Page 1

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

1

USR-IO424T-EWR User Manual

File Version: V1.0.3.01

Page 2

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

2

Contents

USR-IO424T-EWR User Manual ......................................................................................................................... 1

Features .................................................................................................................................................................... 4

1. Get Start ................................................................................................................................................................ 5

1.1. Product introduction ............................................................................................................................... 5

1.2. Basic parameters .................................................................................................................................... 5

1.3. Hardware .................................................................................................................................................. 6

1.3.1. Interface ........................................................................................................................................ 6

1.3.2. LED .................................................................................................................................................. 6

1.3.3. Dimension ..................................................................................................................................... 7

1.4. Test............................................................................................................................................................. 7

1.4.1. Control by serial ........................................................................................................................... 8

1.4.2. Web Server .................................................................................................................................. 10

1.4.3. Control by USR Cloud ................................................................................................................. 10

2. Product function ................................................................................................................................................ 11

2.1. DI input .................................................................................................................................................... 11

2.1.1. Electrical level detection ............................................................................................................. 11

2.1.2. Buttons detection ........................................................................................................................ 11

2.1.3. Pulse counting ............................................................................................................................ 12

2.2. DO output ................................................................................................................................................ 12

2.3. AI input ................................................................................................................................................... 12

2.4. Temperature detection ......................................................................................................................... 13

2.5. Analog self-calibration ......................................................................................................................... 13

2.6. Work mode ............................................................................................................................................. 13

2.6.1. Master mode................................................................................................................................ 13

2.6.2. Slave mode ................................................................................................................................... 15

2.7. Upgrade firmware ................................................................................................................................. 16

2.8. Network ................................................................................................................................................... 16

2.8.1. Ethernet interface ..................................................................................................................... 16

2.8.2. WiFi .............................................................................................................................................. 17

2.9. Serial port ............................................................................................................................................... 17

2.9.1. Basic parameters ....................................................................................................................... 17

2.9.2. Configuration method ............................................................................................................... 17

2.10. Features ................................................................................................................................................ 18

2.10.1. Relay output status hold .......................................................................................................... 18

2.10.2. Conditional control .................................................................................................................. 18

2.10.3. Connect to remote server....................................................................................................... 20

2.10.4. Reset to default by hardware................................................................................................. 21

3. Modbus ............................................................................................................................................................... 22

3.1. Modbus frame ........................................................................................................................................ 22

3.2. Register distribution ............................................................................................................................ 22

4. Contact Us ........................................................................................................................................................... 25

5. Disclaimer .......................................................................................................................................................... 26

Page 3

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

3

6. Update History .................................................................................................................................................. 26

Page 4

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

4

Features

⚫ Support 4-way Relay output.

⚫ Support 4-way input, default is dry contact.

⚫ Support 2-way analog input, default are voltage detection.

⚫ Support 1-way PT100 temperature input.

⚫ Support 8 conditional control command.

⚫ Support Web Server to configure IO424T-EWR.

⚫ Support various function code: 0x01, 0x02, 0x03, 0x04, 0x05, 0x06, 0x0F, 0x10.

⚫ Support socket to connect to remote server and TCP Client.

⚫ Support two work modes: Master mode and Slave mode. Master mode supports connecting to multiple

Modbus RTU devices by RS485 cascading connection.

⚫ Adopt Modbus RTU protocol data processing. Support Modbus TCP/RTU protocol adaptation.

⚫ Support WAN/LAN interface.

⚫ Support connecting to USR Cloud.

⚫ Support FTP remote upgrade.

⚫ Support upgrading by RS485.

⚫ Support hardware watchdog.

⚫ Support various LED to indicate work status.

⚫ Support power supply over-current, over-voltage, anti-reverse connection protection.

Page 5

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

5

1. Get Start

If user has any question, please submit it back to customer center: h.usriot.com.

1.1. Product introduction

USR-IO424T-EWR is network IO product which supports 4-way input/output, 2-way analog quantity detection,

1-way temperature detection and Modbus RTU/TCP protocol. Take ‘Remote control’ as core function and have

high usability. User can easily and quickly integrate USR-IO424T-EWR into own system to realize remote control

which based on Ethernet and local control which based on LAN(WiFi) and RS485.

