Jiffy 4G Operating Manual

Model #___________________

OPERATING MANUAL/PARTS GUIDE

Thank You for purchasing a Jiffy Ice Dril l. When properly m aintained

and serviced, we are confident your drill will provi de you with many

years of trustworthy performance. This manual contains operating

and safety instructions for the Jiffy Series Power Ice Drill. To recei ve

the greatest possible performance and satisfaction from your Jiffy

Power Ice Drill, and to reduce the risk of injury, it is important that

you read and understand the assembly, operati ng, maintenance, and

safety instructions before using your Jiffy Power Ice Drill. Contact

Feldmann Engineering if you do not understand any of the

instructions in this manual.

As with any power tool, safet y precautions must be observed with

the Jiffy Power Ice Drill to reduce the risk of personal injury.

Careless or improper use m ay cause serious injury and/or damage

to your Jiffy Power Ice Drill.

INDEX PAGE

General Information …………………….. 1

Warranty………………………………….. 1

Important Safety Precautions ……………. 2

Pre-Use Procedure ……………………... 2

Assembly of Drill…………………………. 3

Oil & Fuel Recommendations…………… 3

Fueling…………………………………….. 3

Check Before Starting Your Drill……….. 3

Starting Instructions……………………… 4

Operating/Stopping Instructions………… 4

Maintenance and Adjustments…………. 4

Service & Repair Information…………… 4

Diagram of Main Parts, Parts List……… 5

MANUFACTURER’S One Year Limited Warr an ty

(30 days for Commercial and/or Rental Use)

FOR WARRANTY SERVICE – DO NOT RETURN

YOUR DRILL TO THE RET AILER YOU PURCH ASED

IT FROM. CALL TH E JIFFY® CUSTOM ER SERVICE

NUMBER AT 800-344-0712, MONDAY – FRIDAY

FROM 7:00 A.M. T O 4:30 P. M . CST , FOR A RETURN

AUTHORIZATION NUMBER AND INSTRUCTIONS.

Feldmann Engineering & Manufacturing Co., Inc. warrants t he Jiffy

Power Ice Drill to be made of fi rst quality mat erials and workm anship

and will, at its option, repair or re place any drill part thereof found to

be defective in such materials and workmanship if returned to the

factory, prepaid within one year from the date of purchase by the

original purchaser. To obtain warranty service or replacement

instructions, you must have prior approval before shipping

package. Call our customer service department at 800-344-0712

Monday – Friday from 7:00 a.m. to 4:30 p.m. for a return

authorization number. Inbound and outbound transportation

charges are paid by the purchaser. Feldmann Engineering assumes

no responsibility for damage caused by misuse, careless handling, or

where repairs were made or attempted by an unauthorized person.

For replacement parts, call 800-344-0712, Monday – Friday from

7:00 a.m. to 4:30 p.m. CST, or go online to www.jiffyonice.com.

Your Jiffy 4G Drill uses a gasoline-fueled 4-stroke engine:

OIL MUST BE ADDED to engine before ice drill is used for the

first time and must be checked and changed regularly after that

(see page 3).

Your Jiffy 4G Ice Drill must be transported, stored or placed on

the ice with engine spark-plug facing upward or with

powerhead in upright (operating) position. Failure to do so may

result in oil leakage, excessive exhaust smoke or engine

damage.

Manufactured by:

FELDMANN ENGINEERING & MANUFACTURING CO., INC.

520 Forest Avenue Sheboygan Falls WI 53085-2513

Phone: 800-344-0712 Monday – Friday from 7:00 a.m. to 4:30 p.m. CST

FAX: 920-467-6169

e-mail:

Other products: TurfVent™ Lawn Aeration Eqt, BADGER™ Earth Augers

admin@jiffyonice.com website: www.jiffyonice.com

Purchased at________________

Date Purchased______________

Serial #____________________

Drill Size__________________

Register online at

www.jiffyonice.com

Form WM4360 (08/12)

-1-

IMPORTANT SAFETY PRECAUTIONS

Please read this manual carefully. Operate your equipment

according to the safety instructions and recommendations found

throughout this manual. Anyone who uses this equipm ent must read

and fully understand the instructions and be familiar with its

operation.

To receive the greatest possible performance and s atisfaction from

your Jiffy Power Ice Drill, and to reduce the risk of injury, it is

important that you read and understand the assembly, operating,

maintenance, and safety instruct ions before using your Jiffy Power

Ice Drill. Contact Feldmann Engineering if you do not understand

any of the instructions in this manual.

