J.H. Emerson CM-3000, CM-3200 User manual

COUGHASSIST

SERVICE GUIDE

Models CA-3000, CA-3200 Models CM-3000, CM-3200

TABLE OF CONTENTS

FRONT PANEL ASSEMBLY REMOVAL..............................................................................................................3

CIRCUIT BOARD REPLACEMENT......................................................................................................................4

PRESSURE GAUGE REPLACEMENT ................................................................................................................5

PADDLE SWITCH ASSEMBLY REPLACEMENT (CA MODELS ONLY) ............................................................5

FRONT PANEL LABEL REPLACEMENT.............................................................................................................6

VALVE ASSEMBLY REPLACEMENT.................................................................................................................. 6

VALVE ACTUATOR MOTOR REPLACEMENT (CA MODELS ONLY)................................................................7

MOTOR BLOWER REPLACEMENT....................................................................................................................8

PROPER GROUND WIRE ASSEMBLY............................................................................................................... 9

FINAL TEST PROCEDURE................................................................................................................................10

COUGHASSIST SCHEMATICS MODELS CA-3000, CA-3200………………………..……………………………12

COUGHASSIST SCHEMATICS MODELS CM-3000, CM-3200………………………..………………………..…14

Page 2 J.H. Emerson Co.

This Service Guide is for use only by qualified technical personnel.

WARNING - Always unplug the CoughAssist from any electrical power before servicing.

FRONT PANEL PARTS REPLACEMENT - Including Front Panel, Circuit Board, Pressure Gauge, Paddle Switch (CA models only), and Front Label

The only front panel parts that may be replaced without removing the Top Cover are the six control knobs (three

on the CM models), and the Manual Control Lever on the CM models only. Each control knob is held in place by

one setscrew. The Manual Control Lever (CM models only) may be carefully pried off of the valve shaft, as it is

held in place by an interference friction fit only.

In addition, the Pressure Gauge may be “zeroed” without removing the Top Cover. The access hole directly below

the gauge is covered by an adhesive sticker, which may be removed. Zero the gauge, with the unit turned off,

using a small straight blade screwdriver. NOTE: If the gauge cannot be set to “0”, it should be replaced.

Access to all other parts on the front panel require removal of the Front Panel Assembly as follows:

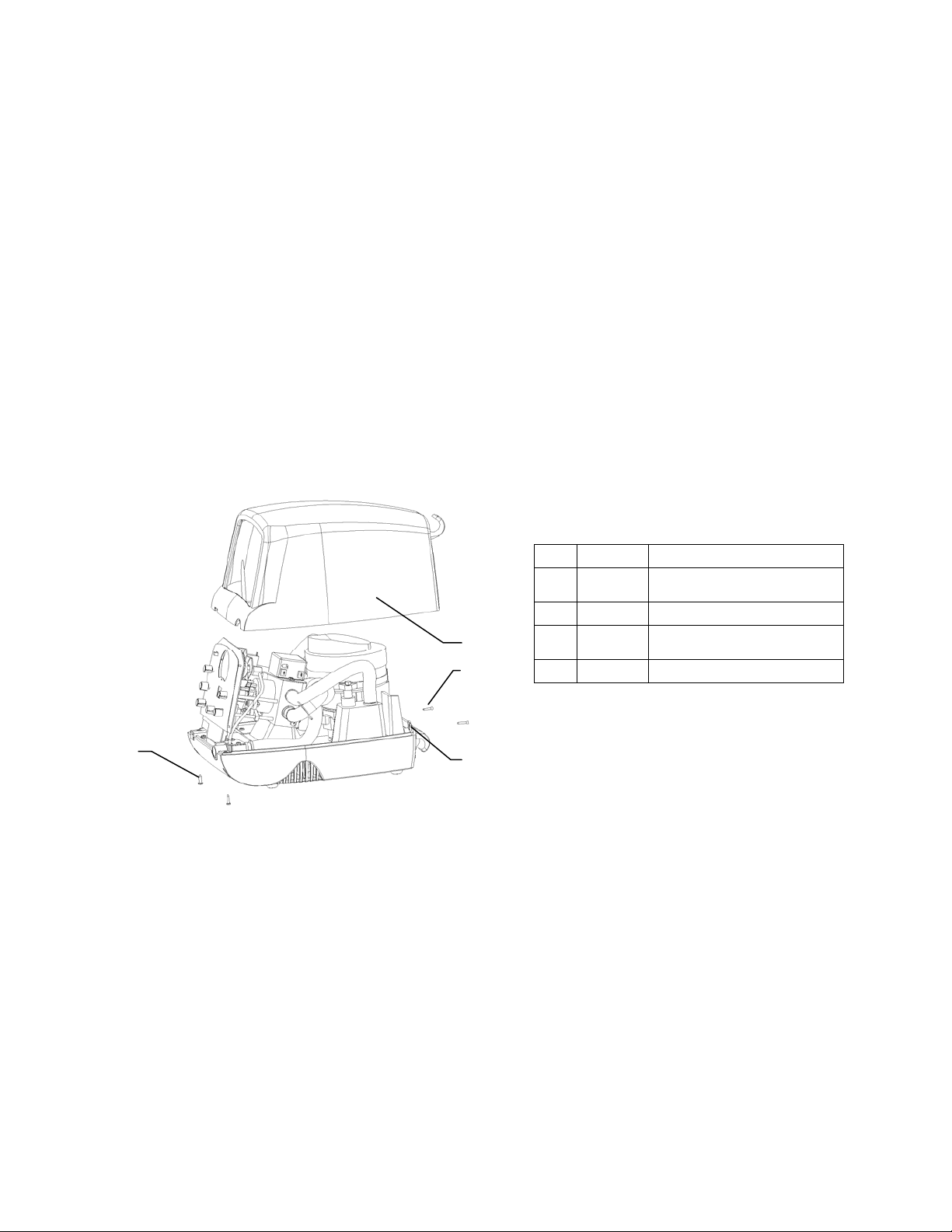

Front Panel Assembly Removal

1. Remove the two flat head screws from the rear of the housing and the two pan head screws from under the

front of the housing. See Figure 1.

Figure 1

Item Part No. Description

1 811-3110

2 325-9204 HOUSING TOP ASSEMBLY

3 813-3110

4 849-3600 TINNERMAN NUT #8 (2 EACH)

SCREW, PAN HEAD 8-32x5/8

(2 EACH)

SCREW, FLAT HEAD 8-32x5/8”

(2 EACH)

1

2. Lift the Top Cover off of the housing.

3. Remove the two control knobs labeled “Inhale Flow” and “Inhale Pressure” on the front panel by loosening

the setscrew on each.

4. On the CM models only, remove the Manual Control Lever by carefully prying it off of the valve shaft.

5. Unscrew the three “plastite” screws holding the panel assembly to the lower housing. See Figure 2. NOTE: A

long Phillips screwdriver is very helpful for access to the three screws.

