P4MBMS

USER'S MANUAL

M/B For LGA775 Pentium 4 Processor

NO. G03-P4MBMS

Rev:1.0

Release date: September 2005

Trademark:

* Specifications and Information contained in this documentation are furnished for information use only , and are

subject to change at any time without notice, and should not be construed as a commitment by manufacturer.

USER’S NOTICE ....................................................................................................................................................ii

MANUAL REVISION INFORMATION ..............................................................................................................ii

COOLING SOLUTIONS........................................................................................................................................ii

CHAPTER 1 INTRODUCTION OF P4MBMS MOTHERBOARD

1-1 FEATURE OF MOTHERBOARD.......................................................................................................1

1-2 SPECIFICATION..................................................................................................................................2

1-3 PERFORMANCE LIST........................................................................................................................3

1-4 LAYOUT DIAGRAM & JUMPER SETTING....................................................................................4

CHAPTER 2 HARDWARE INSTALLATION

2-1 HARDWARE INSTALLATION STEPS .............................................................................................6

2-2 CHECKING MOTHERBOARD'S JUMPER SETTING...................................................................6

2-3 INSTALL CPU.......................................................................................................................................7

2-3-1 GLOSSARY................................................................................................................................7

2-3-2 ABOUT INTEL PENTIUM4 LGA 775 CPU ...........................................................................8

2-3-3 LGA 775 CPU INSTALLATION GUIDE................................................................................9

2-4 INSTALL MEMORY............................................................................................................................18

2-5 EXPANSION CARD..............................................................................................................................19

2-5-1 PROCEDURE FOR EXPANSION CARD INSTALLATION................................................19

2-5-2 ASSIGNING IRQ FOR EXPANSION CARD .........................................................................19

2-5-3 INTERRUPT REQUEST TABLE FOR THIS MOTHERBOARD .......................................20

2-5-4 AGP SLOT.................................................................................................................................. 20

2-6 CONNECTORS, HEADERS.................................................................................................................20

2-6-1 CONNECTORS..........................................................................................................................20

2-6-2 HEADERS...................................................................................................................................24

2-7 STARTING UP YOUR COMPUTER..................................................................................................27

CHAPTER 3 INTRODUCING BIOS

3-1 ENTERING SETUP...............................................................................................................................28

3-2 GETTING HELP...................................................................................................................................28

3-3 THE MAIN MENU................................................................................................................................29

3-4 STANDARD CMOS FEATURES.........................................................................................................30

3-5 ADVANCED BIOS FEATURES ..........................................................................................................31

3-6 ADVANCED CHIPSET FEATURES..................................................................................................

3-6-1 DRAM TIMING SETTINGS....................................................................................................34

3-6-2 AGP TIMING SETTINGS........................................................................................................35

3-6-3 PCI TIMING SETTINGS..........................................................................................................35

3-7 INTEGRATED PERIPHERALS..........................................................................................................36

3-7-1 ONCHIP IDE FUNCTION........................................................................................................36

3-7-2 ONCHIP DEVICE FUNCTION................................................................................................37

3-7-3 ONBOARD SUPER IO FUNCTION........................................................................................38

3-8 POWER MANAGEMENT SETUP......................................................................................................39

3-8-1 WAKE UP EVENTS.................................................................................................................40

3-8-1.1 IRQS ACTIVITIES ................................................................................................... ..............40

3-9 PNP/PCI CONFIGURATION SETUP.................................................................................................41

3-9-1 IRQ RESOURCES ....................................................................................................................42

3-10 PC HEALTH STATUS........................................................................................................................42

3-11 MISCELLANEOUS CONTROL........................................................................................................43

3-12 LOAD STANDARD/OPTIMIZED DEFAULTS ...............................................................................44

3-13 SET SUPERVISOR/USER PASSWORD...........................................................................................45

CHAPTER 4 DRIVER & FREE PROGRAM INSTALLATION

MAGIC INSTALL SUPPORTS WINDOWS 9X/ME/NT4.0/2000/XP .........................................................46

4-1 VIA 4 IN 1 INSTALL VIA SERVICE PACK 4 IN 1 DRIVER............................................47

4-2 VGA INSTALL P4M800CE VGA DRIVER................................................................48

4-3 SOUND INSTALL ALC AUDIO CODEC DRIVER........................................................48

4-4 LAN INSTALL VIA 10/100MB LAN CONTROLLER DRIVER.............................. 49

4-5 PC-HEALTH INSTALL MYGUARD HARDWARE MONITOR UTILITY..........................50

4-6 PC-CILLIN INSTALL PC-CILLIN2005 ANTI-VIRUS PROGRAM...................................51

4-7 USB2.0 INSTALL VIA USB2.0 DEVICE DRIVER........................................................52

4-8 SATA INSTALL VIA SERIAL ATA .................................................................................53

4-9 HOW TO DISABLE ON-BOARD SOUND.........................................................................................54

4-10 HOW TO UPDATE BIOS.....................................................................................................................54

TABLE OF CONTENT

.33

i

USER’S NOTICE

COPYRIGHT OF THIS MANUAL BELONGS TO THE MANUFACTURER. NO PART OF THIS

MANUAL, INCLUDING THE PRODUCTS AND SOFTWARE DESCRIBED IN IT MAY BE

REPRODUCED, TRANSMITTED OR TRANSLATED INTO ANY LANGUAGE IN ANY FORM OR

BY ANY MEANS WITHOUT WRITTEN PERMISSION OF THE MANUFACTURER.

THIS MANUAL CONTAINS ALL INFORMATION REQUIRED TO USE P4MBMS MOTHERBOARD AND WE DO ASSURE THIS MANUAL MEETS USER’S REQUIREMENT BUT WILL

CHANGE, CORRECT ANY TIME WITHOUT NOTICE. MANUFACTURER PROVIDES THIS

MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND, AND WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTIAL OR CONSEQUENTIAL DAMAGES (INCLUDING

DAMANGES FOR LOSS OF PROFIT, LOSS OF BUSINESS, LOSS OF USE OF DATA,

INTERRUPTION OF BUSINESS AND THE LIKE).

PRODUCTS AND CORPORATE NAMES APPEARING IN THIS MANUAL MAY OR MAY NOT BE

REGISTERED TRADEMARKS OR COPYRIGHTS OF THEIR RESPECTIVE COMPANIES, AND

THEY ARE USED ONLY FOR IDENTIFICATION OR EXPLANATION AND TO THE OWNER’S

BENEFIT, WITHOUT INTENT TO INFRINGE.

Manual Revision Information

Reversion Revision History Date

1.0 First Edition September 2005

Item Checklist

5

P4MBMS motherboard

5

Cable for IDE/Floppy

5

CD for motherboard utilities

5

Cable for Serial ATA IDE Port

5

P4MBMS User’s Manual

Intel Pentium 4 Processor Family

Cooling Solutions

As processor technology pushes to faster speeds and higher performance, thermal management

becomes increasingly crucial while building computer systems. Maintaining the proper thermal

environment is the key to reliable, long-term system operation. The overall goal in providing the

proper thermal environment is keeping the processor below its specified maximum case temperature.

Heat sinks induce improved processor heat dissipation through increased surface area and

concentrated airflow from attached fans. In addition, interface materials allow effective transfers of

heat from the processor to the heat sink. For optimum heat transfer, Intel recommends the use of

thermal grease and mounting clips to attach the heat sink to the processor.

When selecting a thermal solution for your system, please refer to the website below for collection of

heat sinks evaluated and recommended by Intel for use with Intel processors. Note, those heat sinks

are recommended for maintaining the specified Maximum T case requirement. In addition, this

collection is not intended to be a comprehensive listing of all heat sinks that support Intel processors.

For vendor list of certified heat sinks and cooling fans, please visit :

http://developer.intel.com/design/Pentium4/components/index

ii

Chapter 1

Introduction of P4MBMS Motherboard

1-1 Feature of motherboard

The P4MBMS motherboard is designed for the use of Intel Pentium 4 Processor in LGA775

Package Processor with the VIA P4M800CE Chipset that delivers a high performance and

professional desktop platform solution. It utilizes the LGA 775 design and the memory size

which is expandable to 2.0GB.

These motherboards use the newest VIA P4M800CE chipset, supports 400MHz/ 533MHz

/800MHz System Bus in data transfer rate.

Supports Hyper Threading/ Prescott CPU

motherboards provided 133MHz/166MHz/200MHz Memory clock frequency, support DDR266

/DDR333/DDR400 DDR Module. The motherboard embedded VIA VT8237 V-Link LPC

South Bridge offer ULTRA

functions to provide speedier HDD throughout that boosts overall system performance.

ATA)

ATA 133

and

Serial ATA with RAID 0, 1, 0+1, and JBOD(S-

The P4MBMS used the VIA VT6103 LAN PHY chip Support Fast Ethernet LAN function

provide 10/100 Mb/s data transfer rate.

. The se

The motherboard also has an integrated 6-channel AC’97 CODEC on board which is fully

compatible with Sound Blaster Pro® that gives you the best sound quality and compatibility.

P4MBMS motherboards integrated S3 Graphics UniChrome Pro Integrated Graphics

Processor with high performance & high quality 3D accelerator supports Ultra-AGPII with

2GB/s bandwidth, built-in MPEG-2/1 Video Decoder and Video Accelerator supports VCD

DVD HDTV decoding and playback, supports graphic and video overlay function. Built-in

programmable 24-bit true-color RAMDAC up to 250MHz pixel clock. Programmable frame

buffer size from 16MB and up to 64MB. For those wanting even greater graphic performance.

