Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Planer/Molder

Model JPM-13CS

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708524

Ph.: 800-274-6848 Revision G2 06/2014

www.jettools.com Copyright © 2014 JET

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provid e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tat e Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

4.0 About this manual .......................................................................................................................................... 5

5.0 Electrical connections .................................................................................................................................... 6

5.1 Grounding instructions ................................................................................................... ............................ 6

5.2 115 Volt operation ...................................................................................................................................... 6

5.3 230 Volt operation ...................................................................................................................................... 6

6.0 On-Off Switch Padlock ................................................................................................................................... 7

7.0 Specifications ................................................................................................................................................. 8

8.0 Glossary ......................................................................................................................................................... 9

9.0 Setup and assembly ..................................................................................................................................... 10

9.1 Shipping contents ..................................................................................................................................... 10

9.2 Unpacking and cleanup ............................................................................................................................ 10

9.3 Assembly .................................................................................................................................................. 10

10.0 Adjustments: Planing ................................................................................................................................. 10

10.1 Depth of cut ............................................................................................................................................ 10

10.2 Adjusting depth of cut scale ................................................................................................................... 10

10.3 Feed rate adjustment ............................................................................................................................. 11

10.4 Adjusting V-Belt Tension ........................................................................................................................ 11

10.5 Knife adjustment ..................................................................................................................................... 11

10.6 Knife replacement .................................................................................................................................. 12

10.7 Adjusting infeed roller and outfeed rollers for planing ............................................................................ 12

10.8 Adjusting chip deflectors for planing ....................................................................................................... 13

11.0 Planing procedure ...................................................................................................................................... 13

11.1 Dealing with warped wood ..................................................................................................................... 13

11.2 Wood Grain ............................................................................................................................................ 14

12.0 Molding setup and adjustments ................................................................................................................. 14

12.1 Installing molding cutters ........................................................................................................................ 14

12.2 Setting feed rollers for molding ............................................................................................................... 15

12.3 Making & installing a bedboard .............................................................................................................. 16

12.4 Making guide rails .................................................................................................................................. 16

12.5 Guide rail placement and attachment ..................................................................................................... 16

13.0 Molding procedure ..................................................................................................................................... 17

13.1 Setting table height for first pass ............................................................................................................ 17

13.2 Back Relief Molding ................................................................................................................................ 18

13.3 Tongue and Groove Molding .................................................................................................................. 18

14.0 Maintenance ............................................................................................................................................... 18

14.1 Lubrication .............................................................................................................................................. 18

15.0 Troubleshooting the JPM-13CS ................................................................................................................. 19

15.1 Mechanical and electrical problems ....................................................................................................... 19

15.2 Performance problems ........................................................................................................................... 20

16.0 Replacement Parts ..................................................................................................................................... 21

16.1.1 Table and Base Assembly – Exploded View ....................................................................................... 22

16.1.2 Table and Base Assembly – Parts List ................................................................................................ 23

16.2.1 Cutterhead and Roller Assembly – Parts List ...................................................................................... 24

16.2.2 Cutterhead and Roller Assembly – Parts List ...................................................................................... 24

16.3.1 Gearbox Assembly – Parts List ........................................................................................................... 26

16.3.2 Gearbox Assembly – Parts List ........................................................................................................... 27

16.4.1 Stand and Motor Assembly – Parts List .............................................................................................. 28

16.4.2 Stand and Motor Assembly – Parts List .............................................................................................. 29

17.0 Electrical Connections ................................................................................................................................ 30

3

Page 4

3.0 Safety warnings

For your own safety, read this in st ruction manual before operati ng the tool.

Wear Eye Protection

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND WRENCHES. Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before turning it on.

3. KEEP THE WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. DO NOT USE IN A DANGEROUS ENVIRONMENT. Don’t use power tools in dam p or wet locations, or

expose them to rain. Keep work area well lighted.

5. KEEP CHILDRE N A WAY . All visitors should be kept at safe distance from the work area.

6. MAKE THE WORKSHOP KID PROOF wi th padlocks, master switches, or by removing starter keys.

7. DON’T FORCE THE TOOL. It will do the job better and safer at the rate for which it was designed.

8. USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was not designed.

9. USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in the line voltage resulting in loss of power and overheating. The table

below shows the correct size to use depending on the cord length and name plate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Volts Total Length of Cord in Feet

120V 25 50 100 150

240V 50 100 200 300

AWG

14 12 Not recommended

Table 1

10. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair

covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also use face or dust masks if the cutting operation is dusty.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

12. SE CUR E WOR K . Use clamps or a vise to hold the work when its practical. It’s safer than using your hand

and it frees both hands to operate the tool.

13. DON’T OVERREACH. Keep proper footing and balance at all times.

14. MAINT AIN TOO LS W ITH C ARE. Keep tool s sharp and clean for best a nd safest performance. Follow

instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits cutters, and the

like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switch is in the off position before

plugging in the machine.

17. USE RECOMMEN DED ACCESSORIES. Consult the owner’s manual for recommended accessories. The

use of improper accessories may cause a risk of injury.

4

Page 5

18. NEVER STAND ON A TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate properly and perform its intended function. Check for

alignment of moving parts, bindi ng of m oving part s, breakage of parts, m ounting, a nd any other conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or

replaced.

20. DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation of the blade or

cutter only.

21. NEVER LEAVE THE TOOL RUNNING UNATTENDED. TURN THE POWER OFF. Don’t leave the tool

until it comes to a complete stop.

22. Some dust created by power sanding, sawing, grinding, drilling and other construction activities contain

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

•

Crystalline silica from bricks, cement and other masonry products.

•

Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

This means that if preca utions are not heeded, it m ay result in minor injury a nd/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly even

death.

4.0 About this manual

This manual is provided by JET covering the safe operation and maintenance procedures for a JET Model

JPM-13CS Planer-Molder. This manual contains instructions on installation, safety precautions, general

operating procedures, maintenance instructions and parts breakdown. Your machine has been designed and

constructed to provide years of trouble-free operation if used in accordance with the instructions as set forth in

this document.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our

web site: www.jettools. com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attem pting assembly

or operation! Failure to comply may cause serious injury!

5

Page 6

5.0 Electrical connections

5.1 Grounding instructions

In the event of a malfunction or breakdown, grounding provides a pat h of lea st resistance for electr ic c urrent to

reduce the risk of electric shock. This tool is eq uipped with an electric cord hav ing an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a m atc hing outlet that is proper ly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor

with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding

conductor. If repair or rep lacement of the electric cord or plug is necessary, do not connect the equipm entgrounding conductor to a live terminal.

Check with a qualified electrician or service personnel if t he grounding instructions

are not completely understood, or i f in doubt as to whether the tool is proper ly grounded. Failure to

comply may cause serious or fatal injury.

Use only 3-wire extension cords that have 3-prong gro unding plugs and 3-pole receptacles that accept the

tool's plug.

