With User to Create Better Product

This manual is only for JGMAERK Magic desktop 3D printer

Magic USER MANUAL

Version:A0

With User to Create Better Product

1

Content

Introduction

1, Attention

1.1 User Safety Issue

1.2 Power Requirements

....................................................................................................................

........................................................................................................................

.........................................................................................................................

..................................................................................................................

1.3 Printer Environmental Requirements

1.4 Filament Usage and Storage

1.5 Important Announcement

2, Product information

2.1 Machine specs

2.2 Machine parts

2.3 Tool box list

3, Machine Assembly

.............................................................................................................................

.............................................................................................................................

.................................................................................................................................

........................................................................................................

......................................................................................................

..........................................................................................................

.........................................................................................

.......................................................................................................

3

4

4

4

4

5

5

6

6

6

7

8

3.1 Machine Parts

3.2 Assembly step

3.2.1 remove packaging

3.2.1 Assembly

3.2.1 cable assembly

.............................................................................................................................

.............................................................................................................................

................................................................................................................................................

4, Printing Instruction

4.1 Main Menu Introduction

4.1.1 Control Panel

4.1.2 Function Introduction

4.2 Operating procedures

4.3 Operating Instructions

4.3.1 Input Power Voltage Adjustment

4.3.2 Leveling

4.3.3 Filament loading

4.3.4 Model printing

4.3.5 Filament Change

4.3.6 Power Failure Recovery Printing

..................................................................................................................................................

...................................................................................................................................

.......................................................................................................................................

......................................................................................................

..........................................................................................................

.........................................................................................................................................

............................................................................................................................

...............................................................................................................

..............................................................................................................

..........................................................................................................

....................................................................................................................................

.......................................................................................................................................

....................................................................................................................................

...........................................................................................................

8

9

9

10

16

18

18

18

18

20

21

21

22

23

24

24

25

5, slice software

...............................................................................................................

26

With User to Create Better Product

2

5.1 software install

..........................................................................................................................

26

5.2 soft instruction

..........................................................................................................................

6, Common Problems and Solutions

7, 3D Printer Maintenance

7.1. Daily maintenance

7.2. Basic maintenance

7.3. Maintenance of Moving Components

8, Supports and service

..............................................................................................

...................................................................................................................

...................................................................................................................

...................................................................................................

..............................................................................

.....................................................................................

27

31

32

32

32

33

34

With User to Create Better Product

3

Introduction

This manual includes detail information of JGMAKER 3D printer Magic use procedure, notice and

maintenance.for user’s safety and make the good use of printer,please this manual carefully before use printer.

Please keep this manual in place, if you lose it you can find it in below two place:

1、In the SD card we had stored a electronic version manual;

2、In our official website (www.jgaurora3d.com) you find the user manual;

Thanks for choice JGMAKER 3D printer, we pledge to provide quality product and service. When in use have

any question, please contact US.

Notes:every printer had been tested before sent out,So there is filament residue on nozzle or sightly scrape

on platform, it would not affect use.

With User to Create Better Product

4

1.1 User Safety Issue

Forbidden to somewhere near flammable gas, liquid and dusty area;

Forbidden for children or untrained people to use the machine alone;

When machine running,forbidden to touch model and nozzle, to avoid scald;

When machine running,forbidden to hands inside machine to avoid pinch;

If machine running over 96 hours, must stop for 1-3 hours;

Make sure connect to ground, don’t modify the plugin, to avoid any damage, electric shock and fire

accidence;

Please the cable we provided, can’t use unqualified power cable;

Spare machine for a long time, please disconnect the cable;

Please in ventilated dry area, to avoid humid and sun cause plastic aging;

When remove support material, high recommend to wear goggle;

Before turn on machine, make sure SD card is removed to avoid any malfunction.

Avoid remove SD to frequently,before insert SD card,must cut off the power for 10 second ,then turn on

machine and insert SD card.

Please keep the package intact,for maintenance purpose.

power plugin should connect to ground.don’t modify the plugin, to avoid any damage, electric shock and fire

accidence.

working voltage is AV 110~230V with 50HZ AC,;

Note:①before machine assembly,please check the machine power voltage is suitable for power supply voltage in

your area.(how to check:through observe hole at the bottom of base, can the voltage switch, if voltage is 220V, it

will show 230V, if it is 110V, it will show 115V. the operation detail is in 3.1 Input Power Adjustment; ②turn off

and on should have time interval over 5 second.

temperature:5℃~40℃,humidity:20%~50%。

attend:under this range machine can work well;if over,might affect the printing result!

If temperature is too low or high, can adjust the hot bed temperature, or slice temperature to reach good

printing result.

1, Attention

1.2 Power Requirements

1.3 Printer Environmental Requirements

With User to Create Better Product

5

1.4 Filament Usage and Storage

Filament Usage : when using machine , please JGMAKER filament. If use third party filament, and cause

damage, will not under our warrant。

Filament Storage:filament should be stored in seal. If not need to use filament, please tear the package,

and store in dry place without dust.

If not obey instruction of any clause in this manual, and cause damage, hurt or accident, we have no

responsible to the result.

This manual’s copyright below to JGMAKER, will no allow any non authority copy.

different batch might slightly different in outlook,some detail improvement might not be informed, contact

our after sales service for detail information.

1.5 Important Announcement

With User to Create Better Product

6

2.1 Machine specs

⑥LCD screen

③filament holder

④Heated bed

① Filament break

⑦USB port

⑧feeding suite

⑨x motor

②extruder suite

⑪SD card slot

⑩leveling nut

⑫ Z axis motor

⑤Rotary button

Model:Magic

Machine size:443*450*472mm

Layer thickness: 0.05~0.3mm

Machine weight:8kg

Print speed:10~150mm/s

(recommend 30~60mm/s)

Packing size:550*465*175mm

Nozzle Temp.:Room temp to 240’C

Packing weight:9.6kg

Nozzle diameter:0.4mm

Build volume:220*220*250mm

Hotbed temp.:Room temp. To 110’C

Platform material:FA special made platform

Filament:PLA/ABS/Wood ect.

LCD screen:blue rotary button

Filament Diameter :1.75±0.05mm

Print:SD card /USB cable

Software language : English, Spanish,France ect.

File format:STL、OBJ、G-Code

Environment : temp.5’C-40’C , humidity

20~50%

Operation system:Windows7/Windows10/XP

Power specs:AC 110/220 for choice

Slice software:Cura/JGcreat(64bit)

