

Settings

Comments

Setting

Description

Sound

Sound

Set sound to "ON" or "OFF"

Display

brightness

Brightness

Can be set from 1-5

Language

/

Chinese or English

Color

System

theme

four styles to choose "default", "style one"、" style

two", " style three "

Location

History

On / Off

Minutes of the last open position

Version

Information

/

Check the software version of the oscilloscope

Restore

Factory

/

Reset

System Settings

1) Sound settings: the main menu, select "System Settings" button, press the "OK" button

to enter the settings interface, via the arrow keys to select "Sound" press "OK" button,

enter the change, left and right keys to select On or Off and then press "OK "button to

confirm.

2) brightness setting: the main menu, select "System Settings" button, press the "OK"

button to enter the settings interface, via the arrow keys to select "Brightness" press "OK"

button to enter modify, add brightness left minus right then press "OK" key to confirm; the

machine can be set brightness 1-5.

3) language setting: the main menu, select "System Settings" button, press the "OK"

button to enter the settings interface, via the arrow keys to select "Language" press "OK"

button, enter the change, left and right keys to select the language and then press the

"OK" button confirm; the unit provided in both Chinese and English display interface.

4) Color settings: language setting: the main menu, select "System Settings" button, press

the "OK" button to enter the settings interface, via the arrow keys to select "System risers"

31

press "OK" button, enter the change, up and down keys to select a topic style and then

press "OK" button to confirm, the unit provides four display style theme.

5) to restore the factory: the main menu, select "System Settings" button, press the "OK"

button to enter the settings interface, via the arrow keys to select "Factory" press "OK"

button, enter the change, left and right keys to select OK or Cancel, then press "OK"

button to confirm the WTR.

10. The storage system

ADO Series can store two reference waveforms, 20 groups of shots (depending on

memory size oscilloscope decision) to the oscilloscope internal memory.

ADO Series provides USB interface, you can save waveform memory shots to the U disk,

the common image BMP image file can be opened by computer software. In addition, two

sets of waveform parameters are stored and can be produced by "reference waveform"

were transferred out, displayed on the screen.

To save a reference waveform:

1) Main menu, select "Universal oscilloscope" (Automotive Oscilloscope select the

corresponding module), press the "OK" key to enter the user interface

2) Press the "time base", "trigger" or "operator" to any of these options, press "F1" to enter

the reference waveform

3) press "F2" to select the source, then press the "F2" Reference Waveform (each source

can save two set of reference waveform Ref1, Ref2), press the "F4" key to save the

reference waveform and displayed by pressing the "F2 "button selected as the reference"

NULL "to close the reference waveform

Store pictures steps:

Any Screenshots:

1) Oscilloscope and automotive modules interface, long press "F2" operating status

(battery indicator on the left side) will be blinking green to being shot, wait a few seconds,

the name of the successful bomb box prompts screenshots and screenshots will appear.

2) Multimeter screenshot will be prompted "is being shot”, will appear successful bomb

box prompts screenshot success.

3) Other interfaces will be prompted being shot, after a successful theme screenshot

bomb box prompt success.

Note: The screenshot function can save 20 or so maps, depending on memory size of the

decision, if prompted screenshot fails, re-theme look, or not, then you see the next

memory to delete a few pictures.

View storage oscilloscope image method:

1) First off the oscilloscope, and then use the data cable to connect the oscilloscope and

the computer, and then press the "F3" key and the "on / off" button until the screen to let

go when the light; this time, the computer will prompt U disk insert, open U disk to see the

pictures taken. After the operation, you must first click Exit U disk mode on the computer,

then disconnect the cable, press the power button to reboot to use it again.

2) to enter the main menu, select the screenshot function, go to theme preview feature to

view screenshots. After the arrow keys can be selected theme, select press "OK" button to

view, press any key to return to the list of shots, "F3" key means to delete the currently

selected theme, "F4" button to remove all screenshots.

32

Waring: Please don’t use any measure function when the USB cable is

connecting with other devices, or this Instrument Will Be Damaged.