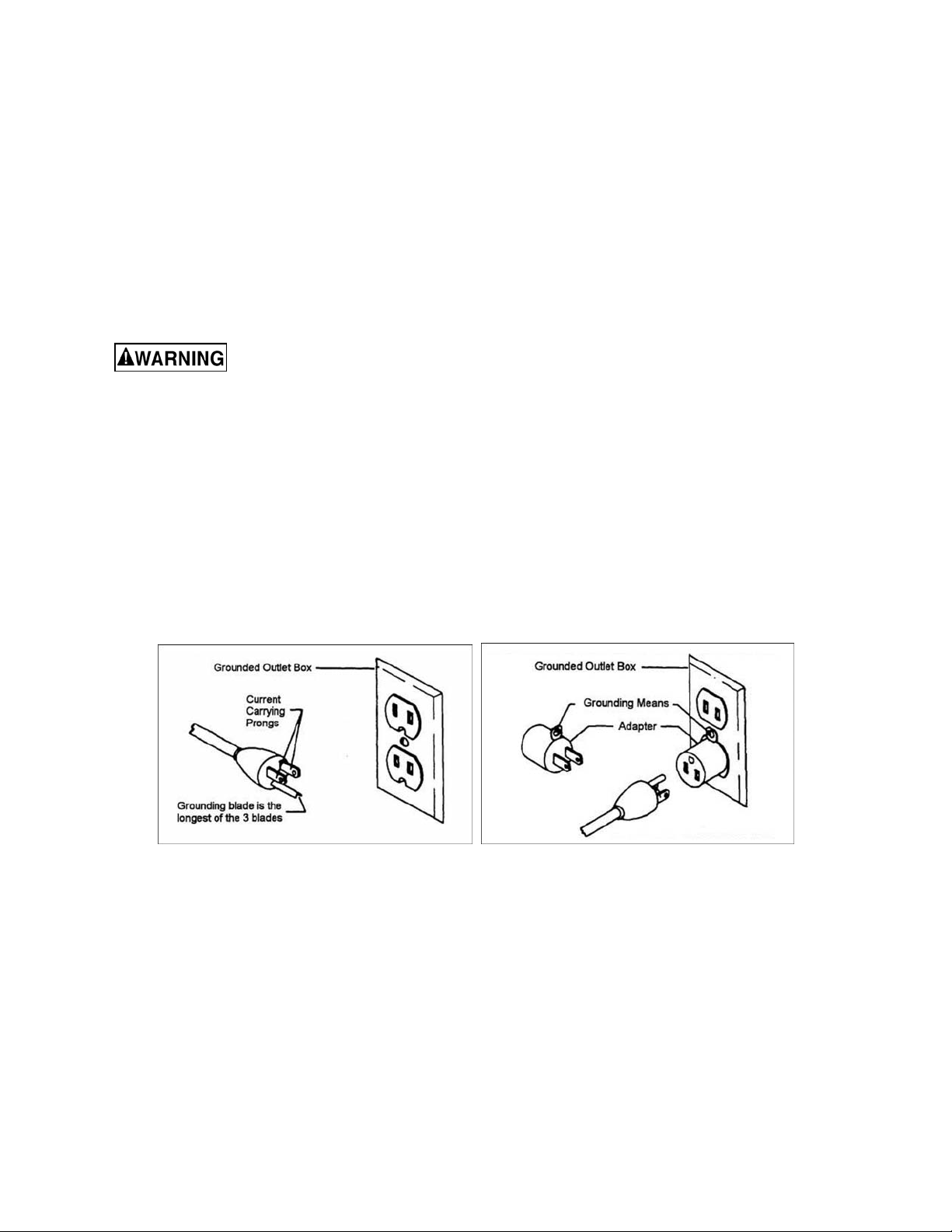

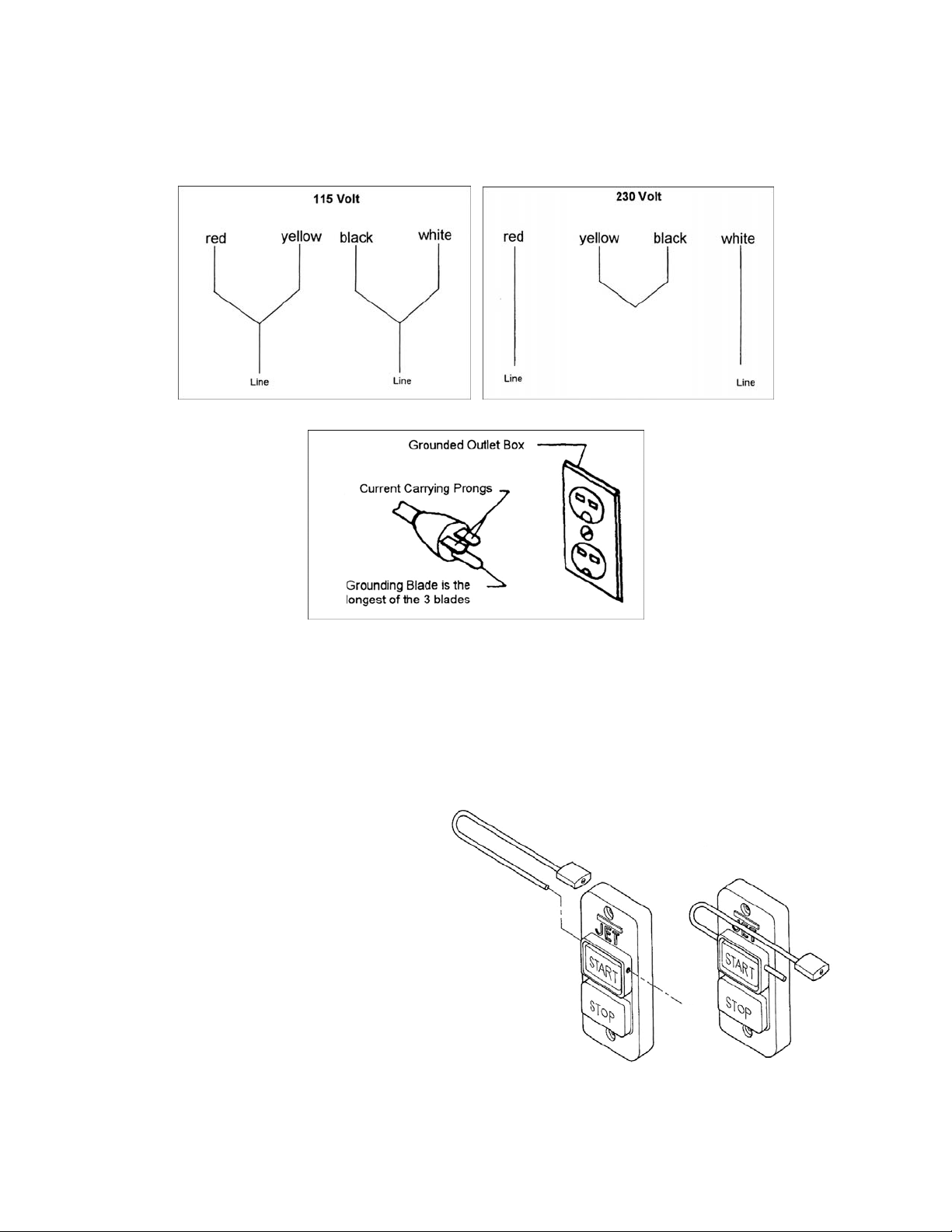

5.2 115 Volt operation

As received from the factory, your planer/molder is ready to run at 115 volt operation. This planer/molder, when

wired for 115 volt, is intended for use on a circuit that has an outlet and a plug that looks like the one illustrated

in Figure 1a. A temporary adapter, which looks like the adapter as i llustrated i n Figure 1b, may be used to

connect this plug to a two-pole receptacle, a s shown i n Figure 1b if a properl y gro unded outlet is not avai lable.

The temporary adapter should only be used until a properly grounded outlet can be installed by a qualified

electrician. This adapter is not applicable in Canada. The green colored rigid ear, lug, or tab, extending from

the adapter, must be connected to a permanent ground such as a properly grounded outlet bo x, as shown in

Figure 1b.

Figure 1a Figure 1b

5.3 230 Volt operation

If 230V, single phase operation is desired, the following instructions must be followed:

1. Disconnect the machine from the power source.

2. Thi s planer/molder is supplied with four motor leads that are connected for 115V operation, as shown i n

Figure 2a. Reconnect these four motor leads for 230V operation, as shown in Figure 2b.

3. The 115V attachment plug, supplied with the planer/molder, m ust be replaced with a UL/CSA listed plug

suitable for 230V operation, similar to the one shown in Figure 3. Contact your local Authorized JET

Service Center or qualified electrician for proper procedures to install the plug. The planer/molder must

comply with all local and national codes after the 230 volt plug is installed.

6

Page 7

4. The planer/molder with a 230 volt plug should only be connected to an outlet having the same

configuration as illustrated by the grounded outlet box in Figure 3. No adapter is available or should be

used with the 230 volt plug.

