WWW.JEVEN.FI

SwingControl unit

Installation guide

Delivery 3

Dimensions and electrical

installation 4

Installation 5

Changing the rotation speed of

TurboSwing 6

Configuration guide 7-9

Automation 10

Table of Contents

WWW.JEVEN.COM

PAG E 2 JEVEN Kitchen ventilation

Contact us: jeven@jeven.fi

010 231 2030

All rights reserved

DELIVERY

SwingControl Unit

Check the delivery receipt for the consignee’s name and address. Also inspect if the package is damaged.

When opening the package check the accuracy of the delivery. Any defiencies must be reported immediately to Jeven.

Please note!

Do not install the device in a position where it is exposed to water.

The ambient temperature must be below +30°C.

CONTENTS

SwingControl is delivered in a cardboard box

36x36x23 cm.

Cardboard box contains power cord, brackets and

SwingControl unit.

1. Power switch

2. Power line filter/ input power

(230 V,10A)

Cable length 2 meter

3,4. PIN-liitin, 4-pol

control current cable(0-10V)

5. Building automation socket

Rj 45 e.g. Modbus

6.

7. Led light off

-error

4

5

7

2

1

6

3

Led light on

-no error

SwingControl unit with two connected TurboSwings.

Power cord Brackets

SwingControl unit

PAG E 3

WWW.JEVEN.COM

JEVEN Kitchen ventilation

All rights reserved

PAG E 4 JEVEN Kitchen ventilation

SwingControl Unit

DIMENSIONS

1

0

25

132

300

200

230

The box is made of polycarbonate

Standard EU 62208,GOST

Impact resistance IK 08

160

Brackets, can also be bent to

the side

ELECTRICAL INSTALLATION

Control current cable0-10V

The safety switch is mandatory and it must be

installed in a visible place and in the immediate vicinity

of the product. The control unit is connected as a

separate input.

The safety switch, socket/outlet box and the cables are

marked with a dashed line are not included in the

delivery.

Control power cables are connected to each TurboSwing

from which they are connected to SwingControl.

One SwingControl can serve max. 20 TurboSwings.

SwingControl unit is connected to the mains for continious

constant power.

SwingControl

unit

Turbo

Swing

Turbo

Swing

Modbus interface

Socket/ Safety switch

Outlet box

230 VAC

230 VAC

230 VAC 230 VAC

Socket

2m

2m

230 VAC

2m

WWW.JEVEN.COM

All rights reserved

Control current cable0-10V

INSTALLATION

SwingControl Unit

SwingControl can be mounted on a wall or pillar, either horizontally or vertically.

Cables that are on top of the hood, should be untied from cable ties and connected to SwingControl in appropriate

locations. Next, connect house automation interface and finally connect the power.

PAG E 5

JEVEN Kitchen ventilation

WWW.JEVEN.COM

All rights reserved

SwingControl Unit

CHANGING THE ROTATION SPEED OF TURBOSWING

Open the control unit cover and change the position of the dip switches.

Rotation speed when switch is ”ON” position is 1100 rpm and 750 rpm

when switch is ”OFF”.

Speed is chosen separately for each TurboSwing unit.

The factory setting is the rotation speed according to plans.