J.H. Emerson Co. Page 3

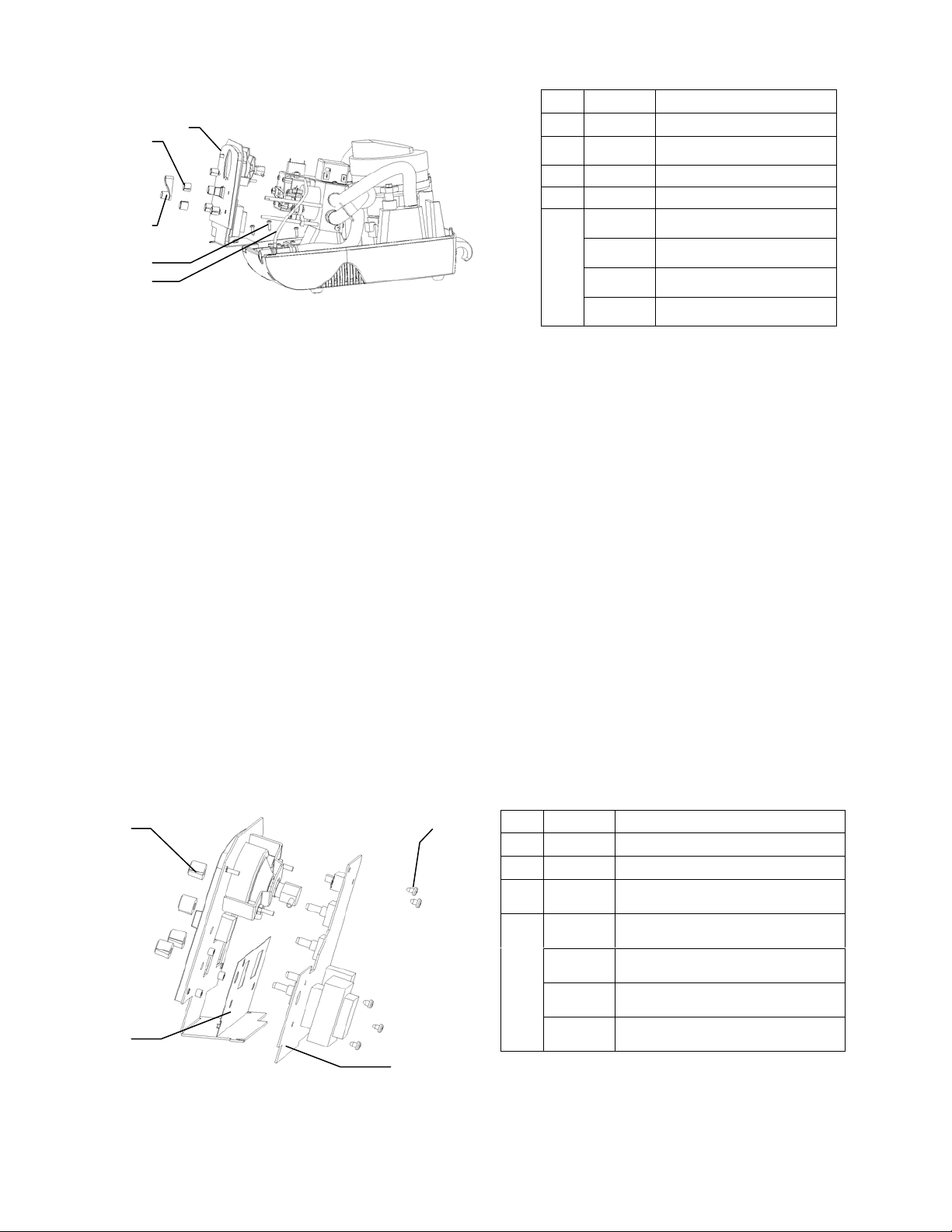

Figure 2

5

4

3

2

1

Item Part No. Description

226-7001 PLASTIC TUBE, 1/8”ID x 8”

1

829-3108

2

325-0252 KNOB, MANUAL (CM only)

3

632-3004 KNOB (2 EACH)

4

325-9202

325-9222

5

325-9226

325-9227

SCREW, PLASTITE #8X1/2”

(3 EACH)

FRONT PANEL ASSEMBLY

FOR CA-3000

FRONT PANEL ASSEMBLY

FOR CM-3000

FRONT PANEL ASSEMBLY

FOR CA-3200

FRONT PANEL ASSEMBLY

FOR CM-3200

6. Slide the panel assembly towards the front, as shown in Figure 2.

7. To completely disconnect the panel from the unit, unplug the three white circuit board connectors (a 6-pin, a

3-pin, and a 2-pin connector), and disconnect the gauge tube from the Pressure Gauge fitting. Also, to

remove the ground wire on the panel, remove the hex nut holding it on the ground stud on the panel

bracket.

WARNING – If the ground wire is removed during servicing, be sure to replace it properly upon reassembly (see

“Proper Ground Wire Assembly”). Failure to do so could result in an electrical shock hazard.

CIRCUIT BOARD REPLACEMENT

1. To gain access to the Circuit Board, first remove the Top Cover and Front Panel Assembly as described

above.

