JIMS 2456-1 User Manual

No.2272-IS

REV E

9-08

A Division of Thiessen Products, Inc.

IInnssttrruuccttiioonn SShheeeett FFoorr ##22445566--11,, 22445577--11,, && 22445588--11

PowerGlide™ Tappet, Standard O.D. is .8425”

Big Twin Single Cam - Fits 1984-present

Sportster - Fits 1986-1990

No.2456-1 STD.

No.2457-1 Oversize +.002”

No.2458-1 Oversize +.005”

®

3. JIMS

Power Glide™ Tappets are assembled with a small amount of oil to ease in the adjustment.

1. These tappets will work best in JIMS®Tappet Blocks #1094 with a running clearance of

.0007” to .0012”.

2. JIMS®Power Glide™ Tappet can also be run in H.D.®blocks with a running clearance

of .0007-.0012.

4. If the pushrods you are using are adjustable proceed as follows.

5. With the Power Glide™ Tappet installed, start with the front tappet at the lowest point on the cam, extend the

pushrod to zero lash (no up and down play, but has a light spin.)

6. Extend the pushrod adjuster 15 wrench flats if pushrods have 24 threads per inch, 17 wrench flats if pushrods have 28 threads, 18 wrench

flats if your push rods have 32 threads per inch, 24 wrench flats if your push rods have 40 threads per inch and 30 wrench flats if your

pushrod has 52 threads per inch. Tighten lock nut. Note: Popular Pushrod adjustments on back of page.

IMPORTANT NOTE: This adjustment will make the pushrod tight, which will bleed the hydraulic lifter. It can take 10-15 minutes, or longer, to

bleed off. It is very important that the engine is not rotated while pushrods are tight. The pushrod will spin with your fingers after the tappet

has bled off.

7. Recheck lock nut, close covers and install clips.

8. Repeat exact procedure on rear set.

9. Turn motor over several times to pump oil into the Power Glide™ Tappet or until the oil light goes out, or oil is returning to the oil tank.

Install tappets per H.D.®Service Manual.

Buell

®

- 1987-90

CAUTION: Use motorcycle oil 20-50w at best and clean the tappet filter screen.

CCoonnggrraattuullaattiioonnss

You and your Harley®have just taken the first steps towards owning the finest precision designed and engineered valve train components known to the

Harley-Davidson

Davidson®motorcycle.

To achieve the best life possible from this tappet (or any other valve train part) you must be aware of some very important issues.

1. Clean! Clean! Clean! You must use the best possible oil and oil filter available for your Harley-Davidson®. Use only motorcycle or air cooled

2. If these tappets are being installed in a motor that has had motor problems, or was rebuilt, wash out oil tank, oil feed lines and motor.

3. If these tappets are replacing a previous tappet and cam problem, please make sure you know what caused the problem in the first place.

4. The first area of concern is that the tappet roller must seat flat on cam. JIMS®tappets are square from the tappet

body to the axle bore within .0002”. If the roller is not seated flat on the cam, it will fail within a short period of time.

5. Second concern: The same holds true for the tappet blocks. JIMS

6. The next important concern is alignment of the cam itself. First, the cam will be, or should be, parallel from the two bearing journals to the lobes

within ±.0002, (this is just the cam). With the cam installed in the motor this can be a lot different. For this reason, JIMS®has a precision machined cam cover

to hold your cam to within .0002” of cam centerline.