Important: In all cases (115 or 230 volts), make certain the receptacle in question is properly grounded.

If you are not sure, have a registered electrician check the receptacle.

Figure 2a Figure 2b

Figure 3

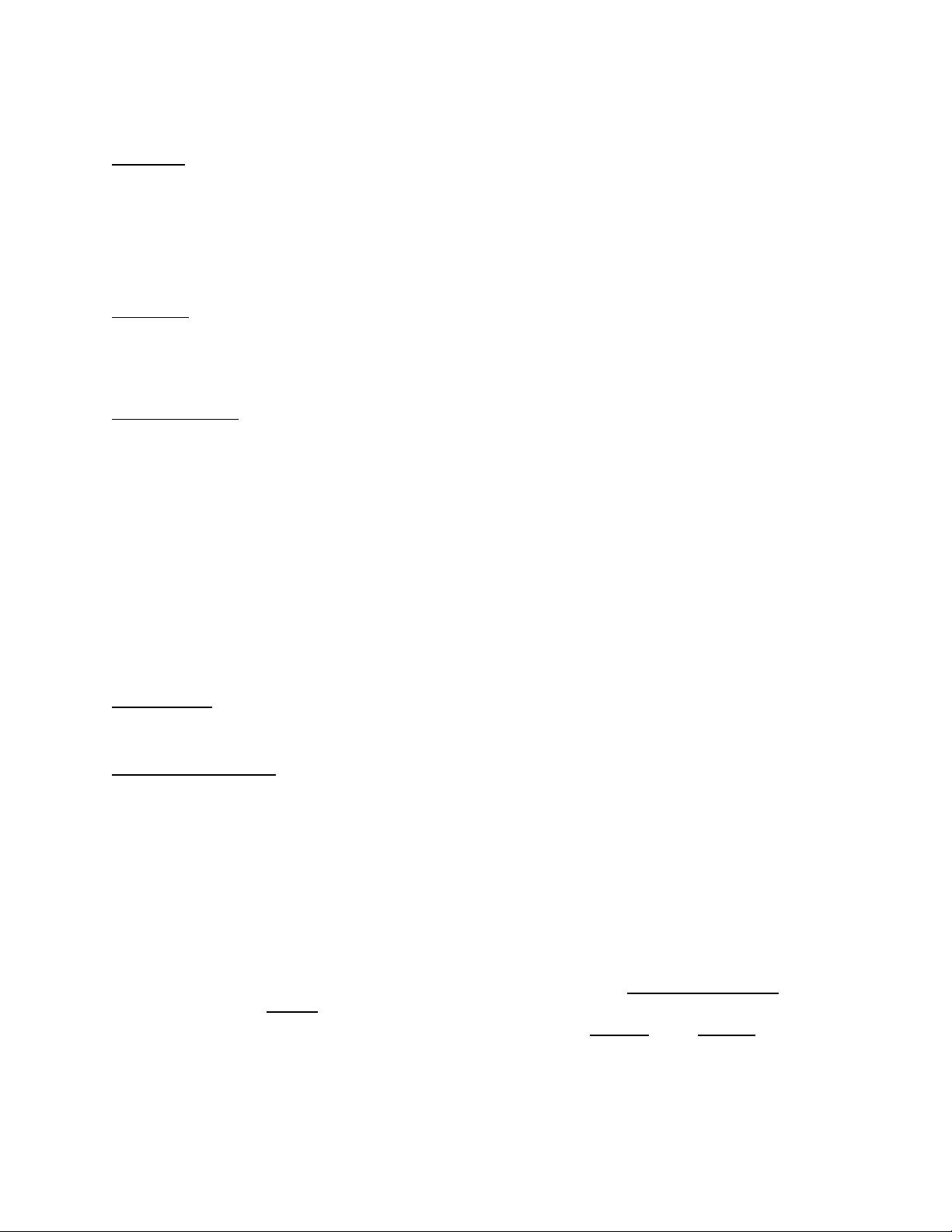

6.0 On-Off Switch Padlock

To safeguard your machine from unauthorized operation and to avoid accidental starting by young children, the

use of a padlock (not provided) is highly recommended.

To lock out an on-off switch (see Figure 4):

1. Open the padlock.

2. Insert through holes in the start button.

3. Close the padlock.

4. Place the key in a safe location.

Figure 4

7

Page 8

7.0 Specifications

Model number ........................................................................................................................................ JPM-13CS

Stock Number ............................................................................................................................................. 708524

Capacities:

Maximum Cutting Width ................................................................................................................. 13” (330 mm)

Maximum Thickness .................................................................................................................. 6-1/8” (156 mm)

Full Width Depth of Cut ............................................................................................................................... . 1/16”

Minimum Planing Length ............................................................................................................... 14” (356 mm)

Cuts per Minute ........................................................................................................................................ 13,500

Feed Rate, Planing ................................................................................................................................... 20 fpm

Feed Rate, Molding .................................................................................................................................. 10 fpm

Cutterhead:

Number of Knives .............................................................................................................................................. 3

Knife Size .................................................................................................................... 13-1/16”L x 1/8”W x 5/8”H

Cutterhead Diameter ................................................................................................................................ 2-9/16”

Cutterhead Speed (RPM) ............................................................................................................................ 4500

Motor and controls:

Motor type ......................................................................... totally enclosed fan cooled, induction, capacitor start

Horsepower ........................................................................................................................................... 1-1/2 HP

Phase .......................................................................................................................................................... single

Voltage ....................................................................................................................... 115/230V (prewired 115V)

Cycle ............................................................................................................................................................ 60Hz

Listed FLA (full load amps) ..................................................................................................................... 15/7.5 A

RPM ............................................................................................................................................................. 3450

Start capacitor ......................................................................................................................... 400MFD, 125VAC

Power transfer ............................................................................................................................................ v-belt

On/off switch ..................................................................................................................................... push button

Motor speed ........................................................................................................................................ 3450 RPM

Power plug installed ..................................................................................................................................... 120V

Recommended circuit and fuse/breaker size1 .......................................................... 30A (115V), or 15A (230V)

1

Dust coll ection:

Dust port outside diameter ................................................................................................................ 4” (100mm)

Minimum extraction volume required .................................................................................... 350 CFM (18CMM)

Dimensions and weights:

Overall Dimensions ........................................................................................ 23-31/32”W x 36-1/2”D x 43-1/2”H

Net Weight (approx.) .................................................................................................................... 225 lb (102 kg)

Shipping Weight (approx.) ........................................................................................................... 262 lb (119 kg)

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

subject to local/national electrical codes.

IMPORTANT:

∗ The use of a dust chute and adequate dust collection system is highly recommended but not

required for most planing operations.

∗ The use of a dust chute and adequate dust collection system is required for all molding operations.

For a complete line of woodw orking dust collectors, contact your local JET d istributor, or visit our website at

www.jettools.com.

