Page 1

Page 2

Page 3

Tally Dascom DM-210/220

I

Important Safety Instructions (English)

Read the following instructions thoroughly before starting up your printer.

• Never carry out maintenance or repair work yourself. Always contact a qualified service

technician.

• Keep this Operator’s Manual in a place which is easily accessible at all times.

• Place the printer on a solid and even base so that it cannot fall.

• Never place the printer in the vicinity of inflammable gas or explosive substances.

• Ensure the printer is connected to a socket with the correct mains voltage.

• Always disconnect the printer from the mains before opening the device to perform

maintenance work or remedy errors.

• Do not expose the printer to high temperatures, direct sunlight or dust.

• Keep all liquids away from the printer.

• Protect the printer from shock, impact and vibration.

• Make sure that both of the printer and the computer are switched off before connecting the

data cable.

• The print head will become very hot during printing; avoid contact with the print head after

printing has finished.

• Do not perform any operation or action in any way other than those provided in this manual.

When in doubt, contact your dealer or your customer support.

Page 4

Tally Dascom DM-210/220

II

Wichtige Sicherheitshinweise (German)

Lesen Sie bitte diese Sicherheitshinweise durch, bevor sie den Drucker in Betrieb nehmen.

Führen Sie Wartungsarbeiten und Reparaturen keinesfalls selbst aus, sondern verständigen

Sie immer einen qualifizierten Servicetechniker.

Bewahren Sie diese Dokumentation an einem jederzeit zugänglichen Ort auf.

Den Drucker auf stabilem und ebenem Untergrund so aufstellen, dass er nicht zu Boden fallen

kann.

Stellen Sie den Drucker keinesfalls in der Nähe von leicht entzündlichen Gasen oder

explosiven Stoffen auf.

Den Drucker nur an eine Steckdose mit der richtigen Spannung anschließen.

Wenn Sie den Drucker vom Netz trennen wollen, den Drucker ausschalten und immer den

Netzstecker an der Steckdose ziehen.

Den Drucker weder hohen Temperaturen noch direktem Sonnenlicht und Staub aussetzen.

Keine Flüssigkeiten mit dem Drucker in Berührung bringen.

Den Drucker keinen Erschütterungen, Stößen oder Vibrationen aussetzen.

Sicherstellen, dass der Drucker und der Computer ausgeschaltet sind, bevor das Datenkabel

angeschlossen wird.

Der Druckkopf wird während des Druckens heiß. Vor dem Berühren deshalb einige Zeit

abkühlen lassen.

Weichen Sie bei der Bedienung des Druckers nicht von den Anweisungen in der

Dokumentation ab. Bei Unklarheiten wenden Sie sich bitte an Ihren Händler oder Ihren

Kundendienst.

Page 5

Tally Dascom DM-210/220

III

Consignes importantes de sécurité (French)

Lire attentivement les instructions suivantes avant de mettre l’imprimante en service.

Ne jamais effectuer soi-même les travaux d’entretien et de réparations. Contacter toujours un

dépanneur qualifié.

Placer l’imprimante sur un support stable de façon à ce qu’elle ne puisse pas tomber.

Ne jamais placer l’imprimante à proximité de sources de gaz aisément inflammables ou de

substances explosives.

Ne connecter l’imprimante à une prise que lorsque la tension est correcte.

Pour déconnecter l’imprimante de l’alimentation principale, mettre l’imprimante hors tension

et toujours débrancher le connecteur secteur de la prise murale.

Ne pas exposer l’imprimante à des températures élevées, à la lumière directe du soleil ou à la

poussière.

Ne pas mettre l’imprimante en contact avec des liquides.

Ne pas exposer l’imprimante à des chocs, impacts ou vibrations.

S’assurer que l’imprimante et l’ordinateur sont hors tension avant de connecter le câble de

données.

La tête d’impression est brûlante pendant l’impression. C’est pourquoi laissez-la refroidir

quelques instants avant d’y toucher.

N'exécutez aucune opération ni action d'une autre manière que celle indiquée dans ce

manuel. En cas de doute, veuillez contacter votre distributeur ou service après-vente.

Page 6

Tally Dascom DM-210/220

IV

Indicazioni di sicurezza importanti (Italian)

Prima di mettere in funzione la stampante, leggere attentamente le seguenti indicazioni.

Non eseguire mai da sé gli interventi di manutenzione e riparazione, ma rivolgersi sempre a

un tecnico di assistenza qualificato.

Conservare le presenti istruzioni per l’uso in un luogo sempre accessibile.

Collocare la stampante su una superficie stabile, per evitare che cada a terra.

Non collocare la stampante in prossimità di gas facilmente infiammabili o di sostanze

esplosive.

Collegare la stampante a una presa di corrente con tensione adeguata.

Per scollegare la stampante dalla rete di alimentazione, spegnere la stampante e disinserire

sempre il connettore di rete dalla presa.

Non esporre la stampante ad elevate temperature né alla luce solare diretta e alla polvere.

Evitare il contatto della stampante con liquidi.

Non esporre la stampante a colpi, scosse o vibrazioni.

Verificare che la stampante e il computer siano spenti prima di collegare il cavo di

trasmissione dati.

Durante la stampa, la testina si surriscal-da notevolmente. Prima di toccarla, se necessario

opportuno quindi lasciarla raffreddare qualche istante.

Non eseguire alcuna operazione o azione se non nella maniera descritta nel presente manuale.

In caso di dubbio, contattare il rivenditore o dalla società incaricata dell’assistenza.

Page 7

Tally Dascom DM-210/220

V

Instrucciones de seguridad importantes (Spanish)

Lea las siguientes instrucciones con esmero antes de poner la impresora en servicio.

Nunca lleve a cabo trabajos de mantenimiento o reparación Ud. mismo, sino consulte a un

técnico de servicio calificado.

Guarde las presentes instrucciones de servicio en un lugar de fácil acceso en cualquier

momento.

Ponga la impresora sobre un base estable de manera que no pueda caer al suelo.

Nunca coloque la impresora en la vecindad de gases de fácil inflamabilidad o sunstancias

explosivas.

Asegure conectar la impresora sólo a un enchufe con un voltaje correcto.

Cuando quiera desconectar la impresora de la red, apague la impresora y siempre tire la

clavija de alimentación del enchufe.