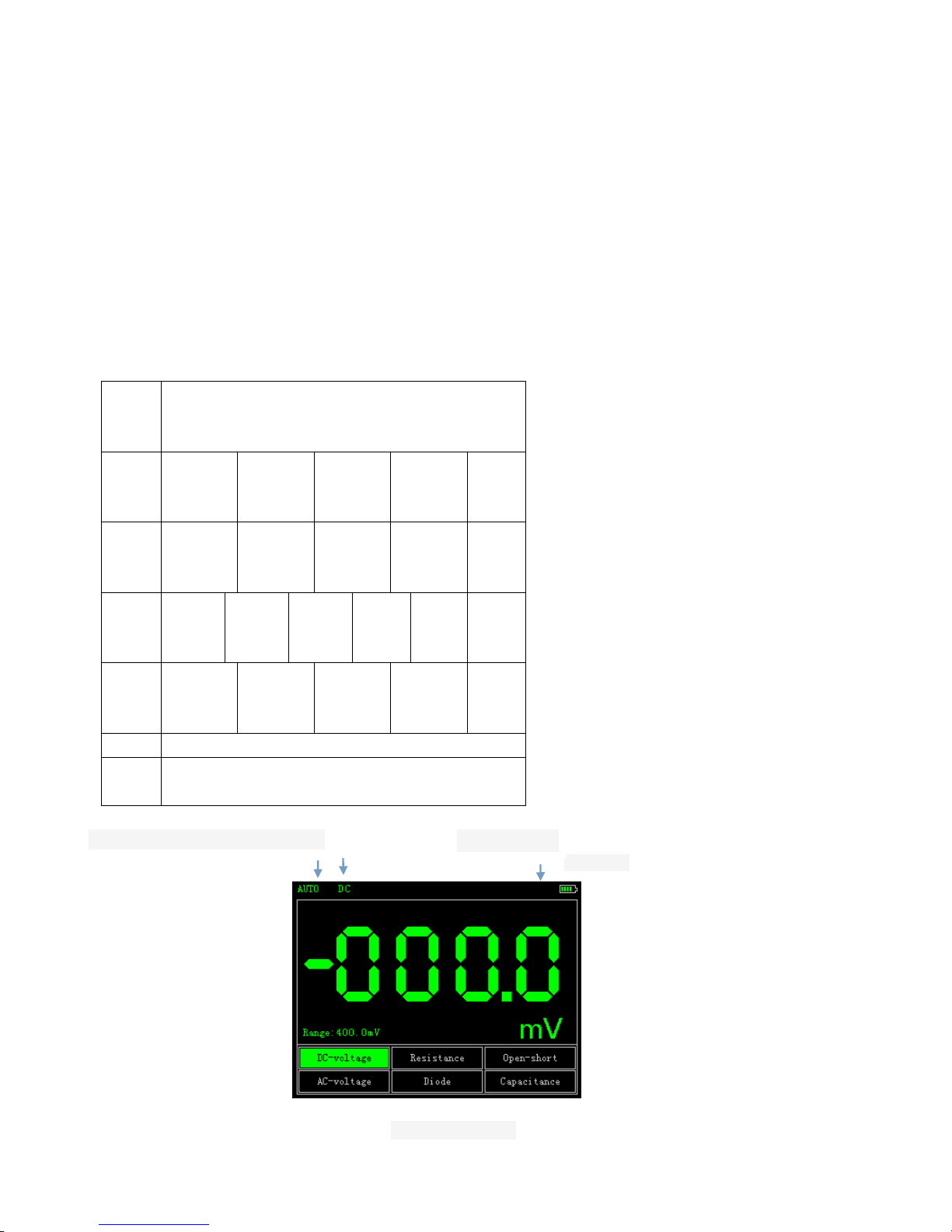

2.3 Multimeter function and operation

This device can be used as a Multimeter or OSC; can be used for measuring DC and AC

voltage, resistance, capacitance, diode, buzzer-off. This device uses TFT full color display,

and has a range display, polarity display, overload display, battery power display.

Meas

ure

Type

Range

DC

Voltag

e

400.0m

V

4.000V

40.00V

400.0V

1000

V

AC

Voltag

e

400.0m

V

4.000V

40.00V

400.0V

750V

Resist

ance

400.0

Ω

4.000

KΩ

40.00

KΩ

400.0

KΩ

4.000

MΩ

40.00

MΩ

Capa

citanc

e

51.2nF

512.0nF

5.120uF

51.20uF

100u

F

Diode

0V-1.5V

Buzze

r-off

Below 60Ω ,buzzer alarm

DC or AC

Electricity

Running state

Display manually or automatically

Meter Interface

33

Measure Method:

Table2-7 Multimeter Operation Key Function

Key

Description

Multimeter

Press this key to enter Multimeter Mode.