P4MBMS provides an AGP slot supports AGP 8X/4X capability and Fast write Transaction.

With USB control as well as capability of expanding to 8x USB2.0 function ports delivering

480Mb/s bandwidth and rich connectivity, these motherboards meet future USB demand also

has built-in hardware monitor function to monitor and protect your computer.

A useful software tool “Magic BIOS” examines the BIOS version automatically with the

correct version available on the web, links the site for users to download the latest version of

BIOS and updates the BIOS. Use “Magic BIOS”, users can download and update BIOS

automatically and completed under the OS easily.

These motherboards provide high performance & meets future specification demand. It is

really wise choice for your computer.

1

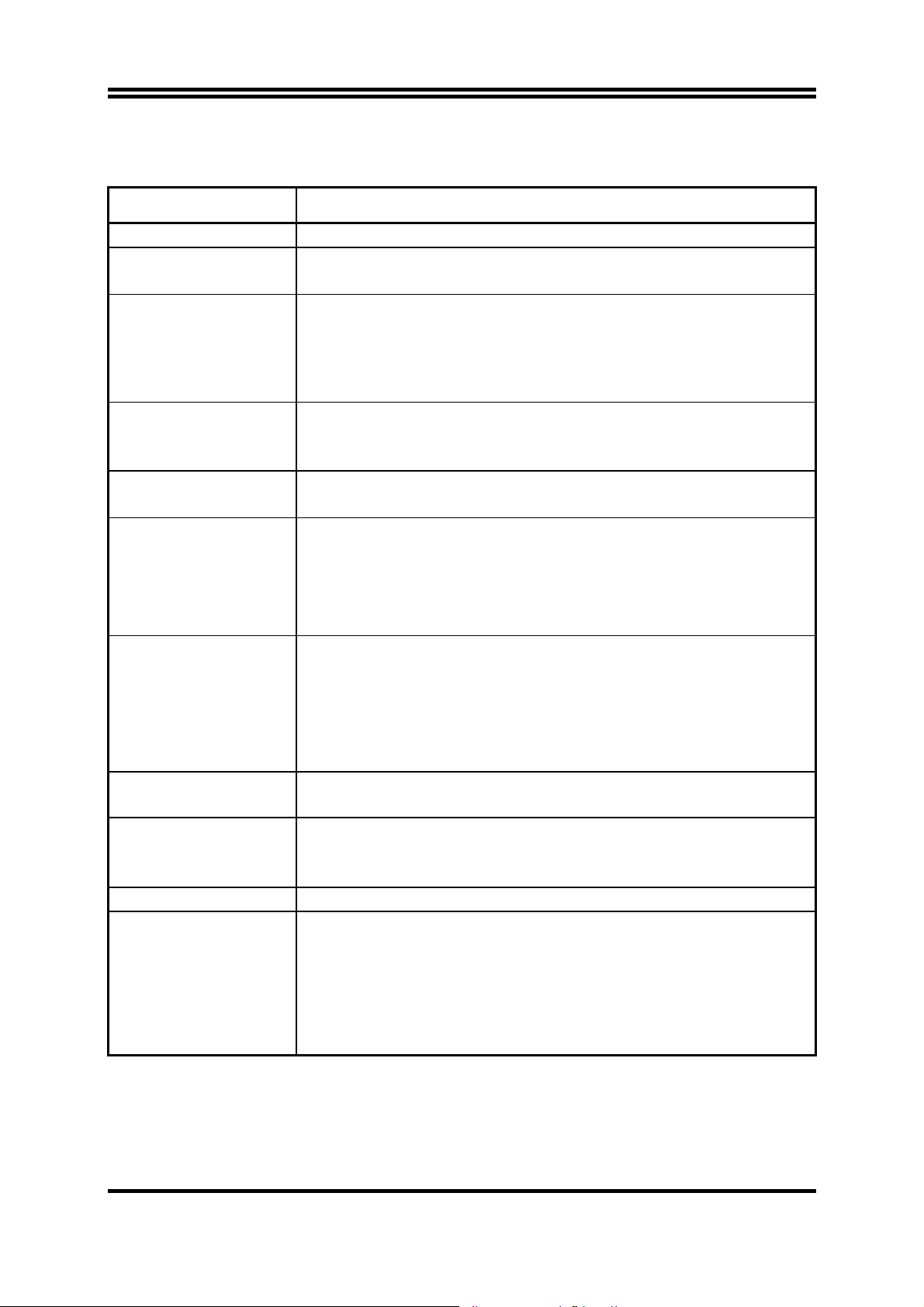

1-2 Specification

Spec Description

Design

Chipset

CPU Socket

(LGA 775 Socket)

Memory Socket

Expansion Slot

Integrate IDE and

Serial ATA RAID

VGA

LAN

Audio

BIOS

Multi I/O

∗ Micro ATX form factor 4 layers PCB size: 24.4x21.0cm

∗ VIA P4M800CE North Bridge Chipset

∗ VIA VT8237R South Bridge Chipset

∗ Support Intel Pentium 4 775-Land LGA Package utilizes Flip-

Chip Land Grid Array (FCLGA4) package processor

∗ Support CPU Frequency 533MHz/800MHz

∗ Support 2.8G/3.0G/3.6G LGA 775 Pentium 4 processor

∗ Reserves support for future Intel Pentium 4 processors

∗ 184-pin DDR Module socket x 2

∗ Support 2pcs DDR266/DDR33/DDR400 DDR Modules

Expandable to 2.0GB

∗ AGP slot x1 support AGP 2.0 & AGP 3.0 for 4X/8X mode

∗ 32-bit PCI slot x3

∗ Two PCI IDE controllers support PCI Bus Mastering, ATA

PIO/DMA and the ULTRA DMA 33/66/100/133 functions that

deliver the data transfer rate up to 133 MB/s; Two Serial ATA

ports provide 150 MB/sec data transfer rate for two Serial ATA

Devices and offer RAID 0, 1, 0+1, JBOD(S-ATA) functions

∗ Integrated S3 Graphics UniChrome Pro Integrated Graphics

Processor

∗ Support Ultra-AGPII with 2GB/s bandwidth

∗ Built-in programmable 24-bit true-color RAMDAC up to

250MHz pixel clock

∗ Programmable frame buffer size from 16MB and up to 64MB.

∗ Support Fast Ethernet LAN function provide 10/100 Mb/s data

transfer rate

∗ AC’97 Digital Audio controller integrated

∗ 6-channel AC’97 Audio CODEC on board

∗ Audio driver and utility included

∗ Award 4MB Flash ROM

∗ PS/2 keyboard and PS/2 mouse connectors

∗ Floppy disk drive connector x1

∗ Parallel port x1

∗ Serial port x1

∗ USB2.0 port x 4 and headers x 4 (connecting cable option)

∗ Audio connector (Line-in, Line-out, MIC)

2

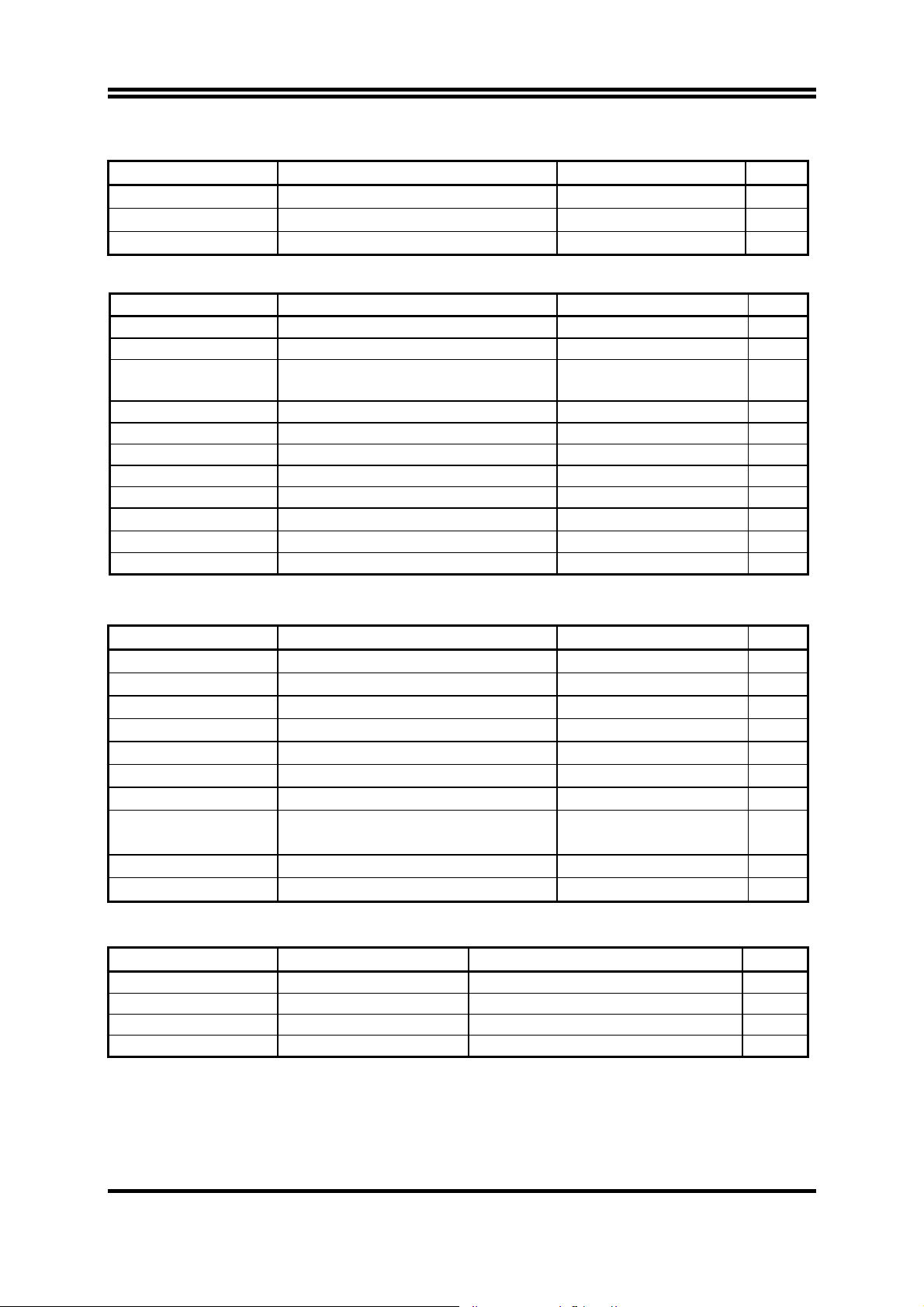

1-3 Performance List

The following performance data list is the testing result of some popular benchmark

testing programs. These data are just referred by users, and there is no responsibility

for different testing data values gotten by users (the different Hardware & Software

configuration will result in different benchmark testing results.)