No exponga la impresora a temperaturas altas, a la luz solar directa y al polvo.

No ponga la impresora en contacto con fluidos.

Nunca exponga la impresora a sacudidas, choques o vibraciones.

Asegúrese de que la impresora y el ordenador estén apagdos antes de conectar el cable de

datos.

La cabeza de impresión se pone muy caliente durante la impresión. Por lo tanto, deje enfriarlo

algún tiempo antes de tocarla.

No permita que se realice cualquier operación o acción de una forma diferente a lo que se

señala en el manual. En caso de duda, póngase en contacto con su comerciante o con su

servicio post-venta.

Page 8

Tally Dascom DM-210/220

VI

Правила по технике безопасности. (Russian)

Прочитайте, пожалуйста, инструкцию по технике безопасности перед включением в работу

принтера.

Не выполняйте технические работы и ремонт техники самостоятельно, но сообщайте о

неисправностях квалифицированным сервисным техникам.

Данная инструкция должна быть всегда доступна каждому пользователю.

Установите принтер на ровном и стабильном месте так, чтобы он не смог упасть на пол.

Ни в коем случае не ставьте принтер вблизи легко воспламеняющихся газов и

взрывчатых веществ.

Включайте принтер в розетку только с соответствующим напряжением.

Если Вы хотите отключить принтер от напряжения, сначала выключите принтер сам и

затем выньте штекер из розетки.

Берегите принтер от нагревания, от попадания на него прямых солнечных лучей и

пыли.

Не допускайте попадания жидкости на принтер.

Нельзя подвергать принтер тряске, ударам и вибрации.

Убедитесь, что принтер и компьютер выключены, только после этого соедините принтер

с компьютером.

Печатающая головка нагревается во время работы принтера. Поэтому подождите

какое-то время, прежде чем дотронуться до нее.

Пользуйтесь принтером так, как это написано в документации. Если у Вас возникают

неясности, обращайтесь с вопросами к Вашим продавцам или в сервисный центр.

Page 9

Tally Dascom DM-210/220

VII

Instruções Importantes sobre Segurança (Portuguese)

Leia as instruções de segurança antes de usar a impressora.

Consulte sempre um técnico qualificado para executar uma reparação .

Coloque a impressora sobre uma base sólida e nivelada, para que ela não sofra quedas.

Jamais instale a impressora nas proximidades de lugares onde haja gás inflamável ou

substâncias explosivas.

Assegure-se de conectar a impressora à tomada elétrica com a voltagem apro-priada.

Quando desligar a impressora da rede, desligue sempre a impressora e retire o cabo da

tomada.

Não exponha a impressora a temperaturas altas ou luz solar direta.

Não aproxime substâncias líquidas da impressora.

Proteja a impressora de choques, impactos e vibrações.

Desligue a impressora e o computador antes de conectar o cabo da rede.

A cabeça da impressora pode ficar muito quente . Portanto, espere algum tempo antes de

tocá-la.

Não faça nenhuma operação ou ação além das recomendadas neste manual. Em caso de

dúvida, contate seu revendedor ou companhia de serviço.

Page 10

Tally Dascom DM-210/220

VIII

Önemli Güvenlik Talimatları (Turkish)

Lütfen, yazıcıyı işletime geçirmeden önce bu güvenlik talimatlarını bütünüyle dikkatle okuyun.

Bakım ve tamir çalışmalarını kesinlikle ve hiçbir surette kendi başınıza yapmayın; her zaman

kalifiye bir uzman servis-teknisyenine haber verin.

Yazıcıyı, üzerinden yere düşmesi mümkün olmayacak sabit ve düz bir zemine yerleştirin.

Yazıcıyı kesinlikle ve hiçbir surette kolayca yanabilecek gaz veya patlayıcı maddeler içeren

nesnelerin yakınına koymayın.

Yazıcı akım kablosunu sadece doğru gerilime sahip bir prize takın.

Yazıcıyı şebeke ağından ayırmak istediğinizde, yazıcıyı kapatın ve ağ-fişini her zaman prizden

çıkartın.

Yazıcıyı ne yüksek ısılı ne de doğrudan güneş ışığına ve toza mâruz kalan mekânlarda

bulundurun.

Yazıcı hiçbir sıvı maddeyle temasta olmamalıdır.

Yazıcı hiçbir sarsıntıya, darbeye veya titreşime mâruz kalmamalıdır.

Veri kablosu bağlanmadan önce hem yazıcının hem de bilgisayarın kapalı olduklarından emin

olmalısınız.

Yazıcının başı basma esnasında yüksek ısıya ulaşıyor. Bu yüzden lütfen dokunmadan önce kısa

süre soğumasını bekleyin.

Yazıcının işletimi ve kullanımında bu dokümantasyondaki talimatların hiç dışına çıkmayın.

Sorunlu görünen hususlarda lütfen imâlatçınıza veya müşteri hizmetleri servisinize başvurun.

Page 11

Tally Dascom DM-210/220

IX

TRADEMARK ACKNOWLEDGEMENTS

“IBM” is a trademark of International Business Machines Corporation.

“EPSON” is a trademark of Epson America Incorporated.

“DEC” is a trademark of Digital Equipment Corporation.

“Centronics” is a trademark of Centronics Data Computer Corporation.

“DOS” is a trademark of Microsoft Corporation.

“SAP” is a trademark of SAP AG.

“Windows”, “Windows 7”,”Windows 8”, “Windows 95”, “Windows 98“, “Windows NT”, “Windows

2000”, “Windows 2003/2008/2013 Server”, “Windows XP” and “Windows Vista” are trademarks of

Microsoft Corporation.

All other product names and company names appearing in this manual are the registered

trademarks or trademarks of the individual companies.