2. Remove the four control knobs (only one on the CM models) by loosening the set screw on each.

3. On the CA models only, unplug the small black circuit board connector next to the Pressure Gauge.

4. Remove the 5 nylon screws holding the Circuit Board to the panel assembly, and slide the board out.

5. To install a new circuit board, first be sure the insulator is resting on the standoffs, as shown in Figure 3,

“Circuit Board Removal”. Slide the board up to the panel, reinstall the five nylon screws, and reconnect the

small black connector next to the Pressure Gauge (CA models only). Also, reinstall the four control knobs

so that the pointers point from 0 to 5 seconds.

Figure 3

2

1

3

4

Item Part No. Description

325-0252 INSULATOR FOR CIRCUIT BOARD

1

632-3004 KNOB (4 EACH)

2

3

4

805-3604

325-9206

325-9223

325-9224

325-9225

SCREW, PAN HEAD, NYLON,

8X32-1/4” (5 EACH)

CIRCUIT BOARD ASSEMBLY

FOR CA-3000

CIRCUIT BOARD ASSEMBLY

FOR CM-3000

CIRCUIT BOARD ASSEMBLY\

FOR CA-3200

CIRCUIT BOARD ASSEMBLY

FOR CM-3200

6. Whenever a new circuit board is installed, the unit must be readjusted for pressure range, as described in

“Final Test Procedure”.

Page 4 J.H. Emerson Co.

PRESSURE GAUGE REPLACEMENT

1. To replace the Pressure Gauge, first remove the Top Cover, Front Panel Assembly and Circuit Board, as

described above.

2. Remove the four 4-40 screws holding the Front Panel Spacer to the bracket, as shown in Figure 4.

Figure 4

4

3

5

Item Part No. Description

1 510-0106 BARBED ELBOW, 1/4FPT X 1/8”

2 325-9212 PADDLE SWITCH ASSEMBLY

3 901-8003

325-9228

4

325-9229

5 501-1011 PRESSURE GAUGE WITH BRACKET

6 811-0104

7 325-0204 FRONT PANEL SUPPORT BRACKET

LABEL – COVER GAUGE ADJUST

HOLE

FRONT PANEL SPACER WITH LABEL

FOR CA

FRONT PANEL SPACER WITH LABEL

FOR CM

SCREW, PAN HEAD, 4-40 X 1/4”

(4 EACH)

3. Loosen the two hex nuts holding the gauge bracket, slide the gauge bracket aside, and remove the gauge

from the front panel bracket. NOTE: On CA models only, take note of how the Paddle Switch Assembly

wires are routed around the Pressure Gauge so they can be placed properly when the gauge is replaced.

4. To install a new gauge, first remove the clear plastic lens from the new gauge by unscrewing it from the

gauge case. Position the gauge in the front panel bracket and install the gauge bracket, tightening the two

hex nuts. NOTE: Do NOT over tighten the gauge bracket nuts. Doing so can warp the front panel bracket.

5. Replace the Front Panel Spacer and Circuit Board Assembly.

6. On CA models only, reroute the Paddle Switch Assembly wires between the gauge and gauge bracket near

the bottom of the gauge, and then around and over the top of the gauge. Reconnect the switch assembly

wires to the small black connector on the circuit board next to the pressure gauge.

PADDLE SWITCH ASSEMBLY REPLACEMENT (CA MODELS ONLY)

1. To replace the Paddle Switch Assembly, first remove the Top Cover and Front Panel Assembly, as

described above. It is not necessary to remove the Circuit Board Assembly.

2. Unplug the small black connector on the circuit board next to the pressure gauge. Slide the wires out from

the gauge bracket. Press the switch out of the panel spacer from behind.

3. To install a new switch, slide the wires through the hole in the panel from the front and press the switch in

place. Be sure to orient the switch with the wires on the top row of switch contacts.

4. Route the switch wires between the gauge and gauge bracket near the bottom of the gauge, and around

the top of the gauge. Reconnect the small black connector to the circuit board near the pressure gauge.

5. Check that the wires on the switch assembly do not extend beyond the ends of the switch contacts, but lead

directly up towards the gauge. This is necessary to ensure that the wires do not interfere with the valve

assembly.

J.H. Emerson Co. Page 5

Loading...

Loading...