Performance Test Report

CPU:

DRAM:

VGA Expansion Card:

Hard Disk Driver:

BIOS:

Windows XP Professional (SERVICE PACK 1)

OS:

P4M800CE

3D Mark 2001SE 2065

3D Mark 2003 122

3D Winbench 2000 (32/32bit) 47.6

PC Mark 2002 CPU/Memory/HDD 7294 / 5915 / 845

PCMark2004

System/CPU/Memory/Graph/HDD 3469/4362/3323/605/3269

Content Creation Winstone 2002 44.6

Content Creation Winstone 2003 48.5

Business Winstone 2002 31.9

Content Creation Winstone 2004 26.1

Business Winstone 2004 21.6

Winbench 99 V1.2:

Business/Hi-end Disk Winmark99 9190 / 32800

Business/Hi-end Graphic Winmark 366 / 1000

SYS Mark 2001/2002 : SISMark 2001/2002 Rating (Internet Content

Creation / Office Productivity)

SISMark 2001 265 (307 / 229)

SISMark 2002 301 (413 / 200)

SISOFT Sandra 2003 :

Dhrystone ALU MIPS 8860

Whetstone FPU MFLOPS 2588 / 5793

RAM Int Buffered iSSE2 MB/S 2829

RAM Float Buffered iSSE2 MB/S 2826

Integer SSE2 IT/S 13813

Floating- Point SSE2 IT/S 22051

QUAKE3 DEMO1/DEMO2 FPS 69.0 / 65.2

Return to Castle Wolfenstein FPS 61.6

Super Pi (1M) Second 54s

WCPUID System/CPU Clock 200.04 / 3000.54

Intel Pentium4 3GHz (FSB 800) Hyper-Threading Support

KINGSTON D328DW 512M DDR400 X 2 PCS Total 1Gbyte Memory

ON BOARD VGA (1024X768X32BIT Color)

IBM IC35L040AVVN07-0 (ATA-100 7200RPM)

Award Optimal default

3

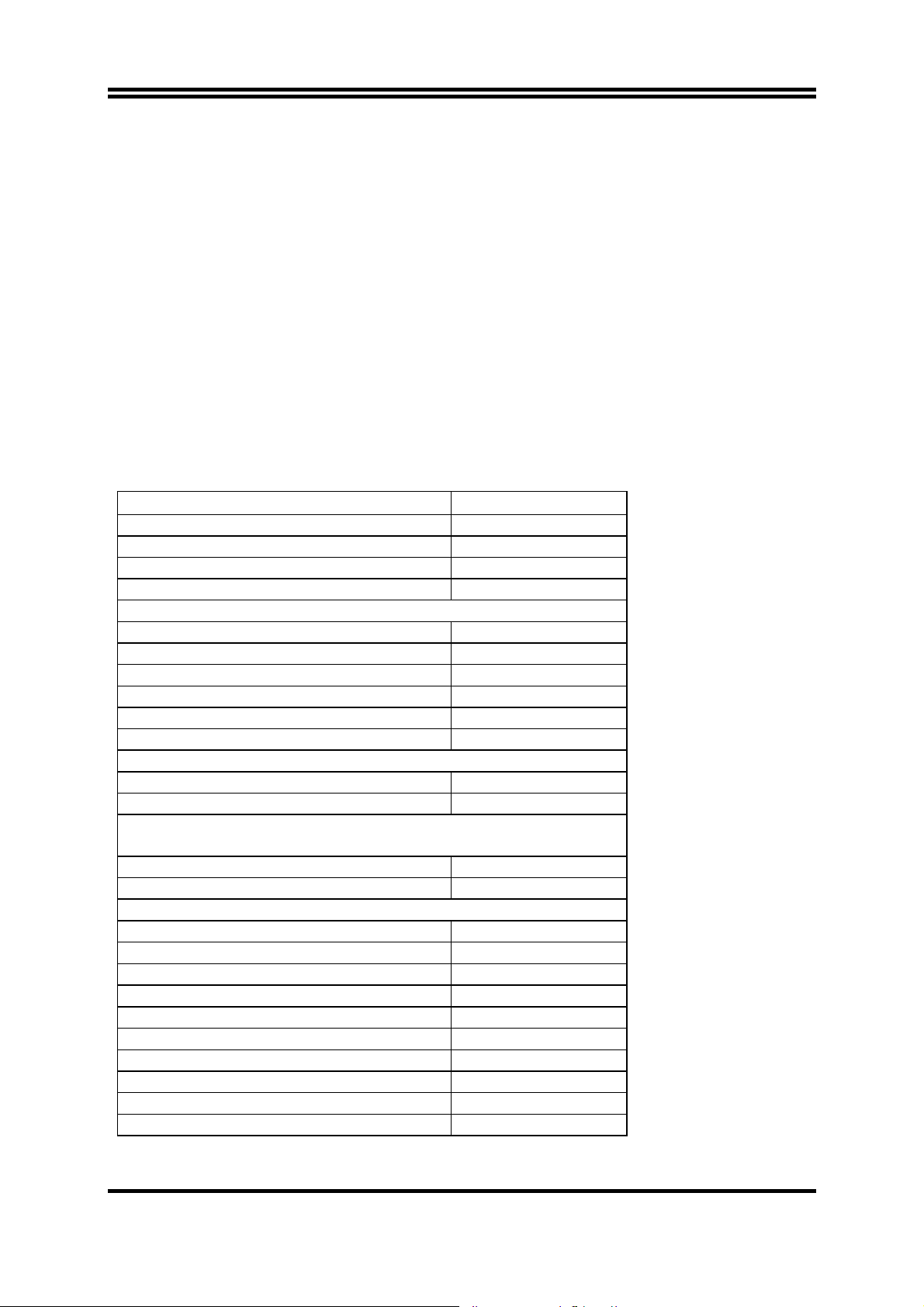

1-4 Layout Diagram & Jumper Setting

PRINT

RJ45

LAN

MIC

PS/2 Mouse

PS/2 Keyboard

K/B Power

ON Jumper (JP1)

PS2 KB/Mouse Port

PC99 Back Panel

SFAN1

USB Port

ATX 12V Connector

USB Port/

LAN Connector

COM1

ATX Power Connector

VGA

LINE-IN

LINE-OUT

USB1

USBLAN

CPU FAN

CPU Socket

Floppy

Connector

DDR Socket X2

VIA P4M800CE

Chipset

ATA 133 IDE

Connector (IDE1, IDE2)

Audio Connector

VIA VT6103

LAN PHY

ITE IT8705F Chip

PCI Slot

4MBit Flash ROM BIOS

6-CH AC’97

Audio Codec

Front Panel Audio

CD Audio

COM2

Connector

4

USB Port

(USB2, USB3)

USB Power

On Jumper (JP4)

AGP Slot

VIA VT8237R Chip

Serial-ATA

Connector (SATA1, 2)

Clear CMOS (JBAT)