Page 12

Tally Dascom DM-210/220

X

Page 13

Tally Dascom DM-210/220

TABLE OF CONTENTS

1 PRINTER INSTALLATION GUIDE ................................................................................................... 1

1.1 Unpacking the Printer................................................................................................................ 1

1.2 Placing the Printer ..................................................................................................................... 2

1.3 Printer Components................................................................................................................... 3

1.4 Connecting the Interfaces .......................................................................................................... 4

1.5 Connecting the Power................................................................................................................5

1.6 Loading Paper............................................................................................................................ 6

1.7 Installing Ribbon Cartridge......................................................................................................... 7

1.8 Installing the Printer Driver ........................................................................................................8

2 CONTROL PANEL OPERATION ..................................................................................................... 10

3 TROUBLESHOOTING ................................................................................................................... 12

3.1 Processing Indicator Error........................................................................................................ 12

3.2 Processing Printing Error..........................................................................................................12

3.3 Removing Jammed Paper......................................................................................................... 12

4 SPECIFICATIONS.......................................................................................................................... 13

4.1 Data Sheet............................................................................................................................... 13

4.2 Interfaces................................................................................................................................. 15

4.2.1 USB interface..................................................................................................................... 15

4.2.2 Cashbox interface ..............................................................................................................15

4.2.3 Serial interface .................................................................................................................. 16

4.2.4 Parallel interface................................................................................................................ 16

4.3 Power Supply........................................................................................................................... 18

5 CHARACTER CODE PAGES ........................................................................................................... 19

6 PRINTING CONTROL COMMAND SETS........................................................................................ 26

FCC STATEMENT............................................................................................................................. 27

DASCOM REPRESENTATIVES.......................................................................................................... 28

Page 14

Tally Dascom DM-210/220

1 Printer Installation Guide

1.1 Unpacking the Printer

Open the packaging, lift the printer out of the cardboard box and remove the remaining packaging

material. Check the printer for any visible transport damage and missing items. If you find any

transport damage or any accessories are missing, please contact your dealer for assistance.

Please keep the packaging material for future transportation.

The shipping list varies with different customized order requirements.

1

Page 15

Tally Dascom DM-210/220

1.2 Placing the Printer

Place the printer on a solid, flat, stable surface; ensuring that the printer is positioned in such a way

that it cannot move, and that there is easy access to the control panel and paper input devices. Also

ensure that there is enough space for sufficient ventilation and for the printed output.

When selecting the printer location, observe the following additional instructions:

Never place the printer near to any flammable gas or explosive substances.

Do not expose the printer to direct sunlight. If you cannot avoid placing the printer near a

window, protect it from the sunlight with a curtain.

When connecting a computer to the printer, make sure the maximum recommended cable

length is not exceeded.

Ensure sufficient distance between the printer and any heating devices or radiators.

Avoid exposing the printer to extreme temperature or air humidity fluctuations. Avoid

exposure to dusty environments.

It is recommended the printer is installed in a position which reduces noise exposure to the

work place during printing.

2

Page 16

Tally Dascom DM-210/220

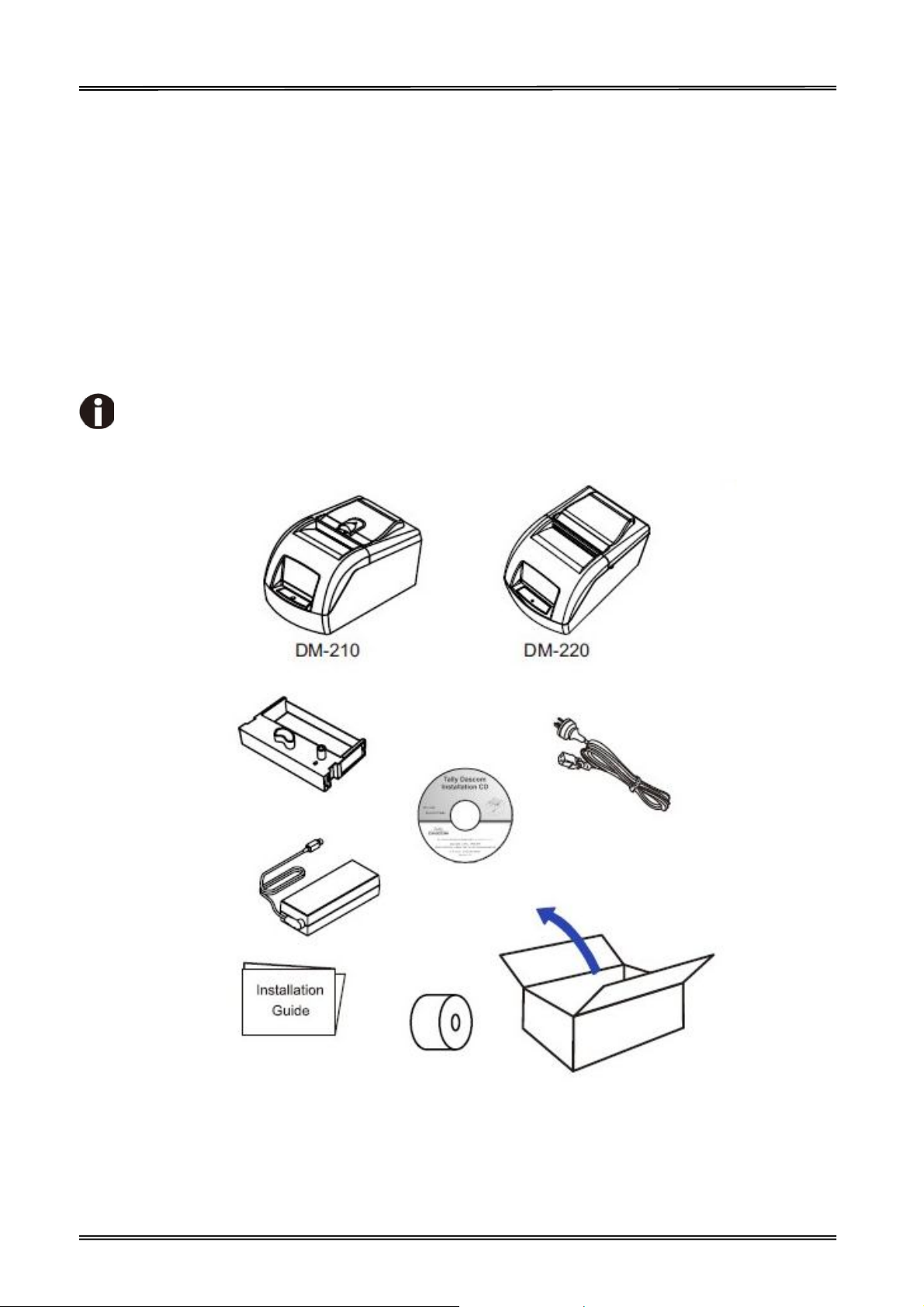

(DM210 only)

1.3 Printer Components

Components Function

Cover Open Key Open the Printer Cover (DM-210 only).