Your Jiffy Power Ice Drill is designed and manufactured to provide

safe and dependable operation, provided it is operated in

accordance with the following safety precautions.

Preventing accidents is the responsibi lity of every power equipment

operator. The safety precautions identified i n this manual must be

fully understood and followed by every operat or of this Jiffy Power

Ice Drill. Review the safety precautions frequently and never take

chances.

Take the time to become f amiliar with your Jiffy Power Ice Drill and

its components, then operate it in a safe manner. Study the

appropriate sections of this manual for the description of the controls

and function of your Jiffy Power Ice Drill. Teach the safety

precautions to all persons who use your Jiffy Power Ice Drill.

Avoid mishandling and abuse of your Jiffy Power Ice Drill.

Handle it with care, as any rough treatment can cause damage

to your Jiffy Power Ice Drill or it can cause a malfunction.

Should the engine stop while drilling, do not at tempt to res tart it

while the drill bit is in the hole.

Never attempt to adjust or repair your Jif fy Power Ice Drill while

the engine is running. Avoid possible i njury from moving parts

by first stopping the engine.

+ Never modify your Jiffy Power Ice Drill in any way. Only Jiffy

ice drills and accessories supplied by Feldmann Engineering or

expressly approved by Feldmann Engineering for use with your

Jiffy Power Ice Drill are authorized for connection and use. The

use of non-Jiffy or unauthorized components may cause

damage or injury.

Check the tightness of screws, nuts, and bolts at regular

intervals and re-tighten if necessary.

Do not wear loose clothing while operating your Ji ffy Power Ice

Drill and keep all clothes and parts of the body (hands, feet,

etc.) clear of the rotating ice drill assembly to avoid being drawn

into the boring drill.

By wearing cleated or spiked shoes, or ice creepers when using your

Jiffy Power Ice Drill, you will f ind it easier t o cont rol the rot ati onal torque

as you drill holes in the ice.

Do not allow children to operate your Jiffy Power Ice Drill at any t ime.

Do not allow adults to operate your Jiffy Power Ice Drill without proper

operational instructions, including all safety precautions.

Do not lend or rent your Jiffy Power Ice Drill without providing the

owner’s manual. Be sure that anyone who uses your Jiffy Power Ice

Drill understands the information contained in this manual.

Give your complete and undivided attention to the proper operation of

your Jiffy Power Ice Drill. To operate it properly, you must be in good

physical condition and mental health and not under t he influence of any

substance (alcohol, drugs, etc.) which might im pair vision, dexterity, or

judgment.

+ Using your Jiffy Power Ice Drill may be strenuous. If you have any

condition that may be aggravated by strenuous activit y, check with your

doctor before operating your Jiffy Power Ice Drill.

+ Do not operate your Jiffy Power Ice Drill when you are tired. Fatigue

may result in loss of control.

+ Do not carry your Jiffy Power Ice Drill or leave it unattended while the

engine is running.

Only run your Jiffy 4G Ice Drill in well-ventilated areas.

Jiffy 4G Ice Drill must be transported, stored or placed on the ice

with spark plug facing upward or with powerhead in upright

(operating) position. Failure to do so may result in oil leakage,

excessive exhaust smoke or engine damage. Always allow engine

to cool before storing.

+ When transporting your Jiffy Power Ice Drill in a vehicle, properl y secure

it to prevent turnover, which may cause oil leakage or engine damage.

+ Gasoline is flammable and caution must be used when handling or

storing it.

+ Do not fill the fuel tank while your Jiffy Power Ice Drill is running, if the

engine is hot, or when your Jiffy Power Ice Drill is in an enclosed area.

Always fill the fuel tank outdoors.

Only use your Jiffy 4G Ice Drill for its intended purpose.

PRE-USE PROCEDURE

Before using your Jiffy Power Ice Drill to drill holes in ice, follow this

procedure to prepare for proper and correct use.

• Find, read, and understand the Jiffy operating/parts manual.

• Assemble the components of your Jiffy Power Ice Drill as indicat ed in

the Assembly of Drill section of this manual.

• Re-read and follow the Starting Instructions section of this manual.