SFAN2

Speaker / Power LED Connector

Front Panel Connector

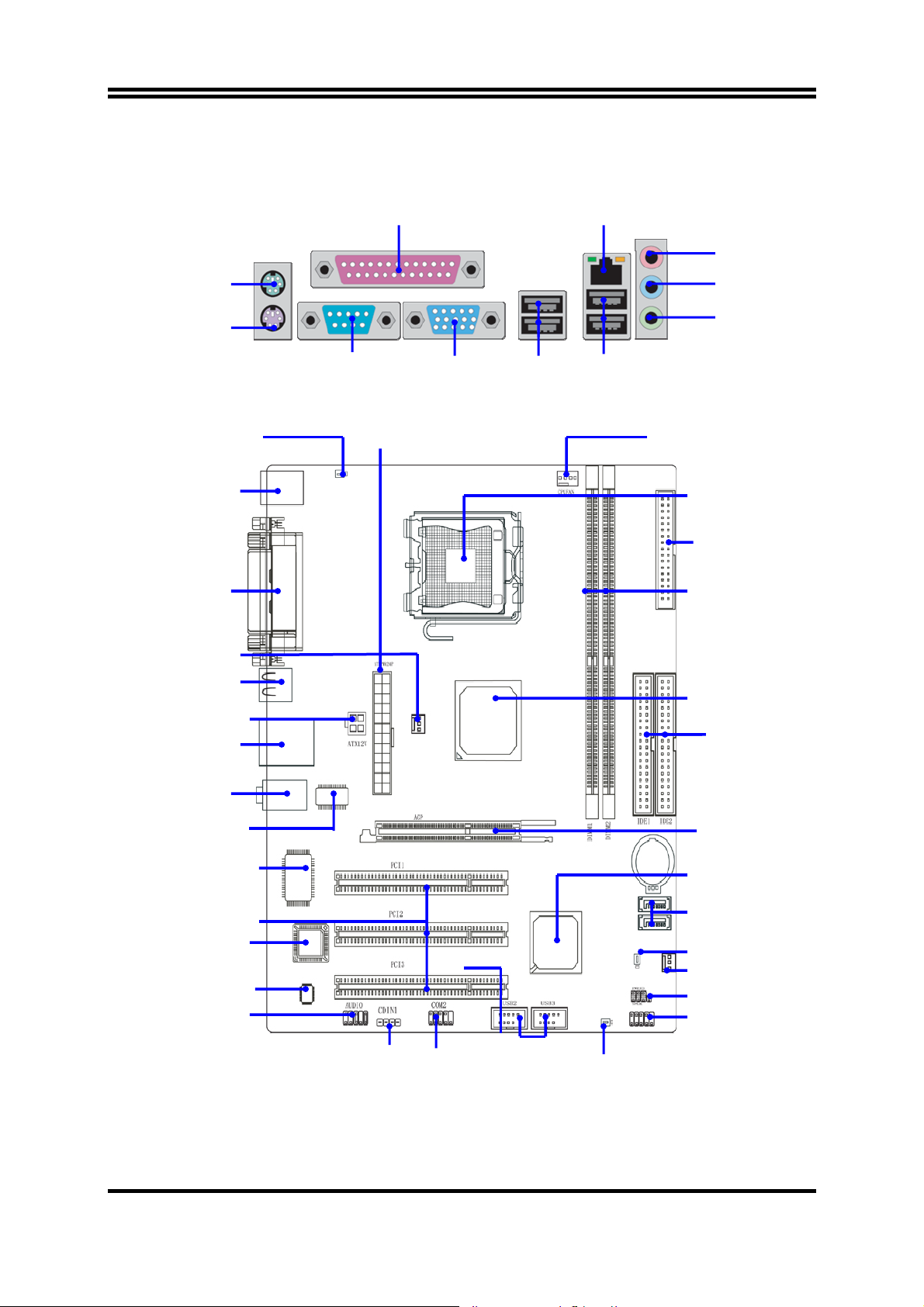

Jumpers

Jumper Name Description Page

JBAT

JP1

JP4

CMOS RAM Clear

Keyboard Power On Enable/Disabled

USB Power On Enable/Disabled

3-pin Block P.6

3-pin Block P.7

3-pin Block P.7

Connectors

Connector Name Description Page

ATXPWR Power Connector 24-pin Block P.20

ATX12V ATX 12V Power Connector 4-pin Block P.21

PS2KBMS PS/2 Mouse & PS/2 Keyboard

Connector

USB1 USB Port Connector 4-pin Connector P.22

USBLAN LAN Port Connector RJ-45 Connector P.22

PARALLEL Parallel Port Connector 25-pin Female P.22

AUDIO Audio Connector 3 phone jack Connector P.22

COM1 Serial Port COM1 Connector 9-pin Connector P.22

VGA VGA Connector

FDD Floppy Driver Connector 34-pin Block P.22

IDE1/IDE2 Primary/Secondary IDE Connector 40-pin Block P.23

6-pin Female P.22

15-pin Female

P.22

Headers

Header Name Description Page

AUDIO MIC header 9-pin Block P.24

USB2, USB3 USB Port Headers 9-pin Block P.25

HD LED IDE activity LED 2-pin Block P.25

RESET Reset switch lead 2-pin Block P.25

SPEAK PC Speaker connector 4-pin Block P.25

PWR LED Power LED 2-pin Block P.25

PWR BTN Power switch 2-pin Block P.25

SFAN1, SFAN2

CPUFAN

COM2 Serial Port COM2 Connector 9-pin Block P.26

CD_IN CD Audio-In Headers 4-pin Block P.26

Expansion Sockets

Socket/Slot Name Description Page

LGA 775 Socket CPU Socket LGA 775 CPU Socket

DDR1, DDR2 DDR Module Socket 184-pin DDR Module Socket P.18

PCI1, PCI2, PCI3 PCI Slot 32-bit PCI Local Bus Expansion slots P.20

AGP AGP 4X/8X Mode Slot AGP Expansion Slot P.20

FAN Headers 3-pin Block P.26

P.8

5

Chapter 2

Hardware installation

2-1 Hardware installation Steps

Before using your computer, you had better complete the following steps:

1. Check motherboard jumper setting

2. Install CPU and Fan

3. Install System Memory (DIMM)

4. Install Expansion cards

5. Connect IDE and Floppy cables, Front Panel /Back Panel cable

6. Connect ATX Power cable

7. Power-On and Load Standard Default

8. Reboot

9. Install Operating System

10. Install Driver and Utility

2-2 Checking Motherboard’s Jumper Setting

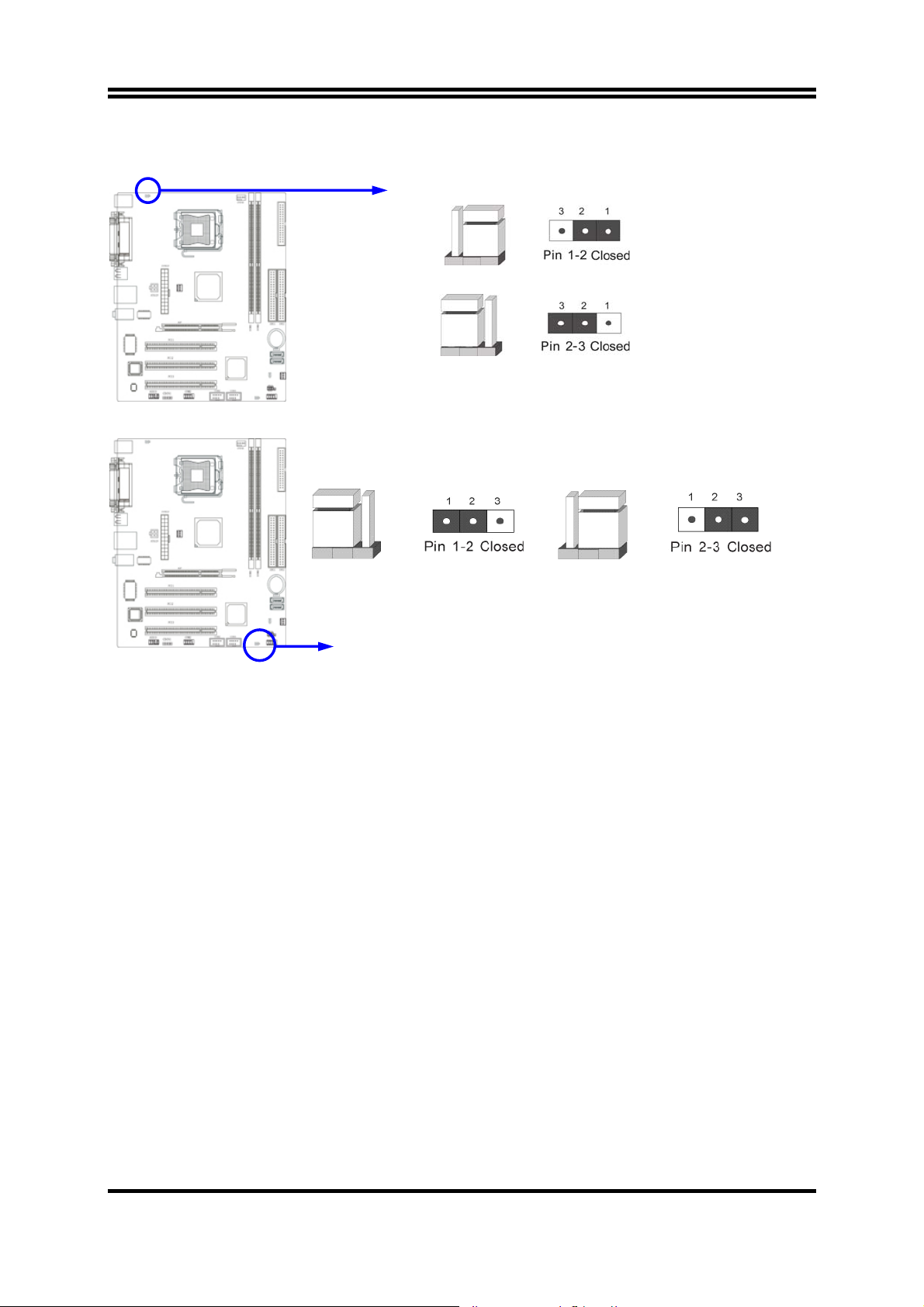

(1) CMOS RAM Clear (3-pin) : JBAT

A battery must be used to retain the motherboard configuration in CMOS RAM short 1-2

pins of JBAT to store the CMOS data.