Open the cover when loading or reloading roll paper.

Top Cover

Open the cover when ribbon cartridge

Power Switch Powers printer ON or OFF.

Power Indicator Shows printer power on or not.

Paper End Indicator Shows roll paper out or not.

Feed Key Press the key to feed paper.

Error Indicator Shows error occurs or not.

Control Panel Shows printer status.

Power supply Socket Connects power cord to the printer.

Cashbox Interface Connects Cashbox interface cable from the cashbox.

USB Interface Connects USB interface cable from the host.

Modular Interface Board Connects serial interface or parallel interface from the host.

3

Page 17

Tally Dascom DM-210/220

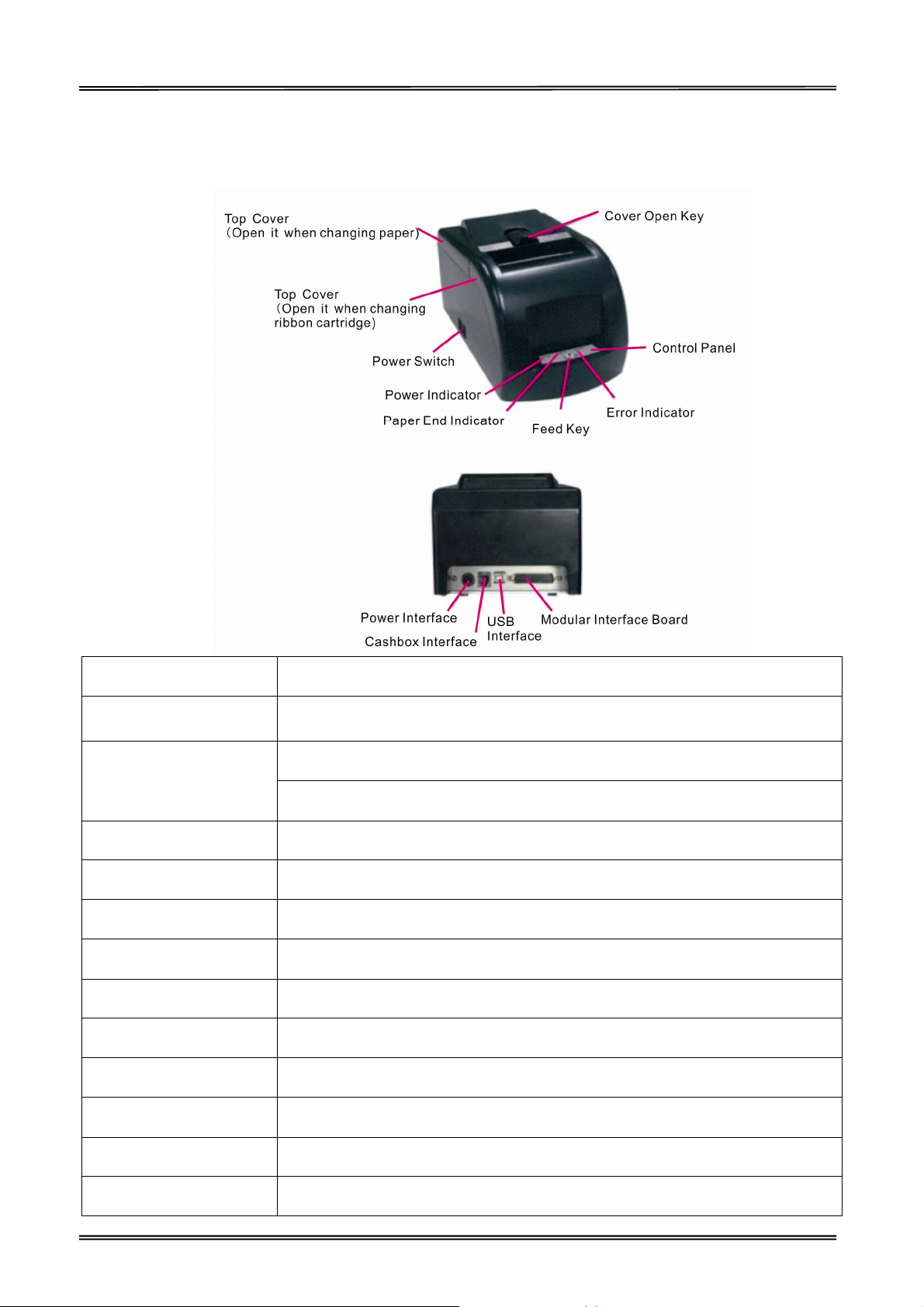

1.4 Connecting the Interfaces

The USB, Cashbox, Serial/Parallel interface are located at the rear of the printer. Choose the

interface which suits your system.

Make sure the printer and the computer are switched off before connecting or

disconnecting the interface cable to prevent electrical damage to the interfaces.

Connecting cashbox interface

Connecting USB interface

Connecting parallel interface (modular, option)

Connecting serial interface (Modular, option)

4

Page 18

Tally Dascom DM-210/220

1.5 Connecting the Power

Checking the printer voltage

Make sure that the device has been set according to your country’s power supply voltage. To

do this, check the rating plate at the rear of the printer. Contact your dealer if the setting is

incorrect.

1. Make sure the printer and the computer are powered off ①.

2. Connect the power cord to the power adapter ②, and connect the power adapter to the power

supply socket at the rear of the printer ③. Ensure the power cord is securely connected. Finally,

connect the power cord plug to a mains socket on the wall ④.

Power on and power off

1. Press the power switch to the “I” position to turn on the printer.

Upon power-on, the Power LED indicator light up.

2. Press the power switch to the “O” position to turn off the printer.

5

Page 19

Tally Dascom DM-210/220

1.6 Loading Paper

1. Keep power on and open the top cover.

2. Insert the end of paper into the entry of paper path, then sent it in with even force until the feeder

motor drives to feed in the paper automatically.