• If the engine does not run satisfactorily, or if you feel it needs an

adjustment of some kind, contact Feldmann Engineering for the

proper repair information. Do not attempt to adjust the engine

operation yourself. Only an authorized service person may make

adjustments to your Jiffy Power Ice Drill’s engine without inval idating

the unit warranty.

• DO NOT RETURN your Jiffy Power Ice Drill TO THE RETAILER

THAT SOLD IT TO YOU. THEY ARE NOT AUTHORIZED TO

PROVIDE REPAIRS OR WARRANTY REPLACEMENT. If you have

any questions concerning s ervice, contact Feldmann Engineering as

indicated in the Service & Repair Information section of this manual.

-2-

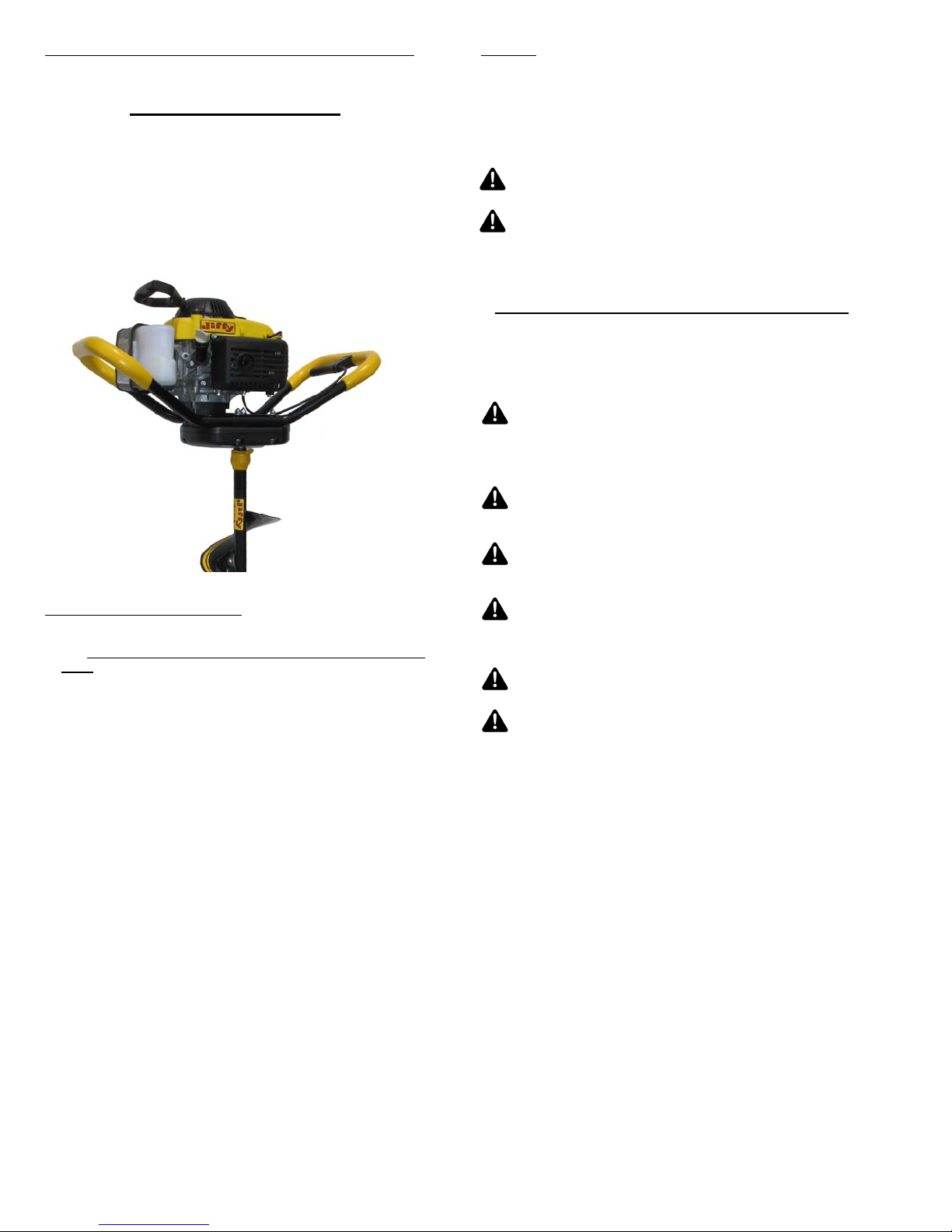

ASSEMBLY AND DISASSEMBLY OF DRILL AND POWERHEAD

Jiffy E-Z Connect™ Collar

Connect drill assembly to powerhead by sliding E-Z Connect™

Collar down and pulling clevis pin out. Then sli de drill assembly onto

output shaft. Reinsert clevis pin through drill assembly and output

shaft, then slide E-Z Connect™ Col lar up and twist collar slightly to

lock pin in place.