To clear the CMOS, follow the procedure below:

1. Turn off the system and unplug the AC power

2. Remove ATX power cable from ATX power connector

3. Locate JBAT and short pins 2-3 for a few seconds

4. Return JBAT to its normal setting by shorting pins 1-2

5. Connect ATX power cable back to ATX power connector

Note: When should clear CMOS

1. Troubleshooting

2. Forget password

3. After over clocking system boot fail

JBATJBAT

1-2 Closed Normal

CMOS RAM Clear Setting

2-3 Closed Clear CMOS

6

(2) Keyboard function Enabled/Disabled: JP1

JP1

1-2 Closed KB/USB Power ON Disable (Default)

JP1

2-3 Closed KB/USB Power ON Enabled

Keyboard/Mouse Power On Setting

(3) USB Power On function Enabled/Disabled: JP4

JP4 JP4

1-2 closed USB Power On Disable

(Default)

USB Power On Setti ng

2-3 closed USB P o wer On Enabled

2-3 Install CPU

2-3-1 Glossary

Chipset (or core logic) - two or more integrated circuits which control the interfaces between

the system processor, RAM, I/O devises, and adapter cards.

Processor slot/socket - the slot or socket used to mount the system processor on the

motherboard.

Slot (AGP, PCI, ISA, RAM) - the slots used to mount adapter cards and system RAM.

AGP - Accelerated Graphics Port - a high speed interface for video cards; runs at 1X

(66MHz), 2X (133MHz), or 4X (266MHz),

or 8X (533MHz)

PCI - Peripheral Component Interconnect - a high speed interface for video cards, sound

cards, network interface cards, and modems; runs at 33MHz.

ISA - Industry Standard Architecture - a relatively low speed interface primarily used for

sound cards and modems; runs at approx. 8MHz.

Serial Port - a low speed interface typically used for mouse and external modems.

Parallel Port - a low speed interface typically used for printers.

PS/2 - a low speed interface used for mouse and keyboards.

7

USB - Universal Serial Bus - a medium speed interface typically used for mouse, keyboards,

scanners, and some digital cameras.

Sound (interface) - the interface between the sound card or integrated sound connectors and

speakers, MIC, game controllers, and MIDI sound devices.

LAN (interface) - Local Area Network - the interface to your local area network.

BIOS (Basic Input/Output System) - the program logic used to boot up a computer and

establish the relationship between the various components.

Driver - software, which defines the characteristics of a device for use by another device or

other software.

Processor - the "central processing unit" (CPU); the principal integrated circuit used for

doing the "computing" in "personal computer"

Front Side Bus Frequency -

the working frequency of the motherboard, which is generated

by the clock generator for CPU, DRAM and PCI BUS.

CPU L2 Cache -

the flash memory inside the CPU, normal it depend on CPU type.

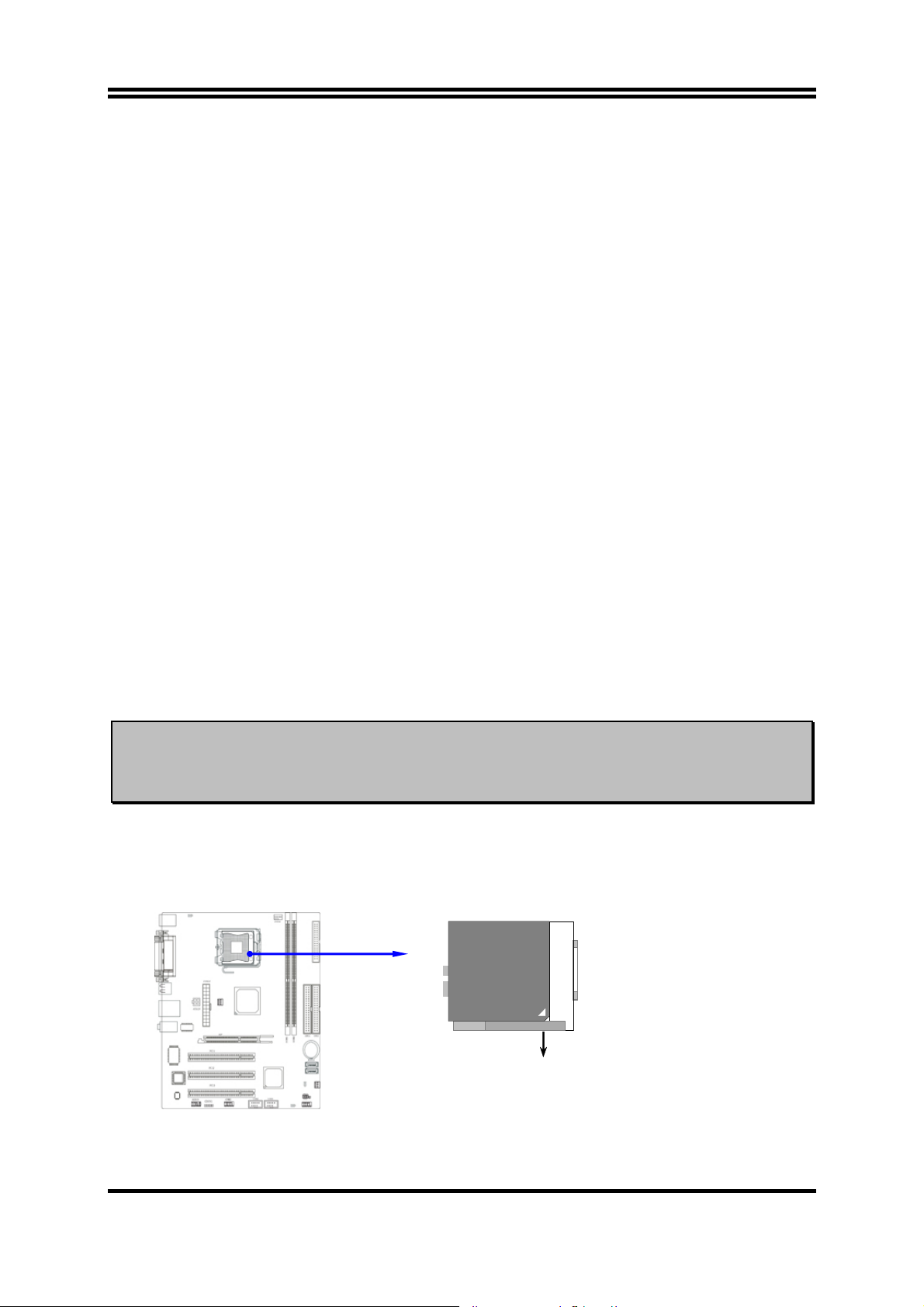

2-3-2 About Intel Pentium 4 LGA775 CPU

This motherboard provides a 775-pin surface mount, LGA775 Land Grid Array socket, referred to as

the LGA775 socket supports Intel Pentium 4 processor in the 775 Pin package utilizes Flip-Chip Land

Grid Array (FC-LGA4) package technology.

The CPU that comes with the motherboard should have a cooling FAN attached to prevent

overheating. If this is not the case, then purchase a correct cooling FAN before you turn on your

system.

WARNING!

To install a CPU, first turn off your system and remove its cover. Locate the LGA775 socket and

open it by first pulling the level sideways away from the socket then upward to a 90-degree angle.

Insert the CPU with the correct orientation as shown below. The notched corner should point toward

the end of the level. Because the CPU has a corner pin for two of the four corners, the CPU will only

fit in the orientation as shown

Be sure that there is sufficient air circulation across the processor’s heatsink and CPU

cooling FAN is working correctly, otherwise it may cause the processor and motherboard

overheat and damage, you may install an auxiliary cooling FAN, if necessary.

.

LGA775

Colden Arrow

CPU LGA775 Socket

When you put the CPU into the LGA775 socket. No force require to insert of the CPU, then

press the level to Locate position slightly without any extra force.