As you can see from some of the examples there are a lot of possible reasons for your valve train to have a shortened life. For this reason JIMS

uously helping you achieve the longest possible life for your valve train.

date of purchase. Merchandise that fails to conform to these conditions will be repaired or replaced at JIMS®option if the parts are returned to us by the dealer (purchaser) within the six (6) month warranty period or within ten (10) days thereafter.

phone call and need no further course of action. A part suspected of being defective must not be replaced by a dealer without prior authorization from JIMS

necessary for JIMS

JIMS

ure. If after an evaluation has been made by JIMS

1.) JIMS

2.) JIMS

3.) JIMS

4.) JIMS

All JIMS

In the event warranty service is required, the original purchaser must call or write JIMS

®

with a copy of the original invoice of purchase and a detailed letter outlining the nature of the problem, how the part was used and the circumstances at the time of fail-

abnormal operation, or any other misuse or mistreatment of the part.

deliver, delay in delivery, delivery in nonconforming condition, or for any other breach of contract or duty between JIMS

any other application.

555 Dawson Drive, Camarillo, CA 93012 • Phone 805-482-6913 • Fax 805-482-7422

®

market. JIMS®tappets, tappet blocks and cam covers surpass the stock requirements and demands of the present and future Harley-

type engine oil. No Substitutes!

®

flange within ±.0002 of an inch.

®

parts are guaranteed to the original purchaser to be free of manufacturing defects in materials and workmanship for a period of six (6) months from the

®

to make an evaluation to determine whether the part is defective, it must be packaged properly to prevent further damage and be returned prepaid to

®

and the part was found to be defective, repair, replacement or credit will be granted.

®

shall have no obligation in the event a JIMS®part is modified by any other person or organization.

®

shall have no obligation if a JIMS®part becomes defective in whole or in part as a result of improper installation, improper maintenance, improper use,

®

shall not be liable for any consequential or incidental damages resulting from the failure of a JIMS®part, the breach of any warranties, the failure to

®

parts are designed exclusively for use in Harley-Davidson®Motorcycles. JIMS®shall have no warranty or liability obligation if a JIMS®part is used in

ADDITIONAL WARRANTY PROVISIONS

tappet blocks are machined to hold the bores perpendicular to the mounting

WARRANTY

®

immediately with the problem. Some problems can be rectified by a tele-

®

and a customer.

®

is contin-

®

. If it is deemed

“From the Track... To the Street!”

1

No.2272-IS

REV E

9-08

FOUR POSSIBLE REASONS THAT MAY KEEP NEW HYDRAULIC UNITS FROM WORKING PROPERLY

IMPROPER FIT • MECHANICAL • CONTAMINATION OF OIL SUPPLY • LOW OIL SUPPLY

1. IMPROPER FIT

a) Not likely, each unit goes through (2) two tests.

b) First the fit is checked twice, .0015” to .0002”.

c) Second, a hydraulic bleed down test is performed first dry, then with 5 weight oil.

2. MECHANICAL

a) Not adjusted properly, readjust per instruction sheet. For 18523-86, 18526-89 and 18522-53PG, the hydraulic unit itself needs to be at

.100 ± .010 below snap ring. For 1029-53 kit the hydraulic unit itself needs to be .050 ± .010 below the snap ring. Some shovel models

from 1978-1980 have tappet blocks with oil drain holes to low. If running a higher lift cam then stock, and sometime even stock, these

blocks will allow oil pressure to bleed off from the tappets, this is most common in the front tappet block.

b) A bent pushrod, loose valve guides, broken valve spring, valve hitting piston, valve hitting valve, rocker bushing loose, rocker tip wear at

valve stem, and lifter roller hitting tappet block. All will cause a noisy valve train.

c) Gear lash: if you did not change the cam at the time you installed new hydraulic units and had no gear lash, but a slight whine motor

when motor was cold, it is safe to say you are OK in this area.

d) Hydraulic valve spring broke, is not allowing valve to seal. We have not seen this on any JIMS

e) If this is the case the hydraulic unit will not hold oil pressure, to check this hold pushrod with your hand (with lifter on the heel of cam valve

shout) push down on pushrod. Hydraulic unit will feel spongy. Do not mistake this for no oil getting to tappet. If all tappets are spongy this

is no oil. If just one tappet is spongy and has been readjusted, and still will not pump up, replace tappet.