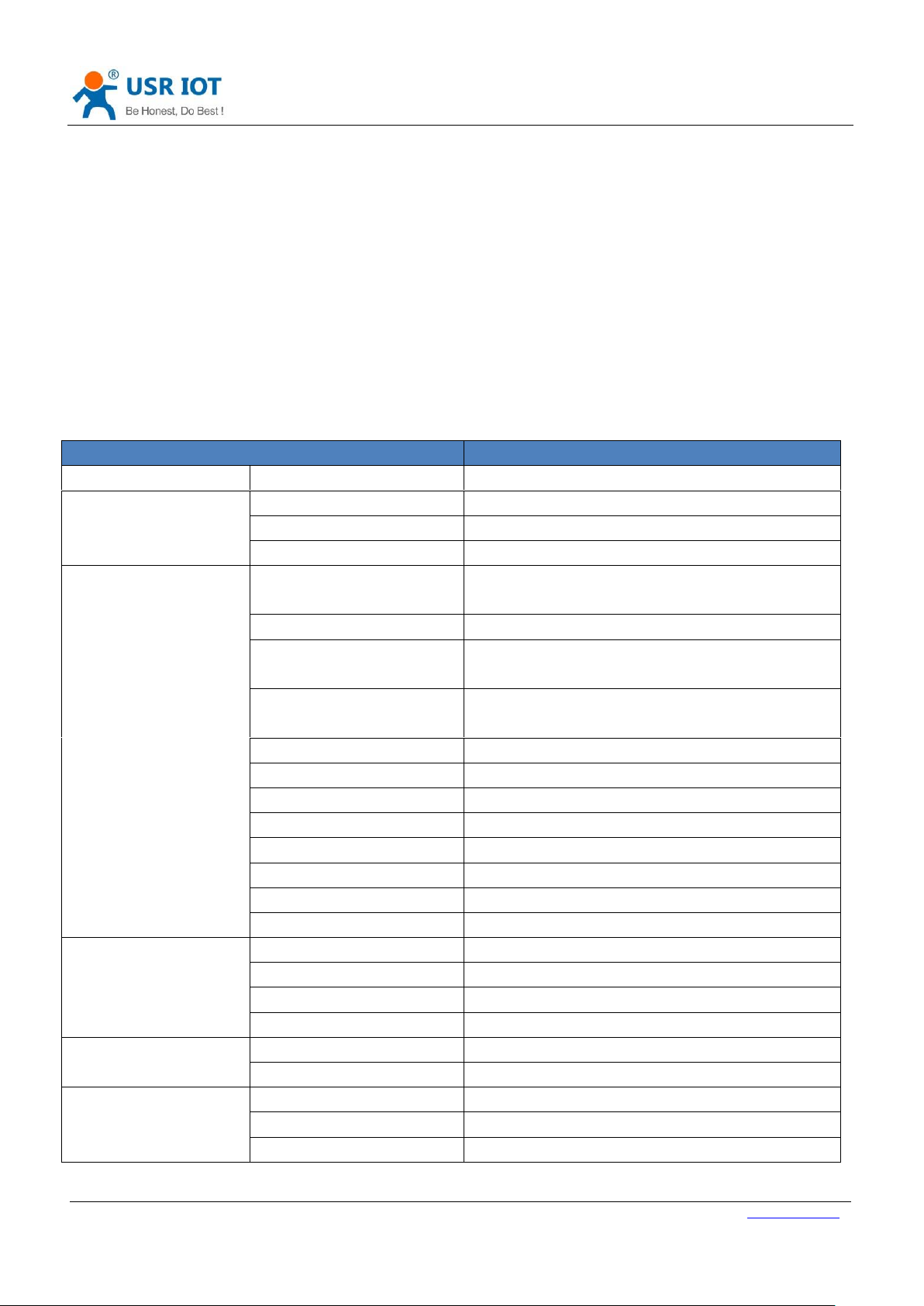

1.2. Basic parameters

Parameter

Value

Ethernet interface

Wired WAN/LAN interface

10/100M WAN/LAN *1

WiFi

Standard

Support 802.11b/g/n

Antenna

2.4G WiFi antenna

Range

100 meters in open area

Hardware parameters

Data interface

Serial port: Support RS485.

Baud rate: 300bps~230400bps

Working voltage

DC: 12V~36V

DI input

Dry contact input, just needing to short-circuit DI

and COM

DO output

AC 220V 5A

DC 28V 5A

Voltage acquisition

Range: 0V ~ 10V

Current acquisition

Range: 0mA ~ 20mA

Temperature detection

Range: -100℃ ~ 200 ℃

Working temperature

-20℃~+70℃

Storage temperature

-40℃~+85℃

Working humidity

5%~95%

Storage humidity

1%~95%

Dimension

123*114*28mm

Software parameters

Work mode

Master mode, slave mode

Configuration command

Modbus RTU

Network protocol

Modbus TCP, Modbus RTU

Application software

Support configuration software

Software function

DNS

Support

Data transmission mode

Support TCP Client

EMC level

ESD

IEC61000-4-2, Level 4

Surge

IEC61000-4-5, Level 3

Group pulse

IEC61000-4-4, Level 3

Figure 1 Basic parameters

Page 6

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

6

1.3. Hardware

1.3.1. Interface

Figure 2 Product interface diagram

➢ Antenna: WiFi antenna.

➢ Ethernet interface: Can be configured to LAN interface or WAN interface.

➢ RS485: RS485 interface.

➢ DO: DO1~DO4 are 4-way output and DO-COM is common interface.

➢ DI: Dry contact input and DI-COM is common interface.

➢ AI1, AI2: Analog input interface and reference ground connects to power supply negative pole. Default is

voltage acquisition mode and please contact to sales personnel if user needs current acquisition mode.

➢ PT100: PT100 three-wire system interface.