2, Product information

2.2 Machine parts

With User to Create Better Product

7

2.3 Tool box list

Reader

SD card

Wrench 7

Wrench 8-10

Allen wrench

Power cable

Screw

钉

T nut

钉

USB cable

Blade

Mark:The others are spare parts or gift

With User to Create Better Product

8

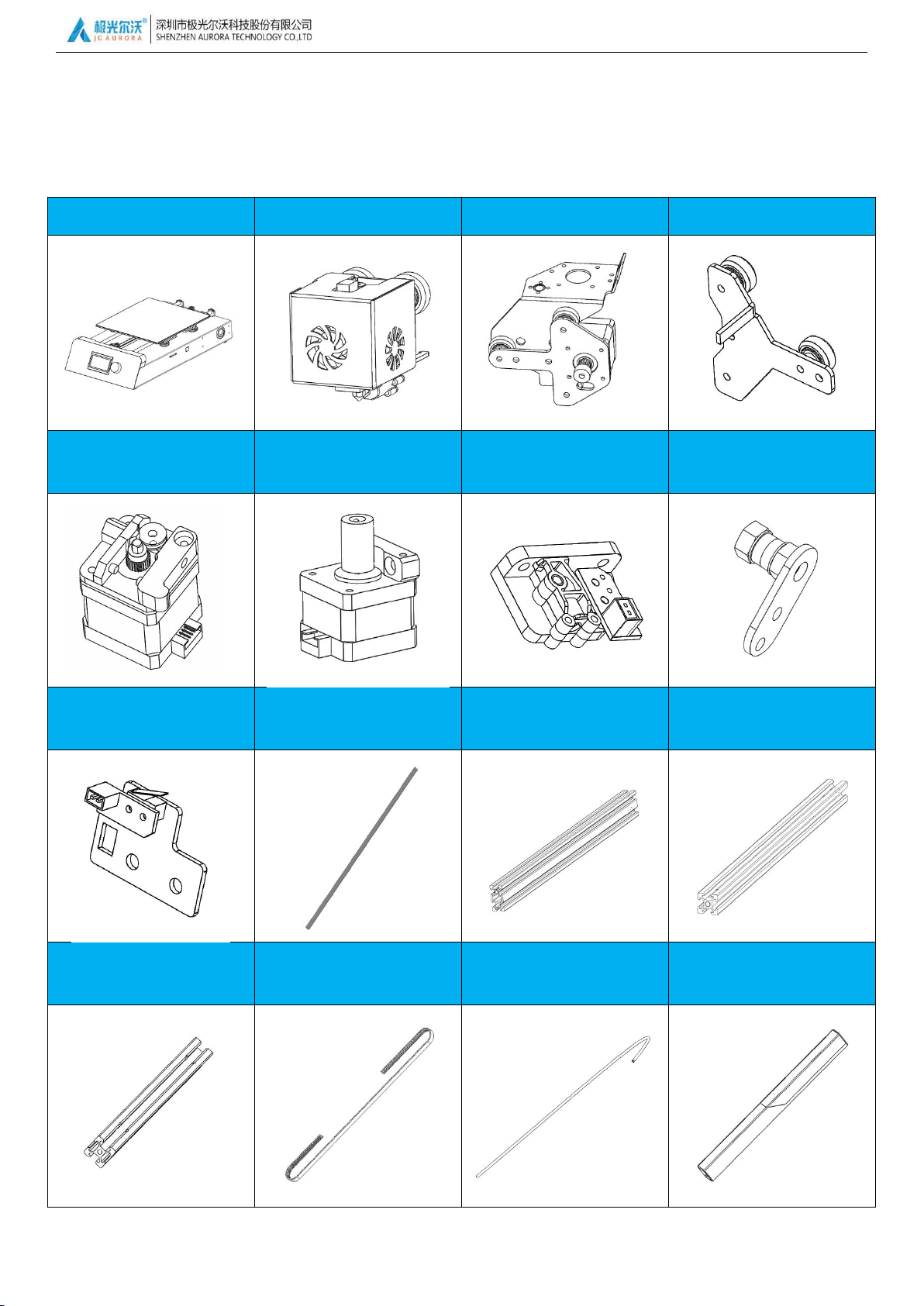

3.1 Machine Parts

1.Y box

2.Extruder suite

3.X right module

4.X left module

5. Feeding motor module

6.Z motor module

7 Filament break detection

module

8.Idler module

9.Z limited witch seat

10.T Lead Screw

11.2040 aluminium profile

12.2020

aluminium profile-340

13.2020aluminium profile-3

50

14.Timing belt

15.Feeding pipe( for

extruder)

16.Top decoration panel

3, Machine Assembly

With User to Create Better Product

9

17.Filament stand

18.User manual

Note :different batch

might slightly different

in outlook,some detail

improvement might not

be informed,Thank

you!

3.2 Assembly step

Step 1:Taking out all parts from box;

Step 2:checking list,pls reference 3.1 machine parts for list&pics;

Step 3:Checking tool and screw list, details as followin listing;

Item

Name

quanitty

pic

①

Hexagon socket bolt with semicircular head M5*8

6pcs

②

Hexagon socket bolt with cylindrical headM5*40

4pcs

③

Hexagon socket bolt with cylindrical head M5*25

4pcs

④

Hexagon socket bolt with cylindrical headM3*8

2pcs

⑤

T nut M5

2pcs

⑥

Wrench 8-10

1pc

⑦

Wrench 7

1pc

⑧

Allen wrench

4pcs

⑨

Reader

1pc

⑩

Memory card

1pc

⑪

Power cable

1pc

⑫

USB cable

1pc

⑬

Blade

1pc

3.2.1 remove packaging

With User to Create Better Product

10

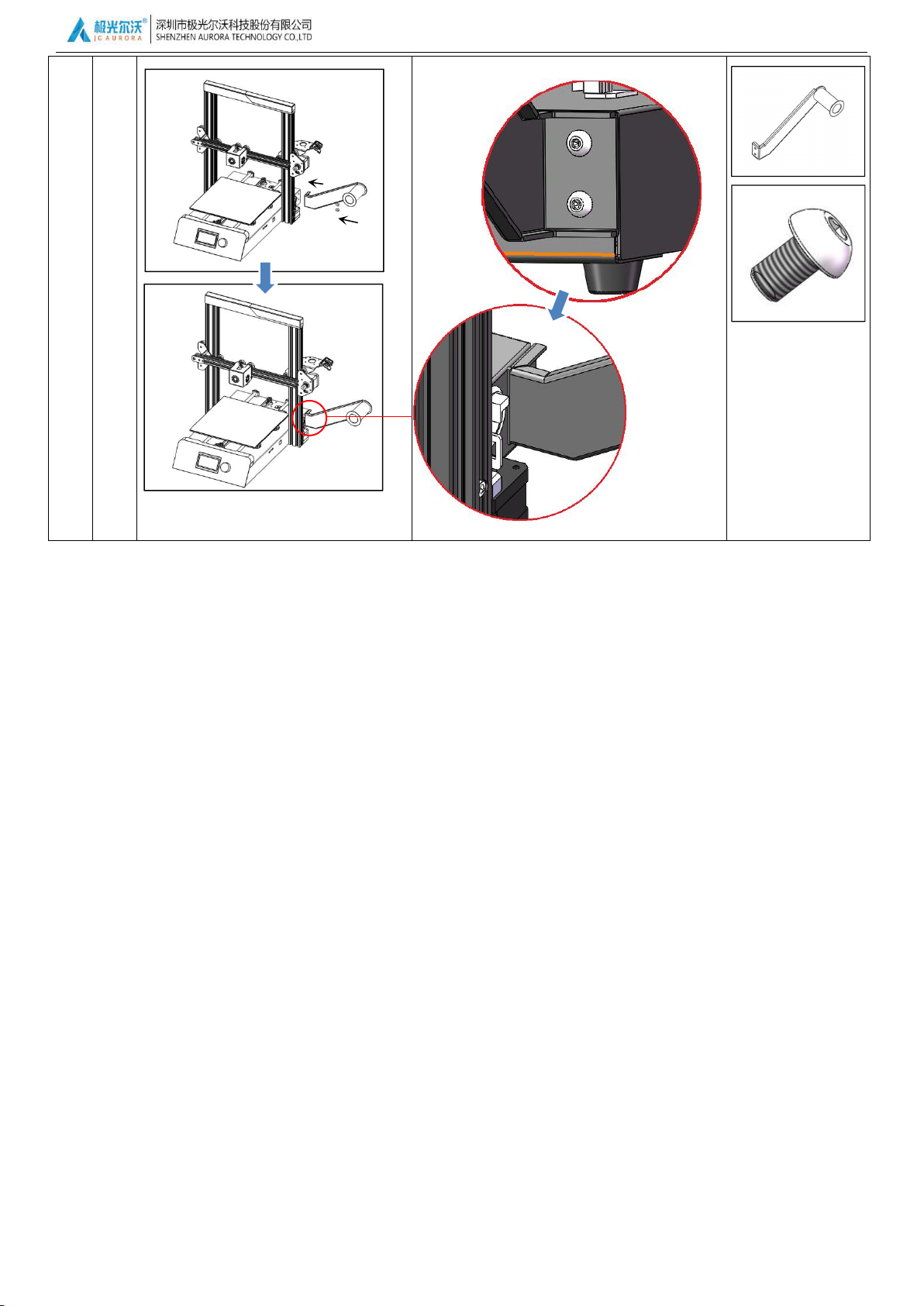

3.2.1 Assembly

For more detail, you can contact our after sales.