Note: Do not remove clevis pin from collar tether.

ENGINE OIL RECOMMENDATION

1. Your Jiffy 4G Ice Drill is powered by a 4-st roke engine. You m ust

add six ounces of Jiffy 4-Cycle 0W40 S ynthetic Oil (Part No.

4288) before starting the engine.

2. Change engine oil at the end of each ice fishing season.

3. Before adding oil to the engine, attach ice drill auger. Place the

powerhead in the upright (operating) position. See Photo Above.

4. Turn oil-fill cap counter-clockwise and remove cap from oil-fill

opening. Note the small oil level indicator on the cap.

5. Slowly pour oil into the engine. Make sure you pour all six ounc es

of oil into the engine.

6. Replace oil fill cap and turn clockwise until it is fastened securely.

7. Check oil level prior to each fishing trip. Add oil as needed. Never

exceed recommended oil level. Over-filling can result in oil

leakage or engine damage.

8. When changing oil, remove oil-fill plug from engine and turn unit

over so oil can be poured into a proper oil disposal container.

After engine oil has been drained, repeat steps 3 – 6 above.

FUELING

1. Gasoline vapor pressure may build up inside of the fuel tank of the

engine depending on weather conditions, the venting system of the

tank, and the fuel used. To reduce the risk of injury from escaping gas

fumes and vapor, remove the fuel cap on your drill slowly to release

pressure build-up.

+ NEVER FILL FUEL TANK INDOORS, W HILE ENGINE IS RUNNING,

OR WHILE ENGIN E IS HOT.

+ NEVER FILL FUEL TANK COMPLETE LY. FILL TANK TO ½ INCH

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE FOR

FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM ENGINE

AND EQUIPMENT BEFORE STARTING ENGINE.

CHECK THE FOLLOWING BEFORE STARTING YOUR DRILL

1. Be sure spark plug wire is ATTACHED to spark plug.

2. Be sure ignition switch is in the RUN (ON) Position.

3. Inspect the machine for proper condition and operation, paying special

attention to the throttle control assem bly, RUN/STOP (ON/OFF) switch,

and drilling assembly.

+ TO REDUCE THE RISK OF INJURY FROM THE TURNING DRILL

ASSEMBLY OR FROM REACTIVE FORCES, THE THROTTLE

ASSEMBLY AND RELATED MECHANISM MUST MOVE FREELY

AND RETURN IMMEDIATELY TO THE IDLE POSITION WHEN

RELEASED.

+ NEVER OPERATE YOUR DRILL IF IT HAS BEEN DAMAGED,

IMPROPERLY ADJUSTED OR NOT COMPLETELY AND

SECURELY ASSEMBLED.

+ NEVER RUN ENGINE IN POORLY VENTILATED AREAS. ENGINE

EXHAUST CONTAINS CARBON MONOXIDE, AN ODORLESS

AND DEADLY GAS.

+ TO REDUCE THE RISK OF INJURY FROM REACTIVE FORCES,

THE OPERATOR MUST HAVE A FIRM GRIP ON THE MACHINE

AND A GOOD FOOTHOLD BEFORE STARTING THE DRI LL AND

OPENING TH E THROTTLE.

+ KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

+ WARNING – TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150° F (65° C) AVOID THESE AREAS TO

AVOID BURNS OR OTHER INJURY.

-3-

STARTING-OPERATION-STOPPING INSTRUCTIONS

COLD STARTING PROCEDURE: Starting engine for the fi rst time or

after engine has cooled off or after running out of fuel.

1. Press primer bulb until gas (return) line is free of bubbles.

2. Check to make sure the rocker switch is in the RUN (ON)

position

3. Move choke lever to FULL CHOKE or (I\I) position.

(operator’s left)

4. Depress throttle control with left hand and grasp the start er

handle in your right hand.

5. Slowly pull starter handle until you feel resistance from

engine, then pull vigorously with short quick pull,

ONCE.

6. Move choke lever to HALF CHOKE and pull starter handle

to start.