PAG E 6 JEVEN Kitchen ventilation

WWW.JEVEN.COM

All rights reserved

SwingControl Unit

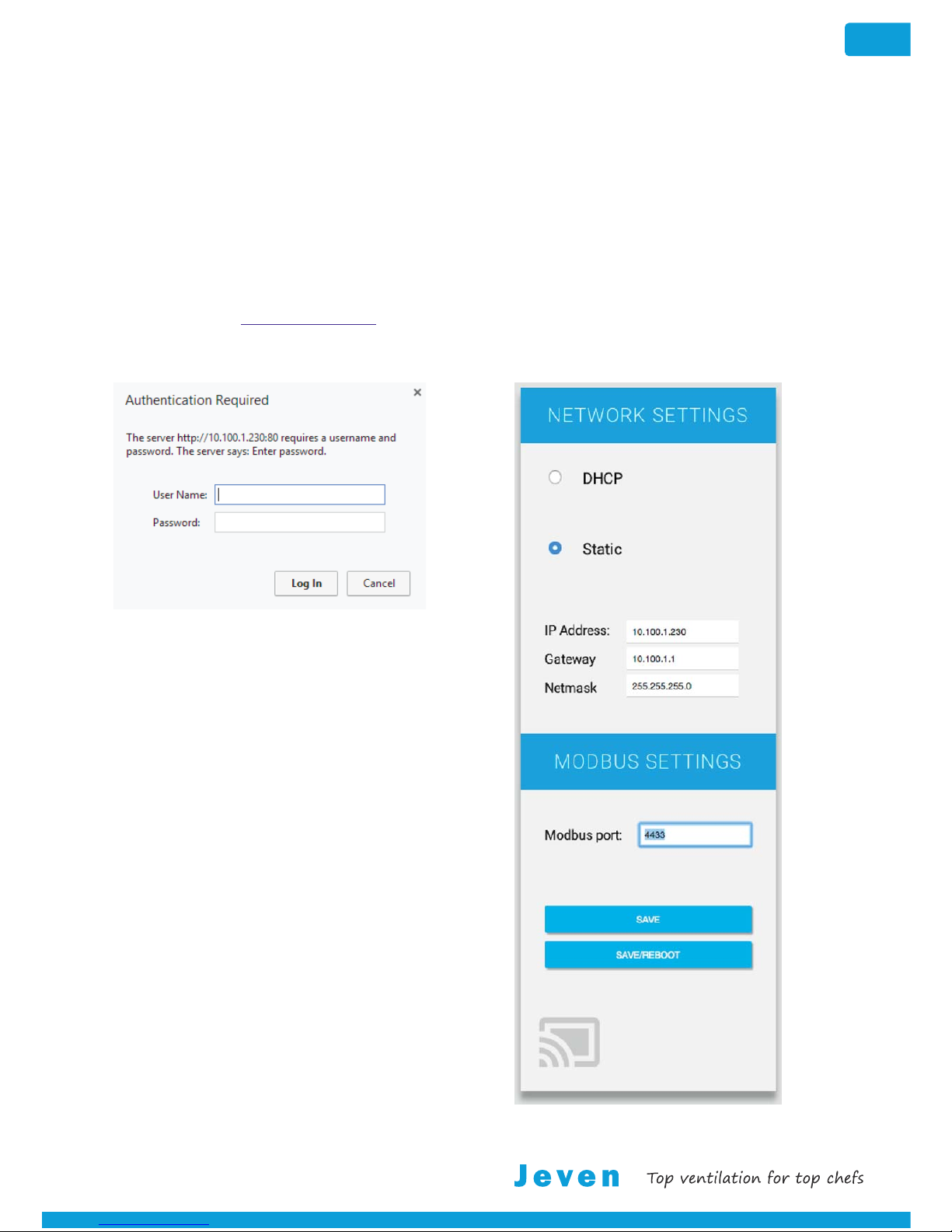

CONNECTING TO SWINGCONTROL

SwingControl contains inbuilt tool for configuring device's LAN settings and Modbus TCP/IP port. Configuration tool

can be used via standard web browser, such as Internet Explorer, Firefox or Chrome. Configuration tool is accessible in

standard http port of SwingControl device. In order to open configuration tool configurators computer must be

configured to the same network as SwingControl. Computer must be connected to SwingControl via crossover

network cable or hub/router.

SwingControl default settings

Default factory settings for SwingControl network are:

IP:192.168.0.123

Gateway: 192.168.0.1

Netmask: 255.255.255.0

Network settings for Windows 7

Windows 7 local are settings must be set so, that it is possible to access SwingControlo configuration tool. To set up

network for this purpose, the following steps need to be taken:

1. Open ”Network and Sharing Center”

2. Choose ”Local area connection”, which will open a dialog named ”Local area connection status”

PAG E 7

JEVEN Kitchen ventilation

WWW.JEVEN.COM

All rights reserved

SwingControl Unit

3. Choose ”Properties” 4. In ”Local area connection properties” choose

”Internet Protocol Version 4(TCP/IPv4)” from the list

and then choose ”Properties”.