suite

step

Assembly process

detail

parts

X

axis

1st

2nd

long

short

4. X left module

3. X right module

13. 2020aluminum

profile-350

2. Extruder module

14. Timing belt

8. Idler module

Note: put the timing belt into the

profile groove first, then,assemble

the extruder module

Note:long or short

means distant of

install hole position。

With User to Create Better Product

11

Suite

Step

Assembly process

Detail

Accessories

Z

axis

1st

2nd

6.Z-axis Motor Suite

9. Z-axis Limit

switch Base

11. 2040 aluminum

profile

11. 2040 aluminum

profile

1. Printer Base

Note : The profile side with the

counterbore is placed on the

outside of the machine.

Cheese head

M5*40

Note:1. The profile side

with the counterbore is

placed on the outside of

the machine.

To easy install the Z-axis

limit swithc base, the

coupling can be remove

first

Couple

With User to Create Better Product

12

Suite

Step

Assembly process

Detail

Accessories

print

er

1st

2nd

12. 2020 aluminum

profile-340

Note: If the installation

holes is not correct, you

can loosen the two

screws in the right

picture and re-lock after

installation.

①

②

screw M5*25

With User to Create Better Product

13

print

er

3rd

4th

10. T type screw rod

Note: After the T-type screw

rod is installed in the

coupling, please tighten the

screws to ensure that the

machine is properly driven.

16. Top decoration

Button-headed

M5*8

Screw position

With User to Create Better Product

14

print

er

5th

6th

7. Filament Sensor

Base

screw M3*8

5. Feeding Suite

Note:When installing, the 3pcs screw on

the component should be unscrewed, the

feeding device and the motor should be

loaded from the top and bottom of the

mounting sheet metal, then reinstall the

Place the other end of the white

guide tube into the feed motor

in the direction of the arrow.