3. CONTAMINATION OF OIL

a) Hydraulic unit may work for a minute and then become noisy, most of the time it is more then one hydraulic unit that will be contaminated

to the point of being stuck in the downward position.

b) Readjust per instruction sheet. If hydraulic unit will not come back up to the top of snap ring, replace hydraulic unit and wash out the entire

oil system.

4. OIL PRESSURE AT NORMAL OPERATING TEMPERATURE, AT ABOUT 2,000 R.P.M., SHOULD BE 12-35 P.S.I..

a) Check lifter filter screen. ( Big Twin )

b) Make sure your getting oil to the lifters. Install oil pressure gauge for top end oil.

c) Lifter to tappet block clearance is best at .0007”-.0012”.

d) Lifters work best with 20w-50w motorcycle oil.

e) If lifters are quiet when cold or low r.p.m., and become noisy as r.p.m. is increased, there is not enough oil pressure or to much clearance

from lifter to block bore. (see “C”)

f) To isolate a possible noisy hydraulic lifter start with a cool motor and the lifter you think is making the noise. With that lifter on the heel of

cam, valve shut, adjust pushrod so lifter unit is all the way compressed down ( very important ) this adjustment will make the pushrod tight

which will bleed down the hydraulic lifter. It will sometimes take (5) five minutes, or longer, to bleed down. Do not rotate engine while

pushrods are tight. Go to the point where pushrod will spin with your fingers. Adjust down a little more until pushrod becomes tight ( you

can just barely turn with your fingers ). Start bike, if it is quiet then you have found the lifter that was not working properly. If it’s still noisy

continue with the next lifter until you have located the the noisy one. Readjust per instruction sheet, or replace lifter.

®

hydraulic units.