➢ Power supply: DC 12~36V power supply. Low power supply will cause IO424T-EWR can’t start.

1.3.2. LED

LED

Function

Status

POWER

Indicate power status

Light after powering module

WORK

Indicate system running status

Blink every 0.5 second after product system running;

Blink quickly during upgrading firmware process.

NET

Indicate network connection status

Light after connecting to remote server

WAN/LAN

Indicate WAN/LAN interface status

Light after connecting to network. Blink if has data

interaction.

Figure 3 LED

Page 7

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

7

1.3.3. Dimension

Figure 4 Dimension diagram

1.4. Test

➢ Connect PC to USR-IO424T-EWR by USB -> RS485 cable

➢ Connect IO424T-EWR’s Ethernet interface to make device connect to internet

➢ Connect antenna to IO424T-EWR and power the IO424T-EWR

➢ After powering on, please wait about 15 seconds and use PC or mobile to search IO424T-EWR’s WiFi

network(Default SSID is USR-IO424T+last four bytes of MAC address and password is www.usr.cn). Then

user’s PC or mobile can access internet.

Note: If user uses USR-IO424T-EWR firstly and can’t access internet with correct connection, it maybe the

following reason: LAN interface network segment is same as USR-IO424T-EWR’s LAN interface network segment.

The solution is: Enter USR-IO424T-EWR’s Web Server(Default IP address is 192.168.10.1) and modify LAN

interface IP address to other network segment, then restart device.

Page 8

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

8

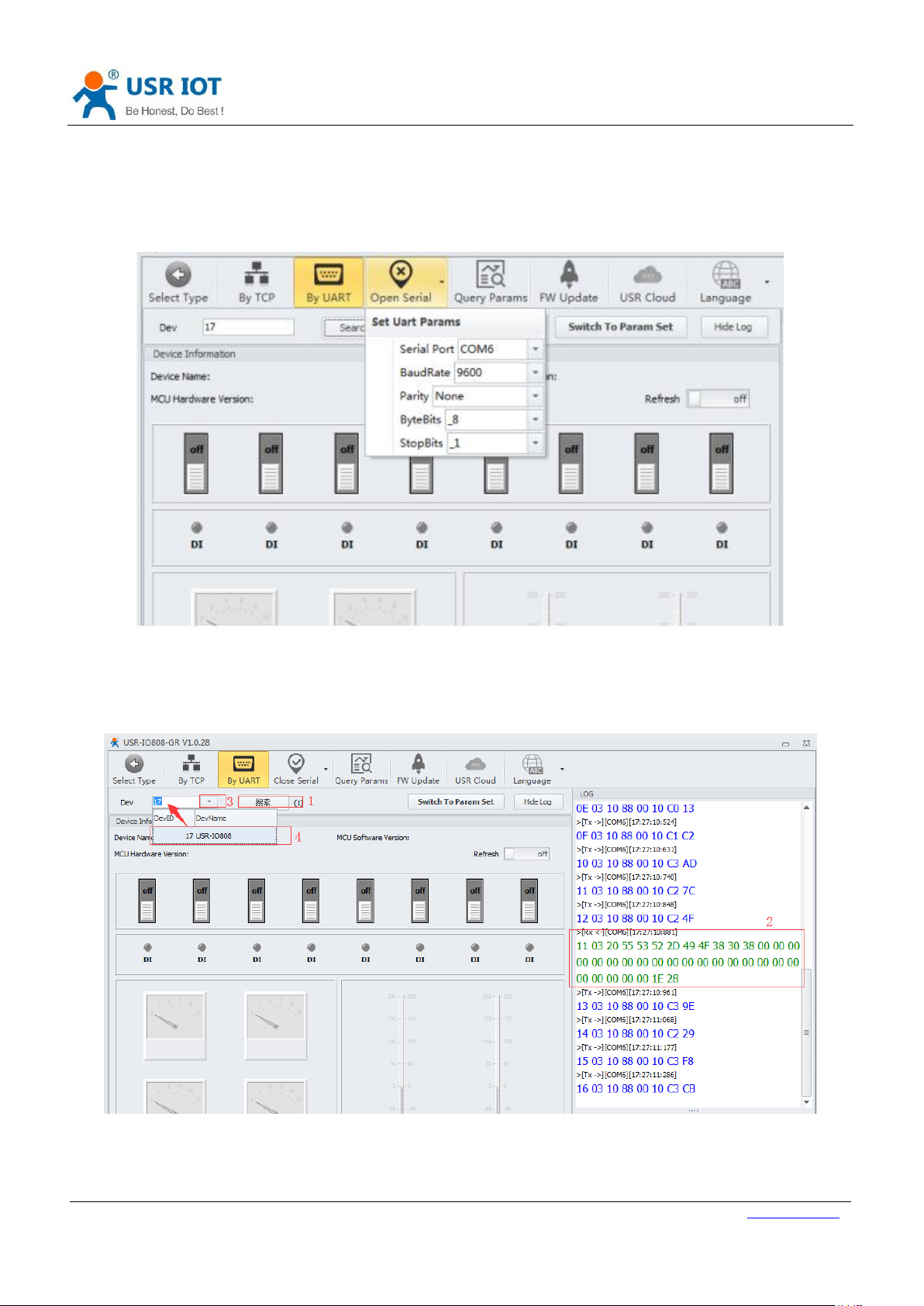

1.4.1. Control by serial

Power IO424T-EWR and connect IO424T-EWR’s RS485 interface to PC. Run setup software USR-IO V1.0.28.exe

and choose IO424T-EWR. Choose correct COM and configure correct serial port parameters as follow(Default

settings is 9600, None, 8, 1):