With User to Create Better Product

15

print

er

7th

17. Filament Holder

Button-headed M5*8

With User to Create Better Product

16

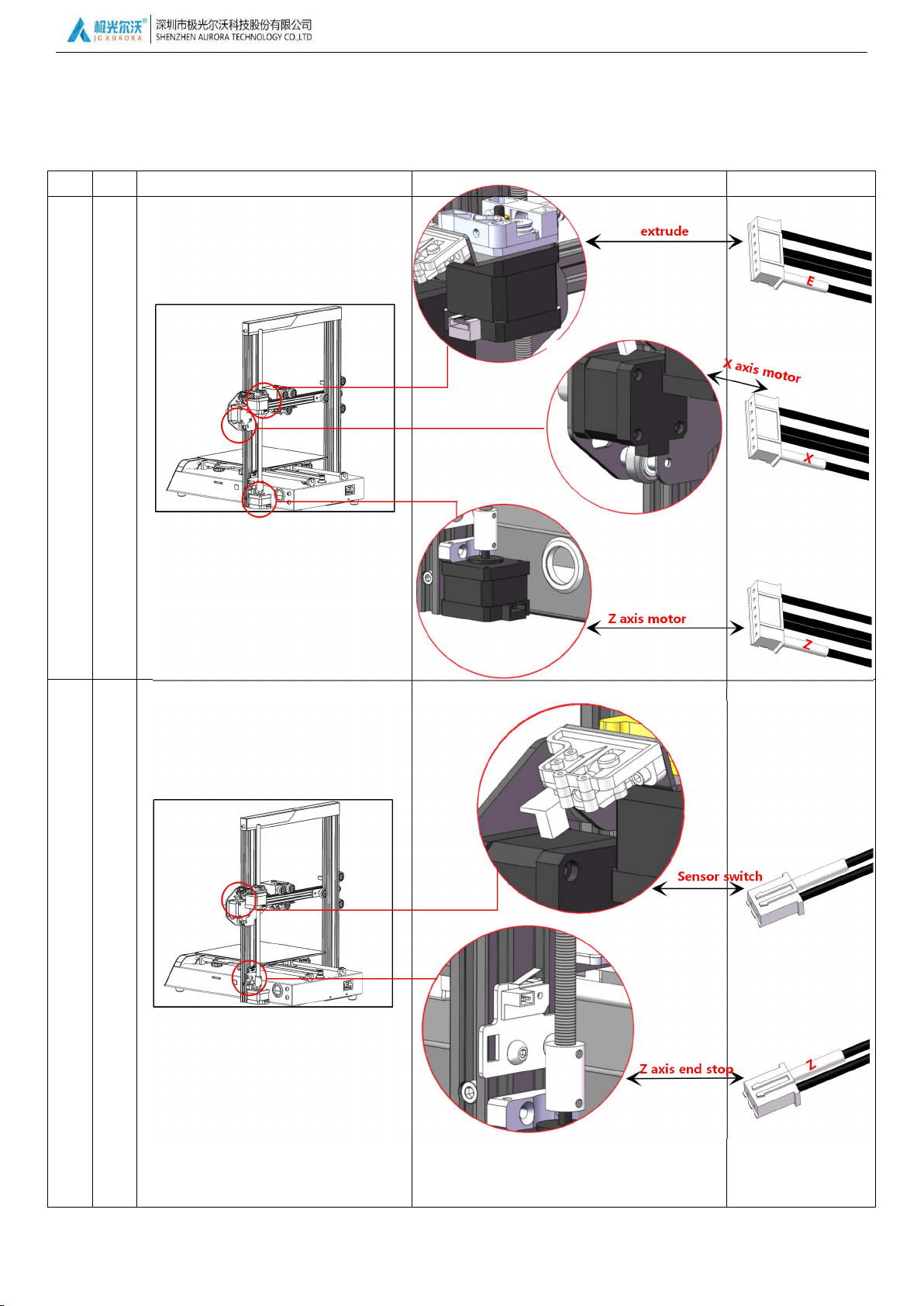

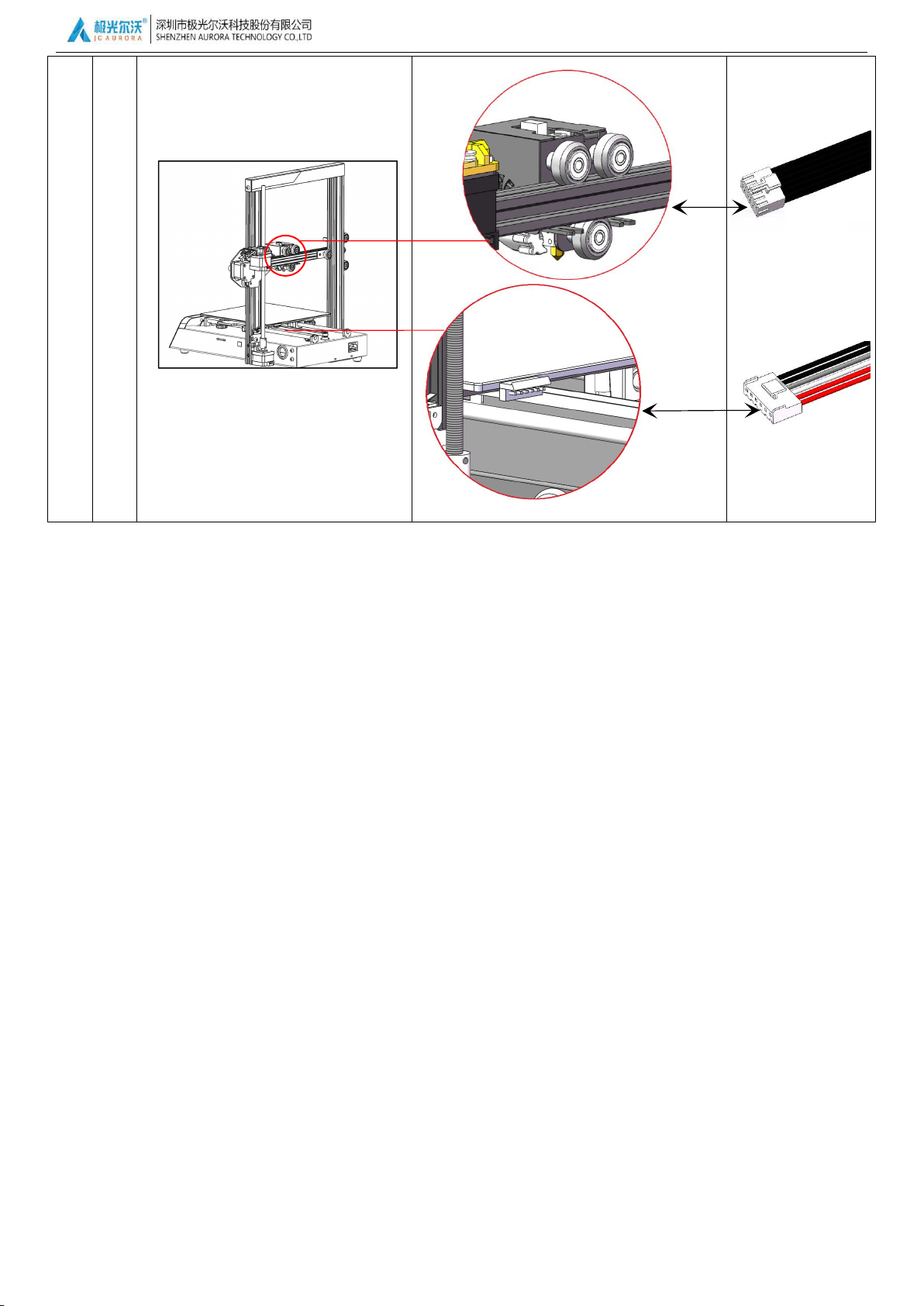

3.2.1 cable assembly

Please refer to the table below or see the installation video of the SD card for the specific process of plugging the cable. If

you do not understand, please contact our after-sales service at the end of this manual.

suite

step

Assembly process

detail

cable

接

线

第

一

步

接

线

第

二

步

With User to Create Better Product

17

第

三

步

eturder

Heated bed

With User to Create Better Product

18

4, Printing Instruction

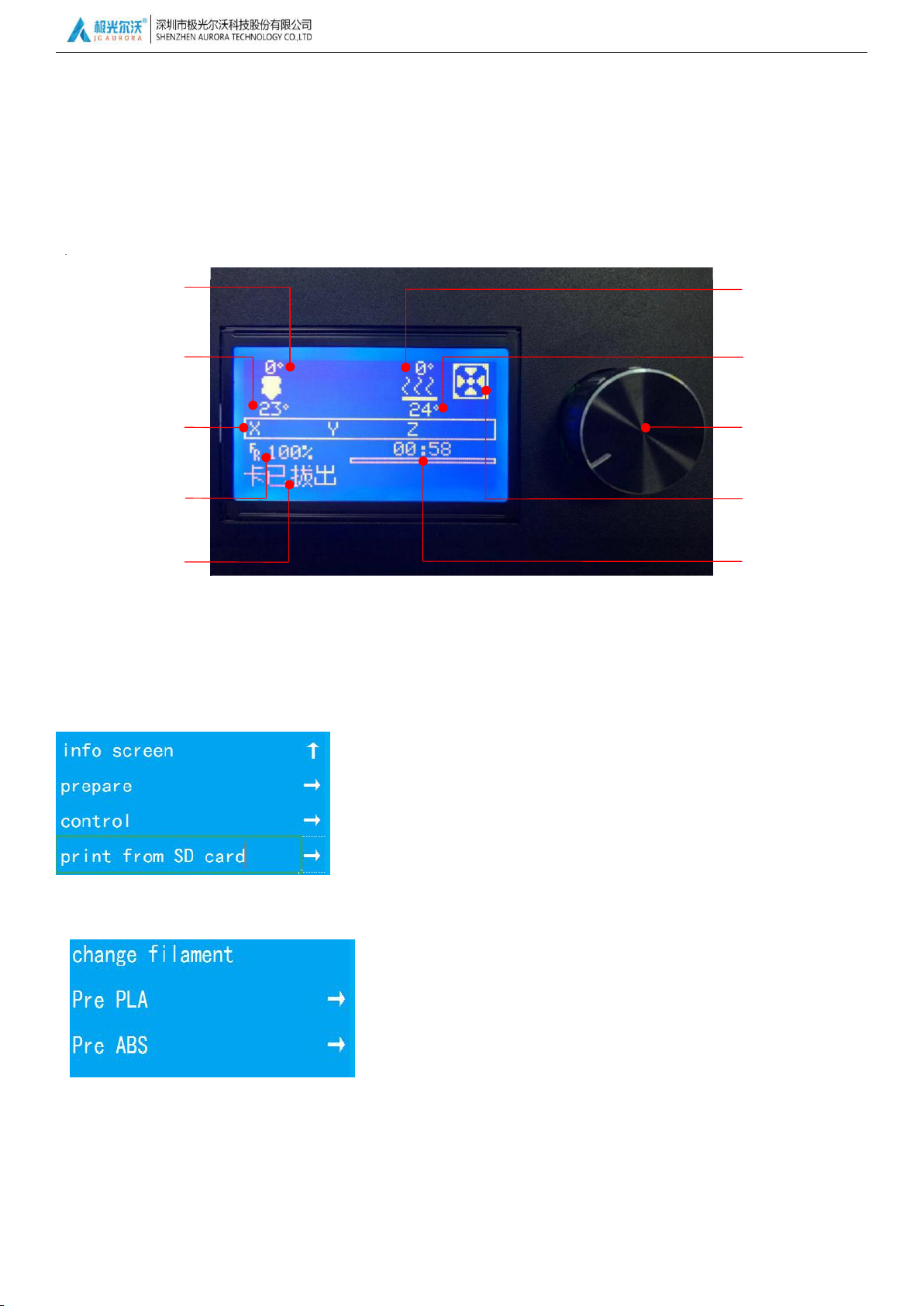

(1)Main Menu:

(2)Preheat:Preheat PLA\Preheat ABS

⑧Adjustment knob

(Rotate Select, Press Ok)

④Speed Adjustment Ratio

⑦Hotbed Actual Temp.