7. If engine doesn’t start after 5-6 pulls, press the primer bulb

5-10 times and repeat with steps 5-6.

8. After engine starts running, move choke lever to OFF

position until engine runs smoothly. Leave in half choke

position in extremely cold weather.

9. To stop engine, push rocker switch to OFF or (O) position.

SPECIAL NOTE: If the engine does not start due to extremely cold

temperatures, move unit to warm environment, remove spark plug and

wipe off excess fuel, replace spark plug and repeat steps 1 thru 8.

Please view starting video on Jiffy website

www.jiffyonice.com

USING YOUR JIFFY 4G ICE DRILL

NOTE: To minimize water splash, back-off throttl e when the

drill breaks thru ice, then raise drill slowly.

NOTE: The clutch slips when the drill is overloaded, when this

happens, raise complete unit slightly to ease load.

NOTE: Remove blade protector from drill assembly prior to

drilling. Reinstall when drilling is complete.

NOTE: If drilling additional holes, carry unit in upright

position by handles only, to next location and proceed

with normal starting and operating instructions.

1. When all holes have been drilled, and engine is stopped, l ay

unit down, resting on wing handle with engine spark-plug facing

upward. Disconnect drill assembly from powerhead by sliding

E-Z Connect™ Collar down and pulling clevis pin from drill

assembly. Do not remove pin from collar tether. Slip drill

assembly off of engine output shaft, then re-insert clevis into

drill assembly and slide E-Z Connect™ Collar up t o cover clevis

pin.

2. Reattach blade protector to drill assembly to prevent damage to

the blade teeth and point.

TRANSPORTING AND STORAGE

1. Disconnect spark plug wire from spark plug and keep it away

from spark plug.

2. Make sure all fuel is drained from fuel tank, and fuel cap is

screwed on tight.

3. Always transport and store powerhead in an upright position

and make sure powerhead and drill assembly are properly

anchored to prevent damage.

4. Never store powerhead with fuel in tank indoors or in enclosed,

poorly ventilated enclosures where fuel fumes may reach an

open flame, spark or pilot light as on a furnace, water heater,

clothes dryer, etc.

5. Always transport and store powerhead with powerhe ad in

an upright (operating) position or engin e spark-plug facing

upward. Make sure powerhead and drill assembly are

properly anchored to prevent damage.

MAINTENANCE AND ADJUSTMENTS

Check SPARK PLUG, periodically.

1. Before removing plug, wipe dirt and debris from spark plug base.

2. Remove and inspect spark plug for carbon build up.

3. Replace spark plug if electrodes are pitted, burned, or porcelai n is

cracked. For replacement use: Autolite® 4194 spark-plug or

equivalent. Failure to use proper s park-plug may result in engine

damage.

4. Check spark-plug gap with wire feeler gauge and set gap at .025”.

5. Install spark plug in engine and tighten securely.

Check THROTTLE CONTROL AND CABLE periodically for proper

operation. If needed, use silicon spray to lubricate throttle cable. DO NOT

use WD-40 because it will freeze.

AIR FILTER – The engine has an air cleaner which helps prevent premature

engine wear and failure. Never

filter properly installed. Clean or replace air filter as needed.

REPLACEMENT TEETH – Improper cutting may be due to dul l or dam aged

drill teeth or drill point. Maint ain sharp blade teeth and point. Preserve the

original factory cutting angles when s harpening your drill. File blade teeth

and use a disk sander to sharpen the point. Only genuine

are to be used.