Figure 5 Open serial

After opening serial port, click ’Search’ to search IO network controller and click ‘停止’ to stop searching after

finding IO network controller. Then choose IO network controller that user wants to configure.

Figure 6 Search IO network controller

Then user can control devices.

Page 9

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

9

Figure 7 Control devices

User can also click ‘Switch To Param Set’ on above figure to enter IO424T-EWR configuration page.

Figure 8 Configuration page

Page 10

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

10

1.4.2. Web Server

The initial parameter of USR-IO424T-EWR to enter Web Server as follow:

Work mode

Network data transparent transmission

Username

admin

Password

admin

LAN interface IP address

192.168.10.1

Figure 9 Initial parameter of USR-IO424T-EWR to enter Web Server

Type 192.168.10.1 into browser address bar and log in with username and password(Both are admin). Then user

can query and configure parameters of USR-IO424T-EWR by Web Server.

1.4.3. Control by USR Cloud

User can type http://console.usr.cn/ into browser address bar to enter USR Cloud web page and login with

username and password. Then user can add device as follow:

Figure 10 Add IO424T-EWR

Choose ‘Networking I/O controller’ as ‘Device type’, write IMEI and SN on IO424T-EWR’s label and click ‘Save’ to

add IO424T-EWR.

After adding IO424T-EWR, power IO424T-EWR and wait LED ‘NET’ light which means IO424T-EWR connects to

USR Cloud. Then user can remotely look over, record and control IO424T-EWR status in real time through USR

Cloud(Monitor->Data list).

Page 11

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

11

2. Product function

USR-IO424T-EWR functional diagram as follow:

Serial port

device(Should

support

Modbus RTU

protocl)

Network

server

Modbus protocol mode

Execute Modbus protocol

RS485

Data transparent transmission mode

RTU check

Data transparent

transmission

RTU check

Communication

module

Modbus

TCP/RTU

protocol

conversion

Input

Output

Switch input

Relay output

Serial

packaging

Temperature

Analog

quantity

PT100

Analog sensor

Figure 11 Functional diagram

2.1. DI input

2.1.1. Electrical level detection

➢ Register address range: 32~35(0x0020~0x0023)

➢ Supported function code: 02(Read discrete input), 03(Read holding register)

➢ Connection: Default is dry contact input. Short-circuit DI and COM will change input status. If user needs wet

contact input can contact to our sales personnel

➢ Electrical level detection: Default status is 0, after short-circuiting DI and COM, status will be 1. Detection

method: 02 function code of Modbus protocol.

Example:

Detect input of the first way, send: 11 02 00 20 00 01 BA 90

Short-circuiting will return: 11 02 01 01 64 88

No short-circuiting will return: 11 02 01 00 A5 48

2.1.2. Buttons detection

➢ Register address range: 48~51(0x0030~0x0033)

➢ Supported function code: 03(Read holding register), 04(Read input register)

➢ Connection: Default is dry contact input. Short-circuit DI and COM will change input status. If user needs wet

contact input can contact to our sales personnel

➢ Electrical level detection: Default status is 0000, after short-circuiting DI and COM and then releasing, status

will be FF00. Detection method: Read button register value by 03 function code of Modbus protocol. After

reading once button register, status will recover to 0000; after executing conditional control, status will also

recover to 0000.

Example:

Detect the first way button, send: 11 03 00 30 00 01 86 95

No button will return: 11 03 02 00 00 79 87

Page 12

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

12

Have button will return: 11 03 02 FF 00 38 77

2.1.3. Pulse counting

➢ Register address range: 64~67(0x0040~0x0043)

➢ Supported function code: 03(Read holding register), 04(Read input register)

➢ Connection: Default is dry contact input. Short-circuit DI and COM will change input status. If user needs wet

contact input can contact to our sales personnel

➢ Pulse counting: Default status is 0, short-circuit DI and COM and then release will count 1. Detection method:

Read pulse counting register value by 03 function code of Modbus protocol. Maximum value of pulse counting

is 65535 and it will restart counting after exceeding 65535. Can’t reset count to 0 and restart product won’t

save count.

➢ Note: Pulse counting won’t filter input waveform and all pulse in the range of detection will be recorded. So

input waveform should keep stable to ensure accurate count.