⑨

Fan speed

③X/Y/ZAxis Coordinate

②Nozzle Actual Temp.

⑥

Hotbed Setted Temp.

①Nozzle SettedTemp.

⑩Print Progress

【Prepare】:Prepare works before printing,Include Move axis、Auto home、

Preheat、Cooling、Disable steppers、change filament etc.;

【Control】:Advanced settings,Include Temperature、Motion、Filament etc.;

【Print from SD】:Print model menu( Shown as Print from SD Card after

insert SD Card or shown as No SD Card after SD Card removed.);

【Preheat PLA\ABS】:Both preheat nozzle and hotbed,the corresponding temperature has been set in 【Control】;

【Preheat PLA\ABS END】:Preheat nozzle only;

【Preheat PLA\ABS Bed】:Preheat hotbed only;

⑤SD Card Status

4.1 Main Menu Introduction

4.1.1 Control Panel

4.1.2 Function Introduction

With User to Create Better Product

19

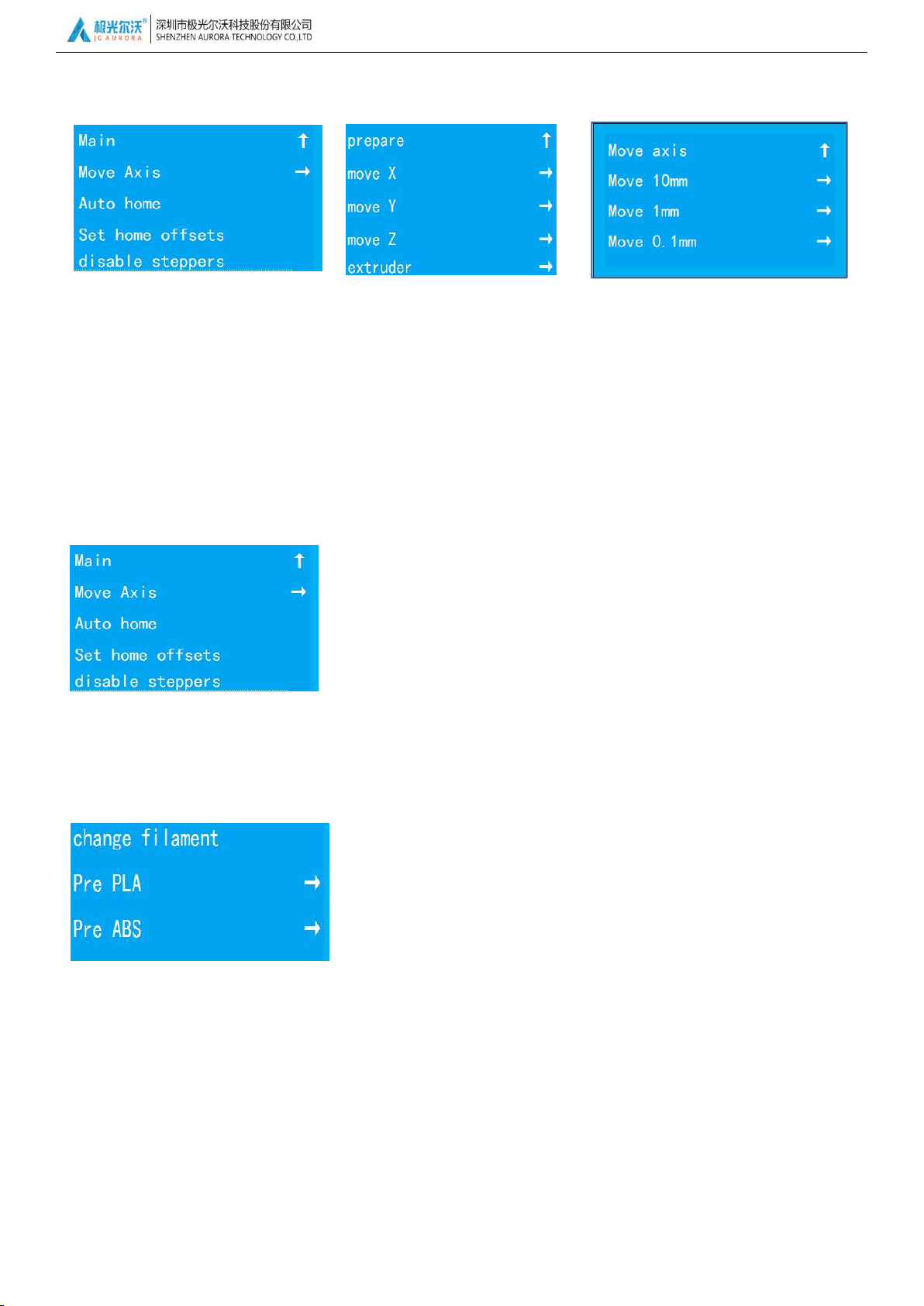

(3)Move axis:Move X\Y\Z\ axis.

(4)Auto Home:Nozzle go back to original place.

(5)Others:Disable steppers\change filament\Cooling

【Move X】:The nozzle moves along the X axis,X+ is away from the original point,X- is close the original point;

【Move Y】:The hot bed moves along the Y axis,Y+is away from the original point,Y-is close the original point;

【Move Z】:The nozzle moves along the Z axis,Z+ is up,Z- is down;

【Extrude】:Load or Remove Filament by hand;

【Move 10\1\0.1mm】:Rotate Knot;

【Disable steppers】:after setted Auto Home and Move axis,the motor is

locked,when you need to move the nozzle and hotbed

by hand,please Disable Steppers first;

【change filament】:change filament now or after print;

【Cooling】:Cancel preheat;

【Auto Home】:Nozzle and Hotbed go back to original place.