8

Page 9

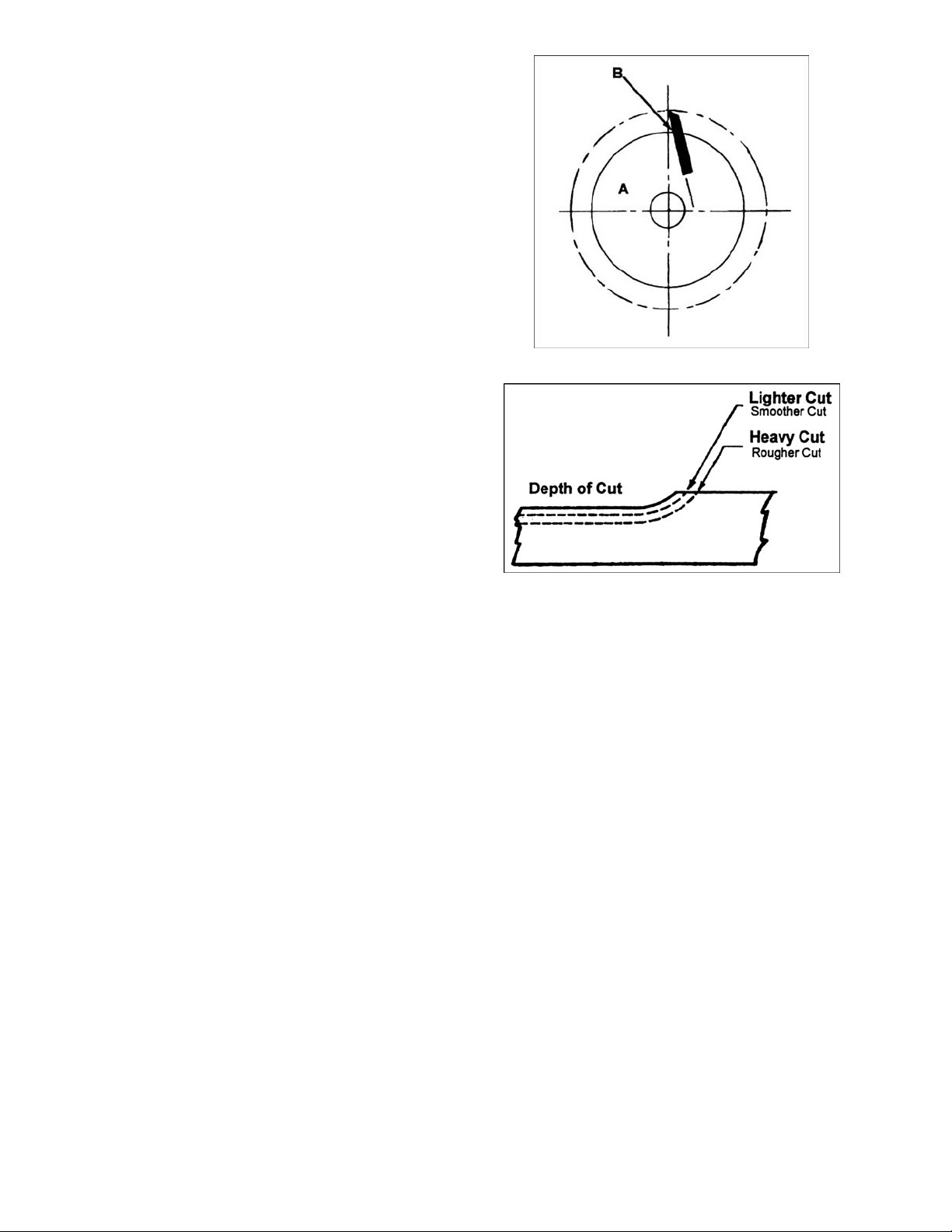

8.0 Glossary

• Cutterhead (A, Fig ure 5) – metal cylinder that

holds the planer knives or the molding cutters.

• Table – part of machine over which the lumber

passes.

• Feed Rollers – two rubber covered cylinders

that push lumber through the machine.

• Planer Knife – one of three knives found in

the cutterhead used for planing. (B, Figure 5)

• Molding Cutter – one of three c utters in a set

with a patterned edge used for cutting a

decorative design into wood.

• Gib – metal bar with adjusting screws that

holds planer knives or molding cutters in the

cutterhead.

• Depth of Cut – depth of cut from workpiece on

a single pass through the machine. (Figure 6)

• Snipe – depression on either end of a planed

board caused by feeding the board into the

machine at an angle to the table or letting the

board end drop down when exiting the planer.

Figure 5

Figure 6

9

Page 10

9.0 Setup and assembly

3. Attach the top side of dust chute with three

M5x10 machine screws, and three M5

washers.

9.1 Shipping contents

1 Molder/Planer

1 Dust Chute

2 Extension Roller A ssemblies

1 Accessory Package, containing:

1 Handle Assembly

1 10/12mm Wrench*

1 11/13mm Wrench*

1 Screwdriver*

1 3mm Hex Wrench*

1 4mm T-Handle Hex Wrench*

1 5mm Hex Wrench*

1 Knife Setting Gauge*

1 Molding Cutter Gauge*

1 Feed Roller Adjustment Wrenc h*

1 Brass Bar*

1 Video

1 Hardware Bag #2 (p/n MHD-17S-A)

1 Operator’s Manual

1 Warranty Card

* included in Hardware Bag #1 ( p/n MHD-17S)

Read and understand all

assembly instructions before attempting

assembly. Failure to comply may cause serious

injury.

9.2 Unpacking and cleanup

1. Finish removing all contents from the shipping

container. Do not discard any shipping

material until the planer/molder is set up and

running properly.

2. Inspect contents for shippi ng damage. Report

damage, if any, to your distributor.

3. Compare c ontents of shipping carton with the

contents list in this manual. Report shortages,

if any, to your distributor.

4. Clean all rust protected surfaces with a mild

solvent or kerosene. Do not use lacquer

thinner, paint thinner, or gasoline; these will

damage painted surfaces.

5. To pre vent rust, apply a light coating of paste

wax to the table surface.

9.3 Assembly

1. Remove dust hood. Check gib screws on

cutterhead for tightness. Reinstall dust hood.

Note: Recheck after five minutes of operation.

Recheck again after every 2 hours of use.

2. A ttach the handle to the post with a hex socket

cap screw.

4. Attach lower section of dust chute with three

M6x8 machine screws, and three M6 washers.

5. Mount extension roller assembly to the midd le

table with four M8x12 hex cap bolts, and four

M8 flat washers. The frame is adj ustable using

these bolts.

6. Use a straight edge to make sure rollers are

level with middle table.

7. The first roller is adjustable by loosening the

hex cap bolts that hold t he roller on the f rame

supports.

8. Repeat steps 5-7 for opposite side roller

assembly.

Never run machine with dust

hood loose or rem oved. Failure to comply m ay

cause serious injury.

10.0 Adjustments: Planing

10.1 Depth of cut

Maxim um depth of cut is 1/8”

up to 5-1/2” wide, and 1/16” on stock over 51/2” wide. Trying to cut more in one pass will

cause stress on machine and could damage

cutterhead.

Thickness planing refers to the sizing of lumber to

a desired thickness while creating a level surface

parallel to the opposite side of the board.

The quality of thickness planing depends on the

operator’s judgment about the depth of cut. Depth

of cut depends upon the width, hardness,

dampness, grain direction, and grain structure of

the wood.

The maximum thickness of wood that can be

removed in one pass is 1/8” on wood up to 51/2” wide and 1/16” on wood wider than 5-1/2”.

When planing hard wood, take light cuts or plane

wood in thin widths.

Make a test cut when working with a new type of

board or different kind of operation. Check the

accuracy of the test cut before working on the

finished product.

10.2 Adjusting depth of cut scale

Use caution when placing

hands near cutterhead. Knives are extremely

sharp. Failure to comply may cause serious

injury.

1. Take a test cut.

10

Page 11

2. Measure the cut piece.

3. Adjust pointer accordingly.

10.3 Feed rate adjustment

The planer/molder has two speeds that feed the

work piece, at 10 feet per minute (FPM) for

improved surface finish when molding and 20 FPM

for faster planing.

To change the feed rate gears:

1. Disconnect machine from power source

(Unplug).

2. Remove acorn nut holding the gear cover.

3. Remove two hex socket cap screws and two

washers.

4. Remove gears and position according to

operation. See gear chart (Figure 7).

5. R eplace screws and washers to hold gears in

place.

6. Replace cover and acorn nut.

10.5 Knife adjustment

Any adjustment or

replacement of knives must be done to all three

knives at the same time. Failure to comply may

result in an out-of-balance cutterhead which

will lead to bearing failure.

Use caution when placing

hands near the cutterhead. Knives are

extremely sharp. Failure to comply may cause

serious injury.

1. Disconnect machine from power source

(Unplug).

2. Remove screws securing dust hood and dust

chute.

3. Remove dust hood and dust chute.

4. With a marking pen, label each knife on the

cutterhead one, two, and three for easy

identification.

