JIMS 1208-1352 User Manual

These instructions are for all models

of 120”, 131” or 135” Alpha, Beta and

Evo Mount Engines.

Rev I

8-12

No.1208-1352

Rev I

8-12

A Division of Thiessen Products, INC

IInnssttrruuccttiioonn SShheeeett FFoorr BBooxx 22 112200””,, 113311”” oorr 113355””

EEnnggiinnee AAsssseemmbblliieess OOrr EEnnggiinnee RRaaccee KKiittss

Box 2 Installation Instructions

CONTENTS:

Note: Use Fig. 1 on this page and Fig.73 in conjunction with the check off list on page 18 & 19 to verify

contents prior to proceeding with any installation instructions.

TOOLS AND LUBRICANT: See Fig. 2.

JIMS No.1235 Piston Ring Expander Tool (Snap On PRS8)

JIMS No.1236 Piston Ring Compressor Set

JIMS No.769 or No.HD-42317 Piston Pin Circlip Installer

JIMS No.1255 Ring Gap Grinder Tool

Feeler gage set, including .0015” through .040” blades

3/8” drive torque wrench (0-25 ft/lbs)

12 point 1/2” deep socket (3/8” drive)

13mm deep socket (3/8” drive)

Non abrasive scouring pad & dish soap for cleaning cylinder bores.

Clean pair of mechanic’s gloves

JIMS No. 4507 Copper Anti Seize Lubricant

Piston Inspection and Preparation

GENERAL NOTES & CAUTIONS:

• Obtain and use a Harley-Davidson Twin Cam service manual specific to your application for

general assembly procedures.

• Unwrap and work with the pistons over a padded surface. A half-dozen new, clean shop towels

under a T-shirt makes a reasonable low-lint cushion.

Fig.1 - Kit items

Fig.2 - Necessary tools

555 Dawson Drive, Camarillo, CA 93012 Phone 805-482-6913 • Fax 805-482-7422

1

No.1208-1352

A Division of Thiessen Products, INC

Rev I

8-12

IInnssttrruuccttiioonn SShheeeett FFoorr BBooxx 22 112200””,, 113311”” oorr 113355””

EEnnggiinnee AAsssseemmbblliieess OOrr EEnnggiinnee RRaaccee KKiittss

• Always handle pistons with great care. While they are capable of withstanding extreme

acceleration loads, they can also be destroyed by a two-foot fall onto a hard surface.

• Piston ring end gaps must be checked and adjusted if required, use a ring gap tool and do the work

away from the engine. Piston ring particles are very hard and should not be allowed anywhere near

the open engine. Make sure you wash your hands after adjusting ring gaps or doing any other

grinding.

• Avoid the use of sandpaper. Keep all abrasives away from your work area and the internal compo-

nents of your new JIMS 120, 131 or 135 Race Kit.

• Do not use pressurized air to clean anything. Its use virtually guarantees damaging particles will get

into your new engine. If at all possible, use liquid cleaners, soft brushes and clean lint-free towels

instead.

STEP 1: Piston inspection

• There should be no dents, dings or gouges on any surface of the pistons. Pay particular attention to

edges and corners especially the corners formed by the piston pin hole and the sides of the pistons.

They should be smooth with no nicks or deformations. If any burrs are noted please contact the

JIMS Tech Department (805-482-6913)

• Inspect the piston ring grooves for any deformations.

• Clean the pistons and then proceed to the next step.

Piston and ring installation information:

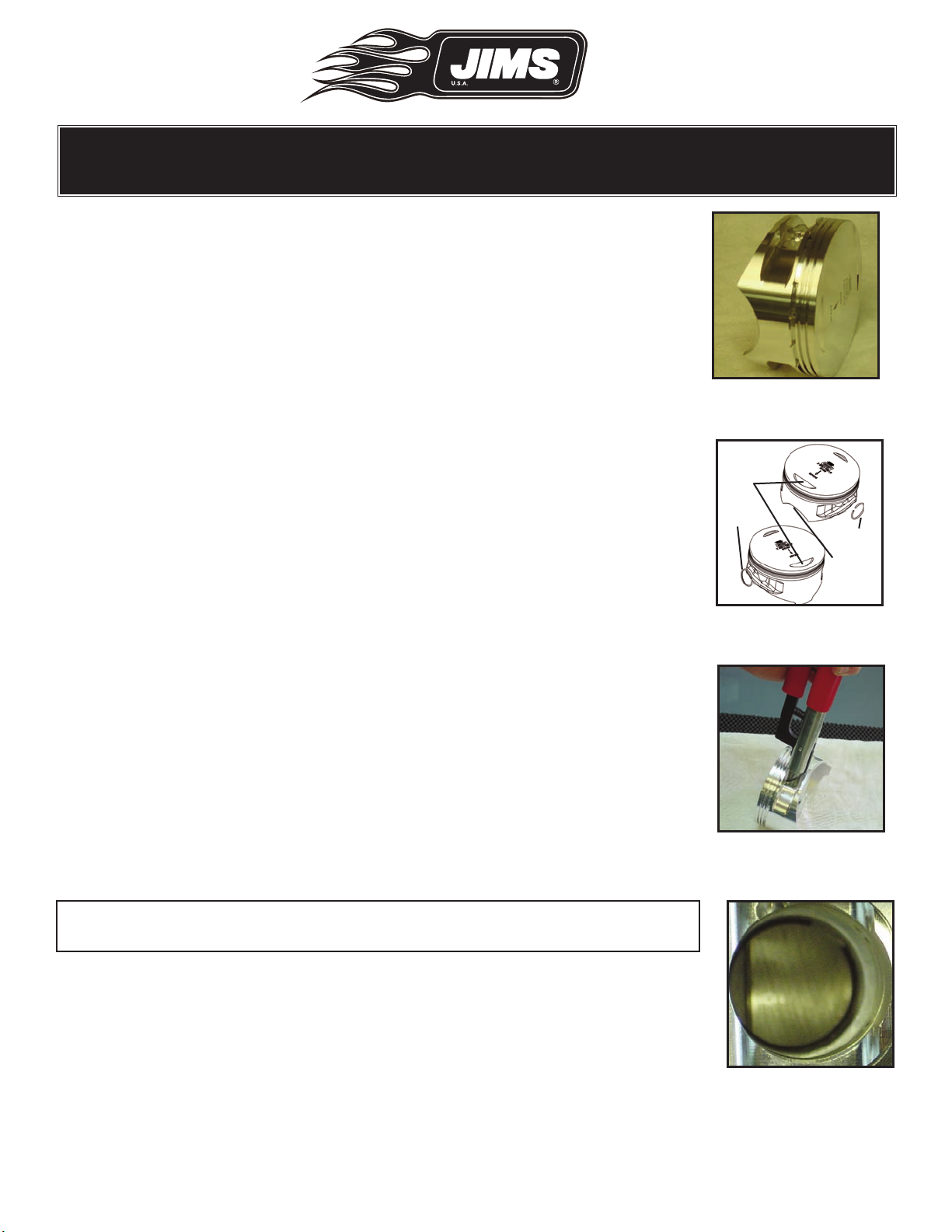

• The 120" flat top piston is shown in Fig. 4, and the 131"/ 135" with a recessed top is shown in Fig.

5. Both the 120" and 131" / 135" piston sets have a rear piston with a notch as shown in Fig. 3 on

the skirt. In the following installations we show figure photos of 120" the ring sets. The installation

of the 131" or 135" ring sets is the same procedure for installation as 120" sets.

Note: 120”, 131” or 135" Piston orientation

There is a front and a rear piston. They are not the same and must be installed correctly. See Fig. 3.

• Both 120”, 131” and 135" pistons have valve reliefs machined into their tops. The intake valve reliefs

are clearly larger to clear the 2.080” diameter intake valves. See Fig.4 and Fig.5.

REAR FRONT

NOTCH

Fig.3 - Inspect pistons

555 Dawson Drive, Camarillo, CA 93012 Phone 805-482-6913 • Fax 805-482-7422

Fig.4 - Intake relief is larger

120” 131”/ 135”

Fig.5 - Intake relief only

2

No.1208-1352

A Division of Thiessen Products, INC

IInnssttrruuccttiioonn SShheeeett FFoorr BBooxx 22 112200””,, 113311”” oorr 113355””

EEnnggiinnee AAsssseemmbblliieess OOrr EEnnggiinnee RRaaccee KKiittss

• The rear piston has a notch on the bottom of the intake side of its skirt.

See Fig.6.

• The rear piston’s notch goes toward the front, or intake side of the

engine.

• The front piston’s intake valve relief points toward the rear of the engine.

See Fig.7.

Rev I

8-12

STEP 2: Piston Pin Clip Insertion

IMPORTANT NOTE:

• Piston pin clip insertion must be done carefully to avoid damaging the

corners of the piston pin hole.

• A crushed corner is a collection of cracks. At the high stress levels this

engine was designed to withstand, one or more of those cracks could

grow and eventually result in piston failure and severe engine damage.

• Use Harley-Davidson tool No.42317 or JIMS Tool No.769 Piston Pin

Circlip Remover / Installer if you have one. This is an excellent tool and

makes the task simple and safe for the pistons. This tool can only be used

for left side of piston.

• Lock ring is to be installed on the left side at this time. See Fig 7

• It is very important you do not scratch or gouge the piston pin bore.

• Place the piston on the clean pad. If using the Harley tool, follow the

directions in your Harley shop manual to insert a piston pin clip into the

left side of each piston. See Fig 8 & 9.

• Check to make sure the wrist pin clip is fully seated in its groove.

STEP 3: Piston Ring Inspection and Preparation Preparation

Fig.6 - Rear only piston notch

Rear Piston

Marked

ntake

I

1st Clip

Left Side

1st Clip

Left Side

Notch

Front Piston

Fig.7 Front Intake Marked

• Wipe excess oil from the piston rings.