With User to Create Better Product

20

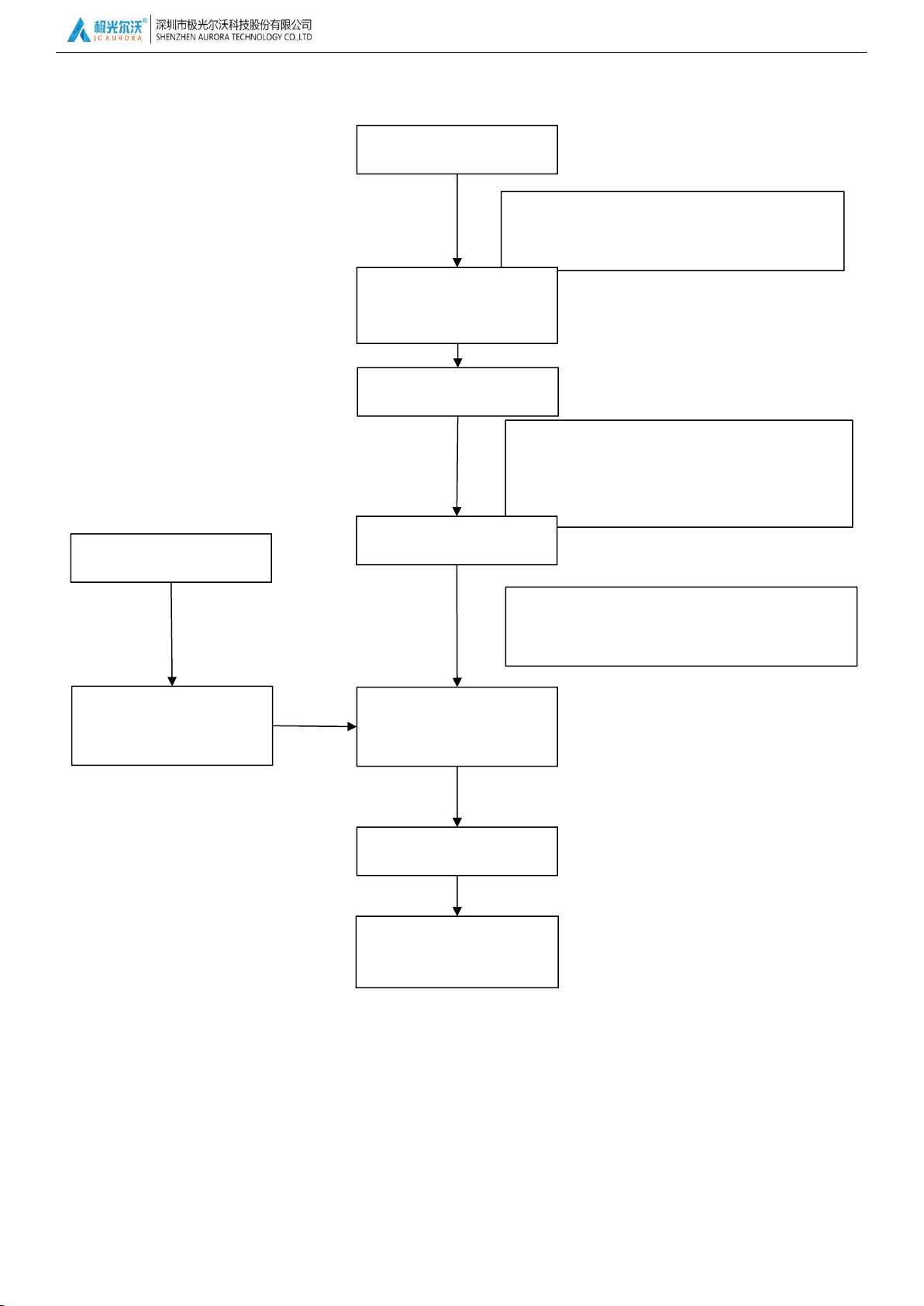

4.2 Operating procedures

The filament comes out smoothly.

More details to check【4.3.3 Filament Loading】

Check Power Voltage

Platform leveling

Install software

Slice model and copy to

SD card

Insert SD card

choose G Code file

Printing

Printing finish,Remove

model

Check the display voltage fit for your local

voltage standard or not?

After leveling,you will feel a little friction when

you move A4 Paper,without scratch on it,more

details to check【4.3.2 Platform Leveling】

Connect power cable,

Power On

Filament loading

With User to Create Better Product

21

4.3 Operating Instructions

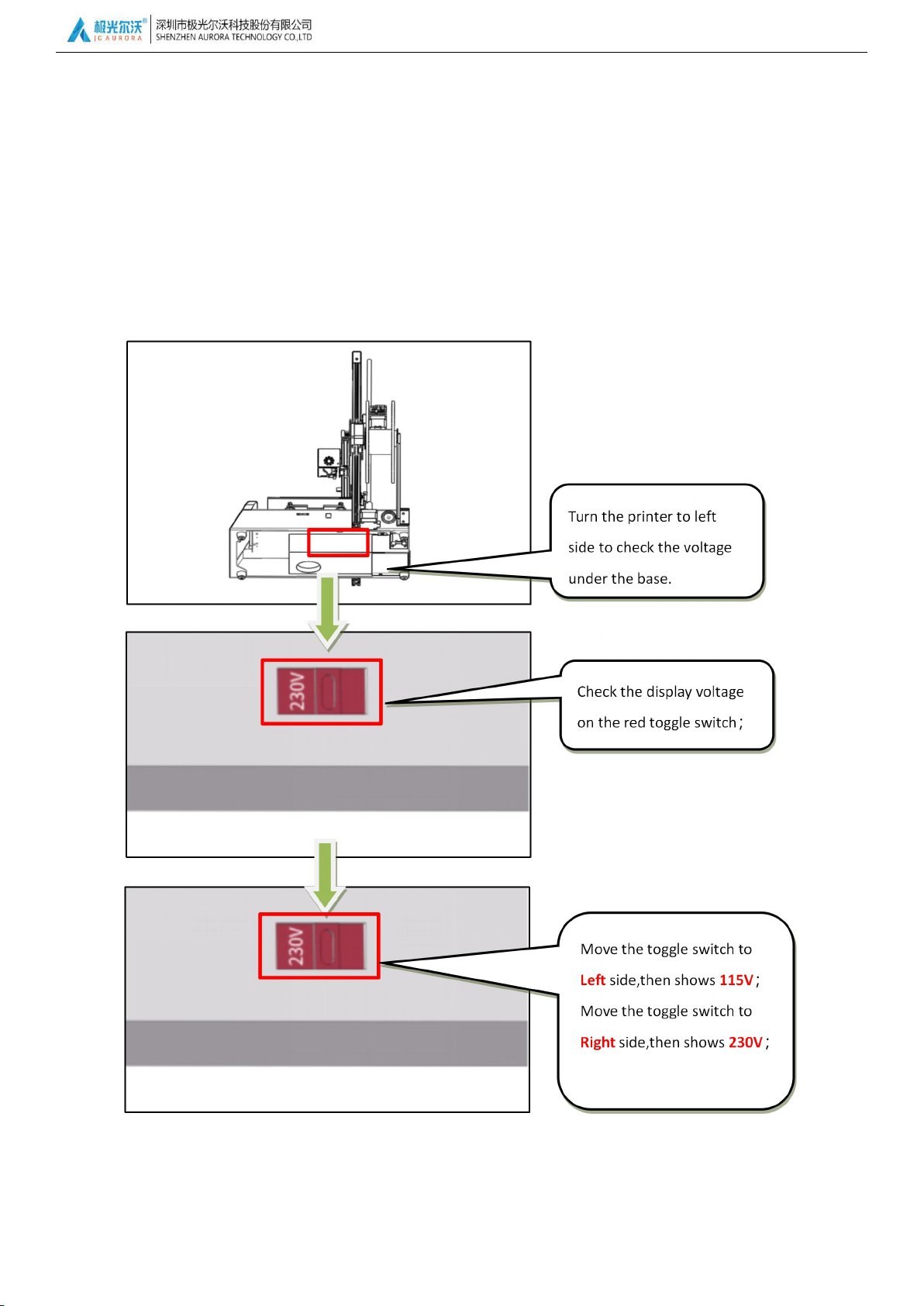

The input power of Magic is select-able AC 115/220,please adjust it according to your local voltage standard as below:

Check the voltage through the hole under the base. (115V means input power is 110V , 230V means input power is

220V),adjust it with red toggle switch to you local voltage standard;

4.3.1 Input Power Voltage Adjustment

With User to Create Better Product

22

4.3.2 Leveling

The first step: Firstly, we should screw all the four leveling nuts counterclockwise, then make leveling.

The second step: Press the control button into the main menu, select “Prepare” → “HOME”, press the button, the

extruder will go to the home place, find “ Disable steppers” in the same menu, now you could move the extruder and hot

bed manually.

The third step: After steppers stopped working, move the extruder to the four corners, then finish leveling.

When the extruder move to the relevant point, place an A4 paper on the platform, move the A4 paper and see the

distance, if the A4 paper is very loose and easy to move, then rotary the nut clockwise to close the gap, on the contrary,

if the A4 paper is quite tight to move, then rotary the nut counterclockwise to increase the gap, until the A4 paper has

a little scratch but no damage when moving, which means leveling finished.