3. Close the top cover

The end of paper should be cut regularly and inserted into the entry of paper path, then sent it

in with even force until the feeder motor drives to feed in the paper automatically.

If paper jams results, pull out the paper when the automatic feeder motor stops. Cut off the

fold side of the paper and reload it.

If black mark is valid, the paper will be fed to the printing initial position.

6

Page 20

Tally Dascom DM-210/220

1.7 Installing Ribbon Cartridge

1. Open top covers to show up the printhead.

2. Turn the ribbon knob on the right side in the direction indicated by the arrow on the cartridge to

remove any slack.

3. Insert the ribbon between the print head and the platen, and press it in until it clicks into place.

4. Turn the knob again to remove any slack.

5. Close the cover.

7

Page 21

Tally Dascom DM-210/220

1.8 Installing the Printer Driver

Installing the Windows Driver (Compatible with Windows)

Switch off the printer before running the printer driver setup.

Your printer CD-ROM comes with Windows drivers. Go to the Drivers folder and run the installer

“DriverSetup.exe”.

Installation guide for USB, serial and parallel driver program

1. Double click the “DriverSetup”. You will see the screen as below. Click “Next” to continue.

2. You might see the screen as below. Select the desired printer driver, and then click “Next” to

continue.

8

Page 22

Tally Dascom DM-210/220

3. Choose the desired port to use, and then click “Next” to continue.

4. Click “Finish” to finish the installation process successfully.

5. You will see the screen as below. Click “OK” to install the printer driver successfully.

9

Page 23

Tally Dascom DM-210/220

2 Control Panel Operation

There are power indicator, paper end indicator, error indicator and feed key in the printer.

When pressing the Feed key, if the black mark detection is off, paper will be fed until Feed key is

released; otherwise, the paper will be fed to the next black mark and stop.

Indicator Illustration

That the green indicator is on indicates that the power is on. Here are the illustrations for error

indicators:

Error

indicator

Blink On Memory Error

Blink Off

Blink Blink

On Blink Paper end

Paper end

indicator

Indications Disposal

Check the SRAM chip, data bus,

address line and selected signal,etc.

The print head is

over-heated

The position of the

carriage is wrong

Recover automatically until the

temperature drops down.

Check the stepper motor of the

carriage, transmission mechanism,

initial position sensor and drive

circuit, etc.

Load paper.

Self-test Printing and Hexadecimal Dumping

Turn off the printer after the ribbon cartridge and roller paper are installed, hold the feed key while

power on, and then the printer will print out the self-test page.

After the self-test completed, if there feed key is pressed, the printer will enter bidirectional printing

adjustment state. If receiving data without pressing feed key, the printer will enter hexadecimal

printing state.

If you do not need to implement the alignment or hexadecimal printing, please switch off the printer

and restart the printer for printer normal operation.

10

Page 24

Tally Dascom DM-210/220

Bidirectional Printing Adjustment

When typefaces are blurred or vertically misaligned, it is necessary to do the bidirectional printing

quality adjustment.

After self-test completed, the alignment parameter for bidirectional printing will change circularly

along with pressing feed key and the printer will print out the reference typeface.

When the printing quality becomes best, in other words, both the upper and lower rows of “H” are

best aligned, you can turn off the power and the printer will save the parameters automatically.

11

Page 25

Tally Dascom DM-210/220

dicator always on and

3 Troubleshooting

Your printer is extremely reliable, but occasionally problems may occur. This chapter provides

information on some of the common problems you may encounter and how you may solve them. If

you encounter problems that you can not resolve, please contact your dealer for assistance.

Read the following instructions before maintenance and avoid operating beyond your capacity, so as

to prevent injury to you and damage to the printer.

3.1 Processing Indicator Error

Phenomenon Potential Problem Solution

Incorrect power supply cable

connections and power outlet

No indicators on

Error In

Paper End Indicator flashes

Error Indicator flashes Print Head overheated Reprint until it cools

The printer does not switch on.

PCB damaged Contact your dealer for assistance

Paper end Reload the roll paper

Check the power supply cable connections and the

power outlet and correct them

Switch on the printer

3.2 Processing Printing Error

Phenomenon Potential Problem Solution

Incorrect roll paper installation Check if the roll paper is installed correctly

Blurred printing or spot

Unqualified roll paper Use recommended roll paper

Paper stucked

Paper can not be fed.

The printer does not switch on.

Open the printer cover, check the paper

path and remove jammed paper

Switch on the printer

Horizon print words missing Printhead pin damaged Contact your dealer for assistance

3.3 Removing Jammed Paper

Turn the printer off and open the top cover.

Open the printer cover and remove the jammed paper.

Printhead may be hot, please move the printhead by moving the carriage.

12

Page 26

Tally Dascom DM-210/220

4 Specifications

4.1 Data Sheet

Print method

Print direction

Resolution

Print speed 4.3lps(4.3 line / sec at 42 columns)

Paper feed

speed

Print

Parameter

Cartridge

Ribbon

Copies

Paper Feed

Memory RAM

Fonts

Detect

Function

Key and

LED Indicator

Power Supply

Paper Handle

Print width

Interface

Power Sleep

Chinese

Alphanumeric

Code page

Black Mark

Detection

Key

Power indicator

Paper indicator

Error indicator

Input

Output

Paper type

Paper width

Paper thickness

Paper roll

diameter

Paper load

Paper cut

9 pin dot matrix (Pin ф0.30mm)

bidirectional logic-seeking

max 160dpiH x 144dpiV

max 5.51ips (14cm/s)

42cpl @ 16.7cpi (7x8 matrix)

Cashbox: DC 24V, 1A, 6 line RJ-11 connector

USB 2.0: Full Speed, standard type B Connector

Serial RS232C: 25-pin Sub-D (f) connector; supports DTR or

XON/XOFF handshaking protocol; baud rate 4800~38400BPS; data

Format 1 initial bit + 8 data bit + 1 or 2 stop bits, no Parity.

Parallel CENTRONICS: 25-pin Sub-D (m) connector, 8-bit parallel;

supports BUSY/ACK handshaking protocol.