8

2-3-3 LGA 775 CPU Installation Guide

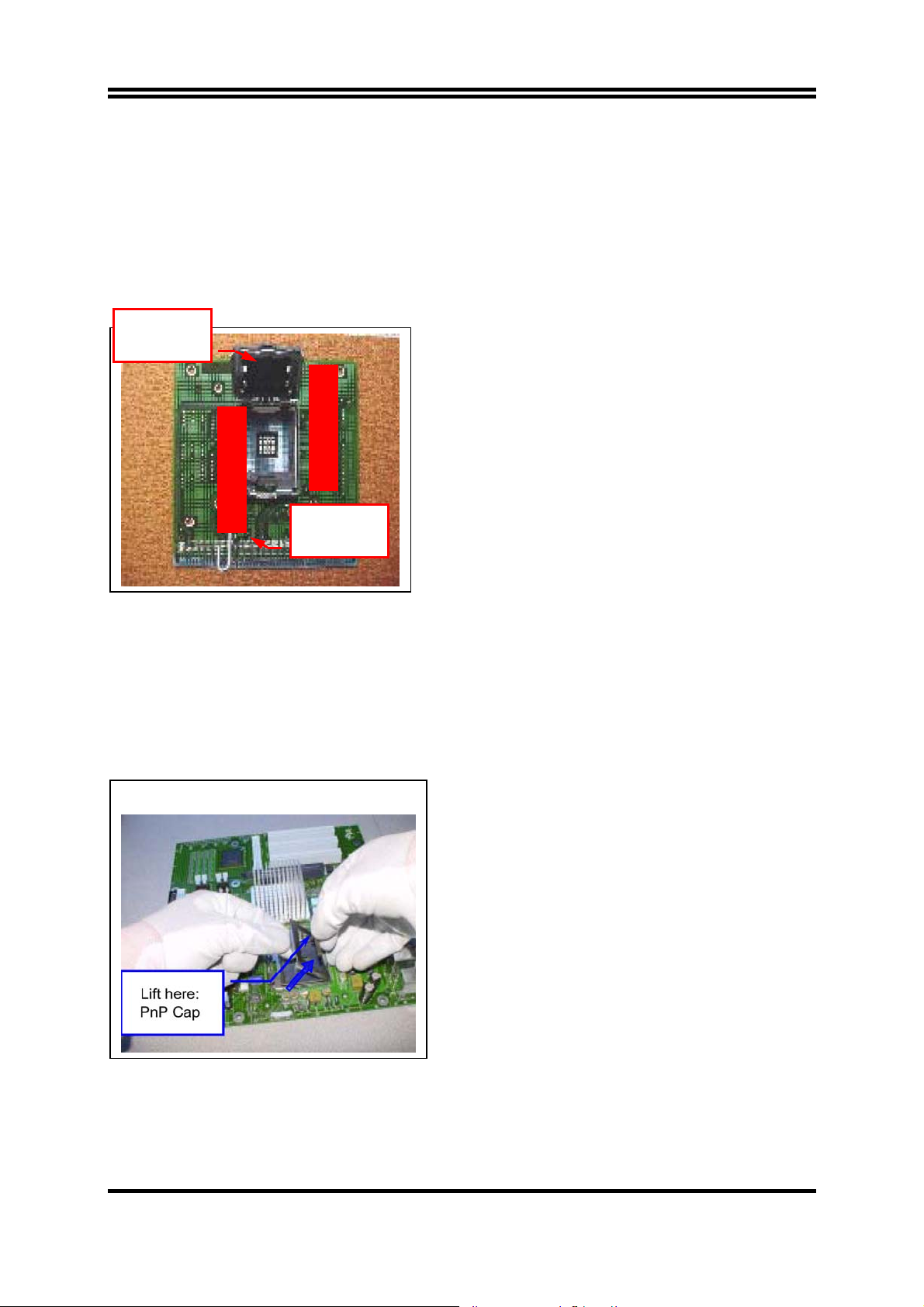

Socket Preparation

1. Opening the socket:

Note: Apply pressure to the corner with right hand thumb while opening/closing the load lever,

otherwise lever can bounce back like a “mouse trap” and WILL cause bent contacts (when

loaded)

Socket Load

Plate Open

i. Disengage Load Lever by depressing down and

out on the hook to clear retention tab

ii. Rotate Load Lever to fully open position at

approximately 135degrees

iii. Rotate Load Plate to fully open position at

Socket Load

Lever Open

approximately 100degrees

2. Remove PnP Cap (Pick & Place Cap)

i. With left hand index finger and thumb to support the load plate edge, engage PnP cap with right

hand thumb and peel the cap from LGA775 Socket while pressing on center of PnP cap to assist in

removal.

ii. Set PnP cap aside. Always put PnP cap back on if the processor is removed from the socket.

iii. Visually inspect PnP cap for damage. If damage observed, replace the PnP cap.

Note: After PnP cap removal, make sure

socket load plate and contacts are free of

foreign material; Refer to Overview Module for

FM cleaning.

Note: Optionally, remove PnP cap after CPU insertion.

This will compromise the ability to visually

inspect socket.

9

3. Visually inspect for bent contacts (Recommend at least 1stpass visual inspection)

NOTE: Refer to the Handling and Inspection Module for 1stand 2ndpass inspection details.

NOTE: Glove images are for illustrative purposes only. Please consult local safety guidelines for

specific requirements

NOTE: Recommend not to hold the load plate as a lever, instead hold at tab with left hand, removing