5. Loosen all lock bar screws on blade number

one.

6. W ith the brass bar and a mallet, carefully tap

on each end on the outside of the set screws

for all three lock bars on knife number one.

This loosens the taper fit of the lock bar.

Figure 7

10.4 Adjusting V-Belt Tension

1. Disconnect machine from power source.

(Unplug)

2. Remove stand cover on left of stand.

3. Loosen four round cap hex socket slot screws

holding motor plate to stand.

4. Push down on motor to tension belt. Belt is

tensioned properly when moderate finger

pressure on belt midway between the two

pulleys causes approximately 1/4” deflection.

5. Tighten four round cap hex socket slot screws.

6. Replace stand cover.

7. Raise or lower knife by turning jack screw.

Knife is at correct height when knife tip just

touches center tip of knife gauge (Figure 8).

Figure 8

8. P lace knife gauge at other end of knife number

one.

9. Raise or lower knife to correct height.

10. Tighten knife bar locking screws. Note: Tighten

each large lock bar independently. Take half

turns alternating on each end until lock bar is

tight against the knife. Tighten small lock bar

after two large lock bars are tight. The small

lock bar requires two spacers to firmly hold t he

knife. Tighten in the same manner as the large

lock bars.

11. Continue to che c k kn ife heig ht w ith g auge u nti l

set screws are firmly tightened.

11

Page 12

12. Repeat steps five through eleven for blades

two and three.

10.7 Adjusting infeed roller and

outfeed rol lers fo r plani ng

10.6 Knife replacement

Use caution when placing

hands near the cutterhead. Knives are

extremely sharp. Failure to comply may cause

serious injury.

1. Disconnect machine from power source.

(Unplug)

2. Remove screws securing the dust hood and

dust chute.

3. Remove dust hood and dust chute.

4. With a marking pen, label each knife on the

cutterhead one, two, and three for easy

identification.

5. Loosen all lock bar set screws on knife number

one.

6. W ith the brass bar and a mallet, carefully tap

on each end on the outside of the set screws

for all three lock bars on knife number one.

This loosens the taper fit of the lock bar.

7. Carefully remove knife.

8. Remove lock bars.

9. Repeat steps 5-8 for knives two and three.

10. Clean cutterhead of any wood chips, pitch,

saw dust, and any other debris.

As a general rule of thumb, the infeed and outfeed

rollers are set 1/8” below the cutterhead (not the

knives) at the factory. To check the feed rollers:

1. Disconnect machine from power source.

(Unplug)

2. Make two blocks out of scrap 2x4 lumber using

the dimensions noted.

3. Mark each block as shown in Figures 10 and

11.

Figure 10

11. Replace lock bars on knife number one as in

Figure 9, paying attention to which direction

they face.

Figure 9

12. Carefully install new or sharpened knife into

cutterhead between lock bar and cutterhead.

Note direction of knife as pictured in Figure 5.

13. Adjust knife. Refer to section in this manual

titled “Knife Adj ustment”, steps seven through

eleven.

14. Repeat steps 11-13 for blades number two

and three.

Figure 11

4. Lower the work table to allow cutterhead block

to slide freely between the table and the

cutterhead. Note: Cutterhead may have to be

turned by hand to rotate a blade out of the

way.

5. Adjust the table height so the block can be

inserted between the table and the cutterhead

with minimum resistance.

6. Remove the block. Do not raise or lower the

table at this point. It will affect the final result.

12

Page 13

7. Insert the b lock labeled “Feed Roller Planing”

into the planer opening.

8. Raise or lower the feed roller until it rests on

top of the block end to end. To adjust the feed

roller (Fig 12):

adjustment allows without contacting the

cu tterhea d and knives.

11.0 Planing procedure

• Loose n the jam nut on both sides of infeed

roller with the wrench provided.

• Turn the threaded bushing counter-

clockwise to raise roller and clockwise to

lower roller.

• Raise or lower roller until it contacts the top

of the block on both ends of the roller.

• Block should slide in and out with a

minimum of force.

• Tighten jam nuts and re-check.

9. Repeat this process with outfeed roller. Retain

the wooden blocks for future use.

Figure 12

10.8 Adjusting chip deflectors for

planing

Adjust the outfeed chip deflector (as shown in

Figure 13) to within 1/4” to 1/8” of planing knive s to

prevent chips from being pressed into the planed

surface of the work piece by the outfeed roller.

Note: Adjusting the chip deflector too close to t he

cutterhead while planing will cause a higher than

normal noise level especially when using a dust

collector. The use of a dust collection system with

the capacity to handle a large volume of material is

highly recommended.

Never stand directly in front of

or behind machine while planing or molding.

Always stand to one side. Failure to comply

may cause serious injury from kickback.

Never attempt to plane a

workpiece shorter than 14” or thinner than 1/2”.

Failure to comply may cause serious injury.

Never plane more than 1/8” on

stock narrower than 5-1/2” and 1/16” o n stock

5-1/2” and wider in one pass. This will cause

stress on machine, lead to premature wear, and

may damage knives and/or cutterhead.

The use of a dust collection

system is highly recommended. If a dust

collection system is not used, remove hose

adaptor from dust hood t o prevent wood c hips

collecting in dust hood and backing up into

machine.

The JPM-13CS is supplied with planing blades

mounted in the cutterhead. Planing can be done at

10 FPM for an improved surface finish or 20 FPM

for faster planing. Work pieces longer than 24”

should be supported with infeed and outfeed

rollers.

1. A djust table height to produce desired depth of

cut.

2. Start machine.

3. Stand to one side and grasp work piece in the

center.

4. Gently slide work piece into infeed side of

planer/molder until infeed roller begins to

advance the work piece.

5. Let go of the work piece and allow the feed

rollers to advance the work piece.

6. Catch the work piece as it comes out the

outfeed side of the planer/molder.

Figure 13

The infeed chip deflector (curved piece attached to

the top cover with three screws and wing nuts)

must be adjusted as close to the cutterhead as the

11.1 Dealing with warped wood

Warp is caused by different grain directions in a

piece of wood drying at different rates during the

drying process.

Wood warped across t he width - C upped wood

is planed flat on one side first, then planed flat on

the other. Ripping the board down the middle will

avoid huge amounts of waste in planing to

thickness.

13

Page 14

Wood warped lengthwise - Feed rollers will

flatten a lengthwise warped board a s if it w ere flat,

but the board will spring back to its original shape

once out of the planer. A lengthwise warped board

must be jointed flat on one side on a j ointer before

being thicknes s planed.

Twisted wood - Twisted lumber or lumber twisted

lengthwise is difficult to thickness plane. The wood

may be so twisted that it cannot be thickness

planed. One possible solution may be to saw the

board into smaller sections and see if the sections

can be thickness plane d.

11.2 Wood Grain

For an improved surface finish with minimal

tearout, always plane the work piece with the grain.

The work piece should be fed into the

planer/molder so that blades are tra veling with the

grain as they finish the cut. The grain should be

angled up toward the rear of the work p iece a s it is

fed into the planer/molder.

12.0 Molding setup and

adjustments

Set feed gear box to 10 FPM. (See illustration and

instruction in section 10.3).

12.1 Installing molding cutters

3. Remove dust hood (B, Figure 14) and dust

chute.

4. Loosen three wing nuts (C, Figure 14) and

slide the curved infeed chip deflector (D,

Figure 14) out of the way.

5. Tighten screws to hold c hip deflector in place.

It is not used in the molding operation.

6. Remove plastic outfeed chip deflector

completely.

7. With a marking pen, label each knife slot on

the cutterhead one, two, and three for easy

identification.

For 2” and under cutters:

• Loosen set screws on 2” lock bar at cutter

number one.

• With the brass bar and a mallet carefully tap

on lock bar outside of set screws to loosen

taper fit of the lock bar.

• Remove spacers.

• Remove lock bar. Note: With 2” wide and

under molding cutters, the planing knives

remain in place (Figure 15).

• Install lock bar but do not tighten at this time.