Yes

NH37701 (Purple), Lifetime: 3000,000 characters (Compatible to

ERC-39)

NH37703 (Black), Lifetime: 1000,000 characters

1+1 (Thickness: 0.05~0.08mm/page; Total thickness: ≤0.16mm)

Friction feed

Max. 32Kbytes data buffer

GB18030_2000 16x16

7x8 and 9x8 ASCII font

PC437/PC850/PC860/PC863/PC865/PC858

In the direction of paper feed:

Mark height 5mm; Mark width min 12mm;

Mark reflectivity < 10%; Non-mark reflectivity > 75%;

Mark to initial print position: 27mm; Mark to tear position 47mm;

Factory default: Mark detection on the right for receipt face; Can be

changed to left using mark control commands.

Feed key

Green LED

Red LED

Red LED

External power adapter

AC 100V-240V 50-60Hz

DC 24V±5%, 2.1A, A-1009-3P interface

Good quality normal white roll paper or carbonized roll paper

76.2±0.5mm (3 inch)

0.06~0.085mm for single paper

Max. OD ф83mm

ID ф10+2/-0mm

Upward cover open and Easy paper loading

DM-210: Manual tear;

DM-220: Auto-cutter; support full cut and partial cut.

Full cut (Cuts the paper completely)

13

Page 27

Tally Dascom DM-210/220

Emulation

Noise

Operating

condition

Storage

Physical Spec.

Reliability

Software

Function

Certification

condition

Dimensions

Color

Weight

Printhead

lifetime

MTBF

Cutter lifetime

(DM-220 Only)

MCBF

Driver program

Utilities

Partial cut (one point left uncut)

Note: The point length is 2% of the paper width.

ESC/POS Compatible command set

The noise level is less than 50 dBA (to be measured following ISO

7779 and ISO 9296).

0~40℃/40~90%RH

-40~55℃/≤93%RH

156×260×130 (L×W×H mm)

Black

Approx. 1.85kg (excluding roll paper)

150,000,000 characters

100,000 hours

500,000 cuts

Conditions: Paper thickness < 0.16mm

Max frequency: 20 cuts/min

10,000,000 lines

32bit: Windows (Win 7/Vista/XP/2000)

64bit: Windows (Win 7/Vista/XP/2000)

Compatible to the EPSON POS Application (ESC/POS OS)

Setup tool (The printer parameter can be uploaded and

downloaded, and the firmware version updating is supported.)

CCC, CE-Mark(CB, EMV, EMC), UL, FCC, REACH, WEEE/RoHS, GCPO,

Labeling/Packaging and Energy Star

14

Page 28

PIN No.

Description

Classic wire color

1 VBUS

Red

2 D-

White

3 D+ Green

4 GND Black

4.2 Interfaces

Power Supply interface, USB interface and cashbox interface are standard interfaces for the printer.

Serial interface and Parallel interface are optional interfaces for the printer.

The interface pin assignment is listed below.

4.2.1 USB interface

USB interface pin assignment

USB interface connector diagram

4.2.2 Cashbox interface

Cashbox interface pin assignment

Pin No.

1 Structure GND ---

2 Cashbox drive signal Output

3 NC Empty

4 DC +24V Output

5 Cashbox drive signal Output

6 Signal GND ---

Cashbox interface connector diagram

Description Direction

Page 29

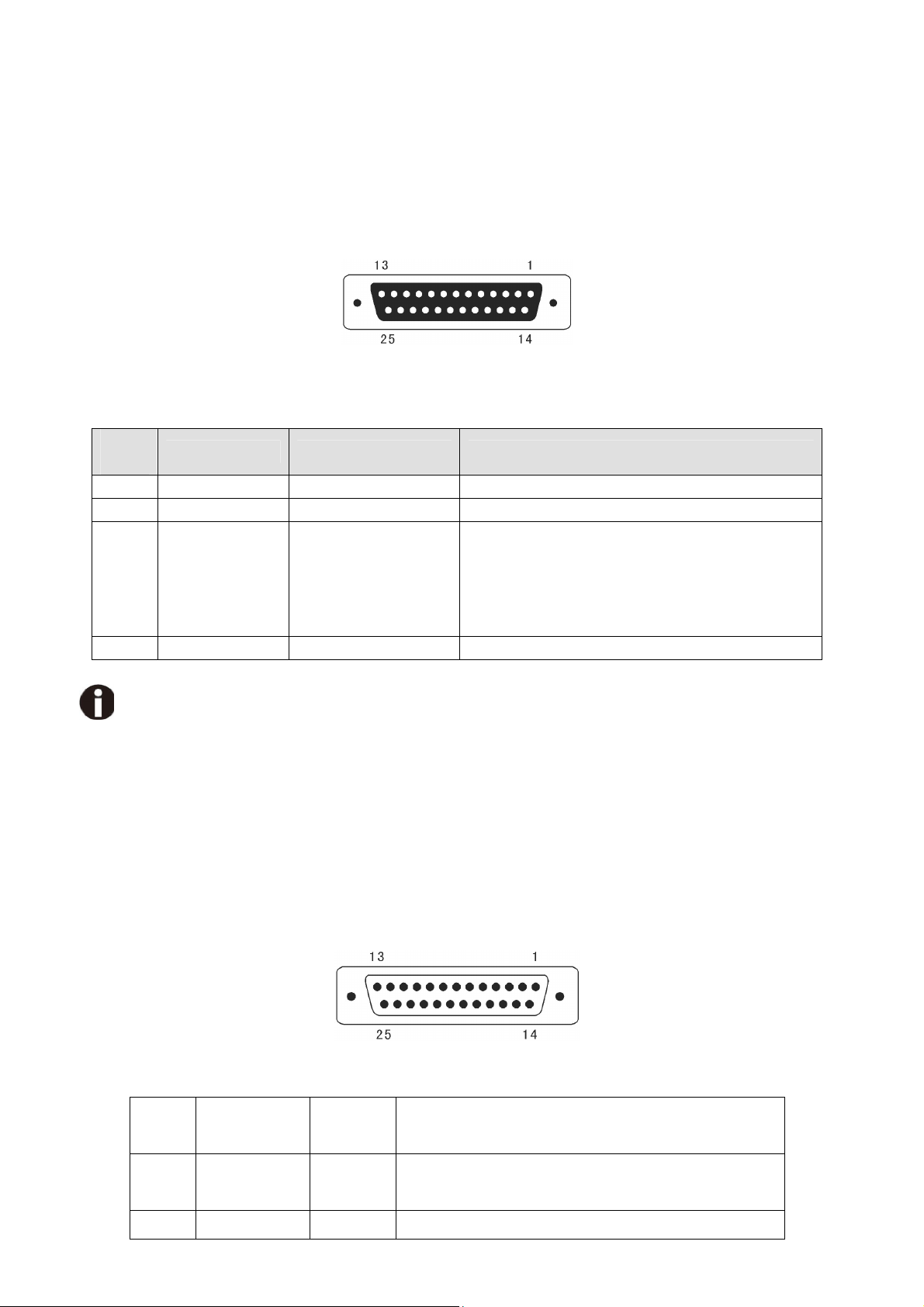

4.2.3 Serial interface

The serial interface of this printer is compatible with RS-232C, use DB25 hole type socket, support