5. Select ”Use the following IP address” and input IP

address, subnet mask and default gateway to match the

settings of SwingControl.

NOTE!

If you are connecting to SwingControl device that has

default factory settings, you can use the values shown

in screenshots. After saving the settings in your

computer, provided that network cabling is done

correctly, you should be able to open SwingControl

configuration panel by pointing you web browser to

address ”http://192.168.0.123”

PAG E 8 JEVEN Kitchen ventilation

WWW.JEVEN.COM

All rights reserved

SwingControl Unit

CHANGING NETWORK SETTINGS AND MODBUS PORT

From SwingControl configuration tool it is possible to

change the device to either use DHCP addressing or static

IP address.

1. Point your web browser to SwingControl's current IP

address, by deafult: http://192.168.0.123

2. Using configuration tool requires you to input the

following user name and password: ”admin”, ”J3V3NSC”

3. Provided the user name and password are correct,

configuration panel should open in your browser.

4. You can choose either DHCP or static IP address. If you

choose static IP address, you must also provide valid IP

address, gateway and netmask that match your network.

5. In modbus settings it is possible to configure

SwingControl to use another port than the default 4433.

6. Finally changes are applied by selecting

”SAVE/REBOOT”. This saves your changes to

SwingControl persisten memory and causes a reboot to

the device. After reboot, new settings are applied.

PAG E 9

JEVEN Kitchen ventilation

WWW.JEVEN.COM

All rights reserved

SwingControl Unit

PAG E 10 JEVEN Kitchen ventilation

AUTOMATION

Rekisteri Tietotyyppi Merkitys

1-24 bool

25-48 bool

0 - Not used

The SwingControl control units can be connected to the building automation system through the Modbus TCP/IP

interface (TCP/IP port 4433). The Modbus interface is available via the Ethernet interface. The SwingControl unit uses

the DHCP protocol for IP requests. If the connected Ethernet network does not allow automatic IP allocation,

SwingControl uses the following fixed settings:

IP: 192.168.0.123

Netmask: 255.255.255.0

SwingControl operates as a so-called Modbus slave device. The current status of each TurboSwing device connected to

a SwingControl unit, including any potential alarms, can be read via the Modbus interface. The registers used by the

Modbus interface are listed in the table below

Example of the use of Modbus registers:

TurboSwing is connected to interface 4.

Real-time device status information is found in the Modbus register number 4.

Possible alarm information is found in the register number 28.

Example reading modbus register with CAS:

Use ”Read holding registers” command.

WWW.JEVEN.COM

All rights reserved

Real-time connected TurboSwing on/off status information.

Status information is not filtered on the basis of the operating conditions.

Also other devices connected to the digital passive inputs of Swing Control

are visible in these registers. For the monitoring of the device alarms, it is

recommended to use separate alarm registers in the register range 25-48.

(See below)

If FALSE, the connected TurboSwing separating plate does not

rotate or rotates too slowly. The device is either off or not working properly.

The LED in the SwingControl device for the TurboSwing device is also off.

If TRUE, the connected TurboSwing is operating normally.

The LED of SwingControl unit is also on.

The Register number corresponds to the connected Turbo Swing device

order number.

The alarm information of the connected TurboSwing device.

Alarms are decided based on the operation parameters of the TurboSwing

equipment. Upon determining an alarm should be triggered, the

SwingControl control unit takes into account the so-called normal

operational conditions and seeks to minimize false alarms.

This register area is recommended to be primarily used in building

automation interfaces.

FALSE means that the TurboSwing device operates in a normal way.

TRUE means the SwingControl unit has identified the corresponding

TurboSwing device is not working properly.

The register number is calculated by adding 24 to the order number of the

connected TurboSwing device.

Loading...

Loading...