Example:

Detect count of the first way, send: 11 03 00 40 00 01 87 4E

Return: 11 03 02 00 00 79 87

2.2. DO output

➢ Register address range: 00~03(0x0000~0x0003)

➢ Supported function code: 01(Read coil), 05(Write single coil), 0F(Write multiple coil)

➢ Connection: DO output is Relay passive output and 4-way will use one COM together. Relay close will connect

DO with COM.

Take the first way Relay control as example:

Query: 11 01 00 00 00 04 3F 59

Control to close: 11 05 00 00 FF 00 8E AA

Control to disconnect: 11 05 00 00 00 00 CF 5A

2.3. AI input

➢ Register address range: 88~89(0x0058~0x0059, voltage acquisition data), 96~97(0x0060~0x0061, current

acquisition data)

➢ Supported function code: 03(Read holding register), 04(Read input register)

➢ Connection: Analog detection adopts public reference ground method to connect(signal + connects to +,

signal - connects to - and reference ground short-circuit to power ground). Voltage detection range: 0 ~ 10V;

current detection range: 0 ~ 20mA.

Take the first way voltage detection as example:

Query: 11 03 00 58 00 01 07 49

Return: 11 03 02 10 00 74 47

Return data: 0x1000, it’s 4096 mV

Note: Analog detection is voltage detection and current detection, default is voltage detection and please ignore

current register value. If user needs to do 0~20mA current detection, please contact to our sales personnel.

Page 13

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

13

2.4. Temperature detection

➢ Register address range: 80(0x0050, temperature acquisition data)

➢ Supported function code: 03(Read holding register), 04(Read input register)

➢ Connection: Input signal of temperature detection is PT100 signal and connection adopts three-wire system.

Single wire connects to + and two interlinked wires connect to two -.

➢ Temperature calculation formula: Actual temperature=(Return value-10000)/100

Example:

Query: 11 04 00 50 00 01 33 4B

Return: 11 04 02 06 92 FA FE

Return data: 0x0692, it’s 1682 and actual temperature=(1682-10000)/100=-83.18℃

2.5. Analog self-calibration

USR-IO424T-EWR supports analog self-calibration(Include two-way voltage value and one-way temperature value

calibration).

➢ Temperature 1 self-calibration register address: 0x00B7~0x00B8

➢ Voltage 1 self-calibration register address: 0x00C7~0x00C8

➢ Voltage 2 self-calibration register address: 0x00C9~0x00CA

Every analog self-calibration will occupy two register address. For example, 0x00B7 and 0x00B8 are temperature

self-calibration register address. Factory default value of two register address both are 10000, prior register

address value represents K and last register address value represents B.

Calculation formula of temperature self-calibration: Temperature output value=(K/10000)*original temperature

output value+(B-10000)/100

Calculation formula of voltage self-calibration: Voltage output value=(K/10000)*original voltage output

value+(B-10000)*10

2.6. Work mode

Default work mode of USR-IO424T-EWR is slave mode. IO424T-EWR will be slave both on network side and RS485

side and IO424T-EWR will discard data if IO424T-EWR receives data not for IO424T-EWR local address.

2.6.1. Master mode

Master mode data flow diagram and connecting to network diagram as follows:

Page 14

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

14

Figure 12 Master mode data flow

Figure 13 Connecting to network in Master mode

In master mode, server can communicate to network IO product IO424T-EWR and Modbus devices which connect

to IO424T-EWR’s RS485 interface. RS485 side can also transmit data to IO424T-EWR directly.

User can configure IO424T-EWR to Master mode by setup software as follow(Configure RS485 mode to 1.DTU):

Page 15

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

15

Figure 14 Configure IO424T-EWR to Master mode

2.6.2. Slave mode

Slave mode data flow diagram and connecting to network diagram as follows:

Figure 15 Slave mode data flow

Figure 16 Connecting to network in Slave mode

In this mode, IO424T-EWR can communicate to network server and Modbus devices on RS485 network. But

network server can’t communicate to Modbus devices on RS485 network.

Page 16

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

16

User can configure IO424T-EWR to salve mode by setup software as follow(Configure RS485 mode to

2.RTUSLAVE):

Figure 17 Configure IO424T-EWR to Slave mode

2.7. Upgrade firmware

User can refer to FAQ <<Upgrading firmware method of USR-IO424T-EWR_V1.0.0>>.

2.8. Network

2.8.1. Ethernet interface

USR-IO424T-EWR’s Ethernet interface supports switching between WAN interface and LAN interface. By

modifying value of corresponding register, USR-IO424T-EWR can realize WAN/LAN switch. User can configure by

setup software as follow:

Figure 18 WAN/LAN switch

Page 17

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

17

2.8.2. WiFi

USR-IO424T-EWR supports WiFi function and AP/STA two WiFi modes,

AP mode:

1. Set WiFi mode to 1(AP mode) and AP’SSID/AP’s password, then restart device.

2. After restarting successfully, use PC or mobile to search IO424T-EWR and connect.

STA mode:

1. Set WiFi mode to 2(STA mode) and SSID/password of the target AP which user wants to connect IO424T-EWR

to, then restart device.