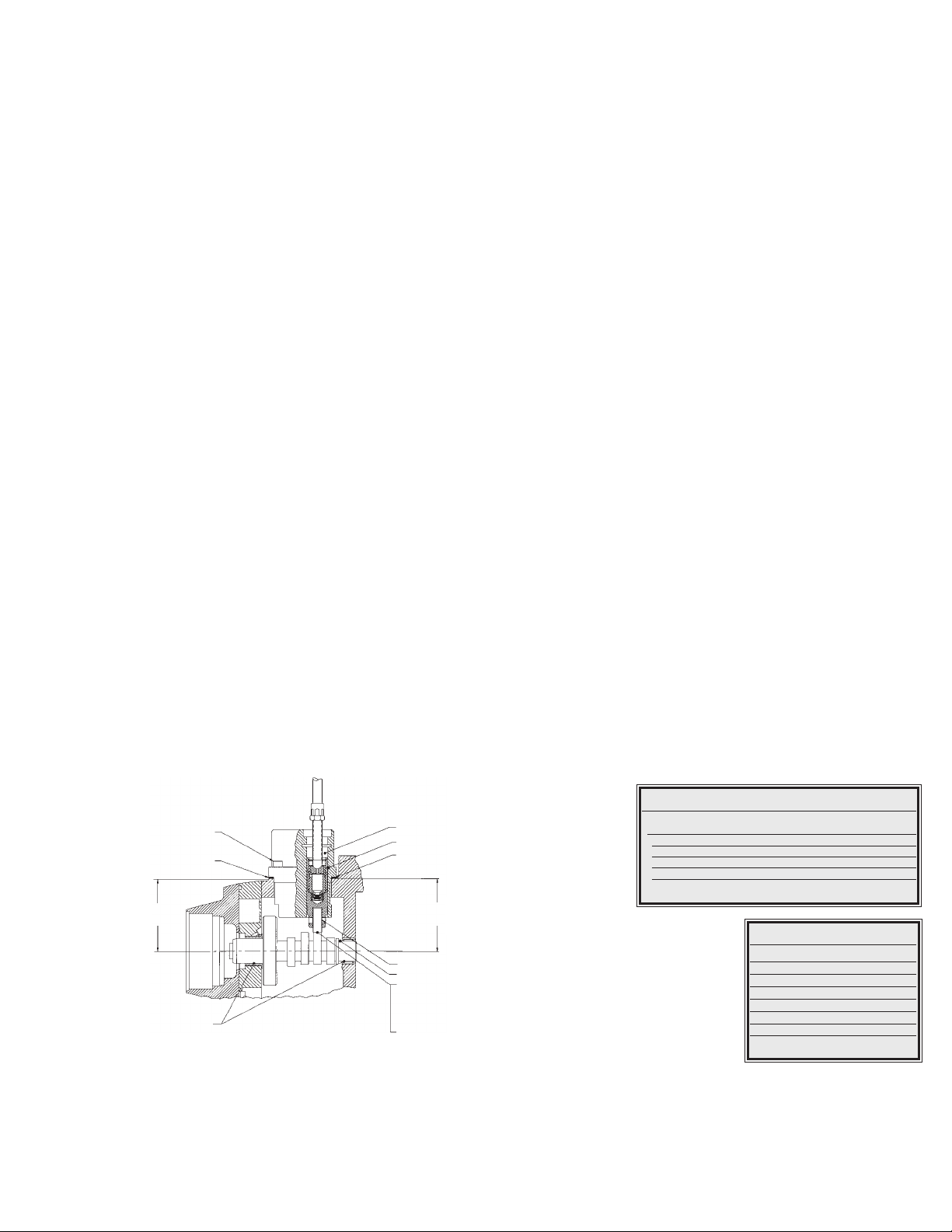

PROPER TORQUE OF SCREWS

FLATNESS OF GASKET

MAINTAINING

PARALLELISM

(OUTSIDE)

CENTERLINE OF CAM BUSHING

IN CAM COVER IS COAXIAL

TO CAM ROLLER BEARING IN CASE

➎

➌

❶

➋

CLEARANCE BETWEEN

LIFTER AND BORE

SQUARENESS OF TAPPET

➍

BLOCK BORE TO CAM LOBE

➑

SQUARENESS OF BORES

➋

TO LIFTER BLOCK FACE

FROM THE DECK TO THE CENTER

➎

SQUARENESS OF AXLE TO ROLLER

➏

CAM SHAFT END PLAY

➒

PARALLELISM OF ROLLER TO CAM LOBE

➐

MAINTAINING COMPLETE SURFACE CONTACT

OPTIMUM CONDITION WITH ROLLER MAKING

➐

FULL CONTACT ON CAM LOBE RESULTS FROM

MAINTAINING CLOSE TOLERANCES

MAINTAINING PARALLELISM

LINE OF THE CAM (INSIDE)

Distance Distance Threads Wrench Total Travel

per turn per flat per inch Flats Distance

.0417 .0069 24 15 .1042”

.0357 .0059 28 17 .1011”

.0313 .0052 32 18 .0937”

.025 .0042 40 24 .100”

.0192 .0032 52 30 .0962”

Pushrod Adjustments

Popular Pushrods

®

JIMS

Andrews 28

Andrews 32

Crane 24 Time Savers

Crane 32

H.D. 32

S & S 32

Rivera 40 Taper Lite

32 Slim-Jims

The following is sometimes mistaken for noisy tappets:

A. The most common being the clearance between cam gear and pinion gear (referred to as gear lash). If you did not change the cam at the

time of installing this kit and had no gear lash but a slight whine when motor was cold it is safe to say you are OK in this area.

B. Rocker arm end play .004” to .010” is good.

C. Oil pressure at normal operating temperature about 2000 r.p.m. should be 12-35 p.s.i. on Big Twin models, and 10-17 p.s.i at 2500

r.p.m. on XL models.

D. Check valve to guide clearance.

“From the Track... To the Street!”

555 Dawson Drive, Camarillo, CA 93012 • Phone 805-482-6913 • Fax 805-482-7422

2

Loading...

Loading...