Note: Depending on cutter width, 1” and under

cutters will require a spa c er next to the cutter.

Cutterhead knives are sharp.

Use extreme caution when working in close

proximity. Never attempt to mold without a dust

chute and dust collection system. Failure to

comply may cause serious injury.

1. Disconnect machine from power source

(Unplug).

2. Remove screws (A, Figure 14) securing the

dust hood.

Figure 14

Figure 15

• Install cutter i n place of spacers. Cutters must

face proper direction and be seated fully in the

cutterhead.

For cutters over 2”:

• Loosen set screws on all lock bars at cutter

number one.

• With the brass bar and a mallet, carefully tap

on lock bar outside of set screws to loosen

lock bar taper fit.

• Caref ully re move spac ers, planing knive s and

lock bars.

14

Page 15

• Install special lock bar that is included with the

knife set. Make sure set screws are loose to

allow locking adjustment. Do not tighten at this

time.

• Install cutter. Make sure it is facing proper

direction and is fully seated in the cutterhead.

8. Install molding cutter gauge with hex socket

cap screw and tighten to hold in place. The

guide may be attached to either side. See

Figure 16.

When using cutters larger than 2” wide, the feed

rollers will have to be set 5/16” below the cutter

head. To set the feed rollers for molding:

1. Following the method for setting the feed

rollers when planing (previously explained in

this manual), make another wooden block

5/16” lower than the cutterhead block. See

Figure 17.

Figure 16

9. Adjust the guide end to meet the cutter edge.

10. Tighten the hex socket cap screw holding the

guide bar and be careful not to move it during

the alignment process.

11. Tighten lock bar set screws to hold cutter in

place. Tighten set screws half turn each side

to uniformly raise the lock bar until tight.

12. Rotate cutterhead to the second cutter insert.

13. Repeat steps for cutter inserts two and three

making sure the cutters are properly

positioned according to the alignment guide.

14. Remove guide.

15. Check that all set screws in the cutterhead are

tight.

16. Replace dus t h ood and dust chute.

17. Run machine for five minutes. Re-tighten gib

screws in cutterhead. Recheck after every 2

hours of use.

Never run the machine with

the dust hood loose or removed. All cutter l ock

bar screws must be firmly seated before

turning on the machine. Failure to com ply may

cause blade and/or cutter ejection resulting in

damage to machine, cutter, and may pose

hazard to operator.

Figure 17

2. Adjust the infeed and outfeed rollers in the

same manne r as sett ing the r ol lers f or pla ning

using this new block.

3. Label this block “feed roller molding”.

4. Save the block for future use.

Never lower infeed and

outfeed rollers beyond 5/16” lower than

cutterhead. This will cause severe stress on

gear box and roller system.

When using molding knives wider than 2”, the first

pass or cut will remove approximately two thirds of

the stock. Test cuts on scrap material will

determine the number of passes required to

complete the cut. Never attempt to complete a

cut with less than two passes on smaller knives

(under 2”) and three passes on larger knives

(over 2”). Generally, the more passes, the better

the finish.

Due to the variety of cutters available, it is

impo ss ible t o cover ever y p ossible se t -up. It is very

important to use test cuts o n scrap material bef ore

attempting cuts on project material.

This machine is designed and intended for use with

three matched knives in sets. Many companies

offer knife sets that included only one knife and two

counter-weights. These cause severe vibration and

can damage the machine.

12.2 Setting feed rollers for molding

The infeed and outfeed rollers will have to be

lowered for most molding operations. The amount

of adjustment required will vary depending on the

size and style of the cutter.

15

Page 16

12.3 Making & installing a bedboard

You must use a board over the

planer/molder table when molding. This

prevents the knives from hitting the table and

allows the knives to cut i nto the guide boards

to clean up the sides of the molding.

1. Disconnect machine from power source

(unplug).

2. Cut a piece of 3/4” particle board 12-7/8” wide

and 31-1/4” long. Note: Board is 12” longer

than the table to allow overhang (6” front and

rear). This increases the work surfaces for

longer pieces of wood stock.

3. Mark and drill four 1/4” holes on the bedboard

that match the pre-drilled holes in the

planer/molder table.

4. Countersink the four drilled holes on the top

side to allow installation of countersunk

screws.

5. Secure the bedboard to the table with four

3/16” x 1-1/2” flat head machine screws, four

3/16” x 3/4” washers and four 3/16” hex nuts.

12.4 Making guide rails

Guide rails are used during the molding process to

align the workpiece with the molding cutters. Using

properly adjusted guide rails assures the workpiece

passes the molding cutters in the same position

using multiple passes.

Guide rails should be the same length as t he table

(31-1/4”) and 2” wide and be made from smooth,

straight hardwood, such as oak, maple, alder, etc.

so they will not damage the cutters when they

contact them. Some molding profiles require the

knives to cut into the guide rails to clean up the

outer edge to complete the cut. (Fig. 18)

Figure 19

12.5 Guide rail placement and

attachment

1. Disconnect machine from power source

(unplug).

2. To assist in proper placement of guide rails, it

is suggested to remove the dust hood and dust

chute to clearly see the cutter knife and rail

placement. It is also helpful to draw parallel

lines on the bedboard to assure proper

alignment of the guide rails from the infeed

side to the outfeed side.

3. Moldi ng cutter must be installed properly i n the

cutterh ead. See “Installing Molding Cutters”.

4. Lower table.

5. Caref ully turn cutterhead so that one cutter is

at the lowest point of the cutting arc.

6. S lide in f irst g uide rai l and pos itio n inside edge

of guide rail to outside edge of the finished

work piece. Note: On many patterns this will

be the outside edge of the knife.

7. Clamp the guide rail to the bedboard using “C”

clamps on both ends. (This can also be done

by nailing with small gauge finish nails. Keep

in mind the guide rails must be positioned

properly before nailing. Be careful with nail

length; do not nail through the bedboard and

into the table). (Fig. 20)

Figure 18

Guides should be cut 1/4” lower than the maximum

thickness of the final workpiece profile. Regardless

of how thick your guide rails are, they must be

notched to clear the infeed/outfeed rollers and antikickback fingers. See Figure 19 for pattern.

Figure 20

16

Page 17

8. Position second guide rail on the table.

Placement of this rail depends on the w idth of

the board and if the board requires outer edge

clean-up. Review molding procedure section

for pre-sizing stock guidelines. When using

knives that require outer edge clean-up, the

workpiece will contact the guide rails only

while wood is feeding into the cutterhead. After

the workpiece passes the cutterhead, the

outfeed roller will hold the workpiece in

position.

9. Clamp or nail second guide rail.

10. Replace dust hood, dust chute and fasten in

place.

11. Connect to the dust collection system.

12. Make sure all adjusting tools and wood stock

are removed from the machine.

TIP: Save money, time, and frustration by

experimenting first with scrap work pieces before

attempting to mold with expensive stock.

13.0 Molding procedure

Never mold without using a

dust collector. Molding without a dust collector

may cause clogging of and damage to machine.

Molding with professional results takes planning

prior to starting. Always take a light cut for the

smoother finish. Pre-sizing wood before molding is

a necessity. Always pre-size the workpiece to 1/16”

of the final thickness before running the workpiece

through the molder.

With profiles that require o uter edge clean-up, the

workpiece should be 1/8” larger than the final width

allowing 1/16” on either side of the cutter. (Fig. 21)

Figure 21

With profiles that only cut the edge of the

workpiece, the workpiece should be the same size

as the final width. (Fig. 22)

Figure 22

Other considerations before molding to consider

are wood hardness, moisture content, degree of

warp, and direction of grain.

Never attempt to mold a

workpiece shorter than 14” or thinner than 1/2".

Failure to comply may cause damage to

machine and/or serious injury to operator.

13.1 Setting table height for first

pass

1. Do not connect machine to power source until

instructed to do so.

2. Lower table to allow insertion of workpiece.

3. While looking into the front opening of the

machine, raise the table until the workpiece

just contacts the infeed roller.