the PnP cap with right hand

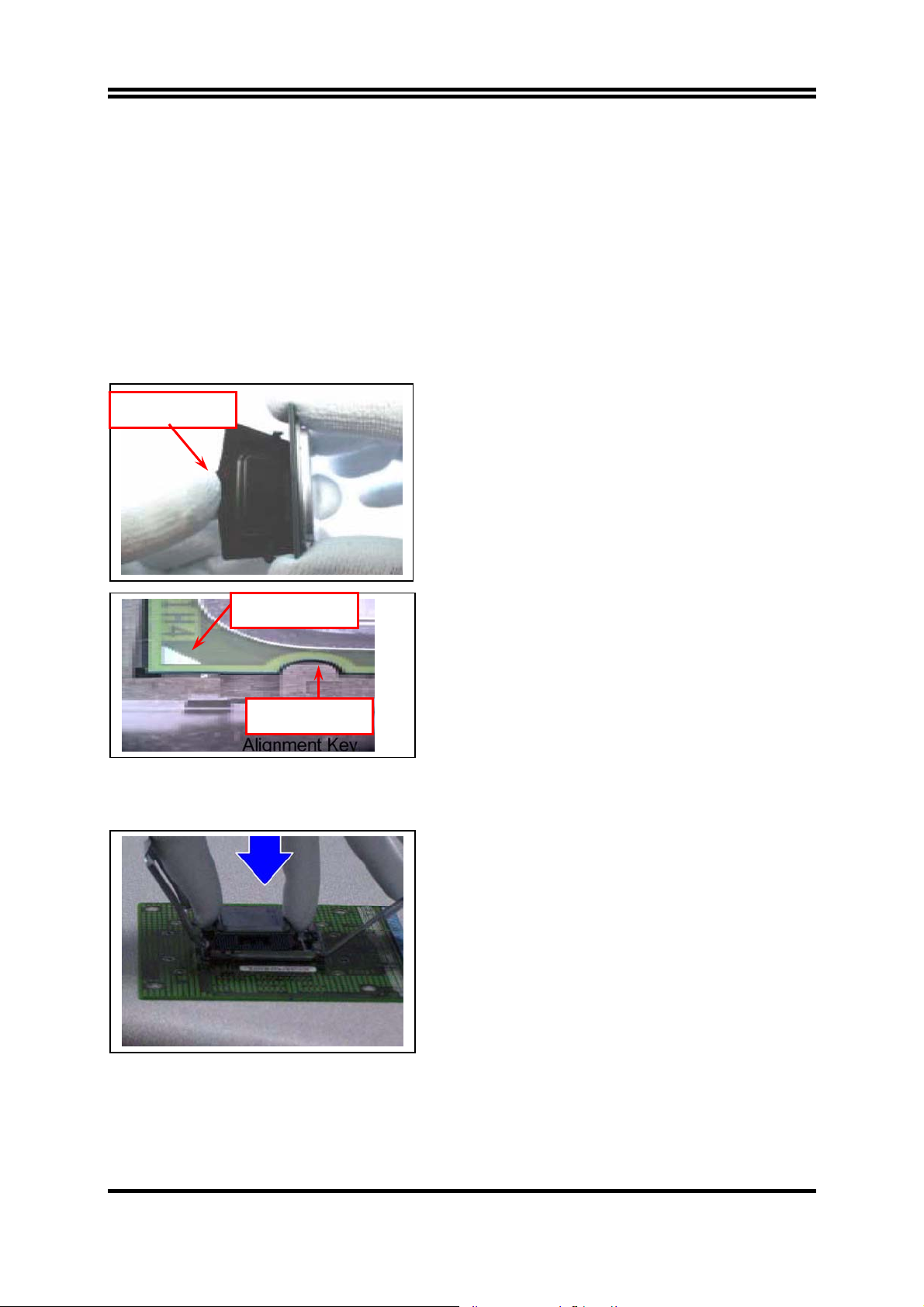

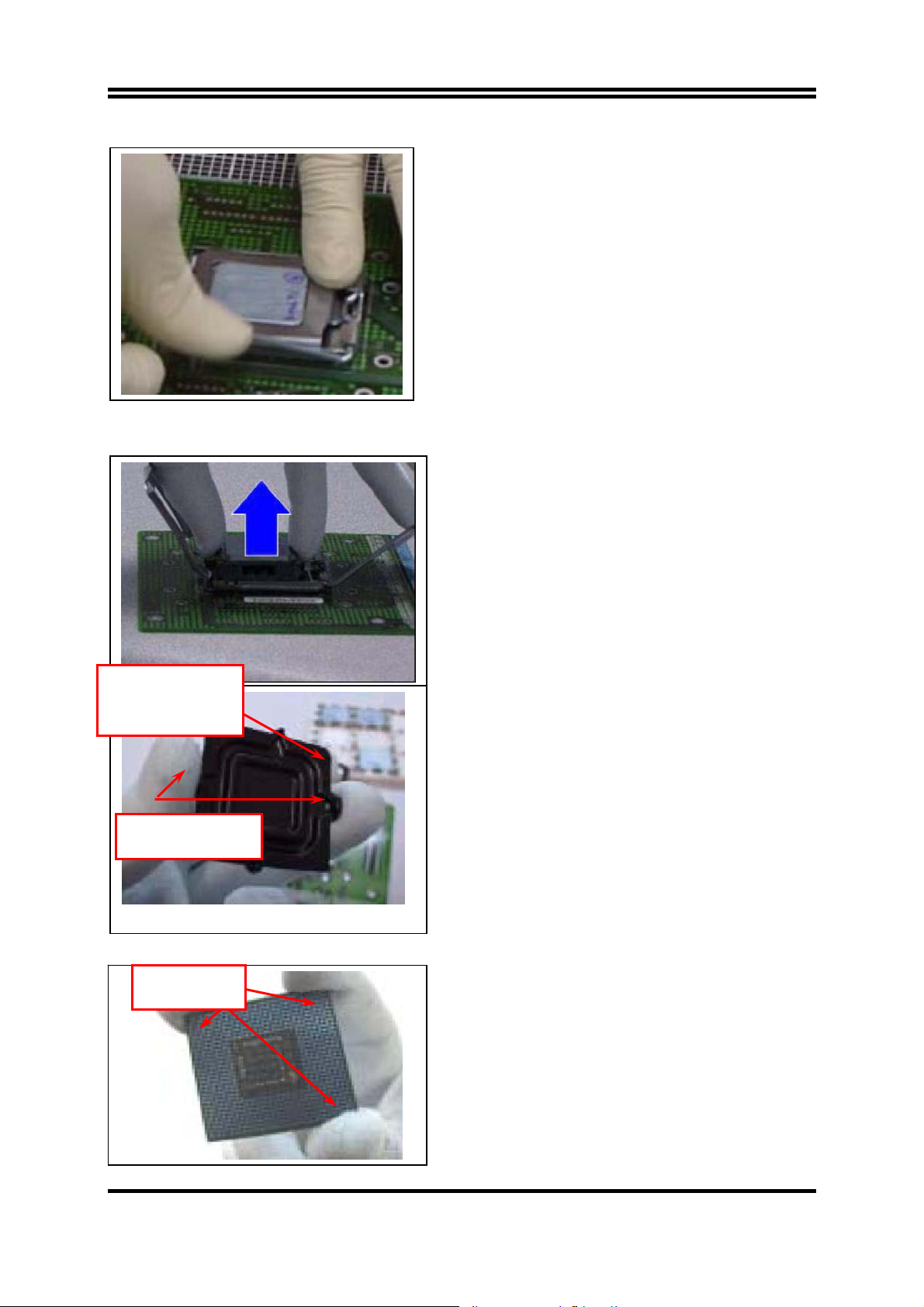

775-land LGA Package Insertion

Press to remove

Pin 1 Indicator

Alignment Key

1. Lift processor package from shipping media by

grasping the substrate edges ONLY.

Note: Orient processor package such that the Pin 1

triangle mark is on bottom left and both key

notches are on left side

2. Land Side Cover Handling: Remove land side cover

with the opposite hand by depressing larger

retention tab and peeling the cover away

3. Set and reserve the land side cover aside.

Note: Always keep the land side cover on the

processor when not in the socket.

4. Visually inspect the package gold pads: Scan the

processor package gold pad array for presence of

foreign material. Refer to Overview Module for FM

cleaning recommendations

5. Orient the package with IHS up. Locate Pin 1 and

the two orientation key notches

6. Carefully place the package into the socket body

using a purely vertical motion

CAUTION: Using Vacuum Pen for installation is not recommended

7. Verify that package is within the socket body and

properly mated to the orient keys

8. Close the socket by

i. Rotating the Load Plate onto the package HIS

ii. While pressing down lightly on Load Plate, engage

the Load Lever.

iii. Securing Load Lever with Load Plate tab under

retention tab of Load Lever

10

775-Land Package Removal

1. Open the Load Plate/Lever with both hands:

With left hand index finger and thumb to support

the load plate edge, engage PnP cap with right hand

thumb and peel the cap from LGA775 Socket while

pressing on center of PnP cap to assist in removal.

2. Pick up 775-land LGA package:

By Vacuum Pen: Place a minimum 9-mm cup at

approximately the center of IHS.

Recommend not to place Vacuum Pen on IHS edge.

Risk of dropping and causing bent contact.

Recommend not to use Vacuum Pen for inserting

CPU By Hand: Index finger to hold load plate hinge

Chamfer on Land Side

Cover (align this with

pin 1 mark on 775-land

LGA package)

Large Retention Tabs

(pointing towards user)

onto

Hold at corners

side and thumb to hold load lever side

3. Lift the package straight up and away.

4. Assemble processors land side cover immediately

to prevent contamination.

i. While holding the processor by the 3 corners, the

other hand lift land side cover from work surface

by grasping at the large retention tabs. Ensure

retention tabs and package are pointing each

other.

ii. Orientate so that land side cover chamfer is

matching with package Pin 1 location.

iii. Hook the first large retention tab on the package

substrate. Then press the opposite tab onto the

substrate.

iv. Place processor with land side cover installed

proper shipping media or other ESD approved

work surface

11

r

5. Visually inspect socket contact array

1. First Pass Inspection

i. Scan socket contact array at varying angles noting the presence of any foreign material

ii. If foreign material can’t be blown off by compressed air, or mechanical damage (Mode1 or 4)

observed, reject the motherboard for further evaluation or socket replacement.

2. Second Pass Inspection

i. Repeat 2 more times to sight down the rows and columns from each of the 4 sides of the socket to

ensure all contacts within the array are inspected

ii. Inspect for Mode2, Mode3, and Mode5 failures

Note: Refer to the Test Module for detail visual inspections

6. Assemble LGA775 socket PnP cap

i. Secure/Hook the back side of PnP cap.

ii. Snap down the front side to fully secure

7. Close the Socket

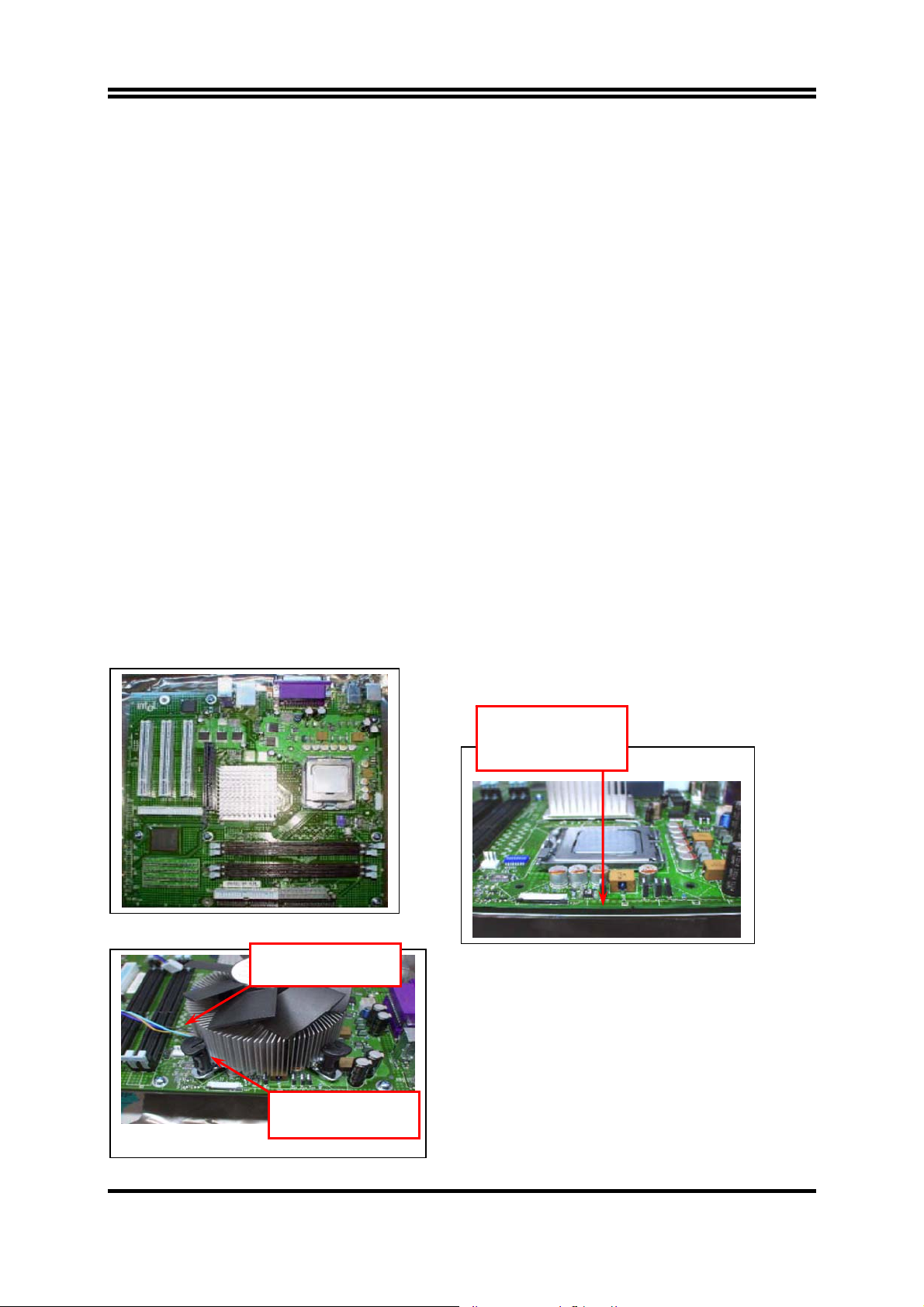

Intel Reference Thermal Solution Assembly

NOTE: Depending on the configuration, Thermal Solution Integration procedure could perform with

M/B alone or with M/B in the Chassis.

Fan cabled on side

closest to MB heade

0.150-inch backside

clearance for fastener

installation

1. Place motherboard on support structure providing

minimum 0.150-inch backside clearance

2. Apply 300 mg of Thermal Interface Material (Shin-

Fastener slots

pointing straight out

Etsu G751) onto center of IHS

12

NOTE: Thermal Solutions that come with IntelR boxed

Apply Thermal

Interface Material

processor use pre-applied thermal interface material

and not grease.