hardware handshaking protocol, the default baud rate and data format are 9600BPS, 8 data bit, no

parity, and 1 stop bit. Below is the pin No of the serial interface socket.

Pin signal definition of serial interface

Pin

No

Signal Name Direction Illumination

2 TXD From printer to PC Send data from printer to PC

3 RXD From PC to printer Printer receive data from PC

When the signal is “negative”, it means that

the printer is “busy” and can not receive

20 DTR From printer to PC

data; While the signal is “positive”, it means

that the printer is “ready” and can

receive the data.

1,7 GND ——— GND

The default baud rate is 9600 BPS and the baud rate can be changed by sending 16 Hex. command 1C

AA 22 XX.

XX: 00 indicates 1200 BPS, 01 indicates 2400 BPS, 02 indicates 4800 BPS,

03 indicates 9600 BPS, 04 indicates 19200 BPS, 05 indicates 38400 BPS.

4.2.4 Parallel interface

The parallel interface of this printer is compatible with CENTRONICS, support BUSY /ACK

handshaking protocol, use DB25 pin type interface.

Pin No. of DB25 pin interface as below

Parallel Interface Pin No.25 Below is the pin signal definition of parallel interface socket:

Pin

Signal Name Direction

Illumination

No

Select trigger, input data when the signal is at

1 /STB Input

falling edge.

2 DATA1 Input These signals indicate the parallel data

Page 30

3

4

5

6

7

8

9

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

DATA8

Input

Input

Input

Input

Input

Input

Input

10 /ACK Output

11 BUSY Output

12 PE Output

13 SEL Output

information from the first to eighth bits. For

each signal, when the logic is “1” indicates “high

level”, when the logic is “0” indicates “low level”.

For responsion pulse, “low” level indicates that

the printer has accepted the data and be ready

for accepting next data.

“High” level indicates that the printer is “busy”

and can not accept data now. “Low” level

indicates “idle”.

Drop down to “Low” level with resistance,

“High” level indicates paper end.

Full up to “High” level with resistance and the

“High” level indicates the printer is online.

15 /ERR Output

Full up to “High” level with resistance and the

“High” level indicates no error.

14 /AUTOFD Input Auto paper feed

16 /INIT Input Initialize the printer

17 /SELIN Input online

18-

GND --- GND,logic “0” level

25

(1) “Input” indicates inputting signals to printer; “Output” indicates outputting signals from printer.

(2) The average logic level of signal is TTL level.Signal Timing Diagram for parallel interface as shown

below:

Page 31

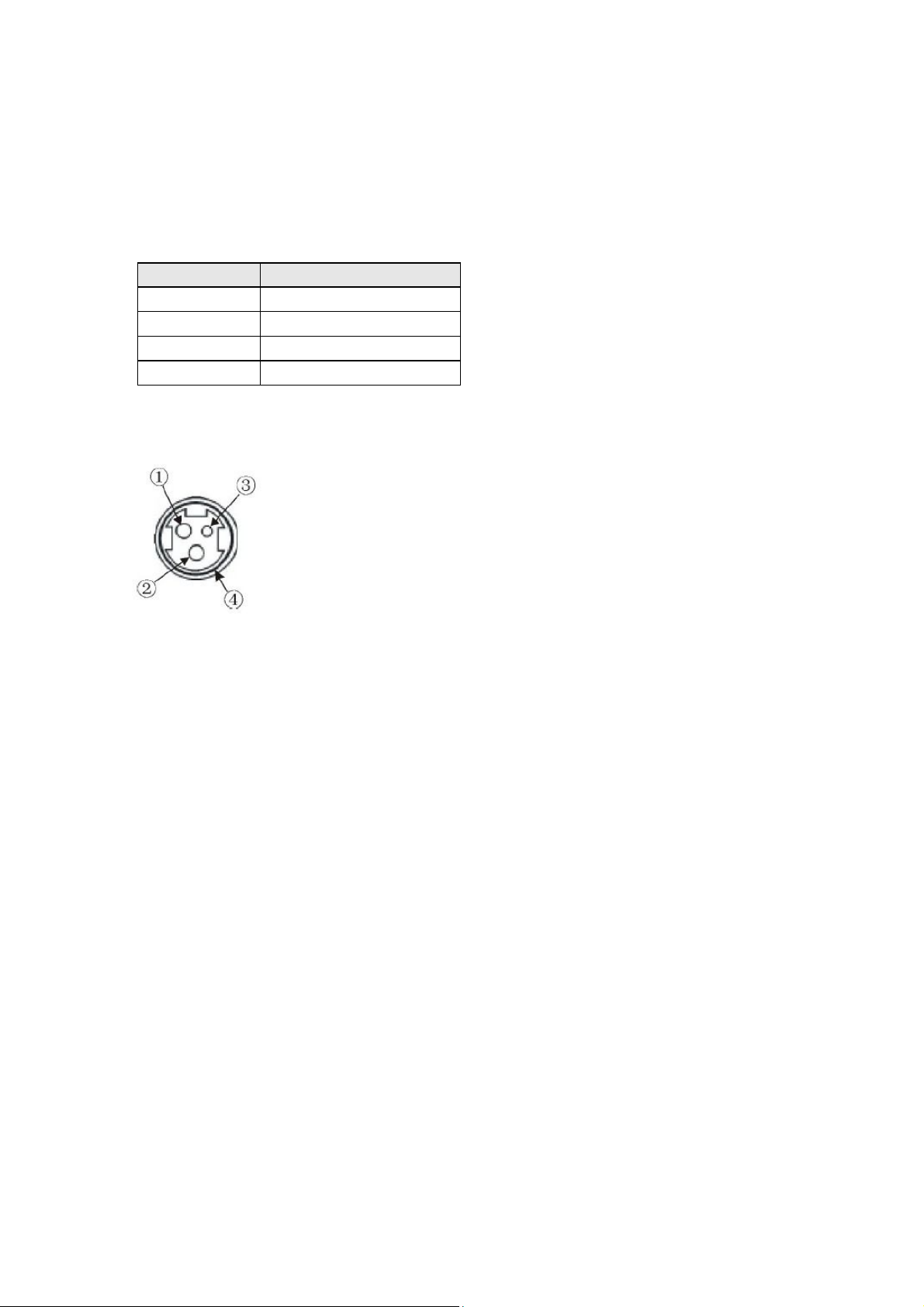

1 +24 V

2

GND

3

N.C

4 F.G.

4.3 Power Supply

The external power supply of this printer is 24VDC,2.1A. The type of power socket is A-1009-3P.

Power supply socket pin assignment

Pin Number

Power supply connector diagram

Signal Name

Page 32

5 Character Code Pages

5.1 Common to all pages (International Character Set: USA)

Page 33

5.2 [PC437: USA, Standard Europe]

Page 34

5.3 [PC850: Multilingual]

Page 35

5.4 [PC860: Portuguese]

Page 36

5.5 [PC863: Canadian-French]

Page 37

5.6 [PC865: Nordic]

Page 38

5.7 [PC858: Euro]

Page 39

Causes the data in the line buffer to be printed and advances the

Causes the line of data to be printed and returns the current

n

6 Printing Control Command Sets

· Be compatible with ESC/POS command set.

List of Commands

ASCII Code Hex Function Illumination

HT 09 Moves the print head to the next horizontal tab position

LF 0A

paper one line.

CR 0D

print position to the left margin.

ESC SP n 1B 20 n Set the space between characters to n/160 inch

ESC ! n

ESC % n 1B 25 n Allow/Prohibit user-defined character

ESC & 1B 26 Set user-defined character

ESC * 1B 2A Set graphic dot matrix

ESC 2 1B 32 Select the line space to 1/6 inch

ESC 3 n 1B 33 n Select the line space to 1/144 inch

ESC < 1B 3C bring the print head back to the left margin

ESC ? n

ESC @

ESC D n NULL 1B 44 n 0 Set/Clear all horizontal tab position

ESC J n 1B 4A n Causes the line of data to be printed and

ESC K n 1B 4B n Causes the line of data to be printed and

ESC R n 1B 52 n Select an International Character Set

ESC U n 1B 55 n Set/Cancel unidirectional printing

ESC c 3 n 1B 63 33 n Select paper end sensor

ESC c 4 n 1B 63 34 n Set to stop printing when paper end

ESC c 5 n 1B 63 35 n Allow/Prohibit feeder key

ESC d n 1B 64 n Causes the line of data to be printed and

ESC e n 1B 65 n Causes the line of data to be printed and

ESC p 1B 70 Produce cashbox drive pulse

ESC t n 1B 74 n Select Character Set

FS !

FS ? c1 c2 1C 3F c1 c2 Cancel User-defined Chinese

FS S n1 n2 1C 53 n1 n2 Set Chinese character space

FS W n 1C 57 n Set/Cancel Four double angle Chinese mode

GS FF 1D 0C Send the black mark paper to the printing initial position

ESC C n 1B 43 n Set the page length to n line space

GS ( F pL pH a m nL nH 1D 28 Set the orientation offset of black mark

FS ( L 1C 28 4C Feed the paper to the cut/tear position

GS V m 1D 56 m Select the cut/tear mode and cut/tear paper

1D 56 m n

ESC i 1B 69 Cut the paper completely

ESC m 1B 6D Cut the paper partially

1B 21 n Set character printing mode

1B 3F n Cancel user-defined character

1B 40 Initialize the printer

advances the paper n/144 inch

advances the paper n/144 inch reversely

advances the paper n line.

advances n line reversely

1C 21 n Set Chinese printing mode

Page 40

FCC STATEMENT

1. This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

a)This device may not cause harmful interference.

b)This device must accept any interference received, including interference that may cause

undesired operation.

2. Changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

This equipment generates uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Re-orientate or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

Consult the dealer or an experienced radio/TV technician for help.

Page 41

DASCOM REPRESENTATIVES

GERMANY

DASCOM Europe GmbH

Heuweg 3

D-89079 Ulm

Deutschland

Tel.: +49 (0) 731 2075 0

Fax: +49 (0) 731 2075 100

www.dascom.com

AMERICAS

DASCOM Americas Corporation

421 W. Main Street,

Waynesboro, VA 22980

USA

Phone:+1 (877) 434 13 77

www.dascom.com

SINGAPORE (ASIA PACIFIC)

DASCOM AP Pte Ltd

21 Bukit Batok Crescent

#29-81, WCEGA Tower

Singapore 658065

Phone: +65 6760 8833

Fax: +65 6760 1066

www.dascom.com

UNITED KINGDOM

DASCOM GB Ltd

Hart House, Priestley Road

Basingstoke, Hampshire

RG24 9PU, England

Phone: +44 (0) 1256 481481

Fax: +44 (0) 1256 481400

www.dascom.com

FRANCE

DASCOM Europe GmbH

117 Avenue Victor Hugo

92100 Boulogne-Billancourt

France

Phone: +33 (1) 73 02 51 98

www.dascom.com

CHINA

JIANGMEN DASCOM COMPUTER

PERIPHERALS CO., LTD

No. 399, Jinxing Road, Jianghai District,

Jiangmen, Guangdong P.R.

China

www.dascom.com

“All rights reserved. Translations, reprinting or copying by any means of this manual complete or in

part

or in any different form requires our explicit approval. We reserve the right to make changes to this

manual without notice. All care has been taken to ensure accuracy of information contained in this

manual. However, we cannot accept responsibility for any errors or damages resulting from errors

or inaccuracies of information herein.”

© 2013 DASCOM Part No: 21.511.902.0040R

Loading...

Loading...