2. After restarting successfully, IO424T-EWR will connect to target AP automatically.

Figure 19 WiFi mode

2.9. Serial port

2.9.1. Basic parameters

Parameter

Range

Baud rate

300~230400

Data bits

7, 8

Stop bits

1, 2

Parity

NONE, EVEN, ODD

Figure 20 Serial port basic parameters

2.9.2. Configuration method

Serial port parameters occupy two registers. Length of protocol is 4 bytes and specific protocol content as

follow(All examples are in HEX format):

Name

Baud rate

Parameter bit

Number of bytes

3

1

Description

Three bytes represent a baud rate

value and high-order in the former

Refer to Figure 22 Serial port

parameter bit

Example 1(115200, None, 8, 1)

01 C2 00

03

Example 2(9600, None, 8, 1)

00 25 80

03

Figure 21 Serial port parameters protocol

Page 18

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

18

Bit number

Representation

Value

Description

1:0

Data bits

10

7 bits data bits

11

8 bits data bits

2

Stop bits

0

1 bit stop bits

1

2 bits stop bits

5:4:3

Parity

000

None

001

ODD

011

EVEN

7:6

No definition

00

Please write 0

Figure 22 Serial port parameter bit

2.10. Features

2.10.1. Relay output status hold

User can configure whether hold Relay output status: After restarting IO424T-EWR or powering on IO424T-EWR

again, hold the Relay output status or reset to disconnect status.

➢ Register address: 182(0x00B6)

➢ Parameter values: 1(0x0001):All Relays hold status after restarting or powering off. 2(0x0002):All relays hold

status after restarting and don’t hold status after powering off.3(0x0003):All relays don’t hold status after

restarting or powering off.

➢ Supported function code: 0x03, 0x04, 0x06, 0x10

Configuration will take effect after restarting.

2.10.2. Conditional control

Conditional control function supports user configuring the conditions to trigger IO changes. It can make using

IO424T-EWR more flexibly and extend application scenario. User only needs to modify conditional control

function register parameters according to the instructions , it will realize corresponding function.

Conditional control function has 32 registers and 8 conditional control commands(Every command occupies 4

registers). Registers distribution as follow:

Storage content

Input register

Output register

Output action

Condition

Threshold

Reserved

Length

1 byte

1 byte

1 byte

1 byte

2 bytes

2 bytes

Address

Range:

16~109

Range: 1~16

1: Disconnect

2: Close

3: Reversal

1 ~ 255

‘Compared

register

values’/The first

two bytes of

time-stamp

Reserved/

Last two

bytes of

time-stam

p

Figure 23 Conditional control function register

➢ Output action(Relay output)

1: Disconnect

Page 19

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

19

2: Close

3: Reversal

➢ Condition

1: Forward direction output follow

2: Backward direction output follow

3: Greater than or equal to

4: Less than or equal to

255: Button action

➢ Control mode

Switching value control: DI input control DO output directly

Semaphore control: DI button semaphore control DO. Press button once, DO act once(Execute action in rising

edge of releasing button).

Detailed explanation:

1. Forward direction output follow

Enable forward direction output follow: Set condition register to 1, input register is corresponding to one way

register address of 4-way input and output register is corresponding to one way register address of 4-way output.

For example, if configure as 0x20 0x00 0x01 0x01 0x00 0x00 0x00 0x00, it represents status of DO1 will follow

status of DI1 which means DO1 will close if DI1 close and DO1 will disconnect if DI1 disconnect.

2. Backward direction output follow

Enable backward direction output follow: Set condition register to 2, input register is corresponding to one way

register address of 4-way input and output register is corresponding to one way register address of 4-way output.

For example, if configure as 0x20 0x00 0x01 0x02 0x00 0x00 0x00 0x00, it represents status of DO1 will be

opposite as status of DI1 which means DO1 will close if DI1 disconnect and DO1 will disconnect if DI1 close.

3. Button control

Enable button control: Set condition register to 255, input register is DI button register and output register is DO

output register. Action can be 1(disconnect ), 2(close), 3(reversal ), threshold register and reserved register can’t

work.

For example, if configure as 0x30 0x00 0x03 0xFF 0x00 0x00 0x00 0x00, it represents detecting DI1 button once

will reverse status of DO1 once.

4. Greater than or equal to

Condition of greater than or equal to action is 03. Input register are voltage register, current register and

temperature register; output register is DO output register. Action can be 1(disconnect ), 2(close), 3(reversal ).

Threshold register is comparison value and program will compare acquisition results of input register with

comparison value. Reserved register can’t work.

For example, if configure as 0x50 0x00 0x01 0x03 0x3A 0x98 0x00 0x00, it represents: 0x50 is the first way

temperature acquisition and 0X3A98 represents 15000(50℃). This condition represents disconnecting the first

Page 20

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

20

way DO output when the first way temperature acquisition result is greater than 50℃.

5. Less than or equal to

Condition of less than or equal to action is 04. Input register are voltage register, current register and temperature

register; output register is DO output register. Action can be 1(disconnect ), 2(close), 3(reversal ). Threshold

register is comparison value and program will compare acquisition results of input register with comparison

value. Reserved register can’t work.