Press “ ” or “ ” to select Mesure Type

Press “ ” or “ ” to tune the Range

Multimeter’s RUN/HOLD key.

Note 1: Multimeter’s default range is "Auto" position, for manually setting the

range, first predicted your Measurements..

Note 2: Display screen show flashing “ ”means Multimeter is

running;” MANU” means manually set the range.

⒈ DC and AC Voltage measuring

① The Black Pen connect to the COM interface on the top of the device(the

black interface),and the Red Pen connect to VΩ interface(the red

interface)

② Press “ON/OFF” key until the system is started, then press “Multimeter”

key to switch to Multimeter Function.

③ Press “ ” or “ ” to select “DC voltage” or “AC Voltage” measuring.”DC

Voltage” has a Shortcut,”F1”.

④ Connect the test pen to the measured voltage, the device will read the

value and show on the screen (it can also read negative value.).AC Voltage

has no polarity. This device’s default Range is “Auto”, you can press “ ” or

“ ” to change the Range.

⒉ Resistance measuring

① Press “ ” or “ ” to select Resistance mesuare.it has a shortcut,”F2”.

② Put the pen on the two side of the resistor, device can read it’s value.

Maybe you should set the Range manually.

⒊ Capacitance measuring

① Press “ ” or “ ” to select Capacitance mesuare.

② put the pen on the two side of the capacitance, device can read it’s value.

Note: Capacitance measuring can’t set Range.

⒋ Diode and Buzzer-off measuring

① Press “ ” or “ ” key to select “Diode” or “Buzzer-off” measuring. Buzzer-off

measuring has a shortcut ,”F3”.

② Put the pen on the two side of the Diode or the line, device can read it’s value.(The

value when measuring diode, it’s diode Conduction voltage drop)

③ When mesuareing resistance is below 60Ω, buzzer alams.

Attention:

a. The device has forward and reverse voltae, when the diode connected reversed, the

value is negative.

34

b.Diode and Buzzer-off mearusing only have “Auto” Range.

c.When measuring,must keep “Sound” On, or the Buzzer can’t alarm.

Ways to setup:

1、press the "back" button, until the main menu through the arrow keys to select

the "Settings", click "OK" button to enter the setting

2、using the arrow keys select "sound", click "OK" button appears bomb box,

through the left and right button to select the open and click "OK" button to confirm

5、 Data Hold Function

"Run / Stop" button is pressed on the instrument, the data will remain being displayed on

the display even if the input signal changes, or eliminate, the value is not changed

Waring 1: When using Multimeter, the OSC dector must not connect to

GROUND.

Waring 2: Please select the appropriate Range before measure object.

Waring 3: When the USB cable is connect to other devices, must not

measur, or the device will be damaged.