SERVICE & REPAIR INFORMATION

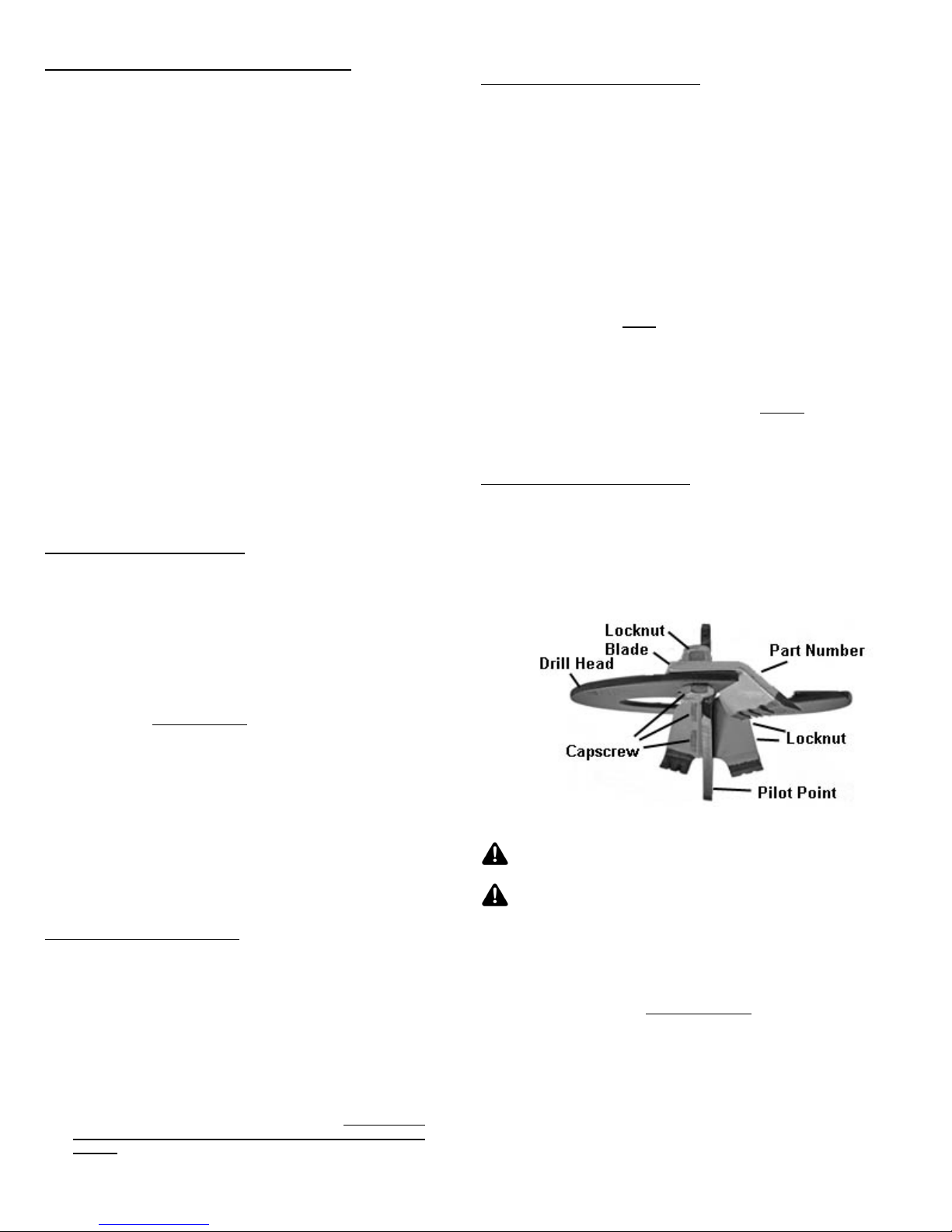

BLADE TEETH REPLACEMENT INSTRUCTIONS – When replacing blade

teeth, the beveled edge of teeth and the head of the capscrews should face

the ice. The stamped part number on the teeth should face away from the

ice, as shown in the diagram. Use two 7/16” wrenches to remove the

capscrews. When attaching blades, finger tighten all fasteners, then fully

tighten with wrenches.

CAUTION – THE BLADE TEETH ARE SHARP AND SHOULD BE

HANDLED CAREFULLY TO AVOID FLESH CUTS OR INJURY.

ENGINE SPEED – NEVER TAMPER WITH ENGINE SPEED

CONTROL SYSTEM, OVERSPEEDING THE ENGINE CAN BE

DANGEROUS AND MAY CAUSE PERSONAL INJURY OR DAMGE

TO UNIT. TAMPERING WITH ENGINE SPEED CONTROL SYSTEM

WILL VOID ENGINE WARRANTY.

For engine adjustments, repairs or warranty service not covered in this

manual, visit our web site at

Jiffy service dealers or call our customer service number at 800-344-0712

Monday – Friday from 7:00 a.m. to 4:30 p.m. CST. When requesting

warranty service, Jiffy® ice drill proof of purchase (sales receipt ) establishes

the date of sale and the start of the warranty period.

run an engine without a com plete, clean air

Jiffy® blade teeth

www.jiffyonice.com, visit one of our authorized

-4-

Loading...

Loading...