For example, if configure as 0x50 0x00 0x01 0x04 0x3A 0x98 0x00 0x00, it represents: 0x50 is the first way

temperature acquisition and 0X3A98 represents 15000(50℃). This condition represents disconnecting the first

way DO output when the first way temperature acquisition result is less than or equal to 50℃.

Note:

Input register is 0 means close this conditional control and execute button action once will clear button register. If

multiple conditions will lead to paradoxical result, program will execute two results quickly. If forward direction

output follow and backward direction output follow lead to paradoxical result, disconnecting and closing will

revolve.

2.10.3. Connect to remote server

User can modify related register parameters of remote server to realize IO424T-EWR connecting to remote server.

Procedure as follow:

1. Power the IO424T-EWR and connect IO424T-EWR’s RS485 interface to PC. Run setup software(User can refer

to 1.4.1.Control by serial), modify remote server address and remote port as follow:

Figure 24 Configure remote server parameters

2. Restart IO424T-EWR to make configuration take effect.

3. Login remote server and open the port.

4. Wait IO424T-EWR LED ‘NET’ light which means IO424T-EWR connect to remote server successfully, Then user

can transmit Modbus TCP/RTU command from server side to control IO424T-EWR and receive response from

IO424T-EWR.

Page 21

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

21

2.10.4. Reset to default by hardware

User can reset to default settings by pressing Reload button. After powering on, press Reload button 3 seconds to

15 seconds, then release it, IO424T-EWR will reset to default settings. Less than 3 seconds or more than 15

seconds will be considered as misoperation and don’t handle it.

Page 22

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

22

3. Modbus

3.1. Modbus frame

Modbus RTU:

Figure 25 Modbus RTU frame

USR-IO424T-EWR data format conform to general Modbus frame format. IO424T-EWR can analyse Modbus RTU

protocol and execute related operations.

Modbus TCP:

Figure 26 Modbus TCP frame

USR-IO424T-EWR can analyse received network Modbus TCP protocol data and transfer to Modbus RTU protocol

to do data processing. IO424T-EWR can also be used in Master mode and transfer Modbus RTU protocol to

Modbus TCP protocol and transmit to server.

3.2. Register distribution

USR-IO424T-EWR register instructions:

1. Register base address is 0x0000.

2. In following register distribution table, MCU parameters and communication module parameters must operate

together.

3. Setup software USR-IO adopts UTF-8 coded format.

4. Register store HEX format data.

Register address

Register content

Parameter description

Applicable function code

Device I/O

0x0000~0x0003

Switch value output

0xFF00 means ON, 0x0000

means OFF;

1 means ON, 0 means OFF

0x01, 0x05, 0x0F

Page 23

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

23

0x0020~0x0023

Switch value input

1 means ON, 0 means OFF

0x02

0x0030~0x0033

Button input

Button detection. Reset to 0

after reading once

0x03, 0x04

0x0040~0x0043

Pulse counting

Count range: 0~65535. Reset

to 0 after reaching maximum

0x03, 0x04, 0x06, 0x10

0x0050

Temperature detection

PT100 temperature detection,

range: -100~200℃

0x03, 0x04

0x0058

Voltage 1 detection

0-10V voltage detection

0x03, 0x04

0x0059

Voltage 2 detection

0-10V voltage detection

0x03, 0x04

MCU parameter

0x0068~0x0069

Time-stamp

Current time-stamp

0x03, 0x04

0x006A~0x006C

Year, month, day, hour,

minute, second

The format of ‘year, month, day,

hour, minute, second’ is Bcd

code. Such as

[0x18,0x01,0x01,0x08,0x24,0x

56] represents 2018-1-1

8:24:56

0x03, 0x04, 0x10

0x006D

Week

0x0001-0x0007 represents

Monday to Sunday

0x03, 0x04

0x008E~0x0091

Conditional control

command 1

Refer to 2.10.2. Conditional

control

0x03, 0x04, 0x10

0x0092~0x0095

Conditional control

command 2

0x0096~0x0099

Conditional control

command 3

0x009A~0x009D

Conditional control

command 4

0x009E~0x00A1

Conditional control

command 5

0x00A2~0x00A5

Conditional control

command 6

0x00A6~0x00A9

Conditional control

command 7

0x00AA~0x00AD

Conditional control

command 8

0x00AE~0x00AF

RS485 interface

Refer to 2.9.2. Configuration

method

0x03, 0x04, 0x10

0x00B0

RS485 mode

Master mode(0x0001)

Slave mode(0x0002)

0x03, 0x04, 0x06, 0x10

0x00B1

Modbus address

Slave

address(0x0001~0x00FD)

0x03, 0x04, 0x06, 0x10

0x00B2

Work mode

Modbus mode(0x0001)

Firmware upgrade(0x0002)

0x03, 0x04, 0x06, 0x10

Page 24

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

24

0x00B3

Global parameters

configuration

Default(0x0000),

restart(0x0001), reset to user

default settings(0x0002),reset

to USR default

settings(0x5555), save current

settings as user default

settings(0xAAAA)