Attention: Any question, please watch the video in SD CARD or consulting our engineers via email.

FOUR POINTS LEVELING

With User to Create Better Product

23

4.3.3 Filament loading

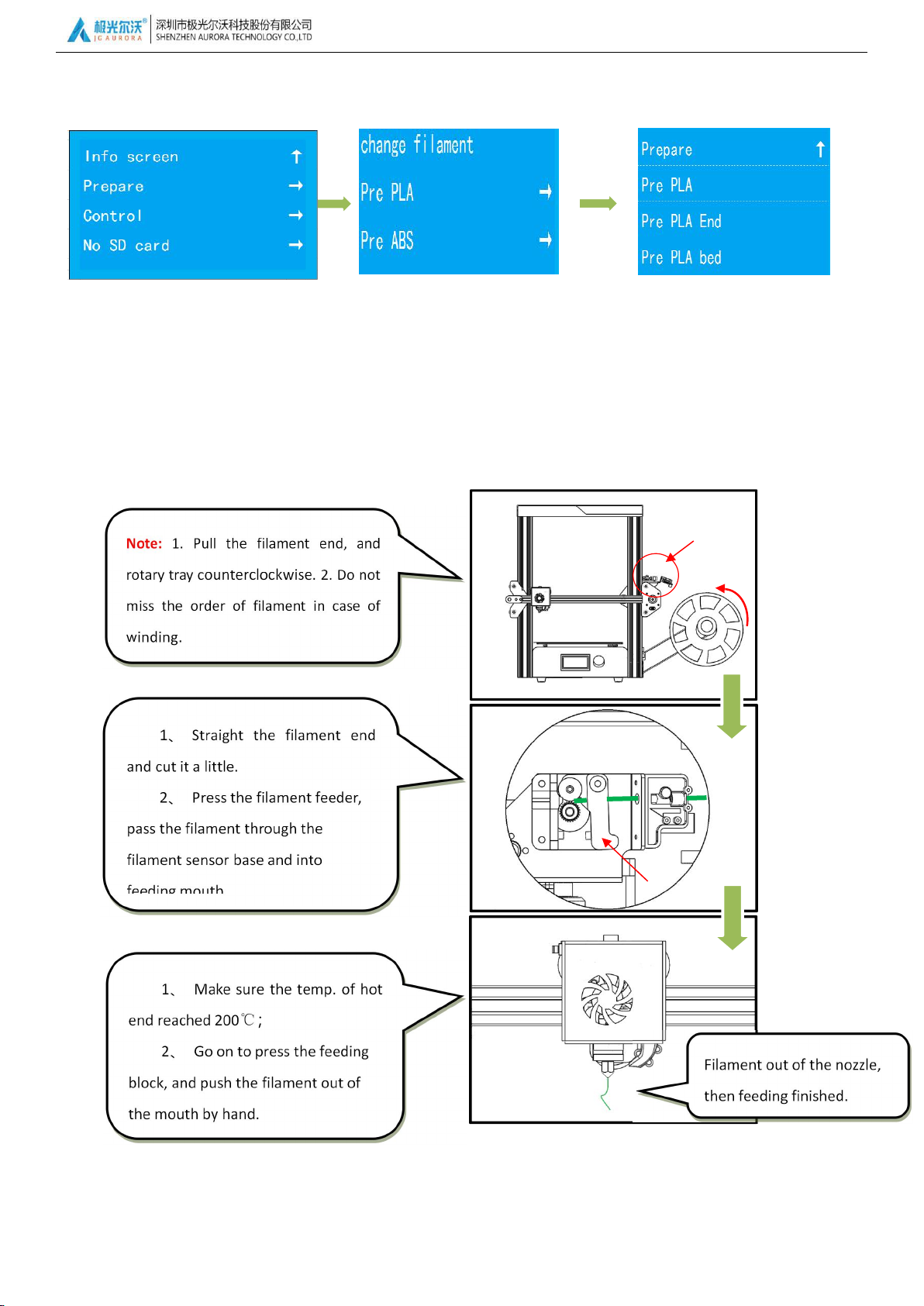

The first step:Press the button into the main menu, select “ Prepare” → “Preheat PLA”→ “Preheat PLA”, press the button

then extruder and hot bed begin heating.(Temp. in reference:PLA≈200 ℃,ABS≈240 ℃). Attention: We take the PLA as

an example in this manual.

he second step: When preheating, you could place the filament to the filament holder, press the feeding block in the left

side, load the filament into the filament feeder and lock the filament there.

The third step: After preheating finished, go on to load the filament to the nozzle part until filament out of the nozzle.