4. Rec ord the height of the table as indicated on

the scale to either side of the table.

5. Lower the table and remove the workpiece.

6. Raise the table back up to the recorded

measurement.

7. Raise the table one full turn above the

recorded measurement to allow adequate feed

roller pressure. This measurement is now the

starting point for this particular job.

8. Connect the machine to the power source,

start the dust collector, and start the machine.

9. Insert the work piece until the infeed roller

begins to advance the workpiece.

10. Let go of the work piece and move to one side

of the machine.

11. Retrieve the work piece from the outfeed side

of the machine. Note: It is our experience that

on the first pass using some cutters, the

material may feed in a jerky motion. If this

occurs, raise the table during the cut until the

workpiece begins to advance smoothly. This

point now becomes your first pass

measurement.

17

Page 18

12. Run all stock to be molded through the

machine at this time. Note: If you are

molding several boards with the same

profile and have to make several passes to

complete the profile, you must run all

boards through at each setting. This

assures all stock will match the desired

shape. This is especially important when

splicing molded boards together such as

crown molding or baseboards.

13.2 Back Relief Molding

Back relief molding is used to create a better fit

over irregular surfaces. With less wood contact, the

molding matches irregular surfaces more easily.

The back relief cut is formed on the work piece

first; then the workpiece is molded to its finished

shape. (Fig. 23)

Figure 23

13.3 Tongue and Groove Molding

Tongue and groove molding is accomplished in the

same manner as other types of molding. Keep in

mind the edge guide must be tal ler to adequately

support the work piece. The edge guides must be

set 3/4” below the lowest point the cutter will travel.

Cutting the groove first allows adequate support

when cutting the tongue (Figure 24).

Figure 24

14.0 Maintenance

Disconnect machine from power source

(unplug).

• Keep anti-kickback pawls clea n and operating

smoothly to prevent injury due to kickback.

• Lubricate table with furniture wax or

automotive paste wax for smoother feeding of

workpiece. Do not use a lubricant that will

affect the workpiece’s ability to accept stains

or protective finishes.

• Replace feed rollers, blades, and cutter knives

if they become damaged. Sharpen blades and

cutters when they become dull.

14.1 Lubrication

Disconnect machine from power source

(unplug).

• Coat the elevating screws with light automotive

bearing grease once a month.

• Lightly coat the chain drive and gears with light

automotive grease once a month.

• Lubricate four columns with 10W machine tool

oil once a month.

18

Page 19

15.0 Troubleshooting the JPM-13CS

15.1 Mechanical and electrical problems

Trouble Probable Cause Remedy

Table difficult to

adjust.

Chain is jumping. Inadequate tension. Adjust chain tension.

Machine will not

start/restart or

repeatedly trips circuit

breaker or blows

fuses.

Lack of lubrication on corner posts and

screws.

Sprockets misaligned. Align sprockets.

Sprockets are worn. Replace sprockets.

No incoming power. Verify power connections to planer.

Building circuit breaker trips or fuse

blows.

Loose electrical connections.

Motor failure.

Miswiring of the unit.

On/off switch failure.

Lubricate corner posts and screws.

Verify that planer is on a circuit of

correct size. Check amp setting on

motor. If circuit size is correct, there is

probably a loose electrical lead.

Go through all the electrical

connections on the planer including

motor connections, verifying the

tightness of each. Look for any signs of

electrical arcing which is a sure

indicator of loose connections or circuit

overload.

If electric motor is suspect, you have

two options: Have a qualified electrician

test the motor for function or remove

the motor and take it to a qualified

electric motor repair shop and have it

tested.

Check to confirm all electrical

connections are correct and properly

tight. Make any needed corrections.

If the on/off switch is suspect, you have

two options: Have a qualified electrician

test the switch for function, or purchas e

a new on/off switch and establish if that

was th e problem on changeout.

19

Page 20

15.2 Performance problems

Trouble Probable Cause Remedy

Snipe.

Fuzzy grain. Planing wood with high moisture

Torn grain. Too heavy a cut. Adjust proper depth of cut.

Rough/raised grain. Dull knives. Sharpen or replace knives.

Rounded, glossy

surface.

Poor feeding of

lumber. Inadequate feed roller pressure.

Wavering molding

pattern.

Tearing out at end of

molding.

Uneven depth of cut

side to side.

Board thickness does

not match depth of cut

scale.

Table rollers not set properly. Adjust rollers to proper height.

Inadequate support of long boards.

Uneven feed roller pressure front to

back.

Dull knives. Sharpen or replace knives.

Lumber not butted properly.

content.

Dull knives. Sharpen or replace knives.

Knives cutting against grain. Cut along the grain where possible.

Dull knives. Sharpen or replace knives.

Too heavy a cut. Adjust proper depth of cut.

Planing wood with high moisture

content.

Dull knives. Sharpen or replace knives.

Feed rate too slow. Increase feed rate.

Cutting depth too shallow. Increase cutting depth.

Planer table rough or dirty.

Belt slipping on pulleys. Ti ghten belt.

Surface of feed rollers too smooth.

Improper guide setup. Review proper guide setup for molding.

Improper guide setup. Review proper guide setup for molding.

Inadequate outfeed pressure. Adjust feed roller tension.

Knife projection not uniform Adjust knife projection.

Table not parallel to cutterhead. Adjust table/cutterhead parallelism.

Depth of cut scale is incorrect. Adjust depth of cut scale.

Support long boards with extension

rollers.

Adjust feed roller pressure.

Butt end-to-end each piece of stock as

they pass through.

Remove moisture by drying, or use

different stock.

Remove moisture by drying, or use

different stock.

Adjust feed roller tension. If proper

tension cannot be achieved, replace

feed rollers.

Clean pitch and residue from table, and

apply paste wax.

Lightly roughen feed roller surface with

sandpaper.

20

Page 21

16.0 Replacement Parts

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday (see our website for business hours, www.jettools.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to serve you quickly

and accurately.

21

Page 22

16.1.1 Table and Base Assembly – Exploded View

22

Page 23

16.1.2 Table and Base Assembly – Parts List

Index No Part No Description Size Qty

1 ................ MHA-B01W ............... Cover (left) ............................................................... ...................................... 1

2 ................ TS-0680021 .............. Flat Washer ............................................................. 1/4 ................................. 8

3 ................ TS-1503011 .............. Hex Socket Cap Screw ............................................ M6x8 ............................. 8

4 ................ MGA-B05 .................. Scale (inch) .............................................................. ...................................... 1

5 ................ MHA-B02................... Middle Table (serial # 6082715 and lower).............. ...................................... 1

.................. MHA-B02AW ............. Middle Table (serial # 6082716 and higher) ............ ...................................... 1

6 ................ MGA-B29 .................. Guide (left) ............................................................... ...................................... 2

7 ................ TS-1534031 .............. Pan Head Machine Screw ....................................... M6x10 ........................... 4

8 ................ TS-1551041 .............. Lock Washer ............................................................ M6 ................................. 4

9 ................ MGA-B15 .................. Guide (right) ............................................................. ...................................... 1

10 .............. MHA-B03................... Column .................................................................... ...................................... 4

11 .............. MHA-B04................... Leadscrew (left – serial # 6082715 and lower) ........ ...................................... 1

.................. MHA-B04A ................ Leadscrew (left – serial # 6082716 and higher)....... ...................................... 1

12 .............. MHA-B05 W ............... Base......................................................................... ...................................... 1

13 .............. MGA-B09 .................. Anch or Plate ............................................................ ...................................... 2

14 .............. TS-1503031 .............. Hex Socket Cap Screw ............................................ M6x12 ........................... 4

15 .............. TS-1551041 .............. Lock Washer ............................................................ M6 ................................. 4

16 .............. MHA-B20................... Pointer ..................................................................... ...................................... 2

17 .............. TS-1532022 .............. Pan Head Machine Screw ....................................... M4x8 ............................. 2

18 .............. MHA-B06................... Leadscrew (right – serial # 6082715 and lower) ...... ...................................... 1