Fig.8 - Install left clip

• Run the rings through your fingers to feel for any burrs.

NOTE: If burrs are discovered, see Appendix 1 (pg.18) for instructions

on deburring. You must Wash rings after deburring.

• Lightly lubricate with clean H-D 20W-50 oil and slip one piston pin

into a piston (either piston will do).

Fig.9 - Fully seat left clip

555 Dawson Drive, Camarillo, CA 93012 Phone 805-482-6913 • Fax 805-482-7422

3

No.1208-1352

A Division of Thiessen Products, INC

IInnssttrruuccttiioonn SShheeeett FFoorr BBooxx 22 112200””,, 113311”” oorr 113355””

EEnnggiinnee AAsssseemmbblliieess OOrr EEnnggiinnee RRaaccee KKiittss

• Place a cylinder on the bench, top end up.

• The cylinder’s bore should be clean to the touch and lightly oiled.

See Fig. 10.

End Gap Measurement See Fig. 11.

Rev I

8-12

• Piston Ring end gap range:

• Top ring: .017” to .022”

• Second ring: .022” to .030”

• Oil control rails: .015” to .030”

• Record your end gap measurements in the chart on page below. Tilt and

start a piston ring into the bore. The most common and perhaps easiest way

to do this is to first insert the side of the ring opposite the gap. Then, flex

each ring end into the bore. Use your fingers to control twist as you insert

the ring. See Fig. 12.

• When the ring is in the bore, use the piston to force it down the bore until

the piston pin is slightly below the top of the cylinder. See Fig. 13.

• Remove the piston.

• The piston ring is now square with the bore and positioned for end gap

inspection.

• Use a feeler gage as pictured to measure the width of the gap. You may

stack two blades if necessary. See Fig. 11.

• Remove each ring by hooking it with a finger on the side opposite the gap

and pulling smoothly and gently out of the cylinder bore.

Front Piston Rear Piston

Top Ring

Second Ring

Oil Control Rails

Fig.10 - Clean cylinder bore

Fig.11 - Feeler gauge gap

Fig.12 - Carefully twist in

• Start measuring with all piston rings to one side of the cylinder.

• After each ring is checked:

• Place rings having passed the end gap test on the opposite side of the cylinder.

• Place each of those failing the end gap test on a piece of paper and write

their measured end gap on the paper.

• When you have finished, separate and cover the piston rings not requiring

additional fitting.

555 Dawson Drive, Camarillo, CA 93012 Phone 805-482-6913 • Fax 805-482-7422

Fig.13 - Press ring down

4

No.1208-1352

A Division of Thiessen Products, INC

Rev I

8-12

IInnssttrruuccttiioonn SShheeeett FFoorr BBooxx 22 112200””,, 113311”” oorr 113355””

EEnnggiinnee AAsssseemmbblliieess OOrr EEnnggiinnee RRaaccee KKiittss

STEP 4: End Gap Adjustment:

• It is unlikely you will need to adjust the first and oil control ring end gaps. However it is likely

you will have to adjust the second ring end gap, if you do, the amount will be very small. Please

do not hurry the procedure and remove only a little material at a time.

• For the best result, use a piston ring gap tool to remove metal from the ends of the rings.

• Do not work near the open engine.

Piston ring gap tool:

• Determine how much material must be removed from the ends of the ring.

It will probably be only a few thousandths of an inch. If, say, a 2nd compression ring’s end gap was .013” then you would need to remove a total of

.004” from the ends to meet the minimum gap standard of .017”.

• Remember, JIMS

ring, and material removal can be very rapid.

• Fit the ring into the tool according to the tool’s instructions.

• Gently rotate the cutter and remove a very small amount of ring material.

See Fig. 14.

• Remove and clean the ring. Deburr if needed. Then, re-insert it into the bore.

Square it using the piston as before and measure the end gap.

• Check the end gap often as you work, especially when you work with your

first ring.

®

No.1255 piston ring end gap tools file both ends of the

Fig.14 - Rotary ring cutter

Fig.15 - Square ring ends

Flat jeweler’s file:

• It is not necessary to remove material from both ends.

• It is important to get the filed end square. When the two ends are brought

together, they should be as nearly parallel as possible. See Fig.15.

• Devise a method to clamp or control the piston ring as you file it. You could

use a clean smooth-jawed vise, with soft jaws or a machinist’s vise. See Fig.

16.

• An alternate method might be to use a flat, hard, sharp cornered object like

a thick glass plate or even a piece of hard wood. Place the ring end over the

edge of this piece and hold it in place with the pressure of your hand as you

gently remove a bit of material with the file.

• Do not be tempted to do the work in the air using your hand as the vise.

• As you start to file, be sure the file is at right-angles to the end of the ring.

Make the angle between file and ring square from both the top and side.

See Fig. 17.

555 Dawson Drive, Camarillo, CA 93012 Phone 805-482-6913 • Fax 805-482-7422

Fig.16 - Clamp securely

Fig.17 - Square ring end

5

Loading...

Loading...