0x03, 0x04, 0x06, 0x10

0x00B4

MCU software version

For example, 0x0112 means

version V1.1.2

0x03, 0x04

0x00B5

MCU hardware version

For example, 0x0110 means

version V1.1

0x03, 0x04

0x00B6

Relay status after

restarting

All relays hold status after

restarting or powering

off(0x0001);

All relays hold status after

restarting and don’t hold status

after powering off(0x0002)

All relays don’t hold status after

restarting or powering

off(0x0003)

0x03, 0x04, 0x06, 0x10

0x00B7~0x00B8

Temperature

self-calibration

Device temperature

self-calibration interface

0x03, 0x04, 0x06, 0x10

0x00C7~0x00C8

Voltage 1

self-calibration

Device voltage 1 self-calibration

interface

0x03, 0x04, 0x06, 0x10

0x00C9~0x00CA

Voltage 2

self-calibration

Device voltage 2 self-calibration

interface

0x03, 0x04, 0x06, 0x10

Communication module parameters

0x1021

WiFi mode

AP(1)/STA(2)

0x03, 0x04, 0x06, 0x10

0x1022~0x1031

AP mode SSID

Character string format

0x03, 0x04, 0x10

0x1032~0x1041

AP mode password

Character string format

0x03, 0x04, 0x10

0x1042

WAN/LAN switch

WAN(1)/LAN(2)

0x03, 0x04, 0x06, 0x10

0x1043

Remote connection

identity packet

USR Cloud(1)/MAC(2)/User

editable(3)/Disable(4)

0x03, 0x04, 0x06, 0x10

0x1044~0x1045

LAN interface IP

0xC0A80007 represents

192.168.0.7

0x03, 0x04, 0x10

0x104A

WAN interface IP mode

DHCP(1)/Static IP(2)

0x03, 0x04, 0x06, 0x10

0x104B~0x104C

WAN interface IP

0xC0A80007 represents

192.168.0.7

0x03, 0x04, 0x10

0x104D~0x104E

WAN interface mask

0xC0A80007 represents

192.168.0.7

0x03, 0x04, 0x10

0x104F~0x1050

WAN interface

gateway

0xC0A80007 represents

192.168.0.7

0x03, 0x04, 0x10

0x1051~0x1052

DNS1

0xC0A80007 represents

0x03, 0x04, 0x10

Page 25

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

25

192.168.0.7

0x1055~0x1074

TCP Client remote

server address

Remote server address

0x03, 0x04, 0x10

0x1075

TCP Client remote

port

Remote server port

0x03, 0x04, 0x06, 0x10

0x1076

TCP Server/UDP

Server listening port

LAN listening port

0x03, 0x04, 0x06, 0x10

0x1078~0x107F

Username

Character string format

0x03, 0x04, 0x10

0x1080~0x1087

Password

Character string format

0x03, 0x04, 0x10

0x1088~0x1097

Device name

Character string format

0x03, 0x04, 0x10

0x1098

Device software

version

For example, 0x0112 means

version V1.1.2

0x03, 0x04

0x1099

Device hardware

version

For example, 0x0110 means

version V1.1

0x03, 0x04

0x109A~0x10A9

Target AP’s SSID in

STA mode

Character string format

0x03, 0x04, 0x10

0x10AA~0x10B9

Target AP’s password

in STA mode

Character string format

0x03, 0x04, 0x10

0x10BA~0x10CD

User editable identity

packet

Character string format

0x03, 0x04, 0x10

0x10CE

Identity packet

sending method

Send identity packet after

establishing

connection(1)/Send before

every data package(2)/Both

way(3)

0x03, 0x04, 0x06, 0x10

Figure 27 Register distribution

4. Contact Us

Page 26

USR-IO424T-EWR User Manual Technical Support: h.usriot.com

Jinan USR IOT Technology Limited www.usriot.com

26

Company: Jinan USR IOT Technology Limited

Address: Floor 11, Building 1, No. 1166 Xinluo Street, Gaoxin District, Jinan, Shandong, 250101, China

Web: www.usriot.com

Support: h.usriot.com

Email: sales@usr.cn

Tel: 86-531-88826739/86-531-55507297

5. Disclaimer

This document provides the information of USR-IO424T-EWR products, it hasn’t been granted any intellectual

property license by forbidding speak or other ways either explicitly or implicitly. Except the duty declared in sales

terms and conditions, we don’t take any other responsibilities. We don’t warrant the products sales and use

explicitly or implicitly, including particular purpose merchant-ability and marketability, the tort liability of any

other patent right, copyright, intellectual property right. We may modify specification and description at any time

without prior notice.

6. Update History

2018-05-28 V1.0.3.01 established based on Chinese version V1.0.3.

Page 27

FCC STATEMENT :

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may

cause undesired operation.

Warning: Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving an tenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated

with minimum distance 20cm between the radiator & your body.

Loading...

Loading...