Chapter3 Application Examples

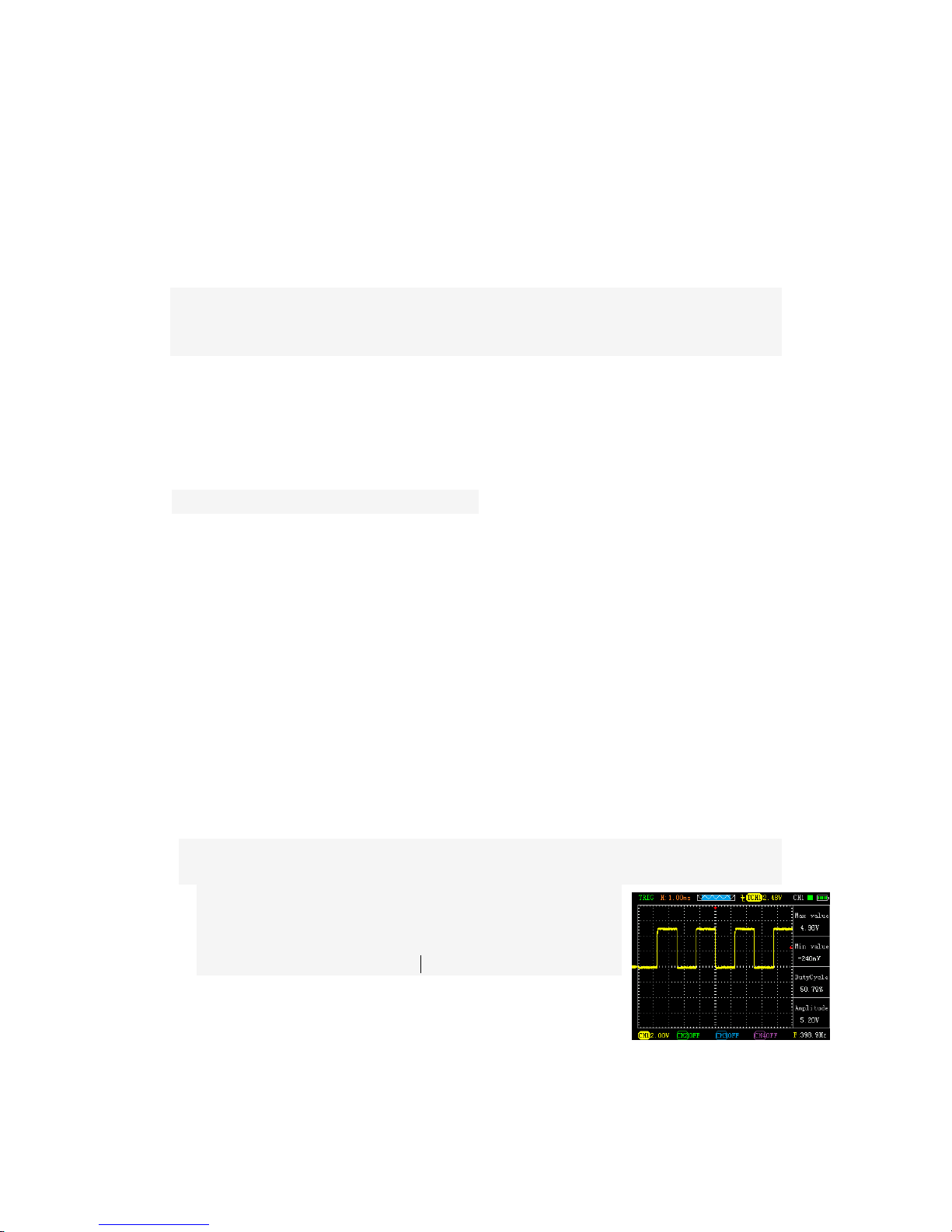

3.1 Singal measure

Measure an unknown signalman show it’s value immediately.

● If you want show the value immediately ,please do as fllows:

① Enter the "Universal oscilloscope”. Set the probe menu attenuation coefficient as 10X,

and switch the probe to 10X.

② Connect the CH1 probe to the test point.

③ Press “AUTO” key.

The OSC will automatically set the optimum waveform display. Then you can adjust the

Vertical or Horizontal scale, until the waveform meets your requirements.

● Automatic measure signal’s voltage and time parameter.

The OSC can automatic measure most signals. To measure the frequency and

peak-peak,follw the steps:

① Enter the "Universal oscilloscope”. Press “AUTO” key, show current waveforms.

②Press "CH1" button to turn pages can be observed maximum, minimum, duty cycle,

amplitude. (CH2-CH4 similar operations)