3. Remove Heat Sink (HS) from packaging media

4. Place HS onto the LGA775 Socket

• Ensure fan cables are oriented on side closest to

fan header

• Align Fasteners with MB through-holes

5. Inspection

• Ensure cables are not trapped or interfere

fastener operation

• Ensure fastener slots are pointing straight out

from heatsink

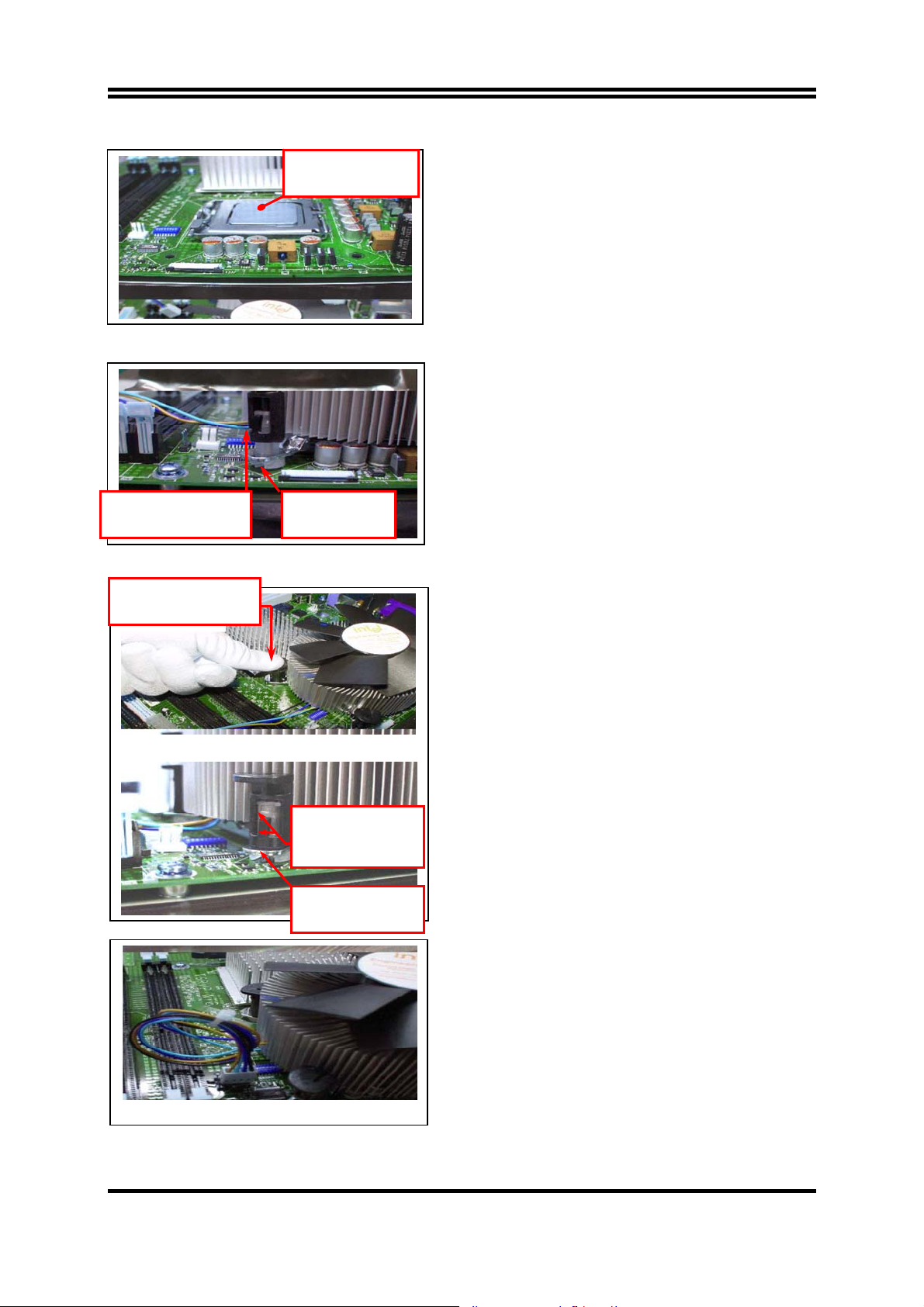

Fastener Cap not

resting against spring

Press Down

(4 Places)

Fastener flush

against MB

Both fastener

halves are flush

against spring

Fastener flush

against spring

6. Actuate fasteners

• While holding HS to prevent tilting, press down on

fastener caps with thumb to install and lock

Repeat with remaining fasteners

7. Inspection

• Verify the fasteners are properly seated

• Ensure both fastener cap and base are flush with

spring and motherboard

8. Connect fan header with Board header

9. Secure excess cable with tie-wrap to ensure

cable does not interfere with fan operation or

contact other components.

13

Intel Reference Thermal Solution Disassembly

1. Rotate fastener cap. turn to un-lock

2. Pull up fastener cap to un-seat 12

1. Disconnect fan cable from motherboard header

2. Turn fastener caps (4) counter-clock wise

90degrees to the un-locked position

• A flat-bladed screwdriver may be used if required

3. Pull up on fastener caps to unseat

4. Manually remove HS with gentle twist motion.

5. To re-assemble the HS, reset the fastener caps to

their original position with the slot perpendicular

to the HS. Then, follow the assembly instructions.

Note: Thermal grease should be reapplied

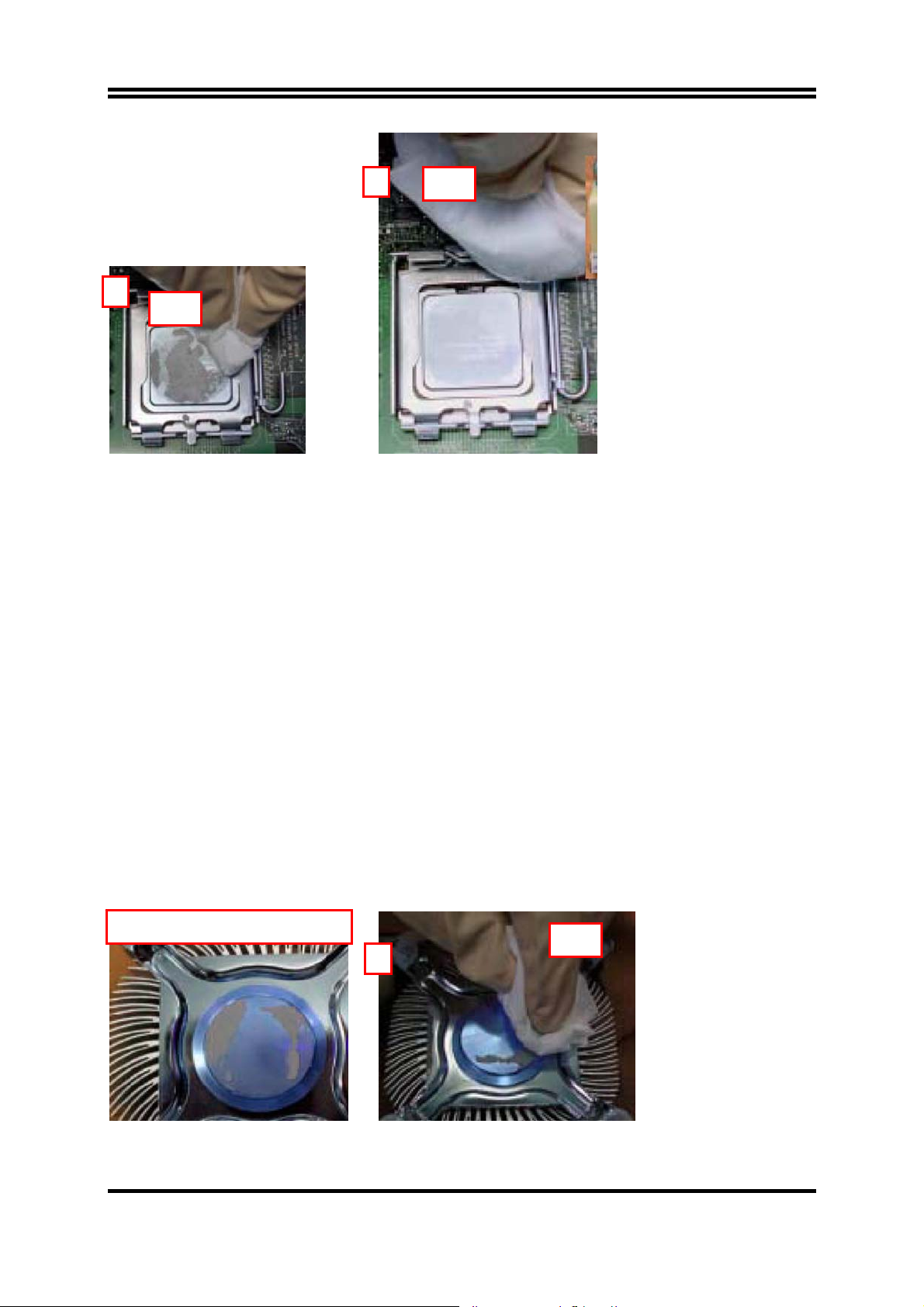

TIM and Grease Removal from CPU

1 2

3

4

14

A

y

6

IP

5

Dry

1. Remove the heatsink from the socket

2. Gently push loose thermal interface material (TIM) to center of processor (pictures 2 and 3)

3. Remove pieces with dry cloth (picture 4)

4. Wipe with dry, lint-free cloth to remove most of the material (picture 5)

5. Wet another lint-free cloth with isopropyl alcohol (IPA) and wipe to clean remaining material

(picture 6)

6. Be careful to remove material from gaps between processor and load plate

7. For thermal grease removal use Step 4-6

TIM and Grease Removal from Heat-sink

Note: Remove and replace the TIM from the heatsink if you are re-using the heatsink on a new

processor

1. Use dry, lint-free cloth and wipe package to remove most of the material

2. Wet another lint-free cloth with isopropyl alcohol (IPA) and wipe heatsink to clean remaining

material

Removal TIM from heatsink

1

Dr

15

Loading...

Loading...