.................. MHA-B06A ................ Leadscrew (right – serial # 6082716 and higher) .... ...................................... 1

19 .............. MHA-B07................... Cover (right – serial #810xxxx and lower) ............... ...................................... 1

.................. MHA-B07U W ............. Cover (right – serial #811xxxx and lower) ............... ...................................... 1

21 .............. MHA-B09................... Gear Box Cover (serial #810xxxx and lower) .......... ...................................... 1

.................. MHA-B09U ................ Gear Box Cover (serial #811xxxx and higher) ......... ...................................... 1

22 .............. 5BB-B07 .................... Hex Nut .................................................................... M8x 25 ........................... 1

23 .............. TS-1504051 .............. Hex Socket Cap Screw ............................................ M8x25 ........................... 4

24 .............. 5GF-B07.................... Chain ....................................................................... ...................................... 1

25 .............. PGE-B14 ................... Sprocket................................................................... ...................................... 2

26 .............. TS-1523011 .............. Set Screw ................................................................ M6x6 ............................. 4

27 .............. PGE-B12 ................... Sprocket................................................................... ...................................... 2

28 .............. PGE-B10 ................... Sprocket Idler/Bracket Bushing ............................... ...................................... 1

29 .............. PGE-B11 ................... Bracket Bushin g

30 .............. MHA-B10................... Pulley Cover ............................................................ ...................................... 1

31 .............. TS-1503021 .............. Hex Socket Cap Screw ............................................ M6x10 ........................... 2

32 .............. TS-0680021 .............. Flat Washer ............................................................. 1/4 ................................. 2

33 .............. TS-1504051 .............. Hex Socket Cap Screw ............................................ M8x20 ........................... 1

34 .............. MGA-B04 .................. Scale (metric)........................................................... ...................................... 1

35 .............. MHA-B11................... Speed Label (serial #810xxxx and lower) ................ ...................................... 1

.................. MHA-B11U ................ Speed Label (serial #810xxxx and higher) .............. ...................................... 1

36 .............. TS-1551061 .............. Lock Washer ............................................................ M8 ................................. 5

37 .............. MHA-C18 .................. Identification Label ................................................... ...................................... 1

.................. JPM13CS-RA ............ Roller Assembly ....................................................... ........................................

38 .............. MHD-Y01A ................ Roller Frame ............................................................ ...................................... 4

39 .............. MHA-Y02A ................ Roller Shaft .............................................................. ...................................... 4

40 .............. MHA-Y02C ................ Roll er ....................................................................... ...................................... 4

41 .............. PJ020804 .................. Bushing .................................................................... ...................................... 8

42 .............. TS-1550041 .............. Flat Washer ............................................................. M6 ................................. 8

43 .............. TS-1482021 .............. Hex Cap Bolt............................................................ M6x12 ........................... 8

44 .............. TS-1490011 .............. Hex Cap Bolt2 .......................................................... M8x12 ........................... 8

45 .............. TS-1550061 .............. Flat Washer2 ............................................................ M8 ................................. 8

2

included in Hardware Bag #2, p/n MHD-S17-A

RE:PGE-B10 ............................... ...................................... 2

23

Page 24

16.2.1 Cutterhead and Roller Assembly – Parts List

16.2.2 Cutterhead and Roller Assembly – Parts List

Index No Part No Description Size Qty

.................. MHA-CW ................... Dust Hood Assembly CP ......................................... ...................................... 1

1 ................ MHA-C01A W ............. Dust Hood ................................................................ ...................................... 1

2 ................ TS-1503011 .............. Hex Socket Cap Screw ............................................ M6x8 ............................. 3

3 ................ TS-0680021 .............. Flat Washer ............................................................. 1/4 ................................. 3

4 ................ 5FA-A10 .................... C-Ring...................................................................... ST W15 .......................... 2

5 ................ PGA-C17 ................... Sprocket................................................................... ...................................... 2

6 ................ 5GF-B08.................... Chain ....................................................................... ...................................... 2

7 ................ MHA-C02 .................. Feed Roller .............................................................. ...................................... 2

8 ................ PGA-C09 ................... Spring ...................................................................... ...................................... 4

9 ................ MGA-C09 .................. Bushing .................................................................... ...................................... 4

10 .............. MHA-C03W ............... Head Body ............................................................... ...................................... 1

11 .............. TS-1504041 .............. Hex Socket Cap Screw ............................................ M8x20 ........................... 4

12 .............. PGE-B19A................. Handle Assembly ..................................................... ...................................... 1

13 .............. TS-2321041 .............. Wing Nut .................................................................. ...................................... 3

14 .............. PGE-B19B................. Bushing .................................................................... ...................................... 1

24

Page 25

Index No Part No Description Size Qty

15 .............. PGE-B19C ................ Stud ......................................................................... ...................................... 1

20 .............. TS-1503021 .............. Hex Socket Cap Screw2 .......................................... M6x10 ........................... 1

21 .............. MHA-C05 .................. Spindle Pulley .......................................................... ...................................... 1

22 .............. TS-0680021 .............. Flat Washer ............................................................. 1/4 ................................. 1

23 .............. TS-1503051 .............. Hex Socket Cap Screw ............................................ M6x20 ........................... 1

24 .............. MHA-C06 .................. Spacer ..................................................................... ...................................... 2

25 .............. TS-1503041 .............. Hex Socket Cap Screw ............................................ M6x16 ........................... 3

26 .............. BB-6203ZZ ................ Ball Bearing ............................................................. ...... ................................ 1

27 .............. 5FK-C06 .................... Key........................................................................... 5x 5x15 .......................... 1

28 .............. MHA-C07 .................. Cutterhead ............................................................... ...................................... 1

29 .............. TS-1513021 .............. Flat Head Screw ...................................................... M5x12 ........................... 6

30 .............. BB-6202ZZ ................ Ball Bearing ............................................................. ...... ................................ 1

31 .............. 5BA-A28 .................... C-Ring...................................................................... RTW35 .......................... 1

32 .............. MHA-C08 .................. Bushing .................................................................... ...................................... 1

33 .............. MHA-C09 .................. Gear ......................................................................... ...................................... 1

34 .............. MHA-C10 .................. Chip Deflector .......................................................... ...................................... 1

35 .............. 5AK-E128 .................. Screw ....................................................................... M6x12 ........................... 3

36 .............. MHA-C11 .................. Anti- Kickback Shaft.................................................. ...................................... 1

37 .............. MGA-C30 .................. Anti-Kickback Finger ................................................ .................................... 36

38 .............. MGA-C34 .................. Anti-Kickback Collar................................................. .................................... 37

39 .............. MGA-C31 .................. Bracket..................................................................... ...................................... 2

40 .............. TS-1551031 .............. Lock Washer ............................................................ M5 ................................. 4

41 .............. TS-1502011 .............. Hex Socket Cap Screw ............................................ M5x8 ............................. 4

42 .............. MHA-C12 .................. Lock Bar (long) ........................................................ ...................................... 6

43 .............. MGA-C22 .................. Lock Bar (s hort) ....................................................... ...................................... 3

44 .............. TS-1524031 .............. Set Screw ................................................................ M8x12 ......................... 18

45 .............. MGA-C23 .................. Lock Bar Spacer ...................................................... ...................................... 6

46 .............. 708366 ...................... Knife (set of 3) ......................................................... ...................................... 1

48 .............. TS-1540071 .............. Hex Nut .................................................................... M10x 1.5 ........................ 4

49 .............. MGA-C07 .................. Adjustment Screw .................................................... ...................................... 4

50 .............. MGA-C05 .................. Adjustment Screw .................................................... ...................................... 4

51 .............. MGA-C06 .................. Nut ........................................................................... ...................................... 4

52 .............. MHA-C19 .................. Warning Label (long) ............................................... ...................................... 1

53 .............. PGE-B13 ................... Bushing .................................................................... ...................................... 1

54 .............. MHA-C20 .................. Washer .................................................................... ...................................... 1