In this case, the signal parameter measurements are shown in

F1-F4 corresponding to the location, you can display the

signal parameter values by pressing the corresponding F1-F4

function key to select. Figure 3-1

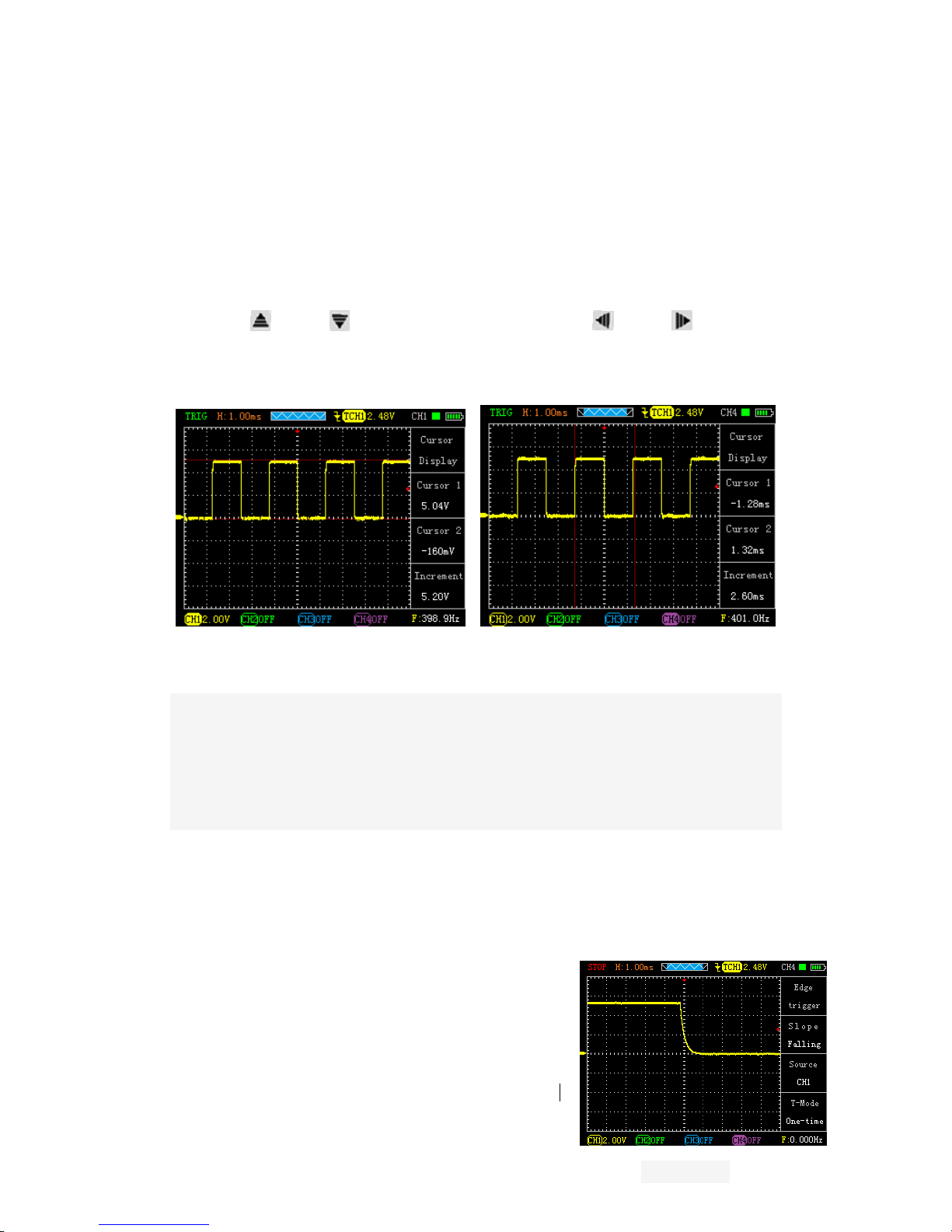

3.2 Cursor measure

This OSC can automatic measure a variety of waveform

parameters. All measurement parameters can be measured

by the cursor.Use the cursor, can measure the waveform parameters quickly. Figure 3-1

Measuring the peak voltage of square wave signal.

35

Take the CH1 for example. if you want to measure the peak voltage of a square wave

signal, do as follows:

① Press “HORI” key to enter the main base cursor

state setting.

②Press “F2” key to set the cursor “ON”; Press “F2” key to set the source as “CH1-CH4”;

press “F4” key to set the type of the cursor “Voltage”.

③Press “HORI” key again to see location of cursor 1 and cursor 2(relative to the

intermediate zero volate reference level) and increment (V_cursor2-V_cursor1)

④ Press “ ” and “ ” to tune the position of cursor 2,“ ” and “ ” to tune the

position of cursor 1;and there position and increment will updating on the screen in

Real-time. See Pic 3-2 and Pic 3-3.