Feeding suite

Feeding suite enlarged view

Feeding block

With User to Create Better Product

24

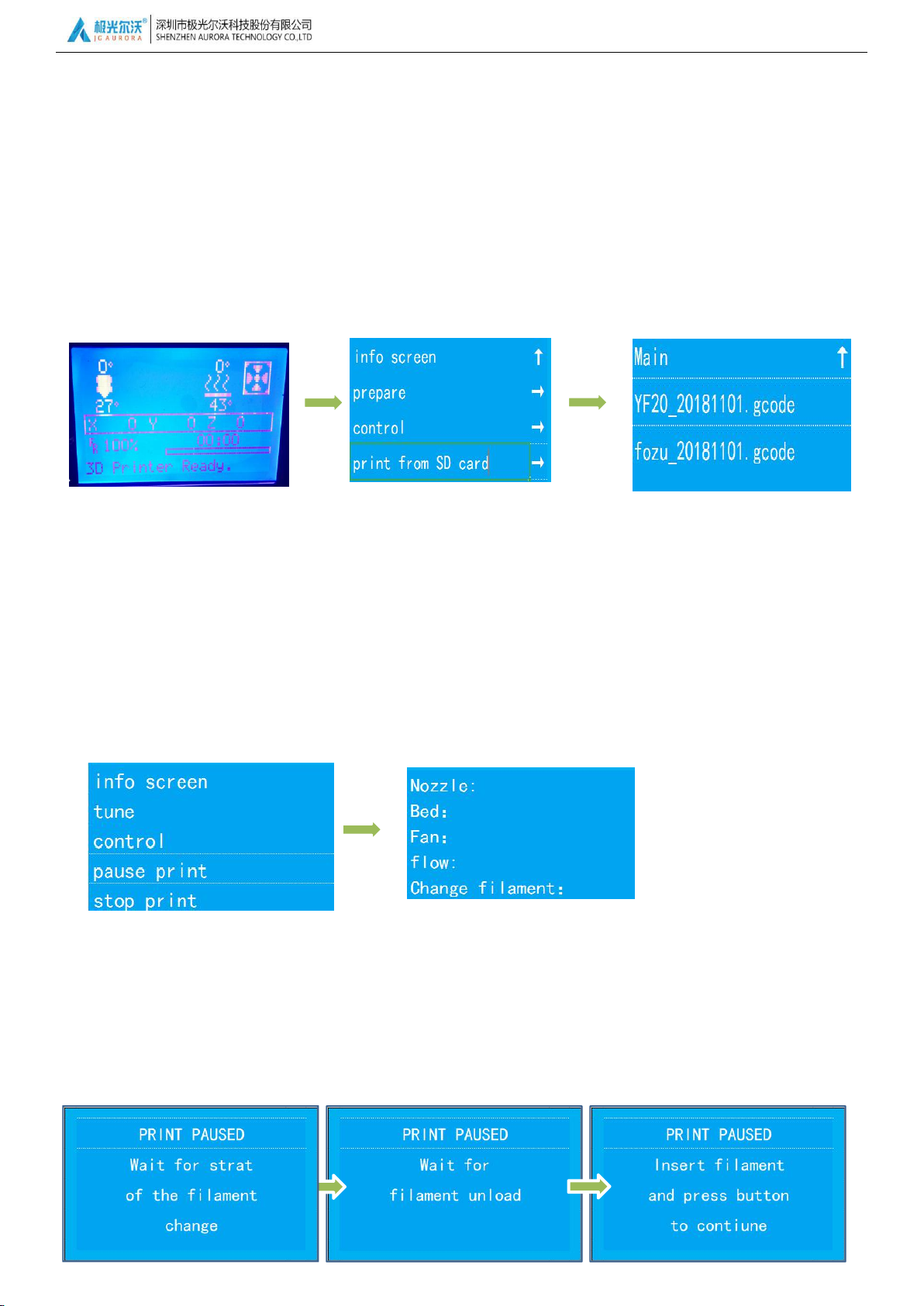

4.3.4 Model printing

The first step: Save the gcode file into the sd card of root directory(Details of slicing, please see the chapter 5).

The second step: Insert the sd card into the port of printer, when shows “ card inserted”, press the button and choose

the file you’d like to print, and make sure of it.

The third step: When temp. reached, printer will start to work automatically.

The fourth step: When model finished, display will show the tips of finished.

The fifth step: Take off the model, please keep in mind to take off the model when printer cooling down.

Attention: At the begging of printing, if the filament cannot paste on the bed, please make leveling again according to the

Chapter 4.3.2.

When printing, filament will be used up, it will need to change the filament as below:

(1)Press the button, select “tune”→ “change filament”, and confirm, wait the printer to pause printing.

(2)After printer paused, it will unload the filament, and shows “Wait for filament unload”.

(3)When unloading finished, display shows “Insert filament and press button to continue”, then insert the new

filament into the mouth and press the button to loading.

(4)When press load, display will shows“Wait for filament load”, until filament out of the nozzle, then select

“Continue” to quit filament change.

4.3.5 Filament Change

With User to Create Better Product

25

Model finished to change filament, should do as below:

(1)Press the button,select “Prepare”→ “change filament”→ “Preheat PLA”.

(2)When press the button to confirm preheating and pause printing, display will shows“ Heating nozzle ,please

wait...”, steps is the same as change in printing. Please do not pull the filament hardly in case of damage to the nozzle.

4.3.6 Power Failure Recovery Printing

In the process of printing, printer stopped printing in sudden, we could use the function of power loss recovery to continue

printing.

With User to Create Better Product

26

5.1 software install

first:copy the file in SD card to computer;

second:Double click software icon, enter setup iterface, setup procedure as below:

5, slice software

With User to Create Better Product

27

Note:because difference of computer system, it might need to repair, before install success!

Third:press finish,then run the software.

first : Double click software

icon,enter into the software interface;

5.2 soft instruction

With User to Create Better Product

28

second:choice printer model,start software,automaticlly come out model choice;

third:software interface instruction

;

With User to Create Better Product

29

fourth:upload model,choice the printing quality you want,in the right corner will show“slicing”,means Gcode is

generating;

With User to Create Better Product

30

fifth:after slice,press right corner【save】button;

sixth:save Gcode or copy it to the SD card,and insert it into SD card slot,then can start print.

Note:for the detail of slice software please check the document in SD card.

With User to Create Better Product

31

6, Common Problems and Solutions

item

Problems

description

Reasons

Solution

1

Filament breaks

at the top of

extruder mouth

A. Filament has run out .

B. Filament was exposed to moisture,

and has become brittle..

C. Filament was plugging the throat.

A. Replace filament before its gone

B. Store filament in air-tight container

when finished printing.Replace with fresh

filament spool.

C. Clean the throat. Refer to video on the

USB stick for instructions.

2

Filament slips in

extruder

Filament is too thin, or has been

ground down by

extruder gear .

Retract filament and cut out the thin

filament section.

3

Temperature is

incorrect.

Temperature sensor is

malfunctioning.

Contact support for advice or

replacement of temperature sensor .

4

Model is

malformed

Timing belts may be too

loose. Timing belt pulley

may be loose.

Check and tighten the screw and belts.

5

Model is

warped

The print bed is not level

Relevel print bed, and retry print.

6

G-code

generation

failed

A、 Incorrect setting or wrong

B、 save path

Choose the correct machine type and

select the correct save path

7

Software

Installation

failed

OS may not be supported

Install only on compatible OS

8

SD card can’t

read

A、 SD card not readed

B、 SD card broken

A、 Take out SD card,turn off printer and

wait for 10 second, then turn on and

insect SD card

B、 Format SD card,and recopy model to

SD card

Note:if no clear about the cause of malfunction, please contact our after sales for technique support.If printer be

cleaned,should relevel the platform,avoid damage during second time printing

With User to Create Better Product

32

7, 3D Printer Maintenance

7.1. Daily maintenance

1) Before using the machine to print, make observe the safety recommendations.

2) Regularly clean and maintain the equipment. Clean the surface of the nozzle, print bed, moving parts

and other parts, to help prevent wear caused by excessive dust.

3) After each repair and maintenance, ensure all disassembled parts have been put back in their original

place to avoid mechanical failures that may be caused by missing parts or incorrect re-assembly.

7.2. Basic maintenance

1) Before operating the 3D printer, it is necessary to inspect the printer, and perform maintenance before

use:

Inspect the nozzle for blockage or damage

Check the printing platform is calibrated and clean.

Check the printer is on a flat surface and is stable.

Check that screws and nuts are tight, and that no parts of the printer are loose or wobbly.

Check whether motion rails require cleaning or lubrication with oil.

When parts or lines are damaged or worn out, you should replace them before printing.

2) In the operation of the 3D printer, ensure not only that the design of each print model does not exceed

the actual printable volume of the device, but also do not allow the machine to work in too high a

temperature or under too much load. Otherwise, not only will it not print the object, but it can also

damage the machine because of overloaded work.

3) For best print results, please remove the filament remaining in the extrusion head after finishing

printing. Seal filament in air-tight containers to prevent material from absorbing moisture, which can

cause filament to become brittle and break during printing.

With User to Create Better Product

33

7.3. Maintenance of Moving Components

oil within the bearings and to lubricate the entire length of the guide rails and polished rods.

If you notice the printer has become noisy, or vibrates excessively, you may need to clean the rail rods

and add some lubricating oil to reduce friction.

To Clean and Lubricate: first, with a clean dust cloth, clean the grease or dust from the moving parts.Then

apply 3-5ml (about 5-8 drops) lubricating oil along the motion rails. Brush the oil along the respective

parts or rail axis, and move the moving parts along the rails back and forth, in order to distribute

With User to Create Better Product

34

8, Supports and service

1. Please see theWarranty Card for details on our policies for repair and support.

2. If your printer is malfunctioning or damaged, for your safety, and to avoid further damaging the printer,

please contact the after-sale service center or our support team for advice first, before attempting

any repair.

Shenzhen Aurora Technology Co., Ltd

Headquarter Address: 5F Building 1 Longquan Technology Park, Tongsheng community,

Dalang street Longhua district, Shenzhen, China 518109

Company homepage: www.jgaurora3d.com

Tel of after sales service center/support team: 0755-29735649 / 66607459

Email of support: support@zgew3d.com or after-sales@3derwo.com

Official website Official Facebook

Loading...

Loading...