Figure 3-2 Figure3-3

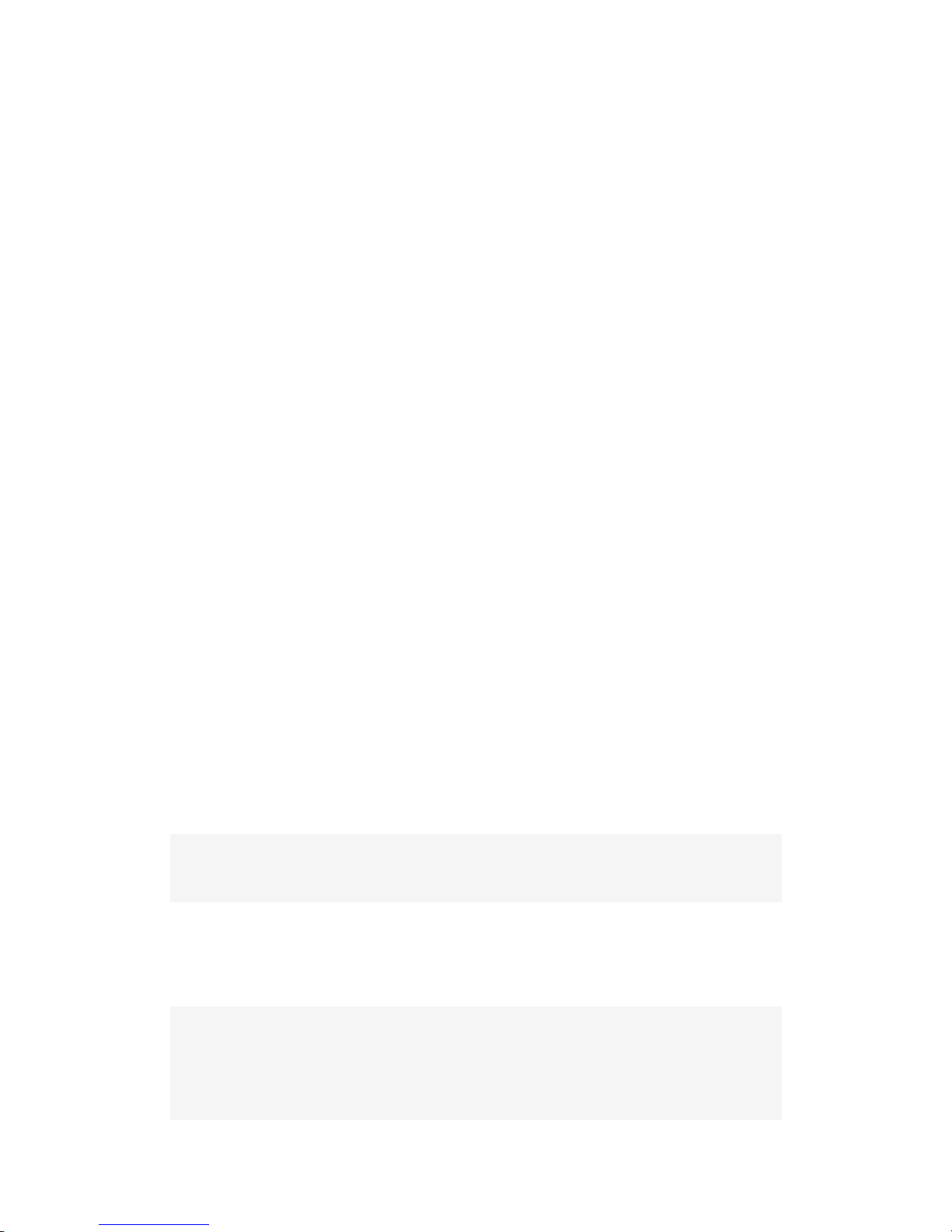

3.3 Capture the Single Signal

Digital storage oscilloscope advantages and features that could easily capture the

periodic signal pulses, glitches, etc. To capture a single signal, this signal first needs to

have some prior knowledge, in order to set the trigger level along. If the case of a signal of

uncertainty, you can automatically trigger mode or normal first observation to determine

the trigger level along.

Steps are as follows:

1、As aforementioned, set the attenuation coefficient of probe and CH1 channel to 10X.

2、Trigger settings:

① Press "CH1” key → press "F3" key to set the coupling to "DC."

② Press the "TRIG" button to display the edge trigger menu settings.

In this menu, press “F1” key to set the edge type “slope down”,press “F2” key to set